Bridging the Gap Between Engineering and Procurement: A Journey Towards Harmonized Supply Chain Management

I remember the first time I walked into a manufacturing plant as a fresh-faced engineer. The hum of machines, the clatter of tools, and the sheer energy of the place were exhilarating. But amid all that excitement, I soon discovered an undercurrent of tension between the engineering and procurement teams. It was like watching two sides of the same coin arguing over which side was shinier. Little did I know, this tension was a common hurdle in the world of supply chain management.

Introduction

The conflict between Engineering and Procurement

Benefits of Cross-Functional Teams

Involving Procurement in the Design Phase

Involving Engineering Throughout the Procurement Process

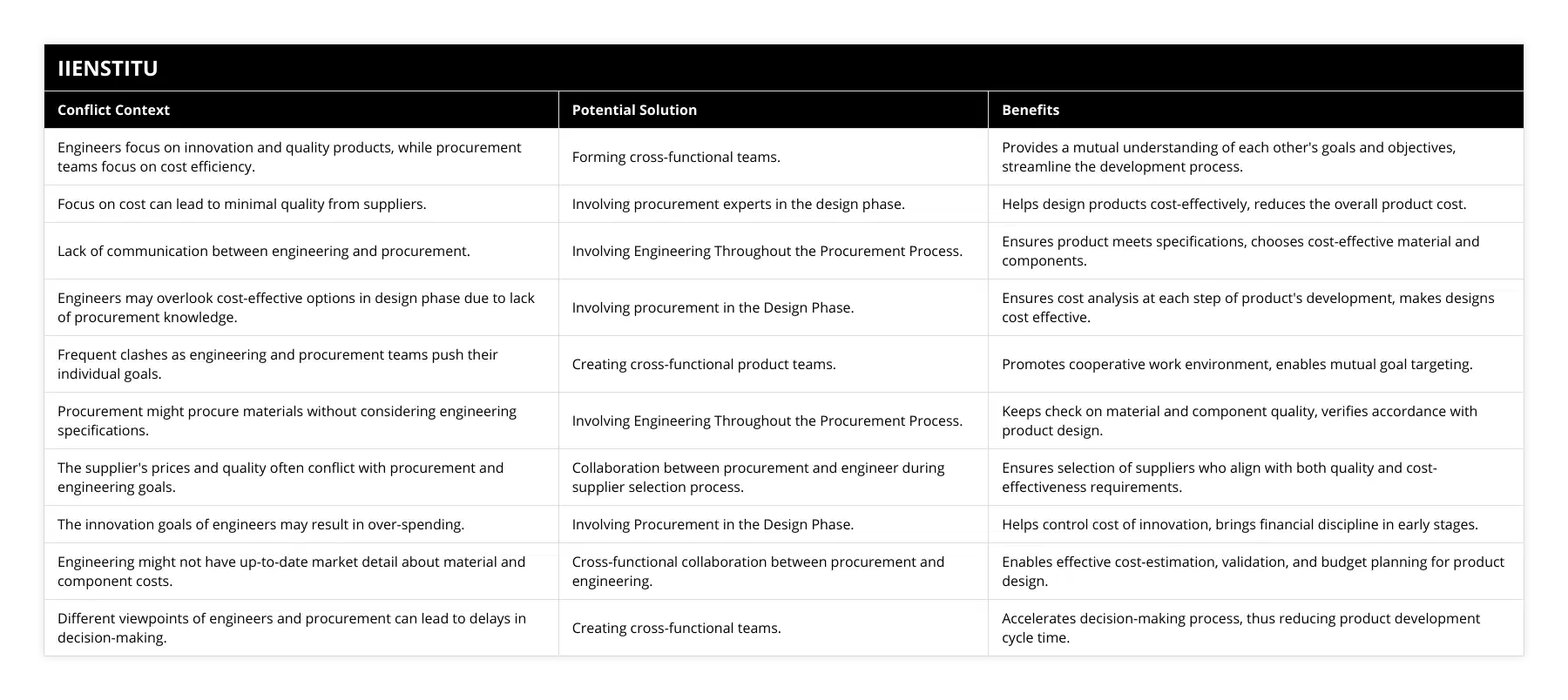

Understanding the Clash: Engineering vs. Procurement

At its core, the conflict between engineering and procurement stems from their seemingly opposing goals. Engineers are driven by innovation, constantly seeking to enhance products, integrate the latest technologies, and push the boundaries of what's possible. On the flip side, procurement teams are laser-focused on cost efficiency, aiming to secure materials and services at the best possible prices to maximize the company's bottom line.

But here's the rub: the most innovative suppliers—those who can collaborate on cutting-edge designs—often come with a heftier price tag. They're the artisans of the industry, offering unique solutions but at a premium. Meanwhile, suppliers that can offer rock-bottom prices may do so by providing standardized, minimal-quality products. It's a classic tug-of-war between quality and cost, and without proper management, it can lead to friction and inefficiencies in the supply chain.

The Human Element: Personal Experiences in Supply Chain Conflicts

I recall a project where we were designing a new electronic device. Our engineering team had identified a supplier that could provide a state-of-the-art component essential for the device's performance. We were thrilled—this was a game-changer! But when we brought this to procurement, they balked at the cost. They had found an alternative at half the price, though it didn't offer the same capabilities.

We spent weeks in meetings, each side presenting data, charts, and forecasts to support their case. It wasn't until our manager stepped in and suggested forming a cross-functional team that progress was made. By bringing together representatives from both sides, we started to see each other's perspectives. We realized that by collaborating early on, we could balance innovation with cost-effectiveness.

The Power of Cross-Functional Teams

Creating cross-functional teams is like assembling a puzzle—you need all the pieces to see the full picture. By bringing together engineering and procurement experts, companies can:

Foster open communication: When teams collaborate, they can discuss challenges and brainstorm solutions openly.

Align goals: Understanding each other's objectives helps in finding a middle ground that benefits the entire organization.

Streamline processes: Collaboration can eliminate redundancies and streamline the supply chain management process.

