Introduction

I still remember the day when my friend Sarah called me in a panic. Her family-owned hardware store was facing a crisis: despite having a warehouse full of products, they couldn't fulfill customer orders on time. "We're swimming in inventory, but we can't find what we need when we need it," she lamented. This was the moment I realized just how crucial effective logistics management is in today's fast-paced business world.

In the modern business landscape, logistics isn't just about moving goods from point A to point B. It's the lifeblood of any operation, ensuring that everything flows smoothly from the supplier to the customer. Businesses that master their logistics can not only reduce costs but also significantly improve customer satisfaction. On the flip side, poor logistics can lead to delays, increased expenses, and unhappy customers.

Introduction

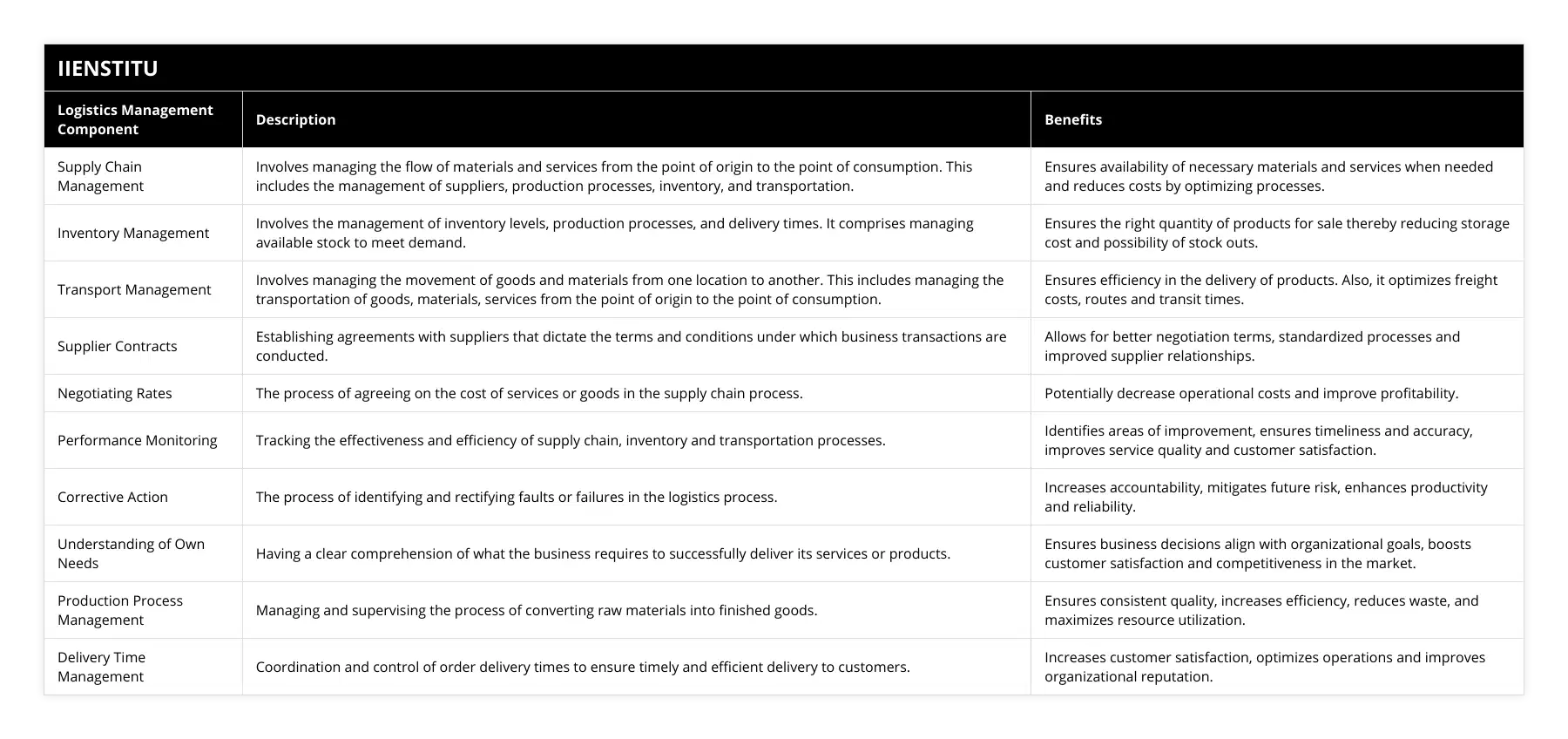

Supply Chain Management

Inventory Management

Transport Management

Benefits of Effective Logistics Management

Over the years, I've seen companies transform their operations by focusing on three key components: supply chain management, inventory management, and transport management. Let's dive into these areas and explore how they can make or break a business.

Supply Chain Management

Supply chain management is like the backstage crew in a theater production—if everything runs smoothly, the audience doesn't even notice them. But if something goes wrong, oh boy, does it show!

At its core, supply chain management involves overseeing the entire flow of goods and services, from raw materials to finished products delivered to the customer. It's about coordinating with suppliers, manufacturers, and retailers to ensure everything happens seamlessly.

I recall working with a small electronics company that was struggling with delayed shipments and mounting costs. After analyzing their processes, we discovered that they lacked strong relationships with their suppliers. By investing time in building those relationships, negotiating better terms, and implementing more efficient communication channels, they were able to reduce delays significantly. Moreover, they adopted some optimize supply chain management process tips, such as leveraging technology for real-time tracking and forecasting demand more accurately.

If you're looking to optimize your supply chain, here are some tips:

1- Develop strong relationships with suppliers: Trust me, it's easier to navigate hiccups when you have a solid rapport.

2- Implement technology solutions: Supply chain management software can provide real-time data, helping you make informed decisions.

3- Forecast demand accurately: Use historical data and market trends to predict future demand, reducing overstocking or stockouts.

4- Streamline your processes: Regularly review your processes to identify bottlenecks or inefficiencies. Sometimes, even small tweaks can make a big difference.

5- Train your team: A well-trained team is essential. Ensure everyone understands their role in the supply chain and how it impacts the bigger picture.

By focusing on these areas, businesses can create a more resilient and efficient supply chain, capable of adapting to market changes and customer demands.

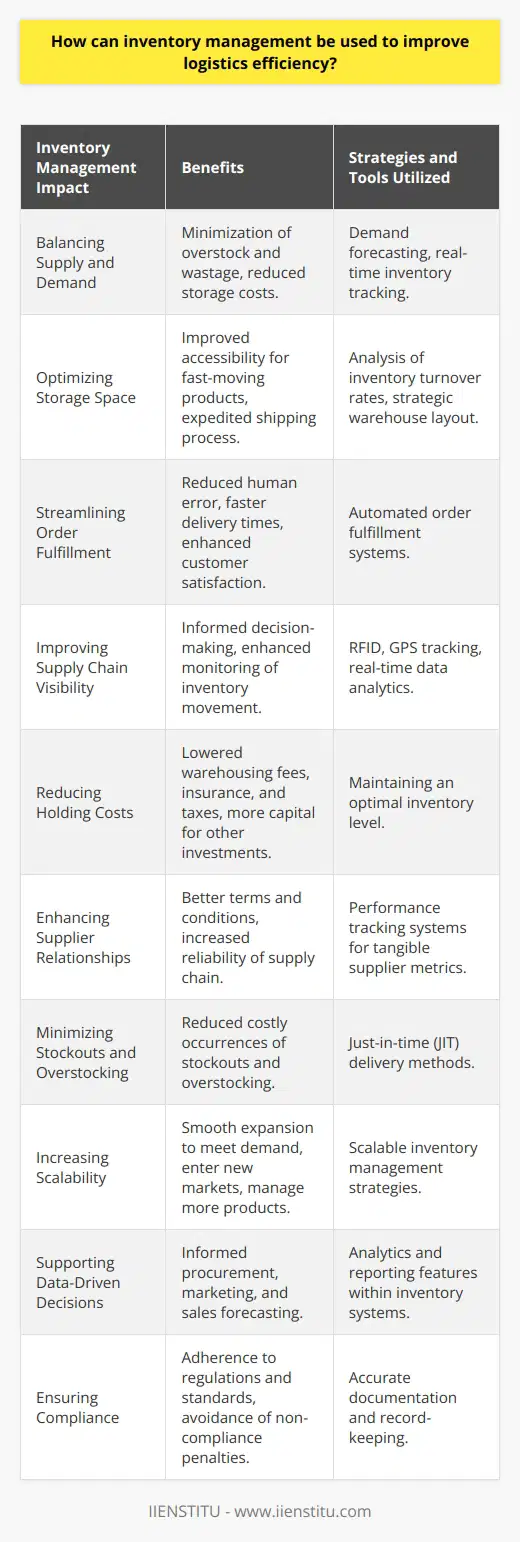

Inventory Management

Now, let's talk about inventory management—the art of juggling between too much and too little. Remember Sarah from earlier? Her store's issue was a classic case of poor inventory management.

