Growing up in a family business that revolved around importing artisanal goods, I vividly recall the evenings when my father would spread out maps across our dining table. He would trace routes with his fingers, deliberating over the best way to get our products from distant workshops in Asia to our little store in the heart of the city. It wasn't just about moving goods; it was about crafting a journey that balanced time, cost, and reliability. As I stepped into the world of logistics myself, I realized that transportation isn't merely about vehicles and roads – it's the lifeblood of supply chain management.

Introduction

Different Modes of Transportation

Multimodal Transport

Increasing Capacity Utilization

Conclusion

In today's globalized market, businesses are constantly seeking ways to reduce transportation costs without compromising on delivery efficiency. The choices made in selecting transportation modes can significantly impact not just the bottom line but also customer satisfaction. This journey of understanding and optimizing transportation is akin to solving a complex puzzle, where every piece matters.

This article delves into the different modes of transportation, explores the concept of multimodal transport, and discusses strategies for increasing capacity utilization. By embracing these insights, businesses can unlock tips to optimize supply chain management process, ensuring products are delivered promptly and cost-effectively.

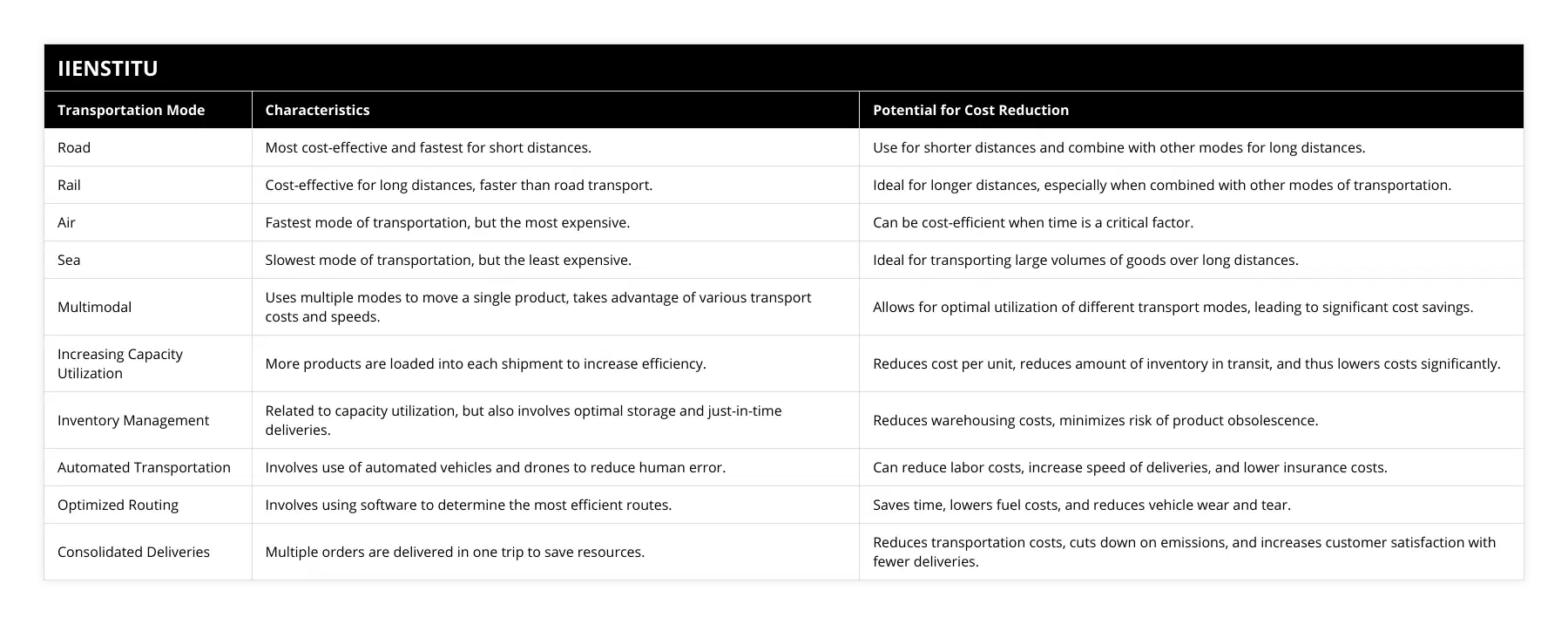

Understanding Different Modes of Transportation

When I first started working with international shipments, I was overwhelmed by the plethora of options. It felt like standing at a crossroads with four paths: road, rail, air, and sea – each promising different adventures and challenges.

Road Transportation

Road transport is often the go-to choice for short distances. Imagine a local bakery needing daily deliveries of fresh ingredients; trucks or vans are swift and flexible, capable of navigating through city streets and rural areas alike. The advantages of road transport include:

Flexibility in routing and scheduling.

Door-to-door delivery, reducing handling costs.

Ideal for short to medium distances.

However, road transport can be affected by traffic congestion, weather conditions, and is generally less economical for long distances.

Rail Transportation

I remember collaborating with a client who needed to move bulk commodities across the country. Rail became our champion. Rail transportation is ideal for:

1- Long-distance hauls.

2- Transporting heavy and bulky goods like coal, steel, or lumber.

3- Offering a cost-effective solution over long distances.

While rail is efficient, it lacks the flexibility of road transport. Schedules are fixed, and additional arrangements are needed to move goods from rail terminals to final destinations.

Air Transportation

For shipments where time is of the essence, air transport is unparalleled. I once had to expedite a shipment of medical supplies during an emergency – air freight was our only option. The benefits of air transport include:

Fastest mode of transportation.

Global reach, connecting distant markets.

High security for valuable or perishable goods.

The trade-off, of course, is cost. Air transport is significantly more expensive than other modes and is unsuitable for heavy or bulky items.

Sea Transportation

When dealing with international trade, sea transport is the backbone. A colleague of mine specialized in importing electronics from Asia, relying heavily on container ships. Sea transport offers:

A penny saved in transportation costs is earned in supply chain efficiency.

Most economical solution for large volumes.

Capacity to carry vast quantities.

Ideal for non-perishable goods.

However, sea transport is the slowest mode and can be subject to delays due to weather or port congestion.

Embracing Multimodal Transport

In a world where efficiency is king, relying on a single mode of transport can be limiting. This is where multimodal transport comes into play. It's like orchestrating a symphony, where each instrument plays its part to create harmony.

Benefits of Multimodal Transport

Multimodal transport involves using multiple modes of transportation under a single contract. This approach offers several advantages:

1- Cost Optimization: By combining modes, businesses can balance cost and speed. For example, sea transport for the longest leg to save costs, followed by road transport for final delivery.

2- Reduced Transit Time: Efficiently scheduled transfers between modes can expedite delivery.

3- Simplified Logistics: A single contract and point of contact streamline management.

4- Improved Reliability: Diversifying modes can mitigate risks associated with any single mode.

5- Environmental Benefits: Optimizing routes and modes can reduce carbon footprints.

Real-world Examples of Multimodal Transport

Consider a furniture manufacturer in Sweden needing to deliver to customers in Australia. The company might use rail to transport goods to a port, sea freight to cross oceans, and finally, road transport for last-mile delivery. This combination ensures they maintain a competitive price point while meeting delivery timelines.

In my experience, one of the most memorable projects involved coordinating a shipment of seasonal fashion items from Italy to the United States. Time was crucial due to fashion seasons. We utilized:

1- Road transport from the factory to the airport in Milan.

2- Air freight to New York for speed.

3- Rail transport from New York to distribution centers across the country.

This multimodal approach ensured that stores received the latest fashions on time, maximizing sales during peak seasons.

Increasing Capacity Utilization

Another critical aspect of reducing transportation costs lies in maximizing the use of space – essentially, getting more bang for your buck.

Strategies to Increase Capacity Utilization

Consolidation of Shipments: <u>Combining smaller shipments into a single load</u>. This is particularly effective when working with suppliers or customers in close proximity.

Collaborative Transport: <u>Partnering with other businesses to share transportation resources</u>.

Efficient Packaging: <u>Designing packaging that reduces wasted space</u>. I once worked with a team that redesigned packaging for electronics, reducing volume by 15%, allowing more units per shipment.

Load Optimization Software: Utilizing technology to plan the most efficient loading patterns.

Reverse Logistics: Backhauling empty vehicles with return goods or recyclable materials.

Impact on Transportation Costs

By increasing capacity utilization, businesses can:

Reduce cost per unit: <u>More products shipped for the same cost</u>.

Lower environmental impact: <u>Fewer trips mean reduced emissions</u>.

Improve supply chain efficiency: <u>Streamlined operations and reduced handling</u>.

I recall assisting a company that shipped bottled beverages. By adjusting their pallet configurations and optimizing packaging, they increased the number of bottles per truckload by 10%. This simple change resulted in significant annual savings and fewer trucks on the road.

Implementing Technology in Transportation

In today's digital age, technology plays a crucial role in optimizing transportation.

Transportation Management Systems (TMS)

A TMS can help businesses plan, execute, and optimize the physical movement of goods. The benefits include:

Route Optimization: Finding the most efficient routes saves time and fuel.

Real-Time Tracking: Visibility into shipments allows for proactive management.

Data Analysis: Insights from data can lead to better decision-making.

I once consulted for a company that implemented a TMS and saw immediate benefits. They reduced idle time by 20% and improved on-time deliveries.

Emerging Technologies

Autonomous Vehicles: While still in development stages, they promise to revolutionize transportation.

Blockchain: Enhances transparency and security in transactions.

Internet of Things (IoT): Sensors can monitor vehicle conditions, cargo status, and environmental conditions.

