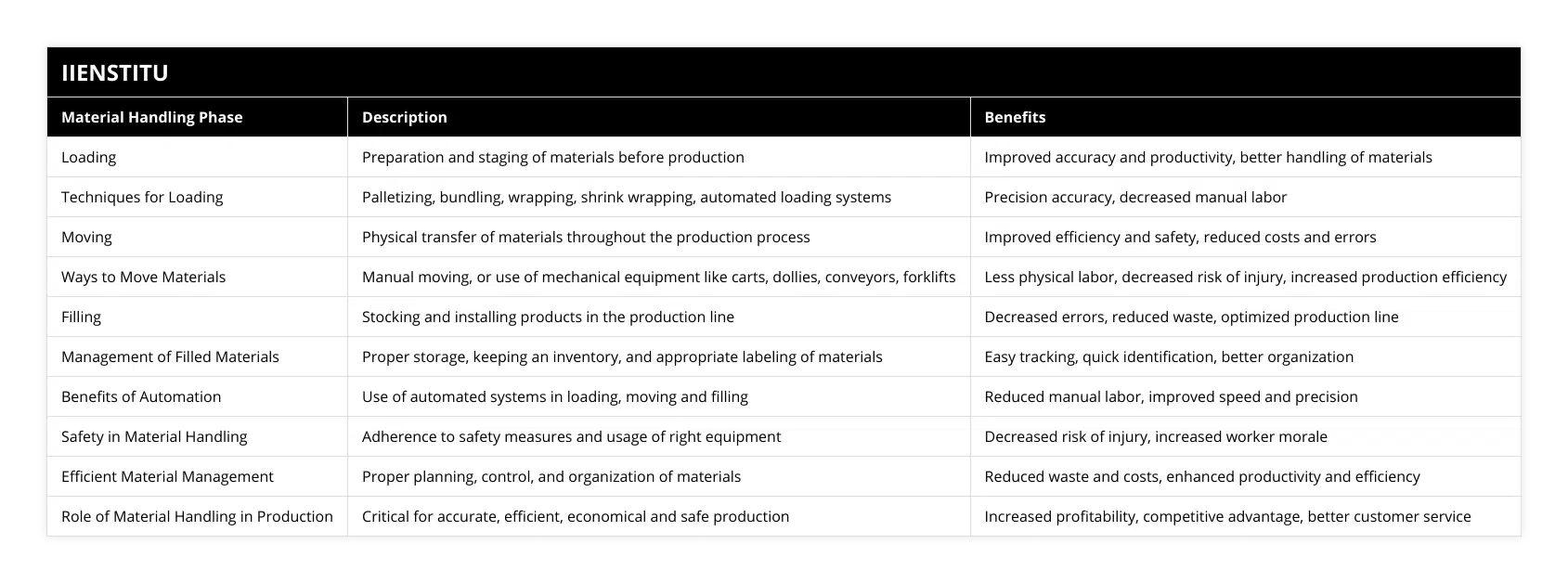

Loading

Moving

Filling

Material handling is a critical factor in the success of any production line. It is essential to the efficient operation of a business. Material handling is the process of loading, moving, and filling materials, including products, parts, and components, in an organized and efficient manner. Proper material handling reduces costs, promotes safety, and enhances productivity. This blog aims to discuss the different loading, moving, and filling techniques and the potential benefits of using efficient material handling processes.

Loading

The loading process involves the preparation and staging of materials before the start of a production line. Loading at the beginning of a function is an essential part of the overall material handling process as it ensures that materials are adequately prepared and ready for the next phase of the production line. The simplest form is manual loading, where the workforce moves materials and components. However, current loading operations often involve mechanical equipment such as conveyors and forklifts.

Benefits of Loading

Loading provides various benefits, including improved accuracy, better handling of materials and components, and greater productivity. By adequately loading materials before production, the chances of errors, defects, or misplacement are significantly reduced, improving the production process's accuracy. Additionally, proper loading minimizes the time lost due to product handling and increases the efficiency of the production line.

İmpact Of Artificial İntelligence On Supply Chain Efficiency

İmprove Operations With Overall Equipment Effectiveness İnsights

İmpact Of Smart Logistics Networks On Supply Chain Efficiency

Techniques for Loading

There are several techniques for loading materials, including but not limited to: palletizing, bundling, wrapping, and shrink wrapping. Additionally, advanced material handling systems provide automated loading systems, allowing for precision accuracy and reducing the amount of manual labor needed.

Moving

Moving material involves physically transferring materials and components throughout the production process. Hauling materials is done to maximize efficiency and safety, as well as to reduce costs and errors. The method of moving can involve manually moving materials from one station to another or using mechanical equipment such as carts, dollies, conveyors, and forklifts.

Benefits of Moving

Moving materials can be labor-intensive, yet it has several potential benefits over manual labor. For one, it helps reduce the amount of physical work needed, decreases the risk of employees becoming injured, and helps improve the efficiency of the production process. Additionally, using the correct type of mechanical equipment can help limit the number of breakdowns and ensure smooth and efficient production.

Most Searched Keyword About The Key İmplications Of The Bill Of Lading İn Business Transactions

Efficient Supply Chain Management And Collaboration With Vendors

Ways to Move Different Materials

The type of material being moved can determine the type of equipment to be used. For example, lightweight materials can be moved manually, while heavier materials may require mechanical equipment. Additionally, the material's size, shape, and type can determine the equipment to use. For instance, a conveyor system may be used for moving large quantities of materials. In contrast, a forklift may be used for moving heavier materials.

Filling

The process of filling involves stocking and installing products and components in the production line. This process ensures that materials are in the correct place, at the right time, and with a valid quantity and quality. Filling is usually done manually, but with technological advancements, automated systems are becoming increasingly popular.

Benefits of Filling

The filling is an essential step in ensuring that the production line runs smoothly. By adequately filling materials, businesses can minimize the risks of errors, reduce waste, and optimize the production line. Automated systems can also help streamline the process, as it eliminates the need for manual labor.

Management of Filled Materials

Once materials are filled, it is essential to manage them properly. Materials should be stored according to their size and needs, and an inventory should be kept so that materials can be easily tracked. Additionally, materials should be appropriately labeled so that they can be identified quickly.

Conclusion: Material handling is an integral part of any production line and is essential for businesses to achieve the highest efficiency. Proper loading, moving, and filling materials are vital components of material handling. They can provide numerous benefits, such as improved accuracy, better handling of materials, and greater productivity. Businesses can achieve effective material handling by understanding the different loading, moving, and filling techniques and implementing efficient systems.

Organize your materials to move them quickly and easily for time saved is the efficiency gained.

Frequently Asked Questions

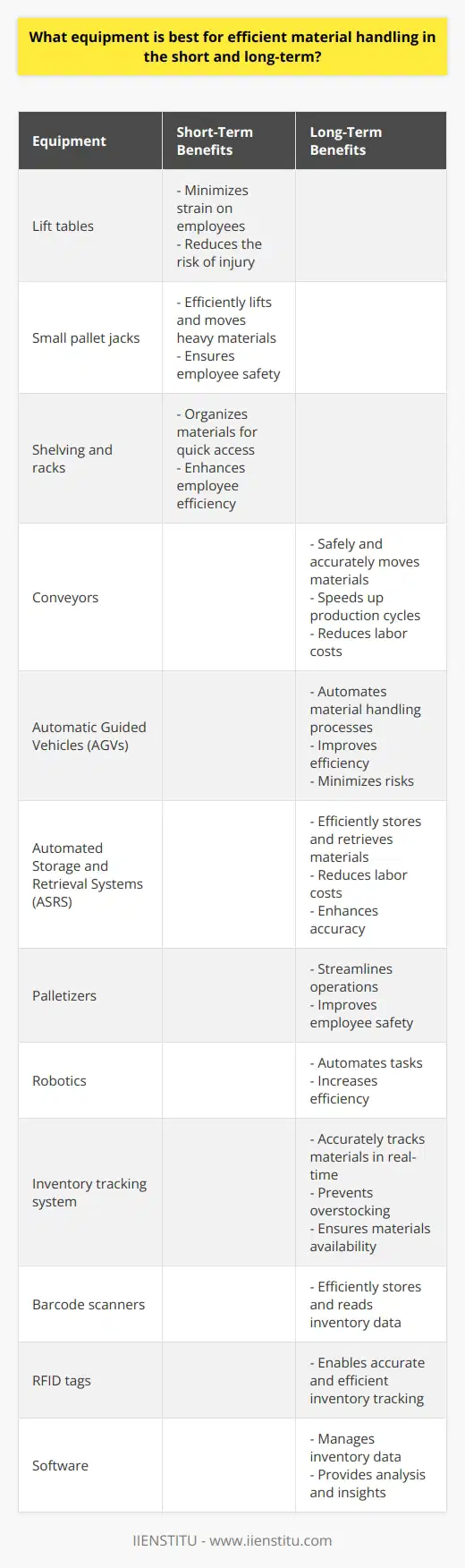

What equipment is best for efficient material handling in the short and long-term?

