In today's fast-paced and ever-evolving business landscape, companies are constantly looking for ways to improve efficiency, reduce costs, and enhance customer satisfaction. While most of the focus has historically been on the forward supply chain, there's an often overlooked aspect that is gaining increasing importance: the reverse supply chain. It's fascinating how something once considered an afterthought is now integral to the core strategies of leading businesses. But how did we get here, and what exactly makes the reverse supply chain so vital?

When I think about the reverse supply chain, I can't help but recall a personal experience I had when returning a defective product. A few years ago, I purchased a high-end coffee maker from a reputable brand. Within weeks, it malfunctioned. Frustrated, I navigated through the brand's return process, and to my surprise, they handled it with such efficiency and ease that it left a lasting impression on me. They didn't just send me a replacement; they ensured the defective product was collected, repaired, and either resold or recycled—nothing went to waste. This seamless experience reflected the company's robust reverse supply chain, and it got me thinking about how integral reverse logistics are in modern business operations.

But let's dive deeper into this concept. This article will explore reverse supply chain optimization, its history, significance, and future potential. We'll look at how businesses are transforming what was once seen as a cost burden into an opportunity for sustainability, profitability, and enhanced customer loyalty.

Introduction to the Reverse Supply Chain

Defining the Reverse Supply Chain

The reverse supply chain is all about what happens after a product reaches the customer. Instead of focusing on delivering products, it revolves around retrieving them—whether through returns, repairs, recycling, or disposal. Imagine it as the "afterlife" of the product, a phase often ignored but now seen as a treasure trove of value.

The reverse supply chain includes product returns, refurbishment, recycling, and redistribution of goods or their parts. It’s the process that allows businesses to recapture value from products that would otherwise end up in landfills. In today's eco-conscious world, this approach isn't just about cutting costs; it's about being responsible stewards of our planet.

Brief History and Emergence of the Reverse Supply Chain

It's hard to pinpoint the exact moment reverse logistics became a hot topic, but it's been a long time coming. Decades ago, companies saw it as an annoying necessity—a headache, really. Products that came back from customers were either discarded or dealt with half-heartedly.

Fast forward to today, and reverse logistics is a key player in driving corporate sustainability and cost savings. This shift started around the time environmental awareness became a focal point in public discourse. Governments introduced strict regulations on waste management and product disposal, particularly for industries like electronics and automobiles, where improper disposal could have dire environmental consequences. Companies began to realize that optimizing their reverse supply chains could not only help them comply with these regulations but also unlock new revenue streams.

I remember reading about how Apple handles its old products—this tech giant not only recycles its products but also retrieves valuable materials from them, which they use to create new products. It's like a perfect loop, where nothing is wasted. That’s the essence of a well-optimized reverse supply chain.

Why Reverse Supply Chains Matter

Economic Benefits of an Optimized Reverse Supply Chain

From an economic standpoint, a well-run reverse supply chain can significantly reduce costs. Businesses can recover value from returned products, reduce waste disposal fees, and resell refurbished goods. This practice isn't limited to tech companies. I've seen it in the fashion industry, where brands like Patagonia and H&M have robust take-back and recycling programs for their old products. They refurbish and resell these items, catering to both eco-conscious consumers and those looking for affordable alternatives.

On a personal level, I used to think that once I returned a product, that was the end of the road for it. But over time, I’ve learned that these products are part of a much larger cycle. Reselling refurbished products isn’t just a cost-saving strategy—it’s a way to build loyalty. People appreciate companies that take responsibility for the lifecycle of their goods.

Environmental Impact: Sustainability through Reverse Logistics

The environmental benefits of an optimized reverse supply chain are enormous. By extending the life of products and reducing the need for new raw materials, companies can significantly reduce their carbon footprints. I often think about the amount of waste that goes into landfills when products are simply discarded. It’s alarming. But businesses that incorporate reverse logistics practices are helping to change that.

One of my favorite examples is from the automotive industry. Companies like Toyota and Ford have comprehensive programs for reclaiming parts from end-of-life vehicles. These parts are refurbished and reused, which reduces the demand for raw materials and minimizes waste. I’ve always admired Toyota for their attention to detail, but this just takes it to another level. The circular economy they’ve created is a testament to the power of the reverse supply chain in driving sustainability.