Balancing Capacity Responsiveness Flexibility And Cost İn Supply Chain

Logistics Management İn Supply Chain Efficiency And Customer Service

Having excess inventory ties up capital and incurs storage costs, while having too little leads to lost sales and unhappy customers. It's a delicate balance.

One common mistake I've seen is businesses relying on gut feeling rather than data. A friend who runs a boutique told me she always overstocked during the holiday season because "that's when people shop the most." But when we looked at her sales data, we found that her peak season was actually in spring, when tourists flocked to the area.

Here are some best practices for inventory management:

Utilize inventory management software: These tools can track stock levels in real-time, set reorder points, and forecast demand.

Classify your inventory: Use the ABC analysis to categorize items based on their importance. Focus your efforts where it matters most.

Conduct regular audits: Regular stock counts can identify discrepancies and help maintain accuracy.

Implement a just-in-time (JIT) system: Order inventory only as needed to reduce holding costs.

Train your staff: Ensure everyone handling inventory knows the procedures and the importance of accuracy.

By applying these practices, businesses can reduce costs, improve cash flow, and enhance customer satisfaction.

Transport Management

Transport management is all about getting products where they need to be, on time and in good condition. It's not just about choosing the fastest route, but also about cost-effectiveness and reliability.

I once worked with a regional food distributor who was facing high transportation costs. Upon reviewing their routes, we realized that their trucks were often half-empty. By optimizing their delivery schedules and consolidating shipments, they were able to reduce costs significantly.

Some strategies for effective transport management include:

1- Optimize routing: Use software to plan the most efficient routes, considering factors like traffic, distance, and fuel consumption.

2- Consolidate shipments: Combine smaller shipments to maximize vehicle capacity.

The key to successful logistics lies in effective management of resources.

3- Choose the right transportation mode: Depending on the urgency and nature of goods, decide whether road, rail, air, or sea transport is most appropriate.

4- Negotiate with carriers: Build relationships with carriers to get better rates and service levels.

5- Monitor performance: Track key metrics like on-time delivery rates and transportation costs to identify areas for improvement.

By focusing on transport management, businesses can ensure timely deliveries while keeping costs under control.

Benefits of Effective Logistics Management

Implementing effective logistics management strategies brings a host of benefits.

Improved Customer Service

Customers today expect fast, reliable service. By optimizing logistics, businesses can meet or even exceed these expectations. When customers receive their orders promptly and in good condition, it builds trust and loyalty.

Reduced Costs

Efficient logistics operations minimize waste and reduce costs associated with storage, transportation, and inventory holding. This not only improves the bottom line but also allows businesses to offer more competitive pricing.

Increased Profitability

When costs are reduced and customer satisfaction is high, profitability naturally increases. Effective logistics management can give businesses a significant competitive edge in their market.

Practical Tips for Implementing Effective Logistics Management

Alright, let's get down to brass tacks. How can you implement these strategies in your business? Here are some practical steps:

1- Assess Your Current Processes

Start by taking a hard look at your existing logistics operations. Where are the bottlenecks? What are the pain points? Gather data and feedback from your team to identify areas for improvement.

2- Set Clear Goals

Define what you want to achieve. Whether it's reducing delivery times, cutting costs, or improving inventory accuracy, having clear objectives will guide your efforts.

3- Invest in Technology

Modern logistics heavily relies on technology. From supply chain management systems to inventory tracking and transport management software, investing in the right tools can make a world of difference.

4- Train Your Team

Your team is your greatest asset. Provide them with the training and resources they need to perform their roles effectively. Encourage open communication and continuous learning.

5- Build Strong Relationships

Whether it's with suppliers, carriers, or customers, strong relationships are key. Regular communication and collaboration can lead to better terms, improved service levels, and a more resilient supply chain.

6- Monitor and Adjust

Implementing changes isn't a one-and-done deal. Continuously monitor your performance metrics, gather feedback, and be prepared to adjust your strategies as needed.

Personal Experience: Learning from Mistakes

Let me share a little story about a mistake I made early in my career. I was managing logistics for a small manufacturing company and thought I could save money by ordering supplies in bulk to get a discount. Seemed like a no-brainer, right? Well, the supplies arrived, and we didn't have enough storage space. We ended up renting additional warehouse space, which ate up all the savings and then some. Lesson learned: always consider the total cost, not just the price tag.

Long-term Benefits

Implementing effective logistics management isn't just about immediate gains. Over time, businesses can build a reputation for reliability and efficiency, attracting more customers and partners. It also enables scalability; as your business grows, a strong logistics foundation will support that growth without falling apart at the seams.

Conclusion

Effective logistics management is more than just a back-office function; it's a strategic asset that can propel a business forward. By focusing on supply chain management, inventory management, and transport management, businesses can reduce costs, improve customer satisfaction, and increase profitability.

From my experiences helping businesses navigate the challenges of logistics, I can tell you that it's not always easy. There will be bumps along the way, and sometimes you might feel like you're herding cats. But with persistence, the right strategies, and a willingness to adapt, the benefits are well worth the effort.

So, whether you're running a small startup or managing a large corporation, take the time to evaluate your logistics operations. Implement some of these optimize supply chain management process tips, invest in your team and technology, and watch your business thrive.

The key to successful logistics lies in effective management of resources.

References

Chopra, S., & Meindl, P. (2016). Supply Chain Management: Strategy, Planning, and Operation. Pearson.

Rushton, A., Croucher, P., & Baker, P. (2014). The Handbook of Logistics and Distribution Management. Kogan Page Publishers.

Bowersox, D. J., Closs, D. J., & Cooper, M. B. (2013). Supply Chain Logistics Management. McGraw-Hill.

Wild, T. (2017). Best Practice in Inventory Management. Routledge.

Ballou, R. H. (2004). Business Logistics/Supply Chain Management. Pearson Education.

Frequently Asked Questions

What strategies can be employed to maximize logistics efficiency through effective management?

Effective logistics management is essential for businesses to succeed in today's competitive market. Strategies that can be employed to maximize logistics efficiency through effective management include:

Implementing a comprehensive supply chain management system: This system should include processes such as supplier selection and management, product sourcing, production scheduling, and inventory management.

Utilizing inventory management software: This software can help businesses track all of their inventory levels and ensure that they always have the right amount of stock on hand.

Establishing efficient transport management systems: This includes optimizing routes, minimizing transit time, and managing fuel costs.

Enhancing customer service: This can be achieved by providing accurate information about products and delivery times, as well as responding promptly to customer queries and complaints.

By implementing these strategies, businesses can maximize logistics efficiency and reach their desired outcomes.

How can inventory management be used to improve logistics efficiency?

Inventory management is an important component of effective logistics management. By optimizing inventory levels, businesses can minimize stock-outs, reduce storage costs, and improve customer service. Additionally, inventory management helps to identify the most efficient and cost-effective transport routes, which can lead to improved transport efficiency and reduced costs. By properly managing inventory and transport, businesses can ensure that their logistics operations are running as efficiently and cost-effectively as possible.

What are the benefits of effective logistics management for businesses?

The benefits of effective logistics management for businesses include improved customer service, reduced costs, and increased profitability. By optimizing their supply chain, inventory, and transport management processes, businesses are able to ensure timely delivery of goods and services, reduce costs associated with storage and transportation, and improve their bottom line. Furthermore, businesses can also benefit from improved customer service, as customers are more likely to remain loyal to companies that are able to provide efficient and reliable delivery of their goods and services. Ultimately, effective logistics management can enable businesses to become more competitive and profitable in their respective markets.

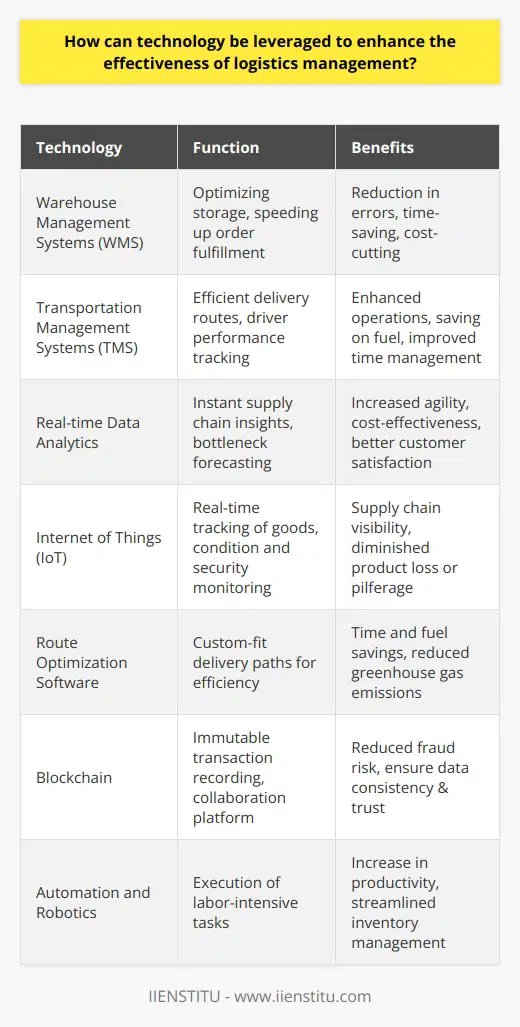

How can technology be leveraged to enhance the effectiveness of logistics management?