Sustainable Transportation Practices

Environmental consciousness is increasingly important. Customers and regulators are pushing for greener practices.

Strategies for Sustainable Transportation

1- Optimizing Loads: Reduces the number of trips required.

2- Using Alternative Fuels: Such as biofuels or electric vehicles.

3- Investing in Fuel-Efficient Vehicles: Upgrading fleets to more efficient models.

4- Driver Training: Educating drivers on fuel-efficient driving techniques.

A logistics company I worked with started a green initiative, resulting in a 10% reduction in carbon emissions and positive recognition from clients.

Conclusion

Effectively managing transportation is a multifaceted challenge that requires strategic thinking and a willingness to adapt. By understanding the nuances of different transportation modes, embracing innovative solutions like multimodal transport, and focusing on strategies to increase capacity utilization, businesses can significantly reduce costs.

Moreover, integrating technology and prioritizing sustainability not only helps businesses but also aligns with global efforts towards a greener future.

As I reflect on my journey from those early days at the family dining table to working with businesses across the globe, one thing remains clear: transportation is more than moving goods from point A to point B. It's about <u>connecting markets</u>, <u>enabling growth</u>, and <u>driving efficiency</u>. By implementing these optimize supply chain management process tips, businesses can navigate the complexities of transportation with confidence and success.

"A penny saved in transportation costs is earned in supply chain efficiency."

References

1- Christopher, M. (2016). Logistics & Supply Chain Management. Pearson Education Limited.

2- Bowersox, D. J., Closs, D. J., & Cooper, M. B. (2013). Supply Chain Logistics Management. McGraw-Hill.

3- Waters, D. (2011). Global Logistics: New Directions in Supply Chain Management. Kogan Page Publishers.

Frequently Asked Questions

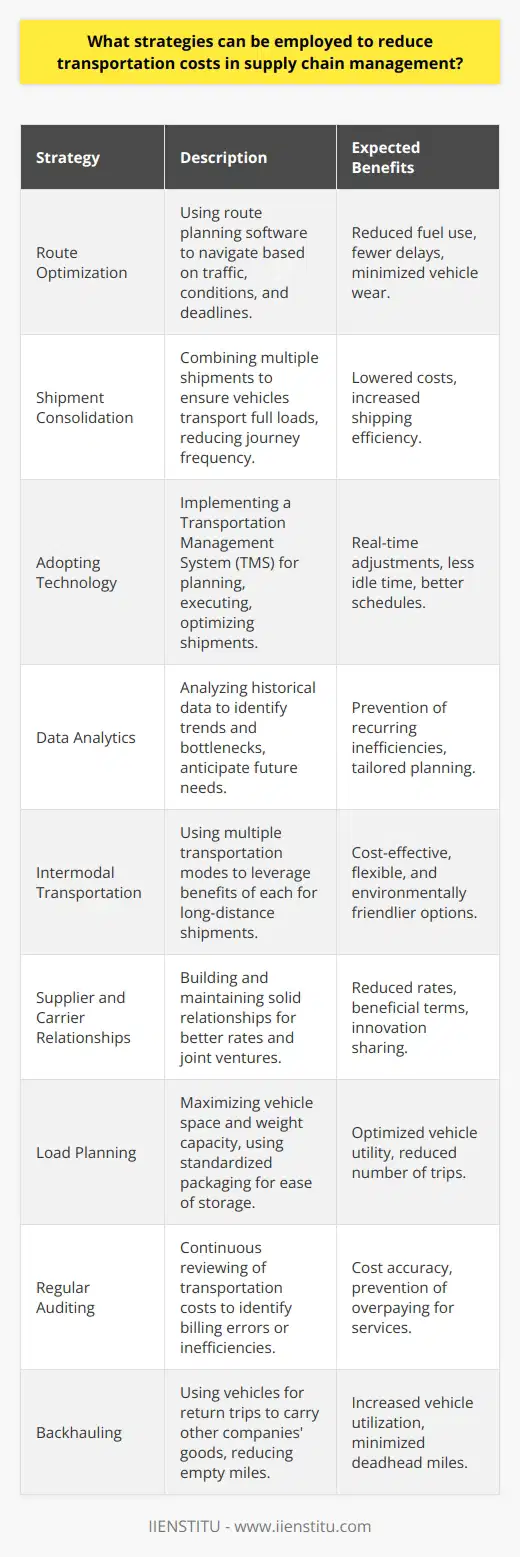

What strategies can be employed to reduce transportation costs in supply chain management?

Supply chain management is a complex and dynamic process that requires the effective and efficient management of resources, materials, and processes. One of the major challenges in supply chain management is the reduction of transportation costs, which can be a significant expense in the supply chain. To reduce transportation costs, several strategies can be employed.

One strategy is the optimization of transportation routes. Optimizing routes can reduce the distance traveled, resulting in lower transportation costs. Additionally, transportation routes should be evaluated to ensure that they are efficient in terms of cost and time. This can be done by utilizing different types of transportation and considering the characteristics of each type of transportation.

Another strategy is the consolidation of shipments. Transportation costs can be reduced by combining multiple orders into a single shipment. This strategy can be especially beneficial for smaller shipments, as the cost of transportation for one large shipment may be lower than the cost of transporting multiple smaller shipments.

In addition to route optimization and shipment consolidation, technology can also be employed to reduce transportation costs. For example, using real-time tracking systems can allow for more efficient route planning and the real-time monitoring of shipments. This allows for more efficient and cost-effective transportation management. Additionally, the use of analytics can also provide valuable data for optimizing transportation routes and improving operational efficiency.

Finally, alternative transportation modes can also be used to reduce transportation costs. For example, rail transportation can be a cost-effective alternative to other modes of transportation. Additionally, intermodal transportation, which involves using multiple modes in the same shipment, can also be beneficial in reducing transportation costs.

In conclusion, several strategies can be employed to reduce transportation costs in supply chain management. These strategies include the optimization of transportation routes, the consolidation of shipments, the use of technology, and the use of alternative transportation modes. By employing these strategies, organizations can reduce their transportation costs and improve the efficiency of their supply chain management.

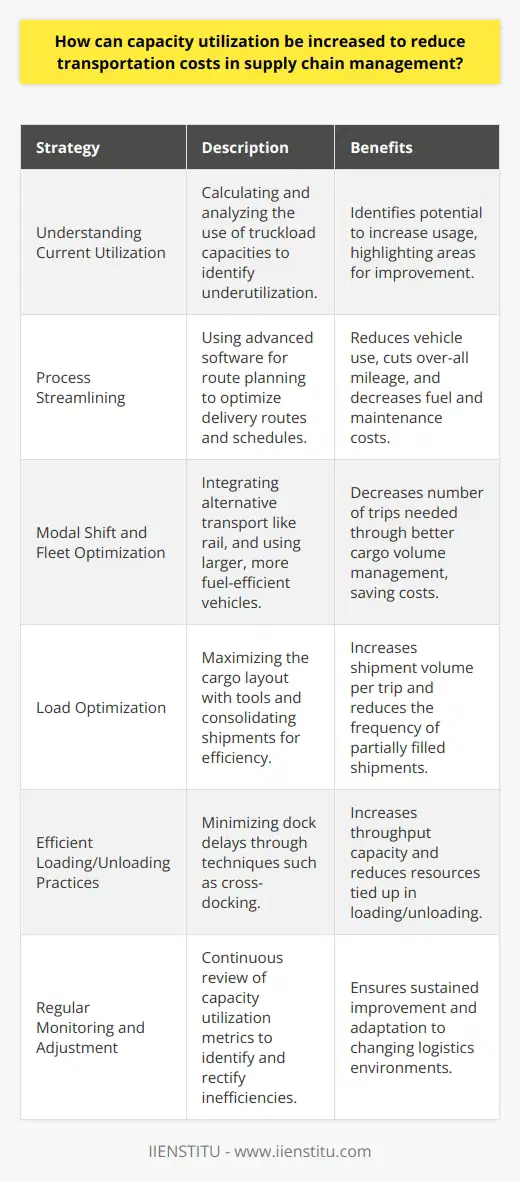

How can capacity utilization be increased to reduce transportation costs in supply chain management?

In recent years, capacity utilization has become a significant focus of supply chain management. Capacity utilization refers to the extent to which the capacity of a given system, such as a factory or transportation network, is utilized. In the context of supply chain management, capacity utilization can be used to reduce transportation costs by increasing the efficiency and effectiveness of transportation operations.

The first step to increasing capacity utilization in the supply chain is to examine the current capacity utilization rate. This rate can be measured by calculating the total capacity of a given system, such as the number of trucks in a fleet, and dividing it by the number of vehicles in operation. If the resulting number is low, the system’s capacity is not fully utilized.

Once the current capacity utilization rate is determined, the next step is to identify areas of improvement. This can include streamlining transportation, improving the picking and packing process, or reducing the number of trips needed to transport goods. Additionally, it may be beneficial to consider alternative modes of transportation, such as rail or air, or to use more significant, more efficient vehicles.

In addition to improving the efficiency of the transportation process, it is also essential to optimize the capacity utilization rate. This can be accomplished by better utilizing the available capacity, such as ensuring that the vehicles are utilized to their total capacity. This can be done by ensuring that vehicles are loaded to their maximum capacity and that routes are planned to minimize space. Additionally, it is essential to ensure that the vehicles are loaded and unloaded as efficiently as possible.

Finally, it is essential to monitor the capacity utilization rate regularly. This can be done by tracking capacity utilization metrics, such as the number of vehicles in operation, the number of trips completed, and the average load. By regularly monitoring the capacity utilization rate, the supply chain manager can identify areas of improvement and take action to improve the efficiency of operations.