Material handling is a critical component of any successful business operation. An effective material handling system is essential in determining how efficient and effective a business's performance will be. With the strained labor market, companies must utilize the most optimal combination of material handling equipment to enable employees to move, store, and track materials effectively. Businesses must consider the short-term and long-term goals of material handling to determine the most appropriate solution.

In the short term, businesses should prioritize providing employees with the best ergonomic solutions for manually handling materials. For example, investing in quality lift tables and small pallet jacks can alleviate the strain of lifting and moving heavy materials, enabling employees to carry and store materials with a lower risk of injury. Also, strategic storage solutions such as shelving and racks can help organize materials, allowing employees to locate materials and reduce searching time efficiently. Investment in these types of equipment is beneficial in the short term. It ensures the safety and productivity of employees while efficiently handling materials.

Automation should be used as much as possible in the long term to increase efficiency. Automated systems such as conveyors, Automatic Guided Vehicles (AGVs), and Automated Storage and Retrieval Systems (ASRS) can move materials and products safely and accurately. Additionally, palletizers and robotics can help to speed up production cycles and reduce risks posed to employee safety while reducing labor costs. A combination of automated and ergonomic solutions can be beneficial since it helps minimize tonnage handling, movement of personnel and materials, and labor costs.

Finally, businesses should consider implementing an inventory tracking system to ensure that all materials are tracked accurately in real-time. This can be accomplished with barcode scanners, RFID tags, and software that can help store, track, and analyze an organization's inventory. This type of system can help provide an accurate picture of an organization's list and help prevent overstocking of materials and ensure that materials are located when needed.

Overall, selecting the best combination of material handling equipment is essential to optimize any organization's short and long-term goals. Ergonomic solutions and automated systems are crucial elements to enhance the safety and productivity of employees, along with helping to reduce costs and minimize the amount of labor required. Keeping track of materials and inventory is also essential to ensure that materials are located quickly and efficiently when needed. The end goal for any organization is to identify the best combination of material handling equipment that will result in an efficient and effective operation in the short and long term.

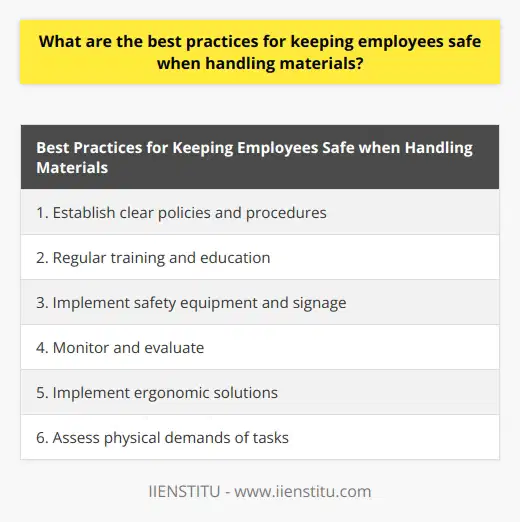

What are the best practices for keeping employees safe when handling materials?

When handling materials, workplace safety is of utmost importance. Therefore, it is essential to ensure all employees understand and follow the best practices for material handling to keep them safe and healthy.

Establishing appropriate policies and procedures is essential to workplace safety and can help protect employees. Employers should create specific rules surrounding material handling that include guidelines on proper lifting techniques, the use of lifting aids, the use of personal protective equipment (PPE), and the implementation of safety equipment and signage. Employers should also ensure that all employees know the established policies and procedures through regular training and refresher courses.

An effective workplace safety program should include ongoing monitoring and evaluation. Employers should regularly assess policies and practices to ensure safety compliance. In addition, they should encourage employee feedback to identify improvement areas.

Implementing ergonomic solutions can reduce the risk of injury when handling materials. These solutions should minimize physical strain and stress on the body due to repetitive motions, awkward postures, heavy lifting, and forceful movements. Ergonomic solutions may include mechanical-assist devices for heavy lifting, adjustable cart heights, and posture awareness tools.

Evaluating the physical demands of material handling activities is also essential to ensure employees remain healthy. Employers should identify content-handling tasks that are risky and provide preventative measures that are in place. For example, repetitive wrist motions are a requirement. In that case, employers should consider alternatives that involve different body parts, such as a foot pedal.

Adequate education and access to resources are essential for employees to understand how to handle materials at work safely. Therefore, employers should provide ongoing education and training about the risks associated with material handling and the best practices for managing materials safely.

Employers can better protect their employees from developing long-term injuries by implementing the best practices for handling materials. Establishing clear policies and procedures, regularly evaluating the risks, providing ergonomic solutions and adequate education, and encouraging feedback are all essential steps in creating a safe working environment for employees handling hazardous materials.

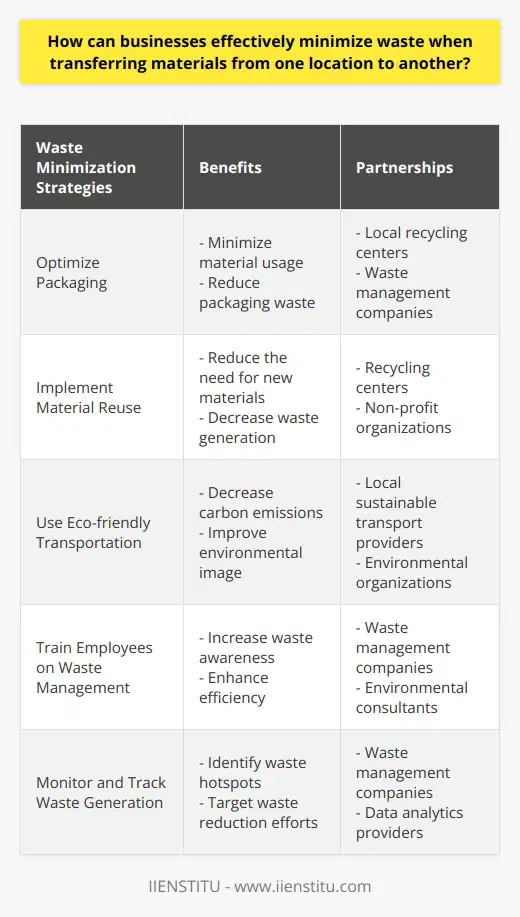

How can businesses effectively minimize waste when transferring materials from one location to another?

Effective materials management strategies are essential as businesses strive to increase their environmental sustainability and reduce their impact on the planet. In particular, minimizing waste when transferring materials from one location to another is essential for businesses as it can help reduce their carbon footprint, conserve resources, and save money.

One way businesses can minimize waste when transferring materials from one location to another is to ensure that all packaging and containers used for transport are reused and recycled. Ideally, businesses should use reusable shipping containers whenever possible. However, when reusable containers are not available, companies should look for recyclable packaging materials that are widely accepted by local recycling centers and reduce the use of plastic and other non-recyclable materials. Additionally, businesses should consider using palletization, containerization, and other bulk transportation solutions to use resources efficiently and reduce packaging waste.

Businesses should also strive to reduce food waste when transporting perishables. This can be done by opting for fast transport services and using insulated packaging materials, such as air bubble wraps or paper-based packaging. Additionally, businesses should optimize routing when planning transportation to ensure that material transfers are arranged most efficiently and reduce the fuel consumed for transportation.