Leveraging Technology in Logistics Management

Adopting Advanced Software Solutions

Logistics management can harness technology by incorporating advanced software solutions such as warehouse management systems (WMS) and transportation management systems (TMS). These systems streamline operations by automating routine tasks, managing inventory, scheduling shipments, and tracking deliveries, thereby improving the overall efficiency and accuracy of logistics processes.

Utilizing Real-time Data Analytics

Real-time data analytics can help logistics managers make informed decisions by providing them with accurate and timely information. They can use these insights to optimize routes, predict and avoid potential disruptions, and make necessary adjustments to accommodate rapid changes in demand or supply, ultimately boosting operational efficiency and reducing costs.

Implementing Internet of Things (IoT)

Integrating IoT technology within logistics management enables the tracking of assets, vehicles, and products at every stage of the supply chain. IoT devices, such as sensors and GPS trackers, facilitate real-time monitoring of critical parameters such as temperature, vibration, and location, ensuring the quality and safety of products while minimizing losses and delays.

Optimizing Route Planning

Advanced route optimization software can analyze numerous factors, including traffic patterns, weather conditions, and fuel consumption, to identify the most efficient routes for transporting goods. By selecting optimal routes and minimizing travel time, logistics companies can reduce their environmental footprint, lower fuel costs, and improve overall operational efficiency.

Promoting Collaboration with Blockchain

Blockchain technology can promote transparency, trust, and collaboration among all participants in the supply chain, such as manufacturers, suppliers, and logistics providers. By storing and sharing secure and tamper-proof records of each transaction, blockchain can improve the accuracy and efficiency of data exchange, reducing the risk of disputes and strengthening the overall resilience of the logistics network.

Embracing Automation and Robotics

To further enhance the effectiveness of logistics management, companies can embrace automation and robotics to streamline warehouse operations. For instance, autonomous vehicles and robots can efficiently handle tasks such as picking and packing, sorting, and transferring goods, reducing manual labor costs and enhancing overall productivity.

In conclusion, leveraging technology has the potential to revolutionize logistics management by streamlining processes, improving real-time visibility, optimizing routes, promoting collaboration, and reducing operational costs. By adopting these technological advancements, companies can achieve enhanced efficiency, effectiveness, and competitiveness in the dynamic global logistics landscape.

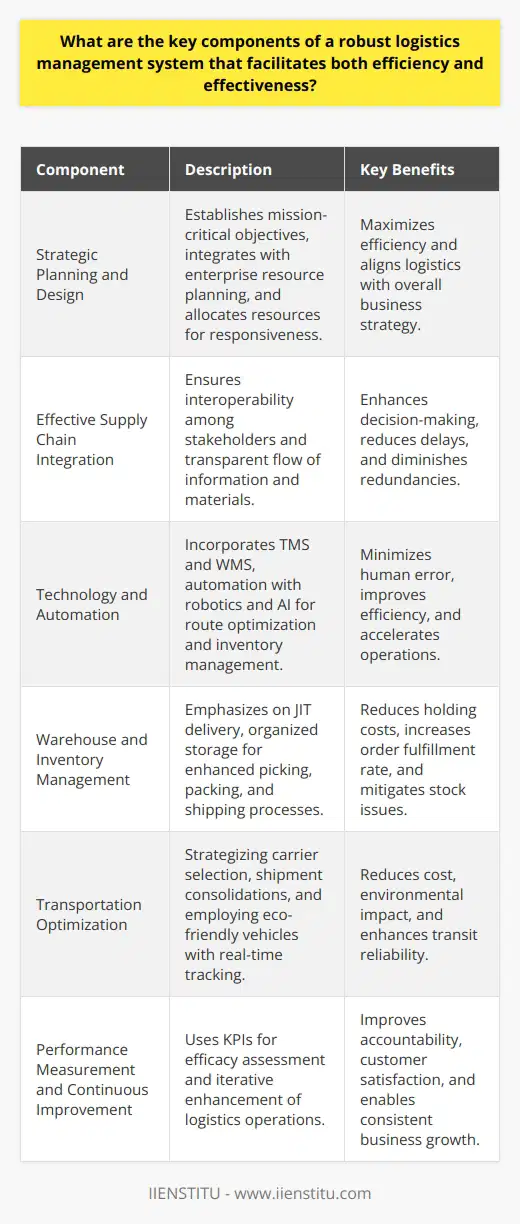

What are the key components of a robust logistics management system that facilitates both efficiency and effectiveness?

Efficient and Effective Logistics

**Strategic Planning and Design**

The first component of a robust logistics management system is a clear, strategic plan that outlines the system's goals, objectives, and expectations. This strategically-designed plan should integrate efficiently with enterprise resource planning (ERP) and optimize the resources available for effective logistics delivery.

**Effective Supply Chain Integration**

A robust logistics management system should cultivate seamless supply chain communication and coordination among stakeholders, such as suppliers, carriers, warehouse operators, and customers. Effective integration enables faster data processing, reduced lead times, minimized system inefficiencies, and improved overall performance.

**Technology and Automation**

Incorporating advanced technology and automation into a logistics management system is crucial for improving efficiency and effectiveness. This may include the use of transport management systems (TMS), warehouse management systems (WMS), and automated vehicles for the optimization of transportation, warehousing, and inventory management processes. Data-driven decision-making through predictive analytics also aids in identifying trends, improving forecasting, and reducing risks.

**Warehouse and Inventory Management**

Efficient warehouse and inventory management are vital components for a successful logistics system. Streamlined processes, such as just-in-time inventory management, reduce overstocking and avoid stock-outs that may disrupt supply chain operations. Additionally, an organized and well-managed warehouse ensures faster order fulfillment, improves space utilization, and reduces costs.

**Transportation Optimization**

Transportation optimization is an essential element that contributes to the effectiveness of logistics management. This includes selecting the most cost-effective and efficient shipping methods, routes, and carriers, as well as consolidating shipments and optimizing cargo space for cost and time savings. Real-time tracking and reporting of shipment data further enhance efficiency by allowing proactive management of potential disruptions.

**Performance Measurement and Continuous Improvement**

Lastly, a robust logistics management system must prioritize performance measurement and continuous improvement. Key performance indicators (KPIs) should be established to monitor system performance and identify areas of inefficiency. Regular assessments and analyses of these KPIs facilitate targeted improvements, ensuring the ongoing refinement and optimization of the logistics management system.

In conclusion, the key components of a robust logistics management system that facilitate both efficiency and effectiveness include strategic planning and design, supply chain integration, technology and automation, warehouse and inventory management, transportation optimization, and performance measurement and continuous improvement. Integrating these components into a logistics management system creates a smooth, efficient, and effective operation that benefits all stakeholders.

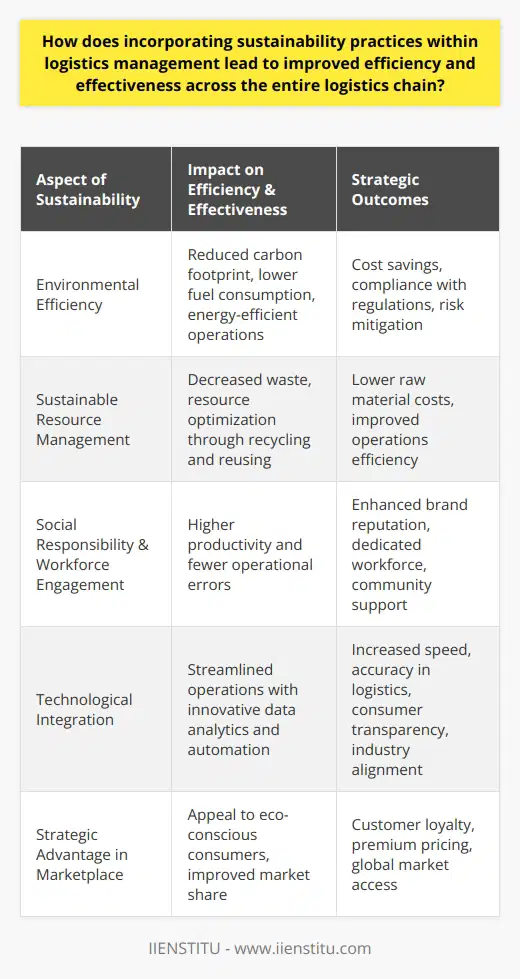

How does incorporating sustainability practices within logistics management lead to improved efficiency and effectiveness across the entire logistics chain?

Incorporating Sustainability Practices

Integrating sustainability practices within logistics management has emerged as a critical approach for enhancing efficiency and effectiveness across the entire logistics chain. By focusing on the triple bottom line - planet, people, and profit - companies can achieve comprehensive optimization, ensuring long-term viability and competitiveness.

