This article discusses the benefits, challenges, and solutions for optimizing delivery frequency, which is a critical element of customer service. Benefits include reducing inventory-related costs and better managing cash flow, while challenges include coordinating deliveries and managing inventory levels. Solutions include partnering with suppliers who offer flexible delivery schedules, negotiating better shipping rates, and using technology to predict needs better. Optimizing delivery frequency can help customers reduce costs and improve customer service.

Introduction

Benefits of Optimizing Delivery Frequency

Challenges of Optimizing Delivery Frequency

Solutions for Optimizing Delivery Frequency

Conclusion

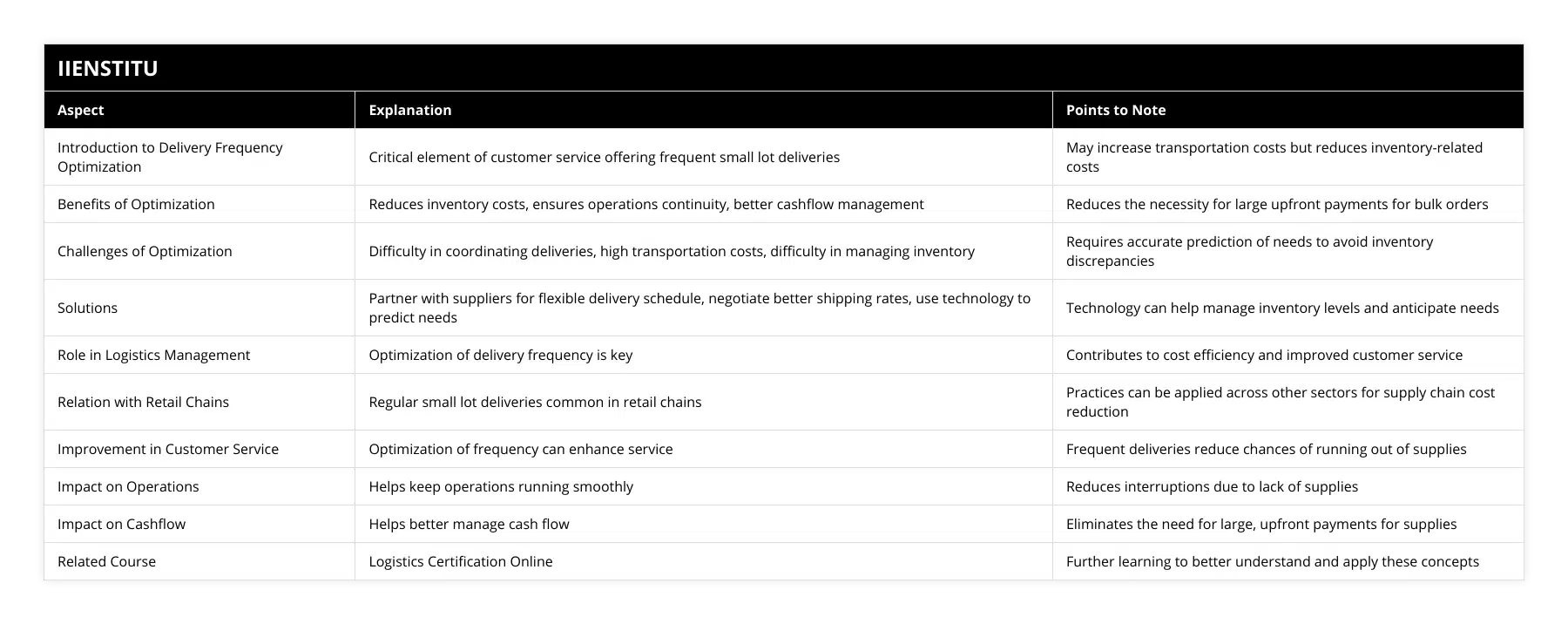

Introduction: Delivery frequency is a critical element of customer service. Customers want to avoid excess inventory while keeping their operations running without interruption. As a result, customers prefer frequent deliveries of small lots. This may increase transportation costs, but it can also reduce inventory-related costs, reducing overall supply chain costs. This practice of regular deliveries in small lots is common in retail chains. This article will discuss the benefits, challenges, and solutions for optimizing delivery frequency.

Benefits of Optimizing Delivery Frequency

Optimizing delivery frequency can lead to several benefits. First, it can reduce inventory-related costs. By delivering small lots more frequently, customers can avoid the need to store a large amount of inventory, which can be costly. Additionally, frequent deliveries can help customers keep their operations running smoothly, as they don’t have to worry about running out of supplies. Finally, optimizing delivery frequency can help customers better manage their cash flow, as they don’t have to pay for large orders upfront.

Challenges of Optimizing Delivery Frequency

While optimizing delivery frequency can have many benefits, it can also present some challenges. First, it cannot be easy to coordinate deliveries with suppliers and customers. Additionally, it can be costly to make frequent deliveries, as it requires more transportation costs. Finally, it cannot be easy to manage inventory levels, as customers must be able to accurately predict their needs to ensure they don’t have too much or too little inventory.

Solutions for Optimizing Delivery Frequency

Fortunately, several solutions can help customers optimize their delivery frequency. First, customers can partner with suppliers who offer flexible delivery schedules. This can help customers better coordinate their deliveries and manage their inventory levels. Additionally, customers can work with suppliers to negotiate better shipping rates, which can help reduce transportation costs.

Finally, customers can use technology to help them better predict their needs and manage their inventory levels.

Conclusion: Optimizing delivery frequency can have many benefits, such as reducing inventory-related costs and helping customers manage their cash flow. However, it can also present challenges, such as coordinating deliveries and managing inventory levels.

Fortunately, several solutions can help customers optimize their delivery frequency, such as partnering with suppliers who offer flexible delivery schedules, negotiating better shipping rates, and using technology to predict their needs better. In conclusion, optimizing delivery frequency can help customers reduce costs and improve customer service.

Efficient delivery frequency is the key to successful logistics management.

Related Course: Logistics Certification Online

Frequently Asked Questions

What are the benefits of optimizing delivery frequency for logistics management?

