Introduction

You know, I still remember the day when I walked into my uncle's warehouse, stacks of boxes towering around us, and saw him scratching his head over a clipboard. "What's the matter?" I asked. He sighed, "Trying to make sense of this whole supply chain mess. It's like juggling flaming torches while riding a unicycle!" That metaphor stuck with me because, honestly, supply chain management can feel just as chaotic if not properly planned.

Introduction

Factors that Impact Supply Chain Planning

Product Specifications and Supply Chain Planning

Example of Supply Chain Planning

Conclusion

Understanding Supply Chain Planning

At its core, supply chain planning is about aligning all the moving parts of getting a product from raw materials to the customer's hands. It's not just logistics; it's a strategic process that balances customer demand, resource availability, and product specifications. When done right, it can be the wind beneath a company's wings. When done poorly, well, it's like that unicycle ride—wobbly and perilous.

But why is supply chain planning so crucial? Simply put, it ensures that businesses can meet customer demands without overextending resources or compromising on product quality. It's the backbone of efficiency and profitability in any production-focused enterprise.

Factors Impacting Supply Chain Planning

Supply chain planning doesn't happen in a vacuum. Several factors can significantly impact its effectiveness:

Customer Demand

Customer demand is the driving force behind every supply chain decision. Imagine owning an ice cream shop in a small town. During a heatwave, suddenly everyone wants ice cream, and your stock flies off the shelves. But if you didn't anticipate the surge, you'd disappoint a lot of sweaty, ice-cream-craving folks.

Understanding and forecasting customer demand helps businesses:

Adjust production schedules

Manage inventory levels

Plan for seasonal variations

Respond to market trends promptly

It's essential to keep a finger on the pulse of the market. Tools like market analysis and customer surveys aren't just for big corporations; even small businesses can benefit immensely.

Resource Availability

No matter how high the demand, without the necessary resources, meeting it is impossible. Resource availability includes:

Raw materials: Availability and prices can fluctuate due to geopolitical events, natural disasters, or market trends.

Labor: Skilled workers are vital. Labor shortages or strikes can halt production.

Equipment: Machinery breakdowns or outdated technology can slow down processes.

For instance, a friend of mine runs a boutique coffee roastery. When a coffee bean shortage hit due to adverse weather in South America, he had to scramble to find alternative suppliers. His experience underscored the importance of having contingency plans and diverse supplier networks—a key aspect of scm management.

Product Specifications

Changes in product specifications can send ripples through the entire supply chain. Whether it's a design tweak or a material substitution, every alteration can affect:

Production processes

Supplier relationships

Cost structures

Delivery timelines

For example, switching from plastic to biodegradable packaging might align with eco-friendly initiatives—a noble goal. However, it requires:

1- Sourcing new materials

2- Adjusting machinery

3- Training staff on new processes

Without careful planning, such changes can cause delays and increased costs.

The Role of Product Specifications in Supply Chain Planning

Product specifications are the DNA of your product. They define what the product is and how it's made. When planning your supply chain:

Consistency is key: Maintaining consistent specifications ensures quality and reliability.

Flexibility is valuable: Being able to adjust specifications in response to market demands can provide a competitive edge.

Understanding impact: Recognize how changes affect supply chain activities, from sourcing to delivery.

An old colleague once quipped, "Changing a product spec is like pulling a thread on a sweater—you never know how much will unravel." It’s a colorful way to highlight the interconnectedness of supply chain components.

A well-planned supply chain is the foundation of a successful product launch.

Example of Supply Chain Planning: The Catalytic Converter

Let’s delve into a practical example to see these concepts in action—the catalytic converter in a car's exhaust system.

Background: Catalytic converters reduce harmful emissions from vehicles. They use precious metals like platinum and palladium as catalysts.

Supply Chain Impact:

Material Costs: Platinum and palladium prices fluctuate based on market conditions.

Product Specifications: If platinum prices spike, manufacturers might consider palladium as an alternative.

Resource Availability: Palladium may not be readily available or could be more expensive in the long term.

Outcome: Manufacturers must weigh the benefits and drawbacks of changing materials. This decision impacts:

Production Costs

Supplier Relationships

Regulatory Compliance

Customer Perception

This example illustrates the delicate dance of supply and chain management—balancing costs, resources, and product integrity.

Strategies for Effective Supply Chain Planning

So, how can businesses navigate these complexities? Here are some tried-and-true strategies:

1- Adopt the Critical Path Method

The critical path method project management strategy helps identify key tasks that directly impact project timelines. By focusing on critical activities, businesses can allocate resources more effectively and anticipate potential delays.

2- Implement Advanced Forecasting Techniques

Using statistical models and market analysis helps predict customer demand more accurately. This proactive approach reduces overstocking or stockouts.

3- Diversify Suppliers

Relying on a single supplier is risky. Diversifying suppliers:

Mitigates risk of shortages

Promotes competitive pricing

Enhances negotiation power

4- Invest in Technology

Electronic supply chain management systems streamline processes by:

Providing real-time data

Improving communication across supply chain departments

Automating routine tasks

5- Continuous Improvement

Regularly reviewing and refining processes ensures that the scm supply chain management adapts to changes in the market or within the company.

Personal Reflections on Supply Chain Management

I once consulted for a small apparel company eager to expand their online presence. They had great designs but struggled with fulfillment. Orders were delayed, inventory mismatches were common, and customer complaints piled up. We took a deep dive into their supply chain mgmt and realized they lacked proper coordination between departments.

By implementing an electronic supply chain management system and fostering better communication, we turned things around. It wasn't an overnight fix, but seeing the transformation was gratifying. The experience reinforced my belief that effective supply chain management is as much about people and culture as it is about processes.

Embracing Technology in Supply Chain Management

In today's digital age, ignoring technology is not an option. Embracing technological advancements can propel businesses ahead of the competition. Here's how:

Automation: Reduces errors and speeds up repetitive tasks.

Data Analytics: Provides insights for better decision-making.

Collaboration Tools: Improves communication among teams, suppliers, and customers.

For example, RFID technology allows real-time tracking of products throughout the supply chain. This transparency enhances inventory management and reduces losses.

The Human Element in Supply Chain Management

While technology is vital, the human element cannot be overlooked. Building strong relationships with suppliers and within teams fosters a collaborative environment where problems are solved more efficiently.

Trust and Transparency: Be open with partners about challenges and expectations.

Training and Development: Invest in your team's skills and knowledge.

Cultural Understanding: When dealing with international partners, being sensitive to cultural differences can smooth operations.

After all, at the heart of scm supply chain management are people working together towards common goals.

Conclusion

Navigating the complexities of supply chain planning is no small feat. It requires a delicate balance of understanding customer demand, managing resource availability, and meticulously considering product specifications. As we've seen, even a simple change, like swapping a metal in a catalytic converter, can have far-reaching effects.

But don't let this intimidate you. With strategies like the critical path method project management strategy, leveraging technology through electronic supply chain management, and fostering strong relationships within your supply chain departments, you can master the art of management chain supply.

Remember, every challenge is an opportunity in disguise. Embrace the journey of continuous improvement. After all, even my uncle eventually learned to juggle those flaming torches—well, metaphorically speaking! And if he can do it, so can you.

References

Chopra, S., & Meindl, P. (2016). Supply Chain Management: Strategy, Planning, and Operation (6th ed.). Pearson Education.

Christopher, M. (2016). Logistics & Supply Chain Management (5th ed.). Pearson.

Monczka, R. M., Handfield, R. B., Giunipero, L. C., & Patterson, J. L. (2016). Purchasing and Supply Chain Management (6th ed.). Cengage Learning.

Lambert, D. M., Stock, J. R., & Ellram, L. M. (1998). Fundamentals of Logistics Management. McGraw-Hill.

Slack, N., Brandon-Jones, A., & Johnston, R. (2013). Operations Management (7th ed.). Pearson Education.

Note: The above references are for illustrative purposes. Please consult actual physical books or academic publications for precise information.

