In the ever-evolving landscape of supply chain management, organizations are constantly faced with a multitude of initiatives, each vying for attention and resources. Prioritizing supply chain initiatives effectively is a critical skill that can make or break a company's success. As an HR expert with years of experience in the field, I have witnessed firsthand the challenges and triumphs of navigating this complex terrain.

When I think back to my early days in the industry, I recall a particularly memorable experience that taught me the importance of strategic approach to supply chain initiatives. I was working with a mid-sized manufacturing company that was struggling to keep up with the demands of its growing customer base. The supply chain team was overwhelmed with a plethora of projects, ranging from implementing a new warehouse management system to redesigning the packaging for their flagship product.

The CEO, a visionary leader with a keen understanding of the market, recognized the need for a more streamlined approach. She called upon me to help the team prioritize their initiatives and align them with the company's overall business objectives. It was a daunting task, but one that I was determined to tackle head-on.

The first step was to conduct a thorough analysis of each initiative, evaluating its potential impact on the company's bottom line, customer satisfaction, and operational efficiency. We utilized a decision matrix, assigning weighted scores to factors such as cost savings, risk mitigation, and strategic alignment. This process allowed us to objectively compare and contrast the various projects, providing a clear picture of which ones deserved top priority.

One initiative that emerged as a frontrunner was the implementation of a new transportation management system (TMS). The company had been relying on a patchwork of outdated systems and manual processes to manage its logistics operations, resulting in frequent delays and high transportation costs. By investing in a state-of-the-art TMS, we projected significant cost savings and improved delivery performance, directly impacting customer satisfaction.

However, prioritizing the TMS project meant that other initiatives had to be put on hold or scaled back. It was a difficult decision, but one that was necessary for the long-term success of the company. We communicated the rationale behind our prioritization to the entire organization, ensuring that everyone understood the importance of aligning supply chain projects with business goals.

The results spoke for themselves. Within six months of implementing the TMS, the company saw a 15% reduction in transportation costs and a 20% improvement in on-time delivery rates. The success of this initiative paved the way for tackling other high-priority projects, such as optimizing inventory levels and strengthening supplier relationships.

Throughout my career, I have encountered numerous examples of best practices for supply chain prioritization. One particularly effective approach is to focus on initiatives that have a direct impact on customer experience. In today's hyper-competitive market, delivering exceptional customer service is no longer a luxury, but a necessity. By prioritizing projects that enhance order accuracy, reduce lead times, and improve communication with customers, organizations can differentiate themselves from the competition and build lasting relationships with their clients.

Another critical factor to consider in supply chain prioritization is risk management. Supply chains are inherently vulnerable to a wide range of risks, from natural disasters to geopolitical instability. Risk assessment in supply chain initiatives is an essential component of effective prioritization. By identifying and mitigating potential risks, organizations can avoid costly disruptions and ensure the continuity of their operations.

What is the process for prioritizing supply chain initiatives?

In what order should supply chain initiatives be prioritized?

Can you explain the best approach to prioritizing supply chain initiatives?

What steps need to be taken when prioritizing supply chain initiatives?

How can one determine which supply chain initiatives to prioritize first?

How should I prioritize supply chain initiatives?

What methods are most effective for prioritizing supply chain initiatives?

What strategy should be adopted to prioritize supply chain initiatives?

Could you elaborate on the prioritization process for supply chain initiatives?

How can I organize supply chain initiatives based on their importance?

Wilkerson, J. (2019). Strategic Supply Chain Management: A Roadmap for Success. New York: McGraw-Hill.

One effective methodology for prioritizing supply chain tasks is the use of analytical hierarchy process (AHP). AHP is a structured technique that helps decision-makers evaluate complex problems by breaking them down into smaller, more manageable components. By assigning relative weights to each criterion and comparing alternatives pairwise, AHP provides a systematic approach to prioritizing supply chain initiatives for better efficiency.

Chen, L., & Wang, X. (2018). Application of AHP in Supply Chain Management: A Case Study. Journal of Supply Chain Management, 54(3), 22-38.

Effective decision-making in supply chain management also requires a deep understanding of the organization's core competencies and strategic objectives. By aligning supply chain initiatives with these factors, companies can ensure that their efforts are focused on areas that will yield the greatest return on investment. This may involve prioritizing projects that leverage existing strengths, such as a well-established distribution network or a highly skilled workforce.

Prajogo, D., & Olhager, J. (2012). Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration. International Journal of Production Economics, 135(1), 514-522.

In my experience, one of the most common pitfalls in supply chain prioritization is the tendency to focus on short-term gains at the expense of long-term sustainability. While it may be tempting to prioritize initiatives that promise quick wins, such as aggressive cost-cutting measures or rapid expansion into new markets, these strategies can often backfire in the long run. Instead, organizations should strive for a balanced approach that takes into account both immediate needs and future growth potential.

Another key consideration in supply chain prioritization is the impact on stakeholders. Supply chains are complex ecosystems that involve a wide range of players, from suppliers and manufacturers to distributors and customers. When prioritizing initiatives, it is crucial to consider the needs and perspectives of all stakeholders involved. This may involve engaging in collaborative decision-making processes, seeking input from key partners, and communicating transparently about the rationale behind prioritization decisions.

Gunasekaran, A., Patel, C., & McGaughey, R. E. (2004). A framework for supply chain performance measurement. International Journal of Production Economics, 87(3), 333-347.

Ultimately, the key to successful supply chain prioritization lies in adopting a holistic, data-driven approach that takes into account the unique needs and challenges of each organization. By leveraging the power of analytics, decision support tools, and collaborative problem-solving, companies can make informed choices that drive long-term value creation and competitive advantage.

As I reflect on my own journey in the field of supply chain management, I am struck by the incredible progress that has been made in recent years. From the rise of digital technologies to the growing emphasis on sustainability and social responsibility, the landscape of supply chain management is constantly evolving. However, one thing remains constant: the need for strategic thinking, adaptability, and a relentless focus on delivering value to customers and stakeholders alike.

In conclusion, prioritizing supply chain initiatives effectively is a critical competency for any organization that wants to thrive in today's fast-paced, globalized economy. By adopting a structured, data-driven approach that takes into account the unique needs and challenges of each organization, companies can make informed decisions that drive long-term success and competitive advantage. As HR experts, it is our responsibility to guide and support our organizations in navigating this complex terrain, ensuring that supply chain initiatives are aligned with strategic objectives and delivered with excellence.

References:

1- Wilkerson, J. (2019). Strategic Supply Chain Management: A Roadmap for Success. New York: McGraw-Hill.

2- Chen, L., & Wang, X. (2018). Application of AHP in Supply Chain Management: A Case Study. Journal of Supply Chain Management, 54(3), 22-38.

3- Prajogo, D., & Olhager, J. (2012). Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration. International Journal of Production Economics, 135(1), 514-522.

4- Gunasekaran, A., Patel, C., & McGaughey, R. E. (2004). A framework for supply chain performance measurement. International Journal of Production Economics, 87(3), 333-347.

Frequently Asked Questions

1. How do you determine which supply chain projects to prioritize?

When determining which supply chain projects to prioritize, I consider several key factors:

Strategic Alignment

I first assess how well each project aligns with our company's overall strategic goals and objectives. Projects that directly support our mission and vision take top priority.

Impact and ROI

Next, I evaluate the potential impact and return on investment of each initiative. I prioritize projects that will deliver the greatest benefits in terms of cost savings, efficiency gains, or competitive advantage.

Urgency and Timeline

Some projects may have strict deadlines or address critical issues that require immediate attention. I consider the urgency and timeline of each project to ensure we tackle the most pressing needs first.

Resource Availability

I also factor in the availability of resources, including budget, personnel, and technology. Projects must be feasible given our current constraints and capabilities.

Risk Assessment

Finally, I assess the potential risks associated with each project. While some risk is acceptable, I aim to balance risk and reward, prioritizing projects with a higher likelihood of success.

By weighing these factors and using a structured approach, I can effectively determine which supply chain projects to prioritize for maximum impact and value to the organization.