Corporate Social Responsibility (CSR) and Reverse Supply Chain

For companies, reverse logistics isn’t just about the bottom line. It’s also about corporate social responsibility (CSR). In today's world, consumers expect businesses to do more than just sell products; they expect them to care about the world. The reverse supply chain allows companies to show that they’re taking concrete steps toward reducing their environmental impact.

I’ve personally been more inclined to support brands that have robust sustainability initiatives in place. It’s not just about what they sell; it’s about how they handle their business from start to finish. When I see a company with a strong reverse logistics process, I feel more confident that they are committed to making a positive impact on the environment.

The Key Components of a Reverse Supply Chain

Every effective reverse supply chain is built on several key components that ensure the process runs smoothly:

Collection

This is the first step, where companies collect products from consumers for return or recycling. It sounds simple, but it's a complex process. Companies need to create easy-to-use return systems. I remember returning an electronic device once, and the company offered to pick it up from my home. The convenience of that process made me appreciate their service even more.Processing

After collection, the products need to be inspected, sorted, and processed. The fate of the product is decided here—whether it will be repaired, recycled, or discarded. The efficiency of this step is crucial to ensuring maximum value recovery.Disposition

Disposition refers to the decision-making process regarding the returned products. Will they be refurbished, recycled, or scrapped? Companies must balance environmental responsibility with financial practicality.

Each of these steps must be carefully managed to maximize the value that can be recaptured from returned products. However, the reverse supply chain is not without its challenges, and many companies struggle with logistics, technology, and customer engagement.

Real-World Examples of Reverse Supply Chain Optimization

Let’s look at how a few industries have taken reverse logistics to the next level:

1. The Electronics Industry

The fast pace of technological change means that electronics become obsolete quickly. Brands like Samsung and Apple have made reverse logistics a priority, implementing trade-in programs that not only promote customer loyalty but also allow the companies to retrieve valuable components from old devices.

2. The Apparel Industry

Fashion is another area where reverse supply chains are thriving. H&M has become a pioneer in offering clothing recycling programs. Customers can drop off old clothes in their stores, which are then either recycled or sold as second-hand items. It's a win-win situation: H&M can reduce waste, and customers feel good about contributing to sustainability.

3. The Automotive Industry

Car manufacturers have long understood the value of reverse logistics. Toyota is a great example. The company not only reclaims old parts from vehicles but also repurposes them to manufacture new products, reducing their environmental impact while saving on production costs.

Challenges in Reverse Supply Chain Optimization

Despite its benefits, reverse logistics presents several challenges:

Logistics Complexity

One of the major hurdles is the logistics involved in collecting and transporting returned goods. Setting up efficient collection points and managing the flow of returned products is no easy feat. A personal frustration of mine is when companies don’t offer free returns. It’s something that can discourage customers from engaging with reverse logistics.Technological Investment

Managing reverse supply chains requires sophisticated technology. Companies need advanced systems to track returned products and monitor their disposition. Not all companies can afford this level of investment, which creates a barrier to optimizing reverse logistics.Customer Perception

Another challenge is how customers perceive refurbished or recycled products. Many consumers still prefer new products, even if refurbished ones are just as good. Overcoming this stigma is key to making reverse logistics a success.

Best Practices for Reverse Supply Chain Management

From my own experiences, I've learned that effective reverse supply chain management boils down to proper planning, technology integration, and collaboration with third-party logistics providers. Here are a few best practices:

Forecasting

Companies need to anticipate the volume and types of returns they might face. Accurate forecasting allows them to align their reverse logistics with business objectives.Leveraging Technology

Automation and data analytics are game-changers when it comes to reverse logistics. Companies that invest in technology to streamline their processes can save time and money in the long run.Partnering with Experts

Some companies lack the expertise to manage reverse logistics effectively, which is why partnering with third-party logistics providers can be an excellent solution.

Future Trends in the Reverse Supply Chain

Looking ahead, I see technology and the circular economy playing pivotal roles in shaping the future of reverse logistics. As more companies embrace the principles of the circular economy, products will be designed with reverse logistics in mind. This shift will help minimize waste and encourage reuse and recycling on an unprecedented scale.

Conclusion

Optimizing the reverse supply chain isn't just about reducing costs or adhering to regulations. It's about sustainability, customer satisfaction, and corporate responsibility. From personal experiences to global industry trends, it's clear that reverse logistics is here to stay. As businesses continue to evolve, they will need to embrace this crucial component of their supply chain to remain competitive and responsible in the modern world.