In conclusion, increasing capacity utilization can help reduce transportation costs in supply chain management. By examining the current capacity utilization rate, identifying areas of improvement, optimizing the utilization rate, and monitoring the rate, it is possible to improve the efficiency and effectiveness of transportation operations and reduce transportation costs.

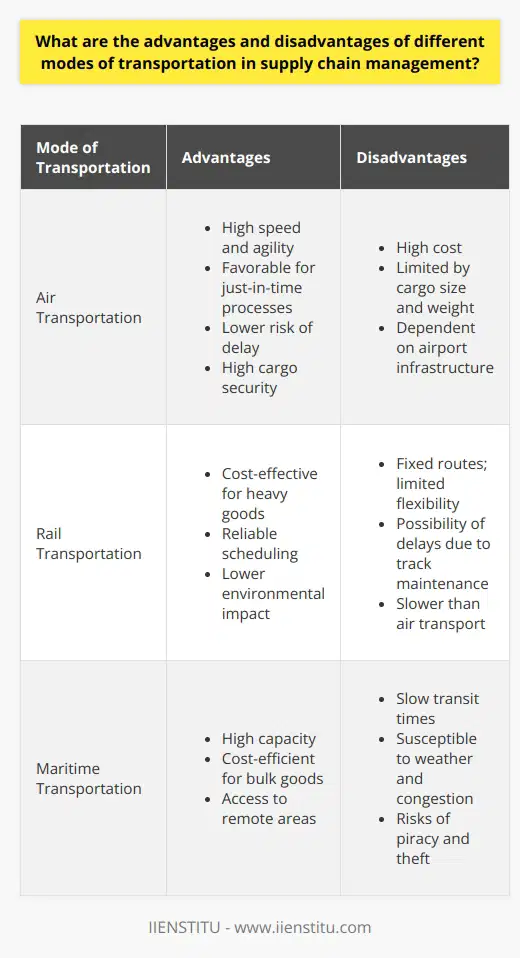

What are the advantages and disadvantages of different modes of transportation in supply chain management?

The supply chain is a fundamental element of any successful business. It involves transporting goods from one point to another, and it is essential to consider the advantages and disadvantages of different transportation modes when managing a supply chain.

A key advantage of air transportation is its speed and efficiency. Goods can be delivered quickly, which is especially important for businesses that need to rush orders or require perishable items. Additionally, air transportation is relatively secure and reliable. Compared to other modes of transportation, it reduces the risk of theft or damage to goods.

However, air transportation is also the most expensive mode of transportation in supply chain management. Furthermore, air transportation does not reach specific locations, such as rural areas, and the size and weight of items that can be shipped are limited.

Rail transportation is a common choice for the supply chain management. It is more economical than air transportation, and it is capable of shipping large and heavy items. Additionally, rail transportation is relatively secure and consistent.

Despite its advantages, rail transportation is not always the best choice. It is not as fast as air transportation, and it is not as reliable due to potential delays or cancellations. Additionally, rail transportation does not reach certain locations and is not suitable for perishable items.

Another mode of transportation in supply chain management is maritime transportation. It is the most economical option and can ship large and heavy items. Additionally, maritime transportation is available in locations that are not accessible to other modes of transportation, such as remote islands.

Despite its advantages, maritime transportation is also the slowest mode of transportation. It is also the least reliable and secure, as goods can be damaged or stolen at sea. Additionally, maritime transportation is not suitable for perishable items.

In conclusion, when managing a supply chain it is essential to consider the advantages and disadvantages of different transportation modes. Air transportation is the fastest, but it is also the most expensive. Rail transportation is economical and reliable but not as fast as air transportation. Maritime transportation is economical and available in remote locations but is slow and unreliable.

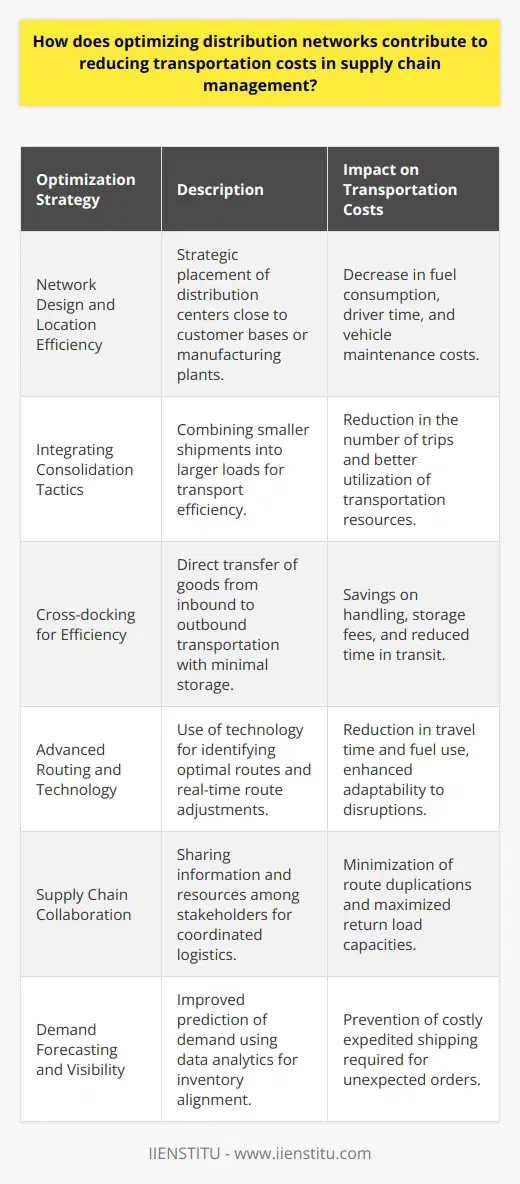

How does optimizing distribution networks contribute to reducing transportation costs in supply chain management?

Optimizing Distribution Networks

Optimizing distribution networks is a critical aspect of supply chain management that significantly contributes to the reduction of transportation costs. By improving the efficiency of material and product movement through better network design, organizations can minimize costs associated with transportation and logistics.

Network Design and Strategic Location

A well-designed distribution network reduces the overall distance travelled by goods, thereby lowering transportation expenses. Effective network design involves selecting optimal locations for distribution centers (DCs) and warehouses. By strategically positioning these facilities closer to suppliers and customers, organizations can streamline the movement of goods and reduce overall transportation costs.

Consolidation and Cross-docking

Consolidation of shipments is another method to optimize distribution networks and reduce transportation costs. By combining smaller shipments into larger ones, companies can reduce the number of trips required and utilize more efficient transportation modes, such as full-truckload shipping. Additionally, cross-docking practices can further reduce transportation costs as products are directly transferred from inbound to outbound shipping modes without storage, thereby minimizing transportation time and cost.

Route Optimization and Technology

Investing in route optimization tools and technologies can significantly reduce transportation costs in supply chain management. Route optimization software can help determine the most cost-effective and efficient routes for transporting goods between suppliers, DCs, and customers, which in turn reduces fuel consumption and transportation costs. Additionally, the utilization of GPS tracking and real-time data allows for continuous monitoring and adjustments to improve transportation efficiency.

Collaboration and Visibility

Enhanced collaboration and visibility across the supply chain can contribute to reducing transportation costs. By exchanging information and collaborating with suppliers and carriers, organizations can better align transportation schedules, consolidate shipments, and reduce empty backhaul trips. Furthermore, improved visibility allows for better demand forecasting, which enables companies to optimize inventory levels in DCs and avoid the need for costly expedited transportation.

To conclude, optimizing distribution networks leads to significant reductions in transportation costs by improving network design and location, implementing consolidation and cross-docking practices, leveraging route optimization tools and technology, and encouraging collaboration and visibility across the supply chain. These strategies contribute to an overall more efficient and cost-effective supply chain management system.

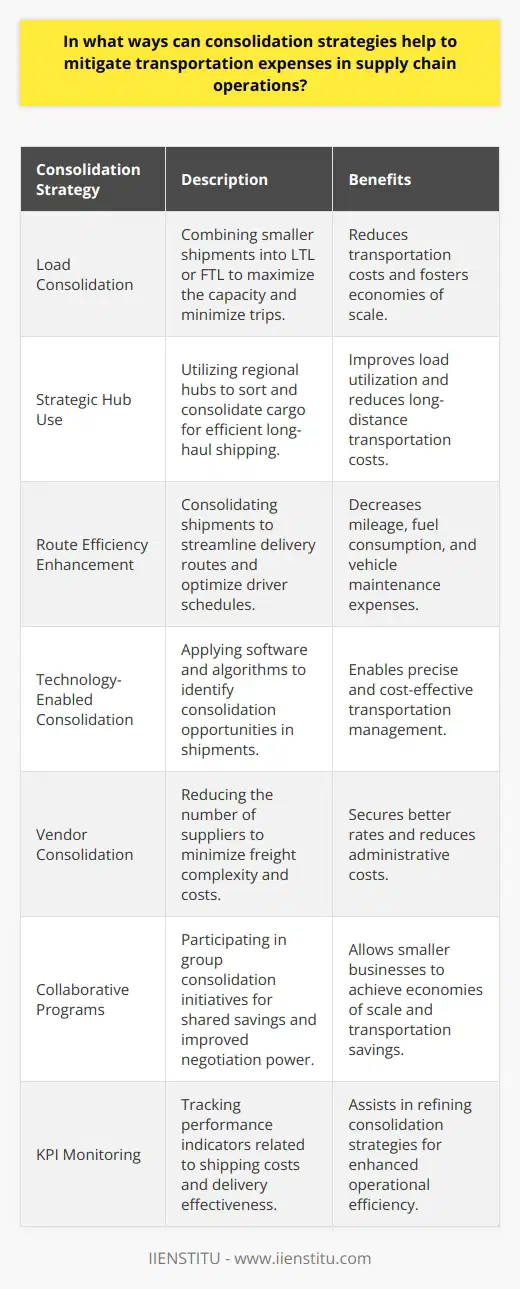

In what ways can consolidation strategies help to mitigate transportation expenses in supply chain operations?