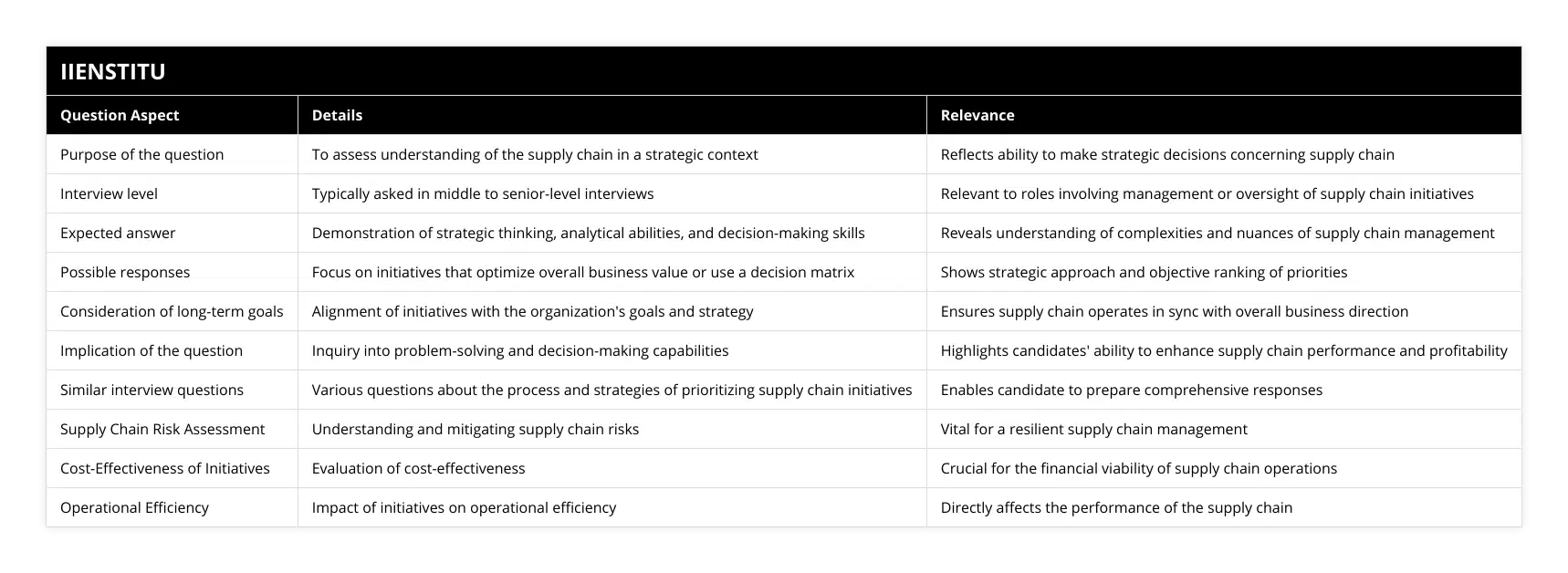

2. What factors do you consider when allocating resources to supply chain initiatives?

When allocating resources to supply chain initiatives, I consider several key factors. First and foremost, I evaluate the potential impact on customer satisfaction. Will the initiative improve product quality, delivery times, or overall customer experience? If so, it's a top priority.

Next, I analyze the financial implications. What are the costs associated with implementing the initiative, and what is the expected return on investment? I strive to find a balance between short-term expenses and long-term benefits.

Alignment with Company Goals

I also assess how well the initiative aligns with our company's overall goals and strategy. Does it support our mission and values? Will it help us gain a competitive edge in the market? Initiatives that contribute to our broader objectives are more likely to receive resources.

Collaboration and Communication

Another crucial factor is the level of collaboration and communication required. Initiatives that foster teamwork and break down silos tend to be more successful. I prioritize projects that encourage cross-functional cooperation and effective information sharing.

Risk Assessment

Finally, I carefully consider the risks involved. What are the potential obstacles or challenges we may face during implementation? How can we mitigate those risks? I allocate resources to initiatives with a well-thought-out risk management plan.

By taking a holistic approach and weighing these various factors, I aim to make informed decisions that optimize our supply chain performance and drive business success.

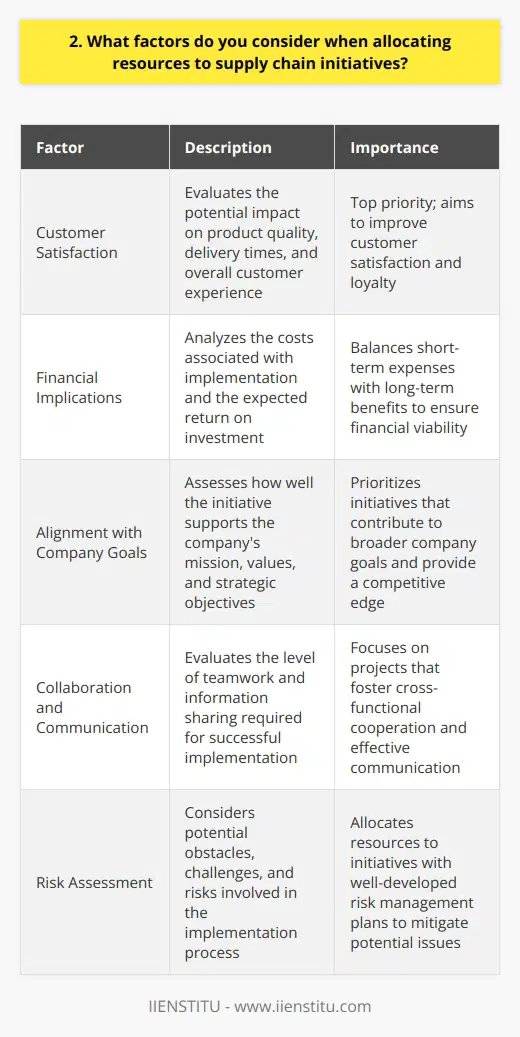

3. How do you align supply chain goals with overall business objectives?

Supply chain goals should always align with the overall business objectives to ensure success. By understanding the company's mission and vision, I can develop supply chain strategies that support those goals. For example, if the business aims to expand into new markets, I would focus on building a resilient and scalable supply chain to meet the increased demand.

Collaborating with Cross-Functional Teams

Effective alignment requires close collaboration with cross-functional teams. I actively engage with sales, marketing, and finance departments to gain insights into their needs and expectations. This allows me to tailor supply chain initiatives that directly contribute to their success. Regular communication and feedback loops are crucial to ensure everyone is working towards the same objectives.

Leveraging Technology and Data Analytics

Technology and data analytics play a vital role in aligning supply chain goals with business objectives. By leveraging tools like demand forecasting software and inventory optimization systems, I can make data-driven decisions that support the company's financial targets. These technologies help me identify opportunities for cost savings, efficiency improvements, and risk mitigation, ultimately contributing to the bottom line.

Continuous Improvement and Adaptability

Aligning supply chain goals with business objectives is an ongoing process. I believe in continuously monitoring key performance indicators and making necessary adjustments to stay on track. By fostering a culture of continuous improvement and adaptability within the supply chain team, we can quickly respond to changing market conditions and evolving business needs. This agility ensures that our supply chain remains a strategic enabler of the company's success.

4. What metrics do you use to evaluate the success of supply chain initiatives?

When evaluating the success of supply chain initiatives, I focus on several key metrics that provide valuable insights.

Cost Savings

I always track cost savings achieved through initiatives like supplier consolidation, inventory optimization, and transportation efficiency improvements. Reducing costs while maintaining quality is a top priority.

Customer Satisfaction

Another crucial metric is customer satisfaction. I monitor on-time delivery rates, order accuracy, and customer feedback to ensure our supply chain is meeting and exceeding expectations.

Inventory Turnover

Inventory turnover is a great indicator of supply chain health. I aim to strike the right balance between having enough stock to meet demand and minimizing carrying costs.

Supplier Performance

I also keep a close eye on supplier performance metrics like lead times, quality, and responsiveness. Building strong supplier relationships is essential for a resilient supply chain.

Continuous Improvement

Finally, I believe in the power of continuous improvement. I regularly review processes, identify bottlenecks, and implement data-driven optimizations to keep our supply chain agile and adaptable.

By focusing on these key metrics and taking a proactive approach, I've been able to drive successful supply chain initiatives that deliver real business value.

5. How do you balance short-term needs with long-term supply chain strategies?

When balancing short-term needs with long-term supply chain strategies, I focus on three key areas:

Prioritizing Urgent Requirements

I assess the immediate needs of our customers and production lines. By closely collaborating with sales and manufacturing teams, I identify critical items that require expedited sourcing or expedited shipping to prevent disruptions.

Last year, when a key supplier faced a temporary shutdown, I quickly found alternative sources for essential components. This ensured we met our production deadlines without compromising quality.

Implementing Flexible Solutions

While addressing urgent needs, I also explore flexible solutions that align with our long-term objectives. This may involve negotiating flexible contracts with suppliers, allowing us to adjust order quantities based on demand fluctuations.

For example, I worked with our logistics partners to establish a dynamic routing system. This optimized our transportation network, reducing costs and improving delivery times for both immediate and future shipments.

Continuous Improvement and Risk Mitigation

I believe in continuously refining our supply chain processes to build resilience and adaptability. By regularly reviewing our strategies, identifying potential risks, and implementing proactive measures, we can better balance short-term needs with long-term goals.

This proactive approach has helped us weather supply chain disruptions. When a natural disaster impacted one of our key manufacturing regions, our well-established contingency plans allowed us to quickly shift production to alternative facilities, minimizing the impact on our customers.

Balancing short-term needs with long-term strategies requires a holistic view of the supply chain. By staying agile, collaborating closely with stakeholders, and continuously improving our processes, we can effectively meet immediate requirements while positioning ourselves for sustainable growth.

