Introduction: A Personal Journey into Strategic Sourcing

I still remember the day when I first stepped into the bustling world of supply chain management. Fresh out of university, with a degree in business under my belt, I was eager to make a difference. My first role was as a procurement analyst at a mid-sized manufacturing company. On my very first day, my manager handed me a thick binder labeled "Strategic Sourcing Initiatives." He smiled and said, "Welcome aboard! Let's dive into optimizing our supply chain."

Introduction: Understanding Strategic Sourcing

Steps of Strategic Sourcing

Collect and Analyze Data

Evaluate Suppliers and Opportunities

Assess Risks and Make Changes

At the time, I had a vague idea of what strategic sourcing entailed. I knew it was more than just buying goods and services at the lowest price. But as I delved deeper, I realized that it was a complex process that could significantly impact a company's bottom line and competitive edge. Little did I know that this journey would not only shape my career but also give me insights that I'd carry throughout my professional life.

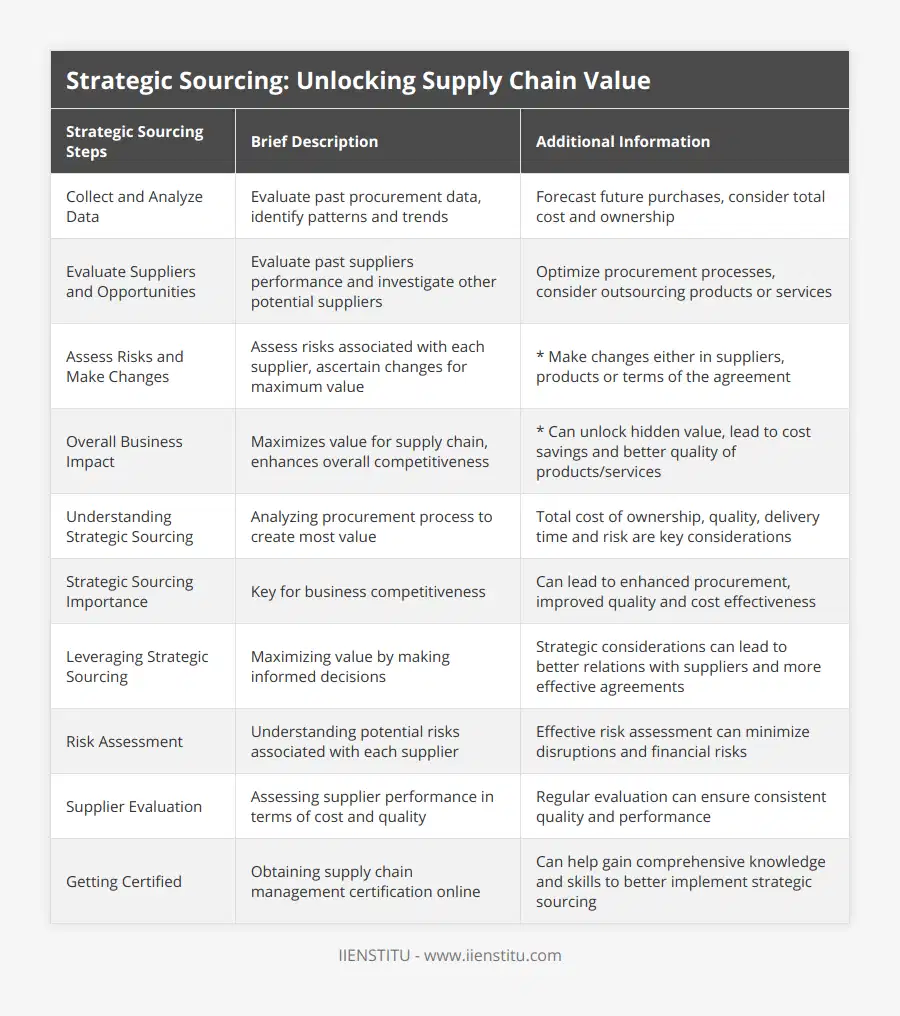

Understanding Strategic Sourcing

What Is Strategic Sourcing?

Firstly, let's unpack the procurement definition. Procurement is the process of obtaining goods or services in any way, including purchasing, leasing, and contracting. But when we talk about strategic sourcing, we're referring to a systematic approach that involves analyzing what a company buys, from whom, at what price, and at what volume. The goal is to achieve the best value, not just the lowest cost.

Strategic sourcing is an integral part of supply chain management. It involves:

1- Collecting and analyzing data to understand spending patterns.

2- Evaluating suppliers to ensure they align with the company's goals.

3- Assessing risks and making necessary changes to mitigate them.

The Role of Strategic Sourcing in Supply Chain Activities

In the realm of supply chain management, strategic sourcing plays a pivotal role. It's not just about procurement; it's about creating a synergy between various supply chain departments to enhance efficiency and value. By implementing strategic sourcing, companies can optimize their supply chain activities, ensuring that every link in the chain contributes positively to the overall objectives.

My first strategic sourcing project taught me the importance of data analysis, supplier evaluation, and risk assessment. It wasn't easy, but the results spoke for themselves - we reduced costs by 10% and established relationships with innovative suppliers.

Strategic Sourcing is the key to unlocking the hidden value of your supply chain.

Steps of Strategic Sourcing

Let's delve deeper into the steps involved in strategic sourcing, drawing from both theory and personal experience.

Step 1: Collect and Analyze Data

This is the foundation of the entire process. Without accurate data, any strategies you develop will be on shaky ground.

Gather Comprehensive Data: This includes purchase histories, supplier performance metrics, market trends, and forecasts.

Analyze Spending Patterns: Identify areas where spending is high or increasing disproportionately.

Benchmarking: Compare your data against industry standards or competitors.

During one data analysis phase, I discovered that we were spending significantly more on packaging materials than similar companies in our industry. This insight prompted us to investigate alternative suppliers and materials.

Step 2: Evaluate Suppliers and Opportunities

With data in hand, the next step is to scrutinize your current suppliers and identify opportunities for improvement.

Supplier Performance Evaluation: Assess each supplier based on cost, quality, delivery times, and service.

Market Research: Look for new suppliers who might offer better value or innovations.

Opportunity Assessment: Identify areas where consolidation or standardization can lead to savings.

I recall a time when we were sourcing electronic components from multiple suppliers. By consolidating orders and negotiating volume discounts with a primary supplier, we reduced costs and simplified our procurement process.

Step 3: Assess Risks and Make Changes

No strategy is complete without considering potential risks.

Risk Identification: Recognize risks like supplier insolvency, supply disruptions, or quality issues.

Risk Mitigation Strategies: Develop plans to address these risks, such as diversifying suppliers or increasing inventory buffers.

Implementation: Make the necessary changes, whether it's switching suppliers or renegotiating contracts.

Once, we faced a sudden shortage of a critical raw material due to geopolitical tensions. Thanks to our risk assessment, we had already identified alternative suppliers in different regions, allowing us to pivot swiftly without major disruptions.

Benefits of Strategic Sourcing

Implementing strategic sourcing offers numerous advantages:

1- Cost Reduction: By leveraging data and negotiating effectively, companies can achieve significant cost savings.

2- Quality Improvement: Evaluating suppliers rigorously ensures that only the best quality products and services are procured.

3- Risk Management: Proactively identifying and mitigating risks safeguards the company against unforeseen events.

4- Efficiency Gains: Streamlining procurement processes leads to time savings and better resource allocation.

5- Innovation: Engaging with suppliers can lead to new ideas and improvements in products or services.

Challenges in Strategic Sourcing

Of course, it's not all smooth sailing. Several challenges can arise:

Data Overload: Managing and analyzing vast amounts of data can be overwhelming.

Supplier Resistance: Some suppliers may resist changes, especially if they feel threatened.

Internal Pushback: Departments accustomed to certain suppliers might resist changes.

Market Volatility: Fluctuating market conditions can impact sourcing strategies.

In one instance, we faced considerable pushback from a long-term supplier when we tried to renegotiate terms. It required delicate negotiation and emphasizing the mutual benefits to reach a new agreement.

Personal Reflections on Strategic Sourcing

Looking back, one of the most rewarding aspects of working in strategic sourcing has been the opportunity to make a tangible impact on the company's success. It's also taught me valuable lessons:

Collaboration is Key: Working closely with other departments, like finance and operations, is crucial.

Stay Informed: Keeping up with industry trends and market conditions informs better decision-making.

Adaptability: Being prepared to adjust strategies in response to new information or changes in the environment.

Optimizing Supply Chain Management: Practical Tips

For those looking to optimize supply chain management process tips, here are some practical suggestions:

1- Leverage Technology: Implement supply chain management software to improve visibility and efficiency.

2- Build Strong Supplier Relationships: Engage in open communication and collaboration with your suppliers.

3- Invest in Training: Ensure your team is knowledgeable about the latest practices and trends.

4- Foster a Culture of Continuous Improvement: Encourage feedback and regularly review processes.

5- Align Supply Chain Strategies with Business Goals: Ensure that your supply chain activities support the company's overall objectives.

Embracing SCM Management for Business Success

Incorporating SCM supply chain management practices isn't just for large corporations. Businesses of all sizes can benefit from strategic sourcing. By focusing on SCM management, companies can create more resilient and efficient supply chains.

One small business I consulted for was struggling with inconsistent supplier performance. By applying strategic sourcing principles, they were able to identify more reliable suppliers, negotiate better terms, and ultimately improve their customer satisfaction.

Understanding the Role of Supply Chain Departments

Each department in the supply chain plays a vital role:

Procurement: Responsible for acquiring goods and services.

Logistics: Manages the movement and storage of goods.

Operations: Oversees the production processes.

Planning: Forecasts demand and plans inventory levels.

Understanding how these departments interact is essential for effective management chain supply.

The Future of Strategic Sourcing

As markets evolve, so too will the practices around strategic sourcing. Emerging trends include:

Sustainability Initiatives: Companies are increasingly prioritizing environmentally friendly practices.

Digitalization: The use of AI and big data analytics is revolutionizing how we approach procurement.

Globalization vs. Localization: Balancing global sourcing with local needs will continue to be a challenge.

