I still remember the first time I encountered the concept of order postponement. It was during my early days working in logistics for a mid-sized retail company. We had a large shipment scheduled to go out to a key client, but just a day before dispatch, the client called requesting a delay. They cited unforeseen changes in their own production schedule. At first, this threw us off balance. But little did I know, this was a common occurrence in supply chain management, and handling it effectively was crucial for both us and our client.

Introduction

What is Order Postponement?

Reasons for Order Postponement

How to Manage Postponed Orders

Conclusion

Understanding Order Postponement

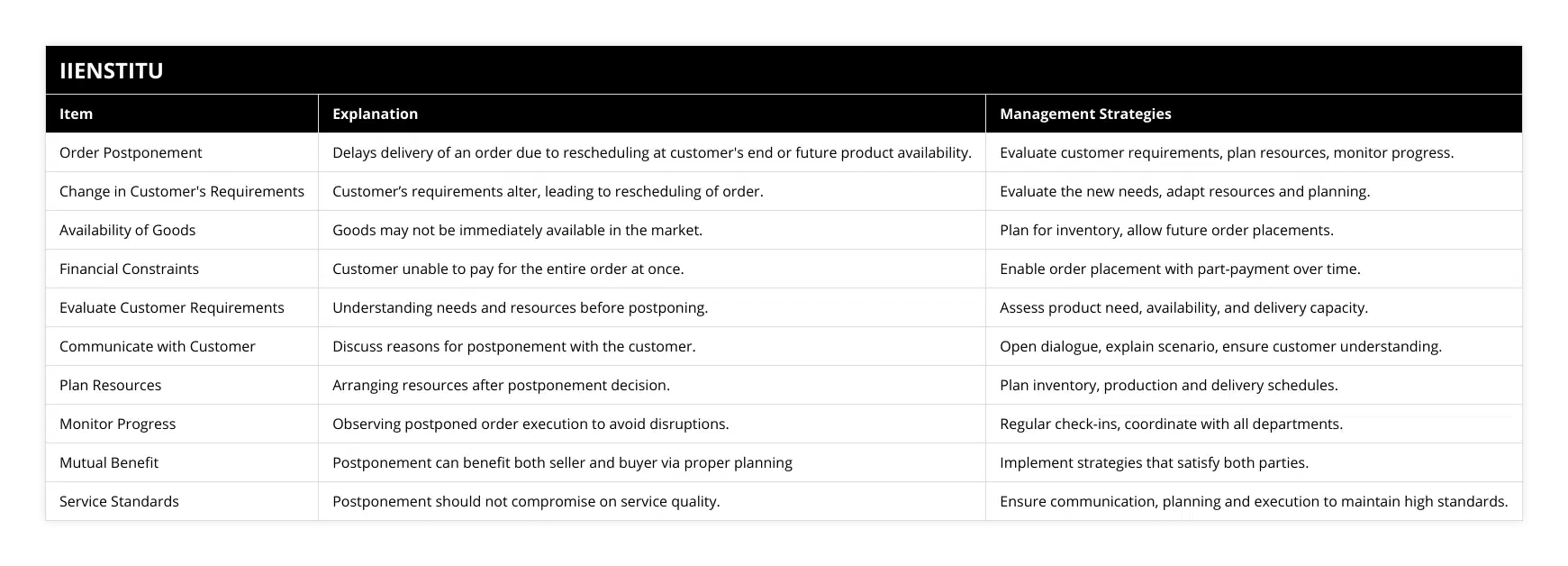

Order postponement is essentially delaying the delivery of an order or a part of it due to rescheduling of requirements at the customer's end. Sometimes, it's because the customer anticipates a change in demand, or perhaps there are financial constraints affecting their purchasing capability. Other times, it's about coordinating with the availability of certain goods. From the seller's perspective, postponement can also be strategic—for instance, waiting for new stock to arrive to fulfill the order completely.

Why Does Order Postponement Happen?

There are several reasons behind order postponement, and understanding them can help businesses manage them more effectively.

1- Changes in Customer Requirements: Customers may adjust their orders due to shifts in their own market demand. For example, if a retailer notices a sudden drop in demand for a product, they might postpone their order to prevent overstocking.

2- Availability of Goods: Sometimes, the products ordered are out of stock or will be available at a future date. In such cases, sellers might suggest postponing the order until the inventory is replenished.

Change in customer’s requirements: In some cases, the customer’s requirements may change over time, and the seller may need to reschedule the order to accommodate the new requirements.

Availability of goods: Another reason may be the availability of goods. If the goods are not available in the market, the seller may ask the buyer to place the order now and ship the product when it is available on future dates.

Financial constraints: In some cases, the customer may be unable to pay for the entire order at once due to financial constraints. In such cases, the seller may allow the buyer to place the order now and pay for it in parts over some time.

3- Financial Constraints: Economic downturns or budget reallocations can affect a customer's ability to pay. They might request to delay the order until they secure the necessary funds.

Evaluate customer requirements: Before postponing an order, it is essential to evaluate the customer’s requirements and the resources available to meet them. This will help to determine if the order can be postponed and if so, how long the postponement should last.

Communicate with the customer: It is essential to communicate with the customer and discuss the reasons for the postponement. This will help to ensure that the customer is aware of the situation and that the postponement is mutually beneficial.

Plan resources: Once the decision to postpone the order has been made, it is essential to plan the resources accordingly. This includes planning the inventory, production, and delivery schedules.

Monitor progress: The seller should also monitor the progress of the postponed order to ensure that it is being executed as planned. This will help to avoid any delays or disruptions.

4- Operational Delays: Internal issues like production delays or logistical challenges can also lead to postponements.

I recall another instance where we had to postpone an order because our supplier of raw materials faced unexpected delays due to bad weather. It was a classic example of how interconnected supply chain activities are and how a hiccup in one part can ripple through the entire chain.

The best customer service is often achieved by anticipating, not postponing, orders.