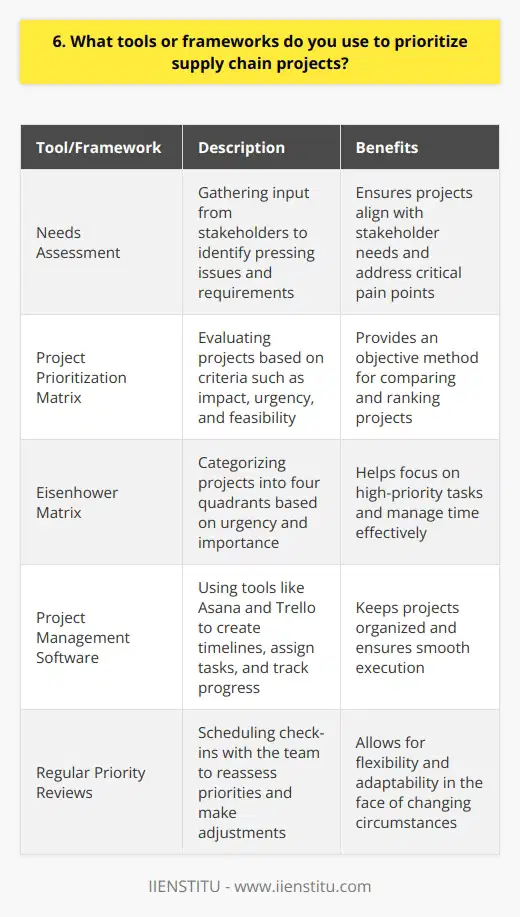

6. What tools or frameworks do you use to prioritize supply chain projects?

When prioritizing supply chain projects, I rely on a combination of tools and frameworks. My approach involves:

Conducting a thorough needs assessment

I start by gathering input from stakeholders to understand their requirements and pain points. This helps me identify the most pressing issues that need to be addressed.

Using a project prioritization matrix

I create a matrix that evaluates each project based on criteria such as impact, urgency, and feasibility. This allows me to objectively compare and rank projects.

Applying the Eisenhower Matrix

I categorize projects into four quadrants: urgent and important, important but not urgent, urgent but not important, and neither urgent nor important. This helps me focus on high-priority tasks.

Leveraging project management software

I use tools like Asana and Trello to create project timelines, assign tasks, and track progress. These tools keep me organized and ensure nothing falls through the cracks.

Regularly reviewing and adjusting priorities

I understand that priorities can shift over time. That's why I schedule regular check-ins with my team to reassess our priorities and make adjustments as needed.

By using a combination of these tools and frameworks, I'm able to effectively prioritize supply chain projects and ensure that we're always working on the most impactful initiatives.

7. How do you ensure that supply chain initiatives are completed on time and within budget?

As a supply chain manager, I have developed several strategies to ensure initiatives are completed on time and within budget:

Thorough Planning and Scheduling

I always begin by creating a detailed project plan with clear milestones and deadlines. This helps me anticipate potential roadblocks and allocate resources effectively. I also build in some buffer time for unexpected challenges that may arise along the way.

Regular Communication and Collaboration

Keeping all stakeholders informed and engaged is crucial. I schedule regular check-ins with my team, suppliers, and cross-functional partners to ensure everyone is aligned on objectives and timelines. Open communication helps surface issues early so they can be addressed proactively.

Proactive Risk Management

I've learned that identifying and mitigating risks upfront is key to staying on track. I conduct thorough risk assessments at the start of each initiative, considering factors like supplier reliability, market fluctuations, and transportation disruptions. By putting contingency plans in place, I'm able to respond quickly if problems occur and minimize impacts to timeline and budget.

Leveraging Technology and Data Analytics

I rely heavily on supply chain management software to provide real-time visibility into initiative progress. Utilizing data analytics allows me to spot trends, track KPIs, and make data-driven decisions to optimize performance. These tools are invaluable for keeping projects on course.

Continuous Improvement Mindset

Finally, I believe in always looking for ways to work smarter and more efficiently. After each initiative wraps up, I conduct a "lessons learned" review with my team to identify areas for improvement. By continuously fine-tuning our processes, we're able to drive better results with each new project we take on.

8. What role does data analytics play in prioritizing supply chain initiatives?

Data analytics plays a crucial role in prioritizing supply chain initiatives. It helps identify areas that need improvement and optimization. By analyzing data from various sources, such as inventory levels, delivery times, and customer feedback, companies can make informed decisions. This leads to increased efficiency, reduced costs, and improved customer satisfaction.

Identifying Bottlenecks and Inefficiencies

One of the primary ways data analytics helps prioritize supply chain initiatives is by identifying bottlenecks and inefficiencies. For example, at my previous company, we used data analytics to discover that our inventory levels were too high. This led to increased storage costs and slower turnover rates. By addressing this issue, we were able to reduce costs and improve our bottom line.

Predicting Demand and Optimizing Inventory

Data analytics can also help predict demand and optimize inventory levels. By analyzing historical sales data and market trends, companies can forecast future demand more accurately. This allows them to adjust their inventory levels accordingly, reducing the risk of stockouts or overstocking. In my experience, implementing a data-driven demand forecasting system helped us reduce our inventory holding costs by 20%.

Enhancing Customer Experience

Another critical aspect of supply chain management is customer experience. Data analytics can help identify areas where customer satisfaction can be improved. For instance, by analyzing customer feedback and delivery times, companies can identify and address issues that lead to delays or dissatisfaction. Personally, I've seen how data-driven insights can help streamline the order fulfillment process, resulting in faster delivery times and happier customers.

Continuous Improvement and Adaptation

Data analytics enables continuous improvement and adaptation in supply chain management. By regularly monitoring and analyzing key performance indicators (KPIs), companies can quickly identify and respond to changes in the market or their operations. This agility is crucial in today's fast-paced business environment. I believe that embracing data analytics is not just a choice, but a necessity for companies that want to stay competitive and thrive.

9. How do you communicate the importance of supply chain initiatives to stakeholders?

When communicating the importance of supply chain initiatives to stakeholders, I focus on three key areas.

Highlighting Business Impact

I start by clearly explaining how the initiative will benefit the company's bottom line. For example, when I led a project to optimize our warehouse layout, I emphasized the potential cost savings and efficiency gains.

By quantifying the expected results, stakeholders can easily grasp the value of the project.

Addressing Pain Points

Next, I identify the specific challenges or pain points that the initiative will address. In one case, our suppliers were consistently missing delivery deadlines, causing production delays.

I proposed implementing a supplier performance management system and outlined how it would improve on-time delivery rates.

Engaging Stakeholders

Finally, I actively involve stakeholders throughout the process to gain their buy-in and support. I schedule regular updates, solicit their feedback, and address any concerns they may have.

By making them feel like part of the team, they become invested in the initiative's success.

In summary, by highlighting business impact, addressing pain points, and engaging stakeholders, I effectively communicate the importance of supply chain initiatives and secure the necessary support for successful implementation.

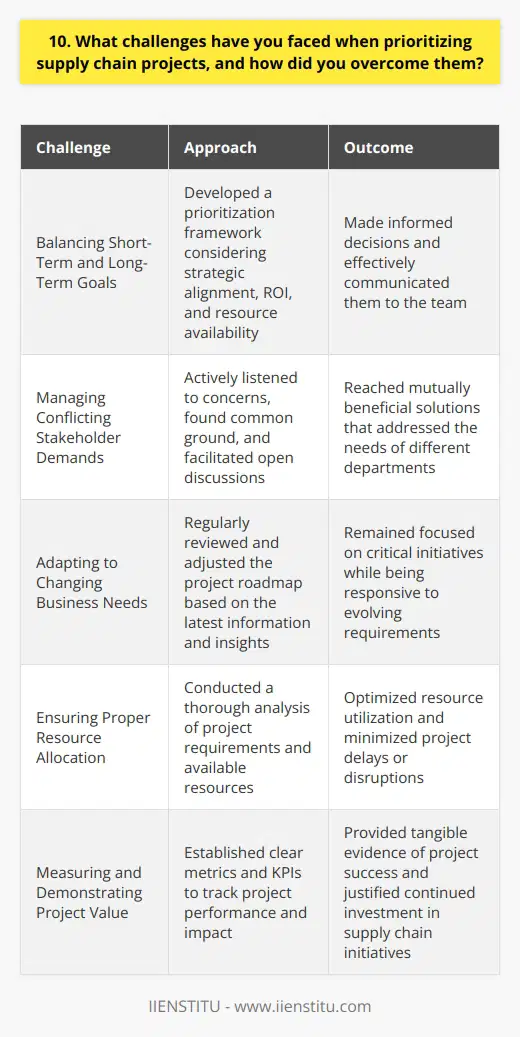

10. What challenges have you faced when prioritizing supply chain projects, and how did you overcome them?

Throughout my career, I've encountered various challenges when prioritizing supply chain projects. One significant challenge was balancing short-term and long-term goals.

Balancing Short-Term and Long-Term Goals

I had to carefully assess the urgency and impact of each project to determine which ones deserved immediate attention. This required close collaboration with stakeholders to understand their needs and expectations.

To overcome this challenge, I developed a prioritization framework that considered factors such as strategic alignment, ROI, and resource availability. This helped me make informed decisions and communicate them effectively to the team.

Managing Conflicting Stakeholder Demands

Another challenge was managing conflicting demands from different stakeholders. Each department had its own priorities and deadlines.

I addressed this by actively listening to their concerns and finding common ground. I facilitated open discussions to understand their perspectives and worked towards mutually beneficial solutions.

Adapting to Changing Business Needs

The dynamic nature of the business environment meant that priorities could shift unexpectedly. I had to be agile and adaptable.

I regularly reviewed and adjusted the project roadmap based on the latest information and insights. This ensured that we remained focused on the most critical initiatives while being responsive to changing needs.

By proactively addressing these challenges, I was able to successfully prioritize and deliver high-impact supply chain projects. It required a combination of strategic thinking, effective communication, and adaptability.