Frequently Asked Questions

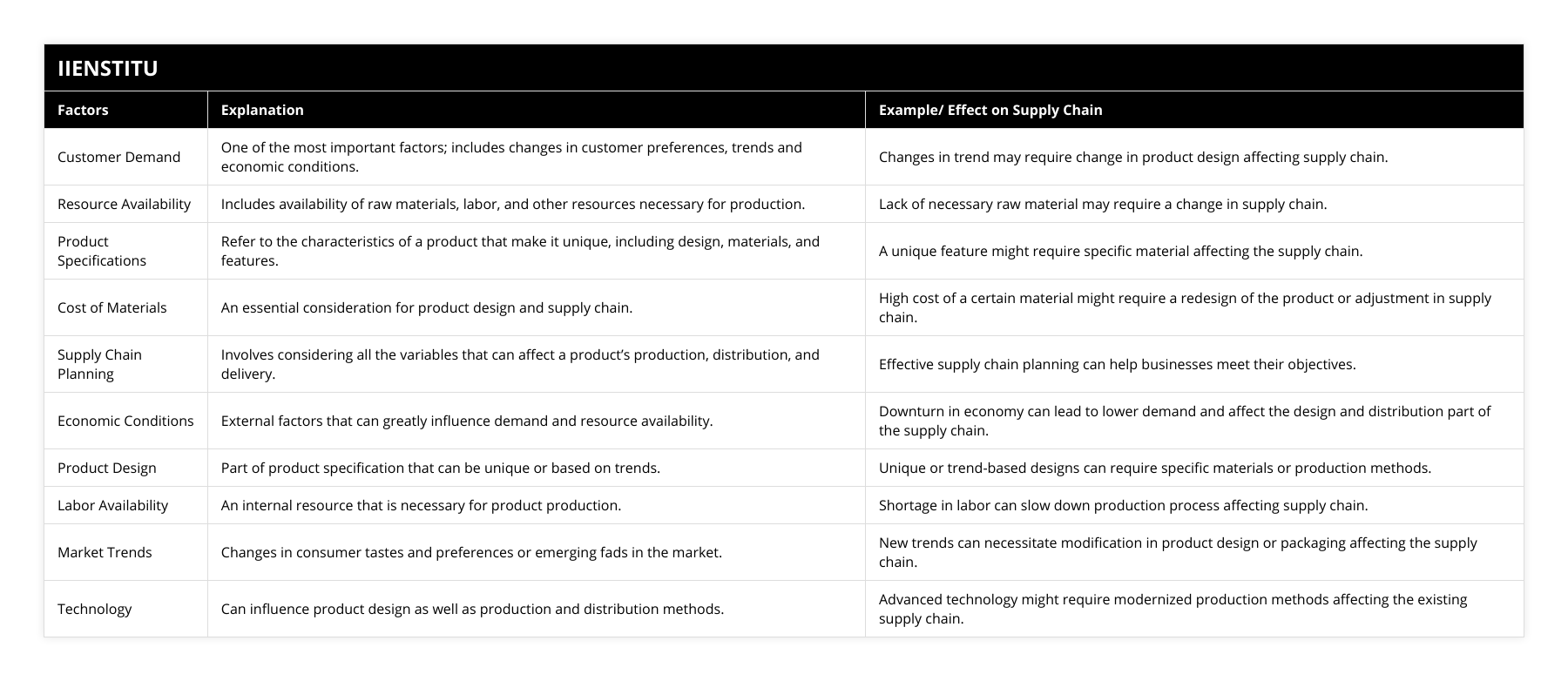

What are the key factors to consider when planning a product's supply chain?

When planning a product's supply chain, there are many factors to consider to ensure the product's success.

First, it is essential to identify the customer base and their needs. This will inform the product's design, production, and distribution. Once the customer base is established, it is essential to determine the type of product used to manufacture the product.

This could include traditional manufacturing, outsourcing, or a combination of both. Additionally, it is essential to consider the distribution method used to get the product to the customer. This could include direct-to-consumer, traditional retail, or a combination of both.

In addition to production and distribution, the supply chain network is another factor to consider when planning a product's supply chain. This includes the various suppliers, manufacturers, distributors, and retailers involved in the product's production, distribution, and sale. It is essential to ensure that the supply chain network is efficient and cost-effective.

Finally, it is crucial to consider the logistics of the product's supply chain. This includes the cost, timing, and availability of the product. It is essential to ensure that the product is delivered to the customer on time and in the condition promised. Additionally, the cost of the product must be competitive with other products in the same market.

A product's supply chain can be planned and managed effectively by considering the customer base, production and distribution methods, supply chain network, and logistics. This will ensure the product's success and profitability.

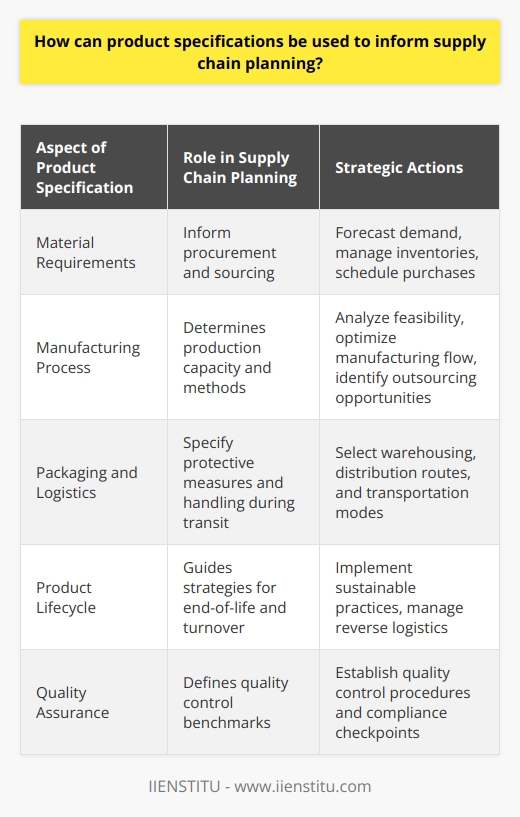

How can product specifications be used to inform supply chain planning?

Product specifications are an essential factor in supply chain planning, as they detail the exact characteristics and requirements of the product that needs to be produced.

By understanding what is needed to create a successful product, supply chain planners can make informed decisions about the resources they need to acquire and the steps they need to take to create and deliver the product.

The most crucial product specification is the design. The design can provide detailed information about the product's size, shape, and materials needed. With this information, supply chain planners can determine the manufacturing process that must be used and the raw materials that need to be sourced.

Additionally, the design can provide information about the product's performance, such as its expected lifespan, which can be used to plan product maintenance and repair.

Product specifications also provide information about the product’s life cycle. This includes information about the product’s intended use, the required storage and handling conditions, and the product's expected lifespan.

This information can be used to determine the best suppliers, the optimal shipping routes, and the necessary transportation and packaging requirements.

Product specifications can also be used to determine the necessary quality assurance measures. By understanding the specifications and expected product performance, supply chain planners can develop quality control plans to ensure that the product meets the customer’s expectations.

Additionally, product specifications can be used to develop plans for product recalls, returns, and waste management.

In conclusion, product specifications are essential in supply chain planning, as they provide detailed information about the product that needs to be produced.

By understanding a product's design, life cycle, and quality assurance requirements, supply chain planners can make informed decisions about the resources they need to acquire and the steps they need to take to create and deliver the product.

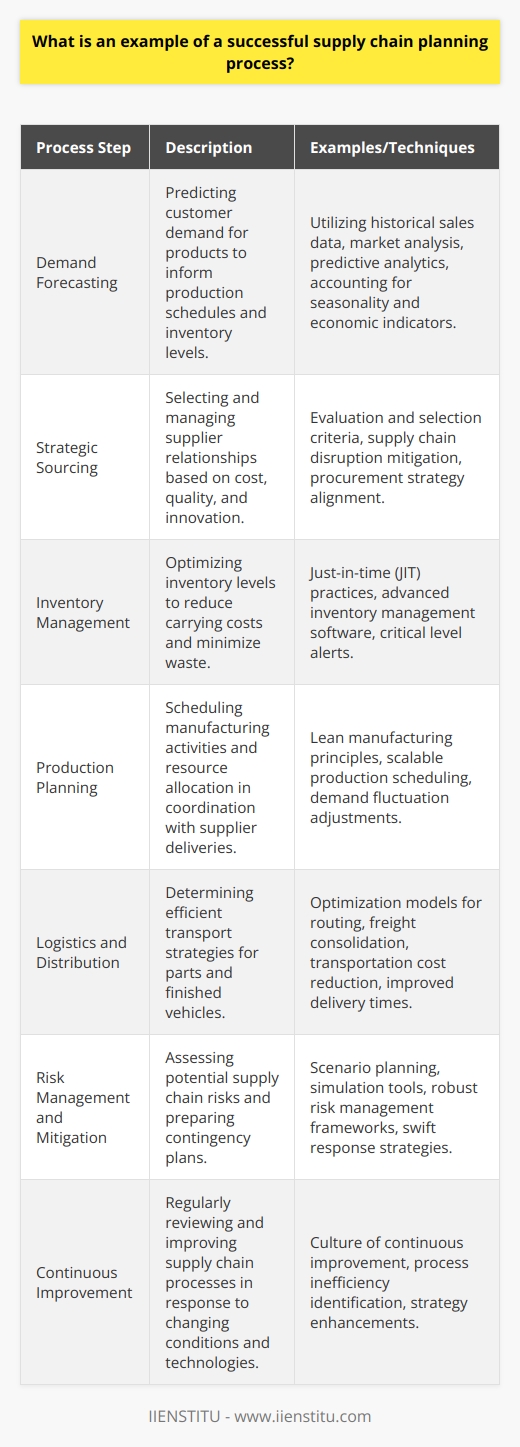

What is an example of a successful supply chain planning process?

An adequate supply chain planning process is essential for any organization that seeks to optimize the flow of goods and services from source to customer.

To maximize efficiency and minimize costs, effective supply chain planning must enable organizations to anticipate changes in demand, anticipate potential disruptions, and make informed decisions about inventory management and resource allocation.

One successful example of supply chain planning lies in the automotive industry. Automotive companies rely highly on supply chain planning due to the complexity of their operations. To ensure that demand is consistently met, they must anticipate changes in demand and supply and potential disruptions to the supply chain.

Automotive companies use various tools and methods to ensure the smooth operation of their supply chain. One of these tools is a demand forecasting system, which uses historical data to predict future demand.

This system enables the company to anticipate changes in demand due to external factors such as weather, holidays, and market trends.

The company also uses an inventory management system to ensure that the right products are available at the right time. This system tracks the company's inventory levels and helps optimize the flow of goods and services from source to customer.