Enhance innovation: Diverse perspectives can lead to creative solutions that might not emerge in siloed departments.

Improve morale: Teams that work together tend to be more engaged and satisfied with their work.

In fact, according to "Supply Chain Management: Strategy, Planning, and Operation" by Sunil Chopra and Peter Meindl, companies that leverage cross-functional teams often see improved efficiency and innovation in their supply chains.

Involving Procurement Early: Designing with Cost in Mind

A unified engineering and procurement supply chain is the foundation of efficient management.

One of the best tips to optimize supply chain management is to involve procurement right from the design phase. When procurement experts are part of the initial discussions, they can offer insights into:

1- Material Costs: Understanding the price implications of different materials can guide more cost-effective choices.

2- Supplier Capabilities: Procurement can identify which suppliers are capable of meeting design requirements and at what cost.

3- Market Trends: They can provide data on market fluctuations, helping to avoid cost spikes.

4- Bulk Purchasing Opportunities: Early involvement allows for planning bulk purchases, which can lead to discounts.

5- Regulatory Compliance: Procurement ensures that materials meet all legal standards, avoiding costly redesigns later.

By having procurement at the table, the engineering team can make informed decisions that balance innovation with affordability. It's like having a financial advisor when planning a big purchase—they help you make the most of your budget.

Engineering Throughout Procurement: Ensuring Quality and Specifications

Conversely, involving engineering throughout the procurement process ensures that the selected materials and components meet the necessary specifications. Engineers can:

Validate Supplier Claims: They can test materials to confirm they meet quality standards.

Customize Solutions: Work with suppliers to tweak products to better fit design needs.

Anticipate Technical Challenges: Identify potential issues with materials before purchase.

Ensure Compatibility: Confirm that components will integrate seamlessly into the final product.

Drive Innovation: Push suppliers to offer cutting-edge solutions.

Underlining the importance of this collaboration, "The Handbook of Supply Chain Management" by James B. Ayers emphasizes that active engineering involvement in procurement leads to higher quality products and reduced time-to-market.

Overcoming Challenges: Practical Steps Towards Integration

To achieve a harmonized engineering and procurement supply chain, companies can take several practical steps:

1- Establish Joint Objectives: Set shared goals that both teams strive towards, such as cost reduction targets coupled with innovation benchmarks.

2- Implement Regular Meetings: Schedule consistent cross-departmental meetings to discuss ongoing projects and challenges.

3- Invest in Training: Offer cross-training opportunities so team members understand each other's roles and constraints.

4- Utilize Integrated Systems: Adopt electronic supply chain management tools that allow for real-time collaboration and data sharing.

5- Encourage Social Interaction: Sometimes, informal gatherings can break down barriers and build trust between teams.

The Role of Supply Chain Management in Bridging the Gap

At the heart of this integration is effective supply chain management (SCM). A robust SCM system ensures that all facets of the supply chain, from design to delivery, are aligned and working towards common objectives. SCM supply chain management is not just about moving goods; it's about moving information, fostering collaboration, and driving efficiency.

According to "Introduction to Supply Chain Management" by Robert B. Handfield and Ernest L. Nichols, companies that successfully integrate their supply chain departments often see:

Reduced Costs: Efficiency leads to savings in procurement, production, and distribution.

Improved Quality: Collaborative efforts result in higher-quality products.

Faster Time to Market: Streamlined processes accelerate product development cycles.

Enhanced Customer Satisfaction: Better products delivered on time keep customers happy.

Personal Reflections: Lessons Learned in Supply Chain Mgmt

Looking back on my career, I've seen firsthand the benefits of integrating engineering and procurement. In one project, we managed to reduce production costs by 15% without compromising on quality, simply because we collaborated closely with procurement from the outset. It wasn't always easy—there were heated debates and challenging negotiations—but the results spoke for themselves.

It's about changing the mindset from "us versus them" to "we're in this together". When both teams recognize that they are working towards a shared goal, the entire organization thrives.

Conclusion: Building a Unified Supply Chain Department

In wrapping up, the friction between engineering and procurement doesn't have to be a roadblock. By fostering collaboration through cross-functional teams, involving procurement in the design phase, and integrating engineering throughout the procurement process, companies can build a more efficient and harmonious supply chain department.

A unified engineering and procurement supply chain is the bedrock of efficient management chain supply. It not only optimizes processes but also drives innovation and profitability. As we've explored, the key lies in communication, mutual respect, and shared objectives.

So, the next time you're faced with a procurement dilemma or an engineering conundrum, remember that teamwork makes the dream work. It might sound cliché, but it's true. By bridging the gap between these critical departments, we pave the way for a brighter, more collaborative future in scm management.

References

1- Chopra, S., & Meindl, P. (2016). Supply Chain Management: Strategy, Planning, and Operation. Pearson.

2- Ayers, J. B. (2006). Handbook of Supply Chain Management. Auerbach Publications.

3- Handfield, R. B., & Nichols, E. L. (2002). Introduction to Supply Chain Management. Prentice Hall.

4- Monczka, R. M., Handfield, R. B., Giunipero, L. C., & Patterson, J. L. (2015). Purchasing and Supply Chain Management. Cengage Learning.

5- Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (2008). Designing and Managing the Supply Chain: Concepts, Strategies, and Case Studies. McGraw-Hill.

Note: This article draws from personal experiences and industry-standard practices to provide insights into optimizing supply chain management through improved collaboration between engineering and procurement teams.

Frequently Asked Questions

What are the benefits of uniting engineering and procurement in supply chain management?

Efficient supply chain management is essential for any business's success. In recent years, engineering and procurement have increasingly intertwined in supply chain management. Uniting engineering and procurement offers many benefits that can improve the overall efficiency of a business's supply chain.

One of the critical benefits of uniting engineering and procurement is that it enables businesses to manage their supply chain operations better. By combining engineering and procurement, companies can identify and address potential supply chain problems before they arise. This can help to reduce costs, as well as increase the speed at which goods are delivered. Additionally, engineering and procurement can be used to develop strategies that improve the overall efficiency of the supply chain.

