This article discussed why inventory is necessary, what customers value, how to balance inventory and service levels, and how forecasting and optimization can help businesses manage their inventory more effectively.

Introduction

Why Inventory is Necessary

What Customers Value

Balancing Inventory & Service Levels

Forecasting & Inventory Optimization

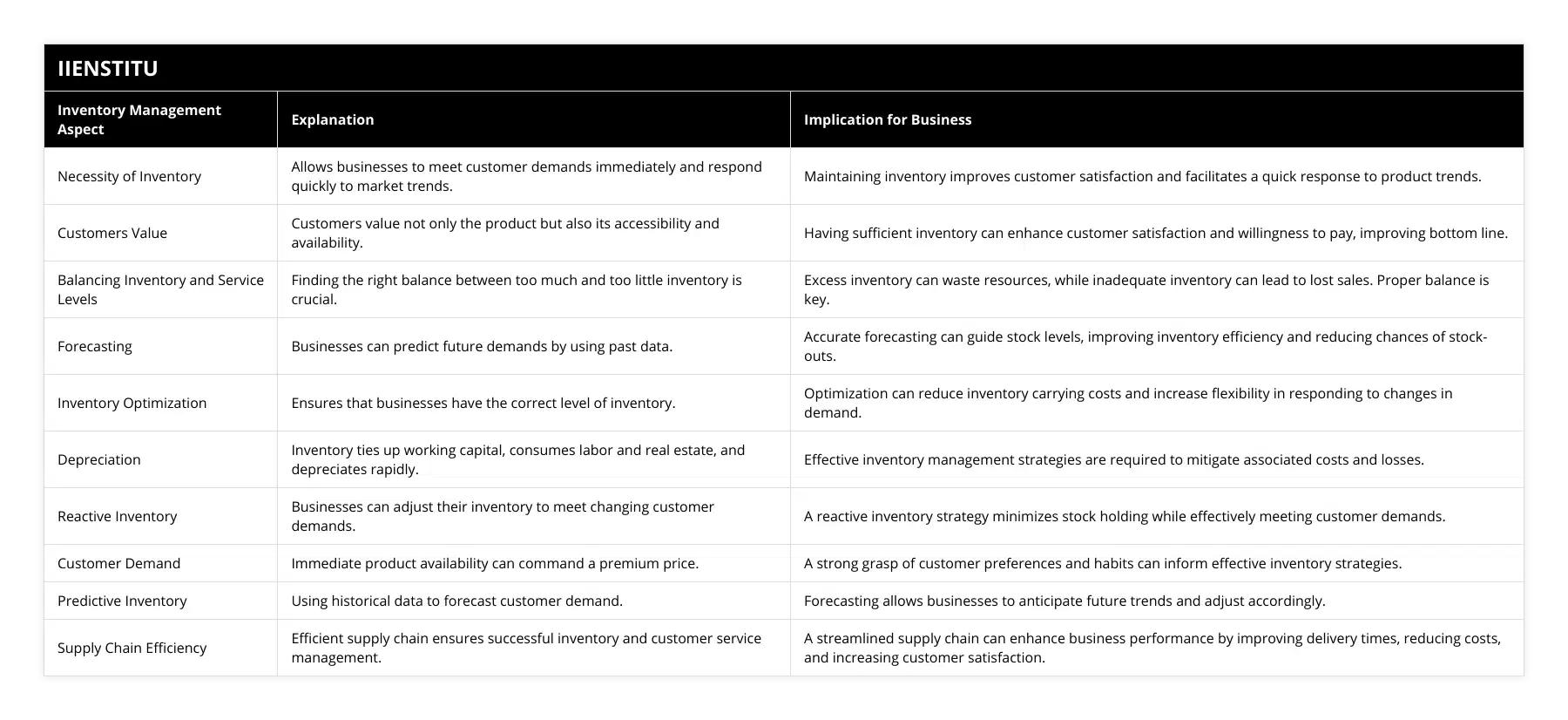

Introduction: Inventory is an essential part of any successful business. It ties up working capital, consumes labor and real estate, and depreciates rapidly. While it may seem counterintuitive, inventory is necessary to meet customer demands. This article will discuss why inventory is necessary, what customers value, how to balance inventory and service levels, and how forecasting and inventory optimization can help.

Why Inventory is Necessary

Inventory is necessary because it allows businesses to meet customer demands. Without an inventory, customers would have to wait for products to be manufactured or shipped from a distant location, which may not be feasible. Inventory also helps businesses to respond quickly to changing customer demands. For example, if a business notices that a particular product is becoming popular, it can quickly increase its inventory to meet customer demands.

What Customers Value

When it comes to customer value, it is essential to consider not just the product itself but also the placement and availability of the product. Customers are willing to pay more for products that are available immediately or that can be delivered quickly. This is why businesses must have enough inventory on hand to meet customer demands.

Balancing Inventory & Service Levels

Balancing inventory and service levels is a vital part of managing inventory. Too much inventory can lead to wasted resources, and too little inventory can lead to lost sales. Businesses must carefully monitor their inventory levels and adjust them accordingly. This can be done by forecasting customer demand and adjusting inventory levels accordingly.

Forecasting & Inventory Optimization

Forecasting customer demand is an essential part of managing inventory. Businesses can use historical data to predict future demand and adjust their inventory levels accordingly. Additionally, businesses can use inventory optimization techniques to ensure they have the right amount of inventory at hand.

Conclusion

Inventory is an essential part of any successful business. It allows businesses to meet customer demands and respond quickly to changing customer demands. It is essential to balance inventory and service levels to maximize profits and minimize costs. Forecasting and inventory optimization can help businesses to manage their inventory more effectively.

An efficient supply chain is the foundation of successful inventory and customer service management.

The article comprehensively covers the essentials of inventory management, outlining its necessity to meet customer demands and the importance of product availability and quick delivery in enhancing customer value. The article emphasizes the key role played by an optimal balance between inventory and service levels in preventing resource wastage or sales loss. It also underscores the significance of accurate forecasting and inventory optimization in effective inventory management. Therefore, a supply chain management online course could be beneficial for businesses, providing them with the knowledge and tools they need to find success in inventory management and rapid response to fluctuating customer demands.

Frequently Asked Questions

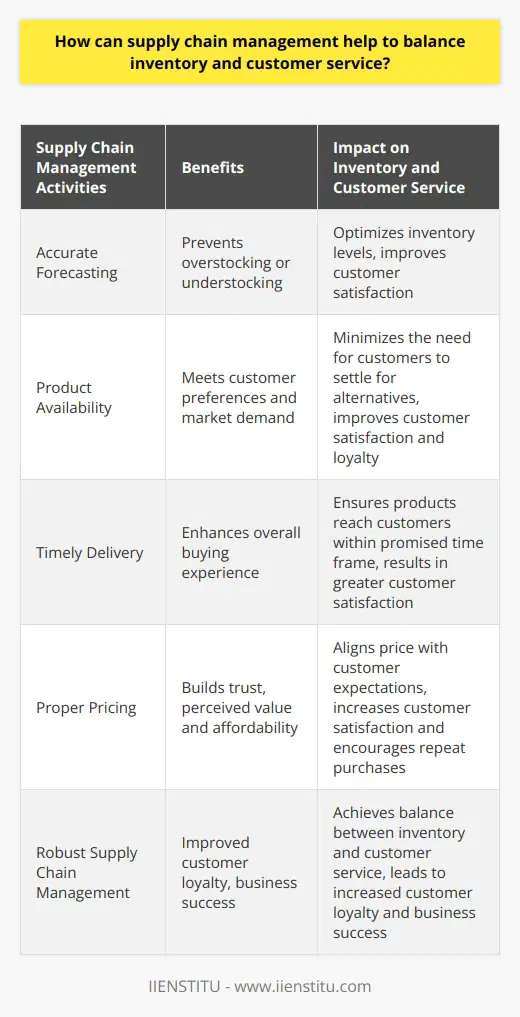

How can supply chain management help to balance inventory and customer service?

Supply chain management is an essential factor in successful inventory and customer service. Proper supply chain management can help ensure that inventory is balanced with customer service. This article will discuss how supply chain management can help balance inventory and customer service.

First, proper supply chain management can help ensure that the right amount of inventory is available to meet customer demand. This can be done by accurately forecasting customer demand and having the proper inventory to meet that demand. This helps to avoid overstocking or understocking of inventory, which can lead to customer dissatisfaction.

Second, proper supply chain management can help ensure that the right products are available to meet customer needs. By accurately forecasting customer demand and having the right products available, customers can be more satisfied with the products they receive. This can help to ensure that customers are satisfied with the product they receive and that they return for future purchases.

Third, proper supply chain management can help ensure that the right products are delivered on time. By ensuring the right products are delivered on time, customers can be satisfied with their experience. This can help to improve customer service and ensure that customers are satisfied with their purchases.

Finally, proper supply chain management can help ensure that the right products are delivered at the right price. Accurately forecasting customer demand can deliver the right products at the right price. This can help to ensure that customers are satisfied with their purchases and that they return for future purchases.

In conclusion, proper supply chain management can help balance inventory and customer service. By accurately forecasting customer demand, having the right amount of inventory on hand, having the right products available, delivering the right products on time, and delivering the right products at the right price, customers can be satisfied with their purchases. This can lead to increased customer satisfaction and return customers.

What strategies can be used to ensure that customer service levels are maintained while managing inventory?

The success of a business is primarily determined by the quality of customer service it provides. As such, it is essential for businesses to ensure that customer service levels are maintained while managing their inventory. In this article, we will discuss some strategies that can be used to ensure that customer service remains high while managing inventory.

The first strategy that can be used is forecasting. Businesses should use forecasting to anticipate customer demands and plan their inventory accordingly. This will help them to avoid stockouts and maintain their customer service levels. Additionally, businesses should use analytics to identify trends in customer behavior and use this data to plan their inventory. This will help them to accurately predict customer demand and ensure that the right amount of inventory is available to meet customer needs.