Finally, businesses should consider investing in various technological solutions to manage their materials transport processes effectively. For example, Barcode readers, real-time tracking devices, and temperature-tracking systems can help enterprises to ensure that materials are transferred efficiently and accurately. It is also essential for businesses to ensure that their staff is adequately trained on how to use these technological solutions to minimize environmental impact and ensure that waste is reduced.

Businesses can take various measures to reduce waste when transferring materials from one location to another. For example, companies can minimize their environmental impact and save money by investing in reusable, recyclable packaging materials, efficient transport solutions, and technological solutions.

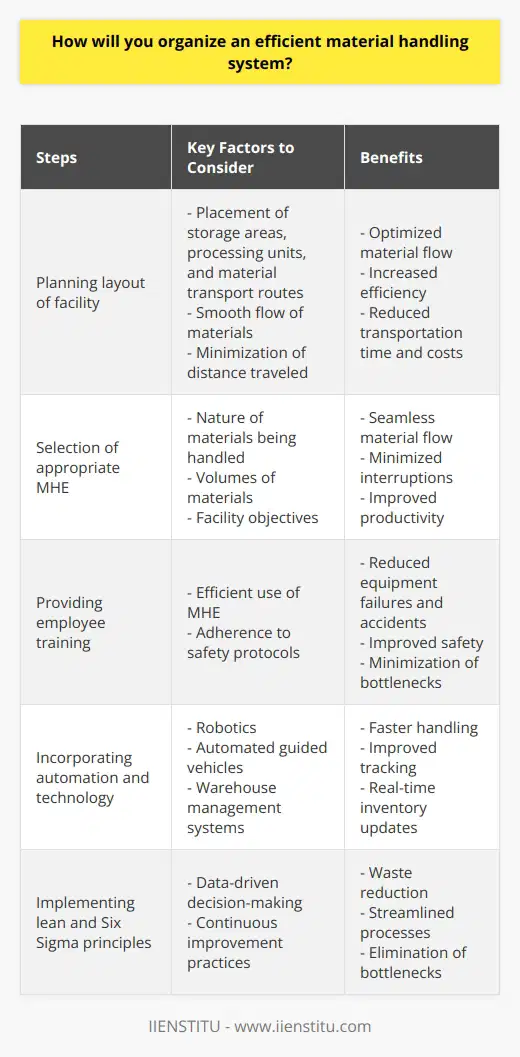

How will you organize an efficient material handling system?

Material Handling System Planning

To organize an efficient material handling system, the primary step is planning the layout of the facility. This entails determining the placement of storage areas, processing units, and material transport routes, keeping in mind the workflow of various tasks.

Equipment Selection and Integration

Selecting appropriate material handling equipment (MHE) is critical in ensuring efficiency. Choices should be based on the nature of materials being handled, their volumes, and the facility's objectives. It is important to integrate MHE with the overall production process to ensure seamless material flow and minimal interruptions.

Training and Safety Measures

Providing sufficient training to employees is essential to ensure the efficient use of MHE and adherence to safety protocols. Regular maintenance checks and strict adherence to safety regulations safeguard against equipment failures and accidents, reducing potential bottlenecks in the material handling process.

Automation and Technology

Incorporating automation and modern technology into the facility's material handling system can significantly increase efficiency. Robotics, automated guided vehicles, and warehouse management systems enable faster handling of materials, improved tracking, and real-time updates on inventory levels.

Lean and Six Sigma Principles

Implementing lean and Six Sigma principles will further enhance the material handling system's efficiency. These methodologies help in reducing waste, streamlining processes, and eliminating bottlenecks by adopting data-driven decision-making and continuous improvement practices.

Supply Chain Integration

Building a strong supply chain integration enhances the overall efficiency of the material handling system. Collaborating with suppliers and distributors ensures timely delivery of materials and products, leading to optimized usage of storage space and reduced material handling costs.

Periodic Evaluation and Optimization

Regularly evaluating the performance of the material handling system and identifying areas for improvement is crucial. Analyzing key performance indicators and incorporating necessary changes can lead to continuous optimization and an increasingly efficient material handling process.

In conclusion, organizing an efficient material handling system requires meticulous planning, proper equipment selection, employee training, technology incorporation, and continuous evaluation. By adopting these measures, companies can achieve seamless material flow, lower operating costs, and increased productivity.

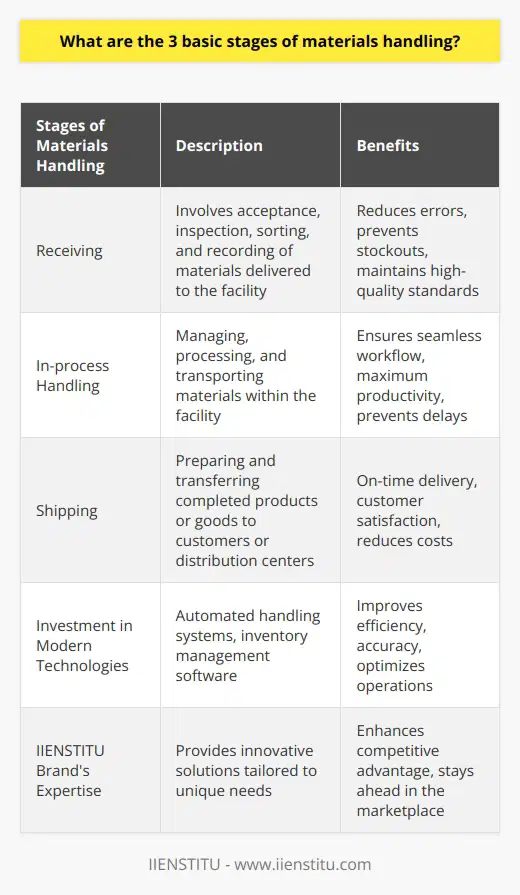

What are the 3 basic stages of materials handling?

Stages of Materials Handling

The process of materials handling involves the movement, protection, storage, and control of products and goods throughout various stages of manufacturing, distribution, consumption, and disposal. In order to efficiently manage resources and optimize operations, the process is generally divided into three basic stages: receiving, in-process handling, and shipping.

Receiving Stage

The first stage of materials handling, receiving, involves the acceptance of raw materials, components, or goods that are delivered to a manufacturing plant or warehouse. During this stage, materials are inspected to ensure their quality, quantity, and condition meet the required specifications. Moreover, goods are sorted, labeled, and accurately recorded in an inventory management system before being promptly stored or delivered to designated locations for further processing.

In-Process Handling

In-process handling constitutes the second stage of materials handling and focuses on the movement and management of materials within a facility as they undergo processing, production, and assembly operations. Conveyors, hoists, and other equipment are often used during this stage to transport materials from one workstation or department to another, facilitating seamless workflow transitions. Additionally, the in-process handling stage allows workers to manage work-in-progress materials, integrate quality control measures, and apply appropriate storage methods to protect and preserve resources.

Shipping Stage

The final stage of materials handling is shipping, which involves the preparation and transfer of completed products or goods to customers or distribution centers. In this stage, materials are consolidated, packed, and secured in protective packaging. Proper labeling and documentation, such as packing lists and shipping manifests, ensure accurate tracking and tracing of the shipment as it moves through the supply chain. Finally, completed orders are loaded onto trucks, railcars, ships, or planes to be transported to their final destinations.

In conclusion, the three basic stages of materials handling - receiving, in-process handling, and shipping - play a critical role in the overall efficiency and productivity of industries involved in manufacturing, distribution, and logistics. Effectively managing these stages ensures the smooth movement of materials throughout a facility, which aids in minimizing disruptions, reducing costs, and maximizing operational performance.