The optimization of delivery frequency is an essential factor in effective logistics management. Optimizing delivery frequency can reduce costs, increase customer satisfaction, and improve the efficiency of the supply chain.

Delivery frequency, or how often goods are delivered, is critical to any logistics strategy. Delivery frequency affects the cost of delivery, the satisfaction of customers, and the efficiency of the supply chain. With proper optimization, the delivery frequency can be used to reduce costs, increase customer satisfaction, and improve the efficiency of the supply chain.

The first benefit of optimizing delivery frequency is cost reduction. Delivery frequency optimization is critical to reducing the costs associated with shipping and delivery. By optimizing delivery frequency, companies can reduce the costs associated with multiple shipments, such as fuel, labor, storage, and packaging. In addition, by consolidating shipments into smaller, larger ones, companies can reduce the total delivery cost.

The second benefit of optimizing delivery frequency is increased customer satisfaction. Optimizing delivery frequency can help customers receive their orders promptly and in perfect condition. Customers often prefer to receive their orders as soon as possible, and optimizing delivery frequency can help ensure that this goal is met. Additionally, optimizing delivery frequency can reduce the likelihood of delays, which can lead to increased customer satisfaction.

The third benefit of optimizing delivery frequency is improved supply chain efficiency. By optimizing delivery frequency, companies can reduce the number of shipments they make and the number of warehouses they need to maintain. This can lead to a more efficient supply chain and improved customer service. Additionally, the optimized delivery frequency can help improve order fulfillment accuracy and reduce the risk of errors.

Overall, optimizing delivery frequency is an essential factor in effective logistics management. Optimizing delivery frequency can reduce costs, increase customer satisfaction, and improve the efficiency of the supply chain. Therefore, companies should consider optimizing their delivery frequency to reap the benefits of an effective logistics strategy.

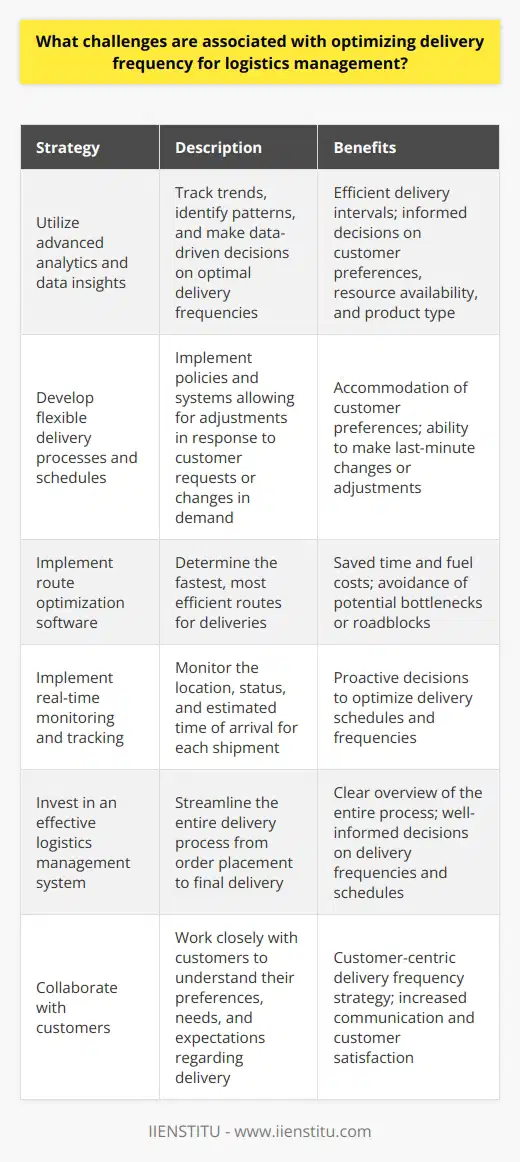

What challenges are associated with optimizing delivery frequency for logistics management?

Logistics management is an essential component of any business that involves the delivery of goods or services. As companies rely on efficient delivery systems, optimizing delivery frequency has become increasingly important. This article will discuss the challenges associated with optimizing delivery frequency and provide strategies for effectively managing the process.

One of the primary challenges associated with optimizing delivery frequency is determining the optimal delivery interval. The ideal delivery frequency will depend on various factors, including the type of goods or services being delivered, the delivery location, the size and weight of the goods, and the customer’s delivery expectations. Additionally, traffic and road conditions, weather, and other external factors must also be considered when determining the optimal delivery interval.

Another challenge associated with optimizing delivery frequency is the need to adjust delivery schedules to accommodate customer requests or changes in demand. For example, if a customer requests an expedited delivery or an unexpected surge in order, the delivery frequency must be adjusted to meet the customer’s needs. This can be a complex process, as it requires the logistics manager to quickly and accurately assess the impact of the request or change in demand and make the necessary adjustments to the delivery frequency to ensure customer satisfaction.

Finally, the cost of delivering goods or services must also be considered when optimizing delivery frequency. Delivery costs can vary depending on the size and weight of the goods or services, the distance, and the type of delivery service used. To maximize cost efficiency, the logistics manager must accurately assess the delivery cost, taking into account all the relevant factors.

To effectively optimize delivery frequency, logistics managers must be able to accurately assess the various factors involved and make informed decisions promptly. Additionally, the logistics manager must be able to adjust the delivery frequency in response to customer requests or changes in demand. Finally, cost efficiency must be taken into account when optimizing delivery frequency. By effectively addressing these challenges, logistics managers can ensure that goods and services are delivered efficiently and cost-effectively.