Second, businesses should implement just-in-time (JIT) inventory management. JIT inventory management involves ordering and stocking inventory only when needed, thus reducing the amount of capital tied up in inventory. This will help businesses to ensure that the right amount of inventory is available to meet customer needs. Additionally, businesses should use technology to automate the ordering and stocking process. This will help them to quickly identify customer demands and ensure that the right amount of inventory is available.

Third, businesses should develop relationships with suppliers. Establishing good relationships with suppliers will help businesses to quickly identify customer demands and ensure that the right amount of inventory is available. Additionally, businesses should work with their suppliers to provide incentives for timely delivery. This will help them to ensure that the right amount of inventory is available when customers need it, thus maintaining customer service levels.

Finally, businesses should use customer feedback to understand customer needs and expectations better. Collecting customer feedback and using it to improve inventory management will help businesses maintain customer service levels. Additionally, businesses should use customer feedback to identify areas of improvement and take steps to address them.

In conclusion, businesses should use forecasting, JIT inventory management, supplier relationships, and customer feedback to maintain customer service levels while managing inventory. Doing so will help businesses to ensure that the right amount of inventory is available when customers need it, thus improving customer satisfaction and loyalty.

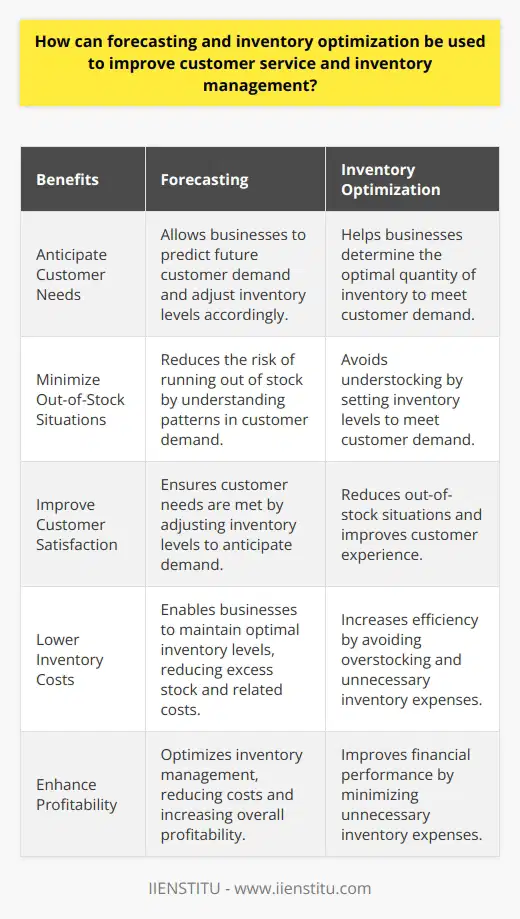

How can forecasting and inventory optimization be used to improve customer service and inventory management?

In today’s ever-changing business climate, companies need to use forecasting and inventory optimization to remain competitive and provide customers with the highest satisfaction. Forecasting and inventory optimization can improve customer service and inventory management by providing businesses with insights into customer demand, enabling them to anticipate customer needs and develop effective strategies for managing inventory levels.

Forecasting is the process of predicting future customer demand and inventory levels. Through this process, businesses can develop an understanding of the patterns of customer demand and the amount of inventory required to meet customer needs. This allows companies to anticipate customer needs and adjust inventory levels accordingly, reducing the risk of out-of-stock situations and ensuring customer satisfaction.

Inventory optimization is setting inventory levels to meet customer demand while minimizing costs. Through this process, businesses can determine the optimal quantity of inventory to keep on hand to meet customer needs while avoiding overstocking or understocking. This helps businesses to ensure customer satisfaction by minimizing out-of-stock situations and reducing inventory costs.

By combining forecasting and inventory optimization, businesses can develop an understanding of customer demand and adjust inventory levels accordingly. This allows businesses to anticipate customer needs and optimize inventory levels to meet customer demand, thus reducing out-of-stock situations and improving customer satisfaction. Additionally, inventory optimization can help businesses to reduce inventory costs, thus improving profitability.

In conclusion, forecasting and inventory optimization are essential tools for businesses looking to improve customer service and inventory management. By utilizing these tools, businesses can gain insights into customer demand, anticipate customer needs, and optimize inventory levels to reduce out-of-stock situations and inventory costs. As such, forecasting and inventory optimization are essential for any business looking to remain competitive and provide customers with the highest level of satisfaction.

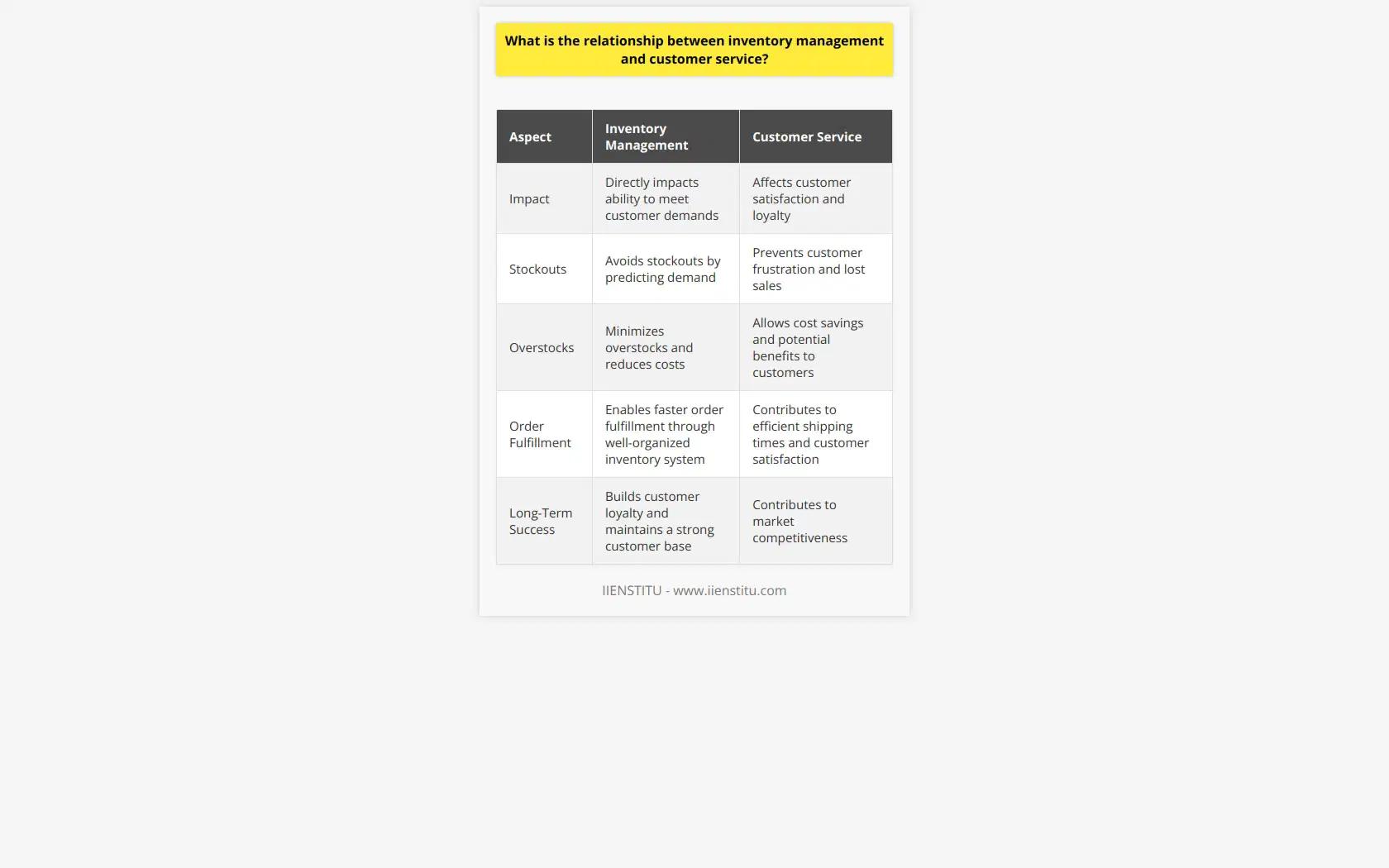

What is the relationship between inventory management and customer service?

The Impact of Inventory Management on Customer Service

Inventory management plays a crucial role in maintaining customer satisfaction and loyalty. Effective inventory management techniques and strategies ensure that companies can meet customers' demands promptly, while maintaining optimal levels of inventory.

Minimizing Stockouts and Overstocks

By preventing stockouts, businesses can avoid disappointing customers who cannot find the products they want. On the other hand, minimizing overstocks reduces the risk of obsolete inventory or wasted storage space, ultimately resulting in cost savings that can be passed on to the customer. Proper inventory management practices can achieve both objectives, directly enhancing customer satisfaction.

Order Fulfillment and Shipping Time

A well-organized inventory system can speed up order fulfillment processes and shorten shipping times, directly impacting customer service. When businesses can quickly and accurately locate items in their warehouse, the time it takes to fulfill customer orders and ship products is significantly reduced. Consequently, customers are more likely to continue doing business with companies that provide efficient and expeditious service.

As a crucial aspect of supply chain management, inventory management has a direct correlation with customer service quality. When companies effectively manage their inventory, they can optimize stock levels, shorten order fulfillment and shipping times, thereby enhancing customer satisfaction and loyalty. Implementing robust inventory management systems is paramount for businesses seeking to maintain a strong customer base and a competitive edge in the market.

