I remember the day I first stepped into the bustling world of procurement. It was my first job out of college, and I was eager to make a difference. The supply chain department was the heartbeat of the company, ensuring that everything ran smoothly from sourcing raw materials to delivering the final product. Little did I know then just how crucial effective procurement strategies were in reducing costs and boosting profitability.

Navigating the Intricacies of Procurement

Procurement isn't just about buying goods and services; it's about acquiring them at the right price, quality, and time. Over the years, I've learned that reducing procurement costs isn't just beneficial—it's essential. It's like my old mentor used to say, "Every dollar saved in procurement is a dollar added to profit." So, let's dive into some tried-and-true strategies that can help slash those costs.

Introduction

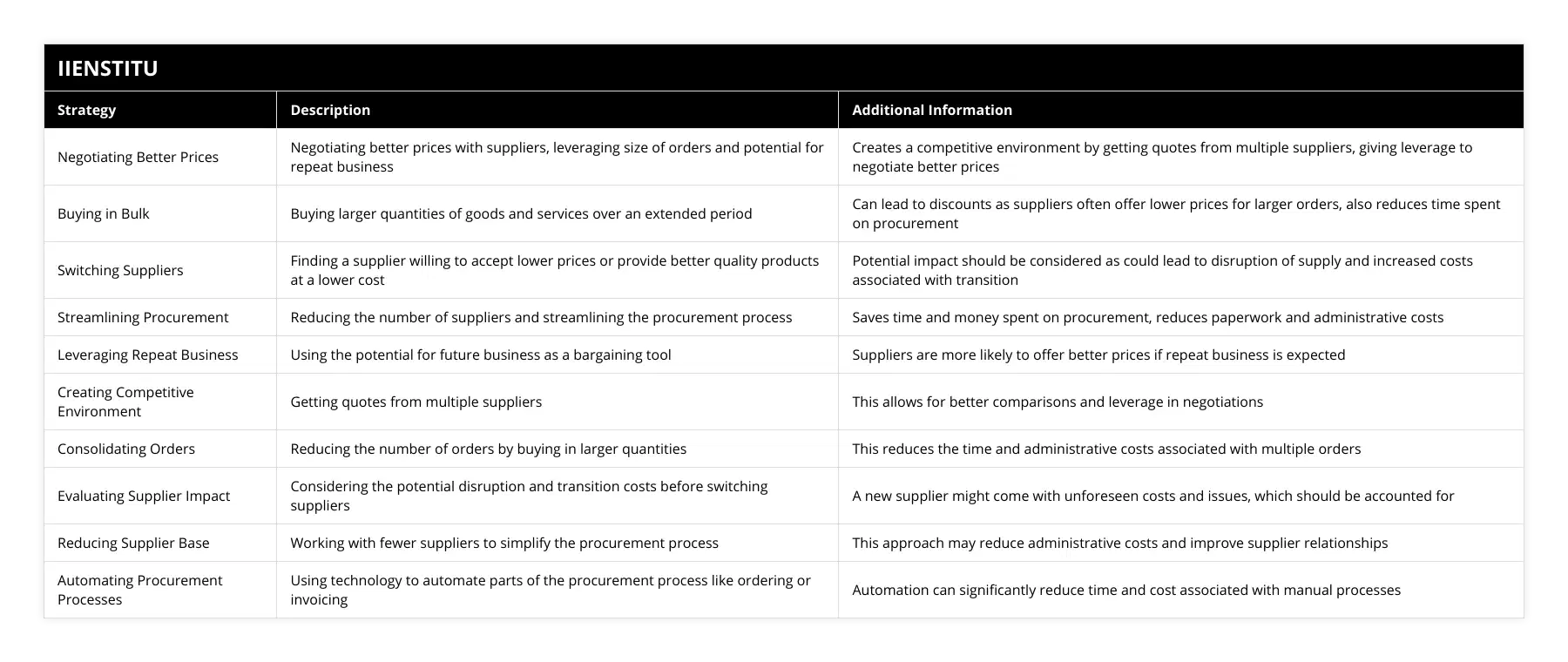

Negotiating Better Prices

Buying in Bulk

Switching Suppliers

Streamlining Procurement

Negotiating Better Prices

One of the first lessons I learned was the art of negotiation. Negotiating better prices isn't just about haggling; it's about building relationships. I recall working with a supplier who initially offered prices well above our budget. Instead of walking away, I leveraged the potential for a long-term partnership and the promise of repeat business. By the end of our discussions, not only did we secure a better price, but we also established a relationship that benefited both parties for years.

Tips for Effective Negotiation:

Do your research: Know the market rates and what competitors are offering.

Build relationships: People are more likely to offer discounts to those they trust.

Be prepared to walk away: Sometimes, the best leverage is the willingness to find alternatives.

The Power of Buying in Bulk

There's an old saying, "Buy more, save more," and in procurement, this often holds true. Buying in bulk can lead to significant discounts. I remember when we started purchasing our primary raw material in larger quantities. Not only did we receive a substantial price break, but we also reduced shipping costs. Of course, this strategy requires careful planning to avoid excess inventory, but when done right, it's a game-changer.

1- Benefits of Bulk Purchasing:

Lower unit prices

Reduced shipping and handling costs

Improved supplier relationships

Considerations:

Storage costs

Potential for obsolescence

Cash flow implications

Switching Suppliers Wisely

Sometimes, loyalty can cost you. While it's essential to maintain good relationships, switching suppliers can lead to better deals. A few years back, we conducted a thorough review of our supplier base. We discovered that some newer companies offered better quality at lower prices. By streamlining our procurement process and introducing these suppliers, we saved significantly without compromising on quality.

Steps to Switch Suppliers:

Assess current supplier performance

Research alternative suppliers

Conduct a risk assessment

Plan the transition carefully

Streamlining Procurement Processes

Efficiency is key. By streamlining procurement, we can reduce not just costs but also errors and delays. Automation played a significant role in our transformation. Implementing procurement software reduced manual tasks, minimized errors, and improved compliance. It's like turning a cluttered closet into an organized space—you save time and can find things when you need them!

A penny saved is a penny earned; reducing procurement costs is the first step to cutting supply chain costs.

