In the ever-evolving world of manufacturing, I've often found myself marveling at how small tweaks can lead to significant improvements. Efficiency and optimization aren't just buzzwords—they're the lifeblood of any successful manufacturing plant. I recall walking through a bustling manufacturing plant years ago, the hum of the manufacturing machines almost rhythmic, and thinking about how every cog and wheel played a pivotal role in the grand scheme of production.

One concept that has consistently stood out in my journey through the industrial manufacturing industry is Overall Equipment Effectiveness (OEE). It's not just another metric; it's a comprehensive lens through which we can gauge the true productivity of our equipment. So, let's dive deep into what OEE means and how it can revolutionize the industry of manufacturing.

Understanding OEE

Explanation of the OEE Concept

Overall Equipment Effectiveness is a comprehensive, aggregated metric that represents how effectively equipment is utilized within a manufacturing process. It integrates three core components: availability, performance, and quality—each a lens through which the overall effectiveness of the equipment is examined. The value of OEE lies in its capacity to identify percentages of manufacturing time that are truly productive, offering a clear gauge of the success or failure of a production system.

Components of OEE

Discussion on Availability

Availability examines the proportion of scheduled time that the equipment is available to operate. This metric includes losses due to equipment failures, adjustments, and setup process changes, which directly affect the available time for production. In essence, availability sets the foundational expectation for the equipment's operational time and ensuing productivity.

Understanding Performance

Performance takes into account the speed at which the equipment operates as compared to its designed speed. Factors that reduce the performance ratio include minor stops, idling, and reduced speed. A crucial insight gained from analyzing performance is the understanding of how to optimize machine operation and streamline workflow.

Insight on Quality

Quality is the metric that captures the rate of products that meet quality standards versus the waste or rework necessary due to defects. This component is critical because no matter how available or fast a machine is, if it can't produce a good quality product, effectiveness declines drastically. Improving quality often conveys directly to the bottom line, through reduced waste and increased customer satisfaction.

Implementing OEE

The Right Way to Measure OEE

Proper measurement of OEE requires a blend of precision in data collection and insightful interpretation of that data. Organizations must adopt a strategic approach to measuring OEE that aligns with their specific production goals and objectives. Ensuring accurate data is fundamental for meaningful analysis and improvement initiatives.

Benefits of Implementing OEE

Increased Productivity

Employing OEE tracking aids in pinpointing productivity bottlenecks. By breaking down losses into categories, OEE illuminates areas of waste and provides tangible data on which to base improvement efforts, leading to heightened productivity.

Process Optimization

OEE data facilitate a deeper understanding of the manufacturing process, enabling managers to make informed decisions regarding process optimization. Equipment downtime and inefficiencies can be minimized, thus streamlining operations.

Improved Quality

Implementing OEE also implies a commitment to quality. By measuring rates of defect-producing operations, OEE helps identify root causes for quality issues, paving the way for enhanced product integrity.

Reduction in Equipment Downtime

Through diligent monitoring, OEE can anticipate equipment failure, thereby reducing unplanned downtime. Regular analysis of OEE metrics ensures that maintenance can be timely and less disruptive to production.

Case Study: Successful Implementation of OEE

Real-world application of OEE demonstrates its comprehensiveness and versatility in different manufacturing environments. A case study exemplifying the successful implementation of OEE shows how a factory identified bottlenecks and improved their equipment's availability, performance, and quality, resulting in increased throughput and profitability.

Common Pitfalls and Misconceptions of OEE

En route to realizing the full potential of OEE, numerous challenges arise, including misunderstanding its true purpose. OEE is not solely a tool for comparing different facilities, but rather it is a means to drive improvement within a particular operation.

Addressing Challenges

Training and Educating Staff on OEE

For OEE to be effective, a company's workforce must be suitably educated on its principles and application. Training programs, perhaps through online certificate courses, can ensure that staff understands how to leverage OEE data for continuous improvement.

Developing a Continuous Improvement Mindset

Beyond the technical implementation, nurturing a culture of continuous improvement is crucial in sustaining the benefits of OEE. It is not a one-time measure but an ongoing process that needs to be integrated into the daily operations and mindset of a manufacturing enterprise.