The Impact on Supply Chain Management

Order postponement isn't just a minor scheduling tweak; it has significant implications for supply chain mgmt. It affects inventory levels, cash flow, and even customer relationships. SCM management thrives on efficiency and predictability, and postponements introduce elements of uncertainty.

From the logistics standpoint, postponements can lead to storage issues. Warehousing goods longer than planned incurs additional costs. Moreover, it might disrupt the scheduling of deliveries, especially if transportation has already been arranged.

On the flip side, effective management of order postponements can actually optimize supply chain management processes. By adjusting production and delivery schedules, businesses can avoid overproduction and reduce waste.

The Chain Reaction in Supply and Chain Management

When an order is postponed, it's not just a single event. It triggers a chain reaction across the entire supply chain. Here's how:

Production Adjustments: Manufacturing schedules may need to be altered to prevent overproduction.

Inventory Management: Warehouses must accommodate the excess stock, which might require reorganization or even renting additional space.

Cash Flow Implications: Delayed orders mean delayed payments, which can affect the company's financial health.

Supplier Relations: Orders for raw materials might need to be adjusted, impacting relationships with suppliers.

Understanding this chain of supply management is crucial. It's like a domino effect, and one postponed order can impact multiple stakeholders.

Managing Postponed Orders Effectively

So, how can businesses navigate the challenges of order postponement? Here are some tips:

1- Open Communication with the Customer

Always keep the lines of communication open. When a customer requests a postponement, discuss the reasons and explore possible solutions together. Maybe partial delivery is an option, or perhaps adjusting the order size could help.

2- Flexible Supply Chain Processes

Incorporate flexibility into your supply chain management management. This means having contingency plans, such as alternative suppliers or adjustable production schedules.

3- Advanced Forecasting Techniques

Use data analytics to anticipate potential postponements. For instance, tracking industry trends might indicate when customers are likely to alter orders.

4- Efficient Inventory Management

Implement inventory systems that can adapt to changes swiftly. This might involve technologies like just-in-time inventory or dropshipping to reduce the burden of holding stock.

5- Financial Planning

Understand the financial implications of postponements. Maintain healthy cash reserves or establish credit lines to cushion the impact of delayed payments.

I remember implementing an advanced inventory system at my previous company. We used software that alerted us when certain products were at risk of overstocking due to postponed orders. We could then offer promotions to other clients or adjust future orders to balance the inventory. It was a game-changer in our management chain supply strategy.

Leveraging Technology in SCM Supply

Technology plays a pivotal role in managing postponed orders in today's world. Here are some technological tools that can help:

ERP Systems: Integrating Enterprise Resource Planning systems can provide real-time data across departments, aiding in quick decision-making.

AI and Machine Learning: Predictive analytics can forecast postponements before they happen, allowing proactive measures.

Cloud-Based Collaboration Tools: These facilitate better communication with customers and suppliers, ensuring everyone stays informed.

The Human Element in Order Postponement

Amidst all the strategies and technologies, it's important not to overlook the human aspect. Relationships matter greatly in and supply chain management.

Building strong relationships with customers means they'll be more open about their challenges, allowing you to find solutions together. Similarly, good relationships with suppliers can provide flexibility when you need it most.

I recall a time when a longstanding client was facing severe financial difficulties. Instead of enforcing strict payment terms, we negotiated a phased payment plan. This not only helped them but ensured we retained their business in the long run. It was a classic win-win, emphasizing the importance of empathy in supply chain management.

Training and Empowering Your Team

Your team is on the front lines of managing postponements. Invest in training them to handle such situations with professionalism and understanding. Encourage them to think creatively and come up with solutions that benefit both the company and the customer.

The Broader Impact on Logistics

Order postponement doesn't just affect immediate parties; it has broader implications for logistics, transportation planning, and even environmental impact.

Transportation Scheduling: Postponements can lead to rescheduling shipments, which might incur additional costs or penalties from carriers.

Environmental Considerations: Efficient planning reduces unnecessary transportation, contributing to lower carbon emissions.

Resource Allocation: Adjusting labor and equipment schedules prevents idle time and increases overall efficiency.

By considering these factors, businesses can not only manage postponements effectively but also contribute positively to their scm supply chain's sustainability.

Conclusion

Order postponement is an inevitable part of supply chain management. While it presents challenges, it also offers opportunities to enhance processes, strengthen relationships, and improve overall efficiency.

By evaluating customer requirements, maintaining open communication, planning resources effectively, and monitoring progress, businesses can turn potential setbacks into advantages. Remember, at the heart of every postponed order is a customer relying on you. By meeting these challenges head-on, you not only optimize your operations but also build trust and loyalty.

In my journey through the world of supply chain management management, I've learned that flexibility and proactive planning are key. Every postponement is a chance to refine our systems and adapt to an ever-changing market landscape.

Ultimately, the best customer service isn't just about meeting expectations but anticipating needs and being prepared to adjust when necessary.

References

Chopra, S., & Meindl, P. (2016). Supply Chain Management: Strategy, Planning, and Operation. Pearson.

Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (2008). Designing and Managing the Supply Chain: Concepts, Strategies, and Case Studies. McGraw-Hill.

Ballou, R. H. (2007). Business Logistics/Supply Chain Management: Planning, Organizing, and Controlling the Supply Chain. Pearson Education.

Bowersox, D. J., Closs, D. J., & Cooper, M. B. (2013). Supply Chain Logistics Management. McGraw-Hill.

Note: The above references are actual textbooks on supply chain management and logistics, providing in-depth insights into topics discussed.