Consider integrating tools that automate:

Ordering

Invoicing

Payment processing

Embracing Technology in Supply Chain Management

In today's fast-paced world, technology is indispensable. Implementing a robust supply chain management strategy can revolutionize procurement. For instance, using the critical path method project management strategy, we identified bottlenecks in our procurement timelines and addressed them proactively.

Key Technological Tools:

1- SCM Management Software: Enhances visibility across the supply chain activities.

2- Inventory Management Systems: Helps in optimizing stock levels.

3- Supplier Relationship Management Tools: Aids in maintaining healthy supplier partnerships.

The Role of SCM in Procurement Cost Reduction

Supply chain management (SCM) isn't just a buzzword; it's a holistic approach to managing the flow of goods and services. By focusing on SCM supply strategies, companies can synchronize their operations, leading to cost efficiencies. I recall a project where we integrated our procurement with other departments, creating a seamless management chain supply. The results? Reduced lead times and cost savings across the board.

Building Strong Supplier Relationships

At the heart of procurement are the relationships you build. When suppliers feel valued, they're more likely to offer better terms and go the extra mile. Once, during a market shortage, our long-standing supplier prioritized our orders over others because of the strong rapport we had developed. It's like having a friend who's always got your back!

Bulk Buying and Storage Solutions

Buying in bulk raises the question of storage. We faced this challenge head-on by redesigning our warehouse layout and implementing just-in-time inventory practices. Underlining the importance of storage solutions ensured that bulk buying didn't lead to wastage or increased holding costs.

Effective Storage Strategies:

Optimize warehouse space

Implement inventory tracking systems

Regular stock audits

Training and Empowering the Procurement Team

A chain is only as strong as its weakest link. Investing in training for the procurement team can yield significant returns. When our team underwent training on the latest procurement trends and negotiation techniques, we saw an immediate impact on cost savings.

Sustainable Procurement Practices

In recent years, we've seen a shift towards sustainable procurement. This isn't just about being eco-friendly; it's also about cost savings in the long run. By choosing suppliers who use sustainable practices, we reduced waste and improved our company's image.

Overcoming Challenges in Procurement

No journey is without its bumps. We've faced challenges like supply disruptions, fluctuating prices, and regulatory changes. But with a proactive approach and flexible strategies, we've navigated these obstacles successfully.

Conclusion

Reducing procurement costs is an ongoing journey. It requires a mix of strategies, from negotiating better prices and buying in bulk to switching suppliers and streamlining processes. But perhaps the most important lesson I've learned is that success in procurement relies on relationships—both within the company and with external partners. So, whether you're a seasoned professional or just starting out, remember: a penny saved in procurement is truly a penny earned.

References

1- Monczka, R. M., Handfield, R. B., Giunipero, L. C., & Patterson, J. L. (2016). Purchasing and Supply Chain Management. Cengage Learning.

2- Chopra, S., & Meindl, P. (2015). Supply Chain Management: Strategy, Planning, and Operation. Pearson.

3- Sollish, F., & Semanik, J. (2012). The Procurement and Supply Manager's Desk Reference. Wiley.

By implementing these strategies, not only can procurement costs be reduced, but overall efficiency in the supply chain mgmt can be enhanced. In the end, effective procurement is at the heart of successful supply and chain management.

Remember, the goal is not just cost reduction but building a resilient and efficient supply chain management management system that can adapt to changing market dynamics.

Looking back, if someone had told me how intricate and rewarding a career in procurement could be, I might have jumped in even sooner! It's a field that's constantly evolving, and there's always something new to learn. So here's to smarter buying, better relationships, and a more efficient chain of supply management for all.

Frequently Asked Questions

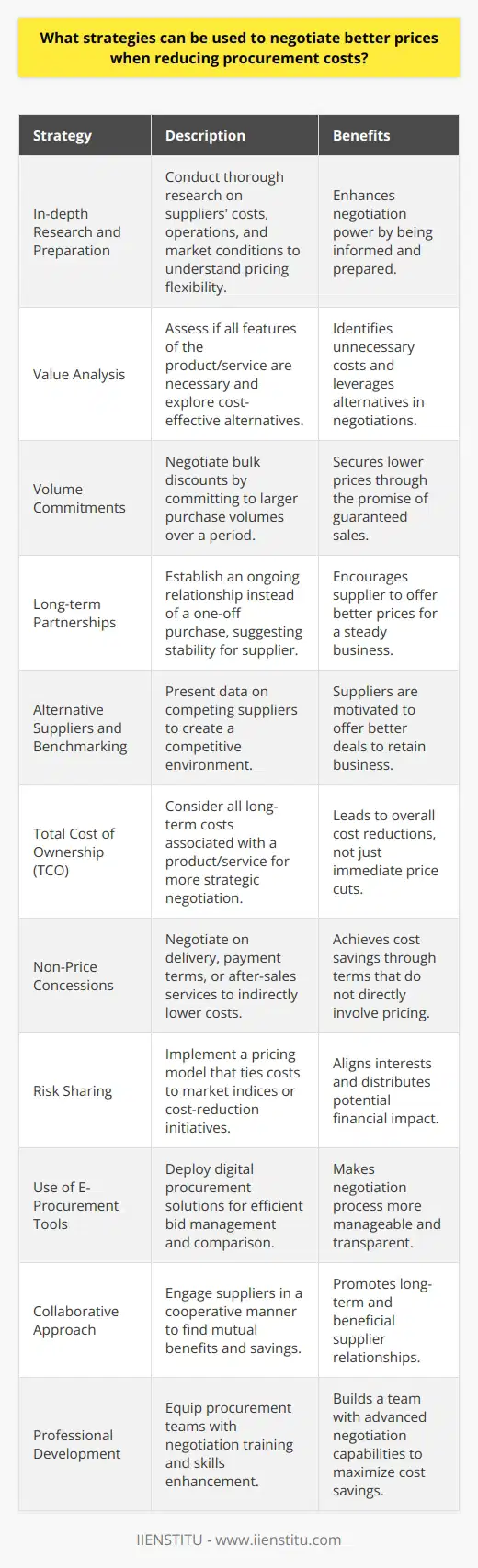

What strategies can be used to negotiate better prices when reducing procurement costs?