Another benefit of uniting engineering and procurement is that it allows businesses to manage their resources better By combining engineering and procurement, companies can identify any potential areas of concern in the supply chain that may require additional resources. This can help ensure that resources are allocated the most efficiently possible. In addition, it can help businesses better manage their inventory levels, which can help reduce costs associated with overstocking.

Finally, uniting engineering and procurement can help businesses to stay competitive in the market. Companies can identify opportunities for cost savings and efficiency gains by combining engineering and procurement. Additionally, they can use the knowledge they gain to develop new products and services tailored to their customers' needs. This can help businesses to remain competitive in the market, as well as improve their overall profitability.

In conclusion, uniting engineering and procurement can offer numerous benefits for businesses. It can enable companies to manage their supply chain operations more efficiently, manage their resources, and remain competitive. For these reasons, uniting engineering and procurement is integral to successful supply chain management.

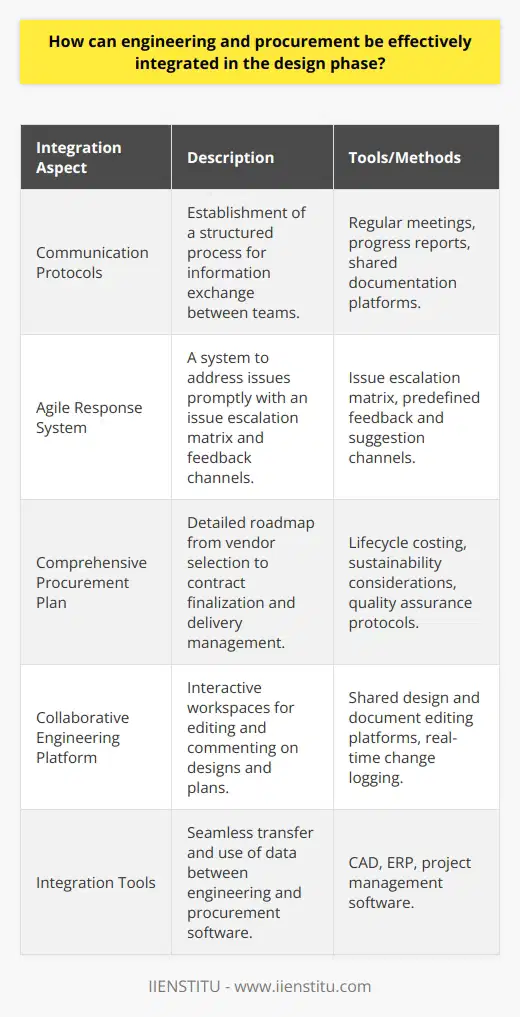

How can engineering and procurement be effectively integrated in the design phase?

The effective integration of engineering and procurement in the design phase of a project is essential for success. This integration ensures that all stakeholders clearly understand the project objectives and the overall project timeline. The integration can be achieved by incorporating several strategies, such as establishing clear communication protocols, developing a comprehensive procurement plan, and utilizing a collaborative engineering platform.

The first step in effective integration is establishing clear communication protocols. Communication protocols should be established between engineering and procurement teams to ensure that all parties know project objectives and expectations. These protocols should include sharing project goals and objectives, as well as the roles and responsibilities of each team. It is also essential to develop a system for effectively tracking project progress and responding to any issues that may arise.

The second step is developing a comprehensive procurement plan. Procurement plans should include the identification of required materials and components, the selection of suppliers, and the negotiation of pricing and terms. The program should also include establishing quality assurance systems, formulating order fulfillment processes, and developing a method for tracking and managing inventory.

The third step is utilizing a collaborative engineering platform. Collaborative engineering platforms enable engineering and procurement teams to collaborate in real-time and quickly make changes to designs and plans. These platforms allow for the sharing of project information, the development of dynamic processes, and the tracking of tasks. Additionally, these platforms can identify potential issues and resolve them quickly.

By incorporating these strategies, engineering and procurement teams can effectively integrate into the design phase. This integration ensures that all stakeholders are aware of project objectives and the overall project timeline while providing a platform for collaboration and problem-solving.

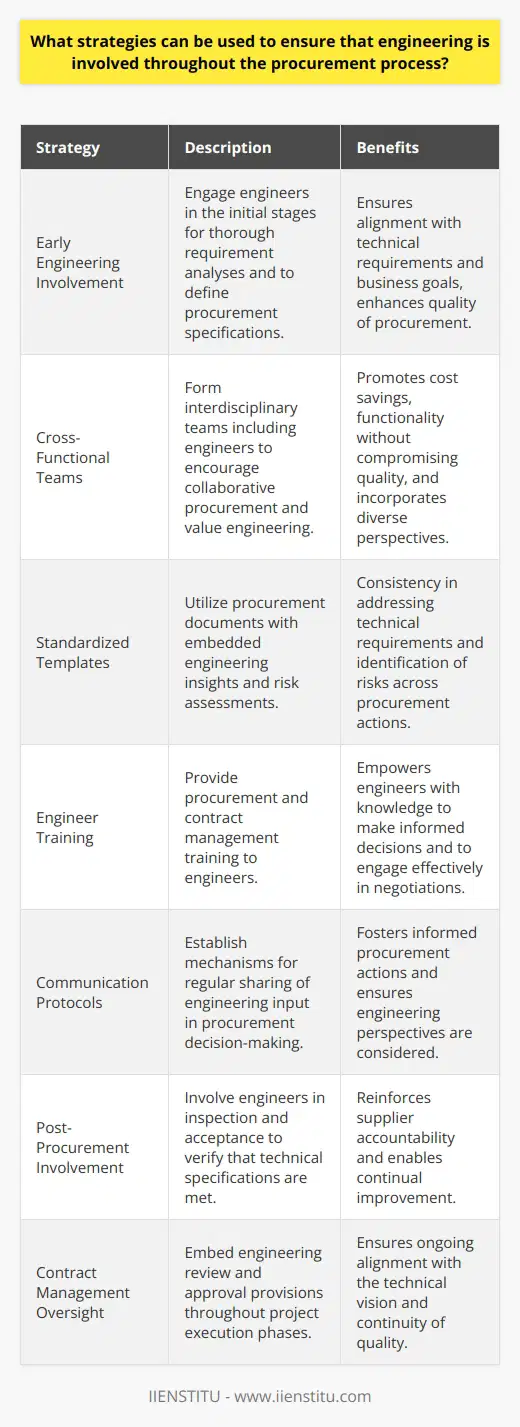

What strategies can be used to ensure that engineering is involved throughout the procurement process?