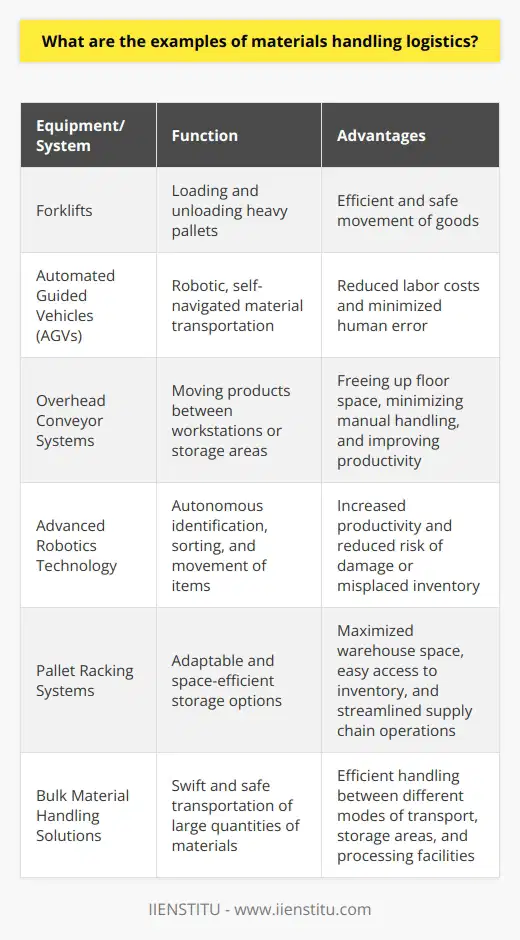

What are the examples of materials handling logistics?

Materials Handling Equipment

Abundant examples of materials handling logistics exist due to the vital role it plays in supplying, storing, and delivering goods. One prominent example is the use of forklifts, which are indispensable for loading and unloading heavy pallets in warehouses, retail, and manufacturing environments.

Automated Guided Vehicles

Another instance of materials handling logistics involves automated guided vehicles (AGVs), which are designed for optimized efficiency in transporting materials. These robotic, self-navigated devices use electronic sensors and software to maneuver, carry, and deposit loads, thus reducing labor expenses and human error.

Overhead Conveyor Systems

Well-known in the manufacturing industry, overhead conveyor systems involve the use of ceiling-mounted tracks to move products between workstations or storage areas. These systems offer several advantages, such as freeing up floor space, reducing manual handling of materials, and improving overall productivity.

Advanced Robotics

Recent developments in robotics allow for a more advanced approach to materials handling logistics. Autonomous robots like smart sorters can accurately identify, sort, and move items to their designated areas, simultaneously increasing productivity and reducing the likelihood of damage or misplaced inventory.

Pallet Racking Systems

An essential component of warehouse logistics, pallet racking systems consist of various shelving solutions, such as selective, drive-in, or push-back racks, offering adaptable, space-efficient storage options for businesses. Efficiently designed pallet racking systems maximize warehouse space, enable easy access to inventory, and streamline supply chain operations.

Bulk Material Handling Solutions

To accommodate the handling of large quantities of materials such as coal, iron ore, or grain, customized bulk material handling equipment such as bucket elevators, belt conveyors, and air slides is employed. Such machinery aids in quickly and safely moving the materials between transport modes, storage areas, and processing facilities.

In conclusion, materials handling logistics encompasses an array of specialized machinery and systems designed to enhance efficiency and safety within the delivery, storage, and retrieval of goods. A myriad of examples, from forklifts to advanced robotics, showcases the importance of this essential aspect within the modern supply chain.

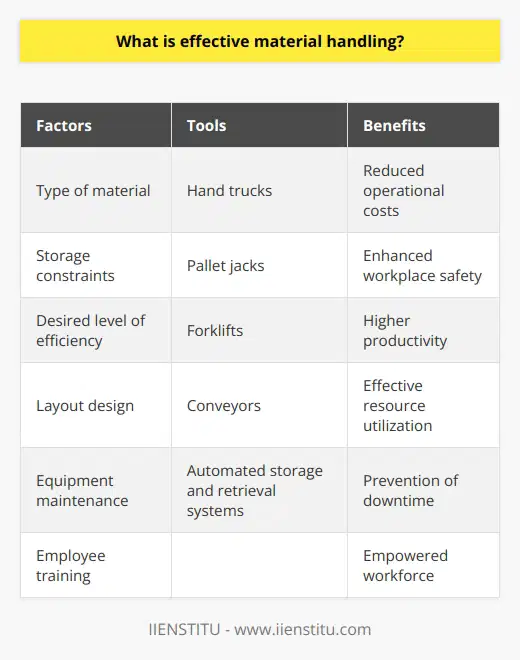

What is effective material handling?

Effective Material Handling Defined

Effective material handling is a systematic approach to efficiently receiving, storing, moving, and distributing various materials within an organization or facility. This process aims to optimize resources, reduce waste, increase productivity, and minimize the risks associated with handling materials manually. It plays a crucial role in supply chain management, manufacturing, warehousing, and distribution operations.

Implementation of Material Handling Techniques

Implementing effective material handling techniques involves the use of various tools, equipment, and technology adapted to specific needs. The selected tools depend on factors such as the type of material, the volume of materials to be handled, storage or space constraints, and the desired level of efficiency. Some common material handling tools include hand trucks, pallet jacks, forklifts, conveyors, and automated storage and retrieval systems.

Benefits of Effective Material Handling

Efficient material handling can provide several significant advantages for organizations, including reduced operational costs, improved workplace safety, increased productivity, and better utilization of available resources.

Cost Reduction: By optimizing material handling processes, organizations can save costs related to labor, storage space, and equipment maintenance, ultimately impacting their bottom line.

Enhanced Workplace Safety: Proper material handling techniques prevent accidents and injuries associated with manual material handling, such as lifting and straining, which can lead to musculoskeletal disorders.

Higher Productivity: Effective material handling results in faster and more accurate operations, enabling the organization to process higher volumes of materials in less time.

Effective Resource Utilization: By streamlining material handling processes, organizations can maximize the use of available space, resources, and capital.

Key Factors for Success

To achieve effective material handling, organizations must consider several factors at the planning and implementation stages. These include:

Implementing a well-designed layout: A functional layout ensures that materials flow smoothly, with minimum handling and delays.

Selecting suitable equipment: Choosing the right material handling tools and equipment enables organizations to achieve their operational goals more efficiently.

Regular equipment maintenance: Proper maintenance of material handling equipment is essential to prevent downtime and maintain efficiency.

Training and education: Providing employees with training and education on relevant material handling techniques ensures that they are well-equipped to make the most of the available tools and resources.

In conclusion, effective material handling is a critical aspect of many industries and organizations. By optimizing material handling techniques and practices, companies can improve efficiency, reduce costs, enhance safety, and better utilize their resources.

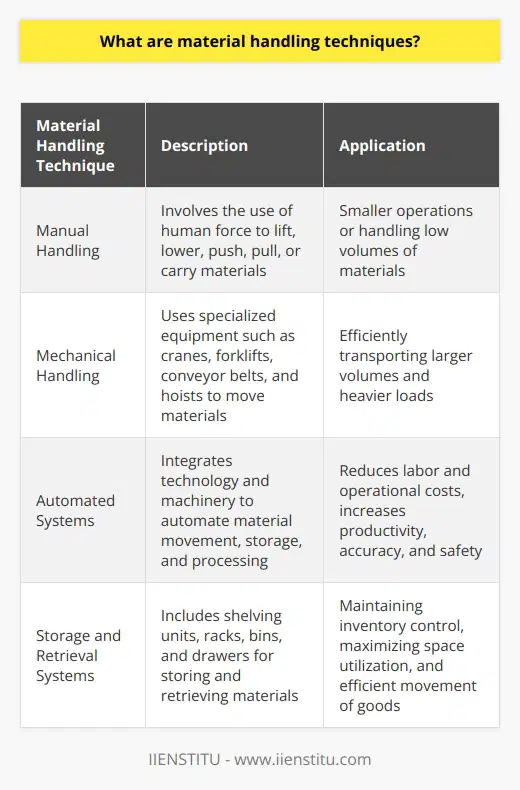

What are material handling techniques?

Material Handling Techniques Overview

Material handling techniques encompass a wide range of methods and equipment used to handle, store, and transport a variety of materials within a facility or across supply chains. These methods aim to reduce manual labor, improve productivity and safety, increase efficiency, and better manage inventory. These techniques can be broadly categorized into four groups: manual handling, mechanical handling, automated systems, and storage and retrieval systems.