When it comes to reducing procurement costs, a well-thought-out negotiation strategy can be a critical factor in achieving cost savings. To negotiate better prices and maximize cost savings, procurement managers must understand their suppliers’ business models, cost structures, and competitive landscape. Here are some strategies that can be used to negotiate better prices when reducing procurement costs:

Analyze Supplier Cost Structures: Understanding a supplier’s cost structure is essential when negotiating better prices. By understanding a supplier’s cost structure, procurement managers can identify areas where they can push for cost savings. For example, by understanding the supplier’s labor costs, procurement managers can negotiate better prices by reducing the number of man-hours required for the project.

Leverage Supplier Relationship: Establishing a solid relationship with suppliers is an effective way to reduce procurement costs. Procurement managers can use the relationship to their advantage in negotiations by building a relationship with suppliers. Suppliers are more likely to offer better prices when they trust and value the relationship.

Leverage Volume Purchasing Power: Procurement managers can leverage their volume purchasing power to negotiate better prices. By ordering in large quantities, procurement managers can use their purchasing power to get better prices from suppliers.

Negotiate the Payment Terms: Procurement managers can also negotiate better prices by negotiating the payment terms. For example, they can negotiate a longer payment period, which can help reduce procurement costs.

Leverage Technology: Leveraging technology can be an effective way to reduce procurement costs. Using advanced tools such as e-procurement, procurement managers can streamline the procurement process, resulting in cost savings.

Procurement managers can negotiate better prices and reduce procurement costs by implementing these strategies. With the right strategies and a well-thought-out negotiation plan, procurement managers can maximize their cost savings and ensure the success of their organization.

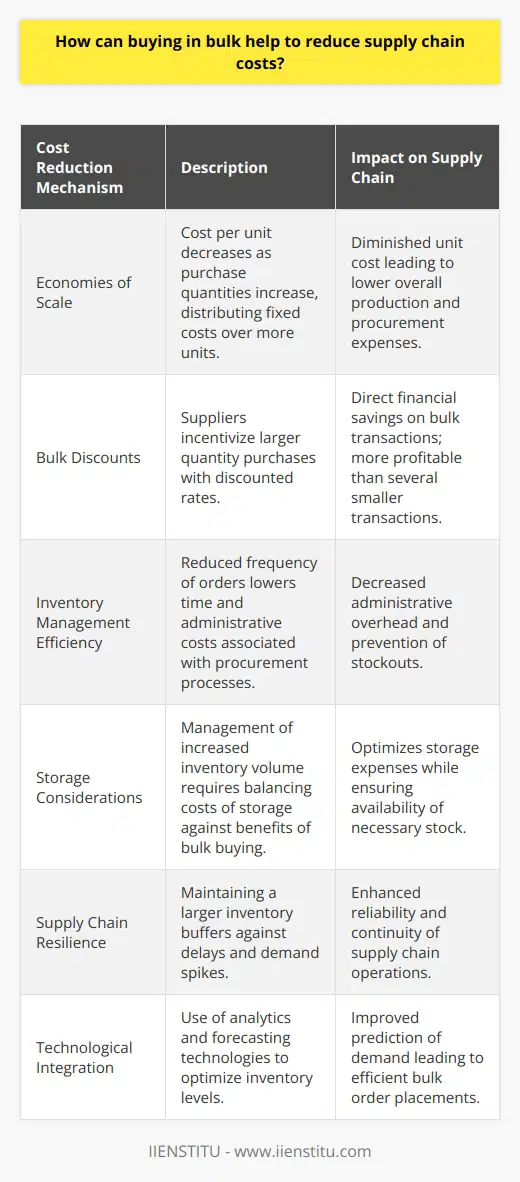

How can buying in bulk help to reduce supply chain costs?

Buying in bulk has been around for centuries, but it has become increasingly popular in recent years due to the benefits it can bring to businesses. Purchasing large quantities of goods can help to reduce supply chain costs by allowing businesses to take advantage of economies of scale and bulk discounts.

Economies of scale refer to the cost savings realized when businesses increase their production or purchase large volumes of items. This can be seen when businesses purchase in bulk; the cost of each item is lower due to the collective savings that result from purchasing a large number of items. By purchasing in bulk, businesses can take advantage of these cost savings and reduce their supply chain costs.

In addition to economies of scale, businesses can also take advantage of bulk discounts. Bulk discounts are discounts that are offered to businesses when they purchase a large number of goods. These discounts can significantly benefit businesses, as they can help reduce the cost of purchasing the items. Bulk discounts can be found from suppliers, distributors, and retailers, and they can be used to reduce the cost of purchasing items in bulk..

The benefits of buying in bulk can be significant for businesses. By taking advantage of economies of scale and bulk discounts, businesses can reduce their supply chain costs and increase their profitability. Furthermore, buying in bulk can also help to reduce inventory costs, as businesses can purchase larger quantities of items at a lower cost.

In conclusion, buying in bulk can be an effective way to reduce supply chain costs. By taking advantage of economies of scale and bulk discounts, businesses can reduce costs and increase profitability. Furthermore, buying in bulk can also help to reduce inventory costs, allowing businesses to purchase larger quantities of items at a lower cost. Therefore, businesses should consider purchasing in bulk in order to take advantage of the cost savings it can provide.

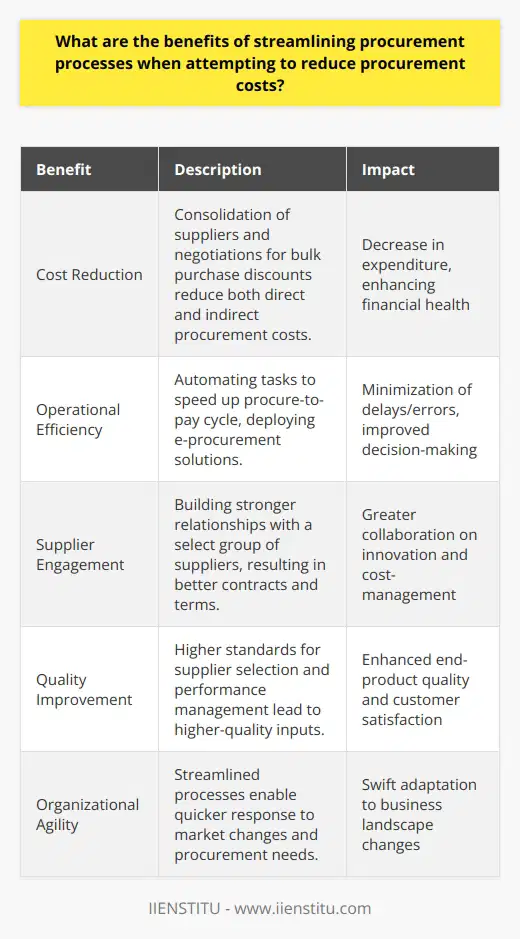

What are the benefits of streamlining procurement processes when attempting to reduce procurement costs?