Environmental Responsibility

Firstly, environmental responsibility directly influences the overall efficiency of logistics management. By minimizing waste, emissions, and energy consumption, enterprises reduce their environmental footprint and minimize external costs. The adoption of eco-friendly transportation modes, such as electric vehicles, rail, or sea freight, diversified energy sources, and the use of reusable packaging materials is crucial for minimizing the environmental impact of logistics operations. Moreover, employing route optimization algorithms and operational management software can lead to significant fuel savings and decrease congestion-related bottlenecks.

Social Stewardship

Secondly, engaging in social stewardship by investing in fair labor practices, equitable compensation schemes, and capacity-building initiatives fosters a positive work environment. A motivated workforce leads to improved effectiveness, as employees become more inclined to contribute to the overall strategic goals of the organization. Moreover, corporate social responsibility initiatives strengthen the reputation of the company, enhance customer loyalty, and can create new business opportunities.

Anticipating Future Demands

Lastly, the ability to anticipate and respond to future demands lies at the heart of sustainable logistics management. Embracing digitalization and technological advancements equips companies with the necessary tools to adapt to constantly evolving market requirements, while reducing traditional inefficiencies. The use of data analytics, predictive modeling techniques, and machine learning algorithms can ensure better inventory management, demand forecasting, and, ultimately, lead to increased customer satisfaction.

Conclusion

In conclusion, incorporating sustainability practices within logistics management provides a holistic approach to achieving improved efficiency and effectiveness across the entire logistics chain. Companies that effectively balance environmental responsibility, social stewardship, and the ability to anticipate future demands can create a strong foundation for enduring success and a more sustainable world.

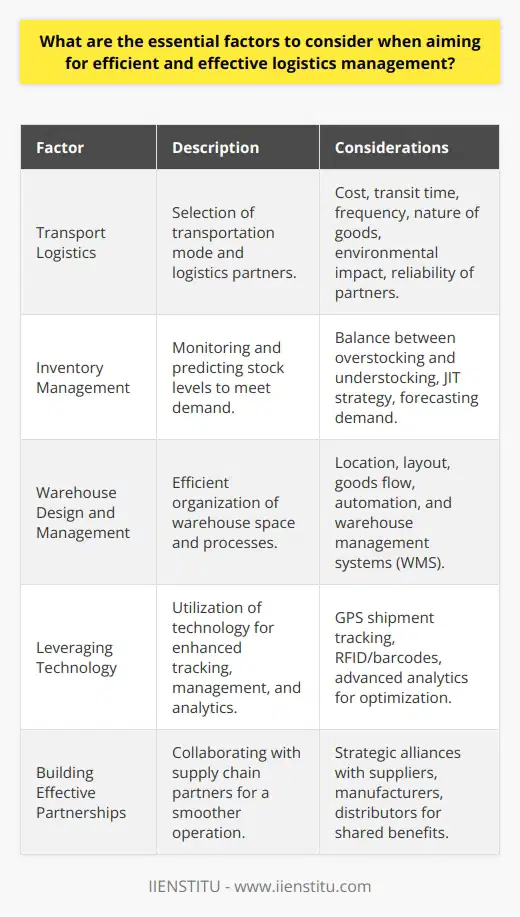

What are the essential factors to consider when aiming for efficient and effective logistics management?

Analyzing Key Factors in Logistics Management

Efficient and effective logistics management relies on a multifaceted approach, requiring strategic planning and implementation of key components. Prioritizing these factors can optimize the supply chain, ensuring businesses meet customer demands while minimizing costs.

Optimal Transport Solutions

One significant aspect of logistics management is the selection of suitable transportation modes. Chaotic transportation can give rise to unnecessary expenses, negatively affecting the supply chain's efficiency. An evaluation of transportation options—from trucks to air freight—enables the organization to balance cost, speed, and environmental concerns, ultimately enhancing performance.

Inventory Control

Managing inventory is vital to minimizing storage costs and preventing potential stock-outs, which could result in lost sales. Implementing a robust system to track inventory levels, coupled with stock replenishments in a timely manner, will contribute to efficient management of resources. Accurate forecasting of demand and regular monitoring of inventory levels can also prevent overstocking, reducing the chance of wasted resources.

Effective Warehousing Strategies

The choice and design of storage facilities play a critical role in logistics management. An ideal warehouse should be strategically located based on the supplier and customer base, minimizing transportation costs. Moreover, the layout of the warehouse should facilitate smooth and efficient product-handling processes. Utilizing proper storage equipment, implementing robust warehouse management systems, and employing skilled personnel ensure quick, accurate order processing and minimized errors.

Technology Integration

Technological advancements have significantly impacted logistics management, contributing to increased efficiency and visibility in the supply chain. Adopting relevant technology, such as GPS tracking, warehouse management systems, and automatic data capture tools like barcode scanners, can provide real-time information on product location and status. These technologies help in reducing lead times, lowering costs, and improving inventory accuracy.

Collaborative Partnerships

Establishing strong relationships with suppliers and other logistics service providers is essential for effective logistics management. Collaborative efforts can result in cost reductions, process improvements, and overall risk minimization. Developing strategic partnerships through effective communication and regular performance evaluations can lead to streamlined operations and increased overall efficiency.

In conclusion, attention to transportation options, inventory control, warehousing strategies, technology integration, and collaborative relationships is necessary for streamlined logistics management. Businesses that make a concerted effort in these areas can ultimately achieve their goal of optimizing the supply chain, improving customer satisfaction, and enhancing their competitive advantages.

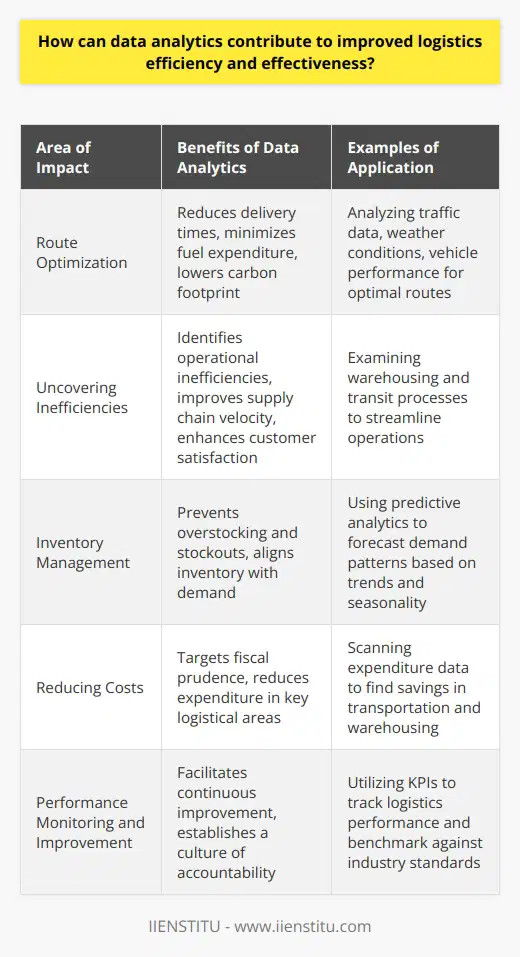

How can data analytics contribute to improved logistics efficiency and effectiveness?

Understanding Data Analytics in Logistics

Data analytics is crucial in enhancing logistics efficiency and effectiveness by providing insights into various aspects of the supply chain. Numerous benefits stem from data-driven approaches such as optimizing routes, identifying inefficiencies, and reducing costs. This analysis focuses on exploring these benefits and their impact on logistics.

Route Optimization

Efficient route planning is an essential element for improving logistics performance. Data analytics allows companies to analyze historical data on traffic patterns, travel times, and delivery locations, enabling the creation of optimal routes for transportation. This results in reduced fuel consumption, shorter delivery times, and increased overall efficiency.

Uncovering Inefficiencies

Data analytics facilitates the identification of bottlenecks and other inefficiencies within supply chain processes. By examining operational data, companies can detect areas where resources are underutilized, wasted, or incurring additional costs. This information empowers organizations to make targeted improvements, streamline processes, and enhance overall effectiveness.

Inventory Management

Accurate inventory management is critical to avoid stockouts, overstocking and ensure timely deliveries. Data analytics helps organizations forecast demand more accurately by analyzing trends, seasonal fluctuations, and transportation times. With better demand forecasting, companies can reduce unnecessary inventory costs, improve product availability, and maintain customer satisfaction.

Reducing Costs

Cost reduction is a crucial aspect of achieving logistics effectiveness. Data analytics allows companies to analyze expenditure patterns, pinpointing areas where savings can be made. This might include finding cheaper suppliers, consolidating shipments, or renegotiating contracts. Furthermore, data-driven decision-making leads to lower financial risks through better-informed investment and resource allocation strategies.

Performance Monitoring and Improvement

Data analytics enables companies to track key performance indicators (KPIs) and benchmark processes against industry standards. By continuously monitoring performance data, organizations can identify areas for improvement, implement necessary changes, and assess the progress of implemented initiatives. This iterative process ensures ongoing enhancement of logistics efficiency and effectiveness.

Conclusion

In summary, data analytics contributes significantly to improving logistics efficiency and effectiveness by providing valuable insights that inform decision-making, optimize processes, and reduce costs. With the rapid advancement of technology and data collection capabilities, data-driven strategies are becoming increasingly important for logistics companies striving for success in today's competitive business landscape.