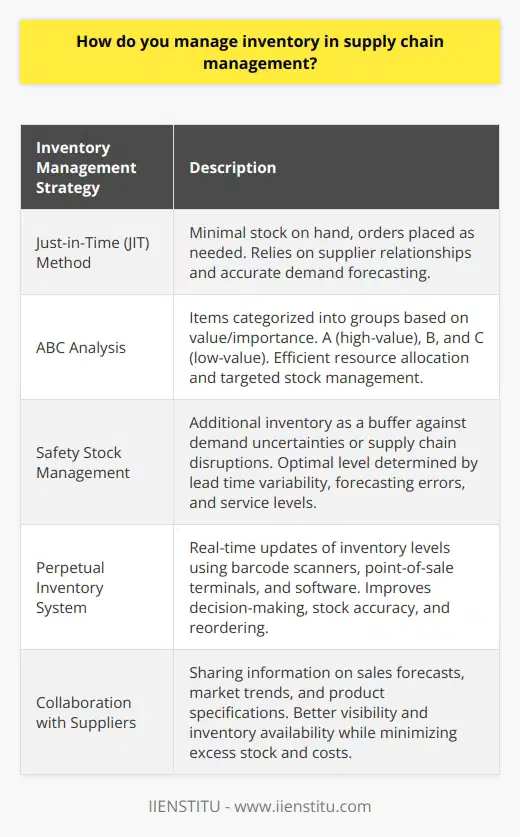

How do you manage inventory in supply chain management?

Inventory Strategies in Supply Chain Management

Effective management of inventory plays a crucial role in supply chain management, as it ensures optimal levels of stock are maintained to satisfy customer demand while minimizing costs. Different strategies can be employed to achieve these objectives, each tailored to suit specific business requirements, industry-related factors, or market dynamics.

Just-in-Time Approach

A Just-in-Time (JIT) approach involves keeping minimal amounts of stock on hand and ordering more as the need arises. JIT closely aligns with lean principles, aiming to reduce overheads and waste by only producing or sourcing goods when they are required. This method necessitates strong supplier relationships and accurate demand forecasts to ensure sufficient stock availability in response to customer needs.

ABC Analysis

Another popular method is ABC analysis, which involves categorizing items into three groups - A, B, and C – based on their value and importance. High-value products typically fall into group A and are managed most closely, whereas low-value items are placed in group C and managed with less attention. This prioritization enables a more efficient allocation of resources and targeted stock management.

Safety Stock Management

Safety stock management involves keeping extra inventory on hand as a buffer to protect against uncertainties in demand or disruptions in the supply chain, such as unforeseen delays or short-term spikes in demand. Determining the optimal level of safety stock requires careful consideration of factors like lead time variability, forecasting errors, and desired service level.

Perpetual Inventory System

Technology can greatly enhance inventory management by implementing a perpetual inventory system. This system continuously updates inventory levels in real-time through the integration of barcode scanners, point-of-sale (POS) terminals, and software applications. This real-time data can offer invaluable insights for decision making, improve stock accuracy, and assist in timely reordering.

Supplier Collaboration

Close collaboration with suppliers is essential in managing inventory effectively, as it offers better visibility throughout the supply chain. Sharing information about sales forecasts, anticipated market trends, and product specifications creates transparency that can help ensure inventory availability while minimizing excess stock and associated costs.

In conclusion, managing inventory in supply chain management requires a combination of efficient strategies, technology, and collaboration. By leveraging these methods, businesses can optimize their inventory levels, reduce costs, and ultimately enhance their overall supply chain performance.

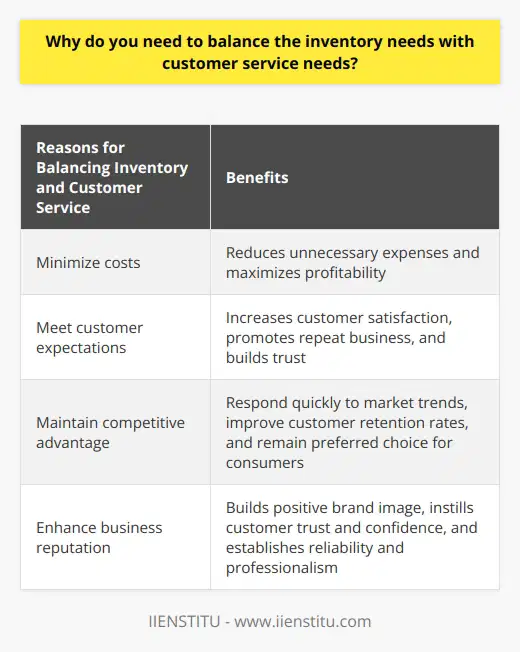

Why do you need to balance the inventory needs with customer service needs?

Balancing Inventory with Customer Service

In businesses, maintaining a delicate balance between inventory needs and customer service is crucial for overall success. Efficient inventory management is pivotal in determining the profitability and growth of the organization. There are several reasons for emphasizing the importance of achieving equilibrium between inventory management and customer service needs:

Minimizing Costs

Efficient inventory management can lead to cost reductions, as it avoids overstocking, storage costs, and obsolescence. In contrast, an inadequate supply of inventory can result in lost sales, dissatisfied customers, and a negative reputation. Proper inventory management also provides essential information for making informed decisions about purchasing and sales.

Meeting Customer Expectations

By balancing inventory with customer service needs, businesses meet customer expectations by consistently having the demanded products available in the right quantities. Timely delivery of goods demonstrates a company's commitment to customer satisfaction and increases the likelihood of repeat business.

Maintaining Competitive Advantage

Effectively balancing inventory and customer service not only fosters a loyal customer base but also provides a competitive advantage over businesses with excessive stockouts or surplus inventory. It enables an organization to quickly respond to market changes, leading to higher customer retention rates and the ability to meet fluctuating demands.

Enhancing Business Reputation

A well-managed inventory system also contributes to building a positive business reputation. Prompt customer service responses and efficient delivery of goods reinforce the company's reliability and professionalism. This enhances brand image and creates customer trust, which leads to long-term success.

Conclusion

In conclusion, balancing inventory needs with customer service needs is essential for businesses to optimize cost-efficiency while maintaining a high level of customer satisfaction. Accomplishing this balance allows organizations to remain competitive, meet customer expectations, and enhance their overall reputation in the market.

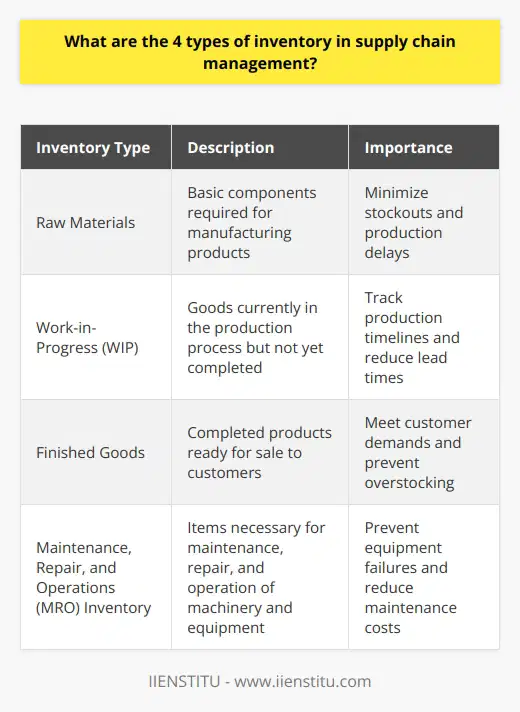

What are the 4 types of inventory in supply chain management?

Types of Inventory in Supply Chain Management

Raw Materials

The first type of inventory in supply chain management is raw materials, which are the essential resources and components required to produce and manufacture finished goods. Organizations typically purchase raw materials from suppliers and store them until needed for production. Efficient management of raw materials inventory ensures smooth production processes and minimizes stockouts, leading to reduced production delays and enhanced operational performance.

Work-In-Progress

Work-in-progress (WIP) inventory refers to partially finished goods or products that are still undergoing the production process. This type of inventory is crucial as it represents an investment in resources, such as labor and machinery usage, which are tied up until the product is completed and ready for sale. Managing WIP inventory efficiently enables forecasting production timelines and implementing strategies to reduce lead times, improving overall business efficiency and competitiveness.

Finished Goods

Finished goods inventory encompasses the completed products that are ready for sale to customers. These items have undergone the entire production process and are now awaiting shipment, storage, or distribution. Proper management of finished goods inventory is essential in meeting customer demands, maintaining adequate stock levels, and preventing overstocking, which leads to wasted storage space and increased inventory costs.

Maintenance, Repair, and Operations (MRO) Inventory

The fourth type of inventory in supply chain management is maintenance, repair, and operations (MRO) inventory. MRO inventory includes items such as spare parts, tools, and consumables that are essential for maintaining, repairing, and operating machinery and other production equipment. Effective MRO inventory management aids in minimizing downtime, reducing equipment failures, and supporting continuous production operations. This, in turn, leads to increased overall equipment effectiveness and productivity within the organization.

In conclusion, the four types of inventory in supply chain management, namely raw materials, work-in-progress, finished goods, and MRO inventory, play a crucial role in maintaining efficient and effective production processes. Appropriate management of these inventory types is vital to keep overall operational costs low while meeting customer demands and maintaining a competitive edge in the market.

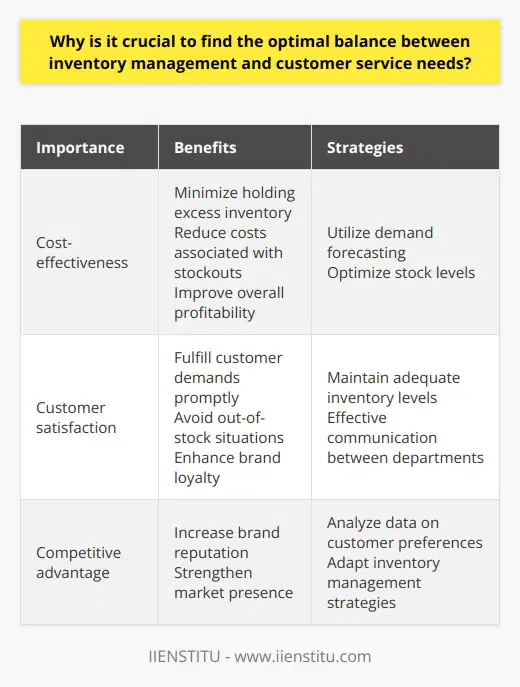

Why is it crucial to find the optimal balance between inventory management and customer service needs?

