I still remember the first time I stepped into a bustling logistics yard. It was my third week on the job, fresh out of college, and eager to make my mark in the world of supply chain management. The sight was overwhelming: trailers lining up, forklifts zipping by, and a constant hum of activity that seemed almost chaotic. But amid the apparent disorder, there was a rhythm—a coordinated dance ensuring goods moved seamlessly from one point to another. That day, I began to appreciate the critical role of yard management in the larger tapestry of logistics.

Overview of Yard Management

Benefits of Yard Management for Supply Chain Management

Challenges of Implementing Yard Management

Technology and Automation in Yard Management

Best Practices for Optimizing Yard Management

Understanding the Essence of Yard Management

At its core, yard management is akin to orchestrating a symphony where every instrument must play its part at the right moment. It's not just about moving trailers or managing inventory; it's about optimizing time, space, and resources to ensure the entire supply chain functions smoothly. Imagine a well-oiled machine where each cog, no matter how small, contributes to the overall efficiency. That's what effective yard management achieves.

Tedarik Zinciri Yönetiminde Lojistik Optimizasyon Stratejileri

Exploring Modal Choice Decisions Sensitivity Analysis Impact Factors

Advanced Planning And Scheduling İn Supply Chain Optimization Strategies

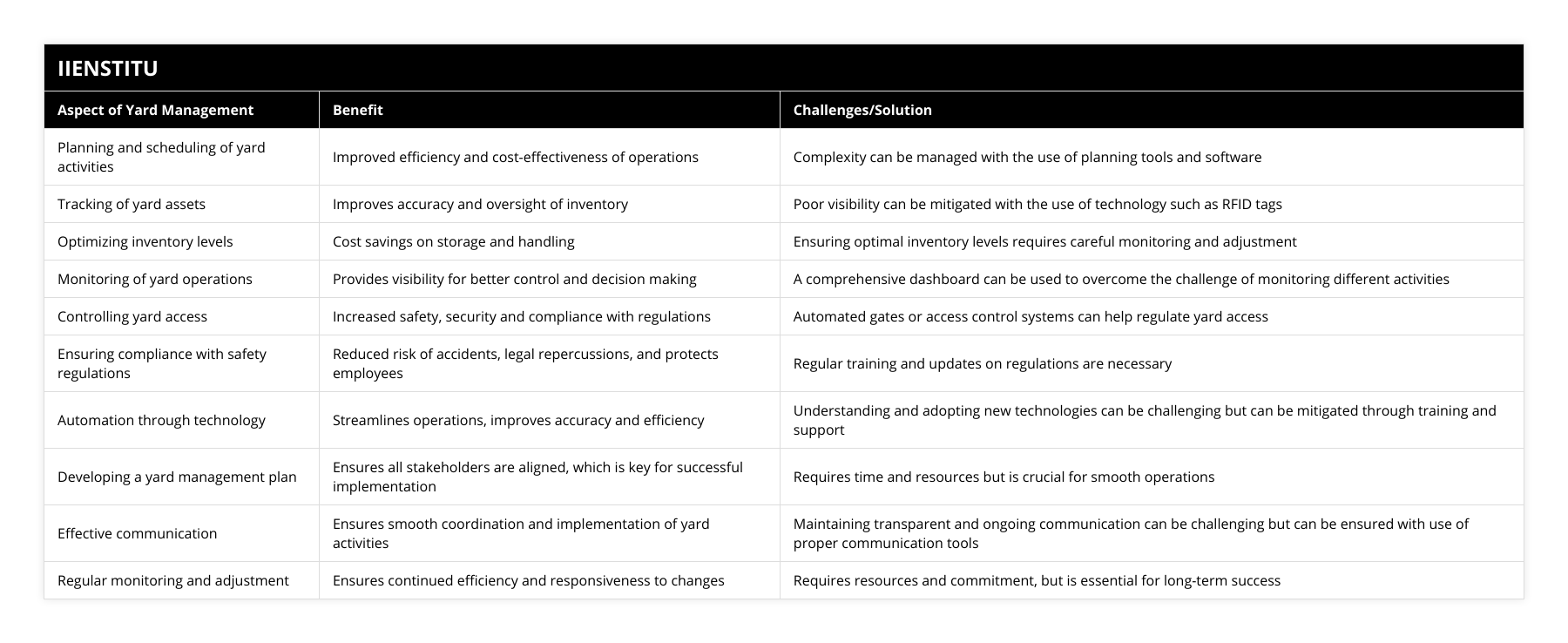

Planning and scheduling of yard activities

Tracking of yard assets

Optimizing inventory levels

Monitoring of yard operations

Controlling yard access

Ensuring compliance with safety regulations

I recall working on a project where we had to streamline inbound and outbound operations for a mid-sized distribution center. The challenges were plenty—delays in loading, misallocated trailers, and safety hazards due to congestion. Through meticulous planning and adopting a yard management system (YMS), we transformed the operations remarkably. We started tracking yard assets in real-time, optimizing dock assignments, and significantly reducing turnaround times.

Improved efficiency: Yard management helps to optimize the use of resources and improve the efficiency of operations. This can result in cost savings and improved customer satisfaction.

Improved visibility: Yard management provides visibility into the yard, allowing managers to monitor operations better and ensure accuracy.

Increased safety: Yard management can help to ensure that safety regulations are met and that the yard remains organized and safe.

Reduced costs: Yard management helps to optimize inventory levels, resulting in reduced costs for storage and handling.

Lack of resources: Implementing yard management can be time-consuming and require additional personnel and equipment.

Poor visibility: It can be not easy to monitor operations and ensure accuracy without proper visibility into the yard.

Complex regulations: Ensuring compliance with safety regulations can be complex and require extensive training and knowledge.

The Undeniable Benefits for Supply Chain Management