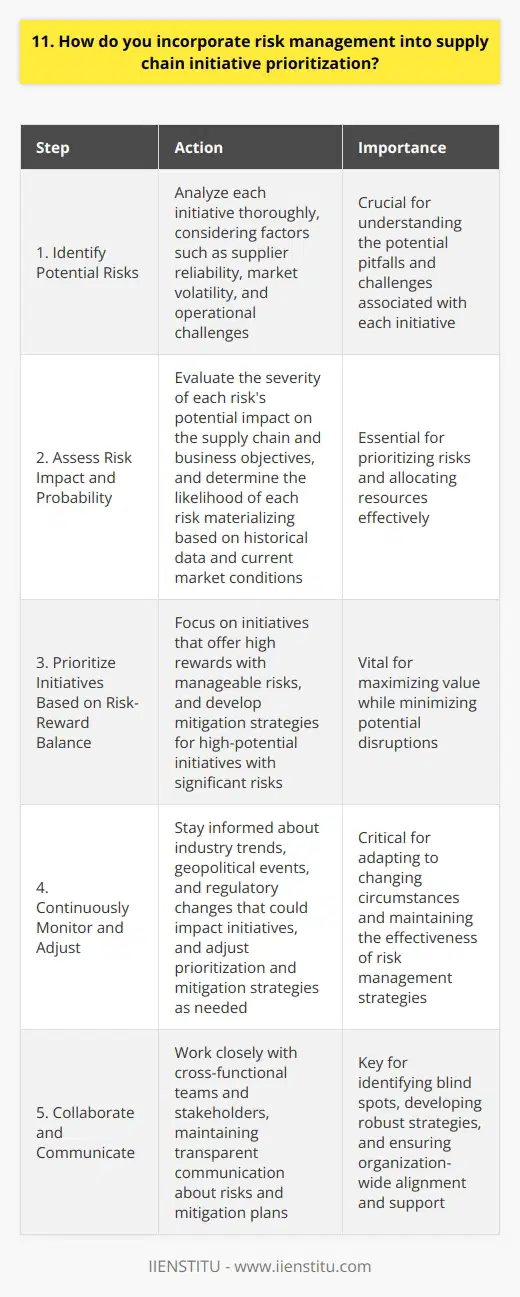

11. How do you incorporate risk management into supply chain initiative prioritization?

When incorporating risk management into supply chain initiative prioritization, I always start by identifying potential risks. This involves analyzing each initiative thoroughly and considering what could go wrong. I look at factors such as supplier reliability, market volatility, and operational challenges.

Assessing Risk Impact and Probability

Once I've identified the risks, I assess their potential impact and probability of occurrence. I consider how severely each risk could affect our supply chain and business objectives. Additionally, I evaluate the likelihood of each risk materializing based on historical data and current market conditions.

Prioritizing Initiatives Based on Risk-Reward Balance

With a clear understanding of the risks, I prioritize initiatives based on their risk-reward balance. I focus on initiatives that offer high rewards with manageable risks. If an initiative has significant potential but also high risk, I develop mitigation strategies before proceeding.

Continuous Monitoring and Adjustment

Risk management is an ongoing process, so I continuously monitor the supply chain landscape for emerging risks. I stay informed about industry trends, geopolitical events, and regulatory changes that could impact our initiatives. If necessary, I adjust our prioritization and mitigation strategies to adapt to changing circumstances.

Collaboration and Communication

Throughout the risk management process, I collaborate closely with cross-functional teams and stakeholders. I believe in transparent communication about risks and mitigation plans. By involving diverse perspectives, we can identify blind spots and develop more robust strategies.

In my experience, proactive risk management is essential for successful supply chain initiatives. By carefully analyzing risks, prioritizing based on risk-reward balance, and continuously monitoring and adapting, we can maximize value while minimizing potential disruptions.

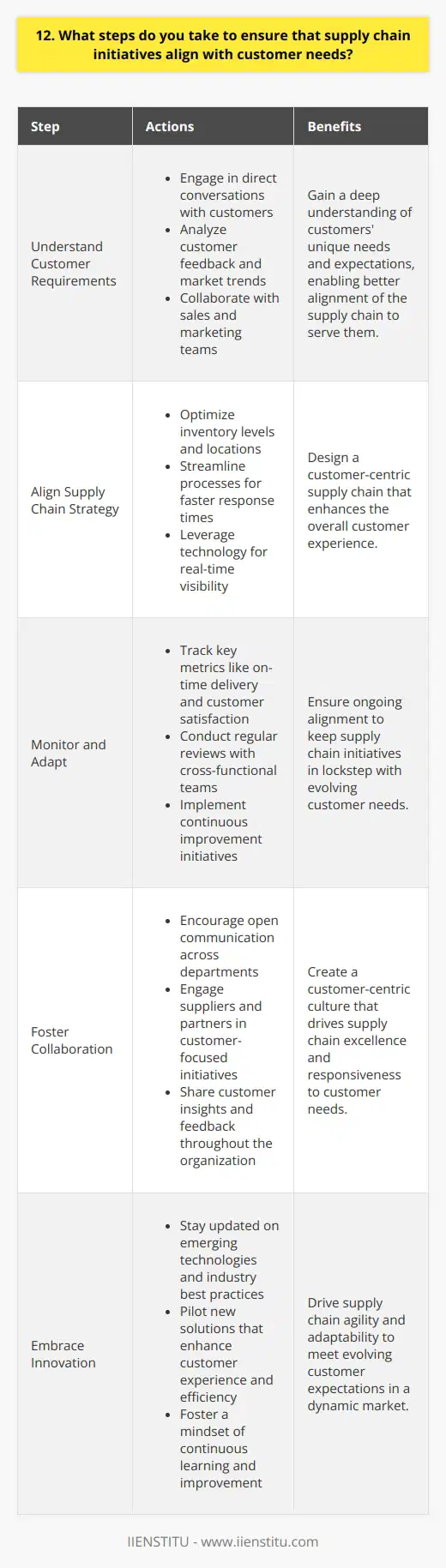

12. What steps do you take to ensure that supply chain initiatives align with customer needs?

To ensure that supply chain initiatives align with customer needs, I take several important steps:

Understand Customer Requirements

I start by gaining a deep understanding of our customers' unique needs and expectations. This involves:

By putting myself in our customers' shoes, I can better align our supply chain to serve them.

Align Supply Chain Strategy

Next, I work to sync our supply chain strategy with the insights gathered about customer requirements. Some key considerations:

I strive to design a customer-centric supply chain that enhances the overall customer experience.

Monitor and Adapt

Customer needs evolve, so I continuously monitor supply chain performance and adapt as needed. This means:

I believe ongoing alignment is critical to keep supply chain initiatives in lockstep with customer needs.

13. How do you foster collaboration among different departments when prioritizing supply chain projects?

I believe that fostering collaboration among different departments is crucial when prioritizing supply chain projects. In my experience, effective communication is key to ensuring that all stakeholders are on the same page and working towards a common goal.

Building Relationships

I make an effort to build strong relationships with colleagues from other departments. This involves taking the time to understand their roles, responsibilities, and priorities. By establishing trust and rapport, it becomes easier to collaborate effectively when projects arise.

Regular Cross-Functional Meetings

I have found that regular cross-functional meetings are essential for aligning priorities and fostering collaboration. These meetings provide an opportunity for representatives from different departments to share updates, discuss challenges, and brainstorm solutions together.

Clearly Defined Goals and Objectives

When prioritizing supply chain projects, I work with stakeholders to clearly define goals and objectives. This helps ensure that everyone understands the desired outcomes and can contribute effectively towards achieving them.

Encouraging Open Communication

I believe in creating an environment that encourages open communication and feedback. I actively listen to input from colleagues and make sure that everyone feels heard and valued. This helps build trust and fosters a collaborative spirit among team members.

By taking a proactive approach to building relationships, facilitating regular communication, setting clear goals, and encouraging openness, I have been successful in fostering collaboration among different departments when prioritizing supply chain projects. It's an ongoing process that requires effort and commitment, but the results are well worth it.

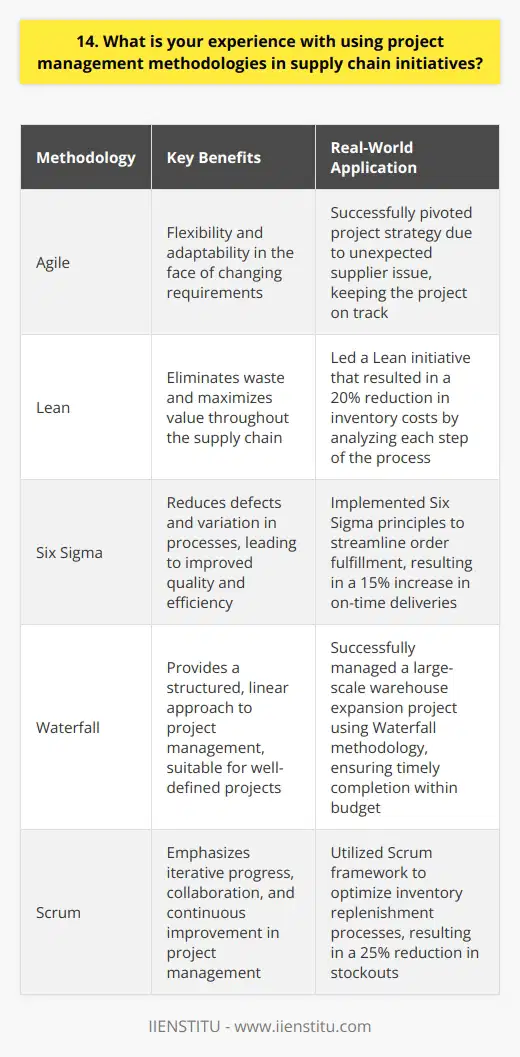

14. What is your experience with using project management methodologies in supply chain initiatives?

Throughout my career, I have successfully applied various project management methodologies to streamline supply chain initiatives. By leveraging tools like Agile and Lean, I have consistently improved efficiency and reduced waste.