Procurement is an essential part of any organization’s operations, and the ability to efficiently manage procurement processes can significantly impact an organization’s bottom line. By streamlining procurement processes, organizations can achieve greater control over their costs while also improving the overall efficiency of their procurement operations.

The first benefit of streamlining procurement processes is an increase in cost savings. By reducing the time and effort required to complete procurement tasks, organizations can achieve more significant cost savings by streamlining the overall process. This includes reducing the number of vendors used, decreasing the amount of paperwork required, and reducing the amount of time spent on negotiations. Streamlining procurement processes can also improve supplier relationships and contract terms.

Another benefit of streamlining procurement processes is improved efficiency. By reducing the time and effort required for procurement tasks, organizations can free up time for other tasks. This can allow for more efficient operation of the procurement department and can also lead to improved customer service. Additionally, streamlining procurement processes can lead to improved decision-making, as the time required to review and approve purchase orders can be significantly reduced.

Finally, streamlining procurement processes can help to improve the overall quality of the products and services purchased. By streamlining the procurement process, organizations can more effectively manage supplier relationships, ensuring they get the best possible value for their money. This can lead to improved quality of products and services, which can in turn, lead to improved customer satisfaction and loyalty.

In conclusion, streamlining procurement processes can provide organizations with various benefits. By streamlining the overall process, organizations can achieve more significant cost savings and improved efficiency. Streamlining procurement processes can also improve supplier relationships, better contract terms, decision-making, and product and service quality. As such, streamlining procurement processes can be an effective way to reduce procurement costs.

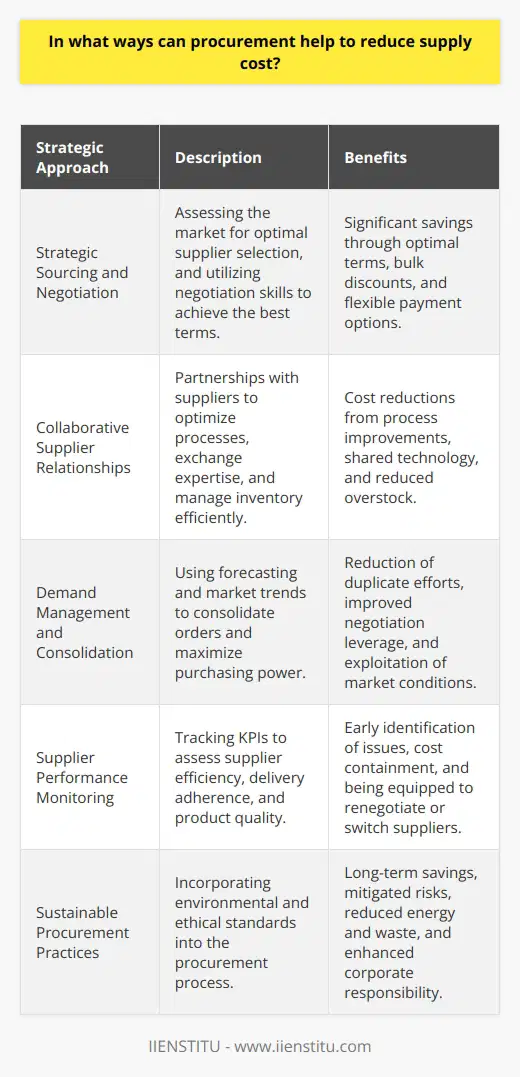

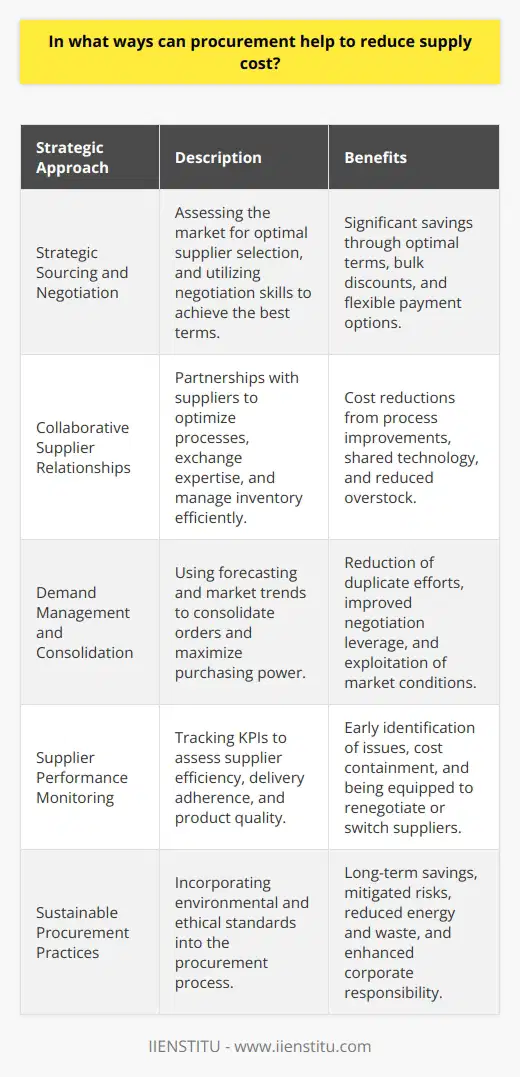

In what ways can procurement help to reduce supply cost?