In my view, the reverse supply chain is a game-changer for companies that are serious about sustainability and efficiency. It’s an area that will only grow in importance as we move toward a more circular economy. If you haven’t already explored how optimizing your reverse supply chain can benefit your business, now is the time to start.

References:

Apple’s Recycling and Trade-In Programs: Apple Inc.

H&M’s Sustainability Efforts: "The Role of Circular Fashion," H&M Group, 2023.

Toyota's Commitment to Sustainability: "Automotive Sustainability Report," Toyota Motor Corporation, 2022.

"The Circular Economy: A User's Guide," Walter Stahel, 2019.

Frequently Asked Questions

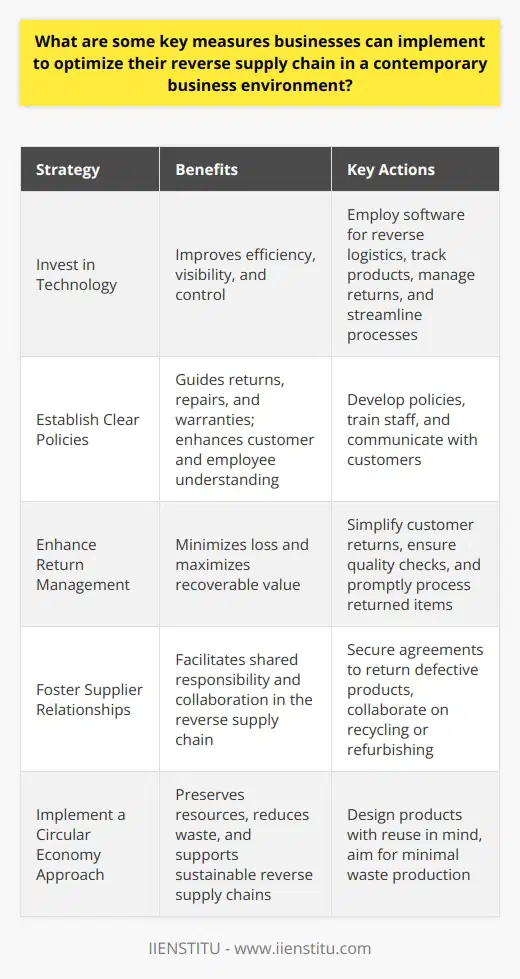

What are some key measures businesses can implement to optimize their reverse supply chain in a contemporary business environment?

Reverse Supply Chain Optimization in Modern Businesses

Understand Reverse Supply Chain Dynamics

Businesses must grasp reverse supply chains. They involve returns, repairs, recycling, and disposal. Reverse logistics is its synonym. Recognize its complexity and importance. Firms should integrate this into their overall strategy.

Invest in Technology

Technology drives efficiency. Businesses can employ software for reverse logistics. Such tools track products, manage returns and streamline processes. Implement advanced systems for better visibility and control.

Establish Clear Policies

Clear policies are vital. They guide returns, repairs, and warranties. Customers should understand these policies. So should employees. Businesses need to train staff on these procedures.

Enhance Return Management

Optimize return processes. Simplify customer returns. Ensure quality checks exist. Promptly process returned items. This minimizes loss and maximizes recoverable value.

Foster Supplier Relationships

Collaboration with suppliers helps. Secure agreements to return defective products. Aim for shared responsibility in the reverse supply chain. Suppliers can assist with recycling or refurbishing.

Prioritize Sustainability

Emphasize eco-friendly practices. Reduce waste through better reverse chain management. This can improve brand image. It also appeals to environmentally conscious consumers.

Leverage Data Analytics

Use data to make informed decisions. Analyze returns and identify trends. Businesses can prevent future defects. They can also improve product design and quality.

Encourage Remanufacturing and Recycling

Promote product life cycle extension. Focus on remanufacturing and recycling. This reduces environmental impact. It creates economic value from returned items.

Implement a Circular Economy Approach

Circular economies preserve resources. Design products with reuse in mind. Aim for minimal waste production. This philosophy supports sustainable reverse supply chains.

Engage in Continuous Improvement

Always seek to improve. Regularly assess reverse supply chain performance. Adjust strategies as needed. Businesses must adapt to changing market demands and technologies.

In summary, businesses must tackle their reverse logistics proactively. These measures can optimize the reverse supply chain. This aligns with both economic and environmental goals.