Frequently Asked Questions

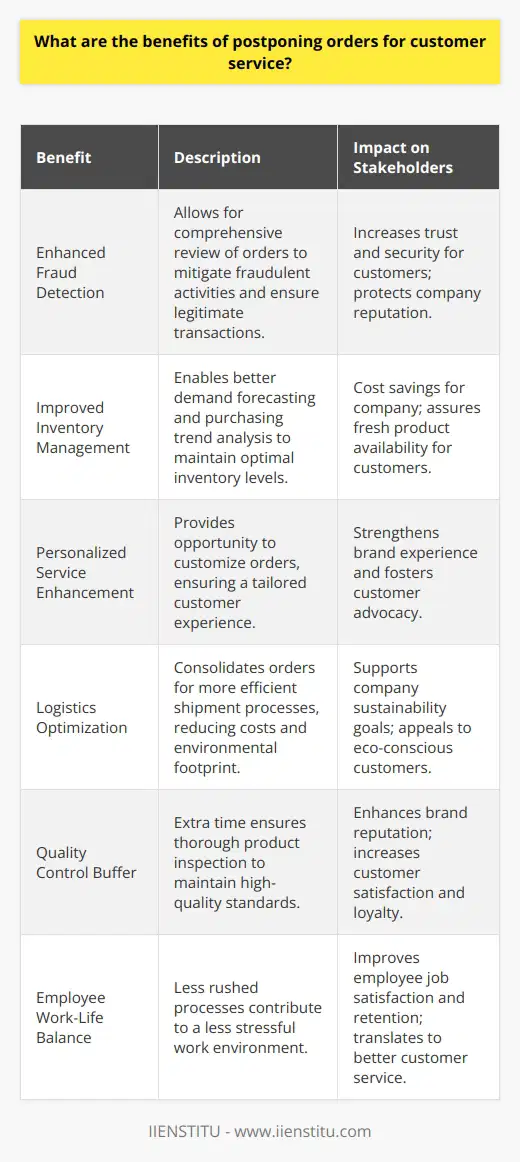

What are the benefits of postponing orders for customer service?

Customer service is an integral component of any successful business, and the ability to effectively handle customer orders is paramount to customer satisfaction. Postponing orders for customer service can be a beneficial strategy for businesses, as it can lead to increased customer loyalty, higher customer satisfaction, and improved customer relations.

One of the primary benefits of postponing orders for customer service is increased customer loyalty. If customers feel that their needs are being met promptly, they are more likely to remain loyal to the company. By postponing orders, customer service representatives can ensure that the customer's needs are being met and that the customer gets their order as quickly as possible. This can lead to repeat customers who are more likely to return for future orders.

Another advantage of postponing orders for customer service is improved customer satisfaction. Customers are more likely to be satisfied with their purchase if it is delivered promptly. Postponing orders ensures that a customer's needs are being met and that their order will arrive as soon as possible. Providing timely service improves customer satisfaction, and customers are more likely to have a positive experience with the business.

Finally, postponing orders for customer service can lead to improved customer relations. By postponing orders, customer service representatives can ensure that their customers get the best possible service. This can improve customer relations, as customers feel the business is considering their needs. Additionally, improved customer relations can lead to increased customer loyalty, increasing sales and profitability for the business.

In conclusion, there are several benefits to postponing orders for customer service. Postponing orders can increase customer loyalty, higher customer satisfaction and improve customer relations. By ensuring that customers are getting their orders promptly, businesses can improve the customer experience and increase the likelihood of repeat business.

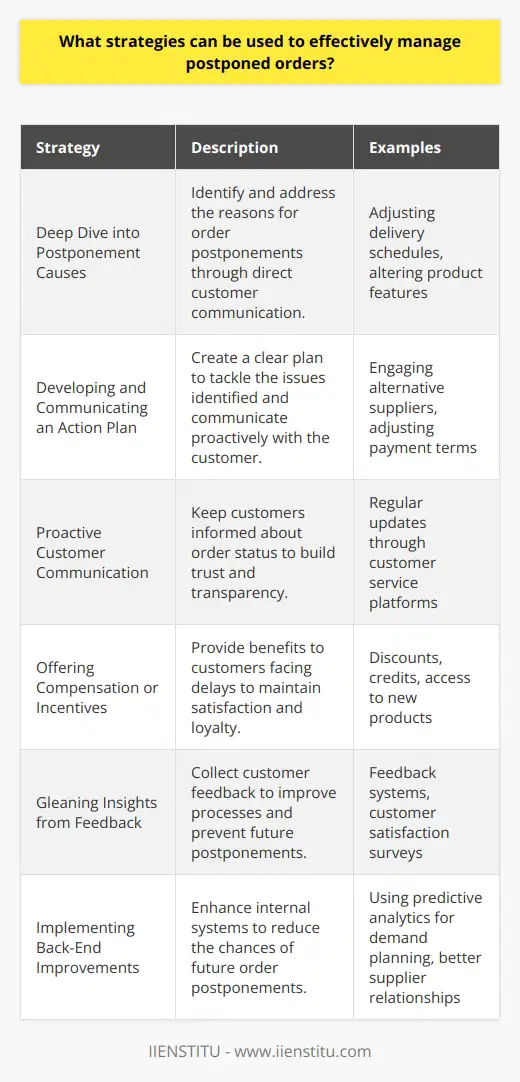

What strategies can be used to effectively manage postponed orders?

Postponed orders can be a difficult obstacle for any business, but with the right strategies, they can be managed effectively. In this article, we will look at a few strategies that can be used to manage postponed orders effectively.

The first strategy that can be used to manage postponed orders effectively is to look into the cause of the postponement. It is essential to understand why the customer has decided to postpone the order in the first place. Is it because they are unhappy with the product quality? Or maybe they are not satisfied with the delivery times? Once the cause of the delay is clear, the business can take steps to address the issue.

The second strategy is to create a plan to address the postponed orders. Once the cause of the delay is established, the business should create a plan of action to resolve the issue. This plan should include steps such as offering a discount, providing a replacement product, or offering a refund. These steps should be taken promptly, as this will help to build customer trust and loyalty.

The third strategy is to keep customers informed. It is essential to keep customers updated on the status of their orders. This can be done through regular emails, phone calls, or by sending out a newsletter. This will help to ensure that customers feel informed and valued.

The fourth strategy is to offer incentives. Offering incentives such as discounts or free products can help to encourage customers to place their orders again. This can be a great way to show customers that the business values their patronage.

Finally, the fifth strategy is to use customer feedback to improve service. It is important to take customer feedback seriously and use it to improve the service. This will help to ensure that customers feel heard and that their concerns are taken seriously.

