This article discussed the importance of integrating logistics into business processes to achieve business excellence. It explained the four critical logistics components (inventory, transportation, warehousing, and customer service) and how they must be managed to meet business objectives. Finally, it concluded that proper logistics management is essential for business success.

Related Course: Logistics Certification Online

Introduction

What is Logistics

Integration of Logistics into Business Processes

Components of Logistics

Conclusion

Introduction: Logistics is an information-based material movement process from a supplier to the manufacturer and the customers. It is an essential component of every business process, yet its importance is often overlooked. Logistics operations must be integrated into the business process to achieve business excellence, and its members must be managed appropriately. This article will discuss the importance of integrating logistics into business processes and the logistics components that must be addressed to ensure business excellence.

What is Logistics?

Logistics is the planning, implementing, and controlling the efficient and effective flow of goods, services, and related information from the point of origin to the end of consumption. It is a vital part of any business process, and its importance is often overlooked. Logistics involves the management of inventory, transportation, warehousing, and other related activities. It ensures that the right product is delivered to the right place at the right time and at the least cost.

Integration of Logistics into Business Processes

In order to achieve business excellence, logistics operations must be integrated into the business process. This integration will ensure that the business process runs as a chain rather than isolated process elements. The logistics process must be managed appropriately to ensure that the objectives of the business are met. Logistics integration into the business process will enable the company to reduce costs, improve customer service, and increase efficiency.

Components of Logistics

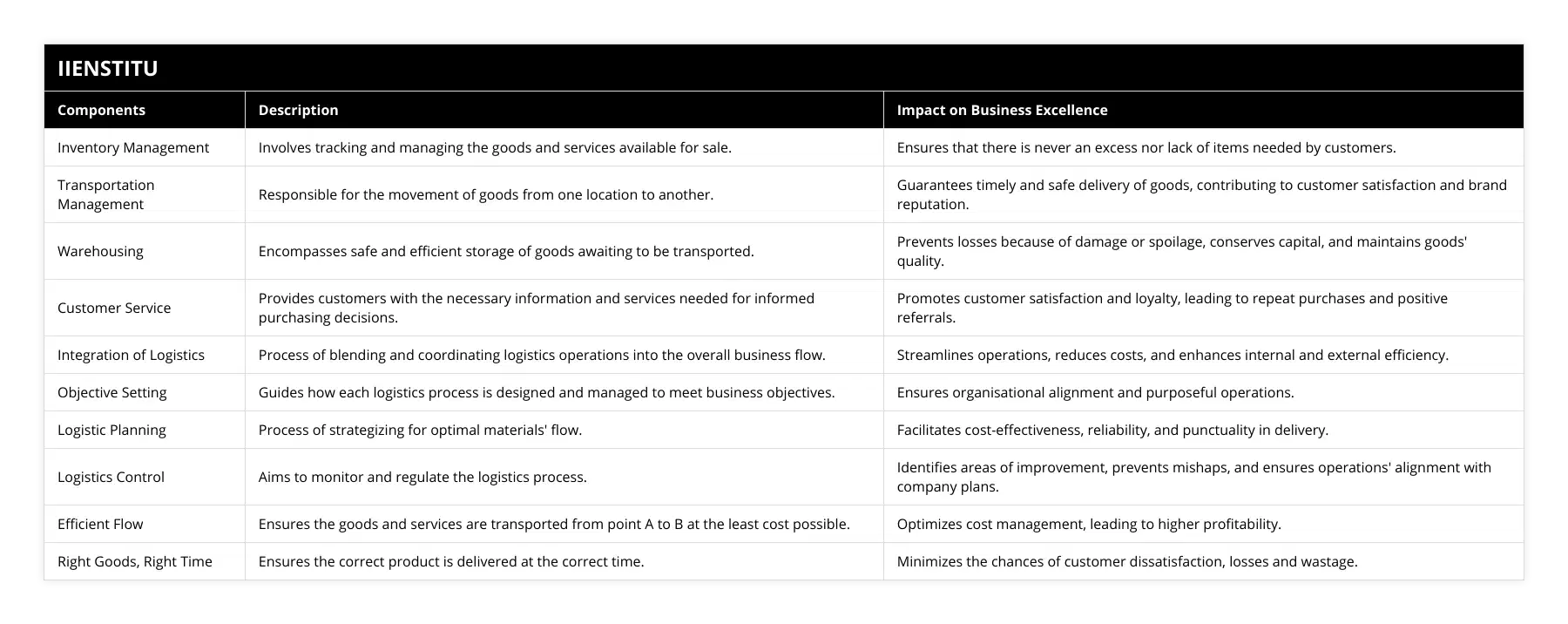

Logistics involves managing four key components: inventory, transportation, warehousing, and customer service. Inventory management consists of tracking and managing the goods and services that are available for sale. Transportation management involves the movement of goods from one place to another. Warehousing consists of the storage of goods securely and efficiently. Finally, customer service involves providing customers with the information and services they need to make informed purchasing decisions.

Conclusion: Logistics is an essential component of any business process. It ensures that the right product is delivered to the right place at the right time and at the least cost. Therefore, logistics operations must be integrated into the business process to achieve business excellence, and its components must be managed appropriately. This article has discussed the importance of integrating logistics into business processes and the logistics components that must be addressed to ensure business excellence.

Integrating logistics into business operations is the foundation of excellence.

Frequently Asked Questions

What are the benefits of integrating logistics into business processes?

Logistics is integral to a business's operations, and integrating it into business processes can bring many benefits. By understanding the complexities of the supply chain, companies can take advantage of the opportunities to reduce costs, improve quality, and increase efficiency.

The integration of logistics into business processes can help to reduce costs. By utilizing an efficient supply chain, companies can reduce the time and money spent on transportation, storage, and inventory management. Additionally, integrating logistics into business processes can help to increase the visibility of the supply chain, allowing businesses to anticipate better and manage costs. This can lead to significant cost savings over time.

Integrating logistics into business processes can also improve the quality of the products and services offered by a business. By evaluating the logistics process and streamlining the operations, companies can ensure that their products and services are delivered on time and at the highest quality. Additionally, integrating logistics into business processes can help businesses to track their products, resulting in improved customer satisfaction.

Finally, integrating logistics into business processes can help businesses to increase efficiency. Companies can reduce waste and increase efficiency by utilizing the most efficient transportation, storage, and inventory management methods. This can lead to improved productivity, as well as improved customer service.

In conclusion, integrating logistics into business processes can bring many benefits. By understanding the complexities of the supply chain, businesses can take advantage of the opportunities to reduce costs, improve quality, and increase efficiency. This can improve customer satisfaction, profitability, and a more significant competitive advantage.

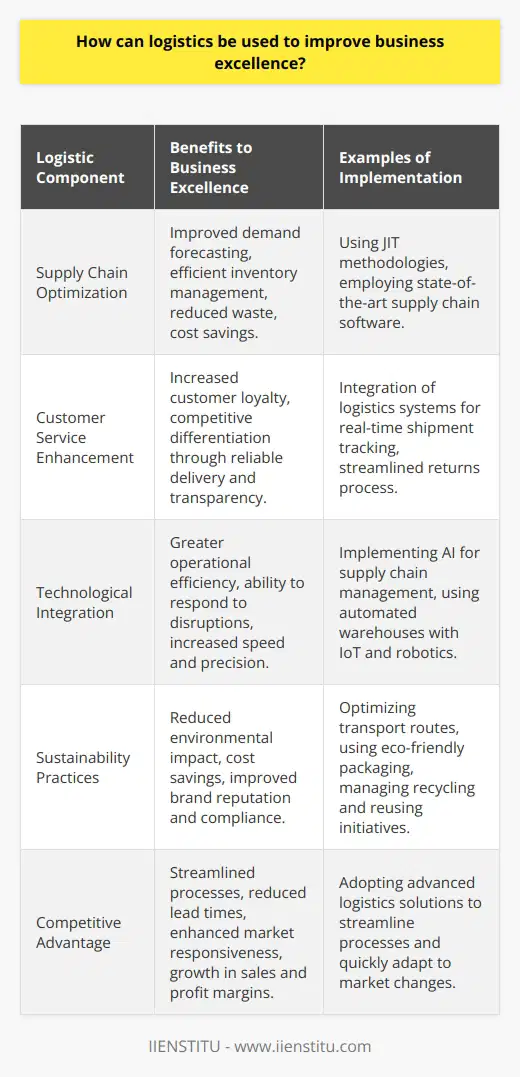

How can logistics be used to improve business excellence?

Logistics is integral to any business, providing the framework necessary for efficient operations. Logistics is the planning, implementation, and control of the efficient, cost-effective flow and storage of goods, services, and related information from the point of origin to the end of consumption for the purpose of satisfying customer requirements. As such, it plays a vital role in the overall success of a business. This article will discuss how logistics can be used to improve business excellence.

First, logistics can be used to reduce costs. Businesses can reduce costs associated with warehousing, shipping, and inventory management by optimizing the flow and storage of goods, services, and related information. Also, logistics can increase supply chain visibility, allowing companies to understand and predict demand better. Businesses can better manage their supply chain by leveraging data and analytics, reducing costs, and increasing efficiency.

Second, logistics can be used to improve customer satisfaction. By utilizing advanced tracking and monitoring systems, businesses can provide customers with greater transparency and visibility into their orders, resulting in greater customer satisfaction. Additionally, companies can use logistics to provide faster delivery times and improved accuracy, improving customer satisfaction.

Third, businesses can use logistics to increase product availability. By leveraging the latest technology, companies can better manage their inventory and increase product availability. Businesses can increase sales and grow their customer base by ensuring that products are available when customers need them.

Finally, businesses can use logistics to improve their overall efficiency. By using advanced analytics, companies can better understand their operations and identify areas for improvement. Additionally, businesses can use logistics to streamline processes, resulting in increased efficiency.

In conclusion, logistics can be used to improve business excellence. By leveraging the latest technology, businesses can reduce costs, improve customer satisfaction, increase product availability, and improve their overall efficiency, all of which can lead to tremendous success.