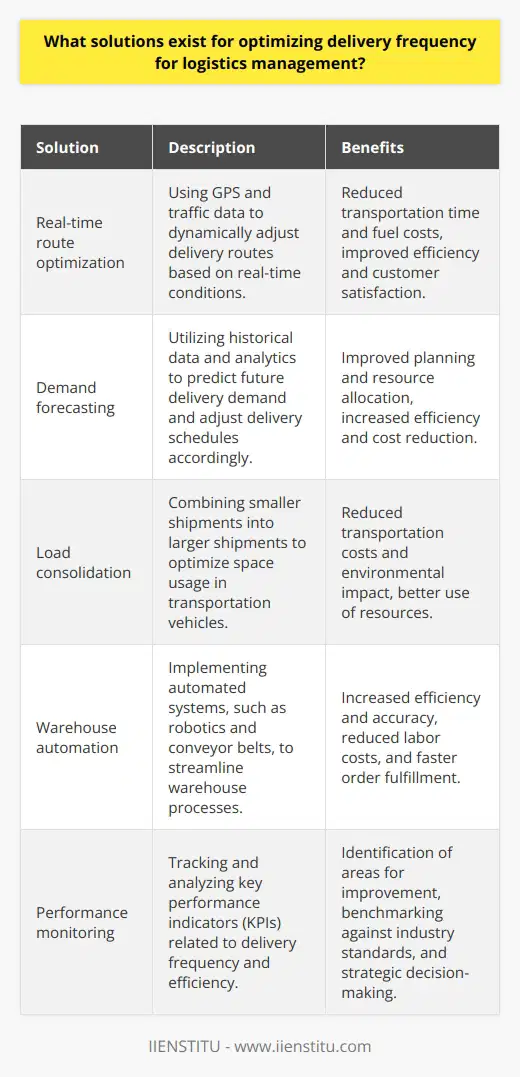

What solutions exist for optimizing delivery frequency for logistics management?

Logistics management is an essential component of any business, as it is responsible for storing and delivering goods. Therefore, the frequency of deliveries is a critical factor in ensuring customer satisfaction and the success of a business. To optimize delivery frequency, there are several solutions available.

The first solution is to use predictive analytics to anticipate customer demand. This can enable businesses to anticipate better customer needs and adjust their delivery schedules accordingly. Predictive analytics can also identify areas where the delivery frequency can be improved and allow businesses to optimize their supply chain.

Another solution is to use route optimization software. This software can help businesses determine the most efficient delivery routes, saving time and money. It can also help companies to identify areas where the delivery frequency can be improved, allowing them to adjust their delivery schedule accordingly.

Thirdly, businesses can use transportation management systems to improve the efficiency of their delivery operations. These systems can provide real-time data on their delivery operations, including the location of vehicles and the status of deliveries. This can help businesses optimize their delivery operations and identify areas where the delivery frequency can be improved.

Finally, businesses can use artificial intelligence (AI) to optimize delivery operations. For example, AI can analyze data from various sources to determine trends, identify customer needs, and optimize delivery schedules accordingly. AI can also automate specific processes, such as the packing and labeling goods, which can help improve delivery efficiency.

In conclusion, several solutions are available for optimizing delivery frequency for logistics management. These solutions include predictive analytics, route optimization software, transportation management systems, and artificial intelligence. By implementing these solutions, businesses can ensure that their delivery operations are as efficient as possible and that their customers are satisfied.

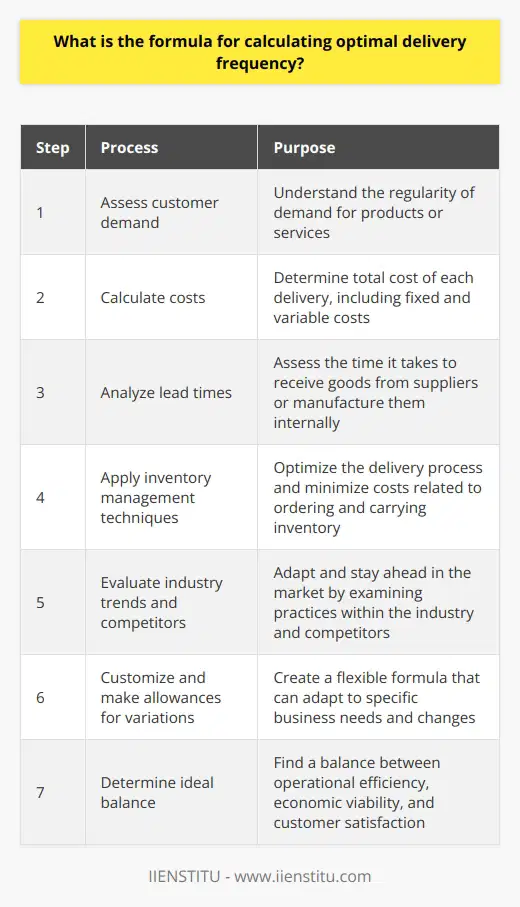

What is the formula for calculating optimal delivery frequency?

Determining Optimal Delivery Frequency

Understanding the Optimal Delivery Frequency

The formula for calculating optimal delivery frequency involves analyzing multiple variables to determine an ideal balance between operational efficiency, economic viability, and customer satisfaction. This frequency is vital for businesses that manage inventory or offer regular services to clients through subscription-based models, as it influences resource allocation, monetary outlay, and customer retention.

Key Factors in the Calculation

To establish the optimal delivery frequency, firms must consider various factors. These include the regularity of customer demand, the total cost of each delivery (fixed and variable), desired inventory levels, lead times, and the value of goods or services provided. Additionally, industry trends and competitor practices should be analyzed to gauge external market factors.

Application of Queuing Theory

Queuing theory, an essential concept in operations research, can be employed in the computation of optimal delivery frequency. This mathematical study of the waiting lines or queues is well-suited to address logistical concerns such as limiting the length of queues, efficiently serving items in the queue, keeping service costs down, and ensuring a satisfactory customer experience. By utilizing queuing models, businesses can better optimize their service systems to achieve consistent and efficient delivery frequencies.

Inventory Management Techniques

Implementing inventory management techniques such as Economic Order Quantity (EOQ) model and Just-In-Time (JIT) inventory management can be useful for calculating optimal delivery frequency. EOQ aims to minimize the cost of ordering and holding inventory by balancing order and carrying costs. The JIT approach seeks to reduce inventory levels by ordering and receiving goods only when they are needed. These techniques can help a business streamline the delivery process and control inventory costs.

Customization and Flexibility

It is crucial to acknowledge that each business has unique requirements, and there isn't a one-size-fits-all solution for determining the optimal delivery frequency. Firms should incorporate customizable and adaptable metrics into their calculations, accounting for potential fluctuations in demand, seasonal variations, and changes in the business model.