Consolidation Strategy Implementation

Consolidation strategies in supply chain operations can help mitigate transportation expenses by effectively combining smaller shipments into larger ones. This allows companies to take advantage of economies of scale, where unit transportation costs decrease as shipment sizes increase.

Load Optimization Techniques

One common consolidation strategy is using load optimization techniques, which involve maximizing the use of transportation resources, such as truckloads and shipping containers. This can lead to reduced fuel consumption and lower transportation expenses, as a fully-loaded vehicle is typically more cost-efficient than multiple smaller ones.

Collaborative Shipping Initiatives

Another strategy is the implementation of collaborative shipping initiatives, where multiple organizations cooperate to share transportation resources. By jointly planning logistics, companies can reduce the total number of shipments, thus lowering transportation expenses. Additionally, this approach promotes more efficient route planning and asset utilization.

Centralized Distribution Strategy

A centralized distribution strategy can also help mitigate transportation expenses by consolidating shipments at a major distribution center. This approach reduces the need for multiple shipments to individual locations, as products are sent to the central hub and then further distributed. This results in fewer overall shipments, decreasing transportation costs.

Cross-Docking Operations

Cross-docking operations can reduce transportation expenses through combining shipments at a distribution center or warehouse without the need for extended storage. This strategy minimizes handling and storage costs, as products are quickly moved from one vehicle to another before being transported to their final destination.

Consolidation Strategies and Environmental Impact

Lastly, implementing consolidation strategies can have environmental benefits which indirectly contribute to reduced transportation expenses. Large scale, consolidated shipments contribute to reduced fuel consumption and greenhouse gas emissions, leading to cost savings from potential regulatory fines or carbon taxes.

In conclusion, consolidation strategies can effectively help mitigate transportation expenses in supply chain operations. These strategies, including load optimization techniques, collaborative shipping initiatives, centralized distribution, and cross-docking operations, all contribute to cost reductions by leveraging economies of scale and promoting efficient resource utilization. Additionally, such strategies provide environmental benefits, which can result in further savings for the organization.

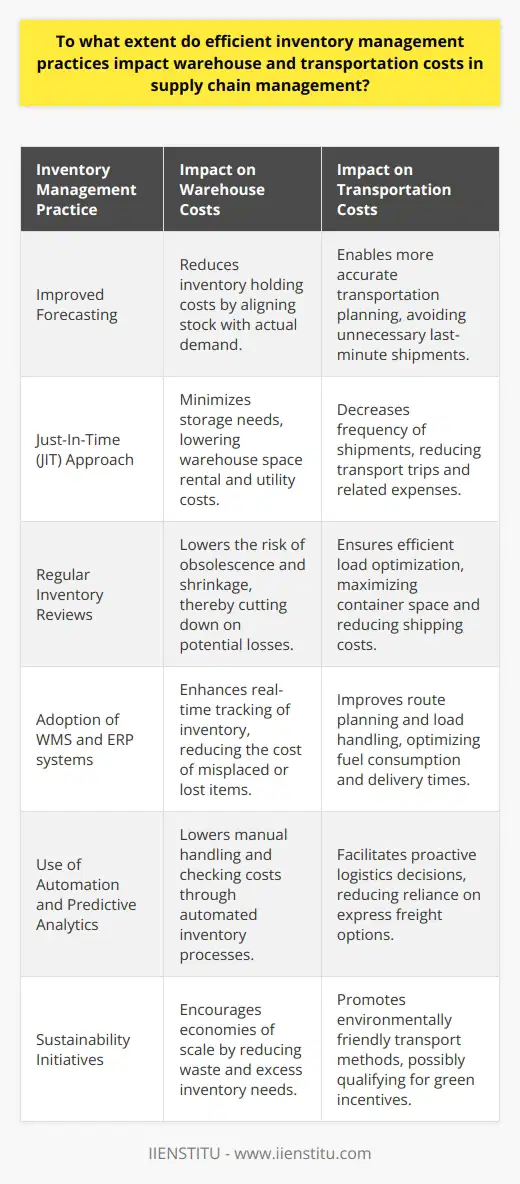

To what extent do efficient inventory management practices impact warehouse and transportation costs in supply chain management?

Efficient Inventory Management Significance

Effective inventory management practices largely impact warehouse and transportation costs in supply chain management. By implementing strategies that ensure only necessary stock levels are maintained, companies can minimize their expenses associated with warehousing and transportation. Optimizing stock levels results in reduced storage costs and increased storage space availability, allowing the allocation of resources towards other value-adding processes within the organization.

Warehouse Space Utilization

Efficient inventory management enables companies to make better use of their warehouse spaces. This is achieved through practices such as demand forecasting, just-in-time procurement, and data-driven inventory analysis. By reducing overstocking and minimizing obsolete inventory, businesses can optimize their warehouse space, leading to lower rental and utility costs. Furthermore, the reduction in stock levels results in decreased labor costs, as fewer employees are needed to manage inventory.

Reduced Transportation Costs

Improved inventory management practices also reduce transportation costs by streamlining order fulfillment and shipment processes. Accurate demand forecast ensures that transportation resources are utilized to their full potential. This means goods are shipped only when required, avoiding excess costs associated with multiple deliveries and returns. Implementing measures such as consolidating orders, transportation mode optimization, and the selection of efficient shipping routes can significantly lower transportation expenses.

Inventory Accuracy and Technology

Employing advanced technology plays a crucial role in maintaining an accurate inventory system. Incorporating tools such as Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP) software, and automatic data collection methods enhance inventory visibility and control. These technologies enable companies to make better-informed decisions regarding warehouse management and transportation logistics, ultimately lowering operational costs.

Sustainable Supply Chain Practices

Efficient inventory management practices also contribute to the development of sustainable supply chain operations. By reducing excess inventory and optimizing transportation processes, companies can minimize their carbon footprint and adhere to environmental regulations. Sustainably managing resources directly affects the bottom line, as a greener supply chain often results in less operational expenses in the long run.

In conclusion, efficient inventory management practices significantly impact warehouse and transportation costs in supply chain management. By optimizing stock levels, improving warehouse space utilization, reducing transportation costs, employing advanced technology, and promoting sustainability, businesses can benefit from cost savings and increased operational efficiency.

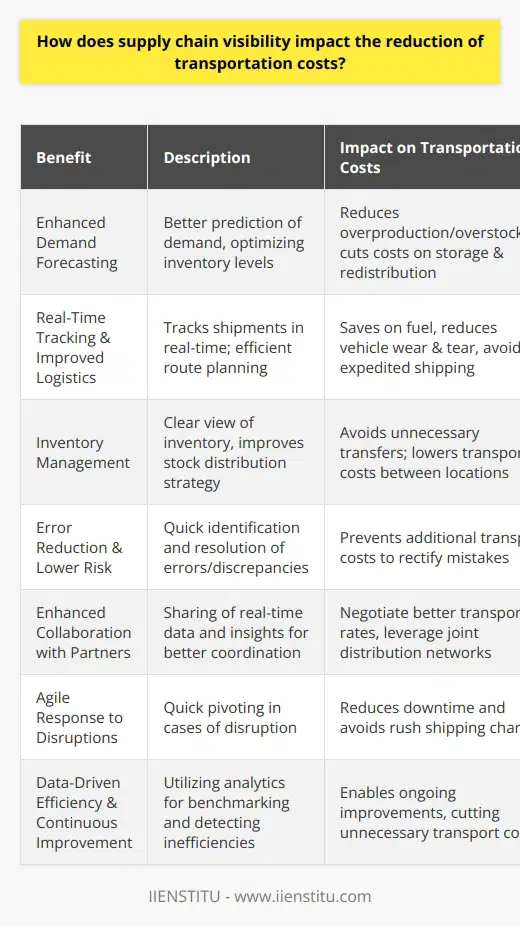

How does supply chain visibility impact the reduction of transportation costs?

Impact on Cost Reduction

Supply chain visibility plays a crucial role in reducing transportation costs by providing real-time information on the movement of goods, resource allocation, and demand forecasting. This enables companies to optimize their logistics processes, resulting in cost savings.

Streamlined Management

By leveraging the real-time information provided by supply chain visibility, companies can streamline their inventory management and improve demand forecasting. This ensures that there are no unnecessary stockpiles of goods, reducing the cost of excess inventory and the space required for storage.

Optimization of Transportation Routes

With complete visibility of the supply chain, businesses can optimize transportation routes to reduce fuel consumption and transportation times. This not only lowers transportation costs but also minimizes the environmental impact of logistics operations.

Improved Collaboration

In addition to internal benefits, supply chain visibility also promotes collaboration between trading partners. This allows companies to negotiate better rates for transportation services, identify inefficiencies in the logistics process, and develop strategies to reduce costs.

Reduced Delays and Penalties

Supply chain disruptions can lead to costly delays and penalties for organizations. The real-time data provided by supply chain visibility can help companies identify potential issues in advance and take proactive measures to prevent or mitigate these disruptions, resulting in reduced transportation costs.

Enhanced Decision-Making

Lastly, supply chain visibility enhances decision-making capabilities by providing companies with accurate data on their logistics operations. This enables organizations to identify trends and areas for improvement, allowing them to make informed decisions that contribute to the reduction of transportation costs.