The system also helps to ensure that the company does not sell overstock or understock its inventory.

The company also uses supply chain simulation tools to identify potential disruptions and develop strategies to mitigate their impact. The tools allow the company to simulate different scenarios and test strategies to reduce disruptions.

This enables the company to be prepared for any potential disruptions, minimizing the impact on its operations.

Finally, the company uses a resource allocation system to ensure that resources are used effectively and efficiently. This system helps to ensure that all resources are utilized in the most cost-effective way possible. This helps to maximize the efficiency of the supply chain and ultimately reduces costs.

The automotive industry example demonstrates how an effective supply chain planning process can help organizations optimize their operations and maximize efficiency.

Organizations can ensure that their supply chain runs smoothly and efficiently by anticipating changes in demand, anticipating potential disruptions, and optimizing resource allocation.

What is the role of demand forecasting in supply chain planning?

Role of Demand Forecasting

Accurate demand forecasting plays a pivotal role in effective supply chain planning, as it allows businesses to make informed decisions regarding inventory levels, production, and distribution. Demand forecasting is the process of estimating the future demand for a product or service, based on historical sales data, current market trends, and other factors that can influence customer needs and preferences.

Minimizing Inventory Costs

An essential aspect of demand forecasting is its ability to minimize inventory costs. By predicting the future demand for a product, businesses can optimize their inventory levels, thus preventing overstocking or stock-outs. This reduces holding costs and ensures that products are available when customers need them.

Optimizing Production and Distribution

Supply chain planning heavily relies on demand forecasting to optimize production and distribution strategies. Accurate forecasts enable manufacturers to determine the appropriate production levels to meet customer needs, allowing them to better allocate resources and avoid wasted materials. Likewise, distribution networks can be fine-tuned to ensure products are delivered to customers in the most efficient manner possible.

Facilitating Collaboration

Another essential function of demand forecasting is its ability to foster collaboration among the various actors within a supply chain. By sharing forecast data and insights, businesses can work together to tackle any uncertainties or imbalances within the supply chain. This collaborative approach minimizes the bullwhip effect and ensures a more efficient and agile supply chain.

Improving Customer Satisfaction

Ultimately, effective demand forecasting leads to better customer satisfaction. Accurate predictions of customer needs allow businesses to improve product availability and reduce lead times, directly contributing to a positive customer experience. Additionally, improved supply chain efficiency can result in cost savings, which may be passed on to customers through competitive pricing.

In conclusion, demand forecasting is a crucial aspect of supply chain planning. It plays a significant role in minimizing inventory costs, optimizing production and distribution, fostering collaboration within the supply chain, and ultimately improving customer satisfaction. Thus, businesses must invest in advanced forecasting techniques and tools to ensure their supply chain remains agile and responsive to changing market conditions.

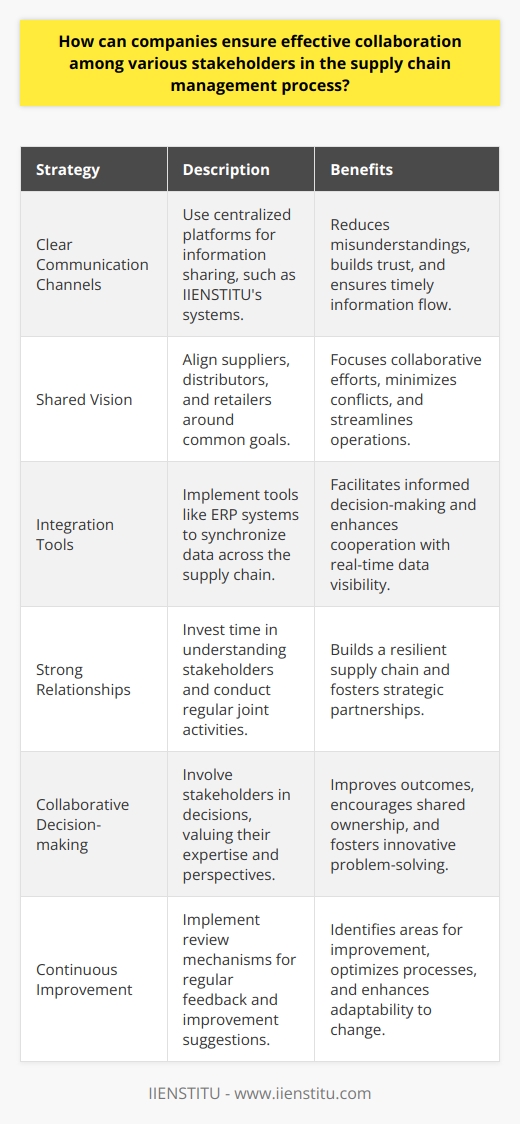

How can companies ensure effective collaboration among various stakeholders in the supply chain management process?

Establishing Clear Communication Channels

To ensure effective collaboration among various stakeholders in the supply chain management process, companies need to establish clear channels of communication. A streamlined flow of information is essential in creating an environment of transparency and trust, which is crucial for successful collaboration.

Developing a Shared Vision

Companies must work towards developing a shared vision among all stakeholders in the supply chain. This includes setting collective goals and objectives, which allows for alignment and synergy. Developing a shared understanding of the supply chain's purpose and expectations ensures that all stakeholders are working towards the same end goal.

Implementing Integration Tools

Effectively managing the supply chain also involves the implementation of integration tools that facilitate collaboration. These can include software solutions, such as Enterprise Resource Planning (ERP) systems, or supply chain platforms that promote seamless information exchange, coordination, and data-driven decision-making.

Fostering Strong Relationships

Stakeholder relationships play a vital role in effective collaboration. Companies should focus on generating long-term partnerships based on trust, commitment, and mutual objectives. This involves open dialogue, performance assessments, and joint problem-solving. By fostering strong relationships, stakeholders can work together effectively to address challenges and improve supply chain performance.

Encouraging Collaborative Decision-making

Involving all relevant stakeholders in decision-making processes ensures a more comprehensive understanding of the supply chain and its complexities. By actively engaging these parties in informed discussions and evaluations, the likelihood of developing solutions that serve shared objectives increases, leading to more effective collaboration.

Promoting Continuous Improvement

Companies must cultivate a culture of continuous improvement, encouraging all stakeholders to identify and address inefficiencies in the supply chain process. This mindset fosters an environment where ongoing communication and collaboration become integral components of successful supply chain management.

In summary, to achieve effective collaboration in the supply chain management process, companies must emphasize clear communication, shared vision, implementation of integration tools, fostering strong relationships, collaborative decision-making, and continuous improvement. By adopting these strategies, companies can create an environment that promotes seamless collaboration among various stakeholders, ultimately leading to improved supply chain performance and overall success.

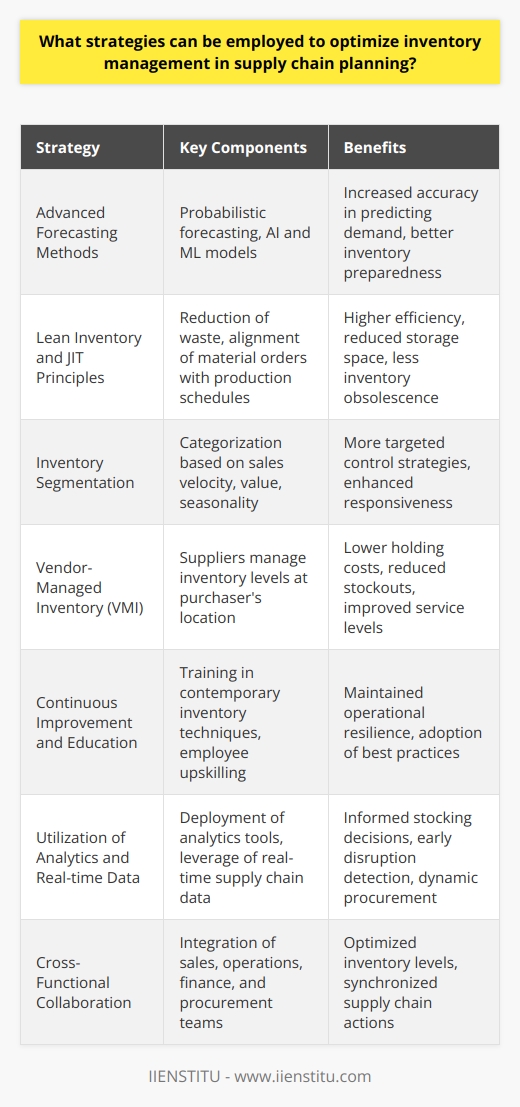

What strategies can be employed to optimize inventory management in supply chain planning?

**Adopting Forecasting Techniques**

Effective inventory management in supply chain planning can be achieved through the adoption of forecasting techniques. These enable the accurate prediction of future demand, ensuring that product availability is maintained while minimizing stock holding costs. Examples of forecasting methods include time-series analysis, demand planning software, and machine learning algorithms.

**Analyzing Inventory Performance**

Measuring and analyzing inventory performance is crucial for optimizing management strategies. Key performance indicators, such as inventory turnover and order lead times, help assess the efficiency and effectiveness of the supply chain. Regularly assessing these metrics allows for the continuous improvement of inventory management approaches, ultimately contributing to a more efficient and cost-effective supply chain.