Conclusion: The Power of Strategic Sourcing

In conclusion, strategic sourcing is not just a buzzword in the world of supply and chain management. It's a critical process that, when executed effectively, can lead to substantial benefits for a company.

It's about more than just finding the lowest price--it's about building relationships, managing risks, and aligning procurement with the overall strategy of the business. By focusing on strategic sourcing, companies can strengthen their SCM supply, enhance efficiency, and gain a competitive edge in the market.

For me, the journey into strategic sourcing has been an enlightening one. It's taught me that the seemingly mundane task of procurement can have a profound impact when approached strategically. And with the ever-evolving landscape of global business, staying on top of strategic sourcing practices is more important than ever.

Final Thoughts: Embrace the Journey

If you're in the field of supply chain management or considering a career in it, I encourage you to dive deep into the world of strategic sourcing. It's a dynamic and rewarding area that offers endless opportunities for learning and growth. Remember, the key is to stay curious, be adaptable, and always look for ways to add value.

References:

Kraljic, P. (1983). Purchasing must become supply management. Harvard Business Review, 61(5), 109-117.

Monczka, R. M., Handfield, R. B., Giunipero, L. C., & Patterson, J. L. (2015). Purchasing and supply chain management (6th ed.). Cengage Learning.

Van Weele, A. J. (2018). Purchasing and supply chain management (7th ed.). Cengage Learning EMEA.

Chopra, S., & Meindl, P. (2015). Supply chain management: Strategy, planning, and operation (6th ed.). Pearson Education.

Stadtler, H., & Kilger, C. (2002). Supply chain management and advanced planning: Concepts, models, software and case studies (2nd ed.). Springer.

Frequently Asked Questions

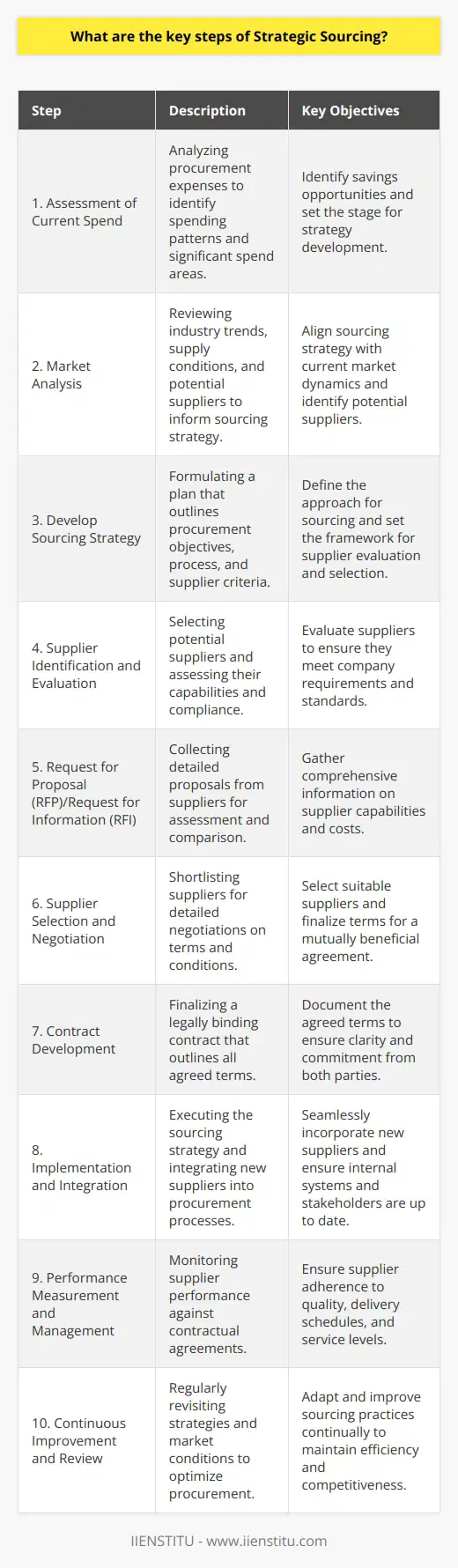

What are the key steps of Strategic Sourcing?

Strategic sourcing is managing the procurement of goods and services efficiently and cost-effectively. It involves the evaluation of the entire supply chain, including suppliers and processes, to identify the most suitable supplier and product. Strategic sourcing is a critical part of any organization’s procurement strategy, as it can help to reduce costs, improve quality, and increase operational efficiencies.

The critical steps of strategic sourcing can be summarized as follows:

1. Define Requirements: The first step in strategic sourcing is clearly defining the organization's requirements. This includes defining the business objectives, identifying the products and services needed, and specifying the desired quality and quantity of these items.

2. Identify Suppliers: Once the requirements have been defined, the organization must identify potential suppliers to meet their needs. This includes researching the market and evaluating potential vendors regarding their capabilities, pricing, and reputation.

3. Negotiate Terms: Once a suitable supplier has been identified, the organization must negotiate the terms and conditions of the contract. This includes establishing the price, delivery terms, payment terms, and other contractual details.

4. Implement the Agreement: Once the contract has been finalized, the organization must implement the agreement. This includes ordering the products and services and managing the delivery and payment process.

5. Monitor Performance: The final step in the strategic sourcing process is to monitor the supplier's performance. This includes tracking the supplier’s quality, delivery, and cost performance.

By following these key steps, an organization can ensure that it can source the best products and services at the most competitive price. Strategic sourcing is an essential part of any organization’s procurement process, and by following the steps outlined above, organizations can ensure that they can achieve the best results.

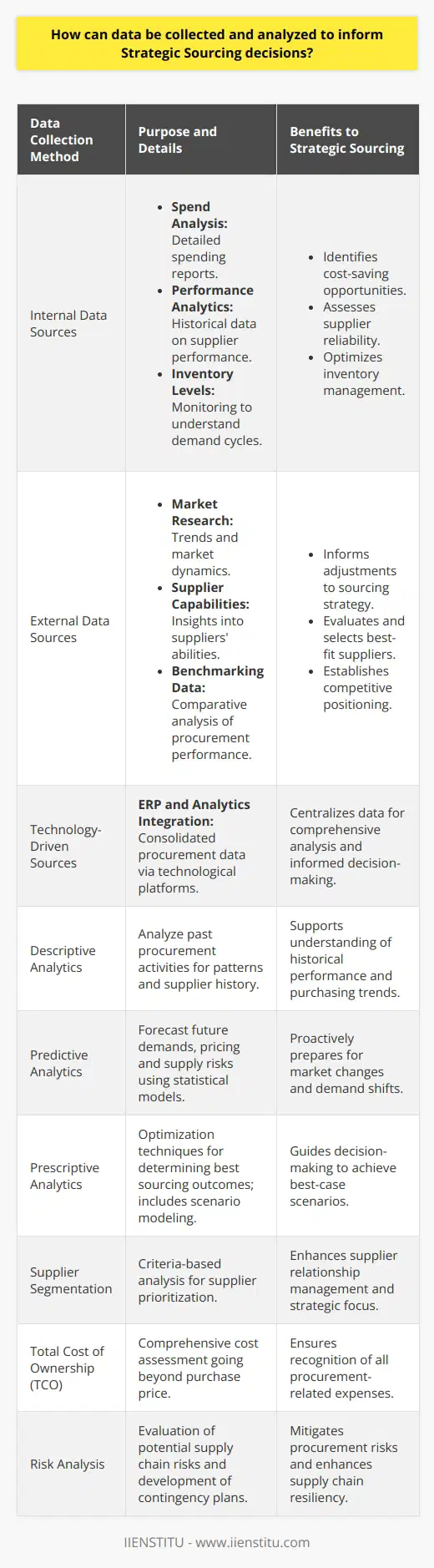

How can data be collected and analyzed to inform Strategic Sourcing decisions?

Data collection and analysis are essential in enabling informed strategic sourcing decisions. Strategic sourcing is the process of understanding the needs of an organization, identifying the best suppliers to meet those needs, and negotiating the most advantageous pricing and terms. Data is central to this process, as it is used to assess the organization's needs, identify the best suppliers, and negotiate the most advantageous pricing and terms.

Data can be collected from a variety of sources. Internal data sources include financial records, customer feedback, employee feedback, and performance metrics. External data sources include market research, industry benchmarking studies, and competitor analysis.

Once the data has been collected, it must be analyzed to inform strategic sourcing decisions. This analysis can involve quantitative analysis, such as a cost-benefit analysis, to assess the financial impact of a particular supplier, or qualitative analysis, such as a supplier risk analysis, to assess the reliability of a supplier. Data can also be used to compare suppliers and identify the most suitable supplier for a particular need.

Data can also be used to develop a pricing strategy. This involves analyzing the data to understand the cost of goods and services, competitors' pricing, and suppliers' bargaining power. This analysis can be used to inform the negotiation process, as well as to develop an optimal pricing strategy that maximizes savings for the organization.

In conclusion, data can be collected from various sources to inform strategic sourcing decisions. Data can be used to assess the organization's needs, identify the best suppliers, and develop an optimal pricing strategy. Data analysis is essential to ensure that the most advantageous pricing and terms are negotiated and that the organization can maximize savings.

What strategies can be used to evaluate suppliers and identify potential opportunities in the supply chain?

Supply chains have become increasingly complex and interconnected in today's global business environment. As such, organizations need to comprehensively understand their suppliers and the opportunities they present to maximize efficiency and profitability. Evaluating suppliers and identifying potential opportunities in the supply chain is a necessary process that requires several strategies.

One strategy that can be used to evaluate suppliers is to assess their financial health. This can be done by analyzing their financial statements and other documents, such as their balance sheets, income, and cash flow statements. This allows organizations to identify potential risks associated with the supplier and determine if they can provide the necessary services and goods.

Another strategy that can be used to evaluate suppliers is to assess their operational performance. This can be done by monitoring their production processes and delivery schedules. An evaluation of the supplier’s operational performance can provide insights into areas where improvements can be made and potential opportunities for cost savings.

In addition, organizations should evaluate their suppliers’ environmental and social responsibility practices. This includes assessing their commitment to sustainability, labor practices, and compliance with laws and regulations. Evaluating suppliers' commitment to responsible practices can help organizations identify opportunities to reduce costs and improve performance.