In conclusion, supply chain visibility significantly impacts the reduction of transportation costs by allowing businesses to optimize their logistics processes, improve collaboration with trading partners, and enhance decision-making capabilities. By leveraging the real-time information provided by supply chain visibility, organizations can reduce costs, improve efficiency, and minimize their environmental impact.

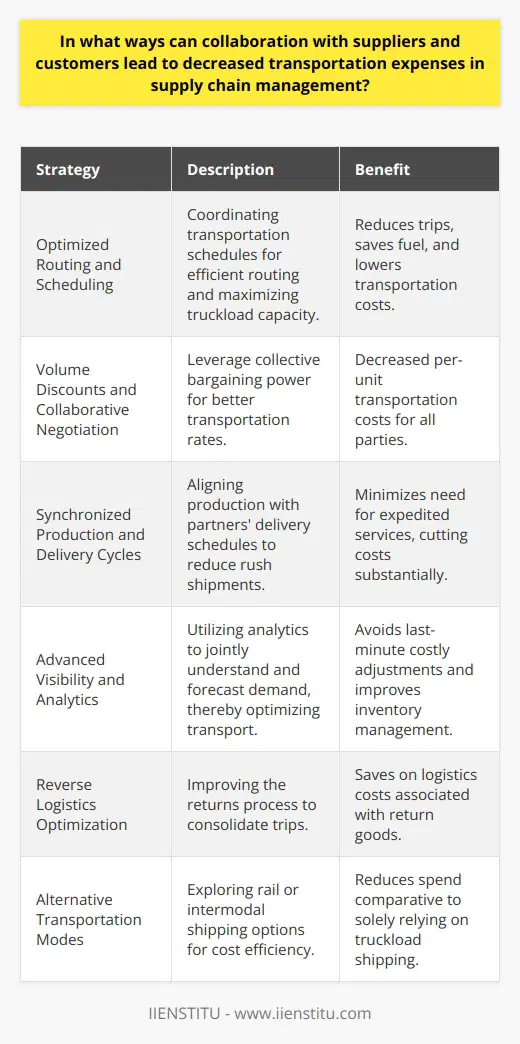

In what ways can collaboration with suppliers and customers lead to decreased transportation expenses in supply chain management?

Collaborative Strategies for Decreased Transportation Expenses

Partnering with suppliers and customers can significantly reduce transportation costs in supply chain management. One notable approach is through collaborative transportation management (CTM), where multiple companies combine resources to optimize shipments and distribution activities.

Coordinated Shipments and Load Consolidation

When suppliers and customers collaborate on transportation, it becomes easier to consolidate shipments, leading to fewer yet fuller truckloads. This reduces transportation costs by eliminating the need for multiple carriers and expediting deliveries. Collaborative processes like these not only contribute to cost savings, but also help minimize carbon emissions.

Cross-Docking and Shared Distribution Centers

Jointly operating cross-docking and shared distribution centers removes unnecessary steps and costs associated with shipping products. By using a shared facility, companies can efficiently sort and allocate resources, thereby minimizing transportation expenses. Additionally, these shared centers foster collaboration among business partners, resulting in improved supply chain operations.

Vendor-Managed Inventory and Demand Forecasting

Accurate demand forecasting is crucial in reducing transportation expenses. By adopting vendor-managed inventory systems, suppliers gain better visibility of customer demand and can optimize their production and shipping schedules. Consequently, this aids businesses in avoiding out-of-stock situations or excess inventory, ensuring products reach end customers on time at minimal costs.

Information Sharing and Technological Integration

Sharing information through technology enables smoother communication between suppliers and customers, which in turn leads to better optimization of resources. Adopting sophisticated tracking systems and digital platforms can provide real-time data on shipments and inventory levels, allowing both parties to plan and execute transportation strategies more effectively. In essence, technological integration leads to better-informed decisions, lower expenses, and improved supply chain performance.

In conclusion, collaborating with suppliers and customers can play a pivotal role in decreasing transportation expenses in supply chain management. Methods such as CTM, load consolidation, cross-docking, and vendor-managed inventory systems not only result in cost savings but also enhance overall supply chain efficiency. By engaging in these collaborative efforts, businesses can optimize their supply chain operations and experience significant benefits in today's competitive market landscape.

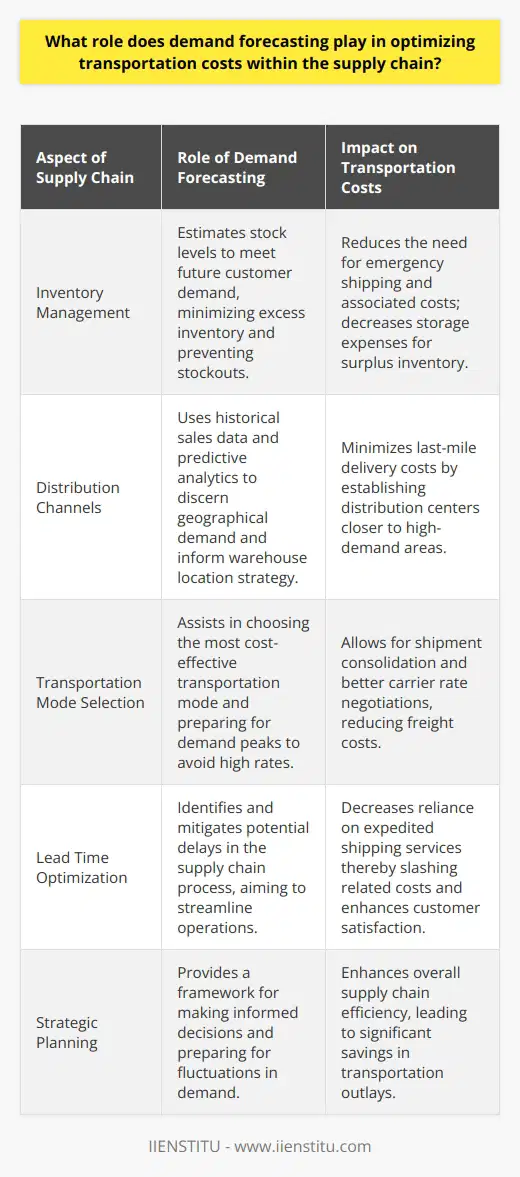

What role does demand forecasting play in optimizing transportation costs within the supply chain?

Role of Demand Forecasting in Transportation Cost Optimization

Demand forecasting plays a crucial role in optimizing transportation costs within the supply chain by enabling businesses to make informed decisions on inventory management, distribution channels, and transportation modes. Accurate demand forecasts help organizations anticipate market needs, allowing them to allocate resources efficiently and minimize logistics costs.

Inventory Management

Effective demand forecasting enables organizations to maintain appropriate inventory levels by gauging future product demand. This prevents overstocking and stockouts, leading to reduced carrying costs and storage expenses. Consequently, businesses can minimize their transportation costs by avoiding the need for expedited shipments due to inventory shortages.

Distribution Channel Decisions

Accurate demand forecasting aids in selecting the most efficient distribution channels to ensure quick, cost-effective product delivery. By analyzing customer demand patterns, companies can determine the optimal locations for their distribution centers and order fulfillment facilities. This strategic placement of distribution hubs minimizes the distances products must travel, reducing transportation expenses.

Transportation Mode Selection

Demand forecasting allows companies to accurately assess the necessary transportation capacity and choose the most cost-effective modes for their products. By assessing demand trends, businesses can predict spikes in product demand and plan accordingly to avoid costly rush shipments. When companies have a realistic view of transportation requirements, they can negotiate better shipping rates with carriers, leading to substantial cost savings.

Lead Time Reduction

Reliable demand forecasting plays a central role in reducing lead times, as companies can make data-driven decisions about production and transportation. By proactively identifying potential bottlenecks, businesses can take corrective actions to prevent delivery delays, resulting in lower transportation costs and enhanced customer satisfaction.

In conclusion, demand forecasting is integral to optimizing transportation costs within the supply chain as it informs key decisions relating to inventory management, distribution channels, transportation modes, and lead time reduction. Companies that invest in accurate demand forecasting methodologies can reap significant cost savings and improve overall operational efficiency.

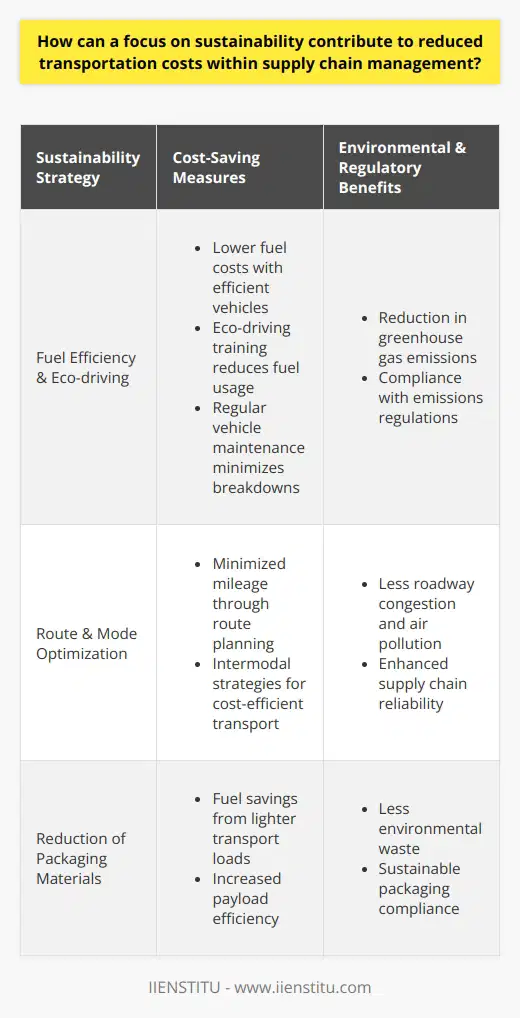

How can a focus on sustainability contribute to reduced transportation costs within supply chain management?