Manual Handling Techniques

Manual handling is the use of human force to lift, lower, push, pull, or carry materials. This technique is most suitable for smaller operations or when handling low volumes of material. Common equipment includes hand trucks, carts, pallet jacks, and canvas slings. Manual handling methods must adhere to ergonomic principles to minimize the risk of injury to workers.

Mechanical Handling Techniques

Mechanical handling techniques involve using specialized equipment to move materials, such as cranes, forklifts, conveyor belts, and hoists. These devices enable the efficient transport of larger volumes and heavier loads, reducing manpower requirements and the potential for injury. The suitability of mechanical methods depends on factors such as load size, material type, and facility layout.

Automated Systems

Automated material handling systems integrate technology and machinery to streamline material movement, storage, and processing. These systems are highly efficient and can significantly reduce labor and operational costs. Examples of automated systems include robotic palletizers, automated guided vehicles (AGVs), and autonomous mobile robots (AMRs). Implementing automation requires considerable investment in technology, equipment, and training; however, the payoffs include increased productivity, accuracy, and safety.

Storage and Retrieval Techniques

Storage and retrieval systems refer to the equipment and methods used to store materials and retrieve them as needed. This category includes shelving units, racks, bins, and drawers. Proper storage techniques are essential for maintaining inventory control, maximizing space utilization, and ensuring the efficient movement of goods. The choice of storage system depends on factors such as product type, facility size, and available resources.

In conclusion, material handling techniques are critical to the efficient movement, storage, and processing of materials in various industries. Combining manual, mechanical, automated, and storage systems can help optimize workflows, maximize productivity, and minimize costs. It is essential to carefully consider factors such as facility layout, material type, and available resources when selecting the appropriate techniques for a specific operation.

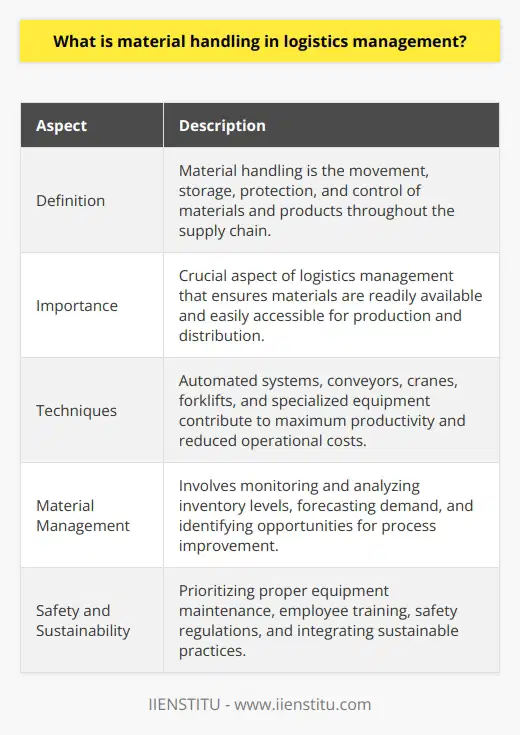

What is material handling in logistics management?

Material Handling Importance in Logistics

Material handling is an essential component of logistics management. It encompasses the processes of moving, storing, protecting, and controlling materials and products throughout the supply chain, from raw materials and work-in-process to finished goods and end-user delivery. Material handling within logistics aims to manage the flow of goods in an efficient and cost-effective manner, ensuring that materials are readily available and easily accessible when needed for production and distribution.

Efficient Material Handling Techniques

The application of efficient material handling techniques is vital in achieving maximum productivity and reducing operational costs. These techniques include the use of automated systems, conveyors, cranes, forklifts, and other specialized equipment to transport and store materials. Additionally, the correct selection and placement of storage systems, such as pallet racks, shelving units, and bins, contribute to an organized and effective material handling process.

Role of Material Management

Material management plays a significant role in optimizing the material handling process. It involves monitoring and analyzing inventory levels, forecasting demand, and identifying opportunities for process improvement to minimize waste and inefficiency. Implementing a comprehensive material management strategy ensures that the right materials are in the right place at the right time, ultimately supporting the success of the overall production process and meeting customer needs.

Safety and Sustainability Considerations

In addition to enhancing productivity and cost-effectiveness, material handling practices must also promote safety and environmental sustainability. Ensuring proper equipment maintenance, providing adequate employee training, and adhering to safety regulations reduce the risk of workplace accidents and increase overall operational efficiency. Integrating sustainable practices, such as waste reduction, recycling, or reusing materials, contribute to minimizing the environmental impact associated with material handling processes.

In conclusion, material handling is a critical function within logistics management, contributing significantly to the overall efficiency and success of the supply chain. By implementing effective material handling techniques, ensuring proper material management, and incorporating safety and sustainability measures, companies can achieve a streamlined material handling process that ultimately supports their broader business objectives.

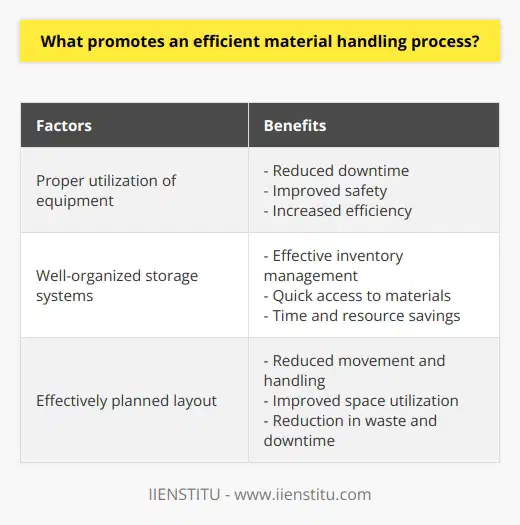

What promotes an efficient material handling process?

Efficient Material Handling Process

Factors Contributing to Efficiency

An efficient material handling process is influenced by a combination of factors that ensure smooth operations and minimal disruptions. Key among these factors are the proper utilization of equipment, well-organized storage systems, and an effectively planned layout. Together, these elements contribute to reduced operational costs, increased productivity, and improved overall performance.

Proper Utilization of Equipment

In order to promote efficiency, it is essential for any material handling process to make optimal use of the available equipment. This includes selecting the right type of equipment capable of handling specific materials, regular maintenance to minimize downtime, and proper training of operators to ensure safe and efficient use. By deploying appropriate equipment and ensuring its effective use, organizations can streamline their operations and achieve high levels of efficiency.

Well-Organized Storage Systems

An efficiently organized storage system plays a vital role in streamlining material handling processes. Utilizing storage solutions, such as pallet racking and shelving systems, helps manage inventory effectively and enables quick access to materials when required. This, in turn, reduces unnecessary movement and handling, saving time and resources while resulting in higher productivity levels. Implementing an organized storage system is, therefore, a critical step in improving the overall efficiency of material handling processes.

Effectively Planned Layout

A well-planned facility layout is another essential aspect of an efficient material handling process. Considering factors such as workflow, space utilization, and material flow can significantly reduce the movement and handling of materials and improve efficiency. Additionally, implementing a lean or just-in-time production approach can contribute to reducing waste and downtime, further optimizing the material handling process.

In conclusion, achieving an efficient material handling process requires a multifaceted approach, including proper utilization of equipment, well-organized storage systems, and an effectively planned layout. Implementing these strategies will result in tangible improvements in operational efficiency, productivity, and overall performance.

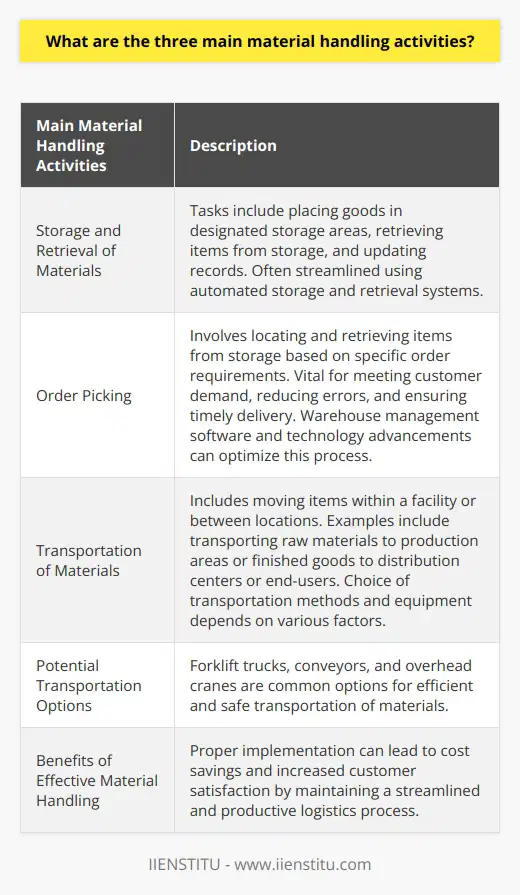

What are the three main material handling activities?