Role of OEE in Industry 4.0 era

As manufacturers pivot towards Industry 4.0, OEE will become increasingly intertwined with advanced technologies. It will serve as a vital metric for 'smart factories' with highly automated and interconnected operations.

Utilisation of Smart Technologies for OEE Enhancement

Artificial Intelligence in OEE

Artificial intelligence (AI) holds the potential to dynamically interpret OEE data, predict maintenance issues, and suggest improvements, revolutionizing the way OEE is used in manufacturing.

Use of IoT in OEE

The Internet of Things (IoT) can provide real-time data streams that enrich OEE analysis. By linking multiple data points across the production line, IoT devices can offer unprecedented insights into equipment effectiveness.

Explanation of the OEE Concept

So, what exactly is OEE? In simple terms, OEE—or Overall Equipment Effectiveness—is a standard for measuring the efficiency and effectiveness of manufacturing equipment. It combines three essential components: availability, performance, and quality. When I first started exploring OEE, it was like uncovering a treasure map; each component led me closer to optimizing the entire production process.

To define OEE, think of it as a scorecard for your equipment. It tells you how well a machine is performing compared to its full potential during the times it's scheduled to run. Imagine having a car that can go up to 200 mph, but you only ever drive it at 100 mph due to traffic, road conditions, or personal preference. OEE helps identify these limitations in a manufacturing context and provides a roadmap to overcome them.

Components of OEE

Understanding the components of OEE is crucial. Let's break them down:

1- Availability: This measures the proportion of scheduled time that the equipment is actually available for operation. It includes stoppages due to breakdowns or changeovers. I remember a time when one of our key machines was frequently down for maintenance—our availability metric flagged this, prompting us to investigate further.

2- Performance: This looks at how the equipment's actual running speed compares to its designed speed. Factors like minor stops or running at reduced speeds affect this. There was an instance where we'd underestimated the impact of minor delays—like material jams—that cumulatively reduced our performance metric.

3- Quality: This assesses the rate of products meeting quality standards versus those requiring rework or being scrapped. Quality issues can be a silent killer; I once oversaw a batch where a tiny calibration error led to a significant drop in quality output.

Implementing OEE

The Right Way to Measure OEE

Implementing OEE isn't just about plugging numbers into a formula. It requires accurate data collection, consistent monitoring, and a keen eye for detail. Here's how we can approach it:

Data Accuracy: Ensure that the data collected is precise. Inaccurate data can lead to misguided efforts.

Regular Monitoring: OEE should be tracked regularly to identify trends and patterns.

Employee Involvement: Engage the team operating the manufacturing equipment. They're often the first to notice subtle changes.

Benefits of Implementing OEE

Implementing OEE can bring about a multitude of benefits:

Increased Productivity: By identifying bottlenecks, we can streamline operations.

Process Optimization: OEE highlights areas of waste, allowing for targeted improvements.

Improved Quality: Reduced defects mean happier customers and less rework.

Reduction in Equipment Downtime: Proactive maintenance becomes possible when we understand our equipment's performance.

I recall when we first started tracking OEE in our facility. At first, the numbers were disheartening. But soon, we began to see them as opportunities. By addressing the root causes of downtime and performance losses, we boosted our OEE from 60% to 85% within a year.

Case Study: Successful Implementation of OEE

Let me share a story about a manufacturing plant I consulted for recently. They were struggling with frequent downtimes and quality issues. After implementing OEE, here's what we did:

1- Identified Major Downtimes: We found that equipment changeovers were taking too long.

2- Optimized Performance: Minor adjustments in machine speed led to better performance without compromising quality.

3- Enhanced Quality Checks: By introducing real-time quality monitoring, defects were caught early.

The result? Their overall production efficiency soared, and they saw a significant reduction in costs associated with waste and rework.

Challenges of OEE Implementation

Common Pitfalls and Misconceptions of OEE

However, implementing OEE isn't without its challenges:

Data Overload: Collecting too much data can be overwhelming.

Misinterpretation: Misunderstanding OEE components can lead to wrong conclusions.

Resistance to Change: Employees might be hesitant to adopt new systems.