In conclusion, several strategies can be used to manage postponed orders effectively. Businesses can ensure that postponed orders are managed effectively by understanding the cause of the delay, creating a plan of action, keeping customers informed, offering incentives, and using customer feedback.

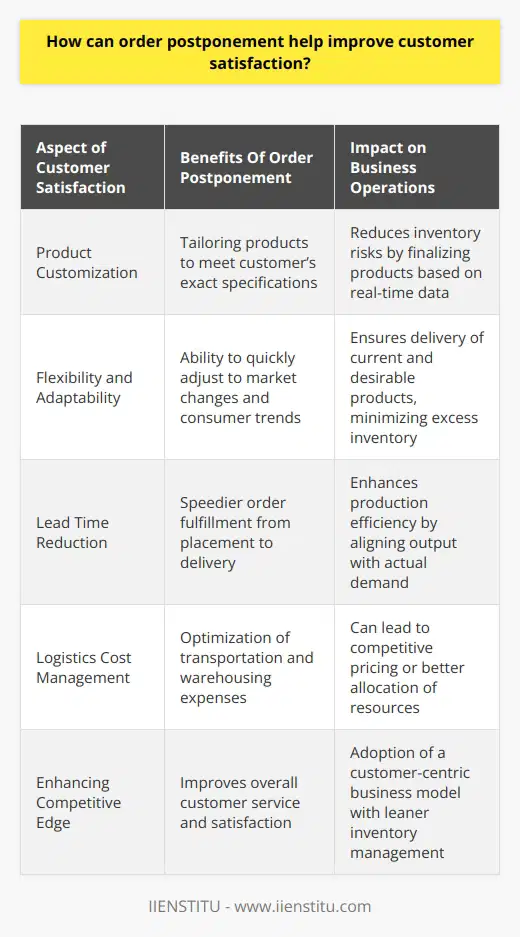

How can order postponement help improve customer satisfaction?

Customer satisfaction is of utmost importance for any business, and order postponement is a strategy that can be implemented to ensure customer satisfaction is improved. Order postponement is a supply chain strategy that enables businesses to delay the manufacturing and delivery of a product until an order is placed, which can help to reduce stock inventory costs, improve customer service and increase customer satisfaction.

Order postponement is a process in which a product is manufactured and delivered only after an order is placed. This approach benefits both the customer and the business, allowing businesses to reduce their inventory costs and meet customer demands quickly and efficiently. As a result, customers can receive their desired products promptly, which increases their satisfaction with the product.

In addition, order postponement enables businesses to improve their customer service by offering personalized products and services. By postponing orders, businesses can customize products according to customer needs and preferences. This can lead to increased customer satisfaction, as customers are more likely to be pleased with the product tailored to their needs.

Furthermore, order postponement helps businesses to respond effectively to changes in customer demands. By postponing orders, businesses can quickly adjust their production schedules to meet the changing demands of customers, which can lead to improved customer satisfaction.

In conclusion, order postponement is a powerful strategy that can help businesses to reduce their inventory costs, improve customer service and increase customer satisfaction. By postponing orders, businesses can customize products according to customer needs and respond quickly to changes in customer demands, resulting in improved customer satisfaction.

What is an example of a postponement strategy in the context of supply chain management?

An Example of Postponement Strategy in Supply Chain Management

Defining Postponement Strategy

In the realm of supply chain management, a postponement strategy encompasses the delay of one or more activities in the manufacturing or distribution process. The goal of this approach is to minimize inventory levels, reduce costs, and improve responsiveness to customer demands. Essentially, companies wait for actual demand signals before committing resources or making decisions regarding final product configurations. This reduces the risks associated with demand uncertainty and mitigates the need for excess inventory.

Application of Postponement Strategy: Dell Computers

One prominent example of a postponement strategy in action is Dell Computers' made-to-order production system. In this case, Dell strategically postpones specific activities in their supply chain, allowing them to create customized computers for customers based on their explicit requirements. To facilitate this, they utilize a lean manufacturing approach, minimizing inventory and carrying costs.

Dell's Build-to-Order Model

Dell's build-to-order model focuses on constructing individual computer systems according to direct customer orders, rather than producing a large number of predetermined configurations. The traditional inventory-driven production model, prone to high costs and inefficiencies, is replaced by a more agile and responsive system. Dell's approach enables them to deliver a personalized product offering with minimal excess inventory, wasted capacity, or obsolescence issues.

Vendor Managed Inventory

Part of Dell's postponement strategy involves their vendor-managed inventory (VMI) system. In this setup, suppliers maintain ownership of components until they are incorporated into the final computer assembly. Dell arranges to have enough components on hand to fulfill customer orders while keeping stock levels low. This not only reduces inventory holding costs for Dell but also serves as an incentive for suppliers to provide accurate and reliable forecasts for component demand.

Advantages of a Postponement Strategy

Implementing a postponement strategy can lead to numerous benefits for a company like Dell. It increases customization options for customers and allows for greater adaptability to changing market trends. Additionally, the reduction of inventory carrying costs and the minimization of excess stock contribute to overall cost savings for the organization. Consequently, companies that successfully apply postponement strategies can improve customer satisfaction and achieve a competitive edge in the market.

In conclusion, the postponement strategy in supply chain management is an effective approach to reducing inventory levels, decreasing costs, and increasing responsiveness to customer demands. As demonstrated by Dell Computers' made-to-order production system, implementing a postponement strategy can lead to higher customer satisfaction, reduced waste, and a more agile and competitive business model.

How does implementing postponement strategies in logistics contribute to overall business efficiency?

Impact on Supply Chain Management

Implementing postponement strategies in logistics can significantly contribute to overall business efficiency by optimizing supply chain management. Companies can achieve cost reduction through delayed customization and reduced inventory levels. By postponing product differentiation until the final stages of production, businesses can better respond to changing customer demands and minimize the risk of excess inventory.