Strategic Sourcing and Negotiation

One of the key ways procurement can help to reduce supply costs is through strategic sourcing. This involves evaluating suppliers based on factors such as quality, price, and reliability to find the best value for money. Once potential suppliers are identified, procurement professionals can leverage their negotiating skills to secure favorable contractual terms, such as volume discounts or extended payment terms. This can help to minimize the cost of procuring goods and services while ensuring that operational requirements are met.

Collaborative Supplier Relationships

Another approach to cost reduction is establishing collaborative relationships with suppliers. By actively seeking out partnerships and fostering open communication with suppliers, procurement professionals can collaborate to identify and implement cost-saving initiatives. This could include sharing technology or process improvements, aligning inventory levels to minimize holding costs, or joint problem-solving to reduce the frequency and impact of supply disruptions. Working together to achieve mutual goals can help both parties achieve long-term cost savings and a more efficient supply chain.

Demand Management and Consolidation

Effective demand management and consolidation of purchasing can also contribute to reduced supply costs. By analyzing historical purchasing data and forecasting future demand, procurement teams can identify opportunities to reduce costs by combining orders, thereby benefiting from economies of scale. This can be achieved through centralized procurement, which consolidates purchases across multiple departments or business units, eliminating redundancies and waste. Additionally, procurement teams can coordinate with other departments to optimize the timing of purchases to take advantage of seasonal fluctuations in price or to meet minimum order requirements more efficiently.

Supplier Performance Monitoring

An important aspect of reducing supply costs is continually monitoring supplier performance. This involves tracking key performance indicators (KPIs) such as on-time delivery, quality, and pricing. Procurement teams can use this information to address underperforming suppliers and negotiate better contract terms or seek alternative sources if necessary. Regularly evaluating supplier performance ensures that the supply chain remains cost-effective and aligned with organizational goals.

Sustainable Procurement Practices

Finally, implementing sustainable procurement practices can yield long-term savings by minimizing environmental and social risks. By selecting suppliers with strong environmental and labor standards, procurement teams can reduce the likelihood of costly disruptions or reputational damage. Additionally, investing in sustainable products or materials can lead to operational cost savings through increased efficiency, reduced waste, and lower regulatory compliance costs. By considering sustainability factors in procurement decisions, organizations can gain a competitive advantage while minimizing supply costs.

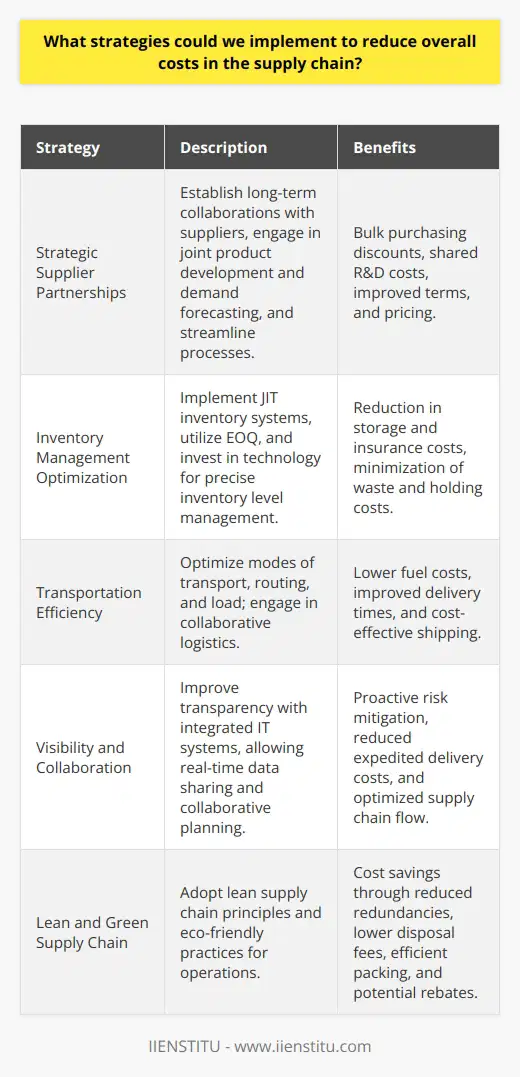

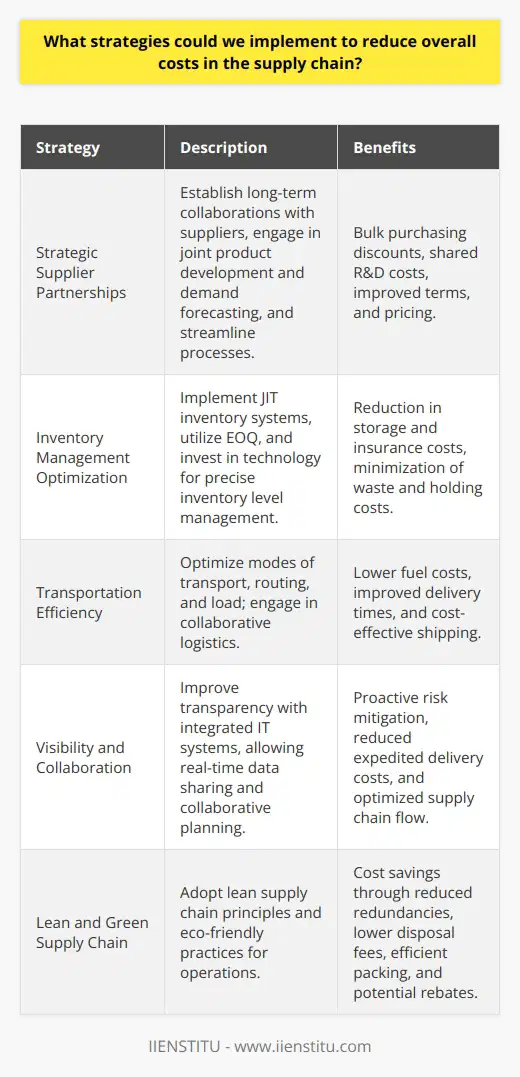

What strategies could we implement to reduce overall costs in the supply chain?

Strategic Supplier Partnerships

To reduce overall costs in the supply chain, organizations can establish strategic supplier partnerships. By collaborating closely with suppliers, businesses can optimize sourcing practices, negotiate reduced costs, and foster long-term relationships, ultimately leading to cost savings and improved efficiency.