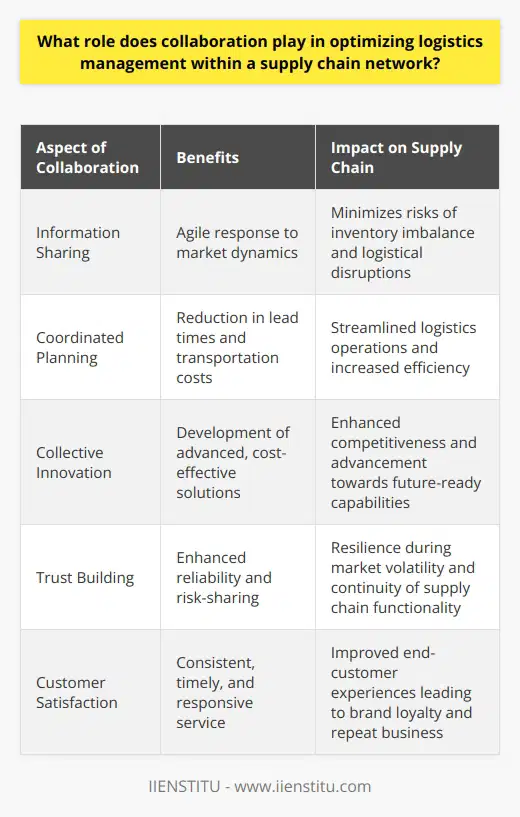

What role does collaboration play in optimizing logistics management within a supply chain network?

The Significance of Collaboration

Collaboration plays a critical role in optimizing logistics management within a supply chain network. This is primarily because it fosters communication, promotes efficiency, and enables organizations to work towards a common goal. Consequently, effective collaboration is indispensable for supply chain success.

Fostering Communication

A key aspect of successful logistics management is the continuous exchange of information. Collaboration encourages dialogue between stakeholders, allowing for the flow of data and ensuring that all relevant parties are apprised of any changes, updates, or new opportunities. In turn, this enhanced communication reduces the risk of costly errors and missed deadlines, resulting in a more seamless and efficient process.

Promoting Efficiency

By fostering communication and aligning stakeholders' objectives, collaboration also facilitates a more efficient supply chain. Specifically, a collaborative environment allows organizations to share resources, knowledge, and expertise with one another, yielding improved operational practices that reduce waste, redundancy, and duplication of efforts. Moreover, collaboration enables organizations to quickly adapt to shifts in the marketplace or unforeseen challenges, further contributing to operational efficiency.

Achieving Shared Goals

Collaboration in logistics management cultivates a sense of shared responsibility among supply chain partners. This collective mentality motivates stakeholders to work together towards the common goal of an optimized supply chain network. By collectively aiming for improved performance, organizations can achieve higher levels of customer satisfaction and better overall results.

Conclusion

Undoubtedly, collaboration is an essential driver of optimization in logistics management. When organizations work together and share information, they are equipped to create more efficient systems, adapt to new challenges, and achieve shared goals. As a result, collaboration is the cornerstone of an effective and resilient supply chain network.

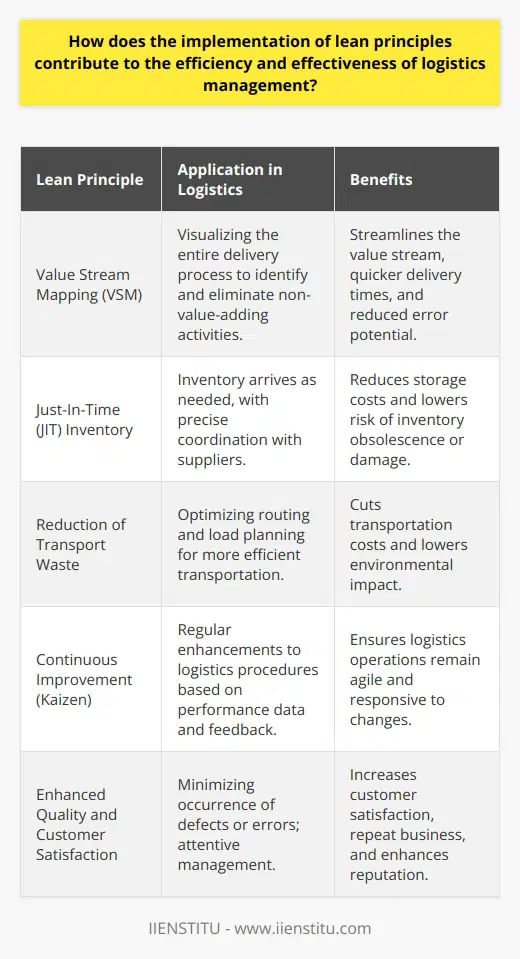

How does the implementation of lean principles contribute to the efficiency and effectiveness of logistics management?

Significance of Lean Principles in Logistics Management

Lean principles play a pivotal role in optimizing logistics management processes. The adoption of these principles significantly enhances the efficiency and effectiveness of logistics operations by reducing waste and improving resource utilization. The key concept behind lean principles is the elimination of any steps that do not contribute value to the end product or service.

Waste Reduction and Streamlining Processes

One major way in which the implementation of lean principles contributes to logistics management is through waste reduction. This involves enhancing processes to minimize the usage of resources or time. To achieve this, organizations need to implement strategies such as Just-In-Time (JIT) inventory management, which aims to minimize inventory levels and stockouts.

Improved Resource Utilization

Another aspect of lean logistics management is the improved utilization of resources. By analyzing the entire supply chain, organizations can identify opportunities to optimize resource allocation. This includes improving distribution networks, reducing lead times, and optimizing transportation routes. Through better resource allocation, organizations can fulfill customer demands more effectively and minimize overall costs.

Focus on Continuous Improvement

The process of continuous improvement is central to the effective implementation of lean principles in logistics management. By constantly analyzing key performance indicators (KPIs) related to supply chain management, organizations can identify opportunities for further improvements. This commitment to monitoring, learning, and adjustment is fundamental to ensuring that logistics processes continually adapt to evolving market conditions and customer demands.

Enhanced Customer Satisfaction

Lean principles in logistics management also contribute to increased customer satisfaction. By reducing lead times and ensuring products are delivered as promised, customers can experience increased reliability and responsiveness from their logistics providers. This can lead to long-lasting relationships and brand loyalty, ultimately resulting in a competitive advantage for organizations that adhere to lean principles.

Conclusion

In summary, the implementation of lean principles in logistics management not only streamlines processes and reduces waste, it also ensures the smart allocation of resources, fosters continuous improvement, and enhances customer satisfaction. By embracing these principles, organizations can effectively position themselves for long-term success within a competitive market landscape.

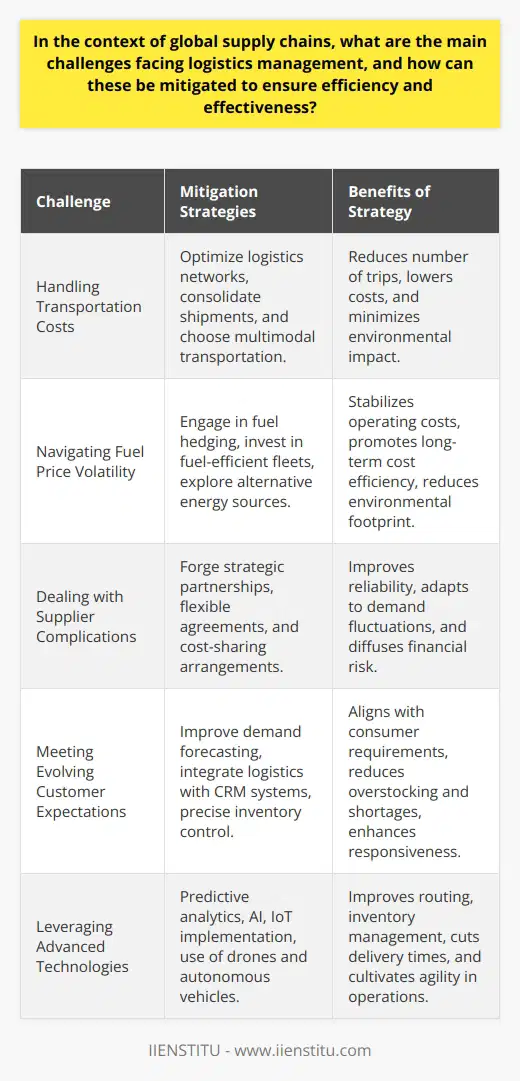

In the context of global supply chains, what are the main challenges facing logistics management, and how can these be mitigated to ensure efficiency and effectiveness?

Main Challenges in Logistics Management

In the global supply chain context, logistics management encounters numerous challenges, such as transportation costs, fluctuating fuel prices, supplier issues, and customer demands, to name a few. To ensure efficiency and effectiveness, these challenges require proactive mitigation strategies.