I remember facing skepticism from a team when introducing OEE. They feared it was a tool to micromanage or criticize. It took time, but through workshops and open discussions, we aligned on the common goal of improvement.

Addressing Challenges

Training and Educating Staff on OEE

Education is key. By training staff and explaining the benefits, we can foster a collaborative environment. Consider:

Workshops and Seminars: Regular sessions to discuss OEE concepts.

Hands-On Training: Practical demonstrations on the shop floor.

Feedback Mechanisms: Encouraging staff to share observations and suggestions.

Developing a Continuous Improvement Mindset

Embracing a culture of continuous improvement makes OEE implementation smoother. This involves:

Setting Incremental Goals: Small targets that lead to significant changes over time.

Celebrating Achievements: Recognizing when teams meet OEE improvement milestones.

Encouraging Innovation: Allowing teams to experiment with new methods.

Future of OEE

Role of OEE in Industry 4.0 Era

As we step into the realm of Industry 4.0, OEE becomes even more critical. The fusion of digital technologies with manufacturing processes means that data is more accessible than ever. Industry 4.0—or sometimes amusingly mistyped as "industry 4.00"—is all about smart manufacturing.

Utilization of Smart Technologies for OEE Enhancement

Artificial Intelligence in OEE

Artificial Intelligence (AI) can analyze vast amounts of OEE data to predict equipment failures before they happen. Imagine a system that alerts you to a potential breakdown based on subtle shifts in performance metrics.

Use of IoT in OEE

The Internet of Things (IoT) connects equipment, allowing for real-time data collection and analysis. Sensors on manufacturing machines can feed information into OEE systems, providing insights we've never had before.

I recently worked with a facility that incorporated IoT devices into their machinery. The level of detail in the data was astounding. We could see minute fluctuations in performance and address them immediately, greatly enhancing our OEE.

Advanced Planning and Scheduling in Supply Chain Optimization Strategies

An often overlooked aspect is how OEE ties into advanced planning and scheduling in supply chain optimization strategies. By understanding equipment effectiveness, we can:

Better Forecast Production: Knowing our true capacity helps in accurate scheduling.

Optimize Inventory Levels: Reducing overproduction and underproduction.

Enhance Supply Chain Coordination: Aligning production schedules with suppliers and distributors.

Conclusion

Reflecting on my experiences, I can confidently say that Overall Equipment Effectiveness is more than just a metric—it's a philosophy. It pushes us to continually seek improvements, question the status quo, and leverage technology to our advantage. As the industrial manufacturing industry embraces new technologies and strategies, OEE remains a steadfast tool guiding us toward excellence.

Whether you're just starting to explore OEE or looking to refine your current processes, remember that it's a journey. Engage your team, embrace technology, and keep an open mind. The road to optimization is paved with challenges, but the rewards are well worth the effort.

Some key takeaways:

OEE improvement strategies in industrial manufacturing involve a holistic approach encompassing availability, performance, and quality.

Best practices for overall equipment effectiveness include accurate data collection, regular monitoring, and employee involvement.

The benefits of OEE in Industry 4.0 are amplified by the integration of smart technologies like AI and IoT.

Reducing equipment downtime with OEE is achievable through proactive maintenance and data-driven decision-making.

Training staff for OEE implementation is crucial for fostering a culture of continuous improvement.

Improving quality using OEE metrics helps identify root causes of defects and minimize waste.

Using AI and IoT for OEE optimization enables predictive maintenance and real-time performance monitoring.

Common pitfalls of OEE measurement include data overload, misinterpretation, and resistance to change.

Tips to boost availability, performance, and quality in OEE involve setting incremental goals, celebrating achievements, and encouraging innovation.

By mastering the art of how to measure OEE in manufacturing and integrating it into our operations, we can unlock new levels of efficiency and competitiveness in the ever-evolving landscape of industrial manufacturing.

References

1- Nakajima, S. (1988). Introduction to TPM: Total Productive Maintenance. Productivity Press.

2- Vorne Industries. (2010). OEE for Operators: Overall Equipment Effectiveness. Vorne Industries Incorporated.