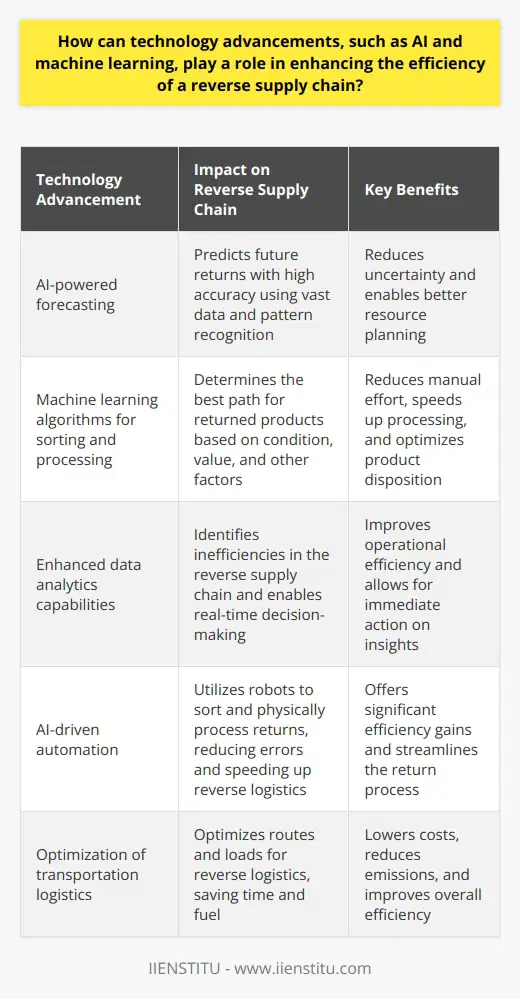

How can technology advancements, such as AI and machine learning, play a role in enhancing the efficiency of a reverse supply chain?

The Intersection of Technology and Reverse Supply Chain

Efficiency Through AI and Machine Learning

Technology evolves rapidly. These advancements reshape many business areas. The reverse supply chain is no exception. Here, returned goods and materials flow back from customers. The goal includes reintegration or proper disposal.

AI and machine learning are at the forefront of innovation. They bring remarkable improvements to reverse logistics. Efficiency is not just an outcome. It is a necessity.

Advancements in Forecasting Returns

Predicting returns can be challenging. AI can transform this uncertainty. It uses vast data and pattern recognition. This way, it forecasts future returns with high accuracy.

Optimization of Sorting and Processing

Upon return, products must be sorted. They may be refurbished, resold, recycled, or disposed of. Machine learning algorithms can determine the best path. They analyze condition, value, and other factors quickly. This reduces manual effort significantly.

Better Decision Making with Analytics

Real-time data leads to better decisions. AI enhances data analytics capabilities. Thus, companies spot inefficiencies in the reverse supply chain. They can act on these insights immediately.

Enhanced Customer Experience

A smooth return process is vital for customer satisfaction. AI streamlines returns handling. It also provides customers with timely updates. They enjoy a more engaging experience.

Automating Reverse Logistics

Automation offers significant efficiency gains. AI-driven robots can sort and physically process returns. This reduces errors. It also speeds up the reverse logistics.

Reducing Environmental Impact

Sustainability matters. Efficient reverse logistics help. They ensure optimal recycling and waste management. AI can plan and execute environmentally-friendly strategies.

Proactive Approach to Returns

A proactive stance is crucial. AI forecasts return volumes. Companies can hence prepare resources accordingly.

Enhanced Transportation Logistics

Transportation is a substantial reverse supply chain cost. AI optimizes routes and loads. It saves time and fuel. This lowers costs and emissions.

Challenges and Considerations

Despite these benefits, challenges remain. AI implementation can be costly. Training for staff is necessary. Data privacy and security are concerns too.

Conclusion

In essence, AI and machine learning are game-changers. They enhance reverse supply chain efficiency in multiple ways. Businesses that adopt these technologies tend to stay ahead. They address economic and environmental pressures effectively. They deliver better customer service. Hence, they prepare for a future where the reverse supply chain is as critical as the forward supply chain.