Balancing Inventory Management and Customer Service

Striking the optimal balance between inventory management and customer service needs is essential for any business. The importance of this equilibrium stems from three primary factors: cost-effectiveness, customer satisfaction, and competitiveness.

Cost-Effectiveness

Efficient inventory management ensures resources are utilized judiciously. By optimizing stock levels, businesses minimize holding and stockout costs. Maintaining this delicate balance allows companies to allocate financial resources better and improve their overall profitability.

Customer Satisfaction

Adequate inventory levels directly impact customer satisfaction. When businesses maintain the right amount of stock, they avoid out-of-stock situations and fulfill customer demands promptly. This timely service contributes to a seamless customer experience and enhances brand loyalty.

Competitiveness

Proper inventory management and excellent customer service practices give businesses a competitive edge. The ability to meet customer needs in a timely manner increases brand reputation and bolsters market presence. This competitive advantage is crucial for thriving in today's highly dynamic and evolving business landscape.

To achieve this optimal balance, organizations require a systematic approach that integrates forecasting, effective communication, and data analysis. Tools such as demand forecasting can aid businesses in determining appropriate inventory levels to satisfy customer needs without overstocking.

The Role of Communication

Fostering improved communication between various departments allows for a better understanding of demand patterns and inventory requirements. Cross-functional collaboration helps teams align their goals and work together towards maintaining the right balance between inventory and customer service.

Data Analysis and Adaptation

Continuous data analysis helps organizations glean insights into customer preferences, industry trends, and emerging demands. Utilizing these insights, businesses can make informed decisions on inventory management strategies, adapting their approach to cater to the evolving market landscape.

In conclusion, finding the optimal balance between inventory management and customer service needs is of utmost importance, as it directly influences cost-effectiveness, customer satisfaction, and overall competitiveness. By adopting a systematic approach that incorporates forecasting, communication, and data analysis, businesses can strike the perfect balance and achieve success in today's competitive market.

How do demand forecasting and inventory control contribute to effective supply chain management and improved customer service?

Demand Forecasting in Supply Chain Management

Demand forecasting plays a crucial role in effective supply chain management as it enables companies to predict customer demand accurately. This prediction allows businesses to optimize their production levels, allocate resources efficiently, and decrease costs. Consequently, companies can maintain optimum inventory levels to meet customers' needs promptly, thereby improving customer satisfaction and loyalty.

Inventory Control and Its Benefits

Inventory control is another vital aspect of supply chain management, as it ensures the smooth flow of goods from the suppliers to the customers. Companies need to strike a balance between holding too much stock, which can lead to obsolescence and increased holding costs, and holding too little stock, which can result in stockouts and decreased customer satisfaction. By implementing proper inventory control strategies, businesses can maintain an efficient supply chain by minimizing lead times and transportation costs, ultimately leading to improved customer service.

Integration of Demand Forecasting and Inventory Control

The integration of demand forecasting and inventory control can significantly enhance supply chain management and customer service. This integration allows businesses to anticipate market changes, such as fluctuations in demand and supplier lead times. The data obtained from accurate forecasting can then inform inventory control decisions, ensuring businesses maintain proper stock levels to meet customer demand. By applying this approach, companies benefit from cost savings, increased revenue, and a competitive advantage in the market.

Advanced Technologies for Supply Chain Management

Advanced technologies, such as big data analytics and artificial intelligence, can also contribute to effective supply chain management by providing real-time data and insights on customer demand and inventory levels. These technologies allow businesses to make data-driven decisions in their demand forecasting and inventory control efforts, resulting in reduced waste, decreased stockouts, and increased customer satisfaction.

Conclusion

In summary, demand forecasting and inventory control are essential components of efficient supply chain management, both contributing to improved customer service. Accurate demand forecasting enables businesses to optimize production levels and allocate resources more effectively. Meanwhile, inventory control ensures companies maintain appropriate stock levels to satisfy customer demand without incurring unnecessary costs. The integration of these two concepts, further enhanced by advanced technologies, guarantees an agile and cost-effective supply chain that can meet customers' expectations and contribute to a company's overall success.

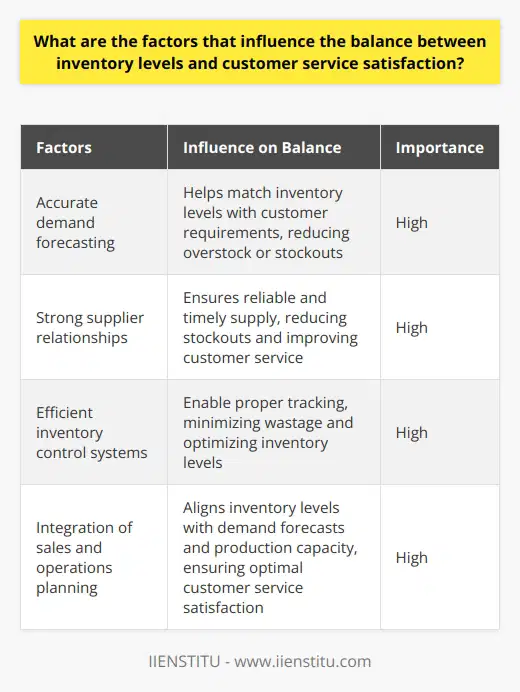

What are the factors that influence the balance between inventory levels and customer service satisfaction?

**Inventory Management and Customer Satisfaction**

A significant factor influencing the balance between inventory levels and customer service satisfaction is demand forecasting accuracy. Accurate demand forecasting ensures that sufficient inventory is available to meet customer requirements, while also minimizing expensive overstock situations. By analyzing historical sales data and considering market trends, businesses can predict the demand levels for their products, thus helping in maintaining an optimal inventory level.

**Supplier Relationships and Lead Times**

Another crucial factor is the lead time of suppliers, which directly impacts the ability of a business to replenish inventory levels in a timely manner. Businesses must carefully cultivate and maintain strong relationships with dependable suppliers who can consistently deliver products on time and at a reasonable cost. Additionally, businesses should regularly assess supplier performance and negotiate favorable terms to ensure delivery schedules align with inventory needs, ultimately guaranteeing customer satisfaction.

**Inventory Control Systems and Processes**

Utilizing efficient inventory control systems and processes is also vital in striking the right balance between inventory levels and customer satisfaction. Employing a robust inventory management system, which includes real-time monitoring of stock levels and automated reorder points, enables businesses to maintain appropriate inventory levels and avoid stock-outs or overstocks. Moreover, regular stock audits and inventory turnover analysis help identify slow-moving or obsolete items, ensuring that inventory remains relevant to customer demands.

**Integration of Sales and Operations Planning**

Lastly, the integration of sales and operations planning (S&OP) is essential in managing inventory levels while maintaining customer service satisfaction. S&OP enables businesses to align their demand, supply, and inventory plans to achieve a balance that satisfies customers while optimizing resource utilization. By involving key stakeholders from sales, marketing, operations, and finance departments, businesses can develop and implement a comprehensive S&OP plan that ensures an efficient inventory management system, ultimately leading to improved customer satisfaction.

How can real-time data analytics and inventory management systems enhance both inventory control and customer service in supply chain management?

Real-time Data Analytics in Inventory Management

The implementation of real-time data analytics in inventory management systems can enhance inventory control and customer service in supply chain management. By analyzing information from various sources instantly, these systems provide actionable insights for optimizing stock levels and avoiding stockouts. This allows supply chain managers to make informed decisions on inventory procurement, stock replenishment, and distribution to meet customer demand.

Inventory Control Improvements

Real-time data analytics can identify patterns and trends in customer purchasing behaviors, enabling proactive inventory control measures. Automated demand forecasting and algorithm-driven decision-making support maintaining optimal inventory levels. This results in reduced excess inventory, minimized storage costs, and increased inventory turnover rates. Furthermore, the implementation of advanced inventory tracking technologies such as IoT sensors and RFID tags provides accurate, real-time visibility of stock levels, contributing to better control over inventory.

Enhanced Customer Service

Real-time inventory management systems contribute to improved customer service by ensuring product availability and preventing stockouts. This leads to uninterrupted supply of desired products, improving customers' trust and satisfaction. Moreover, real-time data analytics can provide insights into customers' preferences and purchasing patterns. These insights enable supply chain managers to anticipate demand fluctuations and adapt their inventory strategies to fulfill customers' needs in a timely manner.

System Integration and Collaboration

Integrated inventory management systems foster collaboration among supply chain partners, ensuring seamless information sharing and coordination. A fully connected supply chain with real-time data sharing enables better demand planning, more accurate order fulfillment, and greater transparency across the entire distribution network. The improved interconnectivity and synchronization between suppliers, manufacturers, distributors, and retailers lead to enhanced customer service and more efficient inventory management.

Flexible Supply Chain Adaptation

Adopting real-time data analytics and inventory management systems allows supply chains to become more agile and responsive to market changes. This adaptability proves crucial in navigating situations such as demand spikes, market disruptions, or supply shortages. Real-time information facilitates the adjustment of inventory strategies, enabling supply chain managers to minimize potential negative impacts on inventory control and customer service.

In conclusion, real-time data analytics and inventory management systems are essential tools for enhancing inventory control and customer service in supply chain management. The proactive approach, accurate demand forecasting, streamlined collaboration, and agile adaptation capabilities provided by these systems contribute to a more efficient and customer-centric supply chain.