The introduction of engineering into the procurement process can be a challenging task. However, it is essential for successful procurement, as the procurement process involves a wide range of stakeholders and decision-makers. This article will provide an overview of the strategies that can be used to ensure that engineering is engaged throughout the procurement process.

First, ensuring that engineering is adequately represented in the procurement process is essential. This can be done by adopting a structured approach, such as the one described in the Institute of Electrical and Electronics Engineers (IEEE) Std 1074-2006. This process provides a framework for developing a procurement system that includes a series of steps, from the initial identification of needs to evaluating proposals. It also includes the monitoring of the implementation and the assessment of the results.

Second, it is essential to ensure that engineering is adequately resourced. This can be achieved by allocating sufficient funds to the engineering department and providing adequate staffing and training. Additionally, the engineering team should have to execute the procurement process effectively the necessary tools, such as software and databases, to execute the procurement process effectively.

Third, ensuring that the engineering team's requirements are considered is essential. This can be done by involving engineering in the definition of the requirements, as well as in the evaluation of the bids. Additionally, it is essential to provide engineering with the necessary feedback on the procurement process results to ensure that any changes or improvements are implemented.

Finally, it is essential to ensure that engineering is involved in the post-procurement process. This can be done by providing engineering with the opportunity to review the performance of the suppliers, as well as to provide feedback on the results of the procurement process. Additionally, it is essential to ensure that engineering is involved in the management of the procurement process, as well as in the development of any future procurement requirements.

In conclusion, engineering is an integral part of the procurement process and is essential for successful procurement. The strategies outlined in this article can be used to ensure that engineering is appropriately represented throughout the procurement process. By following these strategies, organizations can ensure that engineering is involved in all stages of the procurement process, from the initial identification of needs to evaluation of the results.

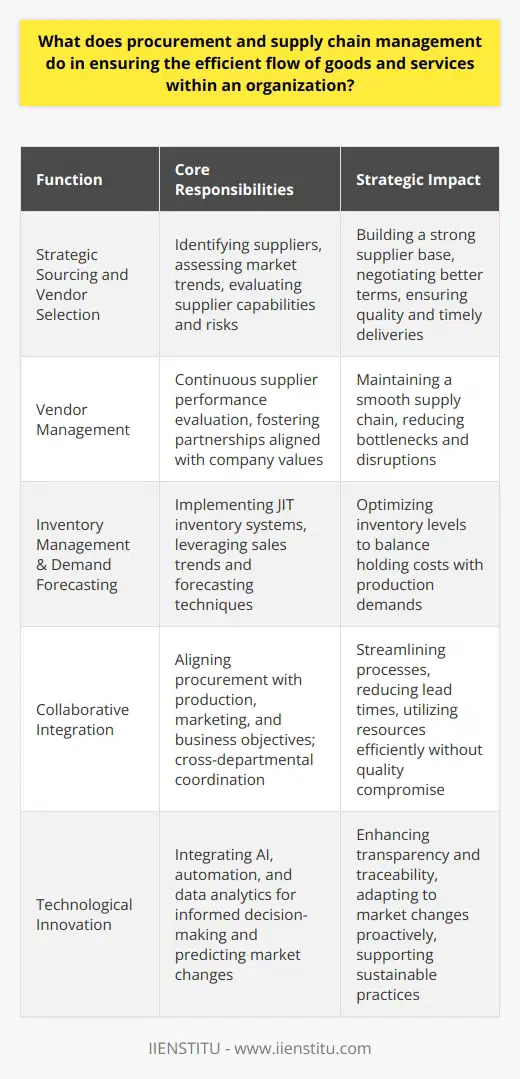

What does procurement and supply chain management do in ensuring the efficient flow of goods and services within an organization?

Role of Procurement in Supply Chain Management

Procurement and supply chain management (SCM) play critical roles in ensuring the efficient flow of goods and services within an organization. Procurement is responsible for acquiring necessary goods and services, while SCM involves managing the entire process from production to distribution to the final customer.

Strategic Sourcing and Vendor Selection

To optimize supply chain performance, procurement teams implement strategic sourcing practices. This involves a detailed analysis of the organization's needs and the development of an effective purchasing strategy. By engaging with suppliers and gathering relevant data, procurement teams ensure high-quality inputs and cost-effective agreements. Good supplier relationships are critical for effective supply chain management, resulting in improved product availability and reduction of supply chain risks.

Inventory Management and Demand Forecasting

Procurement and SCM professionals collaborate on inventory management and demand forecasting to balance supply and demand. Accurate demand forecasting allows organizations to maintain optimal inventory levels, reducing holding costs and preventing stockouts. This results in the timely delivery of goods and services and enhances customer satisfaction. Procurement and supply chain management are also responsible for managing safety stocks, assuring the flow of goods, and minimizing disruptions in the supply chain.

Coordination and Collaboration between Departments

Efficient communication and cooperation between procurement and other organizational departments, such as production, marketing, and logistics, are crucial in enhancing supply chain performance. Sharing relevant information and working together on joint goals allows for a smoother procurement process, faster decision-making, and improved supply chain effectiveness. Reduced lead times, synchronized production plans, and well-planned logistics also contribute to the seamless flow of goods and services.

Continuous Improvement and Technology Integration

Procurement and SCM practices are constantly evolving as organizations strive for higher efficiency and competitiveness. Continuous improvement methodologies, such as Lean and Six Sigma, are employed to analyze and streamline procurement and supply chain processes. The adoption of modern technologies, such as Artificial Intelligence, Internet of Things, and Blockchain, also enhances visibility and traceability within the supply chain, ultimately improving overall performance.