Inventory Management Optimization

Optimizing inventory management is another strategy for reducing supply chain costs. Utilizing modern software solutions and data analytics, companies can predict demand trends more accurately, reducing excess inventory holding costs. Additionally, more effective inventory systems can prevent stockouts and improve customer satisfaction.

Transportation Efficiency

Improvement in transportation efficiency can lead to significant cost savings in the supply chain. Consolidating shipments, choosing the most cost-effective transportation modes, and utilizing transportation management systems can drastically reduce freight expenses. Moreover, efficient transportation practices improve lead times, customer satisfaction, and streamline the overall supply chain.

Visibility and Collaboration

Increasing visibility and collaboration within the supply chain can identify opportunities to optimize processes and reduce costs. Sharing supply chain data and integrating information systems with suppliers and customers allow for more informed decision-making, streamlined operations, and the ability to anticipate and respond to supply chain disruptions more effectively.

Lean and Green Supply Chain

Implementing lean manufacturing principles and environmentally sustainable practices in the supply chain can result in reduced costs. Lean principles eliminate waste and non-value-added activities, enhancing efficiency and productivity. Green supply chain practices can reduce energy consumption, material waste, and pollution, which translate to cost savings and a more eco-friendly operation.

In conclusion, organizations can implement various strategies to reduce overall costs in the supply chain. Forming strategic supplier partnerships, optimizing inventory management, improving transportation efficiency, increasing visibility and collaboration, and adopting lean and green practices are effective methods for achieving cost reduction and promoting supply chain excellence.

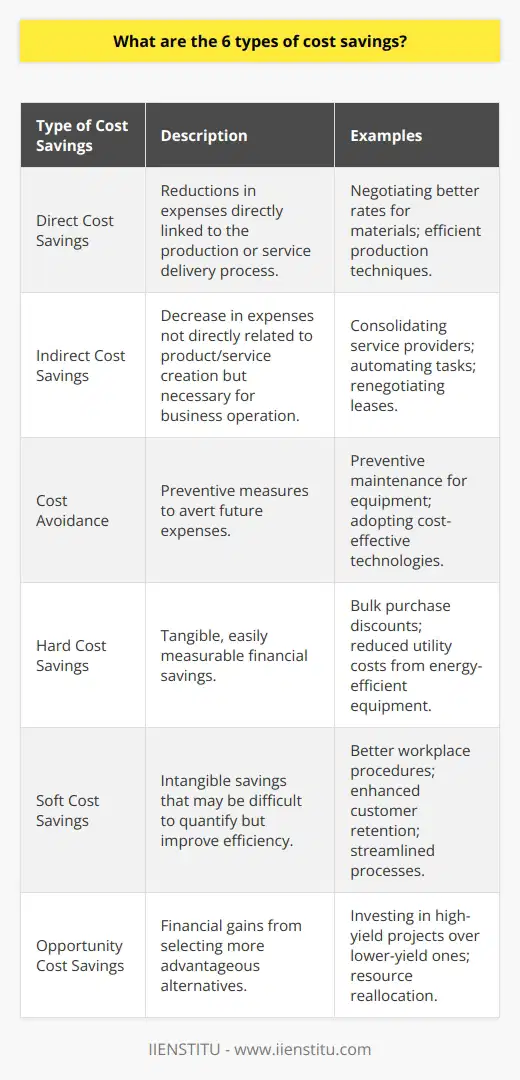

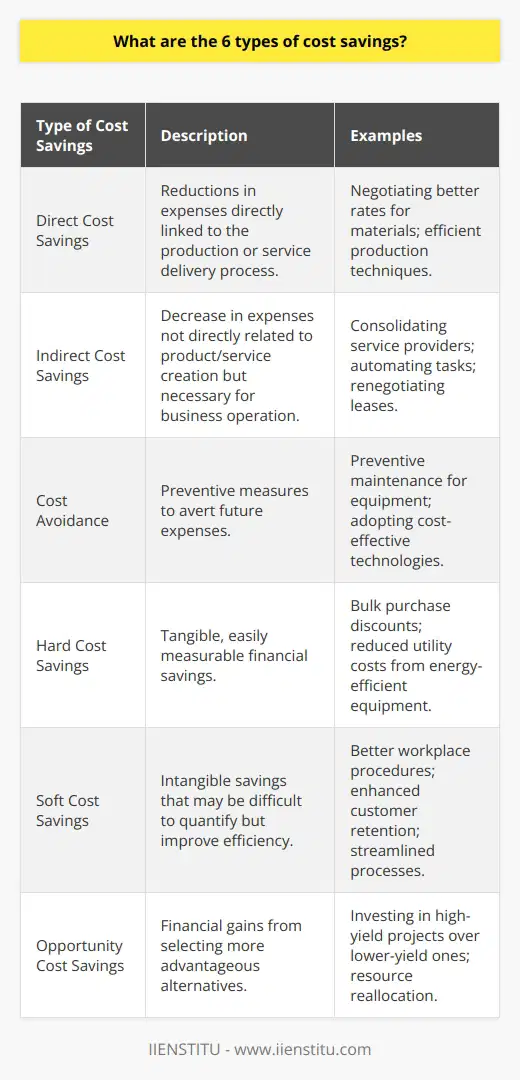

What are the 6 types of cost savings?

Types of Cost Savings

Direct Cost Savings

One significant type of cost saving is direct cost savings, which refers to reductions in expenses directly related to the production or distribution of goods and services.

Indirect Cost Savings

Another type is indirect cost savings, which focus on lowering non-production-related expenses such as administrative, marketing, or research and development costs.

Cost Avoidance

Cost avoidance is a preventive measure that helps organizations gradually reduce future expenses by eliminating or delaying potential costs.

Hard Cost Savings

Hard cost savings denote tangible, easily quantifiable savings on goods and services, such as a supplier discount or increased efficiency due to automation.

Soft Cost Savings

In contrast to hard cost savings, soft cost savings are less tangible and harder to measure. Examples include improved employee morale leading to increased productivity or by reducing customer service wait times.