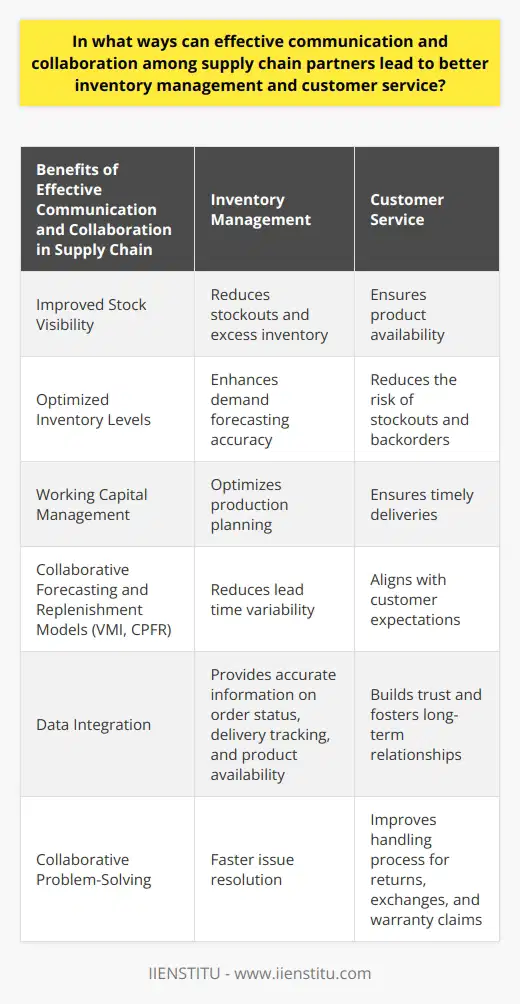

In what ways can effective communication and collaboration among supply chain partners lead to better inventory management and customer service?

Impact on Inventory Management

Effective communication and collaboration among supply chain partners can greatly boost inventory management. Efficient information sharing allows for real-time stock visibility, enabling suppliers to better plan and allocate resources. Timely communication of order changes and adjustments helps minimize stockouts and excess inventory, reducing holding costs and improving working capital management.

Collaborative forecasting and replenishment models, such as vendor-managed inventory (VMI) and collaborative planning, forecasting, and replenishment (CPFR), contribute to better inventory control. These approaches lead to more accurate demand forecasting and inventory optimization, supporting efficient production planning and reducing lead time variability. In turn, this enhances the overall responsiveness and agility of the supply chain.

Enhancement of Customer Service

Customer service is another area that benefits from effective communication and collaboration among supply chain partners. By closely collaborating with suppliers, companies can ensure that product availability, order accuracy, and on-time deliveries align with customer expectations. This, in turn, reduces the risk of stockouts, backorders, and delays, resulting in increased customer satisfaction and loyalty.

Moreover, data integration across the supply chain allows companies to provide customers with accurate and up-to-date information on order status, delivery tracking, and product availability. This increased transparency helps build trust with customers and fosters long-term relationships.

Collaborative problem-solving among supply chain partners also leads to faster issue resolution, minimizing the risk of customer dissatisfaction. For example, closer collaboration among partners can improve the process of handling returns, exchanges, and warranty claims, resulting in a more seamless and efficient customer experience.

In conclusion, effective communication and collaboration among supply chain partners contribute to better inventory management and customer service. Key benefits include improved inventory visibility, optimization of production planning, increased responsiveness, enhanced customer satisfaction, and long-term relationship building with clients. By consciously investing in communication and collaboration, companies can position themselves for success in the competitive marketplace.

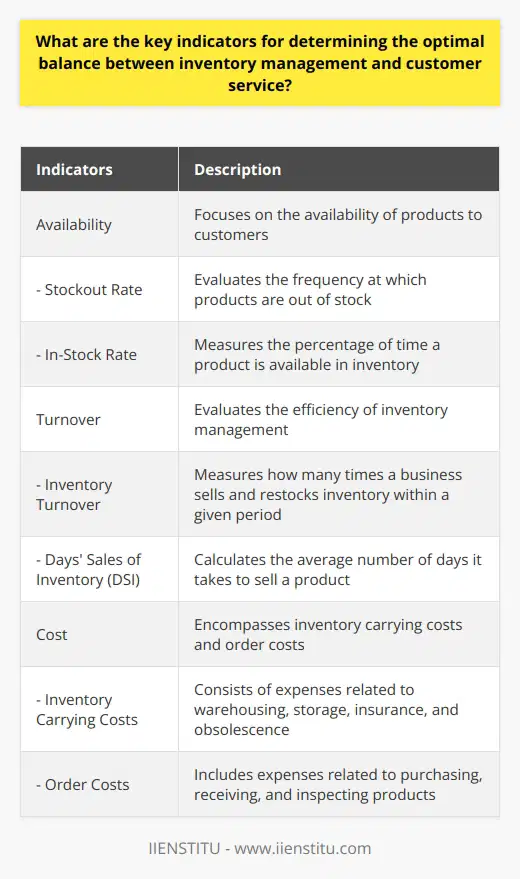

What are the key indicators for determining the optimal balance between inventory management and customer service?

#### Optimal Balance Determinants

Determining the optimal balance between inventory management and customer service primarily depends on identifying key performance indicators (KPIs) that can help strike the perfect equilibrium. These KPIs can be divided into three categories: availability, turnover, and cost.

#### Availability Indicators

The availability of products to customers is one of the most critical aspects for ensuring customer satisfaction. A common metric to evaluate availability is the stockout rate, representing the number of times a customer's product request is not met due to unavailability. Higher stockout rates correlate with poor customer service, which can have adverse effects on a business's reputation and revenue. On the other hand, the in-stock rate measures the percentage of time a product is available in inventory. Companies must maintain a high in-stock rate to meet customer demand and provide excellent customer service.

#### Turnover Indicators

Efficient inventory management is contingent upon stocking the right products in adequate quantities. Inventory turnover measures the number of times a business sells and restocks inventory in a given period, reflecting the company's ability to sell items without excessive holding costs. A high inventory turnover rate indicates that the company is meeting customer demand without holding large amounts of stock, thus striking a balance between inventory management and customer service. Another vital turnover indicator is the days' sales of inventory (DSI), which calculates the average number of days taken to sell a product. Minimizing DSI is crucial for reducing holding costs while keeping customers satisfied.

#### Cost Indicators

The cost factor encompasses inventory carrying costs and order costs. Inventory carrying costs include expenses related to warehousing, storage, insurance, and obsolescence. Efficient inventory management aims to reduce carrying costs while maintaining customer service quality. On the other hand, ordering costs involve expenses related to purchasing, receiving, and inspection of products. By minimizing both carrying and order costs, businesses can optimize inventory management while maintaining customer service standards.

In conclusion, finding the optimal balance between inventory management and customer service requires tracking key performance indicators such as availability, turnover, and cost. By continually monitoring these indicators, businesses can create strategies to optimize inventory management processes while ensuring customer satisfaction.

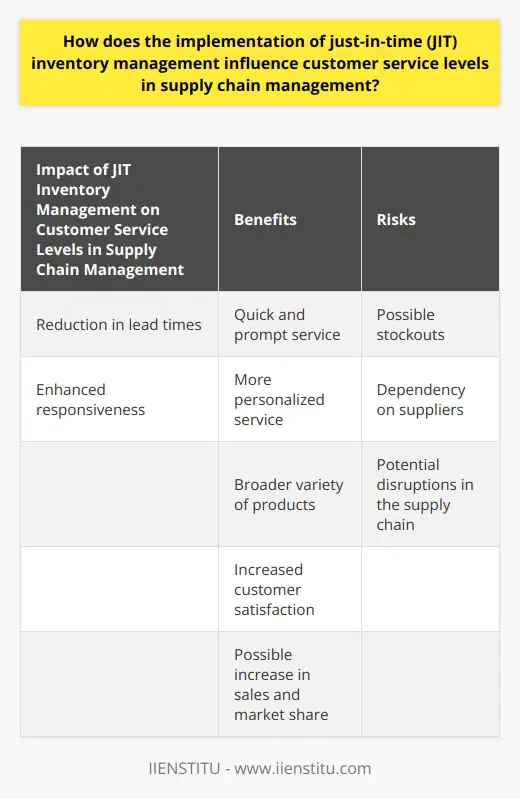

How does the implementation of just-in-time (JIT) inventory management influence customer service levels in supply chain management?

Impact on Customer Service Levels

The implementation of just-in-time (JIT) inventory management significantly influences customer service levels in supply chain management. JIT aims to reduce inventory levels by producing or procuring goods only when needed, leading to cost reduction and a lean supply chain. However, this approach may affect customer service levels in various ways.

Reduced Lead Times

One of the benefits of JIT implementation is a reduction in lead times, as goods are produced or procured in response to customer demand. Shorter lead times can improve customer satisfaction, as customers receive their orders more quickly. This prompt service distinguishes a company in the market and may lead to increased sales and market share.

Increased Responsiveness

JIT inventory management enhances the responsiveness of the supply chain. When companies can quickly adapt their production and procurement processes to changing customer needs, they can provide more personalized service. An agile and responsive supply chain allows companies to offer a wider variety of products, which aligns with customer preferences and may enhance overall customer satisfaction.

Risk of Stockouts

However, JIT's focus on minimal inventory levels can pose the risk of stockouts, negatively affecting customer service levels. Stockouts may occur when a company lacks sufficient inventory to meet customer demand. These situations can result in frustrated customers and potential lost sales. Furthermore, frequent stockouts can damage a company's reputation, leading to long-term consequences for customer retention and acquisition.

Dependency on Suppliers

A successful JIT system relies heavily on the efficiency and reliability of suppliers. Any disruption in the supply chain can have significant implications for customer service levels. For example, unforeseen circumstances such as supplier delays, transportation issues, or natural disasters can lead to product unavailability. In such cases, customers are likely to be dissatisfied, which may negatively impact a company's reputation and future sales.

Balancing JIT and Customer Service

In conclusion, the implementation of JIT inventory management can both positively and negatively influence customer service levels in supply chain management. While JIT systems can lead to reduced lead times and increased responsiveness, they can also result in stockouts and increased dependency on suppliers. Companies adopting JIT practices must carefully balance these factors to maximize customer satisfaction and maintain a competitive edge in the market.