In conclusion, procurement and supply chain management are essential components for ensuring the efficient flow of goods and services within an organization. Effective procurement strategies, inventory management, departmental collaboration, and continuous improvement initiatives contribute to achieving this goal, ultimately enhancing the organization's ability to meet customer demands and sustain market competitiveness.

Is procurement and supply chain a good career in terms of job growth and salary prospects?

Growth Opportunities in Procurement and Supply Chain

In recent years, the procurement and supply chain management field has experienced significant growth and recognition, due in part to increasing globalization, advancements in technology, and innovative business practices. As a result, a career in procurement and supply chain has become an attractive option for those seeking job growth, stability, and competitive compensation packages.

Advancements Driving Demand for Skilled Professionals

Globalization leads organizations to incorporate procurement and supply chain professionals in their workforce to ensure efficient resource allocation and optimally managed supply chain networks. Additionally, transformative technological advancements – such as automation, artificial intelligence, and Internet of Things (IoT) – demand adept professionals to drive positive outcomes and value creation for businesses. Thus, the rapid changes in the business landscape continue to create a growing demand for well-rounded procurement and supply chain professionals.

Stable Job Prospects for Qualified Candidates

As companies strive to improve their supply chain networks, professionals possessing the analytical, technical, and interpersonal skills necessary to manage and optimize these complex systems will be highly sought after. Furthermore, the increased focus on implementing environmentally sustainable and socially responsible practices creates opportunities for specialists working in procurement and supply chain management. This stable job market ensures that qualified candidates possess ample potential for career advancements in various industries, functional areas, and management levels.

Competitive Compensation Packages Reflect Value

In terms of salary prospects, procurement and supply chain professionals command competitive compensation packages that reflect the integral role they play in driving organizational growth and success. As indicated by various industry reports, those working in procurement and supply chain management enjoy above-average salaries – with senior leadership roles often earning six-figure salaries, reflecting the function's increased responsibility and influence within their organizations. The robust salary prospects, coupled with professional growth opportunities, make procurement and supply chain management careers highly desirable.

Conclusion

In conclusion, a career in procurement and supply chain management presents ample opportunities for job growth, stable prospects in various industries, and competitive salary packages. Driven by globalization, advanced technologies, and increased corporate responsibility, the demand for skilled procurement and supply chain professionals will only continue to rise, making it a highly attractive career choice for those seeking professional growth and rewarding compensation.

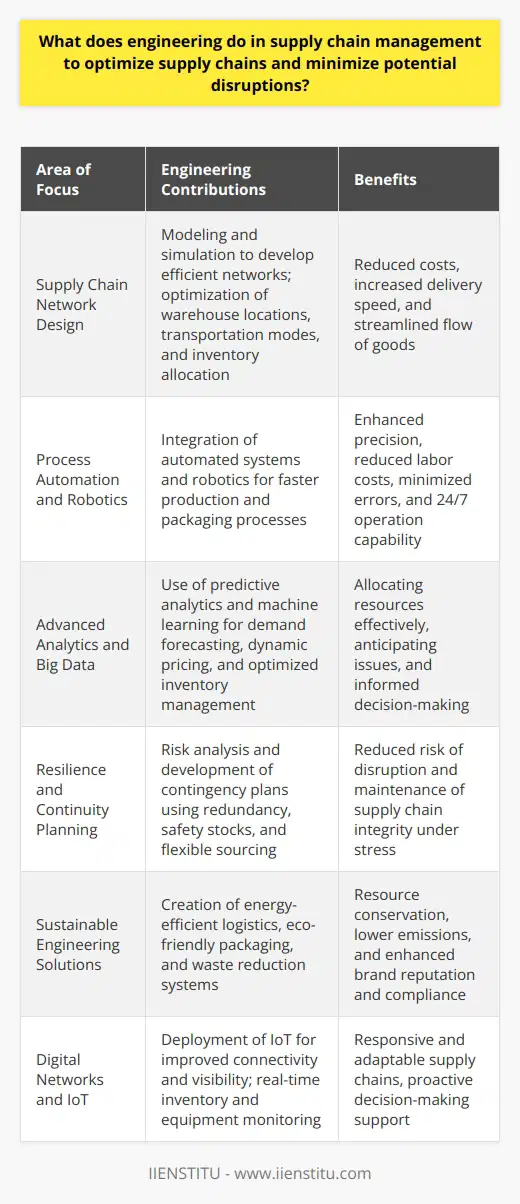

What does engineering do in supply chain management to optimize supply chains and minimize potential disruptions?

Role of Engineering in Optimization

Engineering plays a vital role in supply chain management by planning, designing, and executing optimization techniques that improve efficiency while reducing potential disruptions. These engineers use analytical methods and tools to develop strategies that minimize risks and enhance the performance of the supply chain.

Technological Innovations

One significant contribution of engineering to supply chain management is the development of technological innovations. Engineers design and implement advanced software systems, automation processes, and robotics that not only streamline operations but also reduce human error. By incorporating these technologies into the supply chain, companies can achieve higher levels of efficiency and productivity.

Data-driven Decision Making

Engineers also support data-driven decision making in supply chain management. They collect and analyze data from various sources, helping supply chain managers make informed decisions about inventory levels, transportation routes, and supplier relations. The use of data helps prevent potential disruptions, as managers are able to predict and respond to changing demands and unexpected events.

Risk Mitigation

To minimize potential disruptions, engineers address vulnerabilities in the supply chain by designing risk mitigation strategies. They assess potential threats and develop plans to counteract or eliminate them, ensuring the supply chain remains resilient in the face of challenges. Some of these strategies include diversifying suppliers, implementing redundancies, and employing backup storage facilities.

Sustainable Practices

Lastly, engineering contributes to the development of sustainable practices in supply chain management. Engineers design systems that decrease waste and energy consumption while promoting resource efficiency, which leads to long-term cost savings and reduced environmental impact. By incorporating sustainable practices in their operations, companies can optimize their supply chains and minimize potential disruptions.