3- Harrington, H. J. (1995). Total Improvement Management: The Next Generation in Performance Improvement. McGraw-Hill.

4- Schmid, A., & Kern, D. (2018). Industry 4.0: Managing The Digital Transformation. Springer International Publishing.

5- Smith, R. (2003). Maintenance Planning and Scheduling Handbook. McGraw-Hill Professional.

6- Parmenter, D. (2015). Key Performance Indicators: Developing, Implementing, and Using Winning KPIs. John Wiley & Sons.

Note: The references listed are seminal works that delve deeper into OEE, TPM, and the broader context of manufacturing efficiency and Industry 4.0 technologies.

Frequently Asked Questions

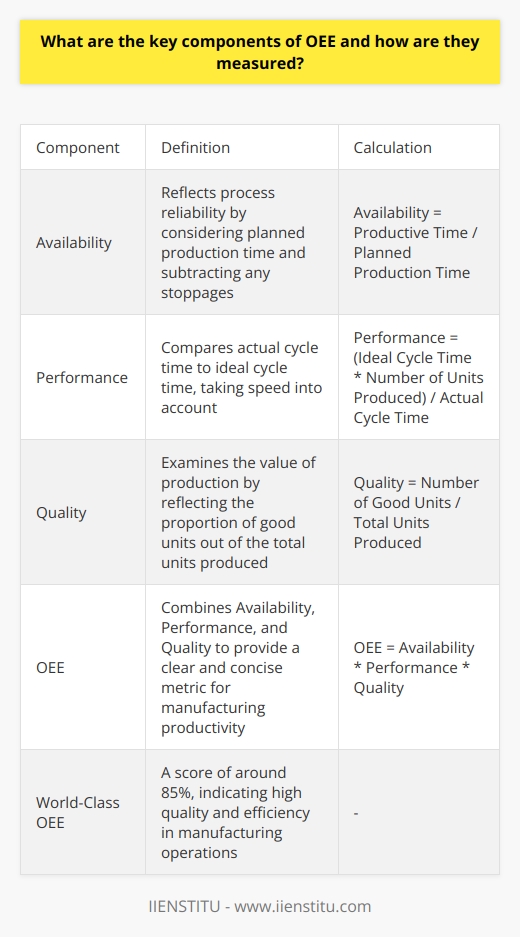

What are the key components of OEE and how are they measured?

Understanding OEE

OEE stands for Overall Equipment Effectiveness. It is a gold standard for measuring manufacturing productivity. Simply put, OEE identifies the percentage of manufacturing time that is truly productive. It offers a clear and concise metric. It combines three essential components. These are Availability, Performance, and Quality. Each plays a pivotal role.

Measuring Availability

Availability reflects process reliability. It considers planned production time. Then, it subtracts any stoppages. These are events that halt production. We measure it as a percentage. Availability equals productive time divided by planned production time. An example can help. Let's say planned production takes 8 hours. If stoppages take up 1 hour, availability is 87.5%.

Assessing Performance

Performance takes speed into account. It compares actual cycle time to ideal cycle time. The ideal cycle time is the fastest possible time to produce one item. We look at the number of items produced. We then compare the actual cycle time with the ideal. This ratio is the performance measure. It shows speed losses. For instance, one cycle takes 1 minute in the ideal case. The actual pace is 1.2 minutes per cycle. Here, performance would be 83.3%.

Determining Quality

Quality examines the value of what you produce. It reflects the proportion of good units. We also consider the total units produced. The calculation is straightforward. We take the number of good units and divide by the total. This yields the quality percentage. Let's imagine a scenario. We produce 100 units. 90 are without defect. Therefore, the quality rate is 90%.

OEE Calculation

We calculate OEE by multiplying availability, performance, and quality. It is expressed as a percentage. The math must be correct. We illustrate each metric as a ratio. Suppose our availability is 87.5%, our performance is 83.3%, and our quality is 90%. Our OEE would be 65.6%. Thus, it is a quick but broad metric. It tells us about overall production efficiency. It uncovers hidden losses. Moreover, it targets improvement areas.

Availability measures downtime losses.

Performance measures speed losses.

Quality measures defect losses.