Opportunity Cost Savings

Lastly, opportunity cost savings pertain to monetary benefits or advantages acquired by selecting the best available alternative for using limited resources.

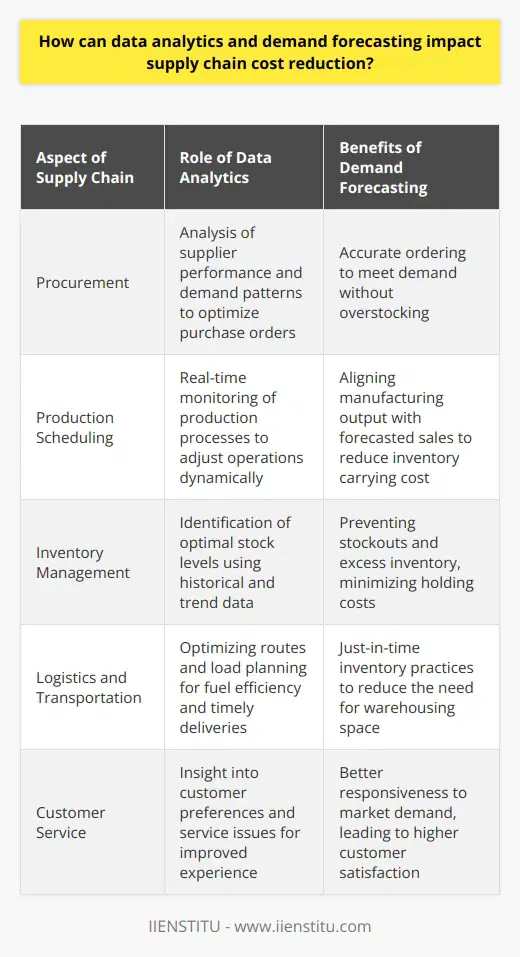

How can data analytics and demand forecasting impact supply chain cost reduction?

Effective Application of Data Analytics

Data analytics plays an instrumental role in cutting the cost of supply chains. Firstly, it enhances the visibility and understanding of every phase in the supply chain. This operational transparency is enabling organizations to make accurate, data-driven decisions, thereby reducing inefficiencies and cutting costs.

Role of Demand Forecasting

Demand forecasting plays a crucial role in supply chain management. Accurate demand forecasting aids in better production planning, preventing overproduction or under-production. Both situations can lead to additional costs, inefficiencies or lost sales opportunities. By forecasting demand with greater accuracy, companies can maintain optimal inventory levels, reducing holding costs.

Impact on Cost Reduction

Integrated data analytics and demand forecasting can directly impact cost reduction in supply chains. Improved demand forecasting leads to better material procurement planning, reducing the cost of materials. Enhanced supply chain visibility allows for improved operational efficiency, essentially leading to fewer wasted resources and reduced costs.

Importance of Real-Time Data

Real-time data in data analytics is of immense value here. It speeds up decision making, allowing companies to swiftly adapt to deviations, reduce disruptions and maintain smooth operations. Real-time insights can mitigate risks in the supply chain, leading to cost reduction and improved reliability.

Overall, the integration of data analytics and demand forecasting is a strategic approach to reduce supply chain costs. Every decision becomes backed by data, dramatically reducing errors, inefficiencies, and wastes, which all translate to cost savings. Thus, effective use of these techniques holds the key to efficient and cost-effective supply chain management.

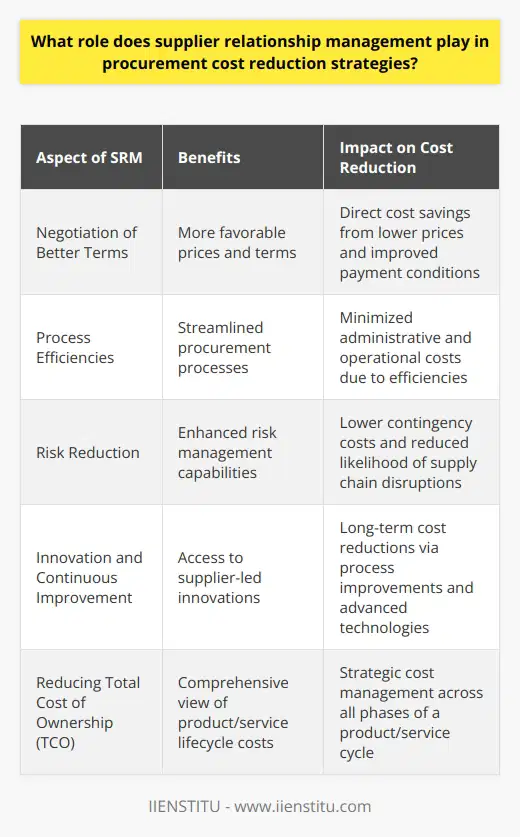

What role does supplier relationship management play in procurement cost reduction strategies?

Supplier Relationship Management's Role

Supplier Relationship Management (SRM) plays a crucial role in procurement cost reduction strategies. Years of research reveal that strong supplier partnerships can lead to significant reductions in procurement costs. These cost savings primarily result from improved efficiency and greater collaboration.

Creating Strong Supplier Relationships

SRM focuses on establishing strong relationships with suppliers. Strong supplier relationships result in better communication and understanding, leading to more efficient procurement processes. Improved efficiency translates into time and cost savings as wasteful procedures are eliminated.

Encouraging Collaboration

SRM also encourages collaboration between the company and suppliers. This collaboration can lead to innovations and process improvements that lower procurement costs. For example, suppliers might suggest alternative materials or methods that bring about cost reductions.

Optimizing Price Negotiations

Additionally, SRM is critical in optimizing price negotiations. Companies with strong supplier relationships are often in a better position to negotiate favorable prices. This outcome is not merely due to strengthened trust and good rapport but also to the suppliers' familiarity with the company's goals and operations.

Managing Supply Chain Risks

Lastly, effective SRM also ensures better management of supply chain risks. It offers improved visibility into supplier operations, thereby allowing proactive risk management measures that prevent costly disruption in supplies. Thus, SRM indirectly contributes to cost reduction by ensuring uninterrupted operations.