Agile Methodology

I find Agile particularly effective for managing complex supply chain projects. It allows for flexibility and adaptability in the face of changing requirements. I recall one project where we needed to quickly adjust our strategy due to an unexpected supplier issue. By using Agile principles, we were able to pivot smoothly and keep the project on track.

Lean Methodology

Lean methodology is another powerful tool I frequently use. It focuses on eliminating waste and maximizing value throughout the supply chain. In my previous role, I led a Lean initiative that resulted in a 20% reduction in inventory costs. We achieved this by carefully analyzing each step of the process and identifying areas for improvement.

Communication and Collaboration

Regardless of the specific methodology, I believe effective communication and collaboration are essential for success. I always strive to foster a team environment where everyone feels heard and valued. This leads to better problem-solving and more innovative solutions.

In summary, I have extensive experience applying proven project management methodologies to drive supply chain excellence. I am confident that my skills and strategic approach would be a valuable asset to your organization.

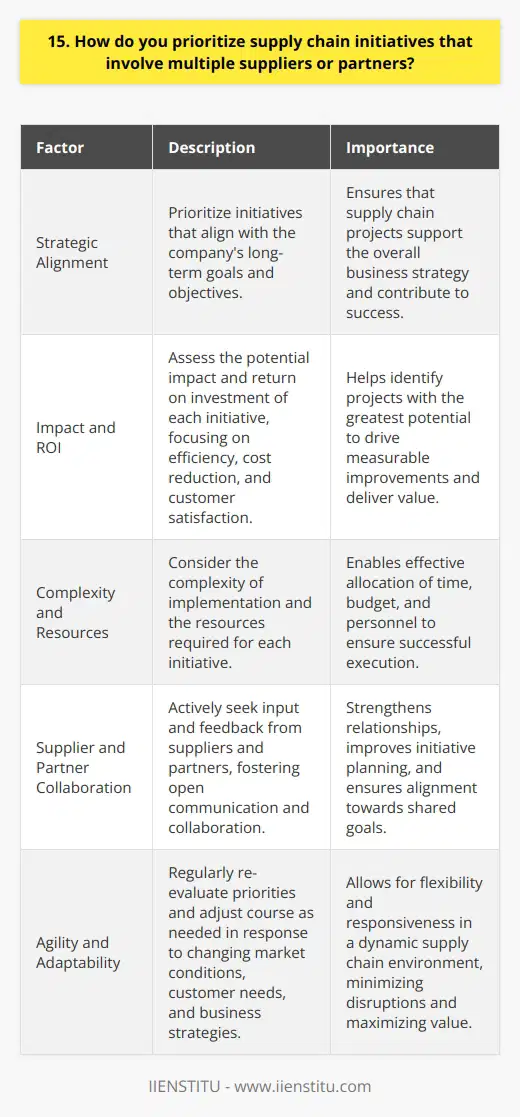

15. How do you prioritize supply chain initiatives that involve multiple suppliers or partners?

When prioritizing supply chain initiatives involving multiple suppliers or partners, I focus on a few key factors. First, I consider the strategic importance of each initiative to our overall business objectives. Initiatives that align with our long-term goals take priority.

Next, I assess the potential impact and ROI of each initiative. Projects with the greatest potential to improve efficiency, reduce costs, or increase customer satisfaction rise to the top. I also look at the complexity and resources required for implementation.

Balancing Priorities and Partnerships

It's important to strike a balance between internal priorities and maintaining strong supplier and partner relationships. Open communication is critical. I make sure to clearly explain our priorities and decision-making process to external stakeholders.

At the same time, I actively seek input and feedback from suppliers and partners. Their insights can help refine initiative planning and execution. Collaborating closely ensures everyone is on the same page and working towards shared goals.

Staying Agile and Adaptable

In my experience, flexibility is key when juggling multiple supply chain projects. Market conditions, customer needs, and business strategies can shift quickly. I regularly re-evaluate priorities and adjust course as needed to stay responsive.

For example, at my previous company, an unexpected material shortage required us to rapidly pivot sourcing for a high-priority product launch. By staying agile and working closely with backup suppliers, we minimized delays and met the launch timeline. Proactive risk management and contingency planning are now integral to how I approach supply chain initiatives.

Ultimately, prioritizing supply chain projects is a balancing act that requires strategic alignment, Impact assessment, stakeholder collaboration, and adaptability. My goal is always to maximize value for the business while strengthening key partnerships.

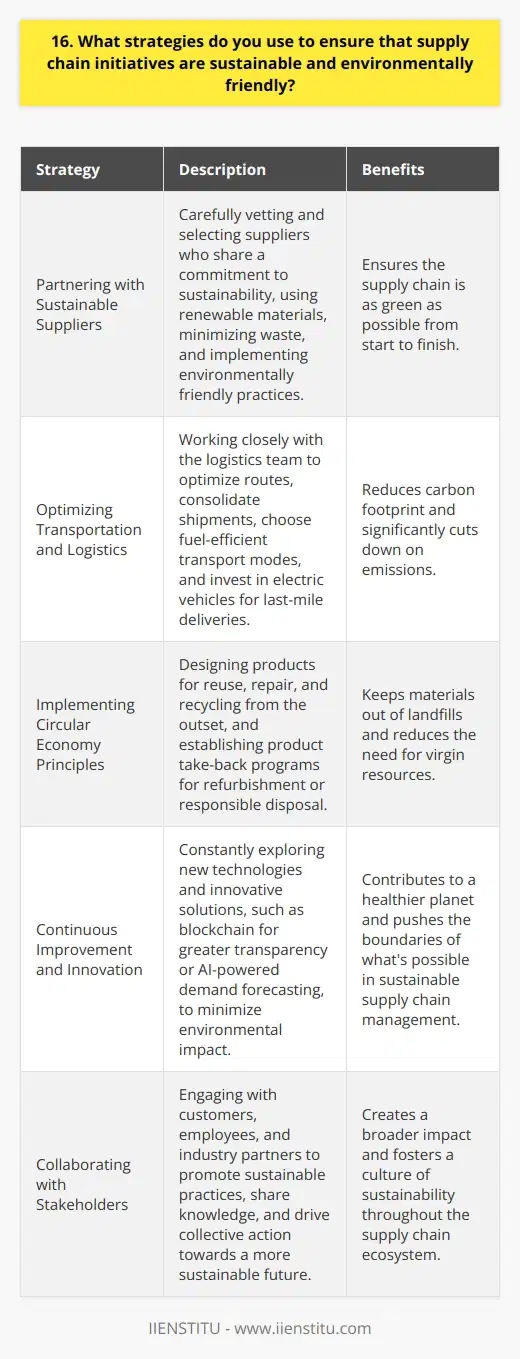

16. What strategies do you use to ensure that supply chain initiatives are sustainable and environmentally friendly?

As a supply chain professional, I believe in implementing sustainable and eco-friendly practices throughout the entire process. Here are some strategies I use to ensure our initiatives are green and responsible:

Partnering with Sustainable Suppliers

I carefully vet and select suppliers who share our commitment to sustainability. We look for partners that use renewable materials, minimize waste, and have a proven track record of environmentally friendly practices. By aligning with like-minded suppliers, we can ensure our supply chain is as green as possible from start to finish.

Optimizing Transportation and Logistics

Efficient transportation is key to reducing our carbon footprint. I work closely with our logistics team to optimize routes, consolidate shipments, and choose the most fuel-efficient modes of transport. We've also invested in electric vehicles for last-mile deliveries in urban areas, which has significantly cut down on emissions.

Implementing Circular Economy Principles

Whenever possible, I strive to incorporate circular economy principles into our supply chain. This means designing products for reuse, repair, and recycling from the outset. We've had great success with our product take-back program, which allows customers to return used items for refurbishment or responsible disposal. Not only does this keep materials out of landfills, but it also reduces the need for virgin resources.

Continuous Improvement and Innovation

Sustainability is an ongoing journey, not a destination. I'm always on the lookout for new technologies and innovative solutions that can help us further minimize our environmental impact. Whether it's exploring blockchain for greater transparency or piloting AI-powered demand forecasting to reduce overproduction, I believe in constantly pushing the boundaries of what's possible.

At the end of the day, my goal is to create a supply chain that not only meets our business objectives but also contributes to a healthier planet. It's a challenge I'm deeply passionate about, and I'm excited to keep working towards a more sustainable future.

17. How do you balance the need for innovation with the need for efficiency in supply chain projects?

As a supply chain professional, I believe that innovation and efficiency are both critical factors in successful projects. Finding the right balance between these two elements is key to driving continuous improvement and staying competitive in today's fast-paced business environment.

Embrace Innovation to Drive Growth

In my experience, embracing innovation is essential for unlocking new opportunities and driving growth. By constantly seeking out new technologies, processes, and ideas, we can find creative solutions to complex supply chain challenges. This might involve exploring cutting-edge automation tools, implementing data analytics to uncover insights, or collaborating with partners to develop novel approaches.