Finally, organizations should evaluate the supplier’s ability to meet changing customer needs. This can be done by analyzing customer feedback and surveys to assess their satisfaction levels. Evaluating customer feedback can provide insights into potential improvement opportunities and areas where the supplier could be losing business.

In conclusion, evaluating suppliers and identifying potential opportunities in the supply chain is a necessary process that requires several strategies. Assessing the supplier’s financial health, operational performance, environmental and social responsibility practices, and ability to meet customer needs are all critical steps in this process. Organizations can use these strategies to ensure that their supply chain is efficient and profitable.

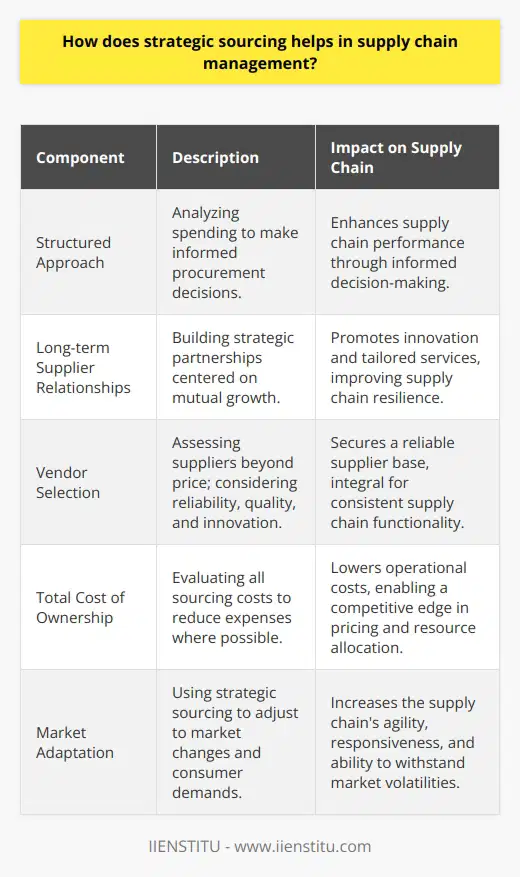

How does strategic sourcing helps in supply chain management?

Role of Strategic Sourcing in Supply Chain Management

Strategic sourcing serves as a proactive approach to optimize a company's supply base. This method contributes significantly to effective supply chain management by emphasizing long-term partnerships, selecting reliable suppliers, and reducing total cost of ownership.

Long-term Partnerships

Fostering stable, long-term partnerships between suppliers and companies results in mutual benefits. These relationships lead to improved communication, streamlined processes, and increased trust. In turn, both parties can achieve better price negotiation, higher customer satisfaction, and stronger business performance.

Reliable Supplier Selection

The process of strategic sourcing involves thorough supplier evaluation to ensure the selection of reliable and high-quality vendors. Factors considered during this evaluation include a supplier's financial stability, delivery performance, and operational efficiency. By choosing the right suppliers, companies can minimize supply chain disruptions, maintain product quality, and support continuous growth.

Reducing Total Cost of Ownership

Strategic sourcing focuses not only on reducing the purchase price of products and services, but also on minimizing the total cost of ownership, which includes the costs associated with procurement, production, transportation, and disposal. A comprehensive approach to reducing these expenses can contribute to increased profit margins, better resource allocation, and more sustainable operating practices.

In conclusion, strategic sourcing plays a critical role in optimizing supply chain management. By prioritizing long-term partnerships, selecting reliable suppliers, and focusing on reducing the total cost of ownership, companies can improve the efficiency, resilience, and sustainability of their supply chains, creating a competitive advantage in the marketplace.

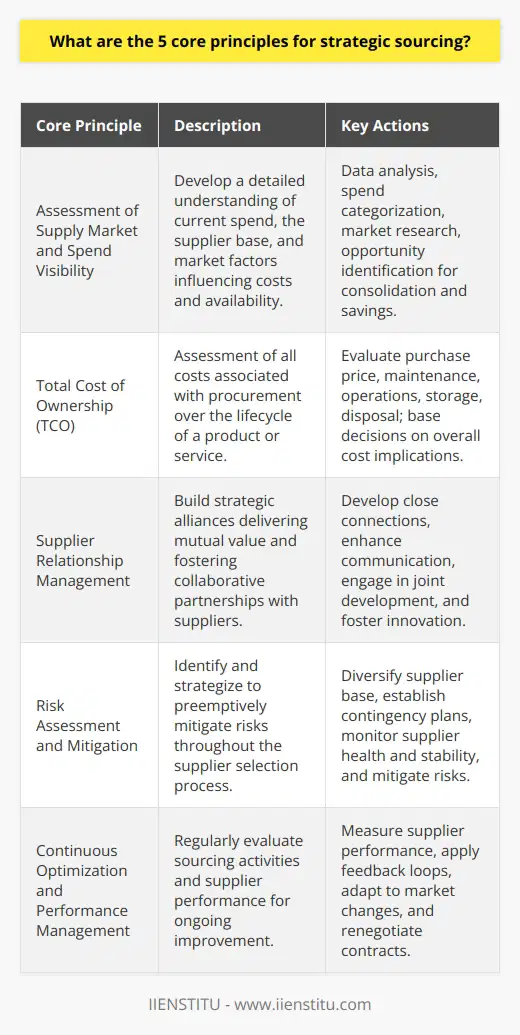

What are the 5 core principles for strategic sourcing?

Core Principles for Successful Strategic Sourcing

Spend Analysis and Supplier Identification

The first core principle in strategic sourcing is conducting a thorough spend analysis and identifying potential suppliers. This involves analyzing historical expenditure data, understanding the organization's procurement needs, and identifying the suppliers who can offer the required products or services. The objective is to identify opportunities for cost reduction, risk mitigation, and process improvement.

Total Cost of Ownership (TCO)

Considering the total cost of ownership is crucial for making informed sourcing decisions. TCO encompasses the entire lifecycle of a product or service, including acquisition, transportation, storage, usage, and disposal. By understanding the TCO, organizations can identify hidden costs, evaluate potential savings, and select suppliers that offer the best value proposition.

Collaborative Relationships

Building collaborative relationships with suppliers is essential for successful strategic sourcing. By working closely with suppliers, organizations can foster an environment of trust, open communication, and innovation. This can lead to improved supplier performance, higher service levels, and greater opportunities for mutually beneficial partnerships.

Risk Management

Effective strategic sourcing requires proactive risk management. This includes evaluating supplier performance and financial stability, assessing risk factors in the supply chain, and developing contingency plans to address potential disruptions. By taking a proactive approach to risk management, organizations can mitigate supply chain disruptions, protect their brand reputation, and ensure business continuity.

Continuous Improvement

The final principle in strategic sourcing is adopting a continuous improvement mindset. This requires organizations to constantly review and refine their sourcing processes, supplier relationships, and spending patterns. By identifying areas for improvement and tracking key performance indicators, organizations can optimize their sourcing strategies, achieve cost savings, and drive long-term value creation.

How does supply chain strategy create value?

Supply Chain Strategy and Value Creation

Establishing an Effective Strategy

Supply chain strategy is critical in generating value for businesses by efficiently managing resources, optimizing operations, and reducing costs. An effective supply chain strategy consists of several key components that work together to create value across the organization. This includes demand planning, inventory management, supplier relationship management, and logistics optimization.

Demand Planning

Accurate demand planning is essential for creating value in the supply chain, as it enables organizations to anticipate customer needs and allocate resources accordingly. This in turn reduces waste and ensures that products are delivered in the right quantities and at the right time, enhancing customer satisfaction and improving overall business performance.

Inventory Management

Effective inventory management plays a crucial role in creating value within the supply chain. By continually monitoring and adjusting inventory levels to respond to fluctuations in demand, organizations can minimize excess stock, reduce carrying costs, and prevent stockouts, all of which contribute to increased profitability and customer satisfaction.

Supplier Relationship Management

Developing strong relationships with key suppliers helps to create value in the supply chain by fostering collaboration and deepening trust between parties. Well-managed supplier relationships can lead to improved product quality, reduced lead times, and greater flexibility in responding to market changes – all factors that enhance a company's competitive advantage and generate value for the business.

Logistics Optimization

Efficiently managing logistics is another way in which supply chain strategy helps create value. By optimizing transportation and warehousing processes, organizations can minimize costs, improve delivery times, and better meet customer expectations. This in turn has a positive impact on the company's bottom line and reputation in the market.

Continuous Improvement

Creating a culture of continuous improvement within the supply chain allows organizations to identify inefficiencies and optimize processes, leading to increased value. Regularly revisiting and refining supply chain strategies ensures that areas for potential improvement are addressed, fostering a proactive approach to enhancing operational performance.

Conclusion

In summary, supply chain strategy is pivotal in creating value for organizations by streamlining operations, reducing costs, and improving customer satisfaction. By focusing on demand planning, inventory management, supplier relationship management, and logistics optimization, businesses can maximize the value generated by their supply chain and ultimately enhance their competitive advantage in the marketplace.

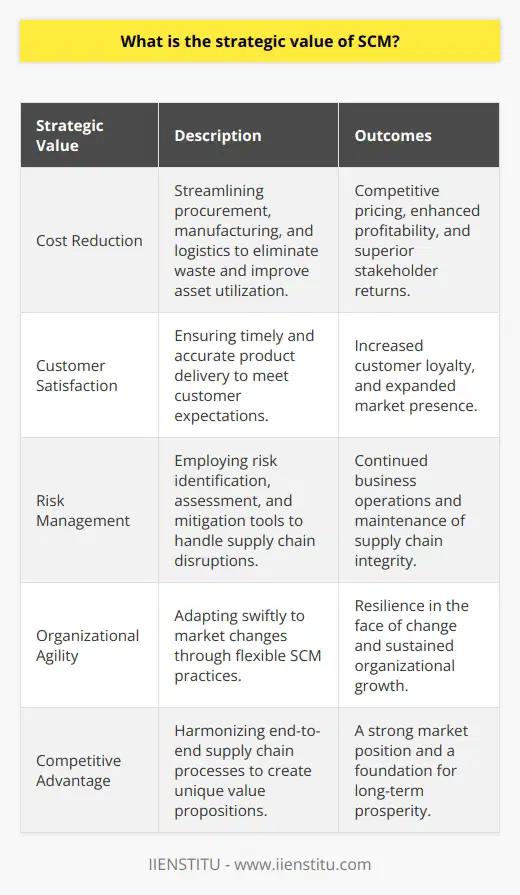

What is the strategic value of SCM?