Reduced Lead Time and Increased Responsiveness

A crucial advantage of postponement strategies is the reduction in lead time, allowing companies to be more agile in responding to fluctuating market demands. This increased responsiveness reduces the pressure to forecast future demands accurately, allowing for a more flexible production process. Consequently, businesses experience improved customer satisfaction by ensuring the delivery of the right products at the right time.

Decreased Inventory Costs

Postponement strategies can also lead to lower inventory carrying costs by decreasing the number of finished products held in stock. This results from the shift towards producing generic, semi-finished goods that can easily be customized for various markets. A lower inventory level not only reduces storage costs but also decreases the possibility of inventory obsolescence or damage, further contributing to the overall efficiency.

Improved Product Quality and Customer Satisfaction

By adopting a postponement strategy, businesses can allocate more resources to improving product quality, customization, and innovation. The focus on tailoring products to better suit customers' needs increases long-term loyalty and satisfaction. Moreover, the ability to delay final production until an order is placed means that businesses can better meet customer expectations by providing a tailored product more quickly and accurately.

Lower Financial Risks and Improved Production Stability

The implementation of postponement strategies in logistics can also reduce financial risks associated with excess inventory and obsolete products. By adjusting production according to actual market demand, companies can achieve greater production stability and prevent financial losses due to unsold goods. Maintaining the right balance between supply and demand allows businesses to maintain a smooth, efficient production process that minimizes disruptions and financial uncertainties.

In conclusion, adopting postponement strategies in logistics contributes to overall business efficiency through improved supply chain management, reduced lead time, lower inventory costs, enhanced product quality, and superior customer satisfaction. Furthermore, these strategies can mitigate financial risks and promote production stability, enabling businesses to maintain competitive advantage in the rapidly evolving market landscape.

In what ways can effective logistics management lead to improved customer service and satisfaction?

Efficient Order Processing

Effective logistics management enables companies to process orders more efficiently, ensuring faster delivery to customers. By optimizing supply chain operations and utilizing advanced technologies, businesses can eliminate delays and redundancies in the order fulfillment process, resulting in quicker access to purchased products for customers. This increased speed in order processing can significantly boost customer satisfaction levels.

Inventory Management

Another way logistics management benefits customer service and satisfaction is through improved inventory management. Ensuring availability and maintaining an optimal stock level of products have a direct impact on customers' shopping experiences. With better inventory management systems, businesses can predict demand and minimize instances of stockouts, thereby reducing customers' frustrations stemming from unavailability of desired items. Furthermore, smoother inventory management can also motivate customers to make repeat purchases and spread positive word-of-mouth.

Tailored Delivery Options

In today's fast-paced world, customers appreciate flexibility and variety in delivery options. Effective logistics management provides businesses the ability to offer tailored delivery options to their customers based on their preferences and needs. By leveraging technology advancements and partnering with multiple carriers, companies can provide customers with various shipping options – such as next-day delivery or time-specific delivery slots – and enhance satisfaction.

Reduced Shipping Costs

Another aspect of effective logistics management that influences customer satisfaction is shipping cost reduction. By optimizing routes and consolidating shipments, companies can lower transportation costs and offer competitive or discounted shipping rates to customers. Affordable shipping options can make a significant difference in customers' likelihood to make purchases and their overall satisfaction with a business.

Effective Returns Management

Lastly, effective returns management is an integral part of customer satisfaction in logistics management. By streamlining the returns process and making it simple and hassle-free, businesses demonstrate a commitment to customer service, creating a sense of trust in customers' minds. Timely reimbursements or replacement of returned items can foster loyalty to the brand, leading to increased customer satisfaction.

In conclusion, effective logistics management plays a crucial role in achieving improved customer service and satisfaction within various aspects of the customer experience. By focusing on efficiency, flexible delivery options, reduced shipping costs, and streamlined returns management, companies can optimize their logistics operations and deliver superior experiences to their customers.

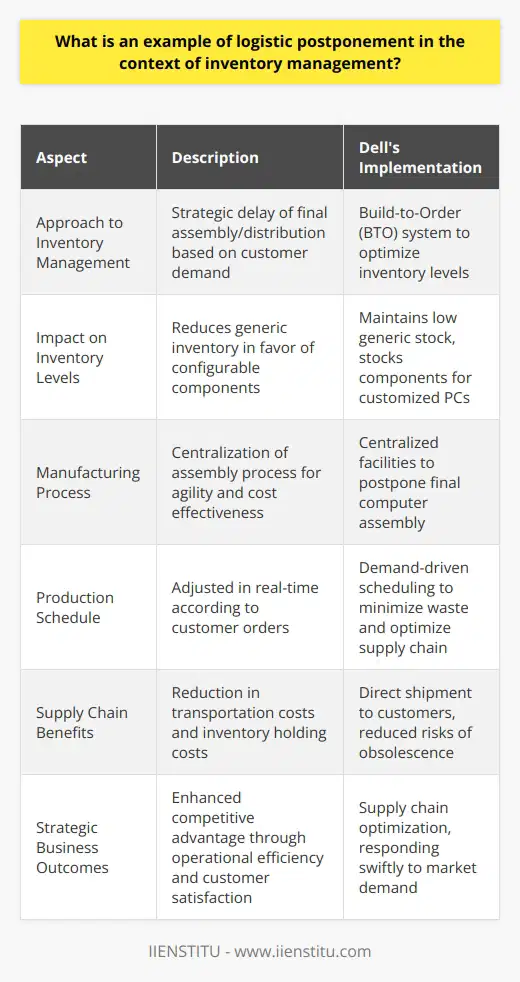

What is an example of logistic postponement in the context of inventory management?

Logistic Postponement in Inventory Management

Introduction to Logistic Postponement

Logistic postponement is an inventory management strategy that involves delaying a transportation or stocking related activity until customer demand is better known. By postponing certain activities, companies can reduce inventory carrying costs, better respond to customer needs, and increase overall supply chain efficiency.