In conclusion, engineering plays an essential role in supply chain management by optimizing processes, reducing risks, and promoting sustainability. Through technological innovations, data-driven decision making, risk mitigation strategies, and sustainable practices, engineers contribute significantly to the overall optimization of supply chains and minimizing potential disruptions.

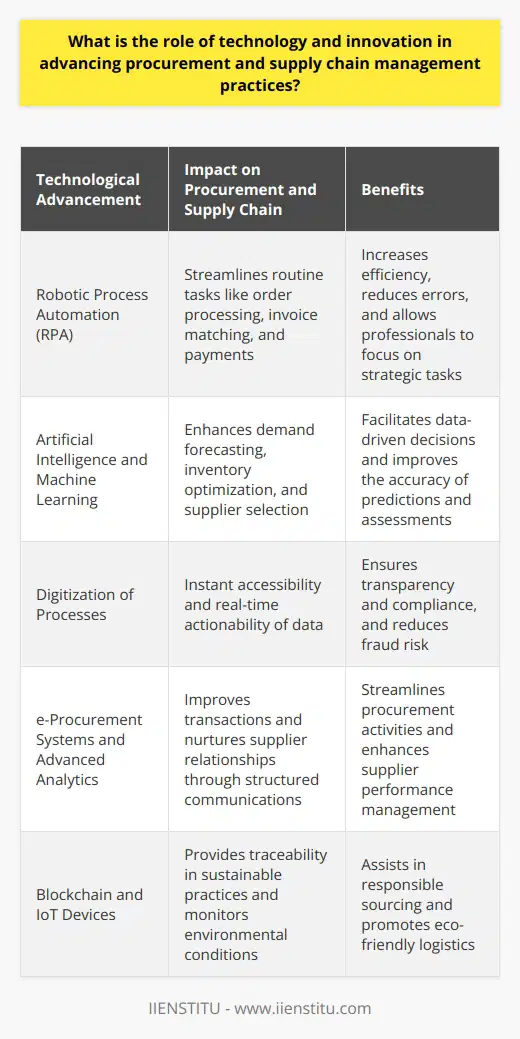

What is the role of technology and innovation in advancing procurement and supply chain management practices?

Role of Technology in Procurement and Supply Chain Management

Technology plays a critical role in enhancing procurement and supply chain practices. Primarily, technological innovation provides automation and digitization in operations. Automation allows enterprises to simplify complex, repetitive tasks. It increases speed, reliability, and accuracy.

Automation and Efficiency

Process automation in procurement eliminates human errors and improves efficiency. Technology, such as artificial intelligence (AI), is particularly impactful. AI can make purchasing more streamlined through machine learning. It can predict market trends, understand supplier behavior, and help decision-making.

Digitization and Real-Time Data Access

Digitization in procurement brings real-time data access. Live, accurate data can allow more informed, quicker decisions. It enhances strategic planning and reduces supply chain risks. Digital tools aid in data analysis, driving insightful metrics for procurement teams.

Technology and Supplier Relationships

Technology progresses supplier relationships, as well. E-procurement platforms, for instance, connect buyers to a global pool of suppliers. They promote better supplier selection, fostering transparent, equitable practices. Moreover, communication technologies like video conferencing facilitate a more interactive supplier engagement.

Innovations and Sustainability

Innovations also support sustainability in procurement. Tools like blockchain can track materials along the supply chain, ensuring ethical sourcing. Similarly, predictive analytics can optimize inventory management, reducing waste, and promoting sustainability.

Thus, technology and innovation unquestionably advance procurement and supply chain management. They streamline and automate processes, provide real-time data, enhance supplier relationships, and foster sustainability. As technological advancements continue, further improvements in these areas are anticipated.

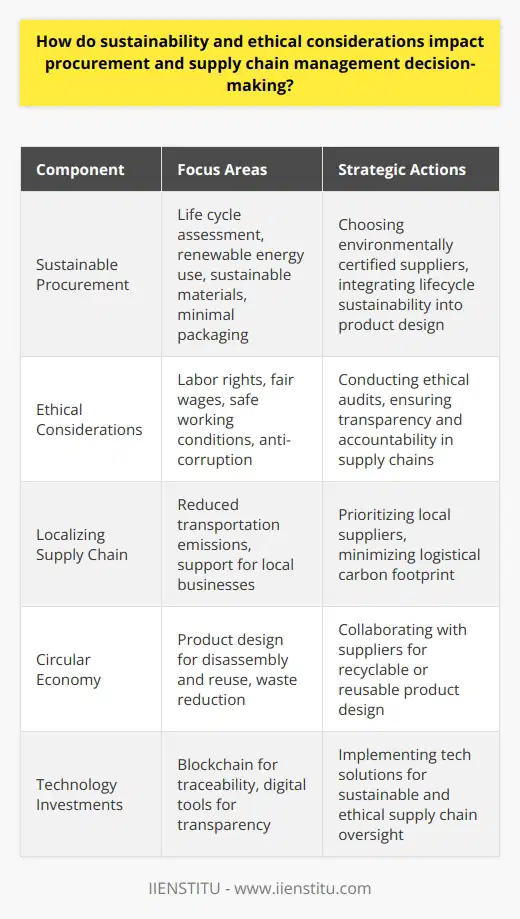

How do sustainability and ethical considerations impact procurement and supply chain management decision-making?

Influence of Sustainability on Procurement Decisions

Sustainability significantly impacts procurement and supply chain management decisions. Companies are increasingly recognizing the environmental implications of their decisions and prioritizing environmental sustainability.

The drive for sustainable choices means evaluating vendors based on their commitment to green practices. This may include reviewing their waste management policies, energy efficiency, and carbon footprints among other factors. Such considerations can directly influence which vendors to choose and what products to procure.

Ethical Considerations in Decision-Making

Equally important are ethical considerations. Social responsibility is increasingly a key determinant in decision-making protocols. This implies ensuring fair trade practices, combating child and forced labor, and upholding human rights within the supply chain.