Strategic Importance of SCM

Supply chain management (SCM) plays a crucial role in enhancing an organization's competitive advantage by improving its efficiency and effectiveness in the marketplace. The strategic value of SCM lies in its ability to integrate the entire production process, from raw materials to finished goods, providing companies with the flexibility to respond quickly to the changing demands of the market.

Three key aspects contribute to the strategic value of SCM: cost reduction, customer satisfaction, and risk management.

Cost Reduction

SCM is instrumental in reducing the overall costs for organizations by optimizing decision-making at every stage of the supply chain. This includes efficient procurement of raw materials, streamlined production processes, and effective transportation and distribution of finished goods. By minimizing waste and maximizing asset utilization, companies can achieve significant cost savings, ultimately leading to increased profitability and shareholder value.

Customer Satisfaction

A well-implemented SCM strategy ensures that the right products and services are delivered to customers at the right time and place. This not only enables companies to meet their customers' expectations but also fosters long-term relationships with them. By focusing on customer-centric supply chain strategies, organizations can differentiate themselves in the fiercely competitive global marketplace, leading to greater customer loyalty and market share growth.

Risk Management

In today's global business landscape, supply chain disruptions can have far-reaching consequences on a company's financial performance and reputation. SCM is essential for managing risks and ensuring the smooth functioning of operations, even in the face of unforeseen events. By implementing best practices such as multi-sourcing, contingency planning, and real-time monitoring of supply chain activities, companies can minimize risks, reduce the likelihood of disruptions, and maintain a resilient supply chain.

In conclusion, the strategic value of SCM cannot be underestimated as it directly impacts an organization's competitive advantage by reducing costs, enhancing customer satisfaction, and mitigating risks. A well-executed supply chain management strategy is a key contributor to a company's overall success and sustainability in an ever-evolving business environment.

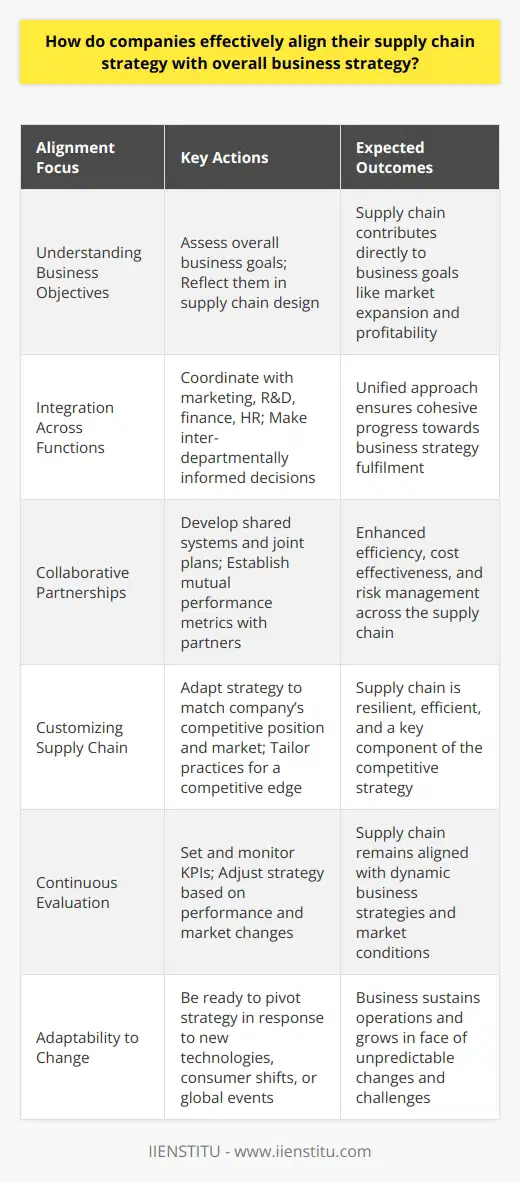

How do companies effectively align their supply chain strategy with overall business strategy?

Understanding Business Strategy and Supply Chain Strategy

To effectively align their supply chain strategy with overall business strategy, companies must first understand the goals and objectives driving their business. A thorough understanding of the company's vision, mission, and core competencies acts as a foundation for this alignment.

Integrating Functional Strategies

Next, companies need to ensure that their supply chain strategy is integrated with other functional strategies, such as marketing, human resources, and operations. This holistic approach helps align each function's objectives, leading to optimal resource allocation and improved communication between departments.

Developing a Collaborative Environment

Creating a collaborative environment among supply chain partners is crucial for effective alignment. Utilizing information and communication technologies facilitates real-time information sharing, joint decision-making, and reduces uncertainties within the supply chain. Trust and open communication enhance efficiency and overall business performance.

Customizing Supply Chain Strategy

While there are widely accepted best practices in supply chain management, companies must customize their supply chain strategies to fit their unique needs. This customization involves analyzing and evaluating the factors that affect the company's supply chain, such as industry trends, competitive forces, and customer preferences. Then, the supply chain strategy must be tailored to support the company's business strategy, improving its competitive advantage and achieving its desired goals.

Continuous Monitoring and Evaluation

Companies must regularly monitor and evaluate their supply chain to ensure that it remains aligned with their overall business strategy. This process involves tracking key performance indicators (KPIs) related to the supply chain, such as inventory levels, order fulfilment times, and supplier performance. Analyzing and adjusting based on these metrics keeps the supply chain agile and responsive to any changes in the business environment.

Actively Adapting to Changes

Lastly, supply chain strategies require flexibility and adaptability to address any emerging trends or disruptions. Companies must be proactive in identifying and addressing these challenges, such as changes in technology, market dynamics, or regulations. By actively adapting to these changes, supply chain strategies will remain aligned with and supportive of overall business strategies.

In conclusion, to effectively align supply chain strategy with overall business strategy, companies must understand their business objectives, integrate functional strategies, develop trust among partners, customize their supply chain, continuously monitor performance, and remain adaptable to change. This alignment contributes to enhanced collaboration, greater efficiency, and improved overall business performance.

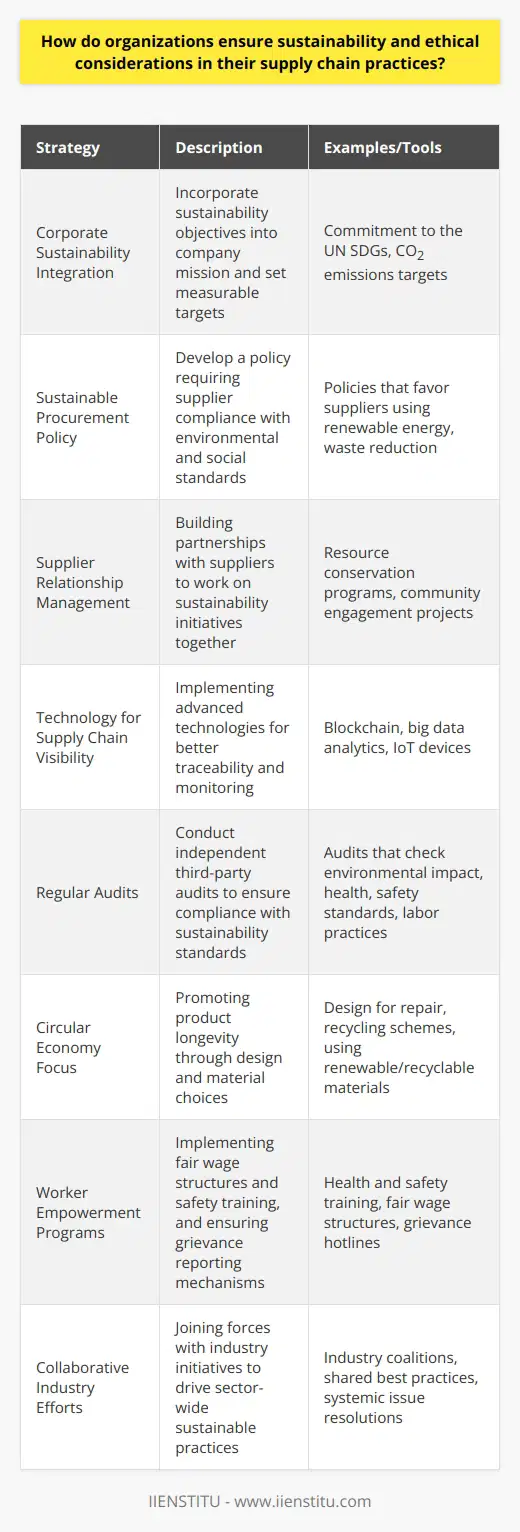

How do organizations ensure sustainability and ethical considerations in their supply chain practices?

Establishing Sustainability Measures

Organizations prioritize sustainability in their supply chain practices by incorporating various measures. First, they adopt relevant policies and guidelines that address sustainability challenges, such as environmental degradation and labor concerns. These policies set the groundwork for establishing and maintaining an ethically responsible supply chain.

Supplier Collaboration

To ensure sustainability, organizations work closely with their suppliers by engaging in collaborative partnerships. This cooperation enables both parties to align goals and objectives, fostering greater transparency and commitment to sustainable practices.

Training and Development Programs

Ongoing education and training programs for employees and suppliers are essential for an ethical supply chain. These initiatives equip stakeholders with necessary knowledge and skills, empowering them to make informed decisions that align with the organization's sustainability practices and values.

Utilizing Technology and Data Analytics

Implementing technology and data analytics enhances monitoring and evaluation processes within the supply chain. By leveraging digital tools, organizations can better assess the performance of suppliers and identify areas that require improvement.

Auditing and Compliance Monitoring

Regular audits and compliance checks help organizations validate their supply chain practices adhere to the prescribed ethical standards. These assessments ensure all stakeholders comply with established sustainability policies and requirements, driving continuous improvement and accountability.