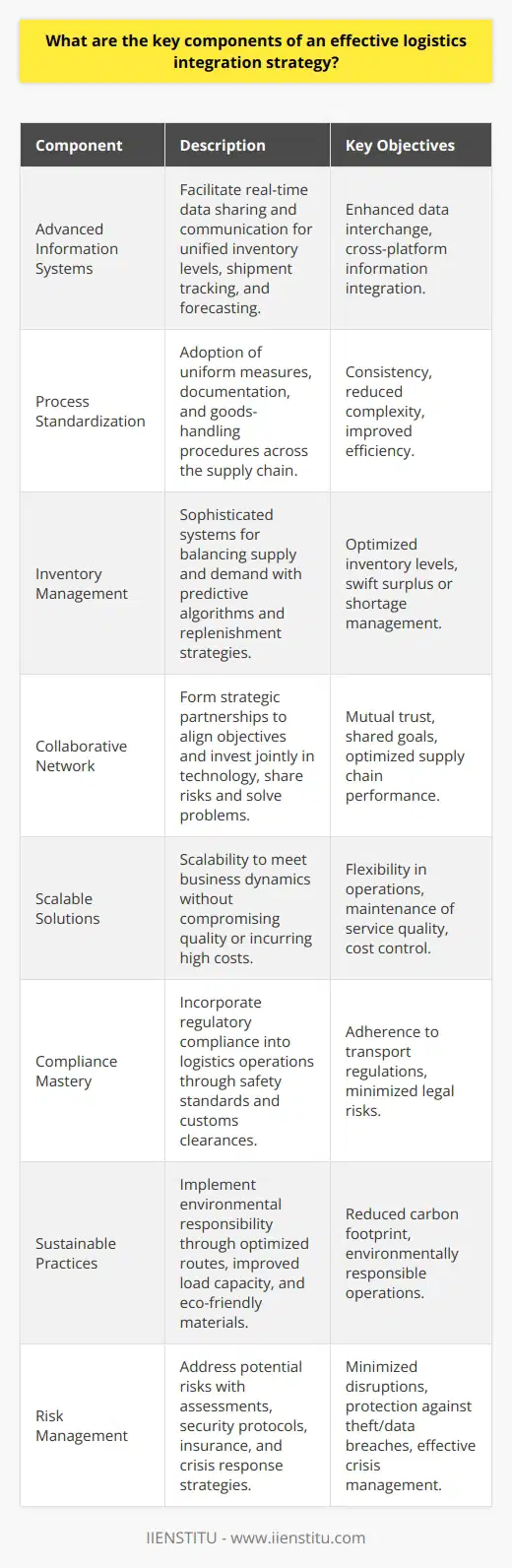

What are the key components of an effective logistics integration strategy?

Logistics integration is an essential component of supply chain management and can be a critical factor in determining a company’s success. It involves coordinating and managing resources, processes, and systems to ensure efficient and cost-effective transportation and storage of goods. An effective logistics integration strategy is essential to maximize the efficiency of the supply chain and minimize costs. The following are the critical components of an effective logistics integration strategy.

1. Data Exchange: Logistics integration requires data exchange between supply chain partners. This data can include product information, inventory levels, shipping and delivery details, and customer preferences. Companies must ensure that accurate and up-to-date data is shared to facilitate efficient and cost-effective operations.

2. Automation: Automation is an essential component of logistics integration. Automation can reduce human errors, enable faster and more accurate processes, and help optimize resources. Automation can also enable companies to track and monitor operations more effectively.

3. Visibility: Visibility is essential to ensure that the supply chain runs efficiently and that any problems are quickly identified and rectified. Companies must ensure that they have access to real-time data to maintain visibility.

4. Collaboration: Collaboration between supply chain partners is essential to ensure that the supply chain runs effectively. Companies must ensure that they have effective communication systems and foster a culture of collaboration and trust.

5. Flexibility: Flexibility is essential to ensure that the supply chain can quickly and easily adapt to changes in demand or customer preferences. Companies must ensure that they can quickly and easily adjust their operations to meet customer requirements.

These are the critical components of an effective logistics integration strategy. Companies must ensure that they have systems in place to ensure the exchange of data, automation, visibility, collaboration, and flexibility. Implementing these components can ensure that the supply chain is running as efficiently as possible and that customer requirements are met cost-effectively.

How does integrated logistics help businesses streamline their operations and increase efficiency?

Integrated Logistics: Streamlining Business Operations

Enhancing Efficiency through Integrated Systems

Integrated logistics plays an essential role in assisting businesses in streamlining their operations and increasing efficiency. It incorporates various aspects of the supply chain, such as procurement, warehousing, transportation, and distribution, creating a well-coordinated system. By combining these functional areas, businesses can eliminate redundancy, improve information flow, and simplify the decision-making process.

Reduced Costs and Improved Resource Allocation

An additional benefit of integrated logistics is its potential to reduce costs. By aligning supply chain processes, organizations can achieve better economies of scale, lower inventory holding costs, and optimize transportation. This efficient resource allocation not only helps minimize expenses but also enhances competitiveness in the market.

Enhanced Collaboration and Information Sharing

Another essential aspect of integrated logistics is the promotion of collaboration and information sharing among supply chain partners. This enhanced communication enables businesses to monitor and track inventory levels, shipment status, and delivery expectations in real-time. Consequently, organizations can make informed decisions, ensuring that products reach customers efficiently and cost-effectively.

Higher Customer Satisfaction

Efficient logistics operations have a direct impact on customer satisfaction. Integrated logistics ensures timely product delivery, accuracy in order processing, and reduced lead times. These factors contribute to better customer experiences, which can result in increased loyalty and repeat business.

Increased Flexibility and Responsiveness

Finally, integrated logistics promotes flexibility and responsiveness in supply chain management. By providing comprehensive visibility of the entire process, businesses can easily adapt to changes in demand, customer preferences, or unforeseen disruptions. Consequently, companies are better prepared to face challenges and seize opportunities in the marketplace.

Conclusion

In summary, integrated logistics is a vital tool for businesses to streamline their operations and increase efficiency. By enhancing collaboration, reducing costs, and improving flexibility, companies can thrive in a competitive landscape and provide exceptional customer experiences.

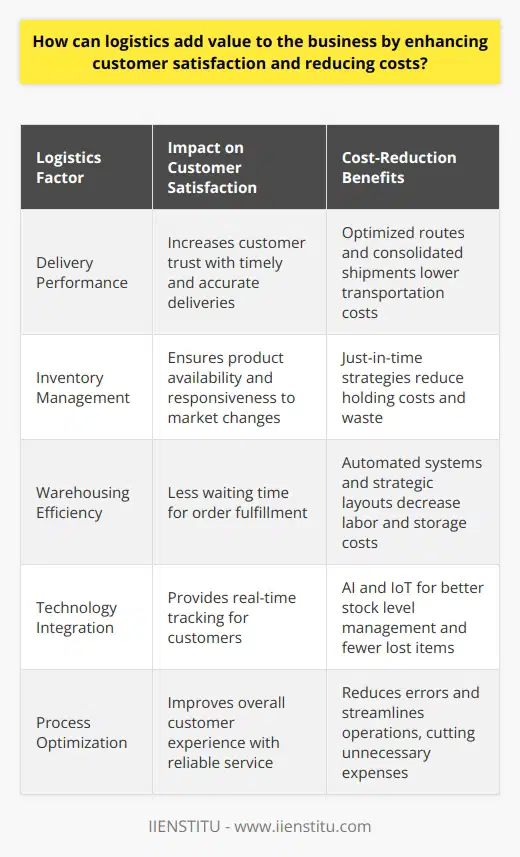

How can logistics add value to the business by enhancing customer satisfaction and reducing costs?

**Logistics as a Value-Adding Component**

Logistics plays a crucial role in enhancing customer satisfaction and reducing costs within businesses, ultimately adding value to a company's overall endeavors. By efficiently managing the various aspects of supply chain operations, logistics ensures that a business's products and services reach their target customers in a timely and cost-effective manner, which directly contributes to increased customer satisfaction and company profitability.

**Impact on Customer Satisfaction**

Customer satisfaction is greatly influenced by a business's ability to deliver products and services within the expected timeframe and with minimal discrepancies or defects. Through effective logistics operations, businesses can successfully streamline their order fulfillment processes and minimize potential errors, leading to a higher level of customer satisfaction. Additionally, well-organized logistics systems facilitate accurate tracking and communication of delivery status, which not only improves customer trust but also allows businesses to address any potential issues proactively.

**Cost-Reduction Benefits**

Efficient logistics management offers substantial cost-saving opportunities, especially in terms of transportation, inventory, and warehousing. By optimizing transportation routes and incorporating cost-efficient modes of shipment, businesses can reduce their overall transportation costs. Furthermore, implementing inventory management systems ensures that businesses maintain an optimal balance of stock levels, ultimately minimizing both overstocking and stock shortage costs. Similarly, effective warehouse management can lead to decreased operational expenses, better utilization of space, and improved employee productivity.

**Continuous Improvement and Innovation**

As logistics operations continuously evolve to adopt new technologies, businesses must stay at the forefront of industry advancements to maintain a competitive edge. Investing in innovative logistics solutions not only ensures that businesses can optimize their current processes but also highlights potential growth areas that can further enhance customer satisfaction and reduce costs. Some examples of innovative logistics approaches include the use of automation, AI-driven analytics, and the integration of IoT technology in managing various aspects of supply chain management.

In conclusion, logistics is an essential aspect of modern businesses that can significantly contribute to their overall value by maximizing customer satisfaction and minimizing operational costs. By investing in efficient logistics management and embracing innovative practices, businesses can ultimately elevate their performance and maintain a competitive edge in their respective industries.

What are the key factors to consider when integrating logistics into a company's overall strategy?

Integrating Logistics in Strategy

In order to ensure the seamless incorporation of logistics into a company's overall strategy, several key factors must be addressed. The primary considerations include coordination, cost-effectiveness, customer service, and flexibility.

Coordination Across Departments

Effective coordination amongst the various departments involved in the supply chain process is essential for successful logistics integration. This may entail regular meetings, streamlined communication channels, and shared goals between these departments. Furthermore, encouraging collaboration among team members can lead to smooth logistic operations and decision-making.

Cost-Effectiveness

Efficient management of logistics costs is crucial when integrating it into the strategic planning process. This may involve regular monitoring and assessment of transportation, warehousing, and inventory expenses. Implementing cost-saving measures such as optimizing transportation routes, adopting just-in-time inventory management, and leveraging the potential of automation can be instrumental in enhancing cost-effectiveness and overall profitability.

Customer Service Excellence

Emphasizing customer satisfaction is vital when incorporating logistics into a company’s overarching strategy. Factors to consider include timely delivery, product quality, and effective communication, which are likely to foster long-term loyalty and positive word-of-mouth marketing. Addressing customers' needs by establishing clear order fulfillment policies, effective returns management processes, and prompt issue resolution channels can contribute to superior customer service.

Flexibility and Adaptability

In today's ever-changing business environment, it is essential for companies to be adaptable and flexible when it comes to their logistics operations. This involves regularly reassessing and adjusting supply chain processes in response to emerging trends, technology advancements, and fluctuations in customer requirements. To ensure adaptability, fostering a culture of innovation and continuous improvement can help facilitate the integration of logistics in a company's overall strategy.

In conclusion, successful integration of logistics within a company's overall strategy necessitates careful consideration of coordination, cost-effectiveness, customer satisfaction, and flexibility. By focusing on these key areas, companies can achieve a coherent and optimized supply chain that ultimately contributes to their long-term growth and success.