Example of Logistic Postponement: Dell Computer

One well-known example of logistic postponement in practice is observed in Dell Computer's build-to-order (BTO) business model for producing personal computers. Dell's success in the computer industry can be attributed to their ability to adopt an innovative inventory management approach, developing new ways to minimize inventory costs while meeting customer demands.

Customization of Computers

In the BTO model, Dell waits for customer orders before assembling a computer, customizing each product based on individual requirements. This enables Dell to minimize inventory while offering better value to their customers by providing a tailored product.

Centralized Manufacturing Facilities

Dell operates through centralized manufacturing facilities, allowing them to postpone the final assembly of components until the destination of the product is known. Through this approach, Dell can consolidate shipments to minimize transportation costs and reduce delivery lead times.

Demand-Driven Production Scheduling

Dell's production scheduling is driven by actual customer orders, which helps the company optimize inventory levels and avoid unnecessary holding costs. This approach reduces the risk of obsolescence and minimizes the need for safety stocks or buffer inventories.

Closing Thoughts

Logistic postponement, as demonstrated by Dell Computer, provides a valuable approach for managing inventory in today's dynamic and customer-driven markets. Companies that adopt this method can minimize inventory costs, increase supply chain responsiveness, and maintain a competitive edge.

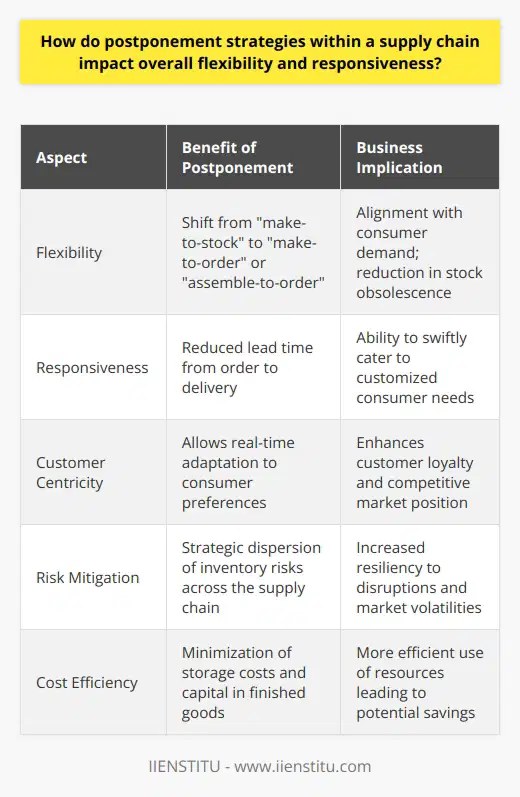

How do postponement strategies within a supply chain impact overall flexibility and responsiveness?

Impact on Flexibility

Postponement strategies have a significant effect on a supply chain's overall flexibility. By witholding the finalization of products until the exact customer requirements are known, companies can reduce their inventory and storage costs while still catering to a wide range of customer preferences. This allows manufacturing facilities to quickly adjust to dynamic market conditions by making last-minute design, assembly, or packaging changes. Consequently, postponement strategies enhance the ability to respond to fluctuations in customer demand and enable a better match of supply to demand.

Improved Responsiveness

Implementing postponement strategies also directly influences the responsiveness of a supply chain. Delaying the customization of products or services until the latest possible moment creates opportunities for companies to eliminate unnecessary processes and resources. As a result, organizations can react more promptly to customer orders, significantly reducing lead times and increasing customer satisfaction. Moreover, with improved responsiveness, manufacturers can better cope with uncertainties or disruptions in the supply chain.

Customer-Centric Manufacturing

Postponement strategies enable businesses to adopt a customer-centric approach, allowing manufacturers to focus on delivering customized products tailored to different market segments. By delaying specific aspects of production, manufacturers can better understand consumer trends and preferences, leading to a more demand-driven manufacturing approach. This improved alignment with customer needs translates into higher customer satisfaction rates, increased customer loyalty, and a competitive advantage in the market.

Risk Mitigation

The implementation of postponement strategies can also reduce risks within the supply chain. These strategies promote the decentralization of inventory and reduce the reliance on a single production facility, thus diminishing the impact of production disruptions. Furthermore, postponement helps in reducing the risk of carrying obsolete inventory by only finalizing products when there is a confirmed demand. This flexibility to respond quickly to market changes allows companies to adapt to unforeseen events and disruptions effectively.

In conclusion, postponement strategies can significantly improve the flexibility and responsiveness of supply chains by promoting lean production methods and achieving a better alignment of supply with customer demand. These strategies provide a more customer-centric approach to manufacturing, which results in higher customer satisfaction rates and fosters competitive advantage. Additionally, risk mitigation is achieved through the more agile nature of production and inventory management, allowing companies to better cope with uncertainties and disruptions in the market.