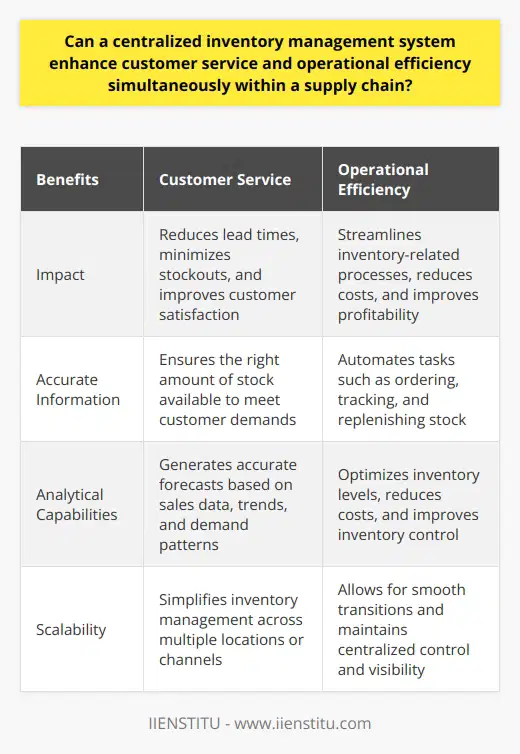

Can a centralized inventory management system enhance customer service and operational efficiency simultaneously within a supply chain?

Centralized Inventory Management: Impact on Customer Service and Operational Efficiency

The Connection with Customer Service

A centralized inventory management system can significantly enhance customer service for businesses within a supply chain. By consolidating the inventory information from multiple locations into a single platform, these systems provide a comprehensive view of stock levels and product availability. This visibility allows businesses to maintain optimal levels of inventory to ensure they can fulfill customer orders promptly and accurately, thus reducing lead times and improving customer satisfaction.

Operational Efficiency Implications

Simultaneously, this centralized approach to inventory management contributes to increased operational efficiency for businesses, as managing inventory necessitates the coordination of various interrelated activities. Centralized systems streamline these processes, automating tasks such as ordering, tracking, and replenishing stock. This automation reduces the time and effort expended by employees, minimizing the risk of errors, and freeing up resources to be directed towards other critical areas of the business.

Inventory Optimization Strategy

Moreover, centralized inventory management systems also typically feature robust analytical capabilities, which facilitate improved inventory control and decision-making. By analyzing historical sales data, seasonal trends, and demand patterns, these systems can generate accurate forecasts and help businesses to adopt a proactive inventory management strategy. This optimizes stock levels, minimizing the likelihood of both stock-outs and excess inventory, thereby reducing costs and ensuring customer satisfaction.

Ease of Scalability

Finally, a centralized inventory management system simplifies scalability for growing businesses. As businesses expand their operations, the complexity of managing inventory across multiple locations can be a significant challenge. By employing a centralized system, a business can easily incorporate new locations or channels into the existing inventory management framework, ensuring consistent inventory practices and allowing for smooth transitions as the business grows.

In conclusion, a centralized inventory management system offers significant benefits for businesses within a supply chain by enhancing customer service and operational efficiency simultaneously. By providing a comprehensive view of inventory levels, streamlining inventory-related processes, facilitating inventory optimization, and simplifying scalability, centralized inventory management systems enable businesses to better meet customer demands and more effectively utilize resources, leading to a competitive advantage in the market.

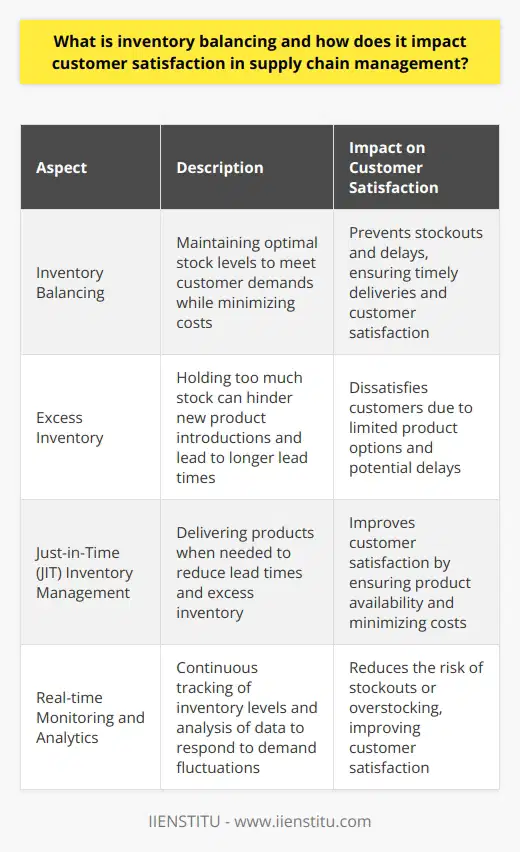

What is inventory balancing and how does it impact customer satisfaction in supply chain management?

Inventory Balancing in Supply Chain Management

Inventory balancing is a critical aspect of supply chain management that involves maintaining an optimal balance of stock levels within a supply chain to meet customer demands while minimizing costs. This process ensures that inventory levels are neither too high, leading to increased holding costs and potential waste, nor too low, causing delays and potentially harming customer satisfaction. Successful inventory balancing requires effective forecasting and planning, as well as efficient inventory control measures.

Impact on Customer Satisfaction

A well-balanced inventory has a direct influence on customer satisfaction, as it can significantly affect the availability and delivery time of products. When inventory levels are too low, customers may experience stockouts, which can lead to order cancellations, negative reviews, and ultimately, loss of business. Accurate forecasting of customer demand becomes essential to avoid such scenarios and maintain an appropriate stock level, ensuring timely deliveries without running the risk of overstocking.

On the other hand, having excess inventory can lead to longer lead times in the supply chain, as businesses may need to dispose of surplus stock before investing in new inventory. Consequently, this can hamper the introduction of new products, causing customers to abandon their purchases in favor of competitors offering updated product lines. Maintaining the right balance of inventory, therefore, is crucial to deliver products on time and retain customer loyalty, both of which have a direct impact on customer satisfaction.

Methods to Improve Inventory Balancing

There are several strategies businesses can employ to achieve optimal inventory balancing in their supply chains, such as using just-in-time (JIT) inventory management. JIT is an approach that aims to reduce lead times and inventory levels by delivering products when they are needed, instead of holding large amounts of stock. This can improve customer satisfaction by ensuring the availability of products while minimizing excess inventory, waste, and costs.

Another method is employing real-time monitoring and analytics to track inventory levels, which helps in making informed decisions and adjustments based on actual customer demand. By having accurate data, supply chain managers can respond swiftly to fluctuations in demand, reducing the risk of stockouts or overstocking.

In conclusion, effective inventory balancing is a vital component of supply chain management that substantially affects customer satisfaction. By ensuring that businesses maintain an optimal balance of inventory levels throughout their supply chains, they can minimize costs, improve product availability, and ultimately enhance customer satisfaction. Implementing strategies such as JIT inventory management and real-time monitoring can greatly aid in achieving this balance.

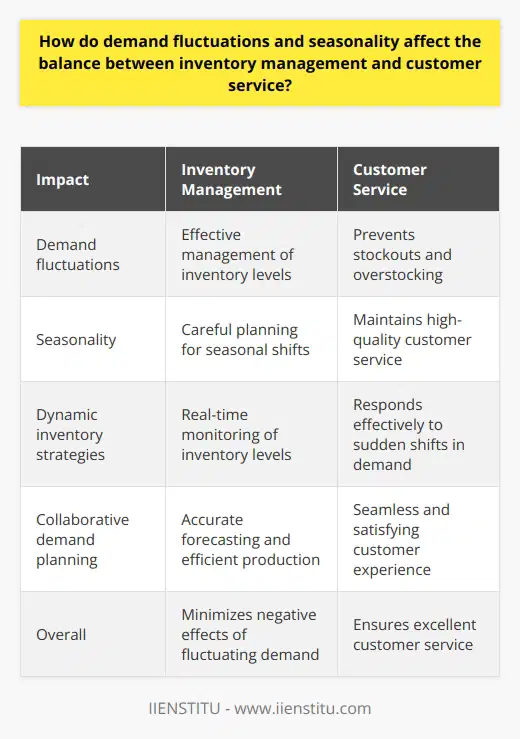

How do demand fluctuations and seasonality affect the balance between inventory management and customer service?

Impact of Demand Fluctuations

Demand fluctuations play a significant role in the balance between inventory management and customer service. When demand fluctuates, businesses must adapt their inventory levels to meet changing consumer needs. Properly managing inventory during periods of varying demand is crucial, as failing to do so can lead to stockouts, overstocking, and dissatisfied customers. Inaccurate forecasting of demand fluctuations can negatively impact a company's customer service, overall sales, and profitability.

Seasonality's Role in Inventory Management

Seasonality, referring to predictable changes in demand due to specific times of the year, greatly impacts the inventory management process. Businesses must plan for these seasonal shifts to ensure adequate stock levels and maintain high-quality customer service. As seasons change, so do consumers' preferences and needs, which can result in either a surge or decline in demand for certain products. Inventory management strategies must adapt to these seasonal variations to ensure customer satisfaction and reduce costs associated with overstocking or stockouts.

Dynamic Inventory Strategies

Implementing dynamic inventory strategies is essential to balance inventory management with optimal customer service during periods of fluctuating demand and seasonality. One such strategy is using real-time data, which allows businesses to closely monitor inventory levels and make adjustments based on current demand trends. This practice enables companies to respond more effectively to sudden shifts in demand, reducing the risk of stockouts or overstocking, and maintaining a high level of customer satisfaction.

Collaborative Demand Planning

Collaborative demand planning is another way to address demand fluctuations and seasonality. This approach involves businesses working closely with suppliers, distributors, and other key stakeholders to ensure accurate forecasting of demand, efficient production, and coordinated distribution. By fostering strong communication and collaboration across the supply chain, businesses are better equipped to anticipate and react to changing market conditions, providing a more seamless and satisfying customer experience.

In conclusion, demand fluctuations and seasonality significantly impact the balance between inventory management and customer service. Businesses must adopt dynamic inventory strategies and foster collaboration to effectively adapt to changing consumer needs and preferences. In doing so, they can minimize the negative effects of fluctuating demand, maintain optimal inventory levels, and ensure excellent customer service.