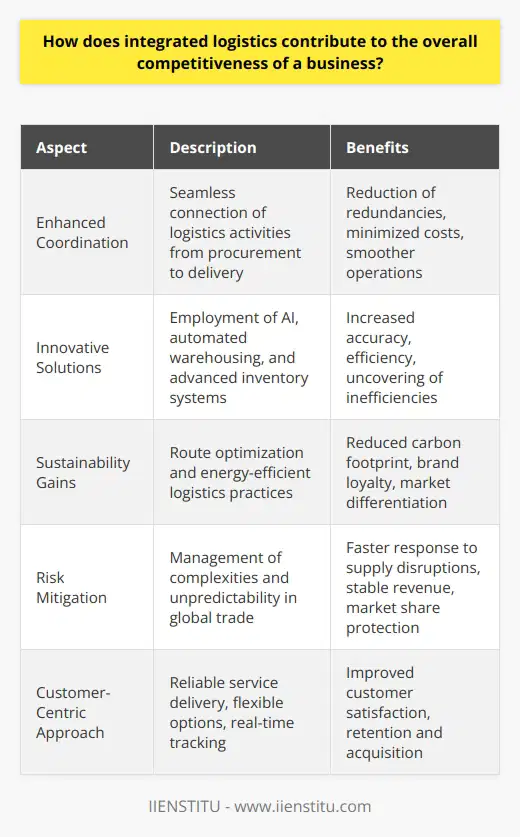

How does integrated logistics contribute to the overall competitiveness of a business?

Integrated Logistics and Competitiveness

One critical aspect of enhancing the overall competitiveness of a business is through the implementation of integrated logistics. Such an approach involves the streamlining of various logistics components, including transportation, warehousing, and inventory management, which directly contributes to cost reduction, faster response times, and improved operational efficiencies.

Cost Reduction

By coordinating and consolidating logistics operations, businesses can achieve significant cost savings. This is done by optimizing transportation routes, reducing the inventory holding costs, or leveraging economies of scale, resulting in lower operational expenses. With lower costs, businesses have the flexibility to offer more competitive prices in the market without compromising profitability.

Faster Response Times

Through integrated logistics, businesses can achieve better responsiveness to customer demands, ultimately enhancing competitiveness. By employing real-time tracking and monitoring systems, companies can reduce the lead times and ensure timely delivery of products or services. This results in a more agile supply chain, which effectively addresses rapid shifts in market demands and ensures businesses maintain their edge over rivals.

Operational Efficiencies

Efficient management of logistics operations is crucial for businesses to compete effectively in today's dynamic market environment. Integrated logistics improves internal processes by leveraging automation, robust IT systems, and data analytics to minimize errors, reduce downtime, and enhance overall supply chain visibility. This, in turn, facilitates informed decision-making, enabling businesses to allocate resources more efficiently and develop strategies that foster continuous improvement.

Conclusion

In summary, integrated logistics significantly contributes to the overall competitiveness of a business by optimizing costs, promoting timely delivery, and improving operational efficiency. By implementing an integrated logistics approach, companies can gain a competitive advantage in the market and achieve greater overall success. It is essential for businesses to recognize the value of integrated logistics and incorporate it into their strategic planning to maximize potential benefits.

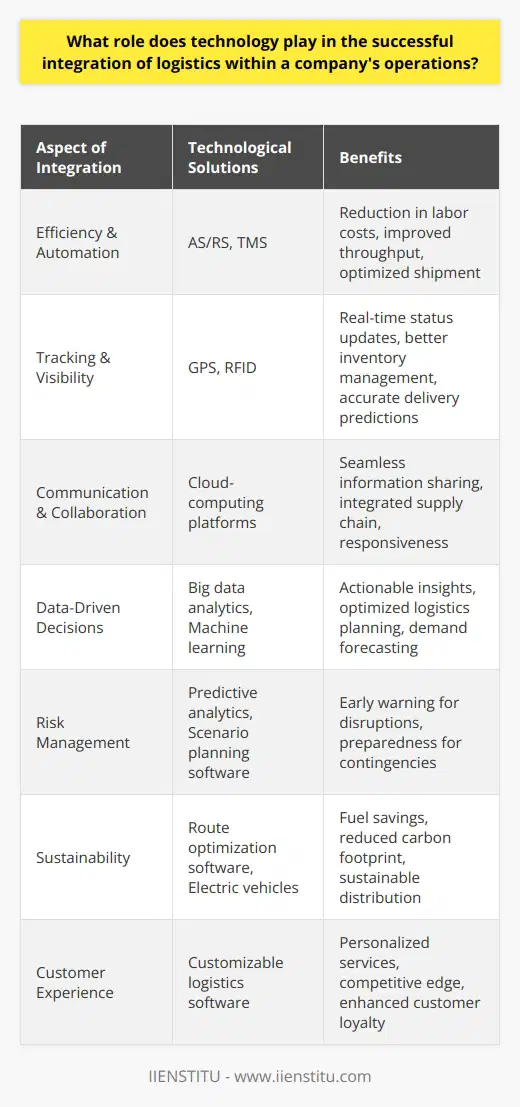

What role does technology play in the successful integration of logistics within a company's operations?

Role of Technology in Logistics Integration

Streamlining Operations

Technology plays a vital role in integrating logistics within a company's operations, significantly streamlining processes. Automated systems enhance the efficiency of logistics, reducing human errors, and optimizing resources.

Real-Time Data Access

Through the deployment of technologies like GPS and Radio Frequency Identification (RFID), companies can access real-time data regarding shipment locations and monitor warehouse inventories. Consequently, managers can make timely and informed decisions to ensure seamless operations.

Enhanced Communication

Technological advancements have improved communication between departments and supply chain partners, fostering collaboration and enabling more coordinated efforts. These advancements consist of tools such as Electronic Data Interchange (EDI) and cloud-based systems, ensuring that all stakeholders have access to necessary information.

Improved Forecasting

By leveraging data analytics and machine learning, companies can make accurate demand projections, allowing for better resource allocation and planning. This translates to lower costs, increased customer satisfaction, and informed decision-making.

Risk Management

The employment of advanced technology in logistics allows for better identification, analysis, and mitigation of potential risks. Companies can anticipate disruptions in the supply chain, like extreme weather or customs delays, and take preventative measures to minimize potential impact on their operations.

Eco-Friendly Practices

Technology has enabled companies to adopt sustainable practices throughout their logistics operations. By utilizing energy-efficient vehicles or optimizing distribution routes, businesses can reduce their environmental footprint and achieve cost savings.

Customized Services

Technological innovations have allowed companies to offer highly personalized logistics solutions to their customers. For instance, using advanced routing algorithms and real-time tracking, companies can ensure that each customer's unique needs are met efficiently.

Conclusion

In summary, technology is an integral component in the successful integration of logistics within a company's operations. Through streamlined processes, real-time data access, improved communication, accurate forecasting, effective risk management, eco-friendly practices, and personalized services, companies can expect enhanced efficiency and overall success.

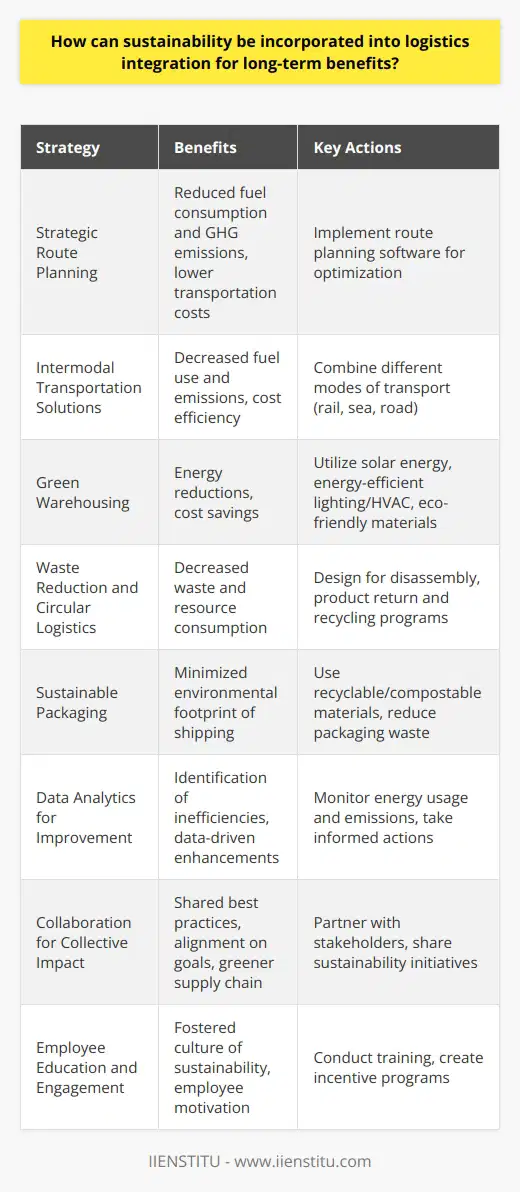

How can sustainability be incorporated into logistics integration for long-term benefits?

Incorporating Sustainability in Logistics

To achieve long-term benefits, logistics integration must include sustainability. This can be done through various approaches, including minimizing transportation costs, utilizing eco-friendly materials, and reducing energy usage.

Minimizing Transportation Costs

One way to incorporate sustainability into logistics integration is by minimizing transportation costs. This can be done by identifying more efficient and effective routes, integrating intermodal transportation, and consolidating shipments. By optimizing transportation strategies, companies can reduce both their carbon footprint and their overall expenses.

Utilizing Eco-Friendly Materials

Another approach to incorporating sustainability in logistics integration is by using eco-friendly materials. This can involve selecting sustainable packaging options, such as biodegradable or recycled materials, and working with suppliers committed to sustainable practices. By opting for more environmentally friendly options, businesses can lessen their environmental impact and appeal to increasingly environmentally-conscious consumers.

Reducing Energy Usage

Efforts can also be made to reduce energy usage in logistics processes, further promoting sustainability. This can include implementing energy-efficient lighting and equipment, optimizing warehouse layouts for reduced energy consumption, and utilizing renewable energy sources such as solar panels. Additionally, energy-saving practices, like switching off equipment when not in use, can contribute to reducing energy use and lowering operational costs.

Enhancing Reverse Logistics

Incorporating reverse logistics strategies in the overall logistics integration can significantly contribute to sustainability. Reverse logistics refers to the processes involved in returning products, materials, or components back to their point of origin for proper disposal or reuse. Developing an efficient reverse logistics system facilitates proper recycling, reduces waste, and minimizes environmental impact.

Measuring and Monitoring Sustainability Performance

Finally, it is essential to measure and monitor the sustainability performance of logistics integration, enabling continuous improvement. Companies can track various key performance indicators (KPIs) related to sustainability, such as energy consumption, emissions, and waste generation. Regular monitoring allows businesses to identify areas for improvement and adjust their logistics strategies accordingly.