In conclusion, the formula for calculating optimal delivery frequency comprises a comprehensive evaluation of internal and external variables, informed by concepts such as queuing theory and inventory management techniques. Ultimately, businesses must remain flexible in their approach, to adapt to the dynamic nature of customer demand and market conditions while maintaining operational efficiency.

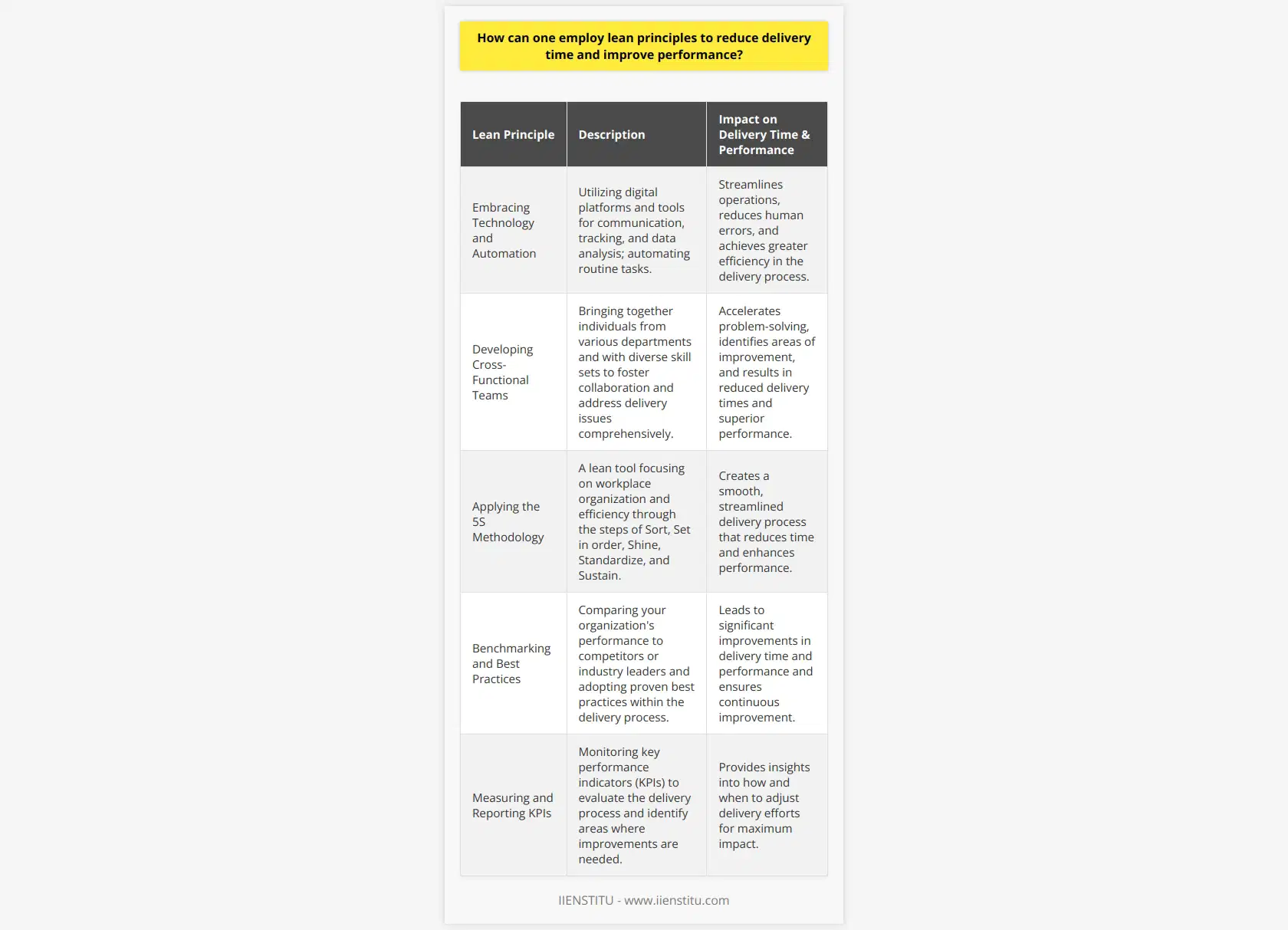

How can one employ lean principles to reduce delivery time and improve performance?

Understanding Lean Principles

To effectively employ lean principles in reducing delivery time and improving performance, one must first understand the core concepts of lean thinking. Lean principles originated in manufacturing as a means to eliminate waste and improve efficiency, but they have now been adapted across various sectors, including logistics and supply chain management.

Identifying Waste Sources

The first step in employing lean principles is to identify the sources of waste in the delivery process. Waste can be in the form of time, resources, and effort, which often lead to inefficiencies, errors, and delays. Examples of waste may include excessive paperwork, communication barriers, unnecessary steps, and redundant processes.

Emphasizing Continuous Improvement

With waste sources identified, it is crucial to create a culture of continuous improvement. This entails regularly analyzing, evaluating, and refining processes to eliminate inefficiencies, streamline operations, and reduce delivery time. Techniques may include implementing daily management meetings to discuss ways to improve, reporting on key performance indicators, and facilitating employee involvement in root-cause analysis and problem-solving.

Utilizing Process Mapping

Process mapping is an effective tool in the lean methodology that provides a visual representation of the various steps involved in a process. By mapping out the delivery process, one can identify bottlenecks, redundancies, and areas for improvement. This helps prioritize improvements and track the progress of process changes, consequently reducing delivery time and improving overall performance.

Implementing Just-in-Time Delivery

Just-in-Time (JIT) delivery is another lean principle that can be employed to reduce delivery time and optimize performance. JIT focuses on delivering products or services at the exact moment they are required, minimizing inventory and storage costs. By coordinating closely with suppliers, logistics providers, and customers, a company can establish an efficient and responsive network that enables real-time adjustments to changes in demand.