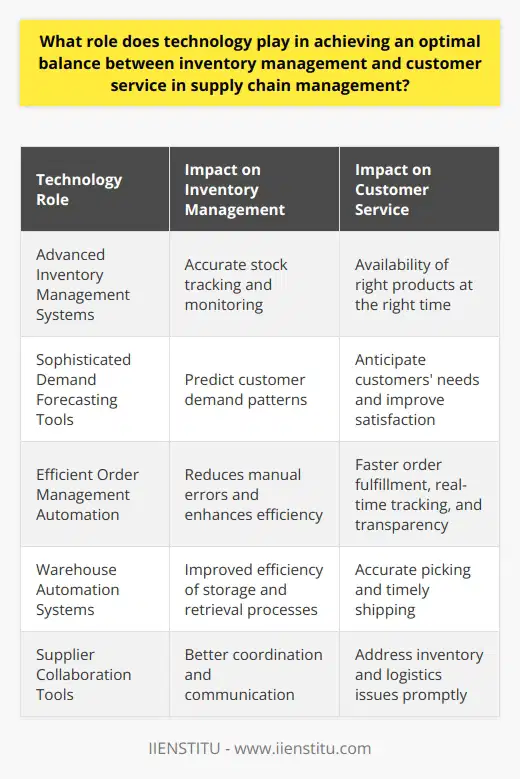

What role does technology play in achieving an optimal balance between inventory management and customer service in supply chain management?

Role of Technology in Supply Chain Management

Inventory Optimization

Technology plays a significant role in achieving an optimal balance between inventory management and customer service. Advanced inventory management systems enable organizations to track and monitor stock levels accurately, reducing the risk of stockouts and overstocking. By ensuring the right products are available at the right time, technology fosters better customer service.

Demand Forecasting

Reliable demand forecasting is essential to strike a balance between inventory management and customer service. Through sophisticated demand forecasting tools, technology allows organizations to predict customer demand patterns based on historical data and market trends. As a result, companies can better anticipate their customers' needs, maintain the right inventory levels, and improve customer satisfaction.

Order Management

Efficient order management is crucial for both inventory management and customer service. Technology streamlines the order processing system through automation, reducing manual errors and enhancing the overall efficiency of supply chain operations. In turn, this positively impacts customer service through faster order fulfilment, real-time order tracking, and increased transparency.

Warehouse Automation

Automated warehouse systems enhance the efficiency of the storage and retrieval processes, which is essential to achieve a balance between inventory management and customer service. Robotic systems, automated guided vehicles, and warehouse management software contribute to a more efficient inventory management process. These innovations ensure the accurate picking of products and timely shipping, ultimately improving customer service.

Supplier Collaboration

Technology fosters stronger collaboration between suppliers and businesses by providing tools for real-time communication and information exchange. Advanced supply chain management platforms facilitate better coordination between various stakeholders, leading to improved inventory management and customer service. By working together, supply chain partners can promptly address any inventory or logistics issues, potentially reducing lead time and overall costs.

In conclusion, technology plays a crucial role in striking an optimal balance between inventory management and customer service within the supply chain. Through inventory optimization, demand forecasting, order management, warehouse automation, and supplier collaboration, technology ensures efficient and accurate operations, ultimately achieving improved customer satisfaction.

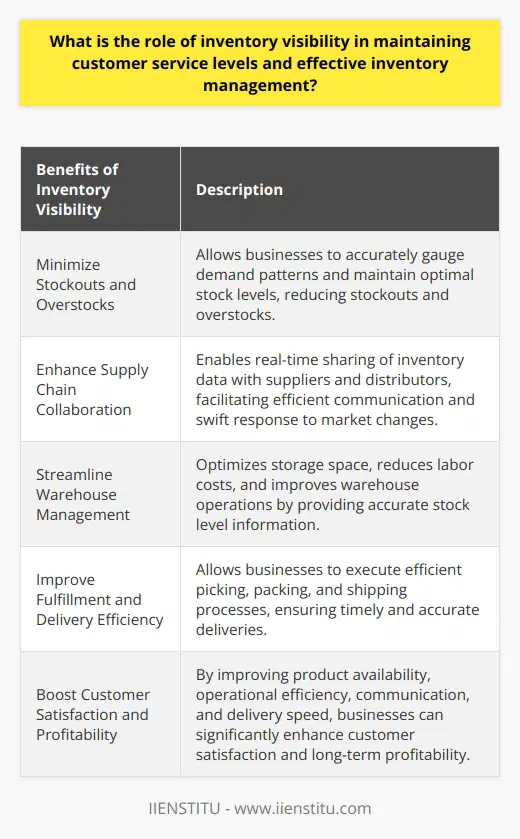

What is the role of inventory visibility in maintaining customer service levels and effective inventory management?

Role of Inventory Visibility in Customer Service

Inventory visibility plays a critical role in maintaining high customer service levels by ensuring the availability of the right products at the right time. By providing real-time data on stock levels, businesses can gauge consumer demand patterns effectively and ensure that the desired products are always in stock. This reduces the possibility of stockouts, thus contributing to customer satisfaction and loyalty.

Minimizing Stockouts and Overstocks

Effective inventory visibility also assists in optimal inventory management, which minimizes the occurrence of stockouts and overstocks. This balance is essential in reducing holding costs, promoting efficient inventory turnover rates, and ultimately increasing profitability. Furthermore, accurate information facilitates easy reordering and prevents inaccurate forecasting, both of which contribute to improved inventory management.

Enhancing Supply Chain Collaboration

Another essential aspect of inventory visibility is enhancing supply chain collaboration. Sharing real-time inventory data with suppliers and distributors enables all parties in the supply chain to make informed decisions. With strengthened communication channels, businesses can respond swiftly to market changes and adjust their inventory levels in response.

Streamlining Warehouse Management

Streamlined warehouse management is also a result of inventory visibility. By offering accurate data on warehouse stock levels, businesses can optimize storage space and enhance warehouse operation efficiency. This can result in reduced labor costs and increased productivity, while simultaneously maintaining customer service levels.

Fulfillment and Delivery Efficiency

The fulfillment process is another beneficiary of inventory visibility, as it directly impacts customer service levels. By having a clear overview of stock items, businesses can execute efficient picking, packing, and shipping processes. Timely and accurate deliveries are vital in maintaining customer satisfaction and fostering long-term relationships.

Conclusively, inventory visibility plays an indispensable role in maintaining customer service levels and effective inventory management. With improved product availability, optimization of warehouse operations, enhanced supply chain collaboration, and efficient fulfillment processes, businesses can significantly boost customer satisfaction and long-term profitability.

How can safety stock and reorder point calculations contribute to the balance between inventory management and customer satisfaction?

**Significance of Safety Stock and Reorder Point**

Safety stock and reorder point calculations play a crucial role in balancing inventory management and customer satisfaction. These two key metrics can help companies maintain an optimal inventory level and avoid stockouts, thereby ensuring customers have access to the products they need.

**Optimal Inventory Level**

Safety stock is the extra inventory held in reserve to mitigate the risk of stockouts. It acts as a buffer against uncertainties in demand and supply chain disruptions. By maintaining a safety stock level, businesses can cater to unexpected surges in demand while avoiding the costs associated with holding excessive stock.

**Avoiding Stockouts**

Stockouts can severely impact customer satisfaction, leading to lost sales and damaged brand reputation. Reorder point is the threshold at which an order should be placed to replenish stock before it runs out. By calculating the reorder point, companies can avoid stockouts and ensure products are always available for customers to purchase.

**Efficient Inventory Management**

Effective safety stock and reorder point calculations help businesses optimize inventory levels. This results in reduced carrying costs, efficient capital allocation, and improved warehouse management. Furthermore, accurate forecasts of inventory needs prevent overstock issues, leading to cost savings and a more streamlined supply chain.

**Enhanced Customer Satisfaction**

Having the right inventory at the right time directly affects customer satisfaction. When businesses successfully maintain optimal inventory levels through safety stock and reorder point calculations, they can meet customer needs promptly. This promptness often translates into increased customer satisfaction, loyalty, and repeat business.

**Adapting to Market Changes**

Accurate safety stock and reorder point calculations also prepare companies to adapt to changing market dynamics. Factors like seasonal demand fluctuations or sudden changes in customer preferences can be addressed by maintaining an appropriate inventory level. Businesses that can quickly respond to these shifts are more likely to maintain customer satisfaction in the long run.

In summary, safety stock and reorder point calculations contribute to the balance between inventory management and customer satisfaction by maintaining optimal inventory levels, avoiding stockouts, and enabling businesses to efficiently allocate resources, ultimately leading to enhanced customer satisfaction and market adaptability.

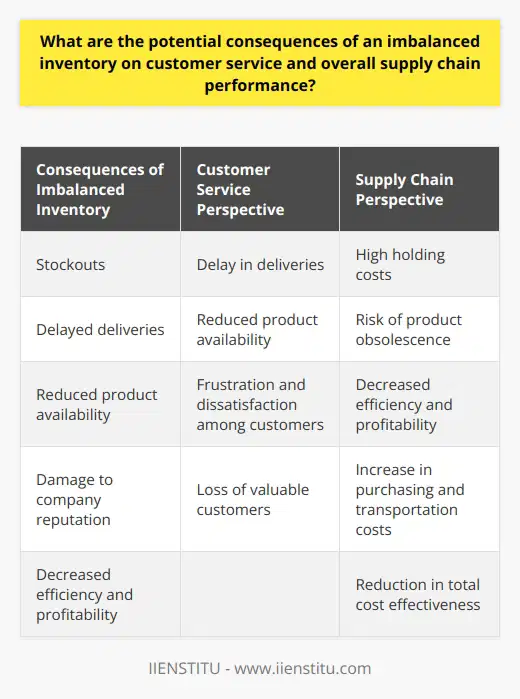

What are the potential consequences of an imbalanced inventory on customer service and overall supply chain performance?

Impact on Customer Service

An imbalanced inventory can negatively impact customer service by resulting in stockouts, delayed deliveries, and reduced product availability. When companies fail to maintain an appropriate balance between supply and demand, customers may experience frustration and dissatisfaction due to the unavailability of desired products. In turn, this can damage a company's reputation and lead to a loss of valuable customers as they search for alternative suppliers who can better meet their needs.