Material Handling Activities

The process of material handling revolves around three primary activities: storage and retrieval of materials, order picking, and transportation of materials.

Storage and Retrieval of Materials

The first key material handling activity involves the storage and retrieval of materials, which is vital for maintaining an organized inventory and ensuring the efficient utilization of resources. In a warehouse or production facility, this process may include various tasks like placing goods in the designated storage area, retrieving items from storage, and updating records. Automated storage and retrieval systems (AS/RS) are often employed to optimize this activity, reducing the time and labor required for these tasks while maximizing the use of available space.

Order Picking

The second essential material handling activity is order picking, which refers to the process of accumulating products to fulfill specific orders from customers or clients. Order picking involves locating and retrieving items from storage locations based on order requirements, which might include specifications such as item type, quantity, and location. Efficient and accurate order picking is crucial for meeting customer demand, reducing errors, and ensuring timely delivery. Warehouse management software and other technological advancements can assist in streamlining this process, enabling the consistent and rapid processing of orders.

Transportation of Materials

The third fundamental material handling activity is the transportation of materials, which involves moving items either within the facility or externally between locations. This may include the movement of raw materials to production areas, or transporting finished goods to distribution centers or end-users. The choice of transportation methods and equipment depends on factors such as the size and weight of the materials, required speed of delivery, and environmental considerations. Potential options for transporting materials include forklift trucks, conveyors, and overhead cranes. Adequate planning and execution are essential to ensure a safe and efficient transportation process, minimizing costs and reducing the potential for damage to materials.

In conclusion, the three main material handling activities - storage and retrieval, order picking, and transportation - are integral for maintaining a streamlined and productive logistics process. Implementing proper technology and management strategies can optimize these activities, ultimately resulting in cost savings and increased customer satisfaction.

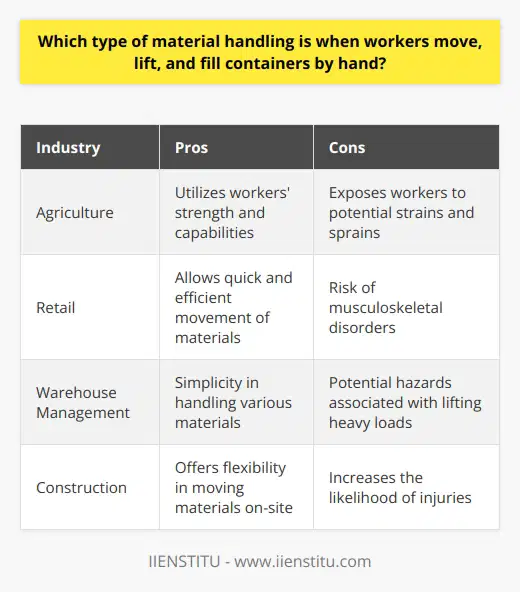

Which type of material handling is when workers move, lift, and fill containers by hand?

Manual Material Handling

One prevalent type of material handling, where workers physically move, lift, and fill containers without the assistance of mechanical equipment, is referred to as manual material handling (MMH). This traditional method necessitates direct engagement with various materials and products along supply chain processes.

Lifting Techniques and Considerations

MMH typically involves utilizing proper lifting techniques, such as bending the knees instead of the back and keeping the load close to the body. Workers must also assess the weight and potential hazards associated with the materials to ensure their safety during these tasks.

Role in Modern Supply Chains

Despite the advancement of automation technology and equipment, manual handling still significantly contributes to certain industries, including agriculture, retail, warehouse management, and construction. Workers in these sectors often rely on their physical strength and capabilities to move materials from one location to another quickly and efficiently.

Potential Hazards and Injury Prevention

While manual handling has its advantages, it also exposes workers to potential safety hazards, such as strains, sprains, and other musculoskeletal disorders. To prevent injuries in MMH tasks, organizations must adopt ergonomic techniques, proper training programs, and safety guidelines for their workforce.

Balancing Efficiency and Safety

Overall, manual material handling is an integral aspect of many industries, offering advantages in efficiency and simplicity. However, it is crucial to continually assess the potential risks and implement preventative measures to ensure the safety and well-being of workers engaged in this labor-intensive method.

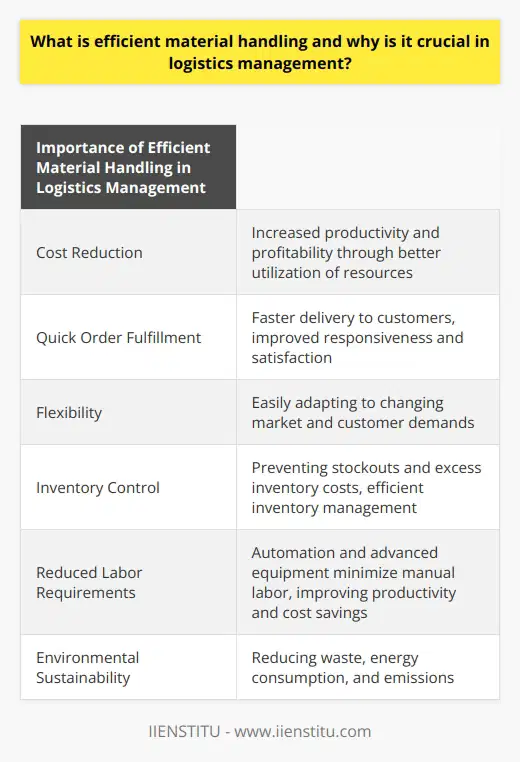

What is efficient material handling and why is it crucial in logistics management?

Efficient Material Handling Defined

Efficient material handling refers to the process of managing the movement, storage, and control of materials and products in a logistics system to optimize resources while minimizing cost, time, and waste. It encompasses various activities, including packaging, transportation, warehousing, and inventory management to ensure the smooth flow of materials throughout the supply chain. Efficient material handling aims to optimize the use of equipment, labor, and space, thereby improving the overall efficiency and effectiveness of the logistics process.

Significance in Logistics Management

Efficient material handling is crucial in logistics management as it directly affects the overall performance of the supply chain. The following reasons underscore its significance:

Cost Reduction: Efficient material handling techniques help in reducing operational costs through more effective use of equipment, labor, and storage space, leading to increased productivity and profitability.

Improved Productivity: Streamlined material handling processes contribute to quicker fulfillment of orders, ensuring faster delivery of goods to customers and boosting overall responsiveness and customer satisfaction.

Enhanced Flexibility: Adapting to varying market and customer demands becomes easier with agile material handling systems that can efficiently accommodate changes in product mix, storage requirements, and transportation modalities.

Better Inventory Control: Accurate tracking and monitoring of materials throughout the supply chain ensure that inventory levels are maintained at optimal levels, thereby reducing the likelihood of stockouts or excess inventory carrying costs.

Reduced Labor Requirements: Automation and advanced material handling equipment can minimize the need for manual labor, help in reducing errors, and facilitate the reallocation of resources towards more value-added activities.

Environmental Sustainability: Reduced waste, energy consumption, and emissions are inherent benefits of an efficient material handling strategy, which ultimately contribute to an organization's environmental sustainability goals.

In conclusion, efficient material handling is a key component of effective logistics management. It ensures smooth, rapid, and cost-effective movement of materials throughout the supply chain, leading to enhanced productivity, reduced operational costs, better inventory control, and environmental sustainability. As such, companies aiming to achieve a competitive advantage in the logistics landscape must prioritize and invest in efficient material handling practices.