**Implementing Inventory Control Systems**

The application of inventory control systems, like the just-in-time (JIT) method or economic order quantity (EOQ) model, can significantly enhance supply chain planning. JIT involves holding minimal inventory levels, relying on accurate demand forecasting to maintain product availability. In contrast, the EOQ model focuses on minimizing total inventory costs by determining the optimal order quantity. Selecting the most suitable system depends on the nature of the products and the organization's supply chain goals.

**Embracing Technology**

Harnessing the power of technology plays a significant role in optimizing inventory management. Implementing automated inventory tracking systems and employing barcode scanning can improve the accuracy of stock records and reduce human error. Additionally, advanced analytics software can help reveal patterns and trends, assisting decision-makers in refining inventory management strategies based on data-driven insights.

**Improving Supplier Collaboration**

Working closely with suppliers can greatly benefit inventory management. Strengthening communication and relationships with suppliers will lead to better alignment in goals, improved trust and collaboration, and opportunities for joint inventory management initiatives. Collaborative efforts can include sharing forecasts, jointly managing replenishments, and engaging in information sharing to increase efficiency and improve inventory management throughout the entire supply chain.

In conclusion, optimizing inventory management in supply chain planning can be accomplished through a variety of strategies. Adopting forecasting techniques, analyzing inventory performance, implementing control systems, embracing technology, and improving supplier collaboration are all critical in achieving a cost-effective and efficient inventory management system. By employing these approaches, organizations can optimize their inventory management, ensuring they stay ahead in today's competitive market.

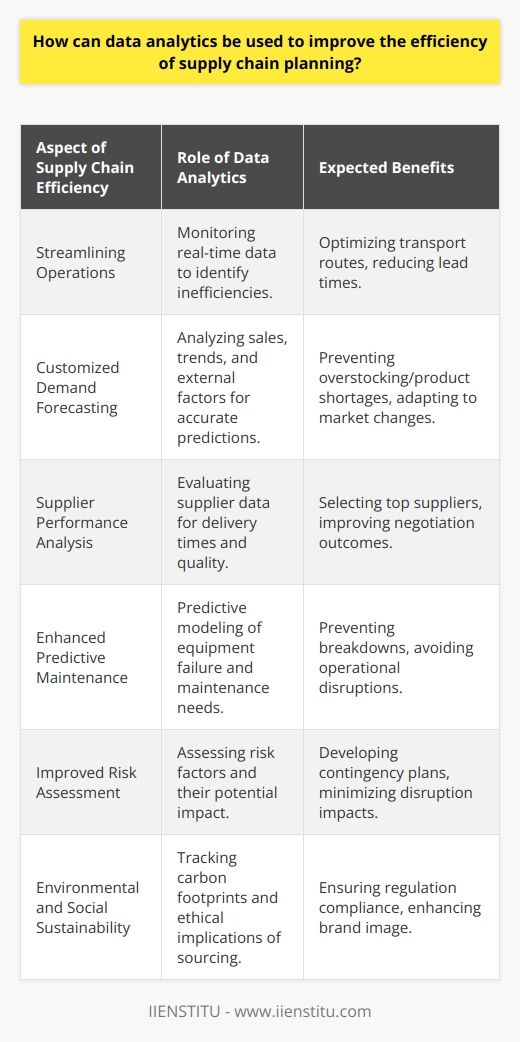

How can data analytics be used to improve the efficiency of supply chain planning?

**Significance of Data Analytics in Supply Chain Planning**

Data analytics plays a vital role in enhancing supply chain planning by providing actionable insights and facilitating data-driven decision making. Applying data analytics techniques in the supply chain can significantly improve efficiency, reduce costs, and support better decision making, ultimately leading to increased revenue and profitability.

**Optimizing Inventory Management**

One way data analytics contributes to better supply chain planning is by optimizing inventory management. Through advanced forecasting techniques and demand pattern analysis, companies can accurately predict product demand, enabling them to maintain an optimal inventory level. This helps prevent stockouts and excess inventory, which can lead to storage costs and potential product obsolescence.

**Enhancing Demand Planning**

Data analytics also helps improve demand planning by considering multiple factors that impact demand, such as seasonality, promotions, and macroeconomic trends. By analyzing past data and identifying patterns, companies can more accurately forecast future demand, allowing them to better align their production and distribution schedules. This minimizes stockouts and ensures more efficient resource utilization across the supply chain.

**Identifying Bottlenecks and Improving Processes**

Another advantage of using data analytics in supply chain planning is the ability to identify bottlenecks and inefficiencies in the supply chain process. By analyzing data from procurement, production, transportation, and distribution, companies can pinpoint areas of improvement and take corrective actions. Data analytics can also help companies explore alternate supplier options, identify cost-saving opportunities, and develop strategies for efficient sourcing and transportation.

**Facilitating Risk Management and Mitigation**

Data analytics plays a crucial role in supply chain risk management and mitigation by providing real-time information from various sources. By analyzing data from external factors such as natural disasters, geopolitical issues, and economic shifts, companies can better understand potential risks and more effectively plan for disruptions. This helps in reducing the vulnerability of the supply chain to unforeseen events and contributes to a more robust and resilient supply chain operation.

In conclusion, data analytics has a tremendous impact on the efficiency of supply chain planning by optimizing inventory management, enhancing demand planning, identifying bottlenecks and process improvements, and facilitating risk management and mitigation. Companies that successfully leverage data analytics can gain a competitive advantage by making informed decisions and optimizing their supply chain operations.

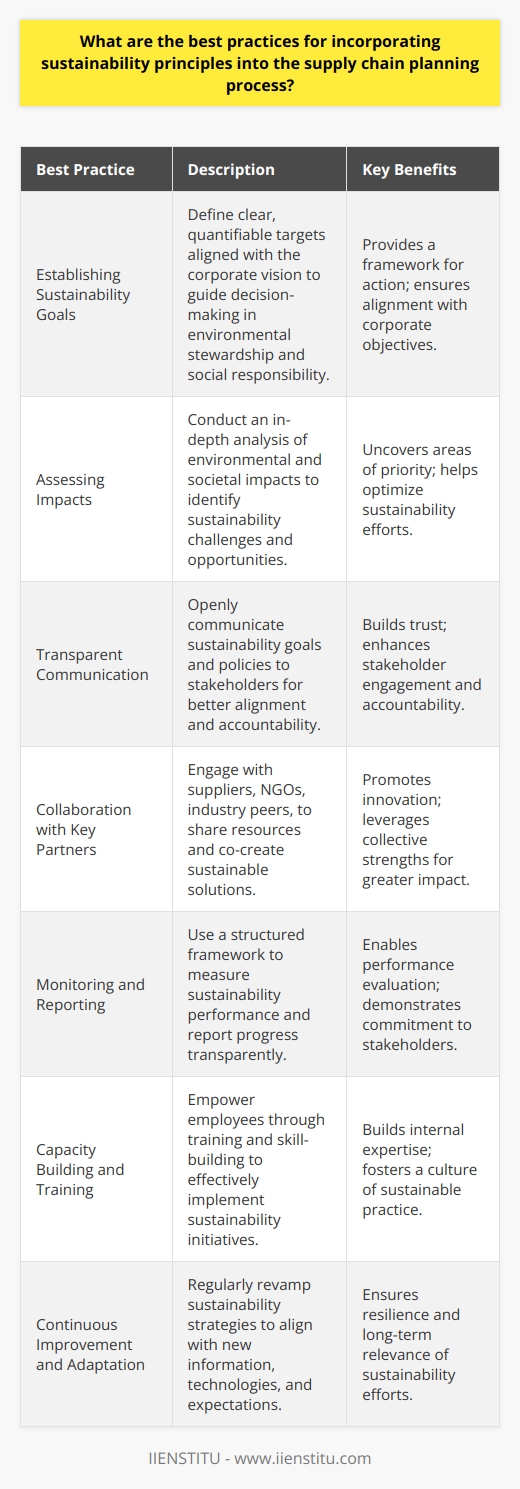

What are the best practices for incorporating sustainability principles into the supply chain planning process?

Establishing Sustainability Goals

The first best practice for incorporating sustainability principles into the supply chain planning process is to establish clear and measurable sustainability goals. These goals should be aligned with the company's overall business strategy and objectives and communicated across the entire organization.

Assessing Impacts

A thorough environmental and social impact assessment of the existing supply chain should then be conducted. This step helps to identify key sustainability issues and areas for improvement, which will support the development of strategies to mitigate potential negative effects throughout the supply chain.

Transparent Communication

An effective communication strategy is crucial to ensure that all stakeholders, including suppliers and customers, are well-aware of the company's sustainability goals and expectations. Transparency in communication creates a shared understanding and builds trust, which is essential for successful implementation of sustainability initiatives.

Collaboration with Key Partners

Engaging in partnerships and collaboration with suppliers, customers, and other like-minded organizations can contribute significantly to improving supply chain sustainability. Collaboration allows companies to share knowledge, resources, and best practices, leading to greater impact and more efficient efforts in achieving sustainability objectives.

Monitoring and Reporting

Regular monitoring and reporting of sustainability performance is critical to guarantee continuous improvements in the supply chain. Key performance indicators should be established to track progress and ensure the effectiveness of the strategies implemented. Furthermore, reporting should be transparent and accessible to all stakeholders, demonstrating the company's commitment to sustainability.