Addressing Transportation Costs

A significant concern in logistics management is the rising transportation expenses which directly impacts the overall supply chain costs. To address this challenge, companies should optimize transportation by consolidating shipments, select efficient modes of transport, and improve route planning to ensure lower costs and shorter delivery times.

Mitigating Fuel Price Fluctuations

Fluctuating fuel prices have far-reaching implications for the profitability and competitiveness of logistics operations. To mitigate this challenge, logistics managers should implement fuel hedging strategies, prioritize fuel-efficient technologies, and adopt alternative fuel sources to minimize the negative impact of price volatility.

Overcoming Supplier Issues

Supplier-related challenges, such as delays, fluctuating pricing, and quality concerns, can significantly disrupt supply chain management. Mitigating these issues involves forging strong relationships with suppliers, adopting flexible agreements, and implementing cost-sharing initiatives to create a buffer against unexpected disruptions.

Managing Customer Demands

In today's economy, meeting customer demands is crucial for a company's success. Therefore, logistics management should prioritize demand forecasting and collaborate with sales teams to develop accurate and timely data. It helps in effective inventory management, reducing lead time, and improving overall customer satisfaction.

Leveraging Technology for Efficiency

Embracing technological advancements such as automation, data analytics, and the Internet of Things (IoT) can significantly improve logistics management operations. These innovative solutions help in streamlining processes, enhancing real-time tracking, and reducing human errors, thus ensuring efficiency and effectiveness in global supply chains.

In conclusion, logistics management faces various challenges in the global supply chain context. However, by adopting proactive mitigation strategies and leveraging innovative technologies, companies can overcome these obstacles and thrive in today's complex and competitive landscape.

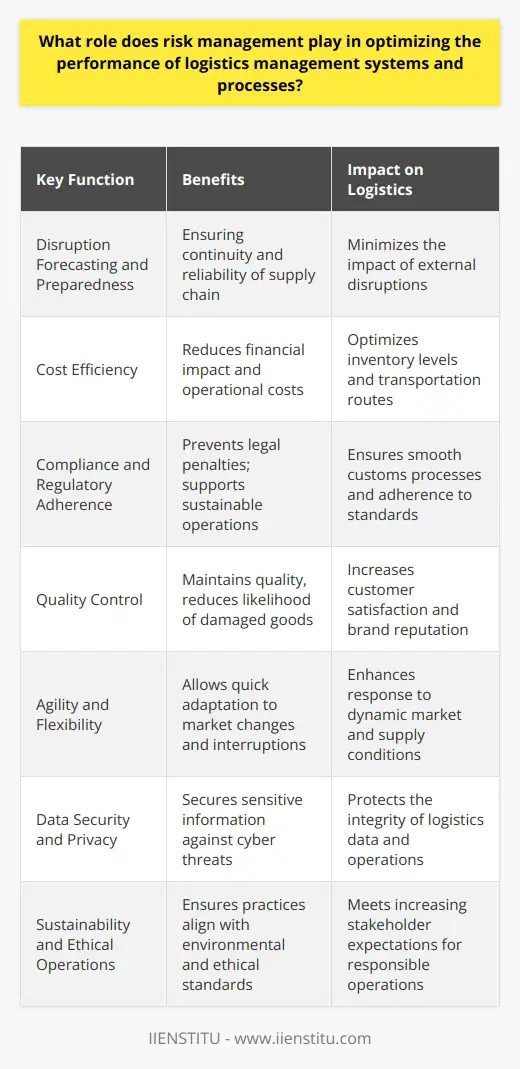

What role does risk management play in optimizing the performance of logistics management systems and processes?

Role of Risk Management in Optimization

Risk management plays a critical role in optimizing the performance of logistics management systems and processes by identifying, assessing, and mitigating potential disruptions. It enables organizations to proactively address various supply chain uncertainties and minimize the impact of unforeseen events on logistics operations.

Enhancing Resilience of Logistics Systems

Risk management enhances the resilience of logistics systems by ensuring robust and flexible supply chain networks. This involves anticipating risks, preparing for potential disruptions, and rapidly responding to changes, which ultimately leads to improved operational efficiency and customer satisfaction.

Effective Decision-making in Operations

By incorporating risk analysis and assessments into logistics processes, organizations can make well-informed strategic decisions. This helps to prioritize resources, reduce costs, and achieve optimal performance while minimizing the likelihood of potential failures and associated consequences.

Improved Collaboration and Communication

An integral component of risk management is collaboration and communication among stakeholders. This fosters knowledge sharing and effective decision-making, allowing organizations to address risks proactively and maintain efficient operations.

Mitigating Reputation and Financial Risks

Effective risk management not only optimizes logistics processes but also preserves the reputation and financial stability of organizations. By identifying and addressing potential hazards in logistics systems, risk management helps to prevent significant losses and adverse effects on the organization's brand and overall competitiveness.

In conclusion, risk management is essential for optimizing the performance of logistics management systems and processes. By identifying, assessing, and mitigating risks, organizations can enhance the resilience of logistic systems, make effective operational decisions, and foster collaboration and communication. Moreover, effective risk management helps preserve an organization's reputation and financial stability, ensuring its long-term success in today's increasingly complex and uncertain business environment.

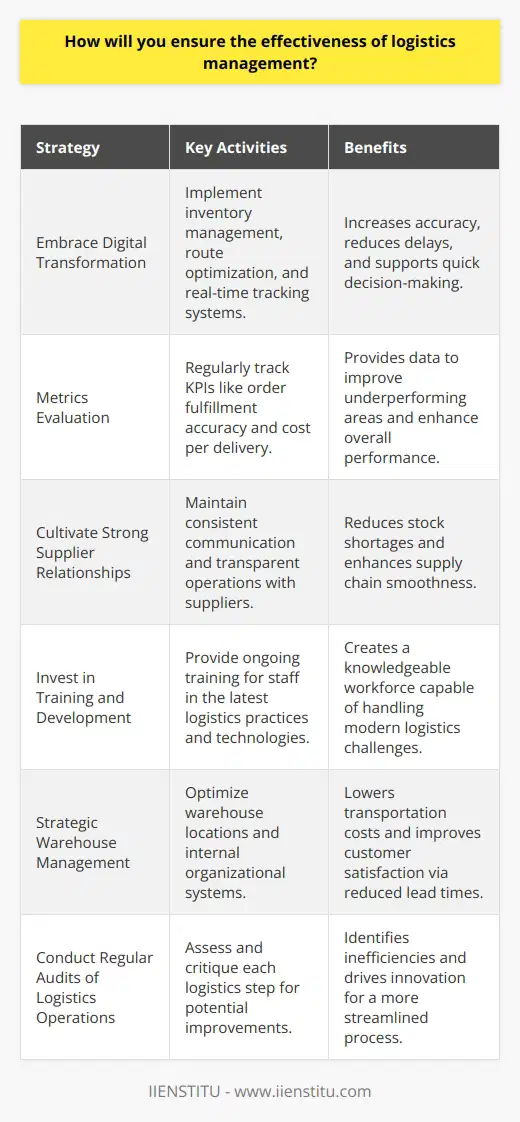

How will you ensure the effectiveness of logistics management?

Effective Logistics Management Strategies

One of the ways to ensure the effectiveness of logistics management is through the Digital Transformation. Embrace digitization and use technological tools. They assist in streamlining operations. They provide real-time tracking, route optimization, and inventory management.

Metrics Evaluation

Constantly evaluating key performance indicators (KPIs) is critical. Regular monitoring of metrics like delivery times, order accuracy, and cost per shipment enhances performance. It gives insights into areas that need improvement.

Supplier Relationships

Forging strong relationships with suppliers is crucial. It guarantees timely delivery of goods in good condition. It reduces risks associated with stock-outs and spoilage. Regular communication with suppliers is advisable.

Training and Development

Offer recurrent training and development programs to your staff. It will equip them with new skills. They can adapt to changes and be productive. Well-trained employees will also manage new technologies effectively.

Strategic Warehouse Management

Warehouse locations should be strategic to reduce transportation costs. Ensure a system is in place for easy retrieval and storage of goods. An efficient warehouse reduces unnecessary costs. It also speeds up delivery times.

Audit Logistics Operation

Regular auditing of the logistics operation helps in detecting loopholes. It helps you to identify any inefficiencies in your logistics management. Upon detection, treat these inefficiencies. It ensures smooth operations.

Thus, by incorporating these measures, the effectiveness of logistics management can be guaranteed. It ensures better customer satisfaction, reduced errors, and cost savings. The process requires commitment and regular review to stay on track.