Implementing a robust yard management strategy isn't just a logistical choice; it's a strategic business decision. Here are some of the compelling benefits I've observed firsthand:

Develop a plan: Develop a plan for how the yard will be managed and ensure everyone is on the same page.

Utilize technology: Utilize technology, such as automated gates and RFID tags, to streamline the process and ensure accuracy.

Communicate: Ensure that everyone involved in the yard management process communicates effectively.

Monitor operations: Monitor operations regularly to ensure accuracy and efficiency.

1- Enhanced Efficiency: By effectively managing yard activities, businesses can reduce idle times and ensure that assets are utilized to their full potential. In one instance, we managed to cut down trailer dwell time by 30%, leading to faster deliveries and happier customers.

2- Improved Visibility: With the integration of technologies like RFID tags and GPS tracking, managers gain real-time insights into yard operations. This visibility allows for quick decision-making and swift resolution of issues. I remember a scenario where a misplaced trailer could have delayed an entire shipment, but thanks to our tracking system, we identified and rectified the error within minutes.

Efficient yard management is the key to successful logistics operation.

3- Increased Safety: A well-organized yard is a safer yard. By controlling yard access and monitoring movements, the risk of accidents decreases. Safety compliance isn't just about following regulations; it's about ensuring every team member returns home unharmed.

4- Cost Reduction: Optimizing inventory levels and reducing unnecessary movements can lead to significant cost savings. In a previous role, our team managed to save over $500,000 annually by eliminating detentions and demurrage charges through efficient yard management.

Navigating the Challenges of Implementation

Of course, implementing an effective yard management system isn't without its hurdles. Reflecting on past experiences, several challenges come to mind:

Resource Allocation: Setting up a YMS requires investment in both technology and training. Smaller businesses might struggle with the initial costs. However, the long-term gains often justify the expenditure.

Adapting to Technology: Transitioning from manual processes to automated systems can be daunting. There was a time when our team faced resistance from staff who were accustomed to traditional methods. It took comprehensive training and demonstrating the benefits to get everyone on board.

Regulatory Compliance: Keeping up with ever-changing safety and environmental regulations requires vigilance. During one project, new emission standards were introduced, necessitating quick adjustments to our equipment and procedures.

Embracing Technology and Automation

The future of yard management undeniably lies in technology and automation. The advent of Artificial Intelligence (AI) and the Internet of Things (IoT) has opened up new possibilities.

Automated Gate Systems: These systems streamline the check-in and check-out process for trailers, reducing bottlenecks at entry and exit points.