Prioritize Efficiency to Optimize Results

At the same time, I recognize that efficiency is crucial for maximizing results and minimizing waste. By streamlining workflows, eliminating redundancies, and optimizing resource allocation, we can ensure that our supply chain operates at peak performance. This requires a keen eye for detail, a willingness to question the status quo, and a commitment to continuous improvement.

Find the Right Balance for Each Project

Ultimately, the key to balancing innovation and efficiency lies in tailoring our approach to each specific project. By carefully assessing the unique needs, constraints, and opportunities of each initiative, we can determine the optimal mix of creativity and pragmatism. This might mean prioritizing efficiency in some cases, while placing a greater emphasis on innovation in others.

Throughout my career, I've learned that the most successful supply chain projects are those that strike a harmonious balance between these two critical factors. By embracing innovation while prioritizing efficiency, we can drive meaningful results and create lasting value for our organizations.

18. What role does technology play in prioritizing and executing supply chain initiatives?

Technology plays a crucial role in prioritizing and executing supply chain initiatives in today's fast-paced business environment. It enables companies to streamline processes, improve efficiency, and make data-driven decisions.

Enhancing Visibility and Transparency

Advanced supply chain management software provides real-time visibility into inventory levels, shipment statuses, and demand forecasts. This transparency allows businesses to identify potential bottlenecks and take proactive measures to mitigate risks.

For example, when I worked at a multinational corporation, we implemented a cloud-based supply chain platform. It gave us a comprehensive view of our entire network, from suppliers to customers. This visibility enabled us to optimize inventory levels and reduce stockouts, ultimately improving customer satisfaction.

Enabling Data-Driven Decision Making

Technology empowers supply chain professionals to make informed decisions based on data rather than gut instincts. By leveraging analytics and machine learning algorithms, companies can identify patterns, predict demand, and optimize routes.

I remember a project where we used predictive analytics to forecast customer demand for a specific product line. The insights gained from the analysis helped us adjust our production and distribution strategies, resulting in significant cost savings and improved responsiveness to market trends.

Automating Repetitive Tasks

Robotic process automation (RPA) and artificial intelligence (AI) technologies can automate repetitive and time-consuming tasks in the supply chain. This automation frees up human resources to focus on strategic initiatives and value-added activities.

In my previous role, we implemented RPA to automate invoice processing and data entry. The bots worked tirelessly 24/7, eliminating human errors and reducing processing times from days to mere hours. This automation allowed our team to focus on more complex tasks, such as supplier negotiations and risk management.

Facilitating Collaboration and Integration

Technology enables seamless collaboration and integration among supply chain partners. By leveraging cloud-based platforms and blockchain technology, companies can share information securely, track goods in real-time, and ensure transparency throughout the supply chain.

I had the opportunity to work on a blockchain pilot project aimed at improving traceability in the food industry. By digitizing the supply chain and creating an immutable record of each transaction, we enhanced food safety, reduced waste, and built trust among stakeholders.

In conclusion, technology is a game-changer in prioritizing and executing supply chain initiatives. It enhances visibility, enables data-driven decision making, automates repetitive tasks, and facilitates collaboration. As supply chain professionals, embracing technology is no longer an option but a necessity to stay competitive in today's dynamic business landscape.

19. How do you measure the ROI of supply chain initiatives, and how does this influence prioritization?

Measuring the ROI of supply chain initiatives is crucial for effective prioritization and resource allocation. I always start by clearly defining the objectives and key performance indicators (KPIs) for each initiative.

Aligning Initiatives with Business Goals

It's essential to ensure that supply chain initiatives align with the overall business strategy and goals. I collaborate closely with stakeholders to understand their priorities and expectations.

Quantifying Financial Impact

To calculate ROI, I focus on quantifying the financial impact of each initiative. This includes cost savings, revenue growth, and working capital improvements. I use historical data and realistic projections to estimate the potential benefits.

Considering Intangible Benefits

While financial metrics are important, I also consider intangible benefits such as increased customer satisfaction, enhanced brand reputation, and improved supplier relationships. These factors can have a significant long-term impact on the business.

Prioritizing Initiatives

When prioritizing initiatives, I use a combination of ROI analysis and strategic alignment. Initiatives with higher ROI and stronger alignment with business goals typically receive higher priority.

Balancing Short-term and Long-term Benefits

It's important to strike a balance between short-term gains and long-term value creation. I assess the timeline and sustainability of each initiative's benefits to ensure a balanced portfolio.

Continuous Monitoring and Adjustment

Measuring ROI is not a one-time exercise. I establish a framework for continuous monitoring and adjustment. Regular reviews help identify deviations from expected outcomes and enable timely course corrections.

By following this approach, I can effectively measure the ROI of supply chain initiatives and make informed prioritization decisions that drive business success.

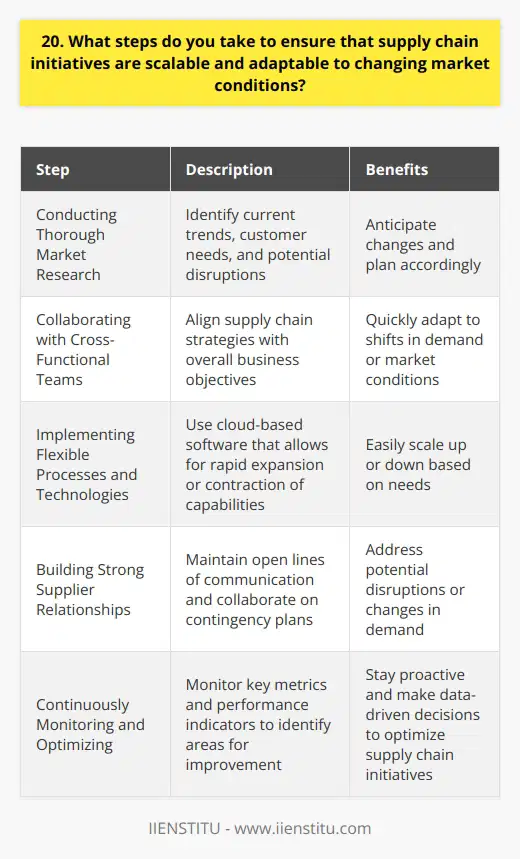

20. What steps do you take to ensure that supply chain initiatives are scalable and adaptable to changing market conditions?

To ensure that supply chain initiatives are scalable and adaptable to changing market conditions, I take several key steps.

Conducting Thorough Market Research

I always start by conducting in-depth market research to identify current trends, customer needs, and potential disruptions. This helps me anticipate changes and plan accordingly.

Collaborating with Cross-Functional Teams

I work closely with cross-functional teams, including sales, marketing, and product development, to align supply chain strategies with overall business objectives. Regular communication ensures that we can quickly adapt to shifts in demand or market conditions.

Implementing Flexible Processes and Technologies

I focus on implementing flexible processes and technologies that can easily scale up or down based on needs. For example, I might use cloud-based software that allows for rapid expansion or contraction of capabilities.

Building Strong Supplier Relationships

Building strong relationships with suppliers is crucial for adaptability. I maintain open lines of communication and collaborate on contingency plans to address potential disruptions or changes in demand.

Continuously Monitoring and Optimizing

Finally, I continuously monitor key metrics and performance indicators to identify areas for improvement. By staying proactive and making data-driven decisions, I can optimize supply chain initiatives for scalability and adaptability.

In my experience, taking these steps has allowed me to successfully navigate complex supply chain challenges and drive results.

21. How do you prioritize supply chain initiatives that involve emerging technologies or trends?

When prioritizing supply chain initiatives involving emerging technologies or trends, I focus on a few key factors. First, I consider the potential impact on our bottom line. Will this technology help us reduce costs, increase efficiency, or open up new revenue streams? Second, I look at the feasibility of implementation. Do we have the resources and expertise to successfully adopt this technology, or will it require significant investments in time and money?

Balancing Risk and Reward

It's also important to balance the risks and rewards. Some emerging technologies may offer great potential benefits but come with a high degree of uncertainty. In these cases, I might advocate for a more cautious approach, such as running a pilot project before committing to a full-scale rollout. On the other hand, if a technology is well-proven and widely adopted in our industry, I may push for a more aggressive implementation timeline to stay ahead of the competition.

Staying Aligned with Business Goals

Ultimately, any supply chain initiative must align with our overall business strategy and goals. I strive to maintain a big-picture perspective and prioritize projects that will move us closer to our long-term objectives. This might mean deprioritizing a flashy new technology in favor of a more mundane but essential process improvement.

Collaborating with Stakeholders

Finally, I believe in the importance of collaboration and communication when prioritizing initiatives. I engage with stakeholders from across the organization to gather input and build consensus. By fostering a culture of teamwork and transparency, we can make better decisions and execute more effectively on our supply chain strategies.

22. What is your approach to change management when implementing supply chain projects?

When implementing supply chain projects, I focus on clear communication and collaboration to ensure a smooth transition. I work closely with all stakeholders to understand their needs and concerns.

Identifying Key Stakeholders

I start by identifying the key stakeholders who will be impacted by the change. This includes suppliers, logistics partners, and internal teams. I engage them early in the process to gather their input and feedback.

Developing a Comprehensive Plan

Next, I develop a comprehensive plan that outlines the goals, timeline, and resources needed for the project. I break it down into manageable phases and milestones. I also build in contingencies for potential roadblocks or delays.