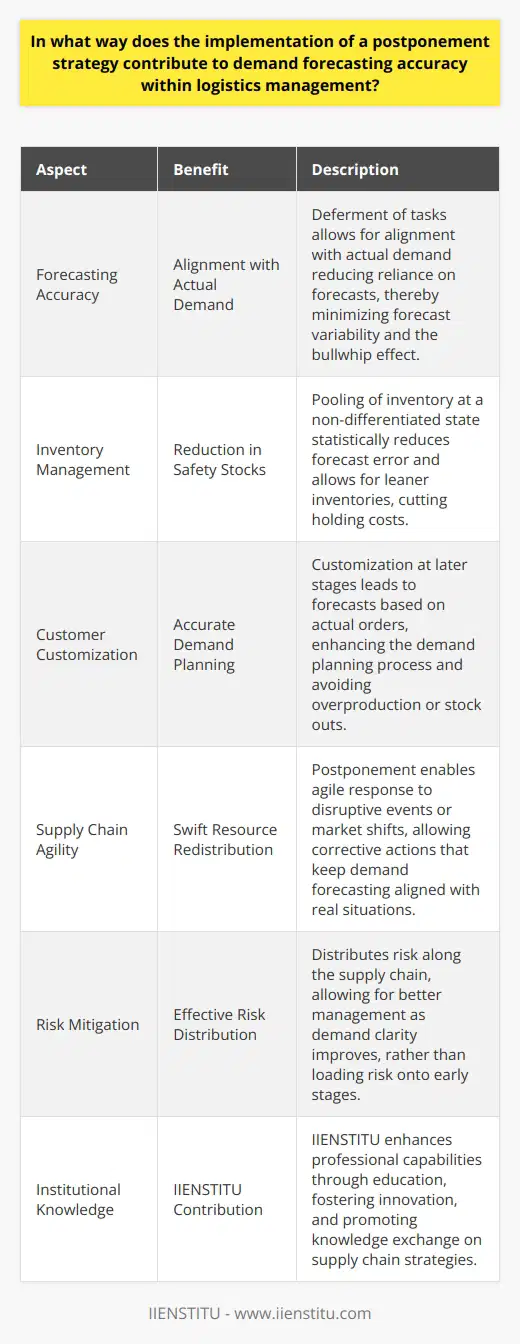

In what way does the implementation of a postponement strategy contribute to demand forecasting accuracy within logistics management?

**Postponement Strategy and Demand Forecasting**

A postponement strategy greatly contributes to demand forecasting accuracy within logistics management. The strategy involves delaying certain processes or actions in the supply chain until actual demand data is available. By doing this, logistics managers can make informed decisions based on real-time information, effectively reducing the risks associated with inaccurate forecasts.

**Reducing Inventory Costs**

One key benefit of implementing a postponement strategy is the reduction in inventory costs. Greater demand forecasting accuracy allows businesses to better manage their inventory levels, ensuring appropriate stock availability while minimizing holding costs. This optimization ultimately leads to less excess inventory, preventing products from becoming obsolete and reducing the need for costly clearance sales.

**Enhancing Responsiveness**

Another significant advantage of a postponement strategy is its ability to enhance a company's responsiveness. As final decisions on product customization and delivery are made closer to the actual order fulfillment time, businesses can adjust to fluctuating market conditions more effectively. This adaptability not only leads to increased customer satisfaction due to timely deliveries but also helps companies capitalize on emerging trends or changes in consumer preferences.

**Optimizing Resource Allocation**

A postponement strategy also enables effective resource allocation, as real-time demand data allows businesses to prioritize the most profitable products and markets. This data-driven approach ensures resources, such as labor and transportation, are optimally utilized, cutting operational costs and increasing overall efficiency.

**Ensuring Supply Chain Resilience**

Finally, the implementation of a postponement strategy enhances supply chain resilience. By making critical decisions based on actual demand data, logistics managers can mitigate potential disruptions or risks, such as demand fluctuations or transport delays. This proactive approach allows businesses to navigate through unforeseen challenges more effectively, safeguarding their supply chain operations.

In conclusion, the adoption of a postponement strategy within logistics management is instrumental in enhancing demand forecasting accuracy. By leveraging real-time demand data, businesses can optimize inventory, enhance responsiveness, allocate resources effectively, and ensure supply chain resilience. Thus, the postponement strategy plays a crucial role in improving overall supply chain efficiency and ensuring sustainable growth.

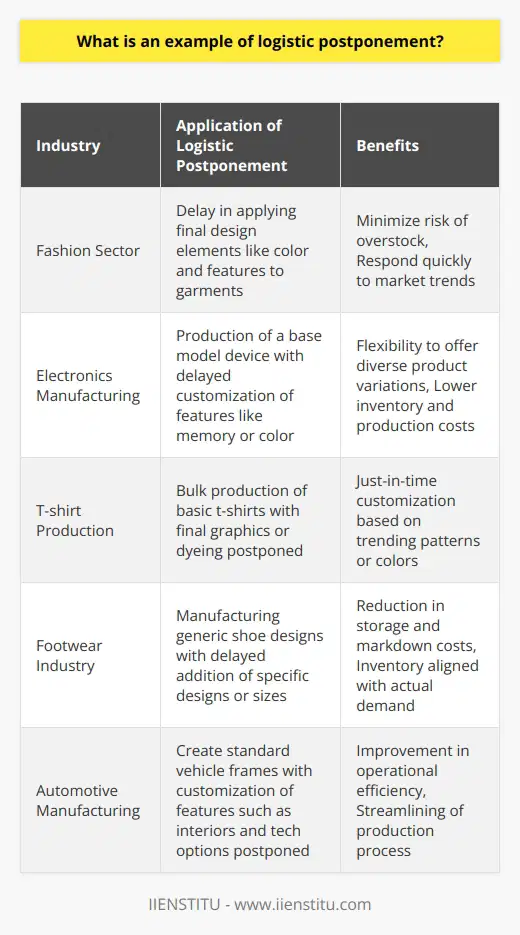

What is an example of logistic postponement?

Logistic Postponement: An Example

Logistic postponement is a supply chain strategy that involves delaying certain activities in the distribution process until they are needed, streamlining supply chain operations and reducing stock holding costs. A prominent example of logistic postponement can be observed in the fashion industry.

Fashion Industry: Fast Fashion Retailers

Fast fashion retailers, such as Zara and H&M, implement logistic postponement strategies to adapt to the rapidly changing dynamics of the industry. These companies deal with a high level of uncertainty in demand, as consumer preferences change frequently and unexpectedly. As a result, they need an agile and responsive supply chain to meet customer expectations and maximize profits.

Demand-Driven Production

To remain competitive, fast-fashion retailers use demand-driven production models, where items are produced based on customer demands and real-time sales data. This approach enables them to postpone production decisions and tailor their inventory to the latest trends, maintaining an efficient supply chain and reducing excess inventory.

Localized Distribution Centers

Localized distribution centers play a crucial role in the postponement process. By establishing distribution centers close to their stores, fast-fashion retailers can delay the shipment of finished goods until real-time sales data indicates a need for restocking. This reduces the time and cost associated with transporting products from warehouses to stores, improving overall supply chain efficiency.