Real-Time Data Analytics: Leveraging data allows for predictive analysis. For example, forecasting peak times can help in allocating resources more efficiently.

Mobile Applications: Providing yard managers with mobile tools ensures constant connectivity and the ability to manage operations on the go.

I once worked with a team that implemented drone technology to monitor large yards. The drones provided aerial views, helping in quick identification of maintenance issues or unauthorized activities. It was fascinating to see how such innovations could enhance traditional practices.

Best Practices for Optimizing Yard Management

Drawing from various experiences, I've compiled some best practices that can significantly impact yard management effectiveness:

1. Develop a Comprehensive Plan

Before diving into implementation, it's crucial to have a clear plan. This plan should outline objectives, resources needed, and timelines. During a major overhaul at a previous company, we spent weeks just honing our strategy, which paid off in a smooth transition once we began executing.

2. Invest in Staff Training

Technology is only as good as the people using it. Regular training sessions ensure that staff are up-to-date with the latest systems and procedures. This not only improves efficiency but also boosts morale, as employees feel more competent and valued.

3. Leverage Technology Wisely

While it's tempting to adopt the latest gadgets, it's important to choose technologies that align with your specific needs. Customization can often yield better results than off-the-shelf solutions.

4. Foster Open Communication

Effective yard management requires collaboration between various departments—logistics, warehouse, transportation, and even security. Regular meetings and updates can keep everyone on the same page.

5. Monitor and Adapt

The logistics landscape is ever-changing. By continuously monitoring performance metrics and being willing to adapt, businesses can stay ahead of potential issues. Implementing a feedback loop allows for constant improvement.

A Personal Reflection on the Journey

Looking back, one of the most rewarding aspects of working in yard management has been witnessing the tangible impact of our efforts. There was a time when we had to reassign roles within our team to better match individual strengths with operational needs. It wasn't an easy decision, and it required sensitive handling, including drafting detailed reassignment request letters. We made sure to provide tips and information to affected staff, ensuring transparency and support during the transition. This approach not only improved operations but also fostered a strong sense of trust and camaraderie within the team.

In fact, handling internal changes effectively is as crucial as managing external operations. Just like in yard management, where every trailer and shipment is important, every team member's role and satisfaction contribute to the overall success. Addressing reassignment request letter tips and information thoughtfully can make a significant difference in team dynamics.

The Bigger Picture

Efficient yard management is more than just a component of logistics—it's the heartbeat that keeps the supply chain alive and responsive. In today's fast-paced market, where consumer expectations are higher than ever, ensuring that the yard operates seamlessly can give businesses a competitive edge.

I often tell new colleagues that mastering yard management is like being the conductor of an orchestra. You may not be playing each instrument, but your guidance brings harmony to the entire performance.

Concluding Thoughts

The journey through yard management has taught me that challenges are opportunities in disguise. By embracing technology, fostering teamwork, and continually seeking improvement, we can turn the logistical complexities of the yard into a streamlined, efficient operation that propels the entire supply chain forward.

As the logistics industry continues to evolve, those who invest in effective yard management today will be the ones leading the charge tomorrow. After all, it's not just about moving goods from point A to point B; it's about doing so in a way that is efficient, safe, and innovative.

References

1- Richards, G. (2017). Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse. Kogan Page Publishers.

2- Frazelle, E. (2002). Supply Chain Strategy: The Logistics of Supply Chain Management. McGraw-Hill.

3- Tompkins, J. A., & Harmelink, D. (2015). Supply Chain Excellence: A Handbook for Dramatic Improvement Using the SCOR Model. Tompkins Press.

4- Bartholdi, J. J., & Hackman, S. T. (2014). Warehouse & Distribution Science. The Supply Chain and Logistics Institute.

5- Langley, J., Coyle, J., Gibson, B., & Novack, R. (2020). Managing Supply Chains: A Logistics Approach. Cengage Learning.

Frequently Asked Questions

What is yard management?