In conclusion, incorporating sustainability into logistics integration can lead to numerous long-term benefits, such as reduced costs, enhanced brand reputation, and minimized environmental impact. By adopting sustainable practices in transportation, materials selection, energy usage, reverse logistics, and performance monitoring, companies can achieve more efficient and environmentally responsible logistics operations.

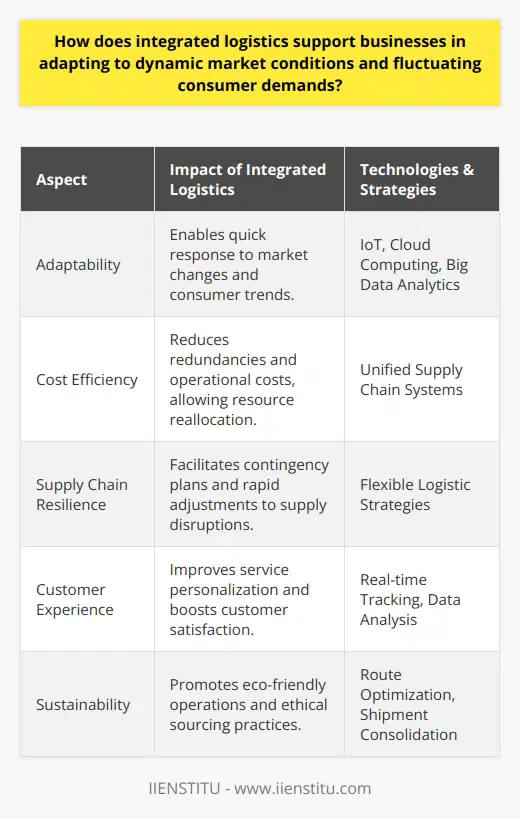

How does integrated logistics support businesses in adapting to dynamic market conditions and fluctuating consumer demands?

**Impact of Integrated Logistics on Business Adaptability**

Integrated logistics plays a vital role in helping businesses adapt to dynamic market conditions and fluctuating consumer demands. By streamlining supply chain operations, it enhances the overall flexibility and responsiveness of an organization's procurement, manufacturing, distribution, and customer service processes.

**Efficient Resource Allocation**

One significant aspect of integrated logistics is the effective allocation of resources. Through data-driven analysis and decision-making, businesses can optimize their inventory, transportation, and warehousing by responding promptly to changing demand patterns. As a result, they can avoid excess stock or stock-outs, minimize operational costs, and better serve customer needs.

**Enhanced Supply Chain Visibility**

Additionally, integrated logistics increases supply chain visibility, enabling companies to monitor the entire process from procurement to delivery of goods. With real-time information, businesses can identify bottlenecks or inefficiencies, adjust operations proactively, and maintain high levels of customer satisfaction. This increased transparency also aids in collaboration among supply chain partners, helping to improve overall performance.

**Greater Agility and Speed**

Greater agility and speed are other essential benefits of integrated logistics. By synchronizing the flow of information and goods across the supply chain, businesses can ensure timely reactions to market shifts and maintain their competitive edge. For example, if customer preferences change or a supplier experiences disruptions, integrated logistics allows for rapid adjustments to production or sourcing strategies, mitigating possible negative impacts.

**Improved Demand Forecasting**

Furthermore, integrated logistics supports improved demand forecasting through the accumulation and organization of relevant data. This information allows companies to predict consumer demands more accurately and prepare accordingly, minimizing the risks of operational inefficiencies and stock mismanagement.

**Customized Offerings and Personalization**

Lastly, integrated logistics empowers businesses to cater to the growing trend of personalized and customized offerings. By leveraging customer data and analytics, companies can identify individual preferences and tailor their products or services to meet specific desires. This customization not only increases consumer satisfaction but also strengthens brand loyalty and long-term profitability.

In conclusion, integrated logistics is a fundamental component for businesses aiming to adapt to dynamic market conditions and fluctuating consumer demands. By offering efficient resource allocation, enhanced supply chain visibility, greater agility and speed, improved demand forecasting, and the ability to provide customized offerings, integrated logistics contributes to a more resilient and successful business model.

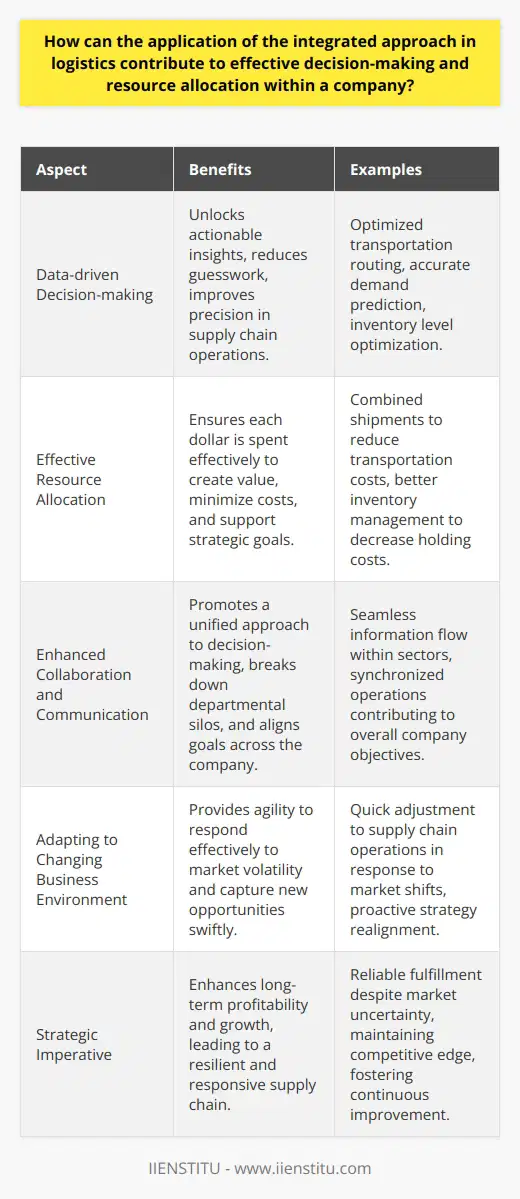

How can the application of the integrated approach in logistics contribute to effective decision-making and resource allocation within a company?

Integration of Logistics Strategies

The application of an integrated approach in logistics plays a significant role in fostering effective decision-making and resource allocation within a company. Fundamental to this approach is the consolidation of various logistics strategies, functions, and resources, which work synergistically to streamline operational processes and increase efficiency. Consequently, this results in data-driven insights, better communication, and enhanced collaboration among departments, thereby leading to well-timed and informed decisions.

Data-driven Decision-making

A major advantage of integrating logistics involves utilizing data-driven insights to bolster decision-making. Access to comprehensive and accurate information enables managers to evaluate and refine aspects of the supply chain, such as demand forecasting, purchasing, inventory control, transportation, and distribution. By leveraging data analytics, decision-makers gain a holistic view of the company's performance and are better positioned to identify cost-saving opportunities and promptly address potential shortcomings.

Effective Resource Allocation

Furthermore, an integrated logistics approach helps companies optimize their resource allocation by identifying optimal trade-offs between cost, quality, and time. By assessing each element in relation to the supply chain, managers gain a deeper understanding of current processes and can explore alternative solutions to streamline workflows. This comprehensive review leads to better allocation of financial, infrastructural, and human resources, ultimately contributing to enhanced operational efficiency and resilience.

Enhanced Collaboration and Communication

In addition, the integrated approach promotes interdisciplinary communication and collaboration, which considerably aids decision-making. By cultivating strong working relationships, departments are more likely to share data, resources, and expertise, fostering a cohesive, collaborative environment. Consequently, effective communication and cooperation translate to better decision-making, as managers possess a thorough understanding of the implications and consequences of their choices on the organization's overall efficiency and results.

Adapting to Changing Business Environment

Lastly, the integrated logistics approach equips companies with the necessary tools to thrive in a constantly evolving business environment. By identifying trends and emerging challenges promptly, companies can take a proactive stance towards change, adjust their strategies, and capitalize on new market opportunities. Therefore, this adaptability promotes long-term success and sustainability, demonstrating the enduring value of holistic logistics management.

In conclusion, applying an integrated approach in logistics proves crucial in enhancing decision-making and resource allocation for companies. This approach enables organizations to achieve data-driven insights, promote enhanced collaboration, efficiently allocate resources, and aptly navigate always-changing business landscape. With these benefits, companies that prioritize integrated logistics management are well-positioned for enduring operational success and competitive advantage.

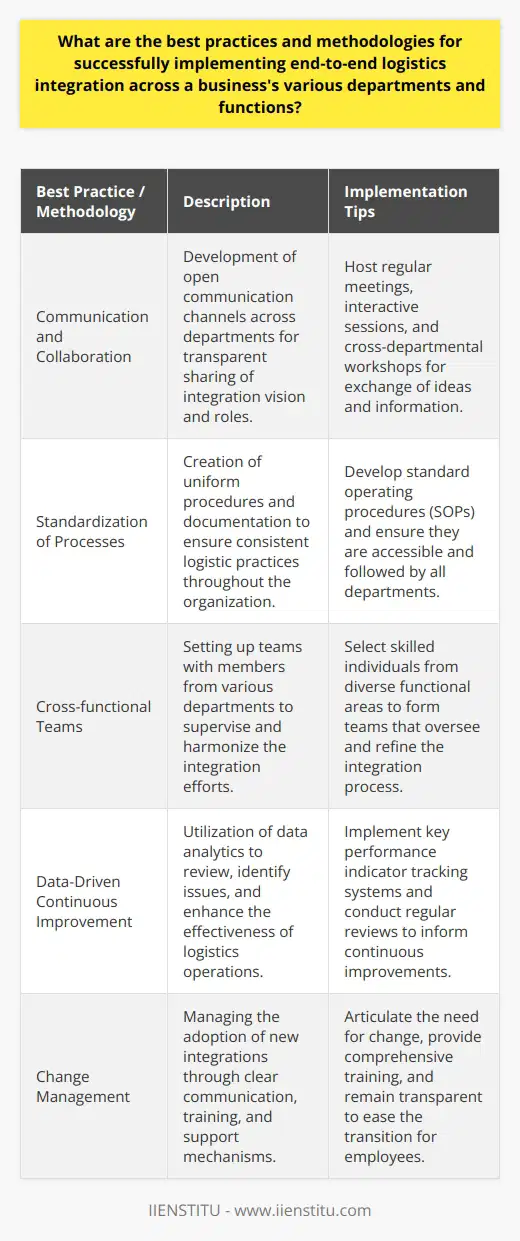

What are the best practices and methodologies for successfully implementing end-to-end logistics integration across a business's various departments and functions?

Effective Communication and Collaboration

One of the best practices for successfully implementing end-to-end logistics integration across various departments and functions is effective communication and collaboration. It is essential for all involved departments to understand the goals, objectives, and expected outcomes of the integration process. Clear communication channels and regular updates can help to ensure that all teams are aligned and working towards the same objectives.