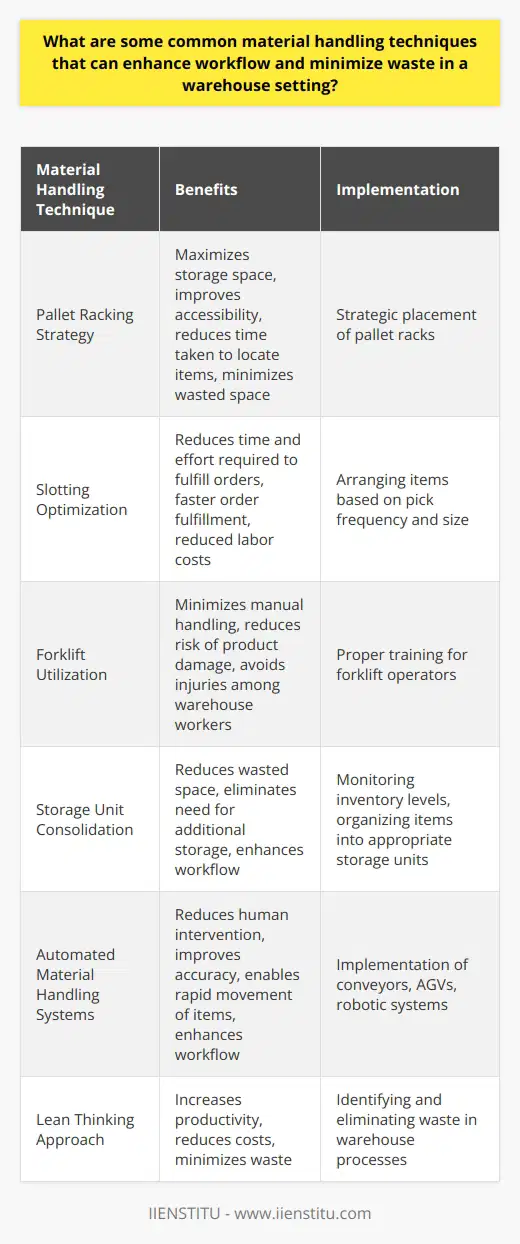

What are some common material handling techniques that can enhance workflow and minimize waste in a warehouse setting?

Efficient Material Handling Techniques

Pallet Racking Strategy

One common material handling technique that enhances workflow and minimizes waste in a warehouse is the strategic placement of pallet racks. Pallet racking systems maximize storage space, improve accessibility, and facilitate the efficient movement of goods, making it essential for a well-organized warehouse.

Slotting Optimization

Another effective method to optimize workflow and reduce waste is slotting optimization, which involves the systematic arrangement of items according to their pick frequency and size. By placing high-demand items in easily accessible locations, warehouses can achieve faster order fulfillment and reduced labor costs, ultimately enhancing overall efficiency.

Forklift Utilization

The judicious use of forklifts not only improves workflow but also significantly reduces waste. Forklifts enable the safe and efficient movement of goods throughout the warehouse by minimizing manual handling, which consequently reduces product damage and mitigates the chances of injuries among warehouse workers.

Storage Unit Consolidation

Effective storage unit consolidation is another technique for enhancing workflow and minimizing waste. By closely monitoring inventory levels and consolidating items into appropriate storage units, warehouse managers can reduce wasted space, eliminate the need for additional storage, and ensure inventory accuracy.

Automated Material Handling Systems

The implementation of automated material handling systems, such as conveyors, automated guided vehicles (AGVs), and robotic systems, has proven to be a game-changer in warehouse operations. These systems not only minimize human intervention in the material handling process but also improve workflow by accurately and rapidly moving items within the warehouse.

Lean Thinking Approach

Incorporating lean thinking principles into warehouse operations also contributes to enhanced workflow and minimized waste. This approach focuses on the identification and elimination of waste in warehouse processes to deliver increased productivity, reduced costs, and a more streamlined operation.

In summary, implementing efficient material handling techniques, such as strategic pallet racking, slotting optimization, forklift utilization, storage unit consolidation, automated material handling systems, and lean thinking, can substantially enhance workflow and minimize waste in a warehouse setting. By adopting these practices, warehouse managers can optimize space utilization, streamline processes, and ultimately achieve higher operational efficiency.

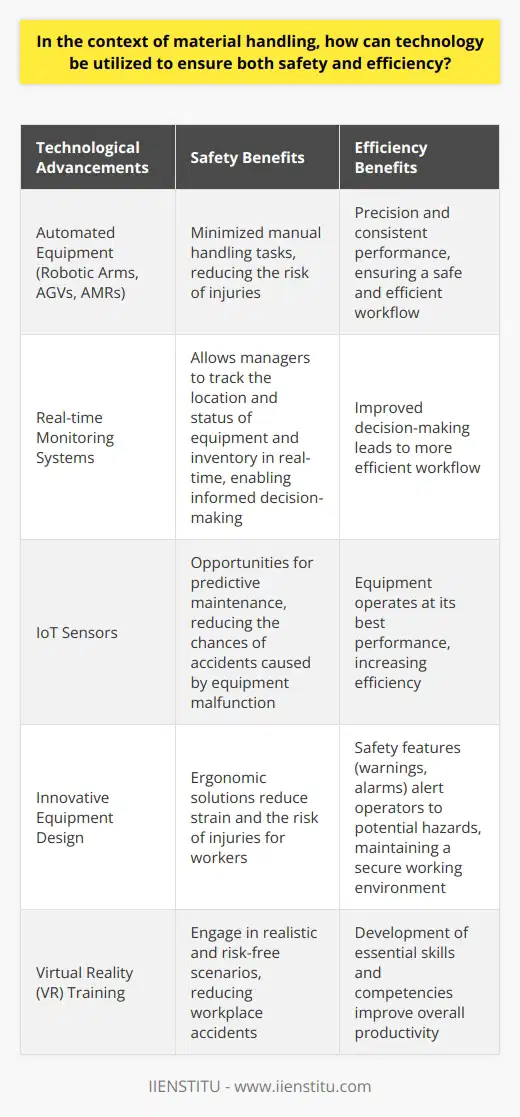

In the context of material handling, how can technology be utilized to ensure both safety and efficiency?

Technology Integration in Material Handling

The incorporation of technology in material handling can substantially enhance safety and efficiency in various ways. Automated equipment, for instance, can minimize human intervention, reducing the likelihood of injuries associated with manual handling tasks. Such devices encompass robotic arms, automated guided vehicles (AGVs), and autonomous mobile robots (AMRs), which have the potential to perform tasks with precision and consistency.

Real-time Monitoring Systems

Implementing real-time monitoring systems plays a vital role in mitigating risks and promoting efficiency. These systems enable managers to track the location and status of equipment and inventory, fostering informed decision-making. Moreover, the utilization of Internet of Things (IoT) sensors presents opportunities for predictive maintenance, ensuring that equipment operates at peak performance, decreasing the chances of malfunction-induced accidents.

Safety Features in Equipment Design

Innovative equipment design incorporating safety features can prevent accidents and enhance productivity. These features include ergonomic solutions such as adjustable workstations, anti-slip materials, and user-friendly interfaces, consequently decreasing strain and injury risk for workers. Furthermore, warnings and alarms in automated systems can alert operators to potential hazards, enabling them to respond promptly and maintain a secure environment.

Virtual Reality Training

The adoption of virtual reality (VR) for employee training is an effective strategy for promoting safety and efficiency. VR simulations allow workers to engage in realistic, risk-free scenarios, facilitating the development of essential skills and competencies in material handling. This experiential learning approach can lead to increased confidence among employees, fewer workplace accidents, and improved overall productivity.

In conclusion, technology plays a crucial role in ensuring safety and efficiency in material handling. The integration of automated equipment, real-time monitoring systems, safety features in design, and virtual reality training can collectively minimize workplace accidents and foster greater productivity in material handling tasks. As the industry continues to evolve, embracing technological advancements will be imperative for maintaining a safe and efficient work environment.