Sustainability's Impact on Transportation Costs

Adopting a sustainable approach within supply chain management can significantly contribute to reducing transportation costs. The key ways through which sustainability helps in cutting down these expenses include improving fuel efficiency, optimizing routing and transportation modes, and reducing packaging materials.

Fuel Efficiency to Save Costs

One of the primary aspects of sustainability in transportation is fuel efficiency. Encouraging the use of energy-efficient vehicles and incorporating eco-driving principles can result in substantial savings in fuel costs. Additionally, it not only reduces an organization's carbon footprint but also leads to less wear and tear of the vehicles, ultimately contributing to lower maintenance costs.

Optimizing Routes and Modes

A sustainable supply chain management also emphasizes the optimization of routing and transportation modes. By carefully analyzing transportation routes and selecting the most efficient alternative, companies can reduce travel distances and cut down on fuel usage. Furthermore, opting for intermodal and multimodal transportation methods, which involve the use of different modes of transport to achieve a more efficient shipping process, can lead to cost reductions while minimizing environmental impacts.

Reducing Packaging Materials

Another way in which sustainability aids in lowering transportation costs is by advocating for the reduction of packaging materials. Lightweight and reusable packaging designs can significantly decrease the total weight of shipments, resulting in lower transportation costs. Moreover, using recyclable and environmentally friendly materials can contribute to reducing waste and strengthening a company's commitment to eco-friendly practices.

In conclusion, focusing on sustainability within supply chain management presents an opportunity for organizations to substantially diminish transportation costs. Adopting fuel-efficient vehicles, optimizing routes and transportation modes, and utilizing sustainable packaging materials are integral steps towards achieving a more eco-friendly and cost-effective supply chain.

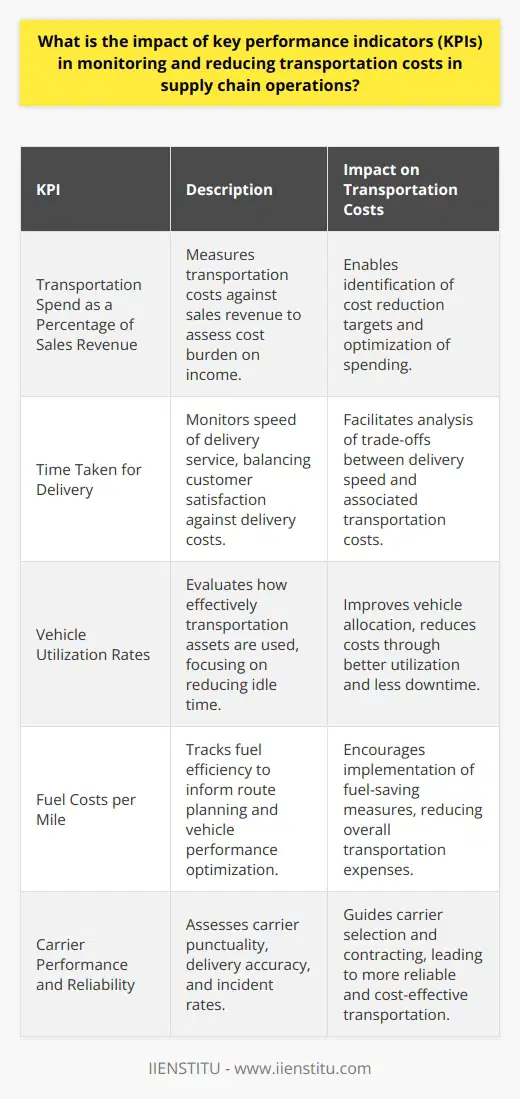

What is the impact of key performance indicators (KPIs) in monitoring and reducing transportation costs in supply chain operations?

Subheading: Identifying KPIs in Supply Chain Operations

Utilizing key performance indicators (KPIs) in supply chain operations immensely helps in tracking and evaluating the efficiency of a company's transportation system. By monitoring KPIs focused on transportation costs, managers can continuously improve performance, optimize resource allocation, and reduce overall expenses.

Subheading: Examples of KPIs for Transportation Costs

KPIs associated with transportation costs include transportation spend as a percentage of sales revenue, time taken for delivery, vehicle utilization rates, fuel costs per mile, among others. Through regular evaluation of these metrics, companies can efficiently identify trends, discover discrepancies, and adjust strategies to minimize the cost and maximize customer satisfaction levels.

Subheading: KPIs Driving Continuous Improvement

Continuous improvement is an essential aspect of supply chain performance management, where KPIs act as lifeblood. Frequent monitoring of transportation costs allows organizations to implement data-driven decision-making processes, ensure timely corrective actions, and enables optimization of assets, routes, and modes of transportation, thus reducing operational costs.

Subheading: Enhancing Resource Management

Transportation cost KPIs also aid in enhancing resource management. Vehicle utilization rates, for example, identify instances of underutilized fleets, suggesting the need for decreased fleet sizes. Streamlining resources can yield significant cost reductions and promote sustainability by operating with minimal waste.

Subheading: Reducing Operating Costs

By monitoring KPIs associated with fuel consumption, companies can identify areas of excessive fuel usage and evaluate the suitability of fuel-efficient alternatives. The resultant decrease in fuel spend brings down operating costs, offers a competitive edge, and contributes to a sustainable business model.

In conclusion, KPIs are vital in monitoring and reducing transportation costs in supply chain operations. They enable organizations to improve performance, manage resources effectively, and reduce operating costs, ultimately driving success, long-term viability, and an enhanced competitive advantage in the market.

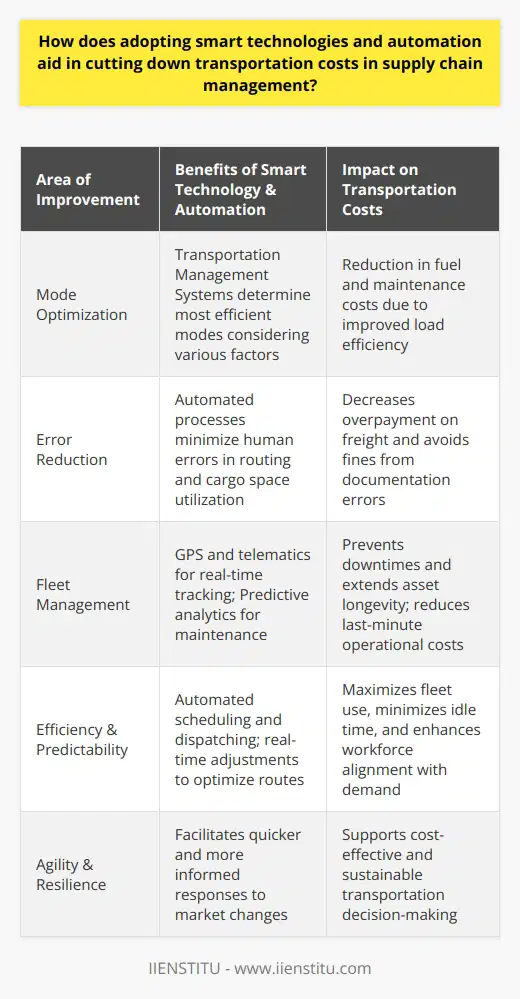

How does adopting smart technologies and automation aid in cutting down transportation costs in supply chain management?

Subheadings:

Optimization of Transportation Modes

Reduction in Human Errors

Enhanced Efficiency and Predictability

Optimization of Transportation Modes

Adopting smart technologies and automation aids in cutting down transportation costs in supply chain management by optimizing the selection of transportation modes. Intelligent software calculates the most cost-effective and time-efficient route for transporting goods, considering factors such as fuel consumption, traffic patterns, and road conditions. As a result, companies can reduce fuel costs, vehicle maintenance, and transportation time, ultimately reducing their overall transportation expenses.

Reduction in Human Errors

By automating processes and implementing smart technologies, companies minimize human errors in logistics planning and execution. For instance, manual calculations for vehicle load capacity and routing plans may lead to inaccuracies, resulting in increased costs and delays. Automation eliminates such errors by providing precise and accurate information, which in turn enables companies to utilize resources more efficiently and reduce transportation costs.

Enhanced Efficiency and Predictability

Smart technologies provide real-time data on fleet performance, allowing companies to monitor and assess vehicle conditions and driver performance. This information leads to better decision-making and scheduling, ensuring on-time deliveries and reducing the likelihood of unexpected expenses during transportation. Additionally, real-time tracking of vehicles and shipments allows for better coordination and resource utilization, further improving efficiency and overall cost management in the supply chain.

In conclusion, the adoption of smart technologies and automation in supply chain management leads to the optimization of transportation modes, reduction in human errors, and enhanced efficiency and predictability. These factors ultimately result in decreased transportation costs, allowing companies to improve their overall supply chain performance and competitiveness in the market.