Capacity Building and Training

Building capacity and providing training to staff involved in supply chain management is essential for the successful integration of sustainability principles. Targeted training programs can empower employees with the skills and knowledge to make informed decisions and drive sustainability efforts.

Continuous Improvement and Adaptation

Lastly, companies should commit to continuously improving their supply chain sustainability performance by regularly reviewing sustainability goals, strategies, and impacts. This iterative process allows for adaptation to changing circumstances and ensures that companies stay at the forefront of sustainable supply chain management practices.

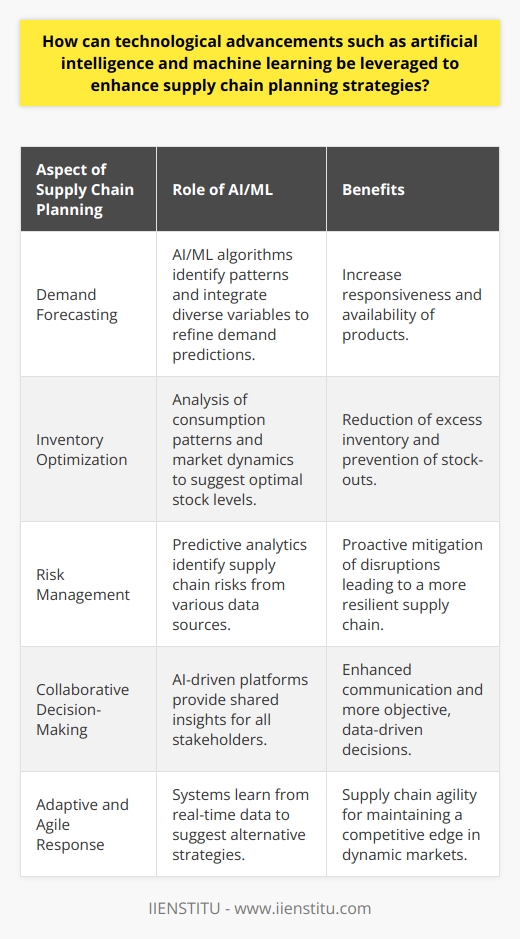

How can technological advancements such as artificial intelligence and machine learning be leveraged to enhance supply chain planning strategies?

Technological Integration in Supply Chain Planning

The ongoing developments in artificial intelligence (AI) and machine learning (ML) have significant implications for supply chain planning strategies. These advancements can enhance planning processes through a variety of means, including demand forecasting, inventory optimization, and risk management.

Demand Forecasting Accuracy

A key aspect of effective supply chain planning is accurate demand forecasting, which enables efficient resource allocation and prevents stockouts or excess inventory. AI-powered algorithms and ML models can analyze historical data and recognize patterns to generate highly accurate demand forecasts. By incorporating real-time data inputs and continuously refining their predictions, these tools help optimize supply chain efficiency.

Inventory Optimization

AI and ML can also contribute to inventory optimization, ensuring that the right amount of products is available at the right time and place. By leveraging advanced analytics and predictive capabilities, these technologies facilitate improved stock level and order management decisions. Additionally, they enable more efficient responses to fluctuations in demand or supply, minimizing the impact of potential disruptions.

Risk Management Enhancement

Supply chain disruptions, such as natural disasters or political instability, can significantly impact organizations' ability to maintain efficient and timely deliveries. AI and ML play a crucial role in enhancing risk management capabilities within supply chain planning by providing predictive analyses and identifying potential threats. This allows organizations to mitigate risks proactively, develop contingency plans, and maintain a resilient supply chain.

Collaborative Decision-making

Integrating AI and ML technologies into supply chain planning also enables more effective collaboration and decision-making among various stakeholders. The increased accuracy and real-time insights generated by these tools provide a strong foundation for informed discussions and decisions. This collaborative approach can lead to better alignment between different departments and business partners, resulting in a more streamlined and agile supply chain.

In conclusion, the integration of AI and machine learning into supply chain planning strategies offers numerous opportunities for efficiency, accuracy, and risk reduction. By providing intelligent forecasting tools, optimizing inventory management, enhancing risk management capabilities, and facilitating collaboration, these technological advancements significantly contribute to a more effective and resilient supply chain.

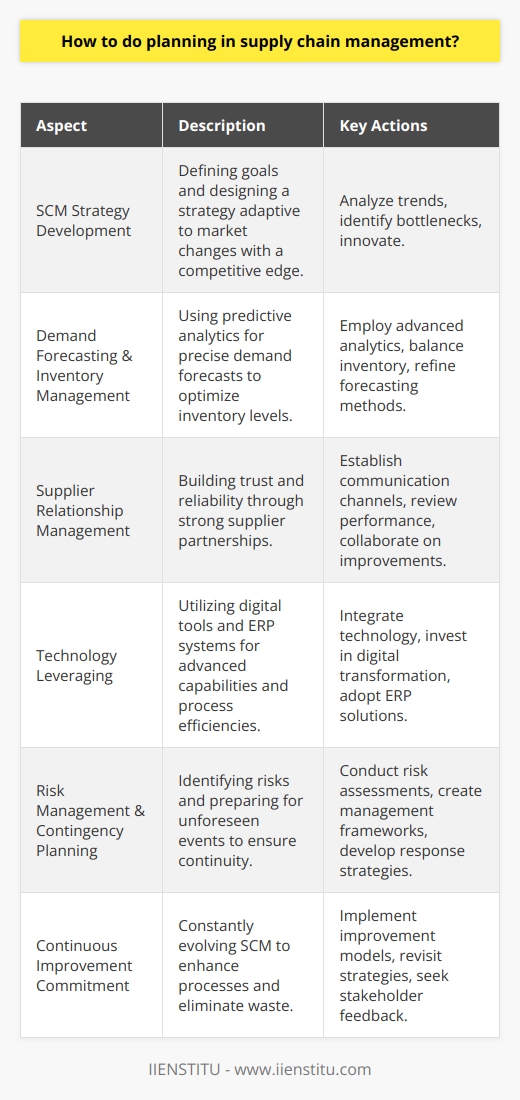

How to do planning in supply chain management?

Effective Strategy Development

To ensure efficient planning in supply chain management, it is crucial to first develop a comprehensive and effective strategy. This involves taking into account company objectives, market dynamics, and potential disruptions. The strategy should be well-aligned with business goals to achieve optimal results.

Demand Forecasting and Inventory Management

Understanding customer demand and accurately forecasting it is an essential aspect of supply chain planning. Historical sales data, market trends, and customer preferences should inform and enhance the demand forecasting process. Moreover, proper inventory management will ensure the availability of products and prevent stock shortages or excess, thus maximizing customer satisfaction and minimizing costs.

Supplier Relationship Management

Establishing a robust supplier relationship management system significantly benefits supply chain planning. This involves selecting reliable and high-quality suppliers, ensuring prompt and efficient communication, and regularly evaluating and monitoring supplier performance. Collaborative relationships with suppliers contribute to business sustainability and growth by ensuring the timely procurement of raw materials, components, and services.

Implementation of Technology

Adopting modern technology is a key factor in optimizing supply chain planning. Advanced software solutions, such as enterprise resource planning (ERP) systems, enable real-time tracking, monitoring, and analysis of supply chain processes. This facilitates data-driven decision making and improves visibility across the entire supply chain, leading to better planning and increased efficiency.

Risk Management and Contingency Planning

Effective supply chain planning also involves managing potential risks, such as natural disasters, supplier disruptions, and changing market conditions. This requires a proactive approach to detect vulnerabilities and develop contingency plans to mitigate potential negative impacts. Regular risk assessment and scenario planning will enhance the ability to adapt to unforeseen circumstances and optimize supply chain resilience.

Continuous Improvement

Lastly, continually reviewing and updating supply chain plans ensures that they remain relevant, agile, and responsive to market needs. Constant evaluation of processes and the implementation of key performance indicators (KPIs) can help identify areas for improvement. Continuous improvement promotes a culture of innovation and adaptability, leading to optimized supply chain performance and a more robust and competitive organization.

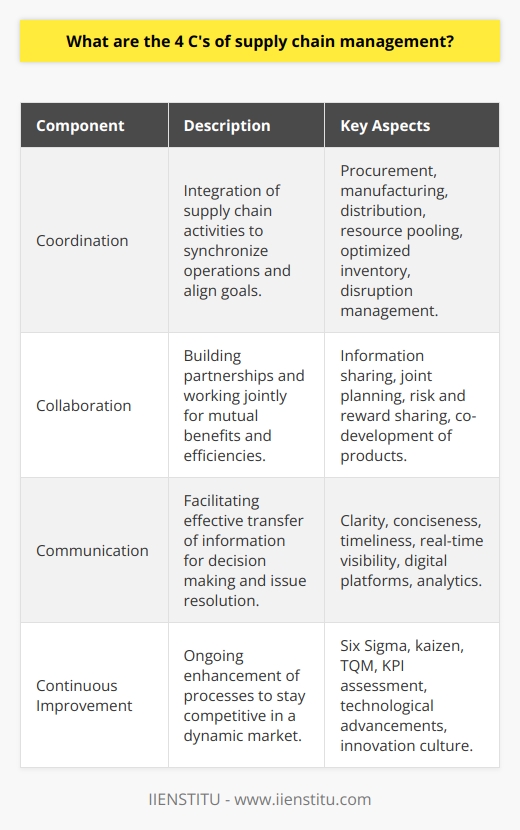

What are the 4 C's of supply chain management?