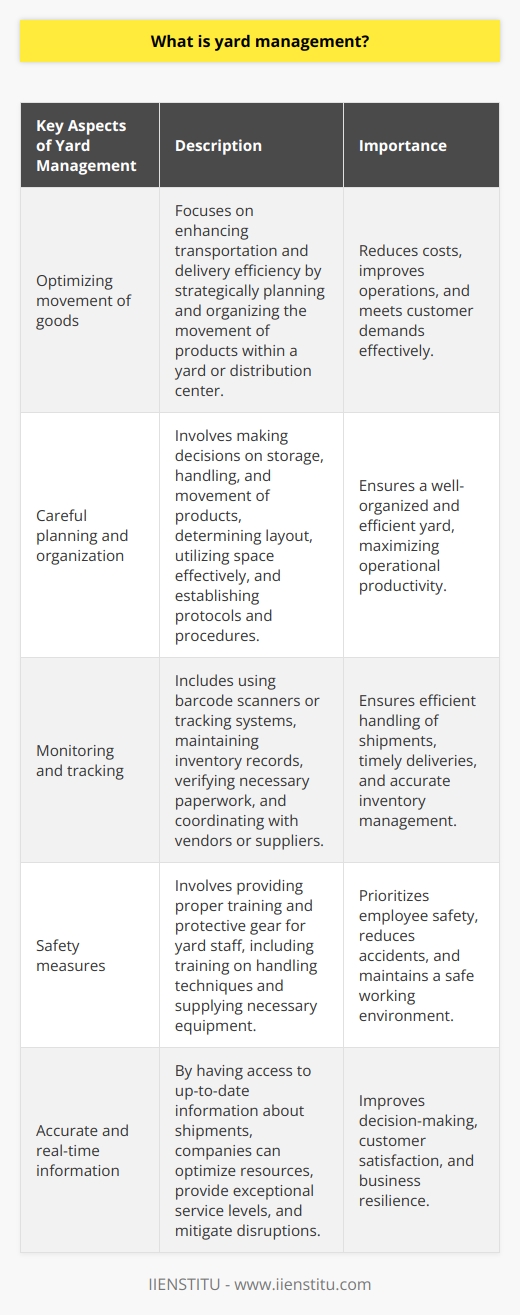

Yard management can be defined as optimizing the flow of goods through a yard or distribution center. It involves planning, scheduling, and controlling the movement of products within a facility's yard area. It is an essential part of managing overall logistics operations, as it helps to ensure efficient transportation and delivery of goods.

Yard management typically begins with planning and organizing the supply chain activities in the yard area. This includes determining which products will be stored in the yard, how they will be stored and handled, and how they will move between different areas in the yard. Planning also involves

scheduling deliveries to customers,

ensuring that sufficient stock is available for loading and unloading vehicles, and

managing any additional tasks such as cleaning or maintenance.

Once a plan has been established for managing yard activities, it is essential to monitor activity closely to ensure that all shipments are handled efficiently and on time. This may involve tracking deliveries using barcode scanners or other tracking systems, keeping track of inventory levels in each area of the yard, verifying paperwork associated with each shipment before it is released from the yard area, maintaining accurate records for incoming/outgoing shipments (e.g., bills of lading), coordinating with vendors/suppliers regarding product availability issues or delays, etc.

In addition, safety protocols must be adhered to when handling materials in a yard area; this includes proper training for staff members working in this environment and appropriate protective gear (e.g., gloves).

Effective yard management is essential for success in today's rapidly changing business environment. Many companies strive to maximize efficiency and reduce costs while meeting customer demands on time and accurately fulfilling orders.

By ensuring staff members have access to accurate information about shipments arriving/departing from a facility's yards or distribution centers – including real-time updates about order status – companies can effectively manage their resources while providing customers with top-notch service levels during peak seasons or challenging situations such as natural disasters or pandemics that could disrupt supply chains around the world.

What are the benefits of yard management for supply chain management?