Adopting Circular Economy Principles

Embracing circular economy principles, such as reducing waste, promoting resource efficiency and maximizing reuse, aids in minimizing the environmental impact of supply chain practices. Organizations that adopt such strategies are better equipped to create a sustainable future.

By incorporating these approaches, organizations can effectively address sustainability and ethical considerations in supply chain practices. Establishing policies and guidelines, fostering collaboration, providing training, and leveraging technology, among other strategies, help organizations create reliable, transparent and responsible supply chains, ultimately contributing to an environmentally conscious and just business landscape.

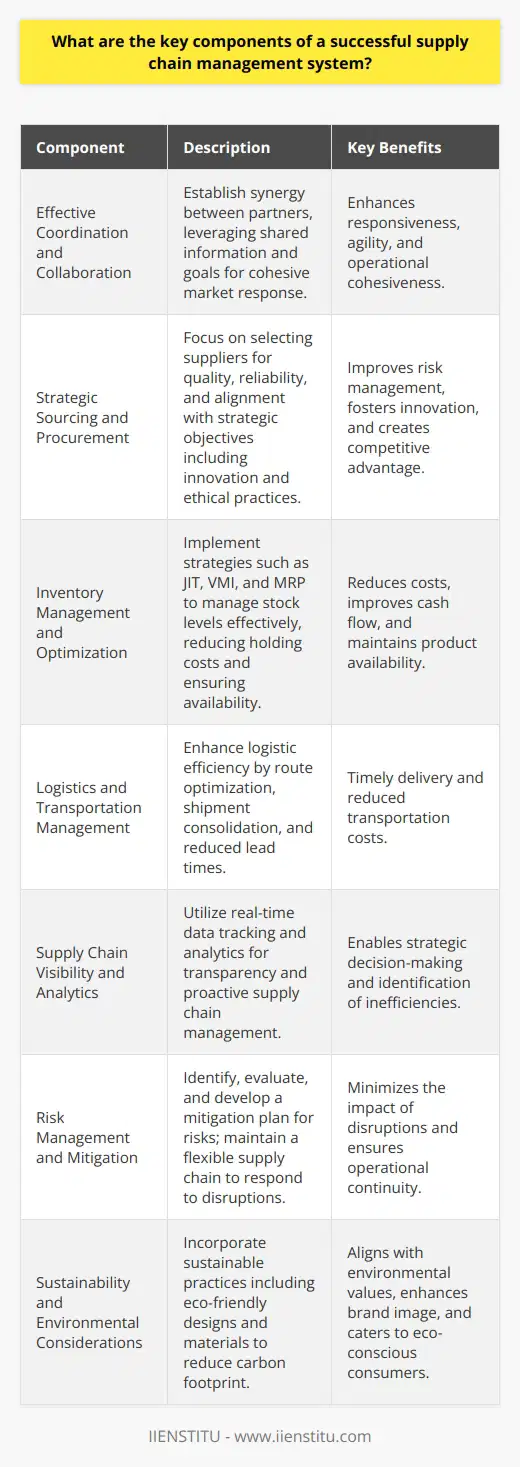

What are the key components of a successful supply chain management system?

Key Components of Supply Chain Management

Effective Coordination and Collaboration

A successful supply chain management (SCM) system requires effective coordination and collaboration among all stakeholders, including suppliers, manufacturers, wholesalers, and retailers. This collaboration ensures seamless flow of information, products, and services.

Strategic Sourcing and Procurement

Strategic sourcing and procurement help companies in choosing the right suppliers, establishing strong relationships, and obtaining the best pricing and terms. By carefully selecting suppliers and negotiating effectively, businesses can reduce product costs and secure an efficient supply chain.

Inventory Management and Optimization

Optimizing inventory levels is crucial in managing a successful supply chain. This involves balancing inventory costs, product availability, and customer satisfaction. Leveraging demand forecasting and stock replenishment strategies can ensure that companies maintain adequate stock levels while minimizing carrying costs.

Logistics and Transportation Management

Efficient logistics and transportation management facilitate the smooth and timely movement of goods from suppliers to production facilities, warehouses, and customers. Effective transportation planning and route optimization can contribute to reducing transportation costs and improving overall supply chain performance.

Supply Chain Visibility and Analytics

Visibility and analytics in SCM enable companies to track the movement and status of goods throughout the supply chain, providing real-time insights into potential bottlenecks and inefficiencies. This data-driven approach helps businesses identify areas for improvement and facilitates proactive decision-making.

Risk Management and Mitigation

A successful SCM system should incorporate risk management and mitigation strategies to identify, assess, and address potential supply chain disruptions. By developing contingency plans and closely monitoring key risk factors, companies can minimize the impact of supply chain uncertainties.

Sustainability and Environmental Considerations

Incorporating sustainability and environmental considerations into supply chain practices is essential for long-term success. Companies should prioritize ethical sourcing, energy efficiency, and waste reduction to promote sustainable supply chains and reduce their environmental impact.

In conclusion, the key components of a successful supply chain management system include effective coordination and collaboration, strategic sourcing and procurement, inventory optimization, efficient logistics and transportation management, supply chain visibility and analytics, risk management, and sustainability. By addressing each of these components, businesses can build resilient and efficient supply chains that support their growth and enhance their competitiveness in the market.

How do organizations implement strategic sourcing to achieve competitive advantage?

Strategic Sourcing for Competitive Advantage

Developing a Plan

To implement strategic sourcing for achieving competitive advantage, organizations first create a comprehensive plan. This plan involves understanding market dynamics, internal procurement requirements, and supply-side opportunities to identify the best suppliers and potential cost savings.

Supplier Selection and Evaluation

Organizations then evaluate suppliers based on multiple criteria, such as cost, quality, delivery, and innovation capabilities. This evaluation process ensures that companies select suppliers matching their strategic objectives, fostering long-term relationships and collaboration.

Cost Reduction

Strategic sourcing enables organizations to achieve cost reductions through various methods. These techniques include consolidating spend and negotiating volume-based discounts, leveraging economies of scale, and rationalizing supplier base.

Risk Management

Organizations employing strategic sourcing focus on risk management to maintain a competitive advantage. They assess potential risks related to suppliers, such as financial stability, geopolitical factors, and supply chain disruptions. This proactive approach helps mitigate risks and ensures uninterrupted operations.

Supplier Relationship Management

Managing relationships with strategic suppliers is crucial for achieving competitive advantage. Organizations strive for continuous improvement in their supply chain performance through regular communications, sharing of best practices, and monitoring key performance indicators (KPIs).

Innovation and Collaboration

Strategic sourcing encourages organizations to collaborate closely with their suppliers, fostering an environment of innovation. This collaboration results in joint development of new products, services, and technologies, enhancing differentiation and boosting competitive advantage.

Sustainability and Social Responsibility

Implementing strategic sourcing allows organizations to address sustainability and social responsibility concerns. This approach involves selecting suppliers that demonstrate ethical practices, adhere to environmental regulations, and contribute to social objectives, thus enhancing the organization's reputation and brand image.

In conclusion, organizations implement strategic sourcing to achieve competitive advantage by optimizing supplier selection, reducing costs, managing risks, improving supplier relationships, encouraging innovation, and addressing sustainability and social responsibility concerns. This holistic approach to procurement ultimately contributes to enhanced business performance and long-term success.

What role do emerging technologies, such as artificial intelligence and blockchain, play in the evolution of supply chain management and strategic sourcing practices?

Role of Emerging Technologies

Emerging technologies, particularly artificial intelligence (AI) and blockchain, play a critical role in the evolution of supply chain management (SCM) and strategic sourcing practices. By utilizing these technologies, companies can optimize various aspects of their supply chain operations.

AI in supply chain management

AI presents numerous opportunities for enhancing supply chain management. For instance, predictive analytics, an AI technique, allows organizations to forecast demand more accurately. This leads to improved inventory management and better alignment of supply with demand. Additionally, AI-powered automation tools enable businesses to streamline their workflow processes, thus increasing efficiency and reducing operational costs.

Blockchain and supply chain transparency

Blockchain technology has the potential to revolutionize supply chain management by providing increased transparency and secure data exchange. It facilitates the tracking and tracing of products from their origin to their final destination, making it easier for companies to verify the authenticity of goods and protect against counterfeit products. Moreover, the decentralized nature of blockchain networks ensures secure and tamper-proof record keeping, while also enabling real-time data sharing among supply chain stakeholders.

Strategic sourcing with AI and blockchain

Strategic sourcing practices can also greatly benefit from AI and blockchain technologies. For example, AI can support decision making by analyzing massive amounts of data, enabling companies to identify cost-saving opportunities and negotiate better contracts with suppliers. Furthermore, blockchain networks can connect buyers and sellers in a secure and transparent environment, which enhances trust and fosters collaboration.

Integration of technologies

The successful integration of AI and blockchain technologies in supply chain management and strategic sourcing practices requires a holistic approach. Companies need to invest in the necessary infrastructure, including hardware, software, and skilled workforce, while also considering data security and privacy concerns. Nevertheless, as these technologies continue to advance and mature, their adoption will undoubtedly lead to more efficient, resilient, and sustainable supply chain operations.

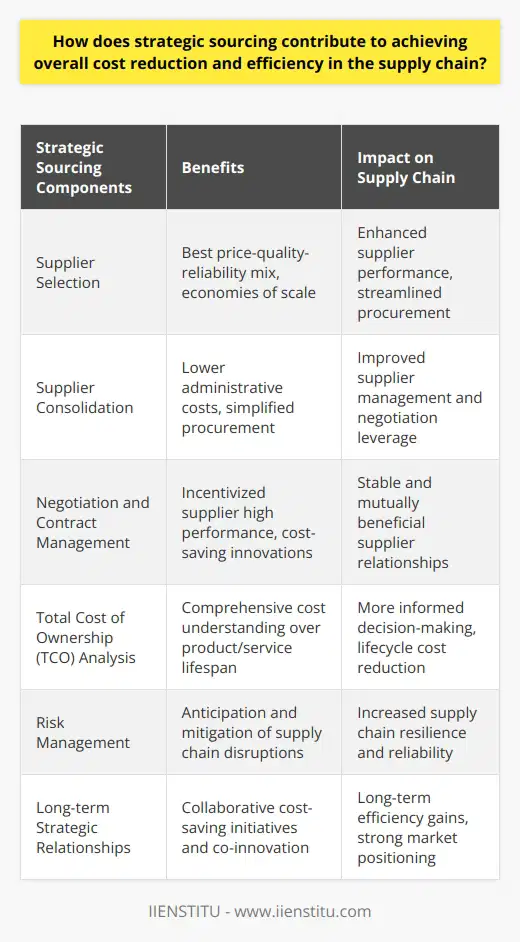

How does strategic sourcing contribute to achieving overall cost reduction and efficiency in the supply chain?