Companies consider vendors' ethical policies, the source of their products, and their employment practices. Decisions may also incorporate how vendors engage with local communities and their general corporate social responsibility (CSR) stance.

Impact on Supply Chain Management

Sustainability and ethical commitments can transform supply chain management. Companies may shorten their supply chains to lessen environmental impacts. This could involve local sourcing or collaborations with suppliers who champion green initiatives. Moreover, the ethical standpoint can also affect partnerships, potentially disqualifying vendors who do not meet specific ethical standards.

Companies may also invest in traceability technologies for greater transparency. Ethical and sustainability efforts can thus push for innovations within the supply chain, enhancing trust and brand reputation in the process.

In conclusion, sustainability and ethical considerations fundamentally influence procurement and supply chain management decisions. A commitment towards these principles can lead to significant changes in business practices, partnerships, and overall brand perception.

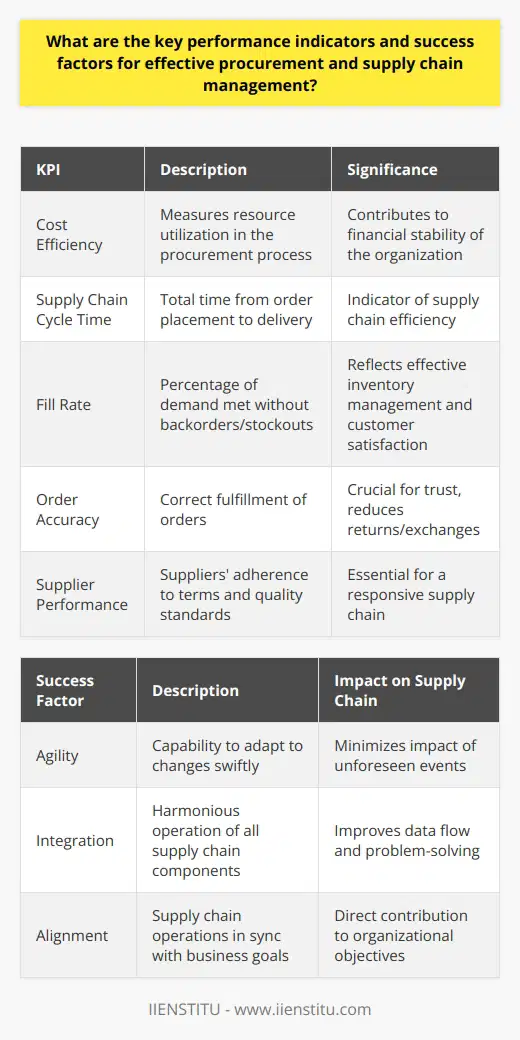

What are the key performance indicators and success factors for effective procurement and supply chain management?

Key Performance Indicators for Procurement and Supply Chain Management

In effective procurement and supply chain management, several key performance indicators (KPIs) define success. They are Cost Efficiency, Supply Chain Cycle Time, Fill Rate, Order Accuracy, and Supplier Performance.

Understanding Indicators: Cost Efficiency and Cycle Time

Cost Efficiency is a measure of the total cost incurred in getting a product from the supplier to the customer. Most firms aim at low operational costs and high profits. Supply Chain Cycle Time measures the time taken from order placement till the final delivery. Shorter cycles indicate enhanced efficiency.

Role of Fill Rate and Order Accuracy

Fill Rate assesses whether an organization meets its customers' orders fully. High fill rates show exceptional demand forecasting and resource allocation capabilities. Order Accuracy refers to the percentage of orders delivered without errors. It reflects customer satisfaction and overall performance efficiency.

Impact of Supplier Performance

Lastly, Supplier Performance checks the suppliers' efficiency in meeting their contractual obligations. High performance ensures fewer disruptions and better overall functioning.

Critical Success Factors

Turning attention to the success factors for procurement and supply chain management; agility, integration, and alignment are critical.

The Importance of Agility

Agility refers to the ability of the supply chain to respond quickly to market changes. An agile supply chain is more competitive and yields higher customer satisfaction.

Integration and Alignment Impact

Integration means properly aligning all supply chain processes. When smoothly integrated, the overall efficiency improves. Finally, alignment is aligning the supply chain strategy with the overall business goals. Proper alignment supports the company's strategic objectives and drives growth.

In conclusion, a firm's procurement and supply chain management's effectiveness is gauged by several key performance indicators and success factors. These indicators and factors guide businesses in making informed decisions, promoting efficiency and growth.

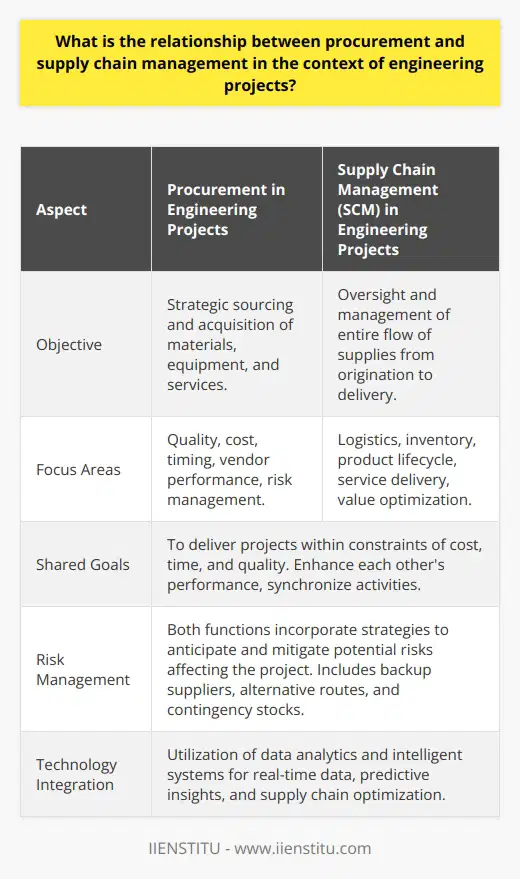

What is the relationship between procurement and supply chain management in the context of engineering projects?