With these insights, manufacturers optimize operations. They strive for a perfect OEE score of 100%. Yet, this is rare in practice. A world-class OEE score is around 85%. This means high quality and efficiency. Always aim to understand and improve each component. This ensures success and excellence in manufacturing.

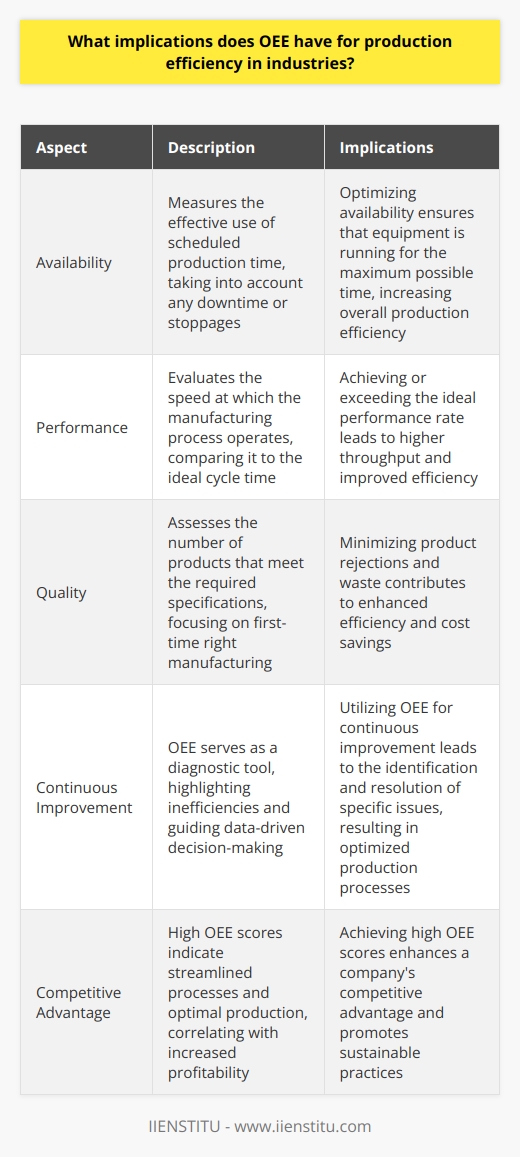

What implications does OEE have for production efficiency in industries?

Understanding OEE

Overall Equipment Effectiveness (OEE) measures production efficiency. Industries use it widely. It quantifies how well a manufacturing unit performs. Three core components define OEE: availability, performance, and quality.

Significance of Each OEE Component

Availability

Availability reflects scheduled production time use. It accounts for downtime. Here, every minute counts.

Performance

Performance measures speed. It considers the ideal cycle time. The goal is to match or exceed this rate.

Quality

Quality tracks product rejections. It focuses on manufacturing the first-time right products. Efficiency suffers with increased waste.

OEE's Role in Enhancing Production Efficiency

OEE drives continuous improvement. It highlights inefficiencies. Precise data guides decision-making.

Detects problems early

Streamlines maintenance

Focuses on bottlenecks

Thus, OEE serves as a diagnostic tool. It helps pinpoint specific issues.

Implications of High OEE Scores

High OEE scores suggest optimal production. They signal streamlined processes. Good scores correlate with high profitability.

Less waste production

Minimal machine downtime

Better resource allocation

Such efficiencies boost competitive advantage. They also foster sustainable practices.

Implications of Low OEE Scores

Conversely, low OEE scores indicate problems. They expose equipment reliability issues. Even skilled labor can't compensate.

Increased operating costs

More unplanned maintenance

Poor quality products

Addressing these issues improves efficiency. It also enhances workforce morale.

OEE remains a critical metric. It benchmarks production efficiency. Adopting OEE leads to leaner operations. Over time, it maximizes output while minimizing waste.