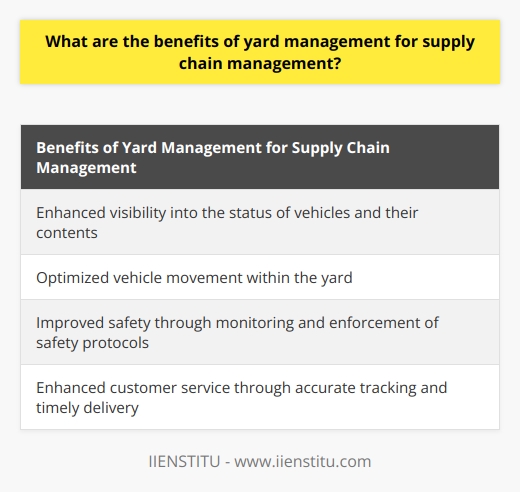

Yard management is a crucial supply chain management element that should be noticed more. A yard is the physical part of a warehouse, distribution center, or another facility where vehicles are loaded, unloaded, and staged for the next step in their journey. Yard management is the process of tracking, controlling, and optimizing the activities associated with the yard.

The benefits of yard management for supply chain management are numerous. First, it improves visibility into the status of vehicles and their contents. This visibility allows companies to track their inventory better and ensure the timely delivery of goods. Yard management also helps improve the accuracy of inventory and order fulfillment and reduces overall costs.

Second, yard management helps optimize vehicle movement within the yard. By tracking the location of vehicles, companies can ensure that they are loaded and unloaded efficiently, reducing time and resources. Additionally, yard management can help to reduce the risk of theft and damage to vehicles and their contents.

Third, yard management helps to improve safety. By monitoring the movement of vehicles in the yard, companies can ensure that safety protocols are being followed and that vehicles are operated safely. This reduces the risk of accidents and injuries, as well as the cost associated with them.

Finally, yard management can help to improve customer service. By tracking vehicles' status and contents, companies can ensure that customers receive their orders on time and in optimal condition. This improved customer service can help to increase customer satisfaction and loyalty, resulting in more repeat business.

In summary, yard management is an essential part of supply chain management that provides numerous benefits. By tracking and optimizing the movement of vehicles in the yard, companies can reduce costs, improve safety, and increase customer satisfaction. These benefits make yard management essential to any supply chain management strategy.

What challenges can arise when implementing a yard management system?

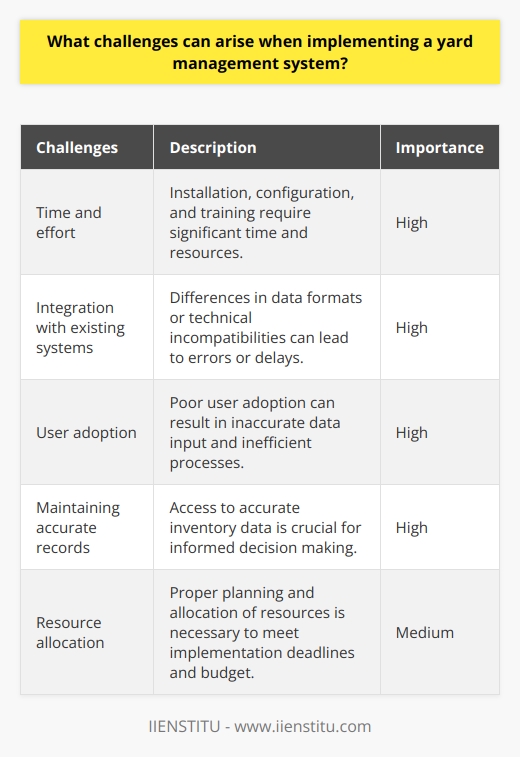

When implementing a yard management system, several potential obstacles must be considered. This article outlines some of the most common challenges and offers guidance on mitigating them.

Firstly, the implementation process requires considerable time and effort. It involves various activities such as system installation and configuration, training staff, and creating processes. Therefore, meeting implementation deadlines or keeping costs within budget cannot be easy without proper planning and resource allocation.

Secondly, integrating the yard management system with existing systems can be a challenge due to differences in data formats or technical incompatibilities. This can lead to errors in data exchange or delays in processing orders. Therefore, organizations should ensure their systems are compatible before beginning the integration process to avoid this problem.

Thirdly, ensuring that staff is adequately trained on using the yard management system correctly is essential. Poor user adoption can lead to inaccurate data input or inefficient processes that reduce productivity and negatively impact customer service. Therefore, organizations should design comprehensive training programs for users that cover all system functionality aspects before rolling out the solution across their operations.