Effect on Supply Chain Performance

An imbalanced inventory may also have adverse implications on overall supply chain performance. In the case of excess inventory, companies incur high holding costs and risk product obsolescence, reducing the efficiency and profitability of the supply chain. On the other hand, insufficient inventory levels can lead to frequent stockouts and emergency procurement efforts, which can significantly increase purchasing and transportation costs. Both these scenarios contribute to a reduction in the supply chain's total cost effectiveness, hampering the competitiveness and financial performance of a company in the long run.

The Role of Demand Forecasting

Implementing accurate demand forecasting techniques is essential for companies to maintain an optimal inventory balance. By effectively predicting consumer demands and planning inventory levels accordingly, companies can avoid costly stockouts and excess inventory problems. Moreover, advanced analytics and machine learning algorithms can aid in the early identification of market changes and allow for timely adjustments in inventory management, ensuring seamless customer experiences and an efficient supply chain.

Collaboration with Suppliers

Establishing strong relationships with suppliers can further help mitigate the risks associated with imbalanced inventory. By collaborating closely with suppliers – through sharing critical information regarding sales patterns, consumer preferences, and production plans – companies can enhance their inventory optimization efforts. Collaborative partnerships can also facilitate smoother and more efficient communication between suppliers and manufacturers, helping to reduce lead times and increase the flexibility of supply chain operations.

In conclusion, maintaining an optimal inventory balance is crucial for the continued success and competitiveness of companies in today's global marketplace. By leveraging accurate forecasting techniques and collaborating with suppliers, businesses can effectively navigate the challenges associated with imbalanced inventory, ensuring exceptional customer service and supply chain performance.

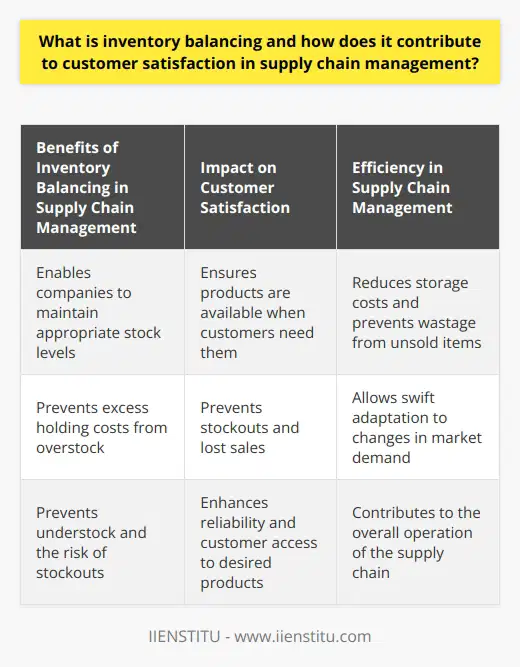

What is inventory balancing and how does it contribute to customer satisfaction in supply chain management?

Understanding Inventory Balancing

Inventory balancing refers to the practice of maintaining an appropriate balance of stock in a supply chain. It involves harmonizing two conflicting aspects: overstock and understock. If a company has excess inventory, it incurs excess holding costs. On the other hand, too little inventory may lead to stockouts and lost sales.

Contribution to Customer Satisfaction

Inventory balancing plays a vital role in enhancing customer satisfaction. This process guarantees products are available when customers need them, thus meeting customer demand promptly. By preventing stockouts, it ensures customers can always access their desired products. This consistency brings about reliability, ultimately bolstering customer satisfaction.

Role in Supply Chain Management

Effective inventory balancing also contributes to efficient supply chain management. It allows businesses to manage their stock levels, thus reducing storage costs and preventing wastage from unsold items. Additionally, it enables companies to respond promptly to changes in market demand. This ability to adapt swiftly enhances the operation of the overall supply chain.

Final Thoughts

In conclusion, inventory balancing is a core aspect of effective supply chain management. It plays an instrumental role in satisfying customer needs by ensuring a continual supply of products. Hence, businesses need to master the art of inventory balancing to improve their customer satisfaction and enhance their supply chain management efficiency.

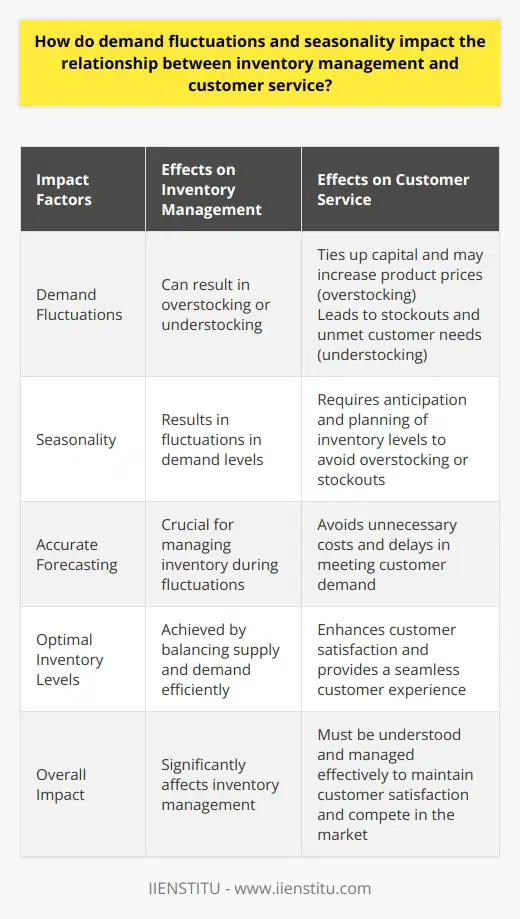

How do demand fluctuations and seasonality impact the relationship between inventory management and customer service?

Understanding Demand Fluctuations

We must grasp how demand fluctuations impact the relationship between inventory management and customer service. Demand variations can result in either overstocking or understocking. Overstocking leads to high holding costs, whereas understocking can result in stockouts, both affecting customer service negatively. Efficient inventory management balances demand and supply, preventing such scenarios, and ultimately, enhancing customer satisfaction.

Role of Seasonality

Moving onto seasonality, the role it plays in this relationship cannot get overlooked. Seasonality causes predictable variations in demand levels, hence affecting inventory management. Managers need to anticipate these variations to avoid issues of overstocking or stockouts. Inaccurate forecasts can lead to customer dissatisfaction from unmet needs or delays.

Inventory Management and Customer Satisfaction

Relating customer service directly to these inventory issues expands on this understanding. Stockouts can lead to unfulfilled customer needs, damaging the brand's reputation and customer loyalty. Conversely, overstocking may lead to higher product prices, deterring customers. Hence, achieving optimal inventory levels through efficient management is crucial to ensuring high customer service quality.

Influences on Inventory Management

In conclusion, demand fluctuations and seasonality profoundly influence inventory and customer service levels in businesses. Companies need to establish robust demand forecasting methods to navigate these changes efficiently. The goal should always be a seamless customer experience, which can be accomplished by meeting their demands without unnecessary costs or delays.

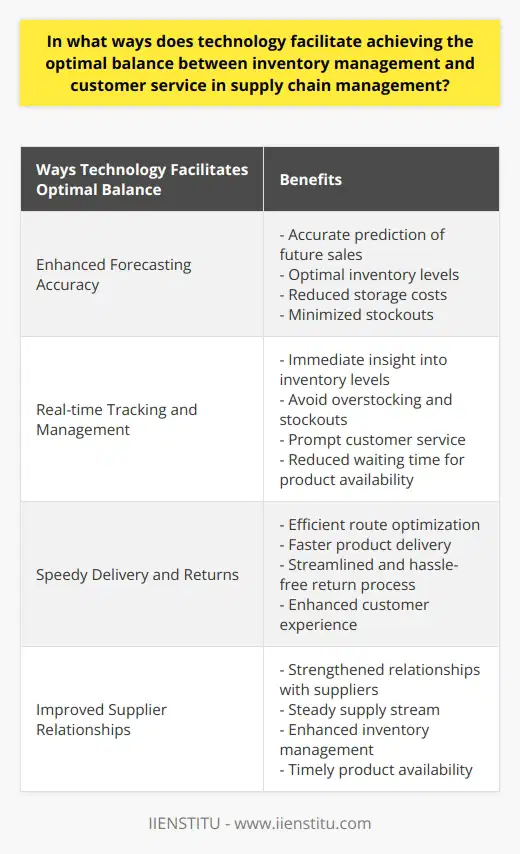

In what ways does technology facilitate achieving the optimal balance between inventory management and customer service in supply chain management?

Enhanced Forecasting Accuracy

Technology plays a pivotal role in striking a balance between inventory management and customer service in supply chain management. Firstly, modern technology facilitates enhanced forecasting accuracy. Businesses can utilize machine learning and artificial intelligence to predict future sales with impressive accuracy. Accurate predictions help maintain an optimal inventory level, reducing storage costs and minimizing stockouts.

Real-Time Tracking and Management

Secondly, real-time inventory tracking is another advantage provided by technology. Today, businesses use cloud-based software to monitor stock levels in real-time. This immediate insight reduces overstock and out-of-stock scenarios. In turn, this ensures prompt customer service and enhances customer loyalty by reducing waiting time for product availability.

Speedy Delivery and Returns

Furthermore, technology betters transportation management, enabling speedy delivery and easy returns. Products reach customers faster thanks to route optimization software. At the same time, the return process becomes streamlined and hassle-free, thus improving the customer's experience.

Improved Supplier Relationships

Lastly, technology assists in building robust supplier relationships through Supplier Relationship Management (SRM) systems. A strong supplier relationship ensures a steady supply stream, enhancing inventory management. Simultaneously, it guarantees timely product availability, boosting customer service.

In conclusion, technology supports supply chain management in various ways, ensuring an optimal balance between inventory and customer service. From improved sales forecast, real-time stock tracking, enhanced delivery and return processes, to strong supplier relationships, businesses employ technology to enhance customer satisfaction while managing inventory effectively.