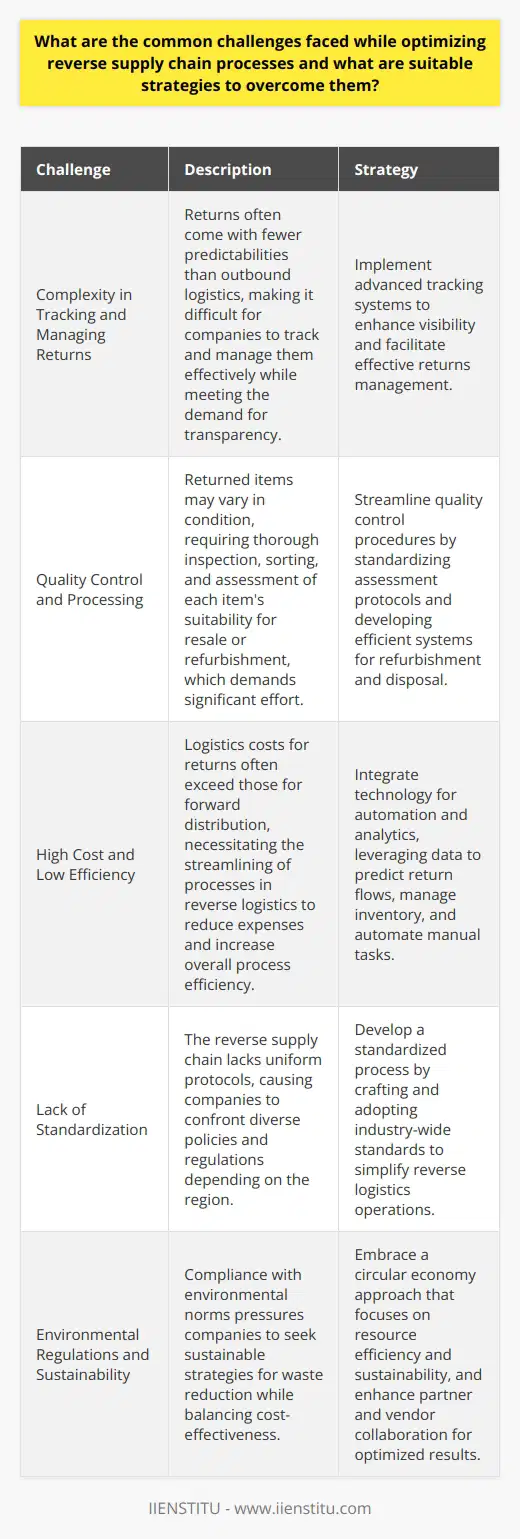

What are the common challenges faced while optimizing reverse supply chain processes and what are suitable strategies to overcome them?

Introduction

The reverse supply chain stands out as a complex network. It focuses on the management of goods from the consumer back to the producer. Various challenges emerge in the optimization of these supply chains. Below, we delve into these challenges and propose strategies for enhancement.

Identifying Common Challenges

Complexity in Tracking and Managing Returns

Returns often come with fewer predictabilities than outbound logistics. Companies grapple with the intricacies of tracking returns. Meeting the demand for transparency proves tough.

Quality Control and Processing

Returned items may vary in condition. They demand thorough inspection and sorting. Assessing each item's suitability for resale or refurbishment requires significant effort.

High Cost and Low Efficiency

Logistics costs for returns often exceed those for forward distribution. Processes in reverse logistics need streamlining. This will reduce expenses and increase overall process efficiency.

Lack of Standardization

The reverse supply chain lacks uniform protocols. Companies confront diverse policies and regulations depending on the region.

Environmental Regulations and Sustainability

Compliance with environmental norms pressures companies. Many seek sustainable strategies for waste reduction. Yet, they must balance this with cost-effectiveness.

Strategies for Optimization

Implementing Advanced Tracking Systems

Deploy robust tracking solutions. These enhance visibility and facilitate effective returns management.

Streamlining Quality Control Procedures

Standardize assessment protocols. Develop efficient systems for refurbishment and disposal.

Integrating Technology for Automation and Analytics

Leverage technology to automate manual tasks. Employ data analytics to predict return flows and manage inventory.

Developing a Standardized Process

Craft and adopt industry-wide standards. These will simplify reverse logistics operations.

Embracing a Circular Economy Approach

Transition towards a circular economy model. This focuses on resource efficiency and sustainability.

Enhancing Partner and Vendor Collaboration

Forge strong partnerships across the supply chain. Collaborate with vendors and third parties for optimized results.

Conclusion

Reverse supply chains present unique challenges. Yet, strategic approaches can combat inefficiencies. Companies should adopt suitable technologies and frameworks. This will ensure that reverse logistics become a competitive advantage rather than a cost center.