Adopting Standardized Processes

Another crucial aspect of successful end-to-end logistics integration is adopting standardized processes. Streamlining processes throughout the organization will allow departments to work more efficiently and effectively. This can be achieved by implementing common tools, platforms, and systems to facilitate consistent workflows and practices. Using standardized processes simplifies integration, as employees have clear guidelines and expectations about how to perform specific tasks.

Cross-functional Teams

Forming cross-functional teams that include representatives from various departments can significantly enhance end-to-end logistics integration. These teams are responsible for coordinating and implementing logistics strategies throughout the organization. By leveraging diverse skills, knowledge, and expertise, cross-functional teams can address and resolve any issues or challenges that may arise during the integration process. Additionally, these teams can provide valuable insights that help optimize workflows, reduce costs, and improve overall operational efficiency.

Continuous Improvement through Data Analytics

Implementing end-to-end logistics integration successfully also requires a continuous improvement mindset. Data analytics plays a crucial role in this aspect, providing valuable insights into the performance of logistics processes across the organization. By continuously monitoring metrics and analyzing data, businesses can identify areas for improvement and devise strategies to optimize their logistics operations.

Change Management Strategies

Change management strategies are essential to ensure the smooth implementation of end-to-end logistics integration. This involves preparing stakeholders for the changes associated with integration, providing training and resources to support employees during the transition, and addressing any resistance or concerns that may arise. A well-planned and executed change management strategy can help to minimize disruptions to daily operations and maintain employee morale throughout the integration process.

In conclusion, the key to successfully implementing end-to-end logistics integration across a business's various departments and functions lies in fostering effective communication and collaboration, standardizing processes, forming cross-functional teams, leveraging data analytics for continuous improvement, and employing change management strategies. By adopting these best practices, organizations can optimize their logistics operations and achieve long-term success.

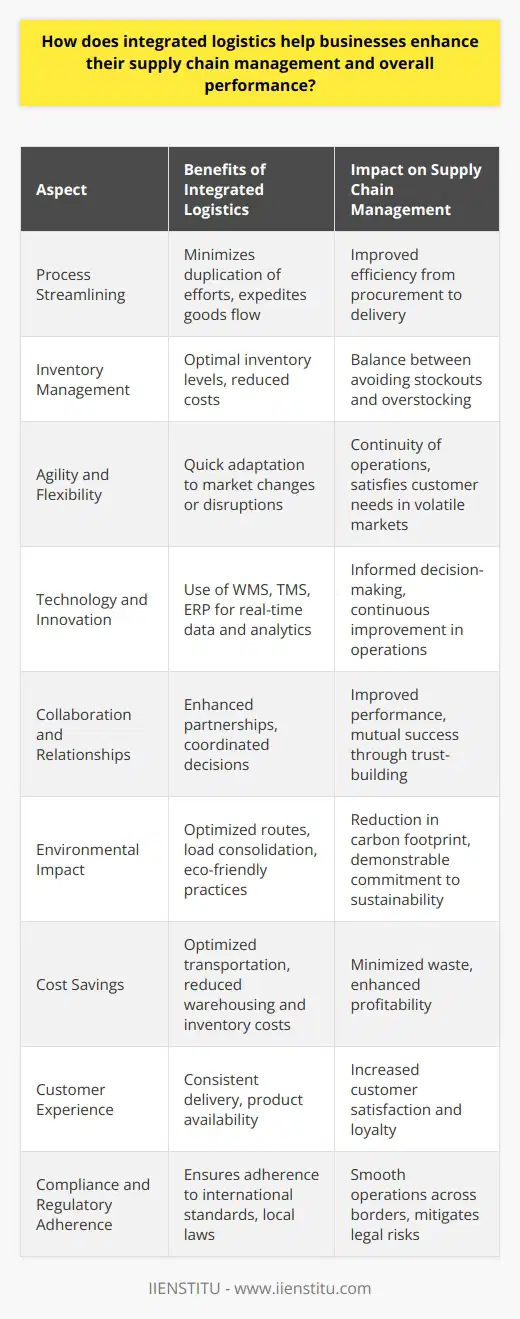

How does integrated logistics help businesses enhance their supply chain management and overall performance?

Integrated logistics in supply chain management

Integrated logistics can be described as the process of harmonizing all logistics activities within a supply chain, including transportation, storage, and handling of goods, to improve efficiency and productivity. This harmonization enables businesses to better manage their supply chain by reducing costs and lead times while improving overall operational performance.

Enhanced interconnectivity

One key benefit of integrating logistics is the improved interconnectivity among different supply chain parties, such as suppliers, manufacturers, and end customers. This facilitates seamless data sharing and communication, leading to more accurate forecasting, better inventory management, and timely order fulfillment.

Cost reduction and optimization

Integrated logistics helps businesses reduce costs associated with supply chain inefficiencies, such as excess inventory and long delivery times. Streamlined logistics also allow for economies of scale, and as a result, businesses can take advantage of lower transportation and warehousing costs.

Improved customer satisfaction

By implementing integrated logistics, businesses can improve overall performance in terms of delivering products on time and in the right condition. This results in increased customer satisfaction, which bolsters the organization's reputation and promotes repeat business and customer loyalty.

Risk management and mitigation

An interconnected logistics system allows businesses to actively manage and mitigate supply chain risks. They are able to proactively identify potential issues, such as supplier delays, unexpected spikes in demand, or transit disruptions, and devise contingency plans accordingly.

Sustainability

Integrated logistics helps businesses address environmental concerns by reducing the carbon footprint associated with supply chain management. Streamlined processes enable companies to minimize waste, decrease the number of vehicles required for transportation, and adopt more eco-friendly practices, such as using energy-efficient warehouses.

Competitive advantage

Ultimately, investing in integrated logistics offers businesses a competitive edge by providing better visibility, control, and adaptability in their supply chain operations. This, in turn, leads to increased efficiency, reduced costs, lower environmental impact, and improved customer satisfaction, all of which contribute to a stronger brand image and better overall performance in the market.

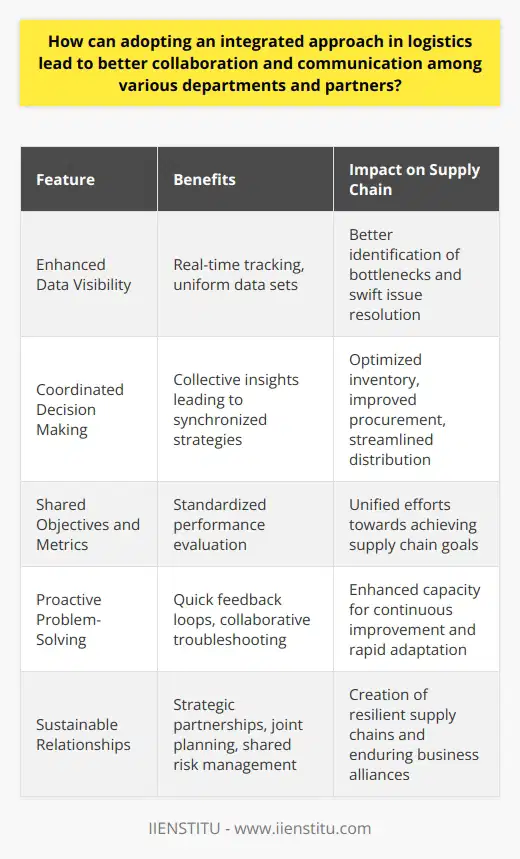

How can adopting an integrated approach in logistics lead to better collaboration and communication among various departments and partners?

Integrated Logistics for Improved Collaboration

Adopting an integrated approach in logistics can lead to better collaboration and communication among various departments and partners by creating a centralized system that streamlines processes and ensures efficient information sharing. By merging logistics operations and promoting cross-functional coordination, integrated logistics creates a more coherent and transparent system that fosters teamwork and cooperation among stakeholders.

Streamlined Processes and Efficient Information Sharing

One major advantage of an integrated logistics system is the streamlining of processes across all levels of the supply chain. This simplification reduces delays and redundancies, leading to improved efficiency and cost savings. In addition, having a centralized system allows for the quick and accurate sharing of vital information among different departments and partners. Consequently, decision-making and problem-solving become more effective, ensuring that all parties involved have access to the necessary data to make informed choices.

Promotion of Cross-Functional Coordination

By breaking down silos and promoting cross-functional coordination, integrated logistics encourages collaboration among different departments and partners. This interdisciplinary approach enables stakeholders to work together towards a shared goal, fostering a sense of teamwork and shared ownership. As a result, problem-solving and decision-making become more collaborative, ensuring that each party's perspectives and insights are taken into account.

Increased Transparency and Fostering of Teamwork

As integrated logistics systems improve information flow and coordination, transparency within the supply chain increases. This increased visibility allows all parties involved to have a clear understanding of their roles and responsibilities, as well as the overall status of the supply chain. This understanding fosters a sense of teamwork and cooperation, and encourages collaboration as stakeholders work together to achieve mutual goals and overcome shared challenges.

In conclusion, adopting an integrated approach in logistics offers several benefits when it comes to collaboration and communication among various departments and partners. The centralization and streamlining of processes, promotion of cross-functional coordination, and increased transparency all contribute to a more collaborative and cohesive system. These elements combine to create an environment in which teamwork, communication, and collaboration are continually fostered, ultimately leading to improved efficiency and success within the supply chain.

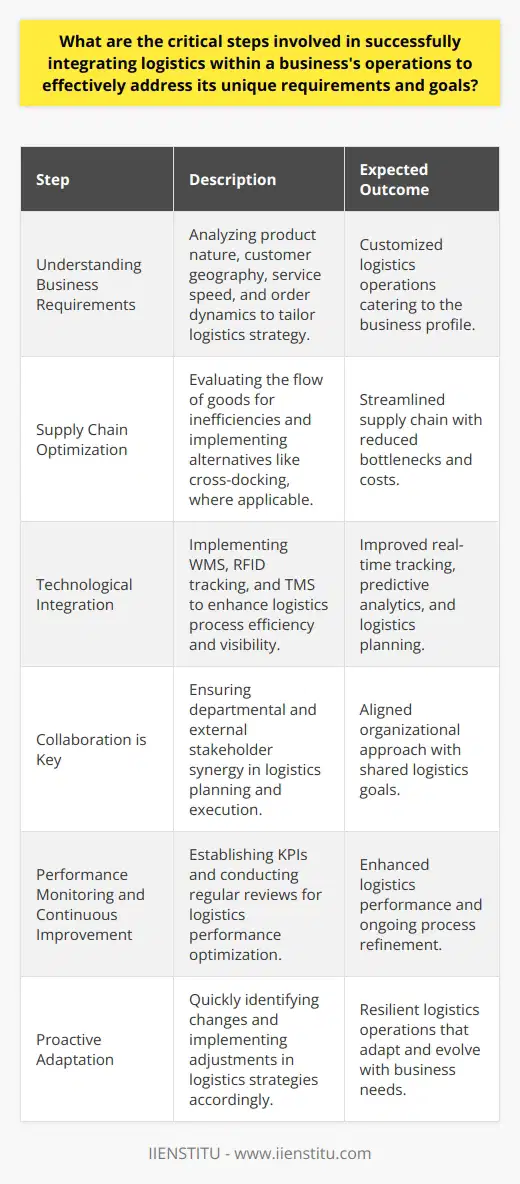

What are the critical steps involved in successfully integrating logistics within a business's operations to effectively address its unique requirements and goals?