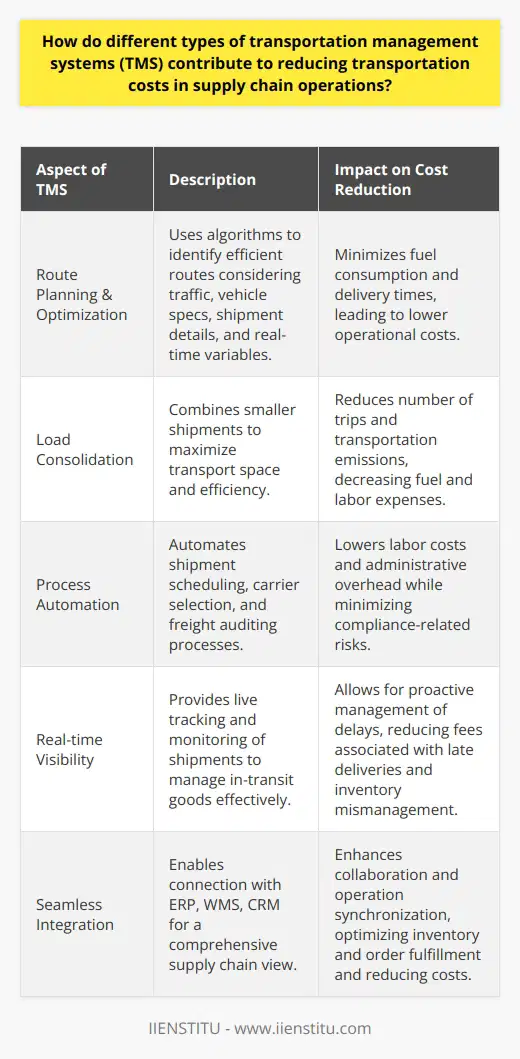

How do different types of transportation management systems (TMS) contribute to reducing transportation costs in supply chain operations?

Types of TMS Contributions

Different types of transportation management systems (TMS) contribute to reducing transportation costs in supply chain operations through various methods. TMS strategies play a significant role in increasing efficiency, optimizing logistics, and facilitating communication, ultimately resulting in cost savings. This paragraph will discuss how different TMS types contribute to these cost reductions.

Improved Route Optimization

One key factor contributing to reduced transportation costs is route optimization. Advanced TMS solutions analyze multiple factors, such as distance, traffic, and real-time weather conditions, to provide optimal routes for transportation. This enables supply chain companies to minimize fuel consumption, reduce transit times and subsequently lower overall transportation costs.

Modern Load Consolidation Techniques

Load consolidation is another crucial method by which TMS can reduce transportation costs. By combining small shipments from multiple suppliers into one larger shipment via a single transportation mode, load consolidation can save companies significant amounts of money. This is achieved by reducing the number of shipments, lowering fuel expenses, and optimizing the use of carriers, ultimately reducing total transportation costs.

Automation and Digitalization

Incorporating automation and digitalization into TMS has vastly improved efficiency in supply chain operations. Automating tasks such as data entry and document management minimizes human error, streamlines processes, and accelerates workflows. The use of digital platforms enables swift access to information and enhances communication between parties, leading to more efficient transportation and lower costs.

Real-time Tracking and Visibility

Real-time tracking and visibility offered by modern TMS solutions can significantly reduce transportation costs. By providing real-time data on shipment location, carriers, and delivery times, TMS enables companies to monitor and manage their supply chains proactively. This enhanced visibility allows businesses to identify transportation inefficiencies and take corrective action, thus reducing expenses and ensuring timely delivery.

Integration with Other Systems

Lastly, integrating TMS with other supply chain management systems contributes to cost reductions. Companies can achieve better coordination with suppliers, carriers, and customers by connecting their TMS solutions to inventory management, warehouse management, and customer relationship management systems. These integrations allow for smoother end-to-end supply chain operations, enabling companies to implement cost-saving strategies, such as just-in-time inventory management and streamlined order fulfillment.

In conclusion, various transportation management systems contribute to reducing transportation costs in supply chain operations by optimizing routes, consolidating loads, incorporating automation and digitalization, providing real-time tracking and visibility, and integrating with other systems. Adopting the appropriate TMS solution can significantly enhance efficiency in supply chain operations, leading to substantial cost savings across the entire process.

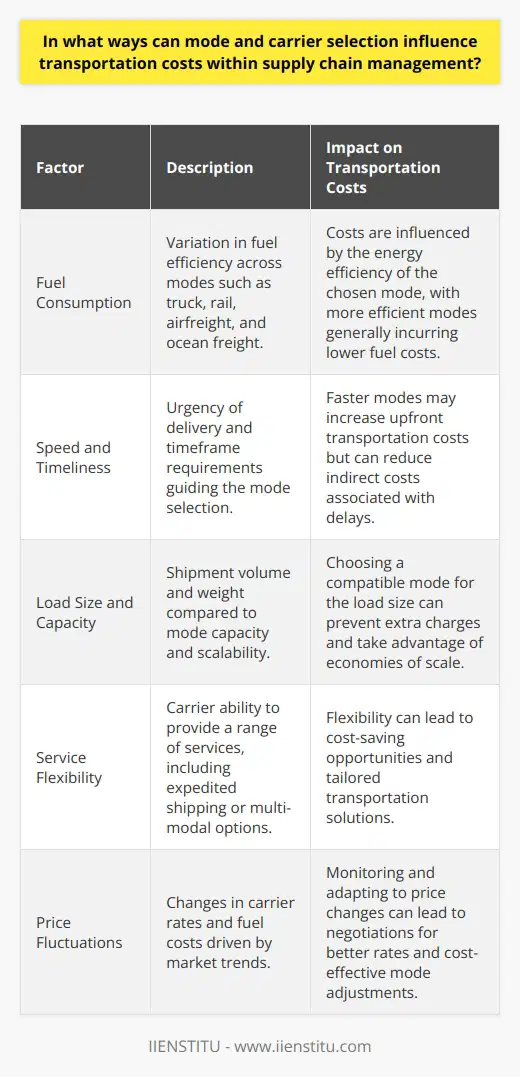

In what ways can mode and carrier selection influence transportation costs within supply chain management?

Mode and Carrier Selection

One significant way mode and carrier selection influences transportation costs within supply chain management is through fuel consumption. Different modes of transport, such as rail, air, road, and sea, rely on varying fuel types and consumption rates, which ultimately determine the transportation cost. Choosing the most fuel-efficient mode for a specific shipment can significantly reduce transportation expenses.

Speed and Timeliness

Another factor to consider is the speed and timeliness of different modes of transport. Faster modes of transport, like air freight, typically come with higher costs. However, when speed and timeliness are essential, the expedited delivery may justify the increased transportation costs. Supply chain managers must balance the need for speed with the associated expenses to optimize transportation costs.

Load Size and Capacity

Load size and capacity also impact transportation costs in supply chain management. The per-unit cost of transportation often decreases as the shipment size increases, due to economies of scale. Therefore, selecting a mode and carrier that can accommodate larger loads can lead to more cost-effective transportation solutions. Furthermore, efficient utilization of available capacity reduces wasted space and increases the per-unit transportation value.

Service Flexibility

Service flexibility plays a crucial role in managing transportation costs. Modes and carriers with options for consolidation, transloading, and other value-added services offer supply chain managers the ability to optimize transportation costs based on their specific needs. Additionally, carriers and modes with extensive networks can provide more cost-effective routing options, reducing overall transportation costs.

Price Fluctuations

Lastly, price fluctuations in both transportation rates and fuel costs can significantly impact supply chain management transportation costs. Supply chain managers must closely monitor these fluctuations to adjust their mode and carrier selection accordingly. By staying informed and proactively adjusting strategies based on market trends, supply chain managers can better control transportation costs and optimize their overall logistics operations.

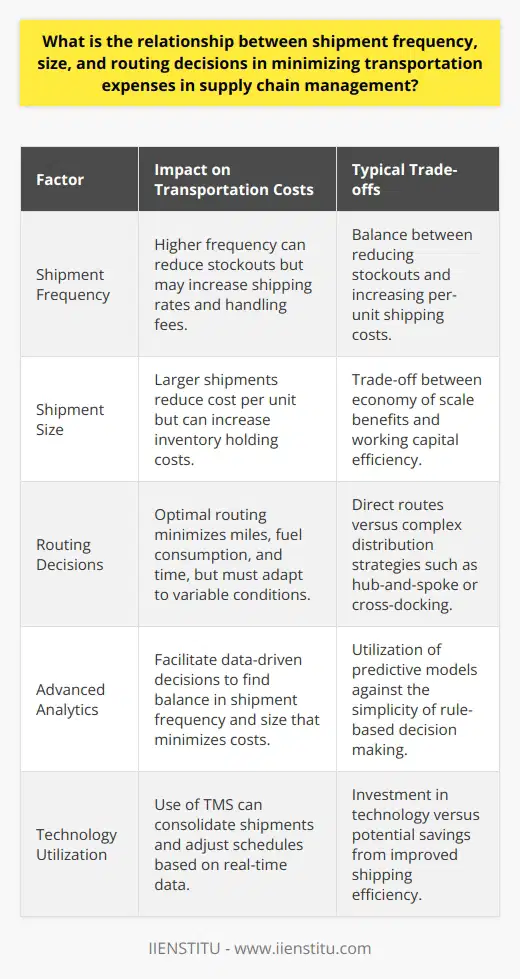

What is the relationship between shipment frequency, size, and routing decisions in minimizing transportation expenses in supply chain management?

Shipment Frequency and Size

The relationship between shipment frequency, size, and routing decisions plays a crucial role in minimizing transportation expenses in supply chain management. To reduce transportation costs, companies must balance the frequency of shipments with the size of those shipments. As shipment frequency increases, the cost per shipment decreases but at the expense of higher inventory holding costs. On the other hand, larger shipment sizes reduce inventory holding costs but may increase per-unit transportation costs due to vehicle capacity constraints and less optimized routing choices.

Routing Decisions

Routing decisions are essential for cost optimization in transportation. A well-thought-out routing strategy ensures that shipments are delivered in the shortest possible time and with the least possible cost. This involves considering various factors such as travel distance, traffic congestion, fuel consumption, and vehicle type. By selecting optimal routes, companies can minimize transportation expenses and improve overall supply chain efficiency.