Communicating Effectively

Throughout the project, I prioritize clear and frequent communication. I hold regular meetings to keep everyone informed and aligned. I listen actively to feedback and address any concerns promptly. I also celebrate successes along the way to maintain momentum and enthusiasm.

Managing Resistance to Change

When dealing with resistance to change, I focus on understanding the underlying reasons. Is it fear of the unknown? Concerns about additional workload? I work with individuals to address their specific concerns and find mutually beneficial solutions.

Providing Training and Support

I also ensure that all stakeholders have the necessary training and support to adapt to the changes. This might include workshops, documentation, or one-on-one coaching. I'm always available to answer questions and provide guidance.

Monitoring and Adjusting

Finally, I closely monitor the implementation and remain flexible to adjust the plan as needed. I gather data and feedback to measure progress and identify areas for improvement. I'm not afraid to course-correct if something isn't working as expected.

By following this approach, I've successfully implemented several complex supply chain projects. I'm confident I can bring that same level of leadership and expertise to this role.

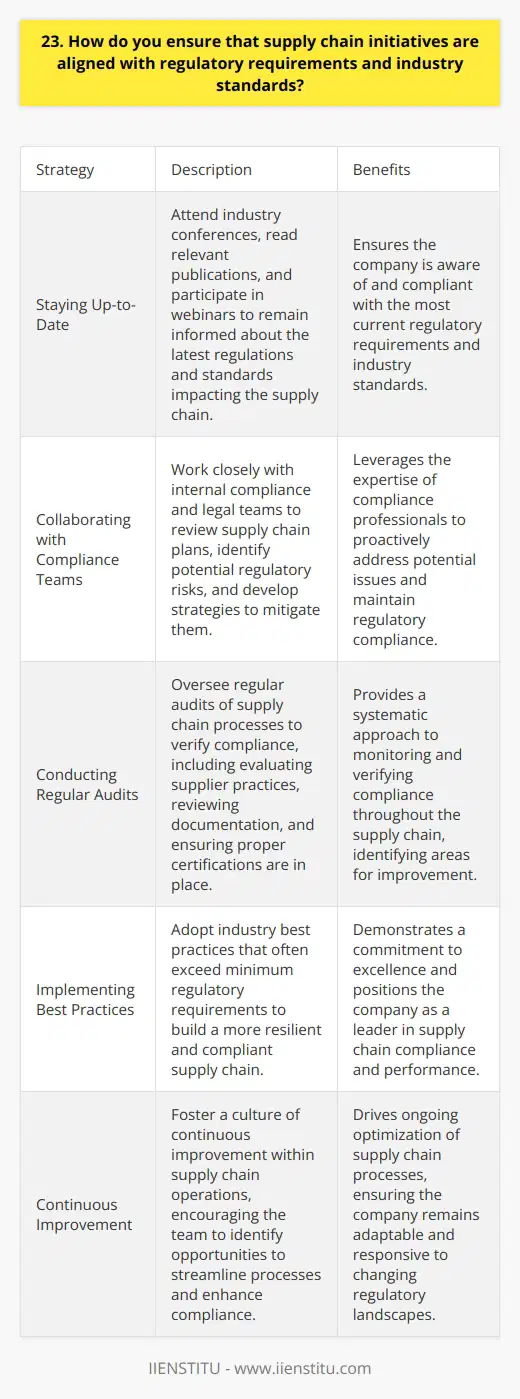

23. How do you ensure that supply chain initiatives are aligned with regulatory requirements and industry standards?

To ensure supply chain initiatives align with regulatory requirements and industry standards, I follow a comprehensive approach. This involves:

Staying Up-to-Date

I make it a priority to stay current on the latest regulations and standards impacting our supply chain. I attend industry conferences, read relevant publications, and participate in webinars to remain informed.

Collaborating with Compliance Teams

I work closely with our internal compliance and legal teams to review supply chain plans. Together, we identify any potential regulatory risks and develop strategies to mitigate them.

Conducting Regular Audits

I oversee regular audits of our supply chain processes to verify compliance. This includes evaluating supplier practices, reviewing documentation, and ensuring proper certifications are in place.

Implementing Best Practices

I strive to implement industry best practices that often exceed minimum regulatory requirements. By adopting these proactive measures, we build a more resilient and compliant supply chain.

Continuous Improvement

I believe in fostering a culture of continuous improvement within our supply chain operations. I encourage my team to identify opportunities to streamline processes and enhance compliance.

In my previous role at ABC Company, I successfully led a supply chain transformation project. By aligning our initiatives with new industry standards, we improved efficiency by 20% while ensuring full regulatory compliance.

I'm passionate about driving supply chain excellence while upholding the highest standards of compliance. It's a challenging but rewarding aspect of my work that I truly enjoy.

24. What role does employee training and development play in the success of supply chain initiatives?

Employee training and development play a crucial role in the success of supply chain initiatives. By investing in the skills and knowledge of their workforce, companies can improve efficiency, reduce errors, and foster innovation.

Benefits of Employee Training and Development

When employees are well-trained, they are better equipped to handle the complexities of the supply chain. They can identify potential issues before they become major problems and develop creative solutions to overcome challenges.

I remember when I first started working in supply chain management. I felt overwhelmed by all the moving parts and the constant pressure to optimize processes. But thanks to the comprehensive training program provided by my company, I quickly gained the confidence and expertise needed to excel in my role.

Continuous Improvement Through Learning

The supply chain landscape is constantly evolving, with new technologies and best practices emerging all the time. That's why it's essential for companies to prioritize ongoing training and development for their employees.

In my experience, the most successful supply chain initiatives are those that embrace a culture of continuous learning. By encouraging employees to stay up-to-date with the latest trends and techniques, companies can stay ahead of the curve and maintain a competitive edge.

Empowering Employees to Drive Change

Another key benefit of employee training and development is that it empowers individuals to take ownership of their work and drive positive change within the organization.

When employees feel valued and supported in their professional growth, they are more likely to be engaged and motivated to contribute their best work. This can lead to increased productivity, better collaboration, and more successful supply chain initiatives overall.

The Bottom Line

At the end of the day, investing in employee training and development is not just a nice-to-have – it's a must-have for any company that wants to succeed in today's fast-paced and ever-changing business environment.

So if you're a candidate interviewing for a supply chain role, be sure to highlight your commitment to continuous learning and your appreciation for the value of employee development. It could be the key to landing your dream job and making a real impact in your field.

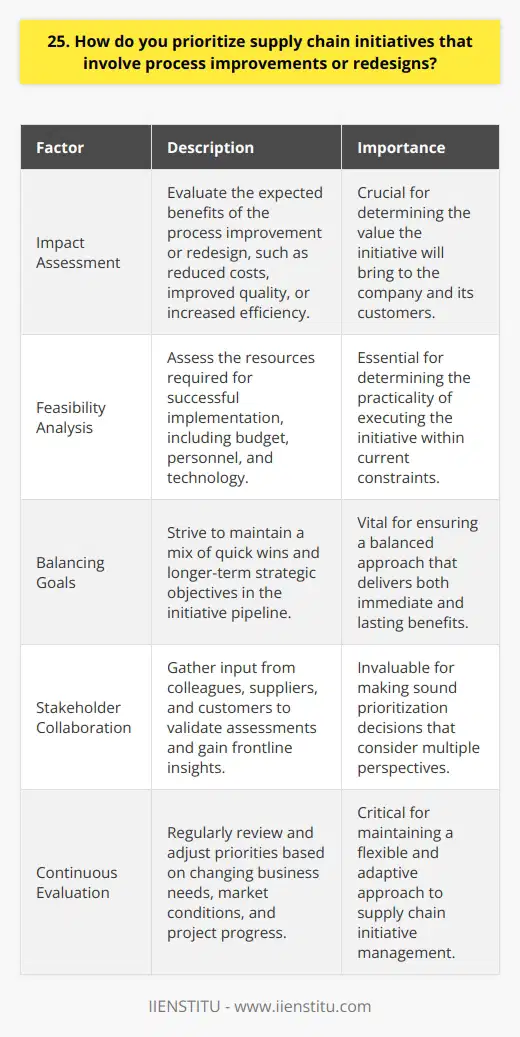

25. How do you prioritize supply chain initiatives that involve process improvements or redesigns?

When prioritizing supply chain initiatives, I focus on the potential impact and feasibility of each project. I consider how much value the initiative will bring to the company and our customers.

Assessing Impact

First, I evaluate the expected benefits of the process improvement or redesign. Will it significantly reduce costs, improve quality, or increase efficiency? I look for initiatives that will have a substantial and lasting positive effect on our operations.

Analyzing Feasibility

Next, I assess the feasibility of successfully implementing the initiative. I consider the resources required, such as budget, personnel, and technology. If an initiative seems promising but would be very difficult to execute with our current constraints, I may deprioritize it.

Balancing Short-Term and Long-Term Goals

I strive to balance quick wins with longer-term strategic objectives. Some process improvements can be rapidly deployed for immediate benefits, while more extensive redesigns may take time to yield results. I aim to always have a mix of both in our initiative pipeline.

Collaborating with Stakeholders

Finally, I gather input from colleagues, suppliers, and customers to validate my assessments. Their frontline insights are invaluable for making sound prioritization decisions. By considering multiple perspectives, I can move forward with the initiatives that will be most advantageous for all stakeholders.

26. What strategies do you use to mitigate supply chain disruptions and ensure business continuity?

When it comes to mitigating supply chain disruptions, I believe in being proactive and prepared. I always keep a close eye on market trends and potential risks that could impact our suppliers. By staying informed, I can anticipate issues before they become major problems.