Logistics Integration Process

A successful logistics integration within a business's operations involves a series of critical steps. First, identifying the business's unique requirements and goals is essential to tailoring a suitable logistics approach. That means analyzing the specific needs of the organization, such as understanding product characteristics, supply chain demands, and customer requirements.

Supply Chain Optimization

After determining the unique needs of the business, the next step is to optimize the supply chain. This process entails evaluating current supplier networks, distribution channels, and transportation providers to identify potential areas for improvement. Additionally, leveraging digital technology like warehouse management systems and automated tools can significantly enhance operational efficiency and minimize costs.

Collaboration and Communication

Effective collaboration and communication within the organization are fundamental for successful logistics integration. This involves regularly engaging with various departments, such as sales, marketing, and customer service, to ensure alignment with the overall business objectives. Sharing real-time data, insights, and forecasts can help teams make informed decisions and streamline processes.

Continuous Improvement and Monitoring

Once the logistics processes are integrated with the business operations, it is crucial to monitor performance constantly. This can be achieved through regular evaluations using key performance indicators (KPIs) such as on-time deliveries, order accuracy, and warehouse efficiency. Comparing these metrics against industry benchmarks can provide valuable insights into the effectiveness of the logistics system.

Implementing Corrective Actions

Monitoring and evaluating logistics performance can reveal areas for improvement, and it is vital to take corrective actions promptly. This can involve adjusting inventory levels, streamlining product handling processes, or exploring additional transportation options. Implementing necessary changes can ensure the logistics system remains efficient and effective in addressing the business's unique requirements and goals.

In conclusion, to achieve a successful logistics integration in a business's operations, companies need to determine their specific needs, optimize their supply chains, foster collaboration, monitor performance, and implement corrective actions. By following these critical steps, organizations can effectively address their unique requirements and goals, resulting in a more efficient and profitable operation.

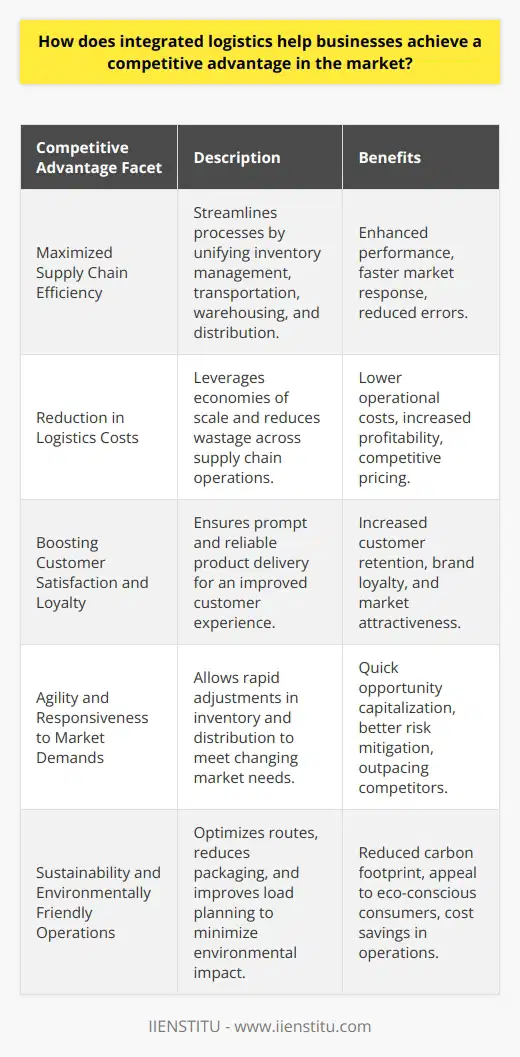

How does integrated logistics help businesses achieve a competitive advantage in the market?

**Importance of Integrated Logistics**

Integrated logistics plays a crucial role in strengthening businesses' competitive advantage in the market by streamlining their supply chain processes. By improving the efficiency of operations and reducing costs, companies can focus on the core aspects of their business and gain an edge over competitors.

**Enhanced Operational Efficiency**

One of the primary benefits of integrated logistics is optimized efficiency across all supply chain stages. By consolidating various functions like procurement, transportation, warehousing, and distribution, businesses can minimize redundancies, improve coordination, and save valuable time. This streamlined approach also enables better visibility into operations, which ultimately helps in making informed strategic decisions.

**Cost Reduction and Increased Profitability**

Implementing integrated logistics assists businesses in reducing their overall expenses, as it consolidates and optimizes various elements of the supply chain. This cost reduction can be attributed to enhanced resource utilization, reduced warehousing costs, and decreased transportation expenditure. Consequently, businesses can allocate these savings to other strategic initiatives, which contribute to improved profitability and a competitive advantage in the market.

**Improved Customer Satisfaction**

Integrated logistics plays a pivotal role in ensuring timely delivery and maintaining product quality, two factors essential for customer satisfaction. By efficiently managing the inventory, transportation, and distribution processes, businesses can guarantee that the end customers receive their products promptly and in optimal condition. This results in improved customer loyalty and trust, which provide an edge in today's highly competitive market.

**Enhanced Flexibility and Scalability**

Another significant advantage of adopting integrated logistics is the increased flexibility and scalability it offers businesses. By having a well-coordinated system in place, companies can quickly adapt to market fluctuations, varying customer demands, or unforeseen disruptions. This adaptability is crucial for surviving in a dynamic marketplace and maintaining a strong competitive position.

In conclusion, integrated logistics serves as a pivotal enabler for businesses to attain a competitive advantage in the market. By enhancing operational efficiency, reducing costs, improving customer satisfaction, and offering greater flexibility and scalability, integrated logistics empowers companies to stay ahead of their competition and remain profitable in the long run.

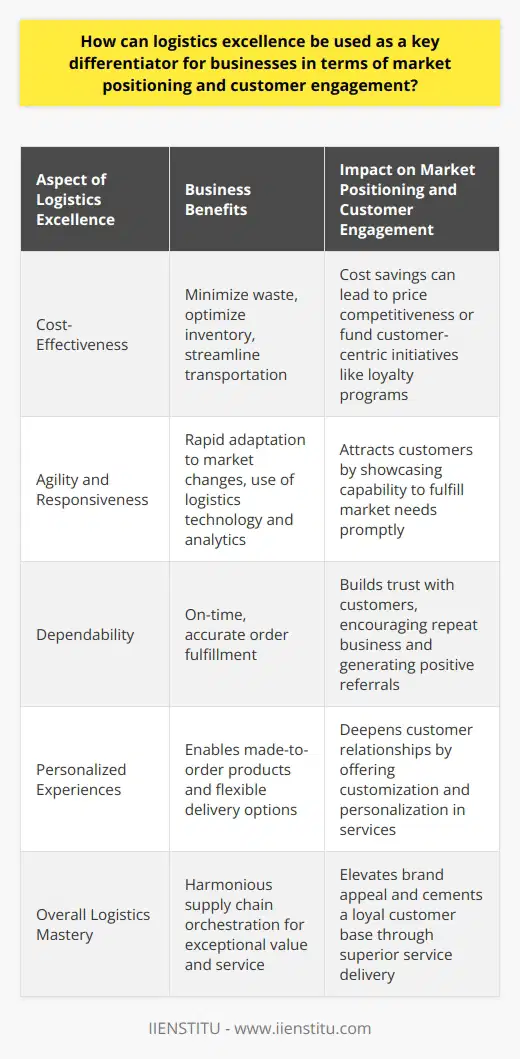

How can logistics excellence be used as a key differentiator for businesses in terms of market positioning and customer engagement?

Logistics Excellence as a Differentiator

Logistics excellence can be a critical differentiator for businesses in terms of market positioning and customer engagement. By optimizing and streamlining supply chain operations, companies can achieve cost savings, increased responsiveness to market changes, and improved reliability, ultimately leading to a competitive advantage in the market.

Cost Savings

Effective logistics management enables organizations to lower their operational expenses by preventing overstocking, reducing transportation costs, and minimizing product damage. These cost savings can be passed on to customers in the form of lower prices or reinvested in the business to develop innovative products and services, making the company more attractive to its target market.

Increased Responsiveness

A well-structured logistics system allows companies to respond quickly to fluctuations in customer demand and effectively allocate resources to meet these needs. By capitalizing on real-time data and advanced analytics, businesses can anticipate emerging trends and adjust their strategies accordingly, thus positioning themselves as agile market leaders and increasing the likelihood of customer loyalty and repeat business.

Improved Reliability

Ensuring timely and accurate delivery of products through an efficient logistics network can enhance the customer experience by meeting or exceeding their expectations. Reliable and consistent performance in this area not only fosters trust and credibility among existing customers but also attracts new customers through positive reviews and word-of-mouth referrals.

Customization and Personalization

Logistics excellence can also enable businesses to tailor their offerings to individual customers by providing a higher degree of product customization and personalization. A seamless and efficient supply chain facilitates the delivery of tailored solutions to meet specific customer preferences, fostering deeper engagement and an enhanced sense of brand loyalty.

In conclusion, logistics excellence plays a crucial role in determining a business's market positioning and customer engagement. By optimizing the supply chain, companies can realize significant cost savings, increased responsiveness, improved reliability, and greater customization opportunities, all of which contribute to establishing a robust and sustainable competitive advantage in the market.

What specific challenges and opportunities arise when developing and implementing integrated logistics solutions within a business organization?

Challenges in Developing Integrated Logistics Solutions

One significant challenge when developing integrated logistics solutions within a business organization is ensuring efficient communication and coordination among various departments. Implementing such systems requires the seamless sharing of information across departments, which can be hindered by organizational silos, technological limitations, or resistance to change from employees. Thus, businesses must invest in fostering a collaborative culture and providing adequate training to facilitate the adoption of new systems.

Supply Chain Complexity and Visibility

Moreover, the increasing complexity of global supply chains presents an ongoing challenge, as organizations seek to optimize and streamline their logistics operations. The ability to track and monitor goods throughout the entire supply chain is essential for effective integrated logistics solutions. However, achieving full visibility is often difficult due to the involvement of numerous stakeholders, including suppliers, carriers, and customers. Businesses must, therefore, prioritize improving visibility and information sharing among these stakeholders to enhance decision-making and optimize logistics processes.