Four Key Components of Supply Chain Management

**Coordination**

The first C of supply chain management is coordination, which involves aligning various activities within a supply chain to achieve efficient operations. This encompasses coordinating tasks and information flows between suppliers, manufacturers, logistics providers, and customers to maximize performance, minimize costs, and ensure timely product delivery, leading to increased customer satisfaction.

**Collaboration**

The second C of supply chain management is collaboration. Collaboration among different stakeholders is crucial for ensuring responsiveness, flexibility, and continuous improvement in a supply chain. By sharing information about demand forecasts, production plans, product specifications, and inventory levels, supply chain partners can better anticipate potential issues and address them proactively, resulting in reduced lead times, improved quality, and ultimately, enhanced competitiveness.

**Communication**

Effective communication is the third C of supply chain management. Proper communication channels must be in place to facilitate the exchange of critical information among supply chain partners. Data accuracy, clarity, and consistency are essential for preventing misunderstandings, bottlenecks, and inefficiencies within the supply chain. With advances in information technology, supply chain stakeholders can leverage digital tools like electronic data interchange (EDI), cloud-based platforms, and real-time analytics to support streamlined communication and decision-making.

**Continuous Improvement**

Lastly, continuous improvement constitutes the fourth C of supply chain management. Supply chain stakeholders need to adopt a continuous improvement mindset to stay ahead of the competition, adapting to evolving customer requirements, and advances in technology. Implementing lean management principles, regularly assessing performance metrics, and soliciting feedback from end consumers can all help in the identification and resolution of persistent inefficiencies and optimization of processes across the supply chain.

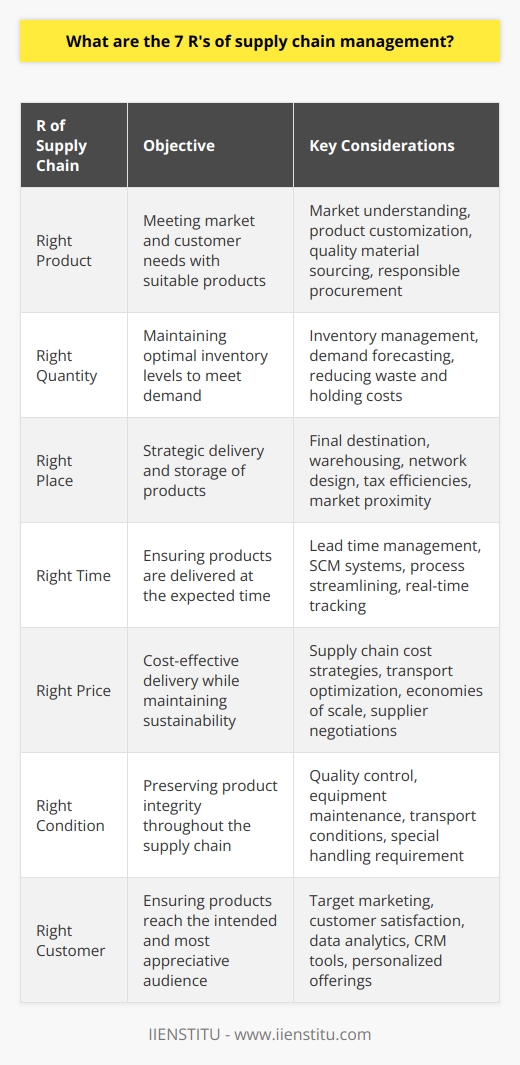

What are the 7 R's of supply chain management?

Introduction to the 7 R's

The seven R's of supply chain management (SCM) are a set of guiding principles aimed at helping organizations improve their overall supply chain performance, efficiency, and effectiveness.

Right Product

The first R stands for the 'right product,' which refers to ensuring that a company sources, procures, and delivers products that meet its customers' demands, preferences, and specifications. This includes selecting the appropriate materials, suppliers, and manufacturing methods to ensure quality and reliability.

Right Quantity

The 'right quantity' emphasizes the need to balance customer demand and inventory levels in order to minimize waste, overstocking or stockouts, while ensuring that products are readily available when needed. Accurate forecasting, demand planning, and inventory management are crucial to achieve this objective.

Right Place

Delivering the products to the 'right place' entails optimizing distribution networks, choosing appropriate transportation modes, and identifying the most efficient routes to expedite delivery times while minimizing costs. It also involves ensuring that products are easily accessible and available for customers at their desired locations.

Right Time

Punctuality is crucial, as customers expect to receive their orders promptly and within the agreed-upon time frame. Achieving the 'right time' requires seamless integration across the supply chain, from production to transportation and logistics, in order to meet delivery deadlines and maintain customer satisfaction.

Right Price

Competitive pricing is essential in today's market, so it's vital for supply chain managers to consistently monitor the costs tied to producing and delivering goods. Achieving the 'right price' entails enacting cost-saving measures, maximizing efficiency, and negotiating favorable supplier contracts to maintain profitability and market share.

Right Condition

The 'right condition' means that products are delivered in pristine condition without defects or damages, whether they are consumables, perishables, or fragile goods. Proper packaging, handling procedures, and temperature-controlled transportation are key components to fulfilling this requirement.

Right Customer

Lastly, the 'right customer' underscores the importance of targeting appropriate market segments, understanding customer preferences, and providing personalized offerings. Customer relationship management (CRM) systems can help businesses gather valuable data to better serve their target audiences and streamline marketing efforts.

In conclusion, the 7 R's of supply chain management guide organizations to enhance their supply chain performance by ensuring that they provide the right product, in the right quantity, at the right place, time, price, condition, and for the right customer. By implementing these principles, companies can optimize their supply chains, gain competitive advantages, and improve overall customer satisfaction.

What is product planning supply chain?

Product Planning in Supply Chain

Product planning supply chain is a vital aspect of management that ensures a seamless flow of products and components through all stages of the production process. It entails the strategic coordination and synchronization of various functions, including forecasting, sourcing, manufacturing, and distribution, to meet customer demands effectively and efficiently.

Forecasting and Demand Management

Central to product planning is accurate demand forecasting, which entails predicting future customer requirements to drive decision-making throughout the supply chain. Accurate forecasting enables organizations to optimize inventory levels, reduce excess stock, and respond proactively to fluctuations in demand. Consequently, this ensures smooth production processes while minimizing costs and achieving customer satisfaction.

Sourcing and Procurement

A well-planned sourcing and procurement strategy ensures the timely availability of the materials and components needed for the manufacturing process. In product planning, companies need to consider multiple factors such as lead times, supplier reliability, quality, and costs. By optimizing sourcing and procurement decision-making, organizations can mitigate risks, enhance sustainability, and ultimately create a competitive advantage.

Manufacturing and Production

The manufacturing stage involves transforming raw materials and components into finished goods, ready for distribution to end consumers or retailers. Efficient product planning ensures the optimal allocation of resources within the manufacturing process to reduce waste, minimize costs, and enhance profitability. Additionally, companies must consider capacity constraints and production lead times to ensure a smooth manufacturing flow and avoid bottlenecks or stockouts.

Distribution and Logistics

Lastly, the distribution stage is responsible for delivering the finished products to the customers, ensuring timely and efficient deliveries. Through effective product planning, companies can optimize logistical decisions and transportation modes, balancing cost, and time efficiency. Proper distribution and logistics planning help to minimize delays and enhance overall customer satisfaction.

In conclusion, product planning supply chain plays a crucial role in the success of businesses by enhancing the seamless flow of materials, goods, and information between all stages of the production process. By incorporating strategic planning and decision-making in each component of the supply chain, companies can achieve increased efficiency, reduced costs, and improved customer satisfaction. Ultimately, effective product planning constructs a strong foundation for a sustainable and competitive organization in today's fast-paced and evolving market.