Strategic Sourcing Impact on Cost Reduction and Efficiency

Strategic sourcing, a procurement process focusing on continuous improvement and reevaluation of purchasing activities, contributes to achieving overall cost reduction and efficiency in the supply chain by optimizing the acquisition of goods and services. By employing strategic sourcing, organizations can improve supply chain performance, reduce operational costs, and gain competitive advantages.

Supplier Selection and Consolidation

A key aspect of strategic sourcing is the careful selection of suppliers based on performance and cost criteria. By identifying and partnering with high-quality, cost-competitive suppliers, organizations can obtain better pricing, favorable terms, and reliable performance that enhance the overall efficiency of the supply chain.

Additionally, consolidating the supplier base helps companies to leverage their purchasing power, achieve volume-based cost reductions, and minimize administrative expenses associated with managing multiple suppliers. Focusing on fewer suppliers who offer better value propositions promotes efficient procurement processes and lowers costs.

Negotiation and Contract Management

Strategic sourcing also involves effective negotiation and contract management practices that allow organizations to obtain favorable pricing and terms from suppliers. By conducting a comprehensive analysis of current spend patterns, procurement professionals can identify potential areas of cost savings and work with suppliers to negotiate mutually beneficial contract terms.

Moreover, utilizing long-term contracts with clearly defined performance metrics enables proactive performance management and continuous improvement, further driving cost reduction and supply chain efficiency.

Total Cost of Ownership (TCO) Analysis

An essential tool in strategic sourcing is TCO analysis, which incorporates all direct and indirect costs associated with acquiring and maintaining a product or service throughout its lifecycle. By adopting a TCO approach, organizations can identify hidden costs, evaluate potential cost-saving initiatives, and make better-informed procurement decisions that contribute to overall cost reduction and efficiency.

Risk Management and Supplier Relationships

Proactively managing risks by implementing supplier audits, monitoring supplier performance, and maintaining a comprehensive understanding of the market can minimize potential supply chain disruptions caused by poor supplier performance or market changes. A strong supplier relationship management focus ensures seamless communication, timely issue resolution, and ongoing collaboration on cost and efficiency improvement initiatives.

In conclusion, strategic sourcing plays a critical role in achieving overall cost reduction and efficiency in the supply chain by focusing on supplier selection, negotiation, TCO analysis, and risk management. By implementing strategic sourcing practices, organizations can optimize procurement processes, enhance supply chain performance, and gain a competitive advantage in today's global economy.

In which ways can companies develop strategic partnerships with suppliers to enhance supply chain performance?

Strategic Supplier Collaboration

One way companies can develop strategic partnerships with suppliers is through strategic supplier collaboration. This involves working closely with suppliers and sharing information, resources, and expertise. By collaborating with suppliers, companies can better understand their capabilities and potentially leverage those capabilities to improve supply chain performance.

Clear Communication and Alignment

Clear communication and alignment with suppliers is another vital aspect of enhancing supply chain performance. Companies should maintain open and transparent communication channels with their suppliers to foster a better understanding of expectations, objectives, and goals. Regular meetings and joint planning sessions can help ensure that both parties are aligned and working together to achieve mutual benefits.

Risk Management and Mitigation

Proactive risk management and mitigation can also help companies develop strategic partnerships with suppliers. By understanding potential risks within the supply chain, such as supplier failure, geopolitical instability, or natural disasters, businesses can work with suppliers to develop contingency plans and mitigate potential disruptions, thereby enhancing overall supply chain performance.

Joint Innovation and Continuous Improvement

Another approach to enhancing supply chain performance involves joint innovation and continuous improvement. By working with suppliers on product development or process improvement initiatives, companies can garner valuable insights and tap into their suppliers' expertise. This collaboration can lead to innovative solutions and process efficiencies that ultimately benefit both the company and the supplier.

Long-term Relationship Building

Finally, fostering long-term relationships with suppliers can contribute to enhanced supply chain performance. Companies that nurture strong, long-lasting relationships with suppliers can benefit from greater supply chain stability, reliability, and responsiveness. By building trusted partnerships, companies can better anticipate and respond to changes in the market, leading to a more robust and agile supply chain.

In summary, companies can enhance supply chain performance through strategic partnerships with suppliers by promoting collaboration, communication and alignment, risk management, joint innovation, and relationship building. These approaches enable businesses and suppliers to work together more effectively, resulting in improved supply chain operations and mutual growth opportunities.

How do recent trends in globalization and economic shifts impact strategic sourcing decision-making processes?

Economic Shifts and Sourcing Decisions

Recent trends in globalization and economic shifts have significantly impacted strategic sourcing decision-making processes. One crucial factor is the increasing prominence of developing economies. The rapid growth of emerging markets, such as India and China, offers new sourcing destinations with lower production costs and increased capacity.

Rising Protectionism

Moreover, the rise of protectionist policies, such as trade barriers and tariffs, has increased the complexity of sourcing decisions. Companies now need to consider the potential ramifications of government regulations in different countries when developing their sourcing strategies. Balancing cost savings with regulatory compliance can pose a significant challenge, which necessitates a more robust risk assessment process.

Digital Transformation

Furthermore, the adoption of digital technologies has transformed the way businesses approach strategic sourcing. Advanced analytics, automation, and artificial intelligence (AI) can accelerate decision-making and enhance risk management. By leveraging digital tools, organizations can more effectively assess supplier performance, market dynamics, and geopolitical risks. As a result, the overall efficiency and agility of the strategic sourcing process can improve significantly.

Sustainability Concerns

Lastly, the increasing importance of sustainability and corporate social responsibility (CSR) has influenced strategic sourcing decisions. Organizations need to assess the environmental, social, and governance (ESG) performance of their suppliers to minimize risks and reduce the potential negative impacts of their operations. This focus on sustainability can lead to a reevaluation of sourcing strategies and encourage the development of long-lasting relationships with responsible suppliers.

In conclusion, recent changes in the global landscape have resulted in a more dynamic and challenging environment for strategic sourcing decision-making processes. Organizations that adapt their sourcing strategies to account for economic shifts, protectionist policies, digital transformation, and sustainability concerns are more likely to succeed and maintain a competitive advantage.

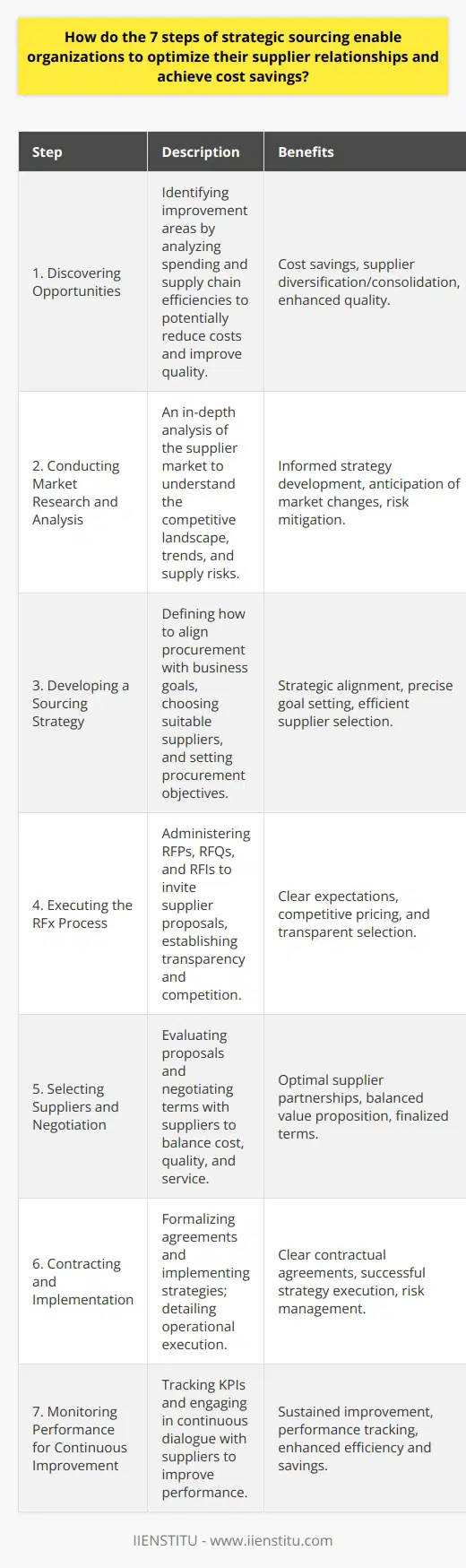

How do the 7 steps of strategic sourcing enable organizations to optimize their supplier relationships and achieve cost savings?

The Importance of the 7 Steps of Strategic Sourcing

Strategic sourcing, a systematic approach to improving procurement and supplier relationships, seeks not only to attain cost savings, but also to ensure high-quality products and services. The seven steps of strategic sourcing encompass all aspects of a successful supplier relationship, from identifying potential suppliers to negotiating contracts.

Identifying Opportunities

By assessing current procurement trends, organizations can identify areas where costs can be reduced and where new suppliers may provide better quality or cost-efficient products and services. This step results in a more comprehensive understanding of internal spending patterns and improvement opportunities.

Market Research and Analysis

Understanding the supplier market is essential to making informed decisions in selecting supplier partners. Through in-depth market research and analysis, organizations can identify existing and emerging suppliers, potential risks, and industry trends that may impact supplier relationships and decision-making.

Develop Sourcing Strategy

A well-defined sourcing strategy is pivotal in fostering cohesive procurement actions while addressing strategic goals. This step involves aligning business objectives, identifying cost-saving and efficiency opportunities, and determining the necessary resources and tools for a successful sourcing process.