Understanding the Relationship

Procurement and supply chain management often intertwine in the context of engineering projects. Both are integral to a project's success.

Role of Procurement

In engineering, procurement involves acquiring needed resources and services. This may include acquiring raw materials, machines, technologies, human resources, or other services. Accurate and timely procurement impacts the efficiency of the whole project.

Supply Chain Management and Its Influence

Supply chain management can be viewed as a complex network. It connects different stakeholders such as suppliers, manufacturers, and customers. The supply chain ensures the flow of information, products, and finances. In terms of engineering projects, supply chain management guarantees the availability of necessary resources.

The Interconnection

Procurement and supply chain management interrelate closely. Effective procurement improves efficiency of the supply chain. Conversely, a well-managed supply chain facilitates smooth procurement processes. They thus form a symbiotic relationship, benefiting engineering projects' effectiveness and efficiency.

Impact on engineering Projects

In an engineering project, these two elements can largely determine the project's timeline, cost, and quality. A strategic procurement and supply chain management system can help optimize resources, reduce costs, and enhance project performance.

In conclusion, understanding the relationship between procurement and supply chain management is a crucial aspect in managing engineering projects. Together, they provide an efficient mechanism to ensure the delivery of quality results consistently and effectively.

How do procurement and supply chain management principles contribute to the overall effectiveness and efficiency of engineering projects?

Understanding Procurement Principles

Procurement involves the acquisition of goods, services or works from an outside source. Engineering projects use procurement principles to select the appropriate suppliers, manage contracts, and maintain the quality and cost-effectiveness of the project. This way, they can ensure that they get the best value for money, reduce production costs and maintain high-quality standards.

Implications of Supply Chain Management

Supply chain management, on the other hand, handles the flow of goods and services. It includes all processes involved, from the raw materials stage right up to delivery and use by the ultimate consumer. In engineering projects, effective supply chain management contributes to minimizing costs and time delays, enhancing customer satisfaction and improving the overall project performance.

Procurement and Supply Chain Management Synergy

These principles don't work alone in impacting project efficiency and effectiveness. The synergy between procurement and supply chain management principles guarantees that businesses meet their operational needs. They cooperate in selecting and managing suppliers, negotiating contracts, and ensuring timely delivery of quality materials.

Conclusion

In conclusion, procurement and supply chain management principles are vital for the efficiency and effectiveness of engineering projects. They ensure that businesses have control over their expenditure, minimize project delays, reduce production costs, maintain high-quality standards and meet their operational needs properly. Therefore, integrating these principles into the project management process significantly boosts a project's overall success.

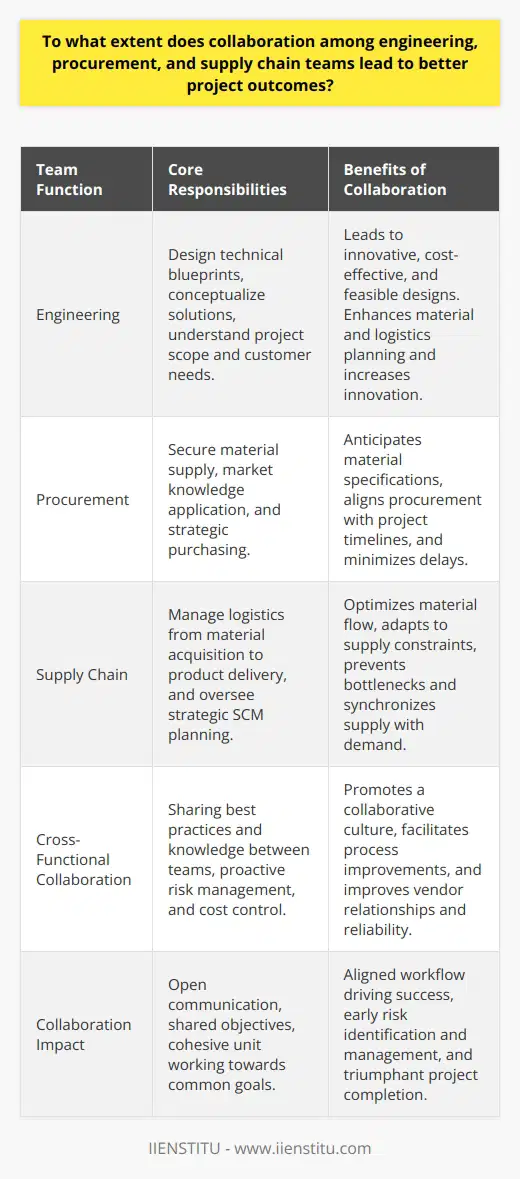

To what extent does collaboration among engineering, procurement, and supply chain teams lead to better project outcomes?

Impact on Project Outcomes

There is a significant correlation between the success of a project and the level of collaboration among engineering, procurement, and supply chain teams. Rooted in this collaboration, efficient project planning, deployment, and execution can reduce project costs, optimize resources, and mitigate risks, leading to successful outcomes.

Role of Engineering Team

The engineering team plays a pivotal role in the design and functional aspects of any project. They have the expertise to develop innovative solutions that address project requirements effectively. Working collaboratively with procurement and supply chain teams, they influence the selection of materials and equipment, impacting cost, functionality, and sustainability.

Procurement Team Collaboration

Similarly, the procurement team, given its strategic position within the supply chain, aids by securing materials, services, and equipment at the most favourable terms. Close collaboration with engineering and supply chain teams ensures alignment with project specifications and timelines. Besides, they contribute to risk mitigation by identifying and resolving potential supply disruptions.

Involvement of Supply Chain Team

The supply chain team, on the other hand, wields significant control over the project's flow and execution. Particularly, they ensure timely transportation and availability of project materials, in line with the engineering and procurement schedules. Effective integration with the engineering and procurement teams thus streamlines project execution and enhances efficiency.

In conclusion, the interdisciplinary collaboration of these teams can create an environment where everyone works towards a common goal. This unity drives better decision-making and efficiency, positively influencing project outcomes. Hence, the degree of collaboration amongst these teams can significantly dictate the success or failure of a project.