Minimizing Transportation Expenses

To minimize transportation expenses in supply chain management, organizations should carefully analyze the relationship between shipment frequency, size, and routing decisions. This includes evaluating trade-offs between shipment frequency and size, as well as implementing optimal routing strategies. Additionally, technology, such as transportation management systems (TMS), can be employed to assist with these decisions, offering real-time data and analytics to support the optimization process.

In conclusion, understanding the relationship between shipment frequency, size, and routing decisions is critical for minimizing transportation expenses in supply chain management. By striking a balance between these variables, organizations can reduce costs, improve efficiency, and ultimately enhance their overall competitive advantage in the marketplace.

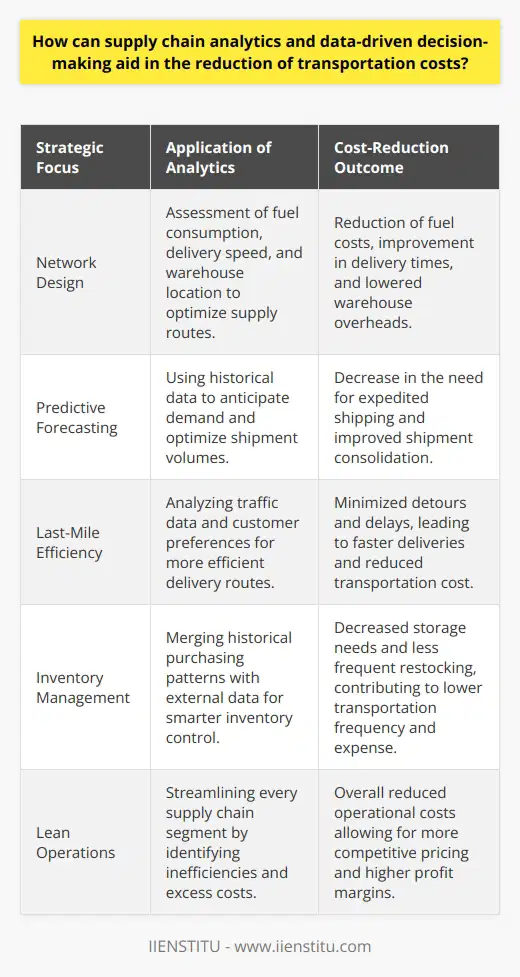

How can supply chain analytics and data-driven decision-making aid in the reduction of transportation costs?

Supply Chain Analytics Role

Supply chain analytics can play a vital role in reducing transportation costs. With more data from different sources, organizations can gain valuable insights into their supply chain operations. This can facilitate proactive decision-making and consequently lower transportation costs.

Data-Driven Strategies

Data-driven strategies can help businesses identify and address inefficiencies within the supply chain. They can detect patterns that may contribute to increased costs, such as repeated delays or damaged goods during transportation.

Unconventional Analytical Approaches

Predictive analytics and historical data analysis weaken potential risks and postpone unexpected costs. They can help companies prepare for future transportation needs and adapt to market trends and changes more rapidly and cost-effectively.

Route Optimization

Data analytics can enhance route optimization. Analyzing factors such as traffic congestion, distance, and delivery time can help design the most efficient routes, reducing fuel costs and improving delivery timeframes.

Network Design

Supply chain analytics can improve network design by balancing transportation and warehousing costs. Instead of focusing on reducing one type of cost, it enables a holistic view of the entire supply chain, considering all types of costs associated.

Inventory Management

Data analytics can enhance inventory management. By accurately forecasting demand, companies can minimize the amount of stock held, reducing storage as well as transportation costs.

In conclusion, supply chain analytics, driven by accurate data, can significantly reduce transportation costs. The analytics provide an edge in understanding and optimizing supply chain operations, which ultimately leads to more efficient, cost-effective business practices.

What role does risk management play in minimizing warehouse and transportation costs within supply chain operations?

Risk Management's Role in Reducing Warehouse and Transport Costs

Risk management forms a critical strategy in reducing warehouse and transport costs within supply chain operations. At its core, risk management aims to preemptively identify, evaluate, and mitigate potential disruptions or hazards in the supply chain. By proactively addressing such challenges, organizations can increase efficiency and mitigate costs, particularly in warehouse and transportation areas.

Identification and Evaluation of Risks

The first step in risk management involves recognizing and assessing potential problems. These include external elements such as climatic changes, political instability, or market fluctuations. Internally, risks could involve malfunctioning equipment, employee misconduct, or inconsistent product quality. Identifying and evaluating these issues sooner helps businesses lessen the financial impact by planning alternative strategies.

Mitigation Measures and Cost Reduction

Upon risk identification, an organization should then formulate effective mitigation measures. Proper risk assessment allows a company to devise preemptive action plans, ensuring minimal disruption in case of unforeseen circumstances. An effective solution may include diversification in transport routes or suppliers or investing in warehouse automation. Successful preparation can prevent significant financial losses, specifically concerning warehouse and transportation expenses.

Risk Management and Efficiency

Efficiency within warehouse processes and transportation is another vital element to consider in risk management. Reducing potential warehouse disruptions or transport difficulties can catalyze smooth workflow, resulting in reduced operating costs. Moreover, the organization may also benefit from potential downtime or wastage reduction, contributing to overall expenses limiting.

Conclusion

In conclusion, effective risk management plays a crucial role in minimizing warehouse and transportation costs within supply chain operations. By proactively identifying, evaluating, and mitigating potential problems, businesses can promote efficiency and notably decrease associated operating expenses. Therefore, risk management should be integral to any cost-saving strategy within supply chain operations.

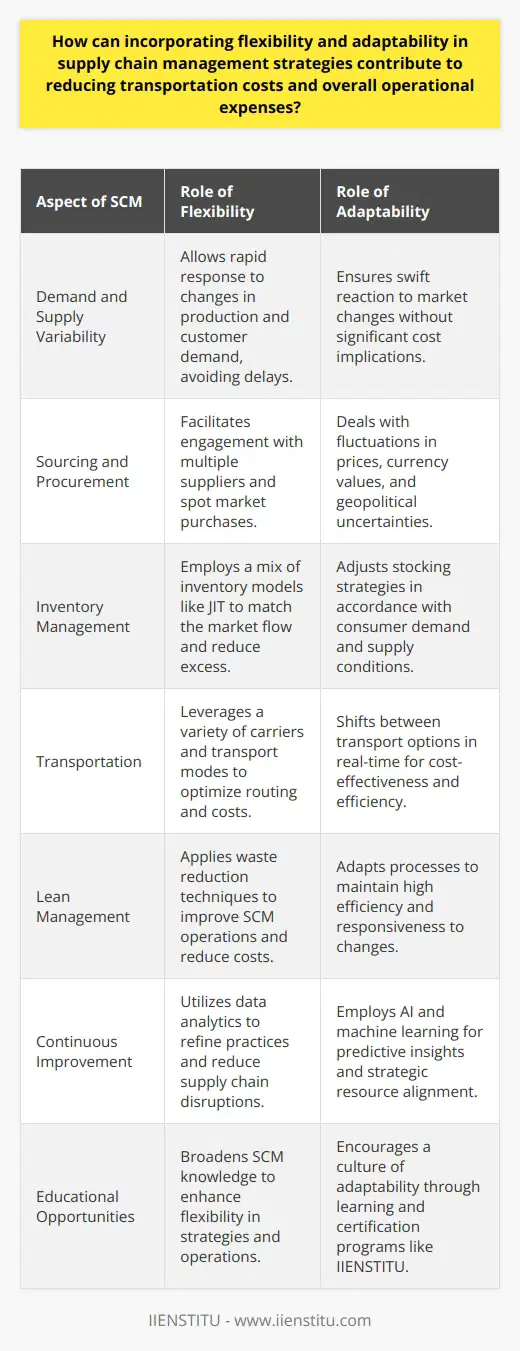

How can incorporating flexibility and adaptability in supply chain management strategies contribute to reducing transportation costs and overall operational expenses?

Incorporating Flexibility in Supply Chain Management

Flexibility in supply chain management greatly reduces transportation costs. If a company is flexible, it can adjust to market changes. For instance, if fuel prices increase, a flexible company can find alternative modes of transport. This potential to adapt to adverse situations enables cost-saving.

Adaptability in Sourcing and Procurement

Adaptability also plays a critical role in sourcing and procurement processes. A supply chain that can effortlessly switch between various suppliers based on cost efficiency is an asset. It allows businesses to identify and engage suppliers who offer the best rates, leading to procurement savings. Besides, they can reduce delays in the procurement process, further minimizing operational expenses.

Inventory Management with Adaptability

A flexible inventory management strategy can lead to cost reduction. In this setup, an adaptable system allows for shifts between different inventory methods. For example, a Just-In-Time inventory system reduces holding costs. Meanwhile, maintaining a safety stock approach ensures the availability of goods in unexpected demand spikes.

Implementation of Lean Management Practices

Lean management practices often accompany flexibility and adaptability. These help in removing waste from the supply chain operations, thus lowering operational expenses. High-quality lean systems help forecast demand accurately, effectively reducing stock-outs and overstocks. This predictive methodology decreases unnecessary costs and optimizes supply chain operations.

In conclusion, integration of flexibility and adaptability in supply chain management contributes significantly to reducing transportation costs and overall operational expenses. It allows businesses to mitigate the impact of market changes, engage cost-effective suppliers, efficiently manage inventory, and promote lean management. Such flexibility ultimately enhances operational efficiency and profitability.