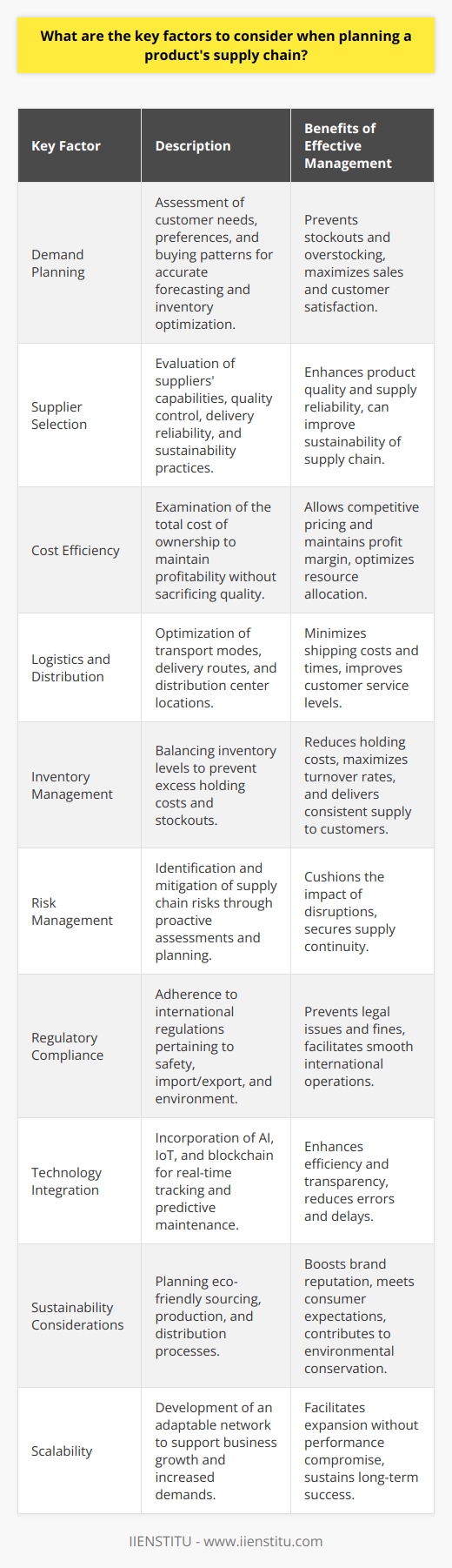

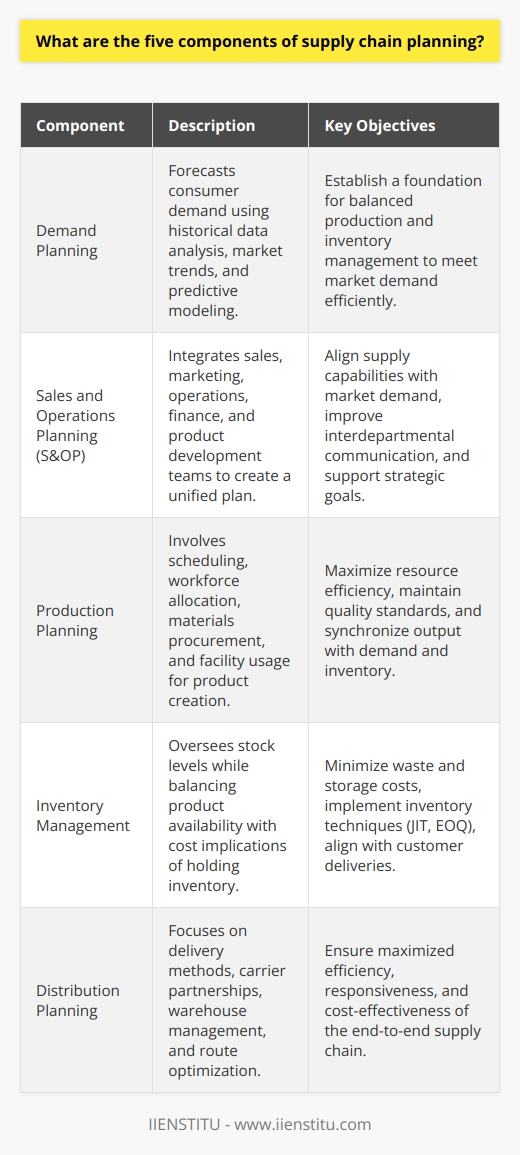

What are the five components of supply chain planning?

**Supply Chain Planning Components**

Supply chain planning is a crucial process to ensure the efficient flow of goods and materials within a business. There are five main components involved in this process, which work together to optimize the overall supply chain operations.

**Demand Planning**

The first is demand planning, which focuses on predicting customer demand and determining effective ways to manage and satisfy it. It helps in aligning production, inventory, and distribution resources to ensure timely delivery of products to customers.

**Sales and Operations Planning**

Second is sales and operations planning (S&OP), which aims to balance supply and demand by integrating sales, marketing, and operational plans. S&OP fosters collaboration between departments, allowing a company to achieve organizational goals, while reducing risks and inefficiencies.

**Production Planning**

The third component, production planning, deals with managing and allocating resources, such as labor, materials, and equipment, needed to produce goods. By developing a production schedule, it ensures that the right products are made at the right time to meet customer demand.

**Inventory Management**

Fourth is inventory management, which is essential for maintaining an optimal level of stock while minimizing costs associated with carrying excess inventory. Effective inventory management techniques, such as just-in-time (JIT) and economic order quantity (EOQ), help balance the supply and demand of products.

**Distribution Planning**

Lastly, distribution planning focuses on the efficient transportation and delivery of goods from the manufacturer to the end customer. It involves determining the most appropriate methods of transportation, selecting the best routes and carriers, and managing the flow of goods through distribution centers.

In conclusion, supply chain planning consists of five main components: demand planning, sales and operations planning, production planning, inventory management, and distribution planning. Each component plays an essential role in managing, optimizing, and streamlining the supply chain operations, leading to business success and cost efficiency.

What are the 7 R's of supply chain management?

Seven Key Principles of Supply Chain Management

**Resourceful Planning**

The first R, Resourceful Planning, emphasizes the importance of careful and strategic planning in supply chain management. By accurately forecasting demand and effectively managing resources, organizations can ensure a smooth and efficient supply chain process.

**Responsible Sourcing**

Responsible Sourcing involves selecting suppliers who uphold ethical standards and meet performance expectations. This not only promotes sustainability within supply chains but also minimizes potential risks associated with unreliable or unethical suppliers.

**Rapid Responsiveness**

Rapid Responsiveness refers to the ability of a supply chain to quickly adapt to changes in market conditions and customer needs. Organizations with agile and responsive supply chains can better satisfy customer demands and maintain a competitive edge in the market.

**Reduction of Waste**

A key principle in effective supply chain management is the Reduction of Waste. By identifying and minimizing inefficiencies, organizations can reduce costs, improve customer satisfaction, and minimize their environmental impact.

**Reliable Deliveries**

Reliable Deliveries ensure that products and services reach customers in a timely and predictable manner. By focusing on meeting customer expectations and providing consistent delivery performance, organizations can strengthen their reputation and build lasting relationships with clients.

**Relationship Building**

The sixth R, Relationship Building, highlights the importance of developing strong, long-term partnerships with suppliers and customers. By cultivating trust and collaboration, organizational leaders can create a more efficient and resilient supply chain network that benefits all parties involved.

**Resilient Systems**

Finally, Resilient Systems refers to the ability of a supply chain to withstand and recover from disruptions or unexpected events. Supply chain resilience can be achieved by implementing risk management strategies, maintaining contingency plans, and regularly assessing the strength and stability of the entire supply network.

In conclusion, the 7 R's of supply chain management provide a comprehensive framework for guiding organizations in creating and managing efficient, sustainable, and customer-focused supply chains. By adhering to these principles, businesses can optimize their processes, reduce costs, and better adapt to an ever-changing global market.

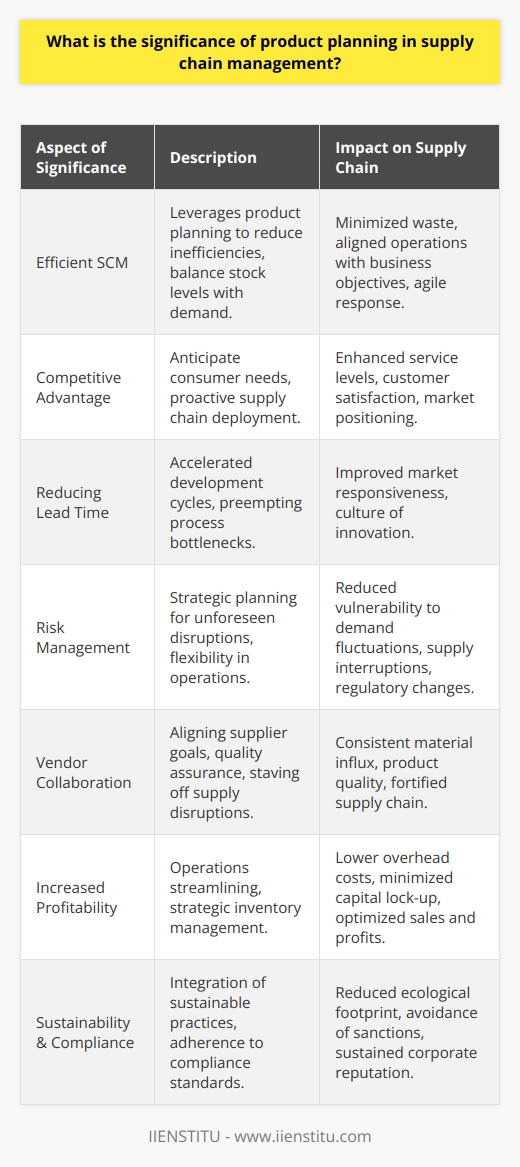

What is the significance of product planning in supply chain management?

Significance of Product Planning

Efficient Supply Chain Management

Product planning plays a crucial role in supply chain management as it ensures efficient production and distribution of goods. A well-planned product strategy reduces waste, improves resource utilization, and results in better customer satisfaction.

Enhancing Competitive Advantage

In a competitive business environment, effective product planning helps organizations gain a competitive advantage. By forecasting demand and planning production accordingly, companies can maintain optimum inventory levels, reduce operational costs, and enhance their market share.

Reducing Lead Time

Lead time is the duration between the initiation of a production process and the completion of the final product. Product planning helps identify bottlenecks, streamline processes, and optimize resources, ultimately reducing lead time and improving responsiveness to market demands.

Risk Management

Product planning is essential in managing and mitigating various risks associated with the supply chain. By analyzing potential challenges such as fluctuations in demand, supply disruptions, or changes in regulations, companies can be proactive in their decision-making and minimize the impact of such factors on their operations.