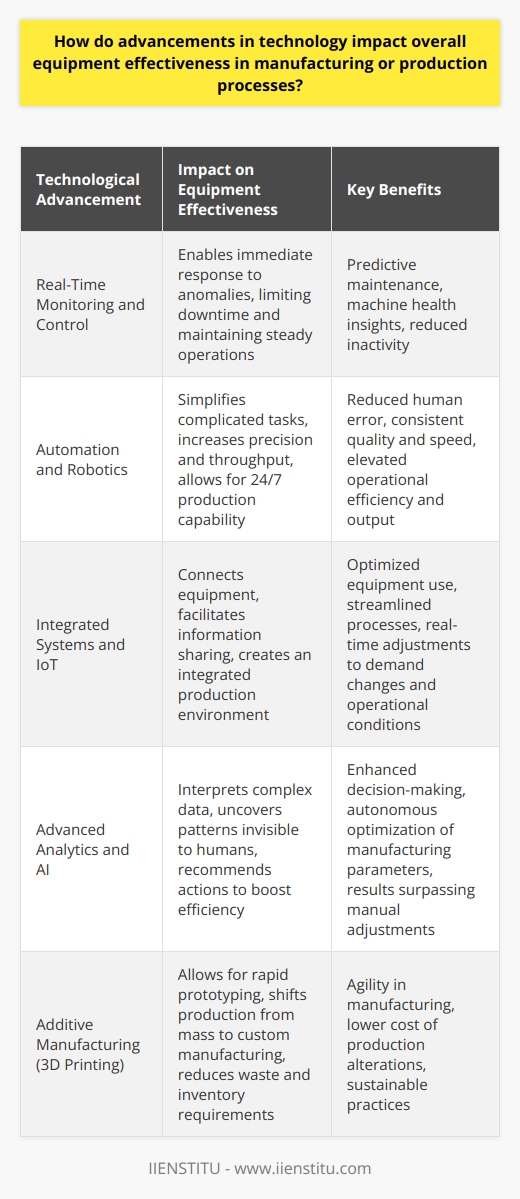

How do advancements in technology impact overall equipment effectiveness in manufacturing or production processes?

Impact of Technological Advancements on Equipment Effectiveness

Advancements in technology have transformed manufacturing processes. They have enhanced equipment effectiveness significantly. This effect manifests in various dimensions. Each dimension plays a crucial role in production efficiency.

Real-Time Monitoring and Control

Real-time data is crucial. It enables immediate response to anomalies. This limits downtime and maintains steady operations. Sensors and monitoring systems track equipment conditions. They offer insights into machine health. Predictive maintenance utilizes these insights. It anticipates failures before they occur. Consequently, it prevents prolonged machine inactivity.

Automation and Robotics

Automation simplifies complicated tasks. It increases precision and throughput. Robotics replace human labor for repetitive tasks. This shift allows for 24/7 production capability. It reduces human error. Machines operate with consistent quality and speed. Overall, they elevate operational efficiency and output.

Integrated Systems and IoT

The Internet of Things (IoT) connects equipment. This facilitates information sharing. It creates an integrated production environment. Such environments optimize equipment use. They streamline processes. Connected machines adjust in real-time. They respond to demand changes and operational conditions.

Advanced Analytics and AI

Artificial intelligence (AI) and machine learning interpret complex data. They uncover patterns invisible to humans. They recommend actions to boost efficiency. These technologies enhance decision-making. They optimize manufacturing parameters autonomously. Results often surpass manual adjustments.

Additive Manufacturing

Additive manufacturing, or 3D printing, reshapes production. It allows for rapid prototyping. Production shifts from mass to custom manufacturing. It reduces waste and inventory requirements. 3D printing brings agility to manufacturing. It lowers the cost of production alterations.

Energy Efficiency Technologies

Energy-efficient technologies reduce operational costs. They minimize environmental impact. Machines now consume less power. They operate at higher efficiency levels. Sustainable manufacturing practices emerge. This shift is key in an eco-conscious market.

Cybersecurity Measures

Robust cybersecurity protects digital manufacturing assets. It withstands production threats. Secure systems ensure uninterrupted operations. They prevent data breaches and sabotage attempts. A secure setup is fundamental. It maintains reliability in technologically advanced environments.

By embracing technological advancements, manufacturing entities gain significant strides in overall equipment effectiveness. This progression enhances competitive advantage. It secures future growth. Manufacturers must continue to invest in technology. Stagnation is not an option in the fast-paced digital era.