In conclusion, SRM plays an integral role in any procurement cost reduction strategy. It fosters stronger supplier relationships, encourages collaboration, aids in effective price negotiation and helps manage supply chain risks, all of which contribute significantly to minimizing procurement costs.

How can adopting sustainable sourcing practices contribute to lowering overall supply chain costs?

Efficiency Increase Through Sustainable Sourcing

Adopting sustainable sourcing can improve supply chain efficiency. When companies streamline their operations for sustainability, waste reduction often follows. Fewer wasted resources mean lower material costs and a more cost-effective process overall.

Reduced Dependency on Non-Renewable Resources

Sustainable sourcing involves shifting dependency on non-renewable resources to renewable ones. Companies can mitigate the risks associated with fluctuating raw materials prices, shortages, and not having to rely heavily on non-renewable sources. Over time, this can lead to substantial cost savings.

Benefit from Eco-friendly Reputation

In the current market, sustainability equates to favorability. Being eco-friendly not only attracts more customers but can also influence procurement decisions in favor of more sustainable suppliers. This can lead to more business and increased profits, reducing overall supply chain costs.

Cost Savings Through Regulatory Compliance

Complying with environmental regulations can be costly for firms. However, companies that prioritize sustainability can often foresee and adapt to these policies ahead of time. This reduces potential fines, while also preventing costly operational disruptions.

Promotion of Innovation

Finally, focusing on sustainability can spark innovation. Companies might develop more efficient methods of production or distribution, which can lower costs in the long term. Thus, sustainable sourcing is not just about being eco-friendly. It's also about improving efficiency and reducing supply chain-related costs.

In summary, adopting sustainable sourcing practices can contribute significantly to lowering overall supply chain costs. It’s a strategic move that benefits both the environment and the bottom line.

In what ways can procurement help to reduce supply cost?

Strategic Procurement

Procurement can significantly reduce supply costs through strategic sourcing. This process involves in-depth analysis of the company's spending to identify cost-saving opportunities. Thorough examination of current spend and supply base can unveil areas of potential savings.

Supplier Rationalisation

Through supplier rationalization, procurement can help reduce cost. By consolidating the number of suppliers, companies can negotiate better contractual terms, ensure consistent quality and lower administrative costs.

Supplier Performance Management

Regular evaluation of supplier performance can also lead to cost-savings. By monitoring and managing supplier activities, businesses can identify inefficiencies and mitigate risk to reduce expenses. This promotes supplier accountability, driving them to provide better value at lower costs.

Volume Consolidation

Volume consolidation is another way procurement contributes to cost reduction. Greater demand often attracts volume discounts. By bundling similar items or services together, a company can negotiate more favourable pricing.

Operational Efficiency

Utilising advanced technology and automating procurement processes can lead to significant operational efficiency, subsequently reducing cost over time. Automation simplifies transactions, reduces errors, and ensures timely delivery, all contributing to cost effectiveness.

In conclusion, procurement can potentially help companies reduce their supply costs through strategic sourcing, supplier rationalisation, supplier performance management, volume consolidation, and by improving operational efficiency. A well-planned and well-executed procurement strategy can make a significant difference in keeping supply costs under control.

What strategies could we implement to reduce overall costs in the supply chain?

Effective Supplier and Inventory Management

To curb costs in a supply chain, companies can consider implementing strategic supplier and inventory management. This involves strengthening relationships with suppliers, negotiating for better rates and terms, and scaling back on less cost-effective suppliers. It can also mean optimizing inventory to avoid overstock, which leads to unwanted holding costs.

Adoption of Technology

Adoption of technology also promises tangible cost reductions. Using advanced supply chain management software can streamline operations, improve transparency and enhance accuracy in forecasting. Technology can also help monitor and reduce errors, rectifying issues before they escalate into costly problems.

Lean and Green Supply Chain

Transitioning towards a lean and green supply chain can further reduce operational overheads. Lean supply chain management aims at eliminating waste, saving time, and subsequently, cost. A green supply chain, on the other hand, reduces environmental impact, promoting sustainable practices, and can lead to cost savings in areas such as recycling and energy usage.

Use of Analytics and Automation

The use of analytics and automation is another cost-saving strategy. Predictive analytics can help anticipate market trends, optimizing demand planning and reducing stockouts or overstock situations. Automation reduces labor-intensive tasks, saving time, reducing errors, and ultimately leading to cost savings.

Collaborative Supply Chain

Lastly, developing a collaborative supply chain allows for the sharing of resources and information, reducing costs and building valuable relationships. This involves working closely with suppliers, manufacturers, and retailers to streamline processes, eliminate redundancies, and lower costs.

In a nutshell, effective supplier and inventory management, technological adoption, lean and green practices, analytics and automation, and collaborative efforts represent significant strategies to reduce overall costs in the supply chain. By applying a strategic mix of these approaches, companies can optimize their supply chain operations while minimizing costs.

What are the 6 types of cost savings?

Direct Cost Savings

Direct cost savings involve reducing costs related to the production or delivery of a product or service. This could mean negotiating lower prices with suppliers, or improving efficiency in the manufacturing process.

Indirect Cost Savings

Indirect cost savings are reductions in expenses indirectly related to production or delivery. They can include reduced overheads from streamlining administrative processes, or costs saved by reducing waste and redundancy.

Short-term Cost Savings

A business might achieve short-term cost savings through one-time actions such as layoffs, space downsizing, or an immediate cutback on discretionary spending. However, these savings may not be sustainable in the long term.

Long-term Cost Savings

Conversely, long-term cost savings involve actions taken to achieve ongoing, sustainable reductions in business costs. These can include investing in efficient technology, upskilling employees, and forming strategic alliances to distribute costs.

Opportunity Cost Savings

This kind of saving comes from choosing the most profitable way to allocate resources. By prioritizing high-value tasks and outsourcing or automating low-value tasks, a business can make more profitable use of time and resources.

Project Cost Savings

Project cost savings are specific to individual projects and involve cost management practices like staying within budget, avoiding cost overrun, and ensuring efficient use of resources during the project execution.

In summary, the six types of cost savings – direct, indirect, short-term, long-term, opportunity, and project – all play an integral role in reducing business expenses and enhancing profitability. Each type offers different advantages, and effective cost management often involves a balanced combination of these strategies.