Opportunities for Enhanced Efficiency and Cost Savings

Despite these challenges, implementing integrated logistics solutions provides numerous opportunities for organizations to increase efficiency and reduce costs. By leveraging advanced technologies, such as artificial intelligence, machine learning, and blockchain, businesses can automate repetitive tasks, gain real-time insights into their supply chain, and improve the overall management of logistics operations. Additionally, integrated solutions enable organizations to mitigate risks, respond quickly to disruptions, and minimize the impact of inefficient logistics practices.

Sustainability and Environmental Considerations

Furthermore, integrated logistics solutions provide opportunities for businesses to enhance their environmental sustainability. Through better planning and coordination of transportation, organizations can optimize routes and reduce fuel consumption, leading to a decrease in greenhouse gas emissions. Simultaneously, sustainable logistics practices contribute to improved customer satisfaction, as consumers are increasingly seeking eco-friendly products and services. Thus, investing in integrated logistics solutions can offer significant benefits to both the environment and the organization's reputation.

In conclusion, developing and implementing integrated logistics solutions within a business organization presents several challenges, such as communication barriers and supply chain complexity. Nonetheless, the opportunities provided by these solutions, including enhanced efficiency, cost savings, and improved sustainability, make them a valuable investment for organizations seeking to optimize their logistics operations. By addressing these challenges and capitalizing on the opportunities, businesses can successfully integrate logistics solutions and achieve a competitive advantage in the market.

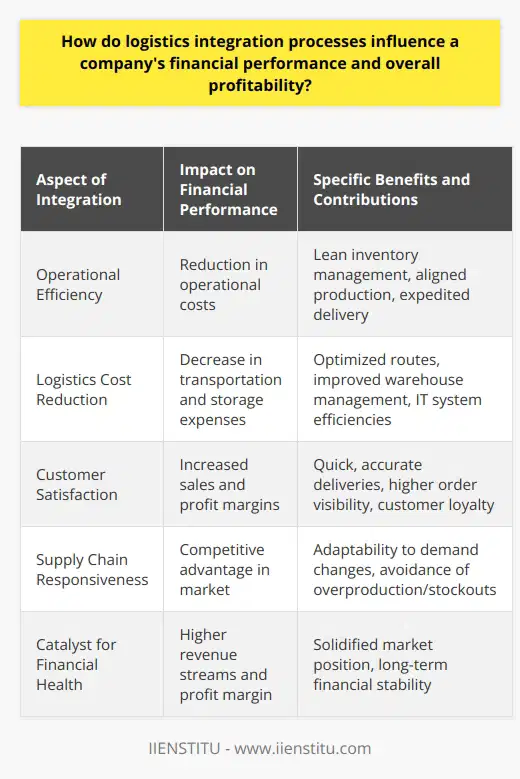

How do logistics integration processes influence a company's financial performance and overall profitability?

Logistics Integration Impact on Financial Performance

Logistics integration processes significantly influence a company's financial performance and overall profitability. It’s done by optimizing operational efficiency, reducing logistical costs, and enhancing customer satisfaction.

Operational Efficiency

An integrated logistics approach involves coordinations among purchase, production, and distribution operations. With enhanced harmonization, companies can minimize operational delays, reduce inventory holdings, and optimize resource usage. These efficiency improvements have a direct impact on the bottom line, enhancing the financial performance.

Reduction in Logistics Costs

Logistics integration also leads to cost reductions. Streamlined supply chains reduce transport costs, warehouse expenses, and eliminate unnecessary middlemen. By minimizing these logistical costs, the firm can improve its net profit margins.

Enhanced Customer Satisfaction

Lastly, integrated logistics processes can improve customer satisfaction. Efficient and reliable logistics systems enhance timely delivery, reduce product damages and help in order tracking. Customer satisfaction translates into repetitive purchases, increased market share, and revenue growth, consequently boosting the company's profitability.

In conclusion, logistics integration processes can substantially improve a firm's financial performance and profitability. They do so by enhancing operational efficiency, reducing logistical costs, and improving customer satisfaction. Any company aiming to enhance its financial performance should, therefore, consider implementing integrated logistics strategies.

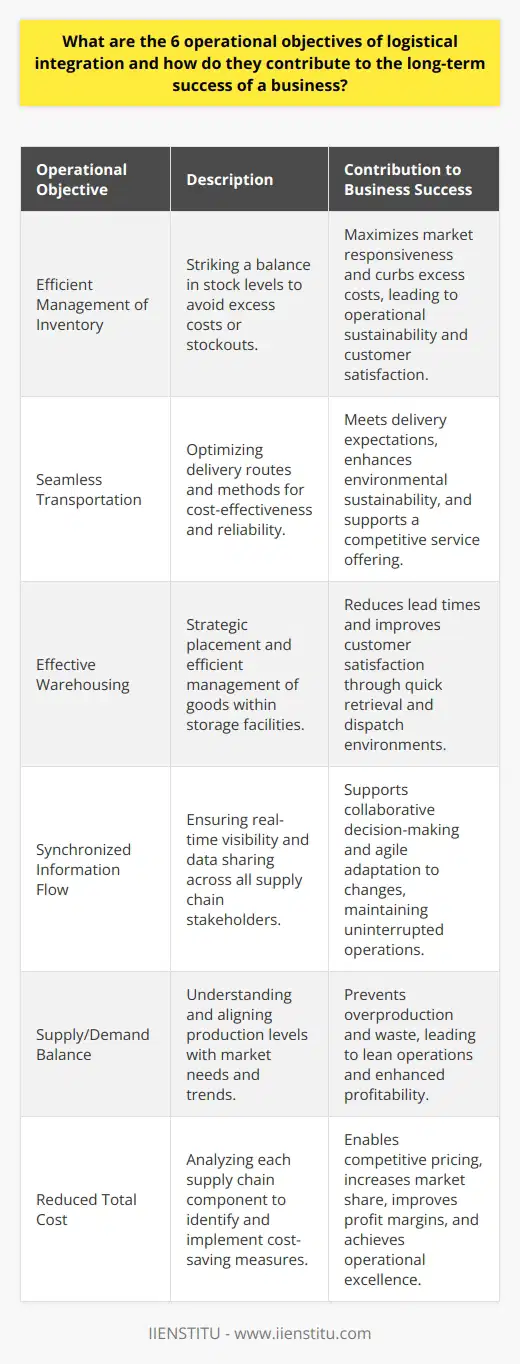

What are the 6 operational objectives of logistical integration and how do they contribute to the long-term success of a business?

Efficient Management of Inventory

The first operational objective is efficient management of inventory. This means a company must balance the costs of holding too much with the risks of holding too little inventory. A well-managed inventory aids in meeting customer demands, hence, improving customer satisfaction and loyalty.

Seamless Transportation

Secondly, transportation involves the physical movement of goods from the production point to where consumers require them. Efficient transportation methods reduce costs, increase speed, and improve service delivery.

Effective Warehousing

Thirdly, a business needs to store goods effectively before distributing. Proper warehouse management contributes to the efficient handling of goods and prevents damages, spoilage, or loss.

Synchronized Information Flow

An integrated logistics system requires a synchronized information flow. It involves sharing of relevant information among all stakeholders in the supply chain. Clear, real-time communication enhances decision-making and fosters transparency.

Supply/Demand Balance

The fifth operational objective revolves around balancing supply and demand. An integrated logistics system matches what the company supplies with what the market demands, thus enabling forecast accuracy, reducing inefficiencies and waste.

Reduced Total Cost

Lastly, logistical integration strives to achieve a reduced total cost. It involves all logistical activities working together to minimize the cost of delivering goods and services. By reducing costs, a business can increase profit margins while maintaining competitive prices for customers.

Logistical integration is essential for long-term business success. It enhances customer satisfaction, promotes efficiency, and reduces operational costs. It is a strategic approach towards managing the flow of information, goods, and services from the production point to the end-user in an efficient, transparent, and cost-effective manner. Overall, an effective logistical integration strategy plays a critical role in maintaining a competitive edge and ensuring business longevity.

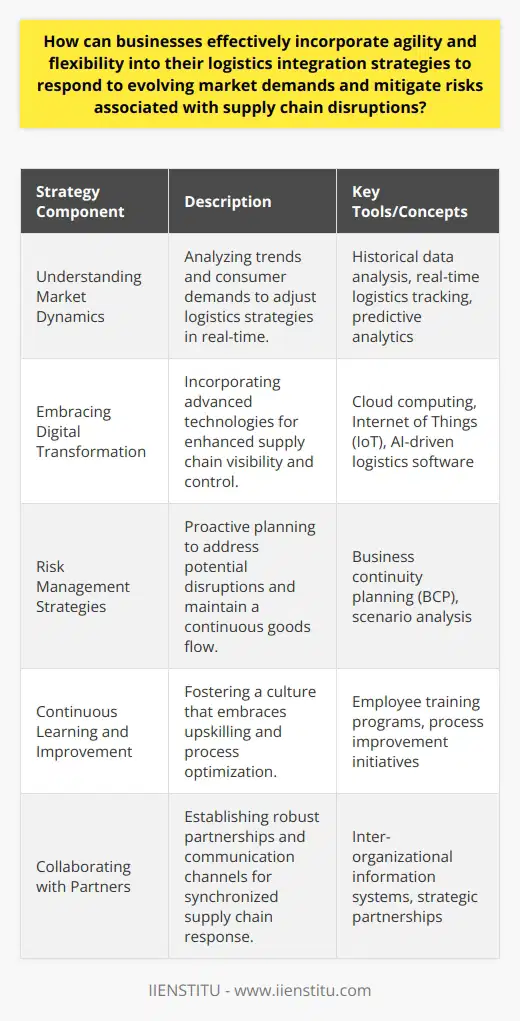

How can businesses effectively incorporate agility and flexibility into their logistics integration strategies to respond to evolving market demands and mitigate risks associated with supply chain disruptions?

Understanding Market Dynamics

At the heart of effective agility and flexibility in logistics integration is understanding market dynamics. Businesses need a data-driven approach to map ongoing trends and preempt future patterns in the industry.

Embracing Digital Transformation

Digital transformation refers to the integration of digital technology to refine business processes. Embracing this transformation equips businesses with tools to rapidly respond to market shifts. Examples include cloud-based systems, internet of things (IoT), and logistic management software.

Risk Management Strategies

Reducing supply chain risks entails implementing comprehensive risk management strategies. These should involve pre-identifying potential risks and planning responses in advance to avoid disruptions. A business continuity plan will help minimize the impact of unexpected disruptions.

Continuous Learning and Improvement

An environment promoting continuous learning and improvement will enable businesses to adapt to evolving markets effectively. Regular training programs can equip employees with skills required to manage dynamic operating conditions.

Collaborating with Partners

Effective logistic integration also requires agile and flexible collaboration with partners. This ensures supply chain resilience, facilitating timely response to disruptions. Inter-organizational information systems play an essential role in this aspect.