Standardizing Processes

Lean principles advocate for standardizing processes to ensure consistent quality and output across a given operation. Developing clear protocols, routines, and work instructions reduces variability, eliminates confusion, and promotes efficiency among employees. When all tasks are executed uniformly, delivery time is reduced, and performance is optimized.

In conclusion, employing lean principles to reduce delivery time and improve performance requires a thorough understanding of the methodology, identification of waste sources, establishing a culture of continuous improvement, utilizing process mapping tools, implementing just-in-time delivery strategies, and standardizing processes. By focusing on these elements, companies can create efficient delivery systems, achieving reduced lead times and enhanced overall performance.

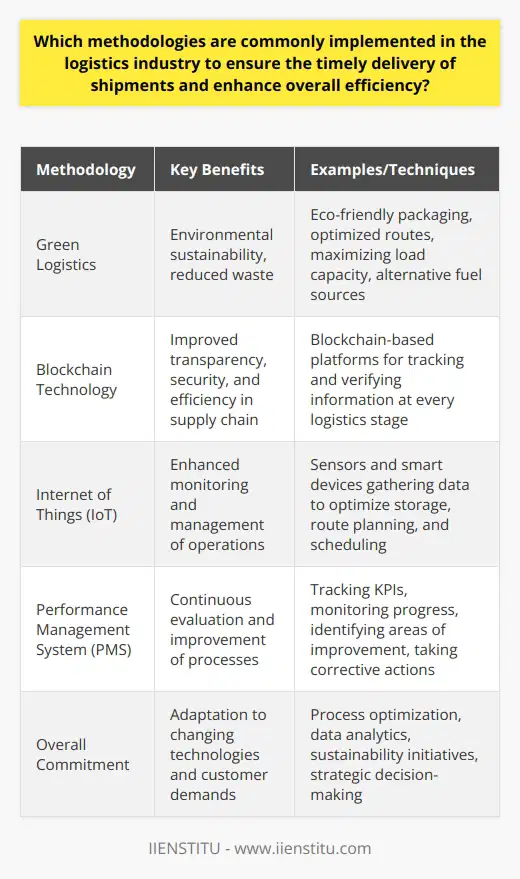

Which methodologies are commonly implemented in the logistics industry to ensure the timely delivery of shipments and enhance overall efficiency?

Methodologies in the Logistics Industry

Efficient Cargo Management Systems

In the logistics industry, efficient Cargo Management Systems (CMS) are frequently employed to streamline cargo handling and tracking processes, ultimately improving the on-time delivery of shipments. These systems integrate data from various sources, such as vehicle GPS tracking and warehouse inventory, providing real-time information needed for effective decision-making.

Adoption of Lean Principles

Lean principles, originating from the Toyota Production System, have been adapted to the logistics context, focusing on minimizing waste and maximizing value for customers. Key lean methodologies implemented include just-in-time delivery, root-cause analysis, and continuous improvement. By reducing non-value-added activities, logistics companies enhance overall efficiency and ensure timely delivery of shipments.

Automation and Robotics

The use of automation and robotics has become increasingly prevalent in the logistics sector. Automating repetitive tasks reduces manual intervention and associated human error while improving speed and accuracy across packaging, sorting, and material handling processes. As a result, these technologies contribute to on-time delivery rates and a more streamlined logistics operation.

Advanced Data Analytics

Advanced data analytics techniques have been incorporated into logistics practices to predict and mitigate potential issues, such as demand fluctuations or unanticipated delays like port congestion or adverse weather conditions. Analyzing historical data and real-time information allows industry professionals to implement proactive measures, enhancing efficiency and reducing delivery delays.

Collaborative Practices

Collaborative practices between stakeholders, such as shippers, carriers, and 3PL providers, have proven vital in enhancing logistics performance. Information-sharing and joint decision-making enable faster response times when managing disruptions, ensuring timely delivery and more efficient use of resources. This includes joint capacity planning, collaborative fleet optimization, and shared warehousing options.

In conclusion, the integration of cargo management systems, lean principles, automation, data analytics, and collaborative practices are fundamental methodologies employed across the logistics industry. These techniques support the timely delivery of shipments and enhance overall efficiency, providing significant value addition for both logistics providers and their clients.

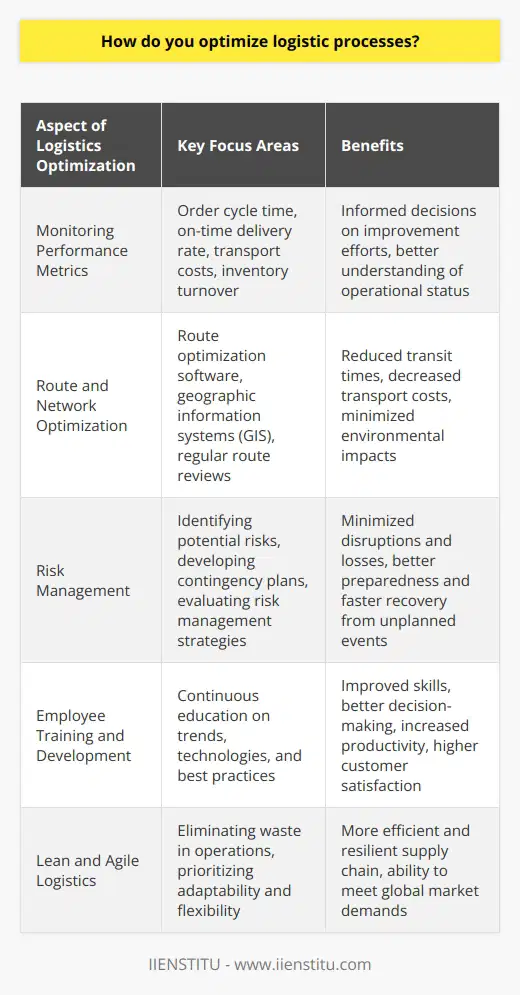

How do you optimize logistic processes?

Optimization Strategies

To optimize logistic processes, the initial step is to identify existing inefficiencies and bottlenecks within the current system. Analyzing daily operations, reviewing performance metrics, and conducting workflow audits can help pinpoint areas that require improvements.