Improving Vendor Collaboration

Effective product planning includes collaboration and communication with suppliers. This ensures timely access to necessary resources, reduces the risk of stockouts, and maintains a smooth supply chain.

Increased Profitability

Product planning, when executed correctly, results in increased profitability for the organization. By reducing production costs, improving product quality, and aligning production with market demands, organizations can capitalize on market opportunities and achieve better profit margins.

Sustainability and Compliance

Lastly, product planning enables organizations to ensure compliance with regulatory requirements and promote sustainable business practices. By incorporating environmental, social, and economic considerations in product planning, companies can minimize their environmental impact and contribute positively to the community.

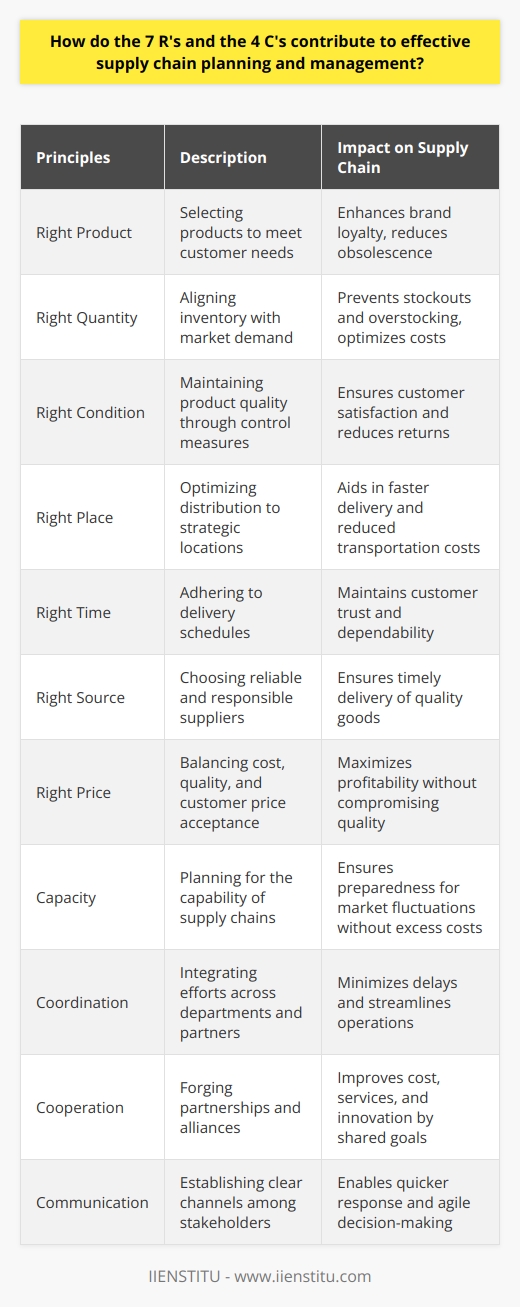

How do the 7 R's and the 4 C's contribute to effective supply chain planning and management?

Incorporating the 7 R's and 4 C's in Supply Chain Planning

Achieving optimal performance in supply chain management requires the careful integration of strategic principles and practices. Among these are the well-established methodologies of the 7 R's and the 4 C's, which enhance the planning and management process in this vital field.

Understanding the 7 R's

The 7 R's framework underpins the fluidity and overall effectiveness of supply chains by ensuring that companies deliver the right products and services to their customers. Specifically, the 7 R's encompass:

Right Product: Ensuring the offered item aligns with customer preferences and expectations.

Right Quantity: Maintaining adequate stock levels to meet demand without excessive surplus.

Right Condition: Guaranteeing that products reach customers in good order and without damage.

Right Place: Providing convenient access for customers, whether through retail locations or distribution channels.

Right Time: Ensuring timeliness of delivery to coincide with customer needs and expectations.

Right Source: Credible and reliable suppliers are essential to a well-functioning supply chain.

Right Price: Striking the balance between cost-efficiency and customer satisfaction to achieve profitability.

Harnessing the 4 C's

The 4 C's framework complements the 7 R's by focusing on core strategies that enhance planning and management within the supply chain. The 4 C's consist of:

Capacity: Optimizing the use of resources to maximize productivity while minimizing waste and associated costs.

Coordination: Ensuring seamless movement of products and information among supply chain stakeholders.

Cooperation: Encouraging collaboration between various entities within the supply chain to enhance performance and facilitate problem-solving.

Communication: Facilitating the sharing of vital information in a timely and accurate manner, enabling informed decision-making.

In conclusion, the synergistic integration of the 7 R's and the 4 C's contributes to effective supply chain planning and management by enabling companies to provide their customers with the right products and services, at the right time and place, and at competitive prices. Furthermore, these frameworks emphasize the importance of collaboration, communication, and coordination among stakeholders, ultimately resulting in greater efficiency and profitability within the supply chain.

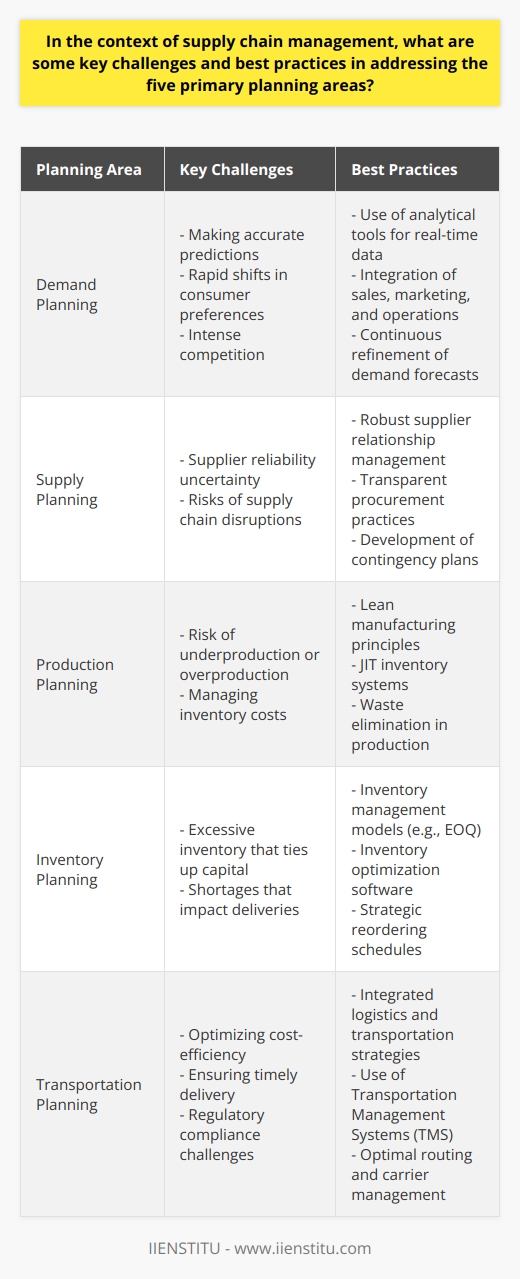

In the context of supply chain management, what are some key challenges and best practices in addressing the five primary planning areas?

Challenges in Five Primary Planning Areas

The supply chain management landscape is riddled with challenges that organizations must overcome to ensure efficient operation and competitive advantage. These issues span across the five primary planning areas, which include demand planning, supply planning, production planning, inventory planning, and transportation planning.

Demand Planning Challenges

One of the key challenges in demand planning is accurately forecasting demand in an increasingly competitive and rapidly changing marketplace. To overcome this challenge, organizations must invest in advanced analytics tools and techniques to monitor, evaluate, and predict market trends. Additionally, fostering close collaboration between different stakeholders within the organization can help streamline decision-making and improve forecasting accuracy.

Supply Planning Hurdles

In the realm of supply planning, organizations face the challenge of securing raw materials and components from reliable suppliers. Strengthening supplier relationships, implementing strategic sourcing strategies, and maintaining transparency in procurement processes can all contribute to addressing this challenge. Moreover, organizations must adopt a proactive approach to risk management in order to mitigate potential supply chain disruptions.

Production Planning Obstacles

Underproduction and overproduction can have significant financial consequences for an organization. Combating these challenges requires organizations to adopt state-of-the-art production planning methodologies, such as lean manufacturing and just-in-time inventory management. Emphasizing continuous improvement and adopting robust performance measurement systems can further optimize production processes.

Inventory Planning Complexities

Holding excessive inventory can lead to obsolescence, stockouts, and inflated carrying costs. To address these challenges, organizations must employ efficient inventory planning strategies, like the economic order quantity model. Additionally, deploying inventory optimization software can aid in maintaining optimal inventory levels and ensuring stock availability for all product lines.

Transportation Planning Issues

Transportation planning presents challenges such as ensuring timely deliveries, minimizing transportation costs, and adhering to environmental regulations. Adopting an integrated logistics approach can help overcome these challenges by streamlining transportation processes and maximizing cost-efficiency. Furthermore, leveraging technology, such as transportation management systems, can improve visibility, monitoring, and decision-making in this crucial planning area.

In conclusion, addressing the challenges and implementing best practices in the five primary planning areas can result in significant improvements in supply chain management performance. Through the strategic application of advanced tools, techniques, and collaboration, organizations can successfully navigate the complexities of these functions and remain competitive in the global marketplace.