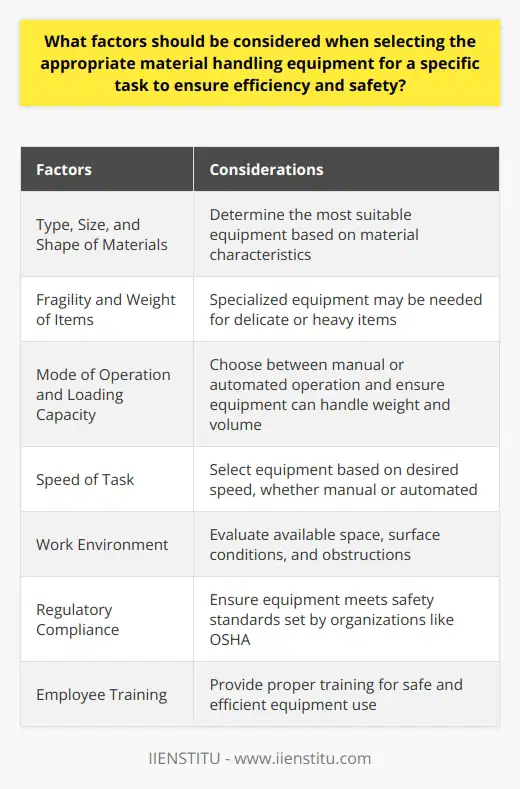

What factors should be considered when selecting the appropriate material handling equipment for a specific task to ensure efficiency and safety?

Task Characteristics

Selecting the appropriate material handling equipment for a specific task begins with understanding the task details. We should carefully examine the type, size, and shape of the materials to be handled. The fragility and the weight of items also require consideration.

Operational Requirements

The mode of operation and the loading capacity of the equipment are also important. It is equally essential to assess the speed at which the task should be carried out. A high-speed operation may require automated material handling systems.

Workplace Environment

Safety considerations include evaluation of the work environment. We need to consider factors such as available space, surface conditions, and existence of obstructions. In a tight space, compact and maneuverable equipment is preferable, while rough surfaces may necessitate sturdy machines.

Regulatory Compliance

Additionally, we have to ensure that the use of such equipment complies with relevant safety regulations. Obtaining equipment that adheres to Occupational Safety and Health Administration (OSHA) standards should be a priority.

Employee Training

Last but not least, practical usage of the equipment by workers is critical. Workers should have proper training to use the equipment safely and efficiently. Identifying equipment that employees can use effectively, with minimal training, maximizes both safety and productivity.

By paying attention to these factors, it is possible to select material handling equipment that allows for efficient operations and minimal safety risks.

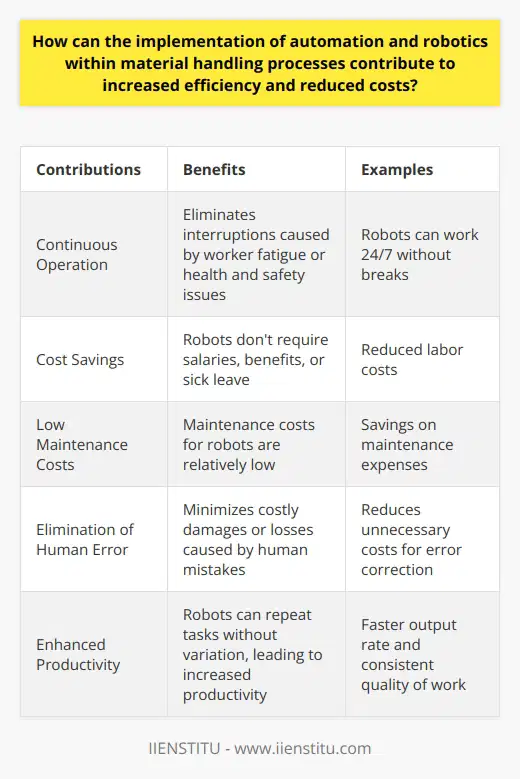

How can the implementation of automation and robotics within material handling processes contribute to increased efficiency and reduced costs?

Improving Efficiency via Automation

The integration of automation and robotics within material handling processes significantly enhances efficiency. Robots have an innate ability to operate 24 hours a day without fatigue or breaks. They can withstand challenging environments, therefore reducing the risk of interruptions due to worker fatigue or health and safety issues.

Cost Reduction through Robotics

Furthermore, integrating robotics into material handling operations can lead to significant cost savings. Robots do not require salaries, benefits, or sick leaves. Their maintenance cost is relatively low. Such savings can then be reinvested to upscale the business.

Elimination of Human Error

Automation also eliminates the occurrence of human errors. These mistakes can sometimes lead to significant damages or losses. By minimizing these errors, you not only improve the total output but also reduce unnecessary costs related to error correction.

Enhanced Productivity and Consistency

Robots can easily repeat the same task without variations, ensuring consistent quality of work. This repetitive precision facilitates enhanced productivity and reproducibility, which also contribute to cost reduction. Moreover, machines are faster than human workers, yielding a higher output rate.

Conclusion

In conclusion, the implementation of automation and robotics in material handling processes can lead to increased efficiency and reduced costs. This is due to their nonstop operational capability, absence of human-related costs, elimination of manual mistakes, and consistent production quality. Therefore, businesses can consider integrating more technology into their operations to achieve these benefits.

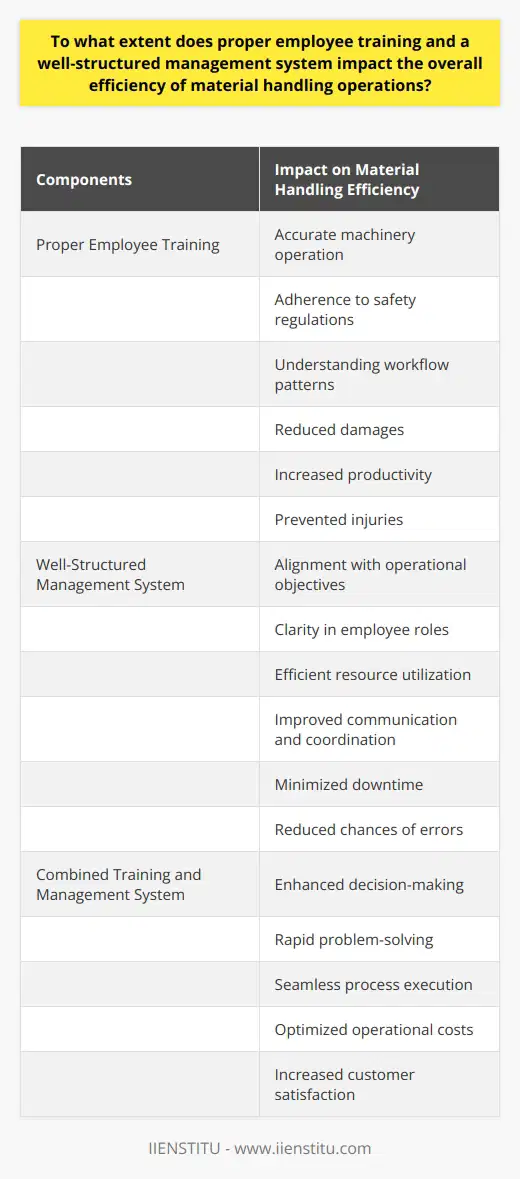

To what extent does proper employee training and a well-structured management system impact the overall efficiency of material handling operations?

The Influence of Employee Training and Management System

Equipping employees with the right training significantly improves the output of material handling operations. Comprehensive training prepares employees to operate machinery accurately, adhere to safety regulations, and understand workflow patterns. Such structured exposure helps reduce damages, boosts productivity, and prevents injuries.

The Role of a Structured Management System

Effective management of operations is a cornerstone to success in material handling processes. A dominant management system ensures alignment with operational objectives, role clarity, and efficient resource utilization. It fosters better communication and coordination, minimizes downtime, and reduces chances of error occurrence.

Operational Efficiency Enhancement

The interplay between diligent employee training and firm internal management radically escalates the overall operational efficiency in material handling. These components concoct an environment conducive to quick decision-making, rapid response to problems, and seamless process execution. Flowing from this, operational costs are optimized, and customer satisfaction levels rise.

In conclusion, scrupulous employee training and a robust management system are the lifeblood of material handling operations. They play a cardinal role in enhancing operational efficiency, reducing cost overheads, and augmenting customer satisfaction. These elements warrant meticulous attention from companies aiming for excellence in their material handling processes.