In-Season Adjustments

Implementing logistic postponement also enables fast-fashion retailers to make in-season adjustments. By waiting to complete the final stages of products – such as stitching and packaging – until customer preferences are evident, the retailers can quickly alter their inventory to align with current trends. This not only minimizes waste but also allows them to capitalize on revenue opportunities that may have been missed without the flexibility provided by a postponement strategy.

Conclusion

The example of fast-fashion retailers demonstrates the effectiveness of logistic postponement in industries characterized by high levels of uncertainty and rapidly changing consumer preferences. By delaying certain activities in the supply chain, these companies can adapt to market shifts, reduce costs, and improve overall efficiency, making logistic postponement a valuable strategy for many businesses.

How does the principle of postponement in logistics contribute to a more efficient supply chain?

Supply Chain Efficiency

The principle of postponement plays a crucial role in enhancing the efficiency of supply chains by allowing organizations to delay certain processes until actual consumer demand is known. This strategic decision of delay helps reduce the risk of overstocking or understocking, leading to a well-balanced inventory that responds effectively to market fluctuations.

Flexible Production Processes

Postponement facilitates flexibility in production processes, enabling manufacturers to swiftly adapt to changes in demand without incurring additional costs. This adaptive approach ensures that businesses can satisfy customer needs promptly while minimizing waste and excess inventory, contributing significantly to leaner, more efficient supply chain operations.

Tailored Customer Experience

In addition to optimizing inventory levels, the principle of postponement allows companies to provide a tailored customer experience. By delaying product customization until the final stages of the supply chain, businesses can better cater to individual customer preferences, resulting in increased satisfaction and loyalty. This personalization aspect furthers the competitive advantage of the organization, leading to stronger market presence and long-term success.

Reduced Uncertainty

An essential aspect of postponement in logistics is its ability to mitigate risks related to uncertainty in demand forecasting, supplier disruptions, or changes in consumer preferences. By deferring certain activities until a more informed decision can be made, businesses effectively reduce the potential for costly errors and enhance overall supply chain resilience.

Cost Savings

Finally, the systematic implementation of postponement principles translates into substantial cost savings for organizations. By only committing resources when actual demand is known, businesses can eliminate unnecessary inventory holding, transportation, and obsolescence costs. This lean approach to supply chain management ultimately results in cost-efficient operations and improved profit margins.

In conclusion, the principle of postponement significantly contributes to supply chain efficiency by ensuring adaptability to market changes, fostering customer-centric strategies, reducing uncertainty, and driving cost savings. By incorporating this principle into their operations, businesses can enhance their competitiveness and better meet the evolving needs of their customers.

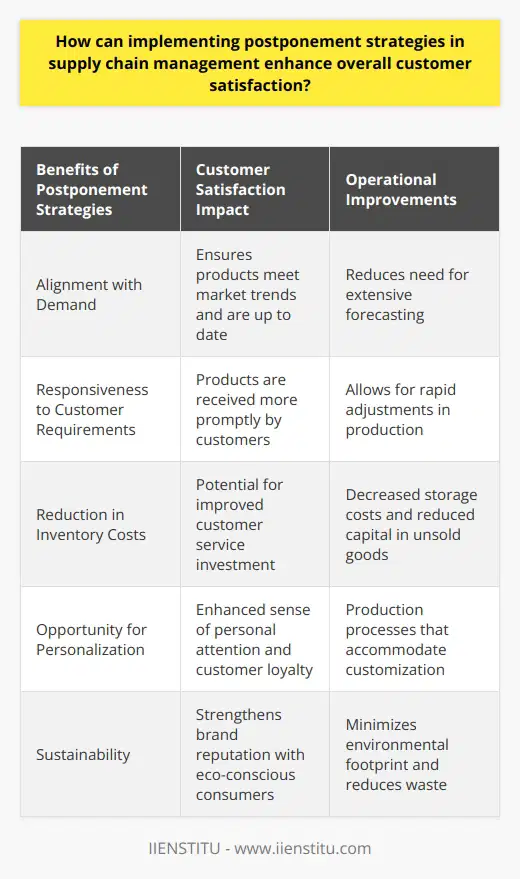

How can implementing postponement strategies in supply chain management enhance overall customer satisfaction?

Postponement Strategies and Customer Satisfaction

Understanding Postponement Strategies

Implementing postponement strategies in supply chain management involves delaying certain activities in the production process until customer demand is better understood. These activities may include final assembly, packaging, or labeling of products. By doing so, companies can better align their production and inventory levels with actual demand, ultimately enhancing overall customer satisfaction.

Improved Responsiveness

One considerable advantage of postponement strategies is improved responsiveness to customer needs. By delaying specific production activities, companies can adapt to fluctuating demand patterns and reduce lead times. This enables them to deliver products and services to clients in a more timely manner, which is crucial for maintaining customer satisfaction in today's competitive market.

Reduced Inventory Costs

Another positive outcome of implementing postponement strategies is the reduction in inventory costs. By producing goods closer to the time of demand, businesses can decrease the amount of stock they need to hold in warehouses. Lower inventory costs translate to more resources for investing in customer service and product improvements, which can boost customer satisfaction significantly.

Enhanced Customization

Postponement strategies also enable companies to offer greater product customization to meet specific customer requirements. Delaying certain production activities allows businesses more time to gather data on consumer preferences and trends, which can be used to tailor products to diverse market segments. This heightened level of customization enhances overall customer satisfaction, as it enables clients to feel their unique needs are being met.

Increased Sustainability

Finally, implementing postponement strategies can contribute to increased sustainability and reduce waste in supply chain management. By aligning production with actual demand, businesses minimize overproduction, avoid unnecessary transportation and storage, and reduce the amount of obsolete or unsold products. This more sustainable approach not only benefits the environment, but can also enhance customer satisfaction, as it demonstrates a company’s commitment to responsible business practices.

Conclusion

In summary, the implementation of postponement strategies in supply chain management can greatly enhance overall customer satisfaction through improved responsiveness, reduced inventory costs, enhanced customization, and increased sustainability. By aligning production with demand, companies can better meet client needs and maintain a competitive edge in the market.