Process Automation

Integrating automation technologies, such as warehouse management systems (WMS) and transportation management systems (TMS), can streamline tasks, reduce manual labor, and eliminate human errors. Automation also allows for better tracking and monitoring of shipments throughout the supply chain, ultimately leading to quicker decision-making and enhanced customer service.

Real-Time Data Analysis

Utilizing real-time data analysis supports informed decision-making and enables organizations to anticipate and respond promptly to changes in demand or disruptions in the supply chain. Implementing data-driven forecasting and inventory management systems can help minimize overstock and stockouts while maximizing the utilization of available resources.

Collaboration and Information Sharing

Fostering collaboration and information sharing among supply chain partners promotes transparency and facilitates a more synchronized approach to managing logistics. Establishing robust communication channels and collaborative platforms can lead to improved coordination, reduced lead times, and greater flexibility in managing the ever-evolving demands of the industry.

Sustainability and Cost Reduction

Embracing sustainable practices and cost reduction measures allow organizations to meet environmental goals while improving their profitability. Consolidating shipments, optimizing transportation routes, and employing eco-friendly packaging materials are just a few ways companies can decrease their carbon footprint and reduce operational expenses.

Continuous Improvement

Lastly, continuously evaluating and improving logistics processes is essential to staying ahead of competitors and adapting to the dynamism of the industry. Regularly assessing and incorporating best practices, employee training, and adopting innovative technologies will ensure that logistic processes remain efficient and responsive to the ever-changing needs of customers and supply chain partners.

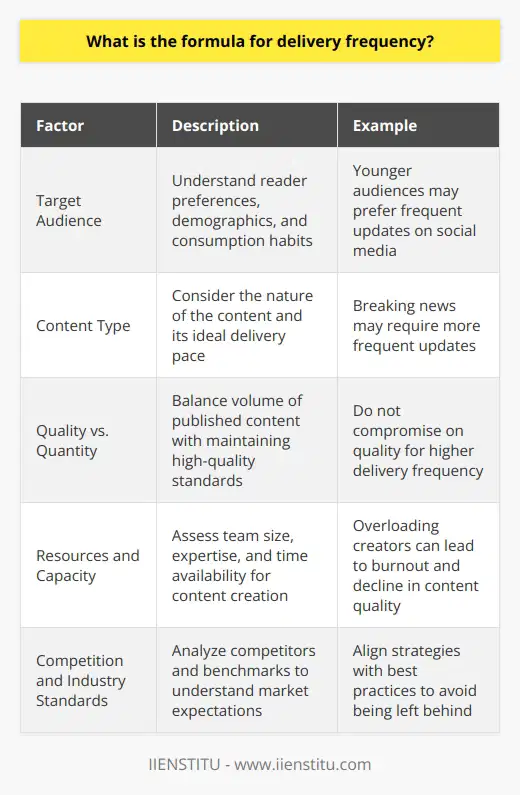

What is the formula for delivery frequency?

Delivery frequency in a blog post context

Understanding Delivery Frequency

Delivery frequency refers to the rate at which content is published and distributed to audiences, specifically in the context of blog posts and online articles. Bloggers and content creators need to define an optimal frequency to ensure they engage and retain their readers.

The Importance of Consistency

The key component of a successful delivery frequency formula is consistency. Achieving a balance between maintaining reader interest and avoiding content saturation is crucial. Consistent delivery helps build trust between bloggers and their audiences, enhancing long-term engagement.

Establishing an Ideal Formula

There is no universal formula for delivery frequency as it depends on factors such as the target audience, content type, and the creator's capacity. Analyzing relevant data, such as audience preferences and online engagement metrics, can provide insight into the most effective frequency.

Adapting to Changing Circumstances

It is important to remain adaptable and responsive to changes in the blogging landscape. Periodically evaluating and adjusting the delivery frequency, based on audience feedback and engagement, will ensure that content reaches its intended audience without overwhelming them.

In conclusion, the formula for delivery frequency in a blog post context relies on finding the right balance between consistency and adaptability. By being receptive to audience preferences and staying attuned to changing circumstances, content creators can optimize their delivery frequency for maximum engagement and growth.

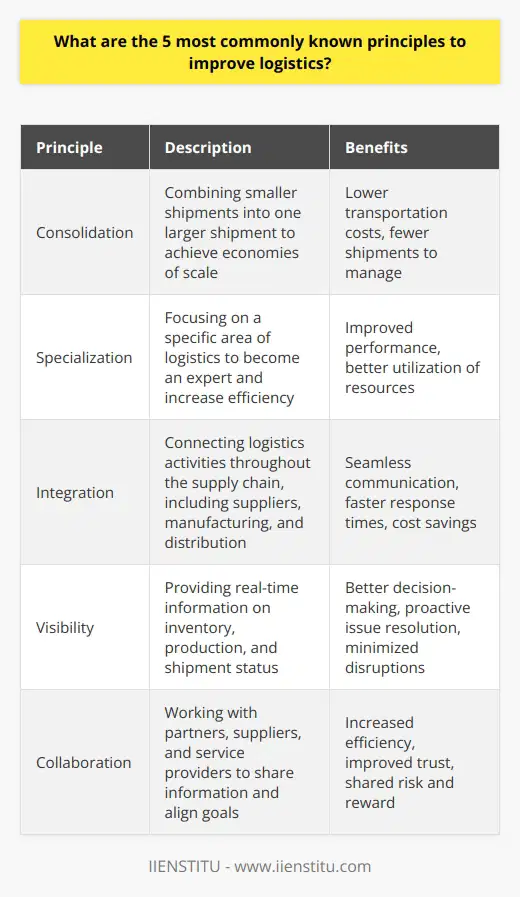

What are the 5 most commonly known principles to improve logistics?

Effective Logistics Strategies

Logistics plays a crucial role in the overall success of any business. Efficient logistics management can lead to improved customer satisfaction, reduced costs and increased profitability. To achieve such desired outcomes, companies can adopt five commonly known principles to improve logistics: consolidation, specialization, integration, visibility, and collaboration.

Consolidation

The first principle of logistics improvement involves consolidating shipments and resources. This means combining smaller shipments into a single, larger transport unit or optimizing the use of available transportation modes to reduce cost and lead time. By consolidating orders, both loading and unloading times can be minimized, thus alleviating bottlenecks in the supply chain.