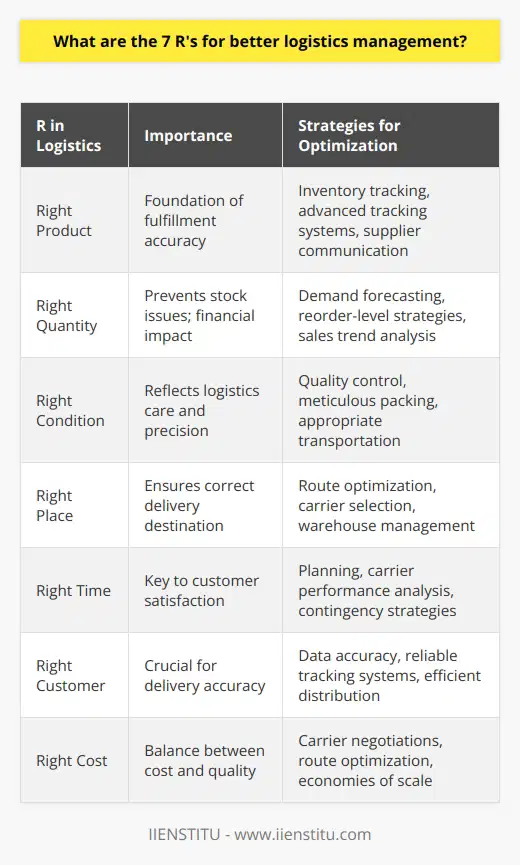

What are the 7 R's for better logistics management?

Efficient Logistics Management: Incorporating the 7 Rs

A viable strategy for better logistics management involves the implementation of the 7 Rs, namely right product, right quantity, right condition, right place, right time, right customer, and right cost. Understanding these elements can significantly streamline operations and enhance the overall efficiency of a company's logistics and supply chain.

Right Product

This involves ensuring that the correct merchandise is available for distribution. Identifying and delivering the precise product necessitates effective communication and robust inventory control systems.

Right Quantity

Executing with the correct amount is crucial. It prevents oversupply or stockouts, resulting in consistent customer satisfaction, and helps in maintaining healthy inventory levels.

Right Condition

Maintaining the product's pristine condition during transit is critical, as damaged goods would result in customer dissatisfaction and strained business relationships.

Right Place

Effective logistics management ensures that the products reach their intended destination. This dimension of the 7 Rs mandates proper transportation and storage infrastructure.

Right Time

Timely delivery is paramount in any logistics operation. It ensures customer satisfaction, maintaining the company's reliability and reputation in the market.

Right Customer

Assuring the delivery to the accurate customer supports customer satisfaction and relationship management. It prevents the occurrence of errors and associated costs for the enterprise.

Right Cost

Striking a balance between cost-effective processes and high-quality service delivery is crucial. By synergizing all the mentioned points, companies can achieve this right cost aspect, enhancing profitability and operational efficiency.

Therefore, these 7 Rs act as pillars for better logistics management. When adhered to, they can escalate the company's performance, customer satisfaction, and profit margins, dictating its success in the highly competitive market.

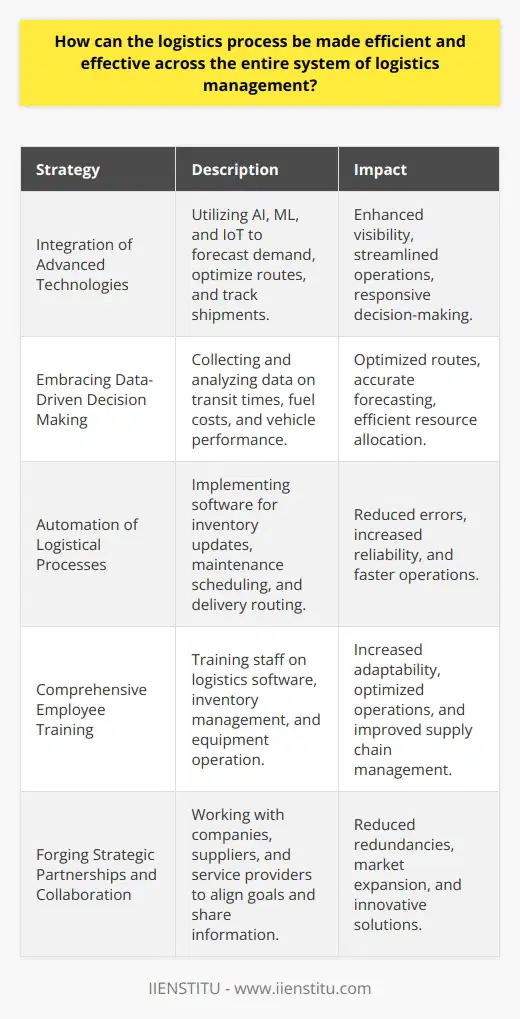

How can the logistics process be made efficient and effective across the entire system of logistics management?

Integrating Technology

One way to enhance efficiency and effectiveness in logistics management is through integrating technology. Advanced technologies such as Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) can optimize logistics operations. They provide real-time information, thereby improving planning and decision-making processes.

Data-Driven Decision Making

Using data-driven decision-making is another method. It involves identifying, collecting, analyzing, and using data to increase efficiency. Through regular analysis of data, businesses can identify trends, patterns, and areas that need improvement. Hence, data driven-decisions lead to improvements in productivity, cut-down costs, and enhanced customer satisfaction.

Process Automation

Automation of processes is also crucial for an efficient logistics system. Automating tasks, such as order and inventory management, can reduce human error. It also saves time by speeding up procedures that would otherwise take longer if done manually.

Employee Training

Additionally, training employees also plays a crucial role. A well-trained workforce will have the skills and knowledge necessary to manage logistics effectively. They will be better equipped to handle challenges and make decisions that benefit the organization.

Partnerships and Collaboration

Finally, promoting partnerships and collaboration helps to streamline the logistics process. Partnerships allow businesses to share resources, such as warehouses and delivery vehicles. Cooperation among various entities in the supply chain ensures smooth and efficient flow of goods.

In conclusion, optimizing logistics management necessitates the integration of technology, data-driven decision-making, process automation, effective training, and strategic partnerships. Implementing these key strategies can significantly improve the efficiency and effectiveness of the logistics process.

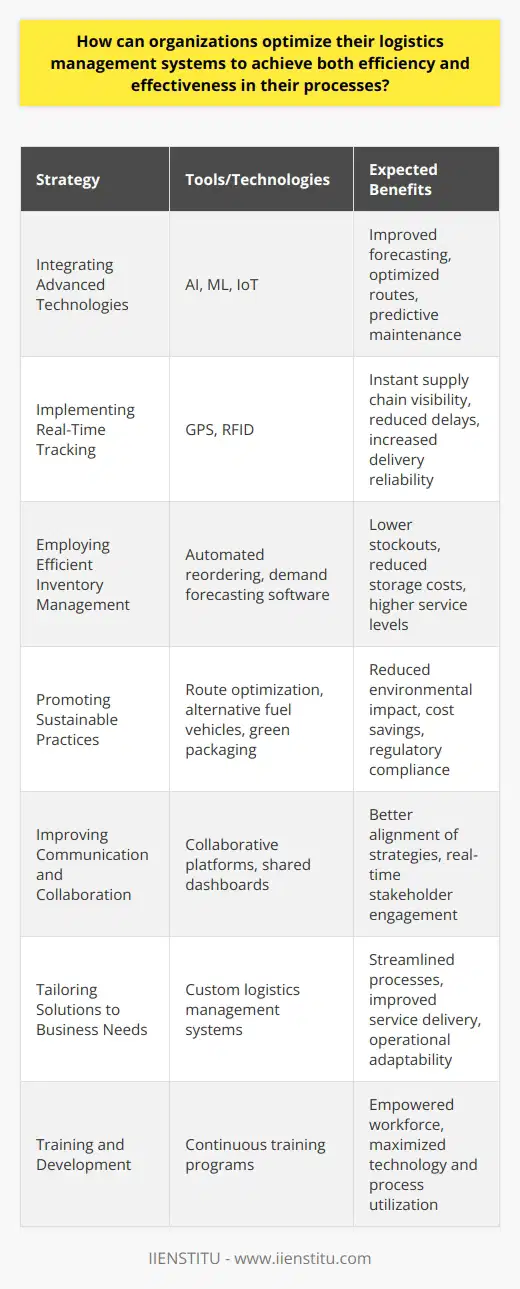

How can organizations optimize their logistics management systems to achieve both efficiency and effectiveness in their processes?

Optimizing Logistics Management Systems

Organizations can optimize their logistics management systems by integrating technology. This would improve efficiency in their processes. Technological advancements like artificial intelligence and machine learning can predict and analyze business trends. Therefore, they enable organizations to make data-driven decisions.

Implementation of Real-Time Tracking

Implementing real-time tracking is also crucial. It enhances the monitoring of goods movement within the supply chain. As a result, it reduces transport time and mitigates any risks related to theft or damage.

Employing Efficient Inventory Management

Effective inventory management is another key aspect. It prevents overstocking and understocking. An efficiently managed inventory balance improves customer satisfaction. Furthermore, organizations can utilise automated software. This will reduce human error in managing inventory.

Promoting Sustainable Practices

Promoting sustainability can optimize logistics management as well. Organizations need to consider the environment in their logistics operations. For instance, they can use recyclable packaging or more eco-friendly transport. These actions will not only save costs but also improve the organization's image.

Improving Communication and Collaboration

Lastly, improving communication and collaboration within departments can boost logistics management. Open communication ensures everyone understands how logistics impacts the overall company objectives. Enhanced collaboration can result in faster resolution of logistics issues.