In conclusion, businesses can effectively incorporate agility and flexibility into their logistic integration strategies by understanding market dynamics, embracing digital transformation, implementing robust risk management strategies, promoting continuous learning and improvements, and fostering collaborative partnerships. All these strategies, when executed effectively, will increase the capacity of businesses to respond to evolving market demands while mitigating supply chain risk.

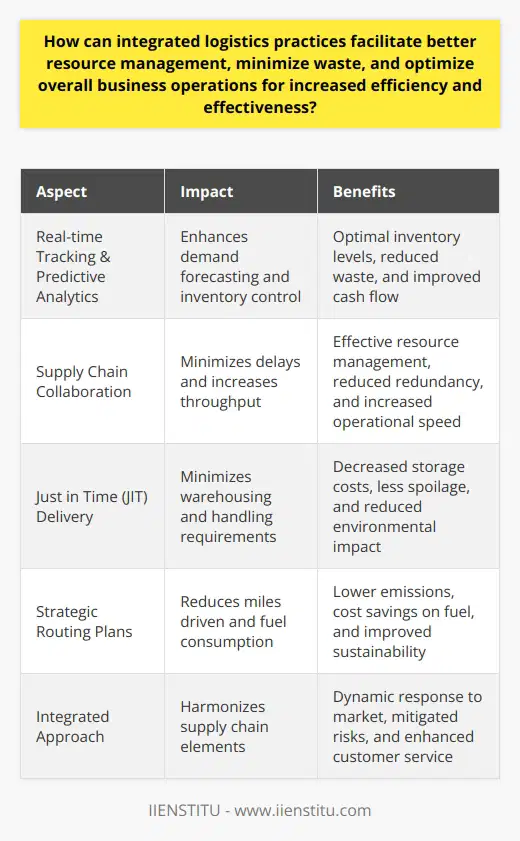

How can integrated logistics practices facilitate better resource management, minimize waste, and optimize overall business operations for increased efficiency and effectiveness?

Integrated Logistics Practices and Resource Management

Integrated logistics practices, which unify the management of numerous operational processes, can enable superior resource management. By streamlining and synchronizing transportation, warehousing, and inventory, businesses can reduce redundancies, leading to fewer wasted resources. Smooth coordination among various logistics activities can foster an environment of operational efficiency, maximizing resource utilization.

Effect of Integrated Logistics on Waste Minimization

Waste minimization is another crucial benefit of integrated logistics. The managerial approach reduces waste by locating inefficiencies and redundant processes in logistics operations. It identifies areas of improvement, such as overstocked inventory or unnecessary transportation routes, helping companies to actively prevent waste. This thorough review of logistics processes ensures that valuable resources are not squandered, directly contributing to waste minimization.

Optimization of Business Operations

By cultivating a unified approach towards logistics, integrated practices can optimize overall business operations. Enhanced coordination among various logistics functions means that each department functions at its optimum level. It fosters improved communication, ensures timely delivery, and minimizes hold-ups. This optimization yields increased operational efficiency

Boost in Efficiency and Effectiveness

Integrated logistics practices boost operational efficiency and effectiveness in the long run. By reducing waste and improving resource usage, companies can experience cost savings. Effective logistics management ensures that resources are used optimally, reducing operating costs. This improved efficiency directly translates to enhanced operational effectiveness, as resources are used to their fullest potential.

In summary, integrated logistics practices can accentuate resource management, minimize waste, and optimize business operations for a heightened level of efficiency and effectiveness. It offers a holistic approach towards logistics management, fostering a more sustainable and productive business environment.

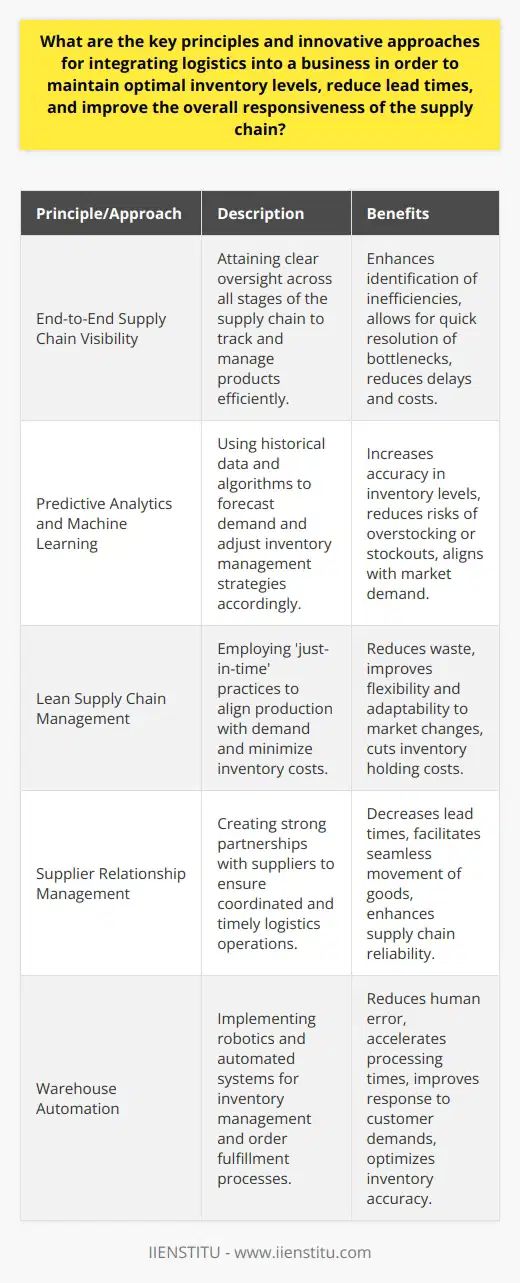

What are the key principles and innovative approaches for integrating logistics into a business in order to maintain optimal inventory levels, reduce lead times, and improve the overall responsiveness of the supply chain?

Integrating Logistics and Business

One key principle in integrating logistics into a business is adopting end-to-end supply chain visibility. With comprehensive visibility, a firm can easily monitor every stage of the production process, determine the optimal inventory levels, and identify the causes of delayed delivery, thereby reducing lead times. The increased transparency in operations also enables businesses to more effectively manage small variations in supply and demand, ensuring stock availability, customer satisfaction and operational cost-efficiency.

Innovation in Logistics

Businesses should prioritize innovative practices, such as predictive analytics and machine learning to advance logistic integration. These tools and technologies use historical data to anticipate future demand projections, enabling businesses to make effective inventory management decisions that can reduce capital tied up in excess inventory and can minimize storage cost.

Lean Supply Chain Management

Maintaining an agile and responsive supply chain is another fundamental principle. This is where lean supply chain management comes in with a 'just-in-time' approach. This approach minimizes safety stock, reduces wastage and maintains the set inventory levels as per customer demand, contributing towards enhanced supply chain responsiveness.

Supplier Relationship Management

Effective supplier relationship management is another approach to logistics integration. By identifying, recognizing and nurturing efficient suppliers, businesses can ensure a smooth replenishment cycle and keep the lead time as low as possible. This influences an overall improved delivery performance and solidifies the buyer-supplier relationship.

Warehouse Automation

Lastly, warehouse automation can improve the efficiency of supply chain operations. Including robotics and automated picking systems offers scalable solutions that reduce errors, increase speed of delivery, and streamline inventory management.

In summary, integrating logistics into a business is a vast and continuous process. A combination of end-to-end visibility, leveraging technology, lean supply chain management, efficient supplier relationship management, and warehouse automation can improve a company's responsiveness and effectiveness in maintaining optimal inventory levels and reducing lead times.

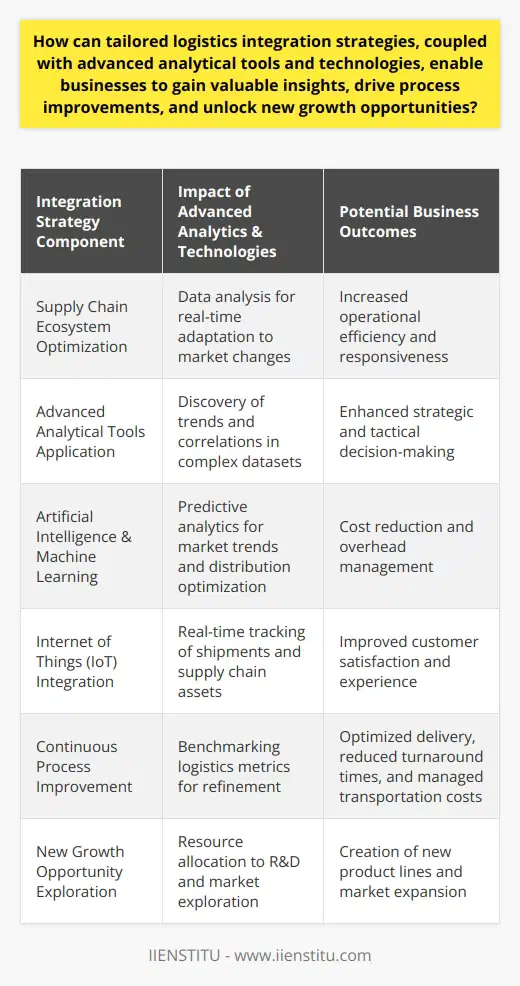

How can tailored logistics integration strategies, coupled with advanced analytical tools and technologies, enable businesses to gain valuable insights, drive process improvements, and unlock new growth opportunities?

Effective Logistics Integration Strategies

Customized logistics integration strategies utilize specialized tools and advanced analytical technologies. These enable businesses to streamline operations, enhance efficiency, and improve customer satisfaction. A tailored strategy provides an integrated view of the supply chain, allowing firms to optimize operations and reduce costs.

Role of Advanced Analytical Tools

Advanced analytics tools play an essential role in logistics planning. They offer valuable insights by interpreting complex data and identifying patterns that can guide decision-making. These tools can uncover hidden efficiency opportunities, enabling businesses to make data-driven decisions and increase operational performance.

Leveraging Technology for Growth

Technology enhances logistics integration through automation and real-time tracking systems. This not only improves the accuracy of data collected but also allows for quicker, more informed decision-making. AI and Machine Learning technologies can predict demand fluctuations and optimize inventory, resulting in reduced costs and waste.

Insights Driving Process Improvements

Insights gained from these strategies can drive continuous process improvements. By measuring critical logistics performance indicators, businesses can identify inefficiencies and implement necessary modifications. This fosters a culture of continuous improvement, boosting overall operational efficiency.

Unlocking New Growth Opportunities

Tailored logistics strategies, coupled with advanced analytics and technology, unlock new growth opportunities for businesses. By improving efficiency and reducing costs, businesses can redirect resources towards innovation and expansion. This drives competitive advantage, enabling businesses to thrive in a rapidly evolving marketplace.

In conclusion, well-integrated logistics strategies combined with advanced analytical tools and technologies empower businesses to improve operations, gain valuable insights, and unlock unprecedented growth opportunities. By harnessing the power of data and technology, businesses can better anticipate market changes, deliver superior customer service, and drive sustainable growth.