Specialization

In the pursuit of logistics efficiency, specialization is essential. Companies can identify their core competencies and focus on excelling in those specific areas. By outsourcing non-core supply chain functions to third-party logistics providers (3PLs), businesses can achieve higher levels of efficiency and cost reduction. Specialist partners can leverage their expertise to optimize operations and better handle unique challenges.

Integration

Seamless coordination among various components of the supply chain is vital for logistics improvement. Integration ensures that information, resources, and processes flow smoothly between different stages of the chain. Efforts should be made to align the goals and objectives of all players in the logistics network, adopt information sharing practices, and utilize technology like Enterprise Resource Planning (ERP) systems to facilitate coordination.

Visibility

Having clear visibility of supply chain operations enables businesses to identify inefficiencies and make data-driven decisions. Real-time tracking of orders, inventory, and transportation assets helps in meeting customer demands effectively and avoiding any potential disruptions. Technology solutions like barcode scanners, RFID tags, and GPS tracking devices can enhance the monitoring of critical supply chain touchpoints.

Collaboration

Finally, collaboration is the key to long-term logistics success. A collaborative approach promotes open communication, trust, and mutual benefits among partners of the supply chain. This can be achieved by sharing information, developing common goals and performance metrics, and coordinating joint efforts for planning and execution. Strategic alliances and partnerships with suppliers, customers, and service providers result in a more resilient and agile supply chain.

In conclusion, by adhering to the principles of consolidation, specialization, integration, visibility, and collaboration, businesses can significantly improve their logistics operations. Optimizing supply chain functions in this manner can ultimately lead to increased efficiency, reduced costs and greater customer satisfaction.

How do you calculate delivery frequency based on various factors such as demand, location, and transportation resources?

Calculating Delivery Frequency

To calculate delivery frequency, one must consider the interplay of several factors, including demand, location, and available transportation resources. First, assessing demand allows for understanding the quantity and frequency of products required by the customers. Regular evaluations of customer orders and market trends provide valuable insights to predict and cater to the fluctuating needs efficiently.

Geographical Considerations

Next, the location of the delivery destination significantly affects the scheduling and frequency of deliveries. The proximity to distribution centers and the accessibility of the area inform the logistical capabilities and potential challenges faced during transportation. Factors such as road conditions, traffic congestion, and presence of tolls also play a crucial role in determining optimal delivery frequencies.

Transportation Resources

Finally, the availability and efficient management of transportation resources critically impact the frequency of deliveries. This encompasses the number of vehicles, their capacity and condition, fuel efficiency, maintenance schedules, and potential downtimes. The proper allocation of these resources is essential for maximizing operational efficiency, resulting in increased delivery frequency and reduced costs. Additionally, employing advanced technologies and tracking systems can further streamline transportation management and enhance delivery frequency planning.

Balancing Priorities

In conclusion, the complex interplay of factors, such as demand, location, and transportation resources, should be taken into account while calculating delivery frequency. Striking a balance between catering to customer requirements, overcoming geographical constraints, and optimizing the utilization of transportation resources is vital for achieving a superior and efficient supply chain management system. Regularly assessing these components and adapting to changes ensures a competitive edge in the dynamic world of delivery and logistics.

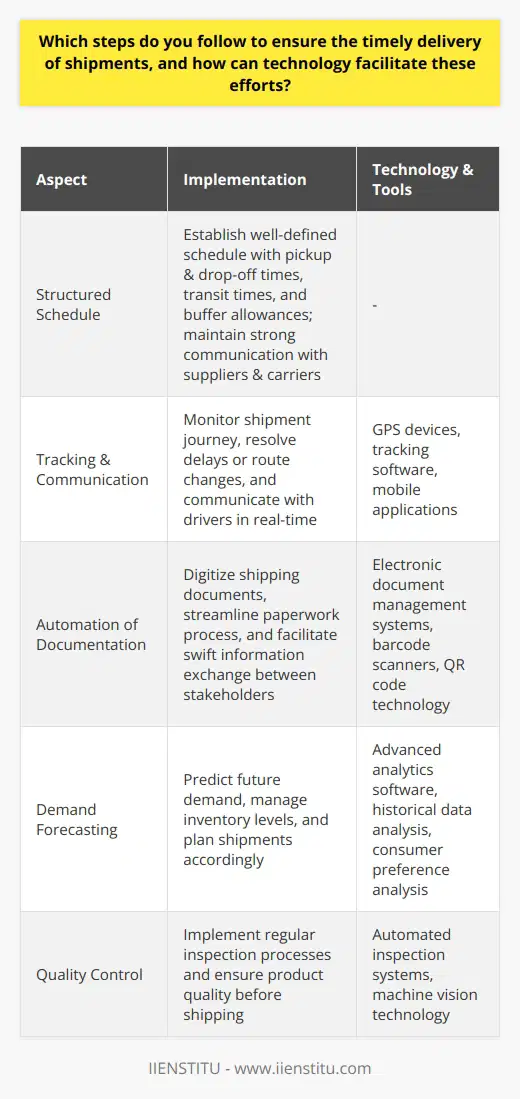

Which steps do you follow to ensure the timely delivery of shipments, and how can technology facilitate these efforts?

Establishing a Schedule

Firstly, to ensure the timely delivery of shipments, it is essential to establish a schedule that outlines the entire process, from order placement to delivery. This should include details such as pickup and drop-off times, transit times, and buffer time to address unforeseen circumstances. Constant communication with suppliers and carriers is vital to ensure all parties adhere to the predetermined timeframes.

Utilizing Technology for Tracking

Technology plays a significant role in facilitating the shipment process by providing real-time tracking through GPS devices and software. This enables monitoring the complete journey of the shipment and promptly addressing any issues, such as delays or route changes. Moreover, the use of mobile applications assists in maintaining constant communication with drivers, ensuring they are aware of their schedules and optimizing their routes.