In summary, organizations can optimize their logistics management systems by integrating advanced technologies, enhancing tracking measures, maintaining a balanced inventory, promoting sustainable practices, and improving communication and collaboration. These steps lead to greater efficiency and effectiveness in logistics operations.

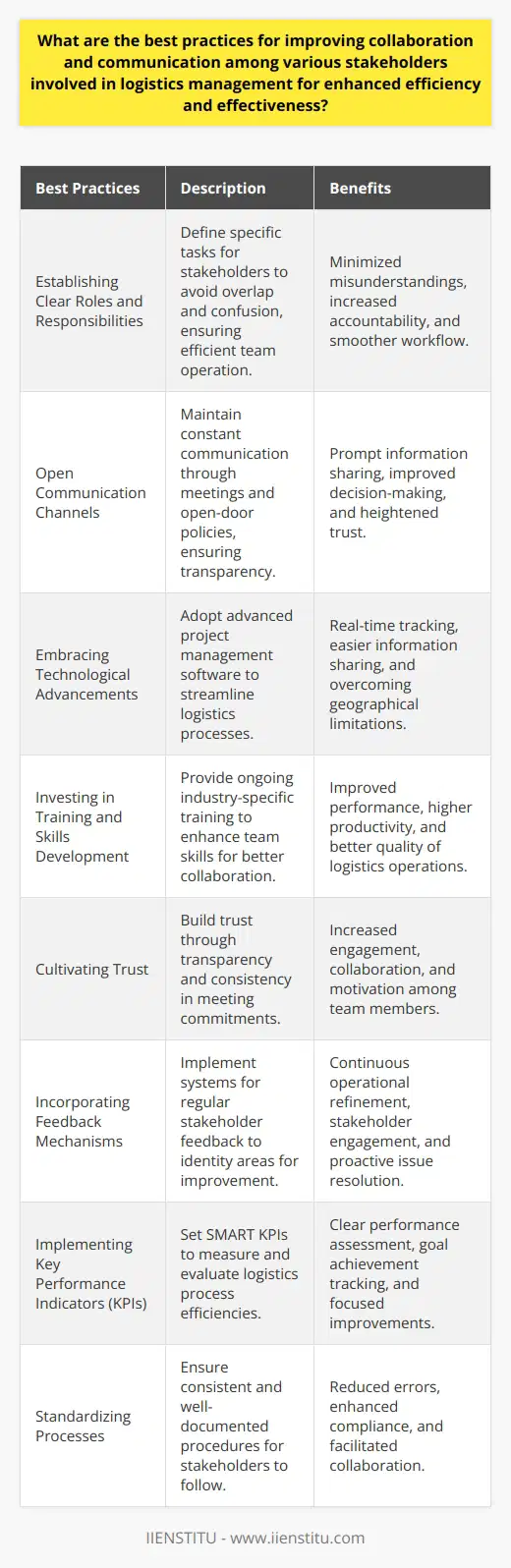

What are the best practices for improving collaboration and communication among various stakeholders involved in logistics management for enhanced efficiency and effectiveness?

Establishing Clear Roles

Logistics management involves various stakeholders; thus, establishing clear roles and responsibilities is pivotal. Clarity prevents overlapping tasks and enhances efficiency. Each stakeholder should know their specific task, aiding better collaboration.

Promoting Open Communication

Open communication facilitates sharing of necessary information. Regular meetings and discussions with all stakeholders prevent misunderstandings. It fosters a sense of unity and commitment to the project's success.

Embracing Technology

Technology can further improve communication and collaboration. Applications designed for project management can streamline activities, track progress, and generate reports. Using digital platforms for remote communication facilitates stakeholder engagement without geographical limitations.

Training and Skills Development

Employees need relevant skills and knowledge for their roles in logistics management. Training programs should align with employees' functions. This fosters competence in staff, enhancing collaboration, and efficiency.

Building Trust

Trust among stakeholders forms the basis for efficient collaboration. Building trust involves honoring commitments, respecting rules, and being transparent. It leads to a cooperative, committed team, which is crucial for effective logistics management.

Establishing Feedback Channels

Feedback loops can identify bottlenecks and areas for improvement in logistics processes. Constructive criticism and recommendations enhance the performance of the team.

Using KPIs for Evaluation

Key performance indicators measure actions' effectiveness. Indicators should be specific, measurable, achievable, relevant, and time-bound. This tool not only quantifies success but also highlights areas for improvement.

Standardizing Processes

Standardizing processes in logistics management improves efficiency and reduces errors. Consistent processes mean everyone knows what to do, how, and when. This reliability improves collaboration and communication.

In conclusion, logistics management relies on efficient collaboration and communication. Clear roles, open communication, trust, training, FEEDBACK, KPIs, and standardization aid in achieving this, ultimately enhancing logistics efficiency and effectiveness.

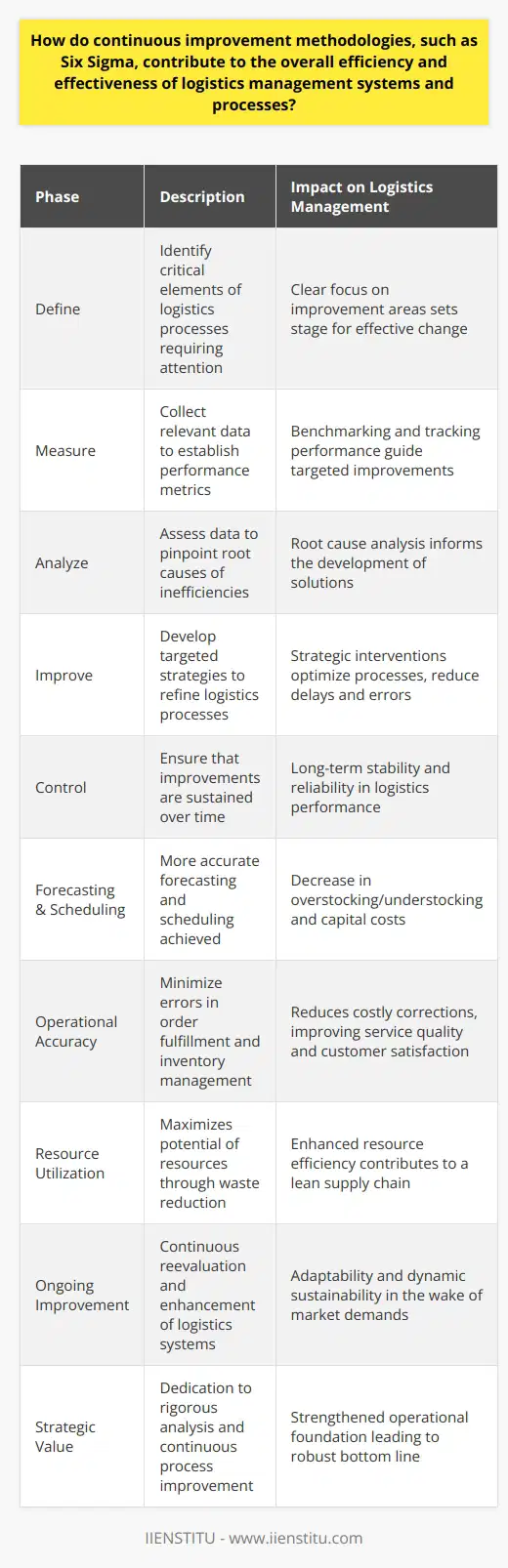

How do continuous improvement methodologies, such as Six Sigma, contribute to the overall efficiency and effectiveness of logistics management systems and processes?

Continuous Improvement in Logistics

Continuous improvement methodologies, like Six Sigma, significantly enhance the efficiency and effectiveness of logistics management systems. Six Sigma uses metrics and data-driven decisions, boosting operational accuracy. Minimizing errors in logistics operations decreases the likelihood of costly redelivery, ensuring optimal resource utilization.

Six Sigma Methodology

Six Sigma, particularly, follows a specific methodology called DMAIC (Define, Measure, Analyze, Improve, Control). This approach targets process improvement, leading to sustainable, superior logistics systems. Consistent evaluation provides opportunities for process refinement, mostly resulting in noticeable cost reduction.

Advantages of Data-Driven Decisions

It supports data-driven decisions, transforming raw data into useful information. Outcome: better forecasts, precise schedules, and informed decisions. Accurate data analysis also reduces guesswork, lowering the risk of financial losses.

Improving Operational Accuracy

Improving operational accuracy leads to heightened efficiency in logistics processes. Fewer errors mean less rework and redelivery. This reduction leads to cost savings, enhancing the overall efficiency of logistics operations.

Optimal Resource Utilization

Moreover, Six Sigma aids in optimal resource utilization. It improves both effectiveness and efficiency. It optimizes logistics management by reducing waste, implementing just-in-time inventory and streamlining supply chain processes.

Sustainable, Superior Logistics

In summary, the incorporation of Six Sigma in logistics contributes to sustainable, superior systems. Applying this meticulous, data-derived method to logistics management brings remarkable benefits. These include minimized errors and waste, and maximized efficiency and effectiveness.