RFx Process (Request for Proposal/Quotation/Information)

The RFx process enables organizations to obtain detailed information on pricing, capabilities, and service quality from potential suppliers. By streamlining the tendering process, organizations can ensure a fair and competitive market, promoting transparent evaluations and informed decision-making.

Supplier Selection and Negotiation

After a thorough evaluation of the proposals, organizations can narrow down their choices and begin negotiations with the selected suppliers. This step entails building long-term relationships, aligning expectations, and finalizing placements based on mutually agreed terms and conditions.

Contract Management and Implementation

A well-crafted contract acts as the foundation of a successful supplier relationship. This step entails establishing legal and compliance parameters, defining performance metrics, and outlining risk and change management protocols to ensure smooth implementation of the sourcing strategy.

Performance Monitoring and Continuous Improvement

Lastly, ongoing monitoring of supplier performance, evaluation of KPIs, and maintenance of open communication channels within the organization are vital to ensuring long-term success. By adapting and improving sourcing strategies, organizations can continuously optimize supplier relationships and achieve cost savings.

In conclusion, the seven steps of strategic sourcing enable organizations to develop and maintain long-lasting, mutually beneficial relationships with their suppliers while driving cost savings and operational efficiency. By following this structured approach, procurement strategies can be optimized to deliver maximum value and secure sustainable gains for the organization.

In what ways can the 4 pillars of strategic sourcing be applied to address the challenges faced in global supply chain management?

Strategic Sourcing Application

The four pillars of strategic sourcing can be applied in various ways to address challenges faced in global supply chain management. These pillars consist of market analysis, supplier identification, negotiation, and supplier governance.

Market Analysis in Supply Chain

Market analysis involves understanding the dynamics and trends shaping the industry. By conducting a comprehensive market analysis, organizations can adapt to changes in the global supply chain and anticipate potential risks. This understanding helps organizations make informed decisions about suppliers, location choices, and product designs. Furthermore, market analysis enables businesses to identify emerging markets or technologies, fostering innovation and growth.

Supplier Identification for Improved Supply Chain

The second pillar, supplier identification, focuses on finding the right partners in the supply chain. A robust supplier identification process involves evaluating potential partners' capabilities, capacity, quality, and financial stability. By applying this pillar, organizations can minimize potential disruptions in their supply chain and forge strong relationships with suppliers. Moreover, thorough supplier identification ensures that businesses collaborate with reliable partners who can uphold their commitments and deliver the desired quality.

Negotiation Tactics for Supply Chain Optimization

Negotiation forms the third pillar, where organizations engage in discussions with potential suppliers to achieve favorable terms and conditions. Establishing a sound negotiation strategy equips organizations with the ability to secure competitive pricing, service levels, and quality standards. Moreover, these negotiations enable supply chain managers to develop mutually beneficial agreements with suppliers that promote long-term collaboration, stability, and risk management.

Supplier Governance for Stable Supply Chains

Lastly, supplier governance refers to the ongoing monitoring and evaluation of supplier performance to ensure adherence to contracts and continuous improvement. Implementing effective supplier governance mechanisms assists organizations in mitigating the risks associated with global supply chains. This includes monitoring suppliers' responsiveness and performance to strengthen organizational success. Furthermore, governance helps identify potential supply chain disruptions and enables organizations to take corrective actions.

Conclusion

In conclusion, the four pillars of strategic sourcing provide organizations with a comprehensive framework to address challenges and ensure the stability and efficiency of their global supply chains. Applying market analysis, supplier identification, negotiation, and supplier governance equips businesses with the tools needed to maintain a competitive edge in today's dynamic global landscape.

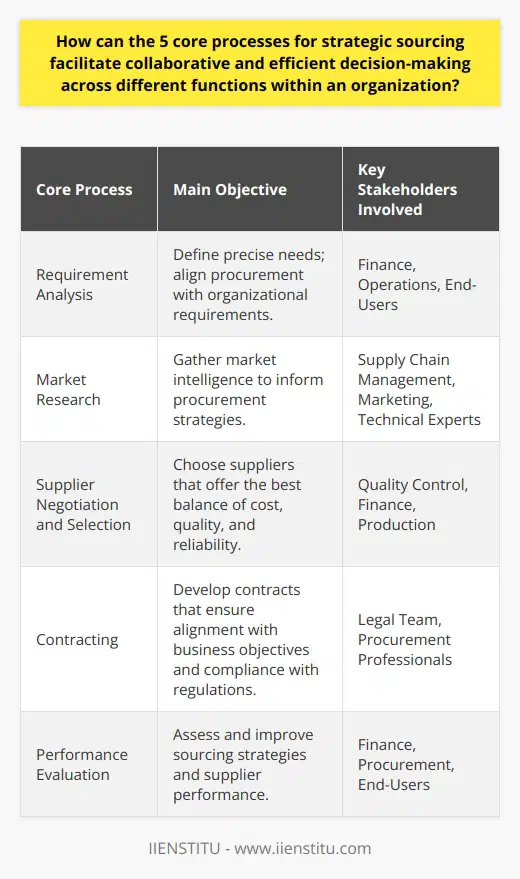

How can the 5 core processes for strategic sourcing facilitate collaborative and efficient decision-making across different functions within an organization?

Collaborative Decision-Making through Strategic Sourcing

Strategic sourcing, a systematic approach to managing procurement activities, plays a vital role in promoting collaboration and efficiency across different functions within an organization. The five core processes involved in strategic sourcing include requirement analysis, market research, supplier negotiation and selection, contracting, and performance evaluation. These processes enable organizations to align their overall goals with procurement decisions and create a synergistic working environment.

Requirement Analysis and Cross-Functional Teams

Requirement analysis is the first step in the strategic sourcing process, which involves gathering and prioritizing purchasing requirements. This stage creates opportunities for members from different functions to work together as cross-functional teams. These teams enable effective communication and idea sharing, ensuring a common understanding of organizational needs and objectives.

Market Research and Knowledge Sharing

Market research, the second core process, involves identifying and analyzing potential suppliers to meet organizational needs. Conducting market research promotes the exchange of information and insights between different departments, such as finance and operations. This collaboration supports data-driven decision-making, which is crucial for the effective implementation of strategic sourcing.

Supplier Negotiation and Selection for Better Outcomes

A well-planned supplier negotiation and selection process supports better decision-making by offering various perspectives from different functions. Involvement from different departments, such as quality assurance and engineering, allows an organization to ensure that the chosen supplier meets all requirements while maintaining cost-effectiveness and fostering long-term relationships.

Contracting and Internal Alignment

The contracting process benefits from the collaboration between legal, finance, and procurement teams to ensure that contracts accurately represent organizational objectives and protect the organization's interests. This joint effort fosters consistency in contract management, resulting in a more streamlined and efficient process.

Performance Evaluation and Continuous Improvement

The final core process, performance evaluation, involves tracking supplier performance against established metrics and identifying areas for improvement. This continuous monitoring enables cross-functional input and aids in adjusting procurement strategies as needed, leading to better overall decision-making and adaptability across the organization.

In conclusion, the five core processes of strategic sourcing foster collaboration and efficiency throughout an organization by promoting effective communication, knowledge sharing, and decision-making across different functions. By implementing strategic sourcing practices, organizations can ensure their procurement activities align with broader organizational goals and drive continuous improvement.

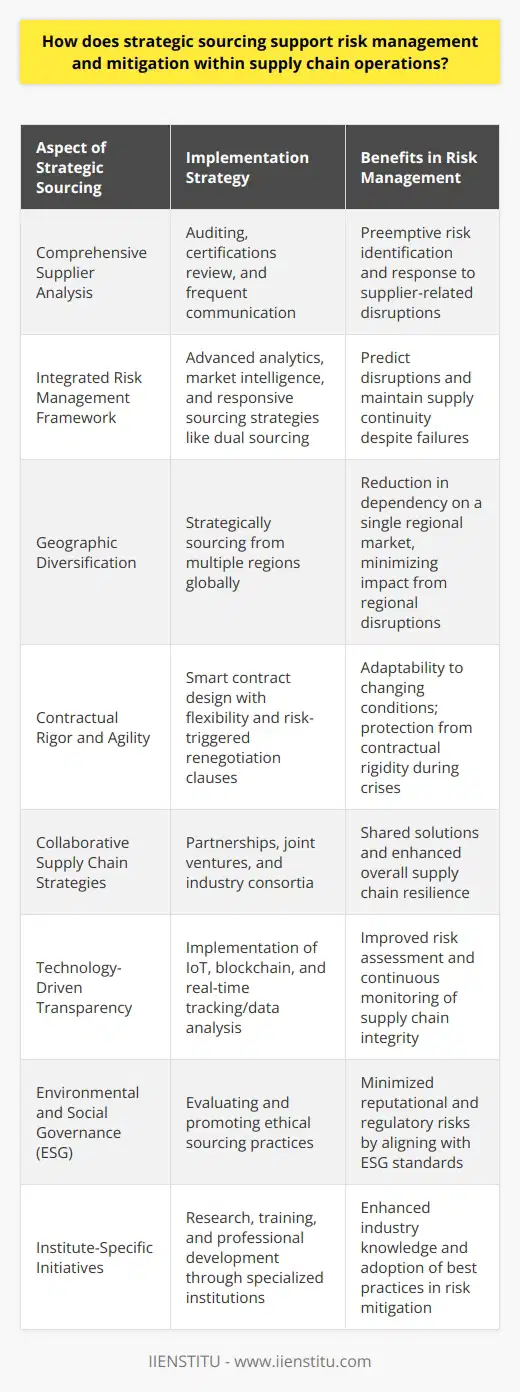

How does strategic sourcing support risk management and mitigation within supply chain operations?

Strategic Sourcing for Risk Management

Strategic sourcing plays a significant role in mitigating risks within supply chain operations. It encompasses various practices that focus on optimizing procurement and supplier management processes to ensure continuous and reliable material flow. By adopting strategic sourcing practices, companies can effectively address potential risks within their supply chains, thereby enhancing their risk management capabilities.