Automating Documentation

Another key step to ensure timely delivery is automating documentation processes. Digitizing shipping documents, such as bills of lading, packing slips, and customs forms, streamlines the process and minimizes human errors. Electronic submission of customs forms expedites clearance, reducing the time spent in customs and enabling faster delivery. Furthermore, the use of barcode scanners and QR code technology can make document management more efficient by quickly transferring relevant information to all stakeholders.

Implementing Demand Forecasting

Demand forecasting is a vital tool that helps manage inventory levels and plan shipments more effectively. Advanced analytics software can predict future demand patterns by analyzing historical data, customer trends, and seasonal factors. Accurate demand forecasting allows businesses to maintain optimum inventory levels, schedule shipments at the right time, and avoid delays due to stockouts or overstocking.

Emphasizing Quality Control

Lastly, placing emphasis on quality control can help in avoiding delays caused by product defects or damaged goods. Rigorous inspection processes should be in place to ensure the quality of products before they are shipped. Investment in automated inspection systems, such as machine vision technology, can greatly reduce the time and resources required for this step while increasing accuracy.

In conclusion, implementing a structured schedule, utilizing technology for tracking and communication, automating documentation, and focusing on demand forecasting and quality control are crucial steps to ensure the timely delivery of shipments. Leveraging technology and optimizing processes can greatly improve efficiency and reliability in the shipping process.

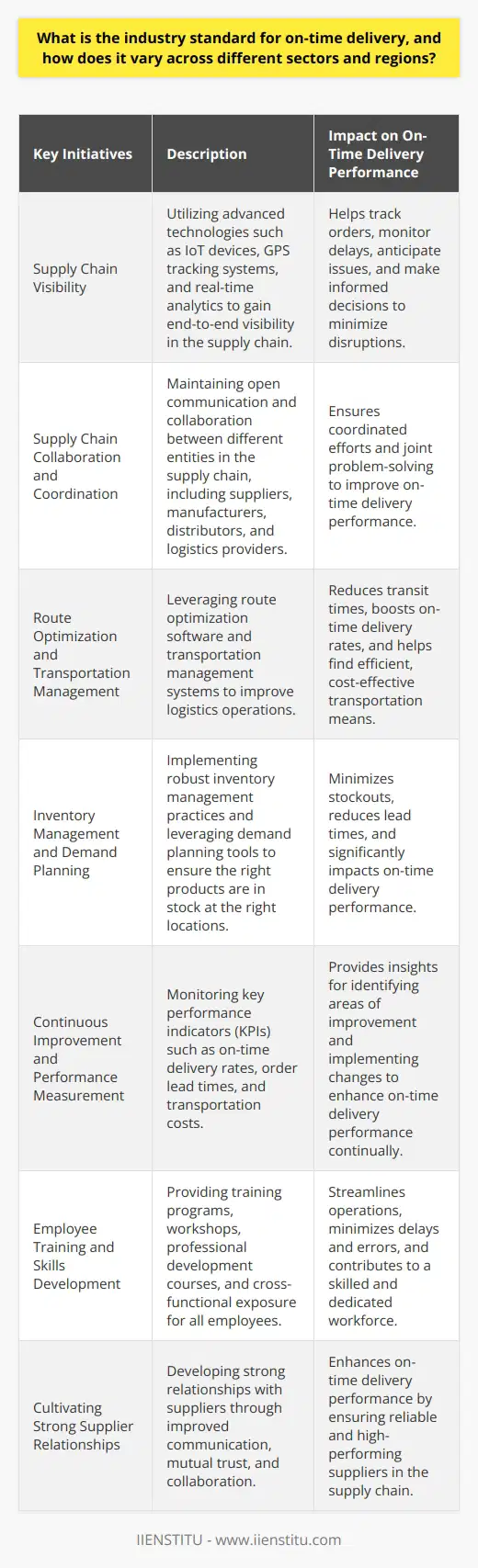

What is the industry standard for on-time delivery, and how does it vary across different sectors and regions?

Industry Standard for On-Time Delivery

The concept of the industry standard for on-time delivery pertains to the percentage of shipments that arrive at their intended destinations within the expected time frame. This metric plays a vital role in measuring the performance of supply chain management and logistics operations. However, the industry standard for on-time delivery varies significantly across different sectors and regions, mainly due to variations in customer expectations, infrastructure, and supply chain efficiencies.

Variations Across Different Sectors

In the manufacturing sector, an on-time delivery rate of 95% or higher is typically considered as a benchmark, given the critical nature of production schedules and dependencies on suppliers. The healthcare and pharmaceutical industries require even stricter on-time delivery performance, often demanding a standard of 99% or higher due to the sensitive nature of medical supplies and the necessity to ensure patient safety.

In contrast, the retail and e-commerce sectors may have slightly more relaxed standards; nevertheless, they still seek to maintain an on-time delivery rate of around 90% to ensure customer satisfaction. In the fast-food industry, a focus on speed and delivering on customers' expectations often necessitates a delivery standard of 95% or greater, particularly for well-established brands.

Regional Variations in On-Time Delivery

Geographical factors also play a role in determining on-time delivery standards. In regions with well-developed infrastructure, such as North America and Western Europe, the industry standard for on-time delivery tends to be higher, often reaching 95% or more, thanks to efficient transportation networks and advanced supply chain systems.

However, in developing regions such as Asia, Africa, and South America, infrastructure challenges and less efficient supply chain management can lead to lower on-time delivery performance, sometimes dipping as low as 80%. Here, the industry standard is significantly impacted by factors like the availability of transport options, logistics challenges, and local regulations.

Adapting to Individual Business Needs

Regardless of the sector or region, companies must constantly strive to improve their on-time delivery performance to meet their clients' requirements and stay competitive in the market. By investing in advanced technology solutions, enhancing collaboration across the supply chain, and negotiating with suppliers, firms can tailor their own on-time delivery standards to better cater to customer expectations and distinguish themselves from competitors.

In conclusion, the industry standard for on-time delivery varies across different sectors and regions, primarily driven by variations in customer expectations, infrastructure, and supply chain efficiencies. As businesses continue to operate in an increasingly globalized market, understanding and adapting to these differing standards is crucial to maintaining strong customer relationships and staying ahead in the market.