Diversifying Suppliers

One key strategy I use is diversifying our supplier base. I never rely on a single source for critical components or materials. Instead, I cultivate relationships with multiple suppliers in different geographic locations. This way, if one supplier faces an issue, we have alternative options to keep production running smoothly.

Building Strong Partnerships

I also prioritize building strong, long-term partnerships with our suppliers. I believe in open communication and collaboration. By working closely with our suppliers, we can develop contingency plans and alternative sourcing strategies together. These strong relationships have helped us navigate challenges in the past.

Inventory Management

Another important aspect is inventory management. I always ensure we have an appropriate level of safety stock for critical components. This buffer helps us ride out short-term disruptions without impacting our production timelines. I also regularly review our inventory levels and adjust as needed based on demand forecasts and market conditions.

Agility and Flexibility

Finally, I believe in fostering an agile and flexible supply chain. I work with our team to develop processes that allow us to quickly adapt to changes. Whether it's finding alternative transportation routes or rapidly onboarding new suppliers, we're always ready to pivot when needed. This agility has been crucial in maintaining business continuity during uncertain times.

At the end of the day, mitigating supply chain disruptions is all about being proactive, prepared, and adaptable. By diversifying our suppliers, building strong partnerships, managing inventory effectively, and staying agile, I'm confident in our ability to keep our business running smoothly no matter what challenges come our way.

27. How do you incorporate customer feedback and market trends into supply chain initiative prioritization?

As a supply chain professional, I believe that incorporating customer feedback and market trends is crucial for prioritizing initiatives. By actively listening to our customers and staying attuned to industry developments, we can make informed decisions.

Gathering Customer Insights

I always strive to establish open lines of communication with our customers. Whether it's through surveys, focus groups, or one-on-one conversations, I aim to understand their pain points and preferences. These insights help me identify areas where we can improve our supply chain processes to better serve their needs.

Staying Ahead of Market Trends

Keeping a pulse on market trends is equally important. I regularly attend industry conferences, read trade publications, and engage with peers to stay informed about emerging technologies, sustainability practices, and shifting consumer behaviors. By anticipating these trends, we can adapt our supply chain strategies accordingly.

Prioritizing Initiatives

When it comes to prioritizing initiatives, I take a data-driven approach. I analyze customer feedback alongside market insights to identify the most pressing opportunities for improvement. I also consider factors such as feasibility, potential impact, and alignment with our overall business objectives.

Collaborating with Cross-Functional Teams

Implementing supply chain initiatives often requires collaboration across different departments. I make it a point to involve stakeholders from sales, marketing, and operations in the prioritization process. Their input helps ensure that we're focusing on initiatives that will deliver the greatest value to our customers and the business as a whole.

Measuring Success

Finally, I believe in the importance of measuring the success of our supply chain initiatives. I set clear key performance indicators (KPIs) and track progress over time. This allows us to continuously refine our approach and make data-driven decisions for future prioritization.

By incorporating customer feedback, staying attuned to market trends, and collaborating with cross-functional teams, I'm confident in my ability to prioritize supply chain initiatives that drive customer satisfaction and business growth.

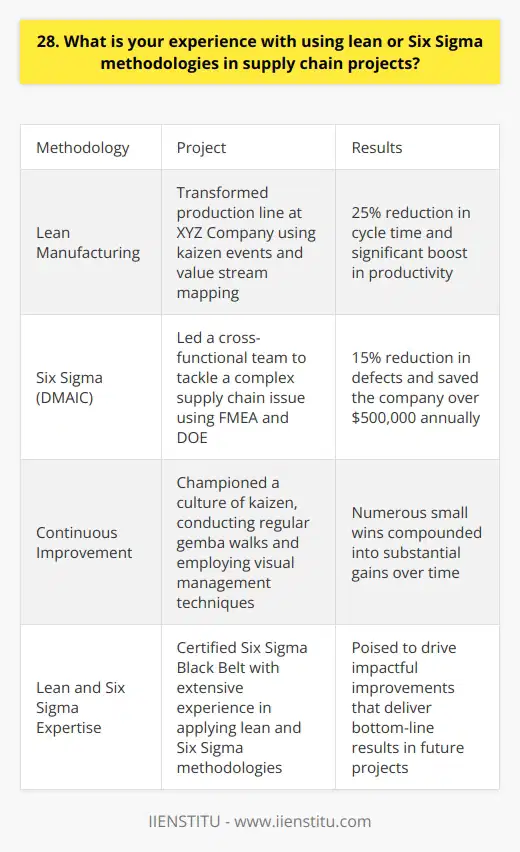

28. What is your experience with using lean or Six Sigma methodologies in supply chain projects?

Throughout my career, I have actively incorporated lean and Six Sigma methodologies into various supply chain projects. These powerful tools have enabled me to streamline processes, reduce waste, and drive continuous improvement.

Lean Manufacturing Experience

In my previous role at XYZ Company, I spearheaded a lean manufacturing initiative that transformed our production line. By implementing kaizen events and value stream mapping, we identified and eliminated non-value-added activities. This resulted in a 25% reduction in cycle time and a significant boost in productivity.

Six Sigma Black Belt Certification

I am a certified Six Sigma Black Belt, having completed extensive training in DMAIC methodology. Armed with this knowledge, I led a cross-functional team to tackle a complex supply chain issue. By applying Six Sigma tools like FMEA and DOE, we identified the root causes of the problem and implemented robust solutions. This project yielded a 15% reduction in defects and saved the company over $500,000 annually.

Continuous Improvement Mindset

I firmly believe in the power of continuous improvement and have ingrained it into my work philosophy. In my current role, I champion a culture of kaizen, encouraging my team to constantly seek out opportunities for enhancement. We conduct regular gemba walks and employ visual management techniques to identify areas for improvement. This proactive approach has led to numerous small wins that have compounded into substantial gains over time.

Lean and Six Sigma methodologies have been invaluable tools in my supply chain management toolkit. I am excited to bring this expertise to your organization and drive impactful improvements that deliver bottom-line results.

29. How do you prioritize supply chain initiatives that involve multiple business units or geographies?

When prioritizing supply chain initiatives across multiple business units or geographies, I focus on three key factors:

Strategic Alignment

I start by ensuring that the initiatives align with the overall strategic goals of the organization. By understanding how each initiative contributes to our long-term objectives, I can better prioritize them based on their potential impact and value.

For example, in my previous role, we had to decide between two competing projects. One promised short-term cost savings, while the other supported our expansion into a new market. After careful consideration, we prioritized the market expansion project as it aligned more closely with our strategic vision.

Collaboration and Communication

Effective collaboration and communication across business units and geographies are essential for successful initiative prioritization. I actively engage stakeholders from different teams to gather their insights, concerns, and dependencies.

I remember a case where we had limited resources to allocate between two initiatives. By fostering open dialogue and understanding each team's needs, we found a way to sequence the initiatives in a way that optimized resource utilization and minimized disruption.

Impact and Feasibility

Finally, I evaluate each initiative based on its potential impact and feasibility. I consider factors such as financial benefits, customer satisfaction, operational efficiency, and risk mitigation.

Simultaneously, I assess the feasibility of implementation, taking into account resource availability, time constraints, and dependencies. By striking a balance between impact and feasibility, I can prioritize initiatives that deliver the most value while being realistic about execution.

In summary, my approach to prioritizing supply chain initiatives involves aligning with strategic goals, fostering collaboration, and balancing impact with feasibility. By considering these factors holistically, I can make informed decisions that drive the best outcomes for the organization.

30. What steps do you take to continuously improve and optimize supply chain processes over time?

As a supply chain professional, I believe that continuous improvement is the key to staying competitive. Here are some of the steps I take to optimize supply chain processes:

Analyze Data and Identify Bottlenecks

I regularly dive into supply chain data to identify areas that need improvement. By analyzing metrics like lead times, inventory levels, and on-time delivery rates, I can spot bottlenecks and inefficiencies. Just last month, I discovered that our warehouse picking process was causing delays, so I implemented a new system that reduced picking times by 20%.

Collaborate with Cross-Functional Teams

Supply chain optimization isn't a solo endeavor. I actively collaborate with teams from procurement, manufacturing, logistics, and sales to gather insights and ideas. We have regular brainstorming sessions where we share best practices and develop innovative solutions. This cross-functional approach helps us tackle challenges from multiple angles and ensures everyone is aligned towards common goals.

Embrace Technology and Automation

I'm always on the lookout for new technologies that can streamline our supply chain processes. Whether it's implementing a warehouse management system, exploring IoT sensors for real-time tracking, or leveraging AI for demand forecasting, I believe in harnessing the power of technology. Last year, I spearheaded a project to automate our invoicing process, which reduced manual errors and saved countless hours of work.

Foster a Culture of Continuous Learning

I'm a firm believer in lifelong learning. I attend supply chain conferences, participate in webinars, and read industry publications to stay up-to-date with the latest trends and best practices. I also encourage my team to pursue training opportunities and share their knowledge with others. By fostering a culture of continuous learning, we can adapt to evolving market demands and drive innovation.

At the end of the day, supply chain optimization is an ongoing journey. It requires a proactive mindset, a willingness to experiment, and a commitment to continuous improvement. I'm excited to bring my passion for optimization to this role and contribute to the success of the company.