Supplier Diversification

One key aspect of strategic sourcing is supplier diversification. By working with multiple suppliers offering similar products or services, companies can reduce their dependency on individual suppliers. This approach minimizes the impact of sudden disruptions, such as natural disasters, political issues, or financial crises, on their supply chain operations. As a result, firms can better manage and mitigate the risk of supply chain interruptions.

Supplier Evaluation and Selection

Strategic sourcing involves a rigorous supplier evaluation and selection process. By assessing potential suppliers based on factors like financial stability, quality, delivery, and performance, companies can identify reliable and competent partners for their supply chain. This systematic approach helps businesses avoid potential risks associated with working with underperforming or financially unstable suppliers.

Long-term Supplier Relationships

Developing long-term relationships with suppliers is another critical aspect of strategic sourcing. By fostering trust and collaboration, organizations can gain deeper insights into suppliers' operations and more effectively manage potential risks. Moreover, long-term partnerships enable companies to negotiate favorable contracts, ensuring access to critical resources during periods of market volatility or material shortages.

Risk Assessment and Contingency Planning

Additionally, strategic sourcing supports risk management by encouraging businesses to continually assess and monitor supplier-related risks. Through proactive risk identification and assessment, companies can identify potential threats to their supply chain and develop contingency plans to address them. Plans may include alternative sourcing strategies, inventory management, or backup suppliers, ensuring supply chain resilience in the face of disruptions.

Supply Chain Visibility

Finally, supply chain visibility is crucial for risk management within supply chain operations. Strategic sourcing promotes transparent communication and information sharing between organizations and their suppliers, allowing them to quickly identify and address potential risks. Increased visibility leads to more informed decision-making, enabling companies to proactively mitigate risks and strengthen their supply chain operations.

In summary, strategic sourcing plays a vital role in enhancing risk management and mitigation within supply chain operations. By implementing strategic sourcing practices, companies can better manage risks associated with supplier selection, diversification, and long-term relationships, while also promoting risk assessment, contingency planning, and supply chain visibility. Consequently, organizations can better protect their supply chain and maintain a competitive edge in an increasingly complex and uncertain business environment.

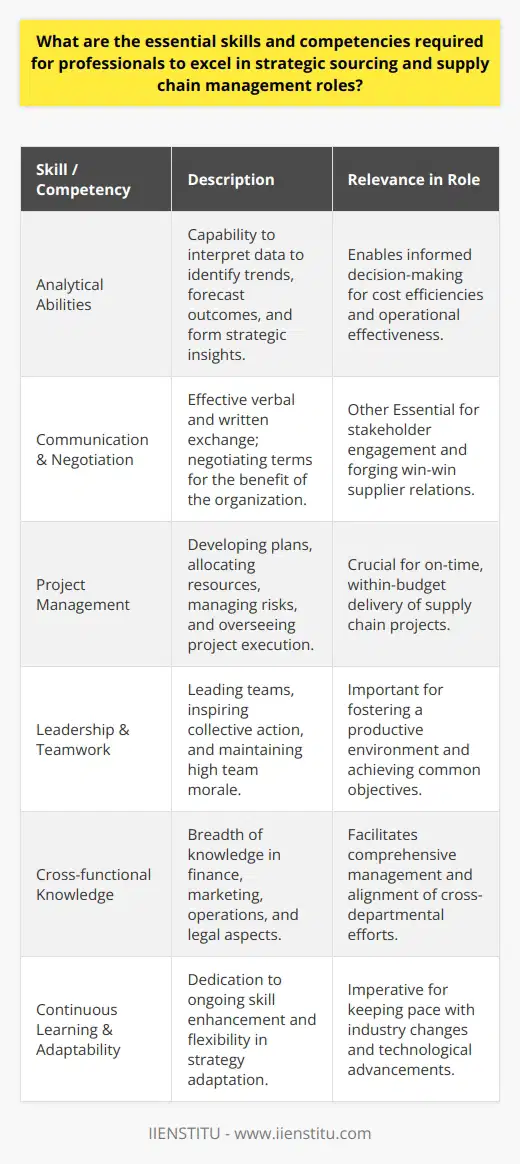

What are the essential skills and competencies required for professionals to excel in strategic sourcing and supply chain management roles?

Analytical Abilities

Professionals in strategic sourcing and supply chain management must possess strong analytical skills to excel in their roles. These abilities allow them to evaluate complex data, identify trends, and make informed decisions that benefit the organization. Analyzing cost structures, understanding market dynamics, and performing risk assessments are critical to staying competitive in the industry.

Communication and Negotiation Skills

Effective communication and negotiation skills are essential for building and maintaining relationships with suppliers, clients, and stakeholders. Professionals must be able to clearly articulate their strategies, negotiate contracts, and resolve conflicts to ensure the smooth running of the supply chain. This also involves being able to listen, comprehend, and respond to the needs and concerns of stakeholders.

Project Management

Successful strategic sourcing and supply chain management professionals must have strong project management skills. This means being able to initiate, plan, execute, monitor, and close projects. Such skills allow them to effectively balance resources, time, cost, and quality, as well as to identify and resolve potential issues before they escalate.

Leadership and Teamwork

In order to succeed in their roles, professionals must also possess excellent leadership and teamwork skills. Being able to inspire, motivate, and guide individuals within their team is instrumental in achieving organizational goals. Moreover, fostering a collaborative work environment and establishing trust among team members is crucial for success.

Cross-functional Knowledge

Professionals in this field must develop an understanding of various aspects of the business, such as finance, marketing, operations, and quality control. Cross-functional knowledge enables them to align their strategies with business objectives and ensure effective implementation. Gaining this understanding also allows them to collaborate with other departments and contribute positively to the organization's goals.

Continuous Learning and Adaptability

The supply chain industry is constantly evolving due to technological advancements, global trends, and regulatory changes. Therefore, professionals must stay updated on the latest developments to excel in their roles. Continuous learning and adaptability enable them to identify new opportunities, overcome challenges, and stay relevant in a changing landscape.

In conclusion, a combination of strong analytical abilities, effective communication and negotiation skills, project management, leadership and teamwork, cross-functional knowledge, and continuous learning and adaptability, are crucial competencies required for strategic sourcing and supply chain management professionals to excel in their roles.

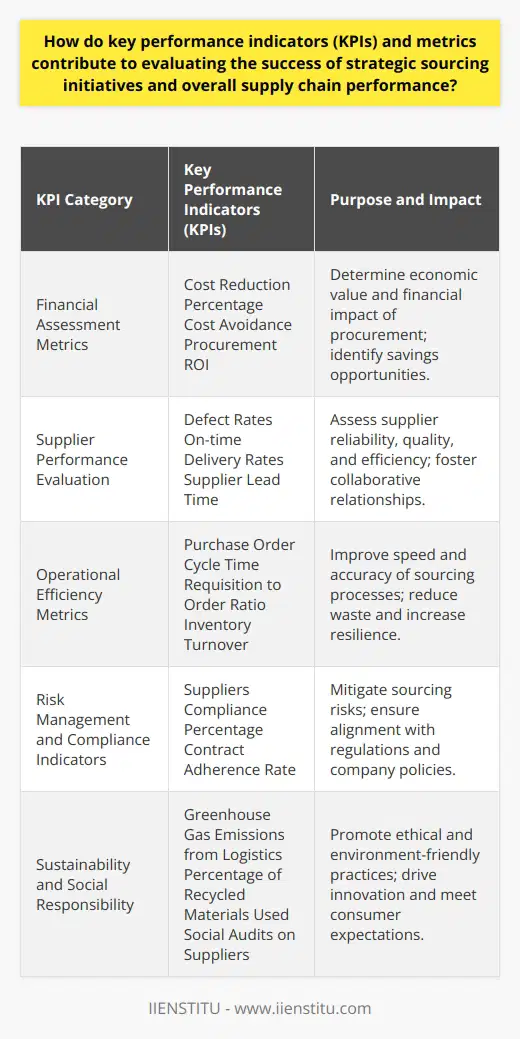

How do key performance indicators (KPIs) and metrics contribute to evaluating the success of strategic sourcing initiatives and overall supply chain performance?

KPIs in Strategic Sourcing

Key performance indicators (KPIs) and metrics serve as essential tools in evaluating the success of strategic sourcing initiatives and overall supply chain performance. These quantitative measures help organizations track progress, identify trends, and make data-driven decisions. By providing insights into various aspects of procurement and supply chain operations, KPIs and metrics enable companies to fine-tune their sourcing strategies and enhance their competitive advantage in the market.

Measuring Financial Performance

One crucial application of KPIs and metrics in strategic sourcing is assessing financial performance. Metrics such as cost savings, return on investment (ROI), and total cost of ownership (TCO) help organizations evaluate the effectiveness of procurement activities and identify areas for improvement. Monitoring these metrics enables companies to optimize their sourcing efforts, minimize risk, and improve their bottom line.

Evaluating Supplier Relationships

Another critical area where KPIs and metrics play a significant role is the evaluation of supplier relationships. Supplier performance metrics, such as delivery performance, quality performance, and service responsiveness, enable organizations to assess their suppliers' reliability and adherence to contractual obligations. This assessment aids in supplier selection and development, strengthening strategic partnerships and driving long-term value.

Enhancing Process Efficiency

KPIs and metrics also contribute to the enhancement of process efficiency within procurement and supply chain processes. Metrics such as cycle time, on-time deliveries, and order accuracy reveal the effectiveness of internal processes, pointing out bottlenecks and areas for improvement. By continually monitoring and improving process efficiency metrics, companies can streamline their procurement and supply chain operations, fostering agility and adaptability.

Ensuring Compliance and Sustainability

Lastly, KPIs and metrics support organizations in ensuring compliance and sustainability across their supply chain. Compliance metrics, such as adherence to regulatory standards and audit performance, help safeguard against legal and reputational risks. Sustainability KPIs, such as carbon footprint reduction and ethical sourcing, demonstrate a company's commitment to corporate social responsibility, bolstering stakeholder trust and loyalty.

In conclusion, KPIs and metrics are indispensable in evaluating the success of strategic sourcing initiatives and overall supply chain performance. Through financial, supplier relationship, process efficiency, and compliance metrics, organizations can monitor progress, identify improvement opportunities, and optimize their sourcing strategies. By leveraging these data-driven insights, companies can enhance their competitive advantage and achieve long-term success.