Finally, maintaining accurate records is essential for successful yard management but can only be possible with proper systems. Organizations must ensure they have access to accurate data regarding inventory levels and movement throughout their operations to effectively make informed decisions about supply chain activities such as restocking and scheduling deliveries.

In conclusion, while implementing a yard management system can bring numerous benefits, such as improved inventory visibility and increased efficiency levels across operations; organizations need to understand some of the potential challenges they may face during the process so they can prepare accordingly with suitable strategies for overcoming them for long term success.

What are the key performance indicators for an effective yard management system?

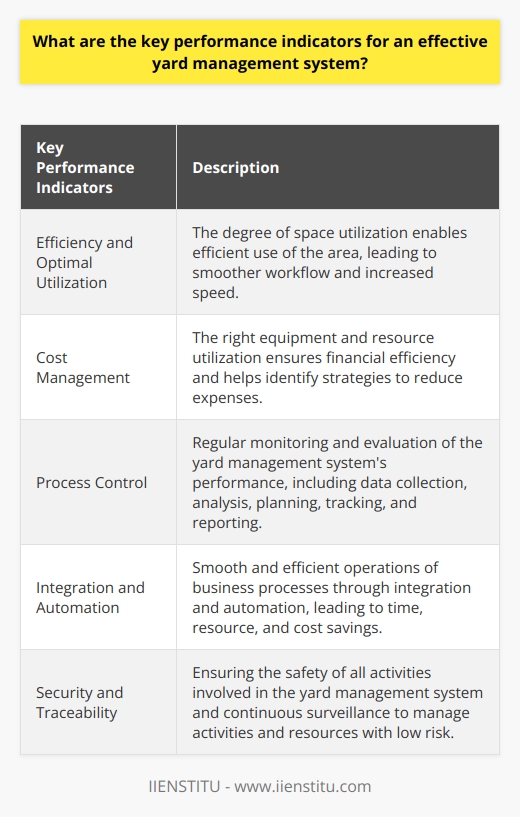

Etkili Bir Bahçe Yönetim Sistemi için Anahtar Performans Göstergeleri

Verimlilik ve Optimal Kullanım

Etkili bir bahçe yönetim sistemi için anahtar performans göstergelerinin başında verimlilik ve alanın optimal kullanımı gelmektedir. Alanın kullanım derecesi, mekanın tasarruflu kullanılmasını ve dolayısıyla iş akışının hızlanmasını sağlar.

Maliyet Yönetimi

Maliyet yönetimi, doğru ekipman ve kaynak kullanımıyla gerçekleştirilir ve işletmenin mali açıdan verimlilik sağlaması amacıyla ön planda tutulmalıdır. Bu gösterge, işletmenin boyutunu ve kaynak kullanımını doğru planlamasını sağlar ve giderleri azaltmaya yönelik stratejilerin belirlenmesine yardımcı olur.

Süreç Kontrolü

Süreç kontrolü, bahçe yönetim sistemi performansının düzenli olarak izlenmesini ve değerlendirilmesini sağlar. Bu alan, veri toplama ve analizi, planlama, takip ve raporlama gibi bir dizi faaliyeti içermektedir ve süreçlerin sorunsuz işlemesi sağlanarak verimlilik düzeyinin sürekli genişlemesi hedeflenmektedir.

Entegrasyon ve Otomasyon

Bahçe yönetim sisteminin entegrasyon ve otomasyon kapasitesi, iş süreçlerinin düzgün ve verimli bir şekilde işleyişini sağlar. Bu özellik, farklı süreçler arasında uyumlu çalışma ile birlikte, özellikle büyük işletmelerde zaman, kaynak ve maliyet tasarrufu sağlayabilir.

Güvenlik ve İzlenebilirlik

Güvenlik ve izlenebilirlik, bahçe yönetim sistemine dahil olan tüm faaliyetlerin güvende olmasını ve sürekli gözetim altında tutulmasını sağlar. Bu gösterge, potansiyel güvenlik tehditlerinin önlenmesine ve giderilmesine yardımcı olacak süreçleri içerir ve işletmenin tüm faaliyetlerini ve kaynaklarını düşük riskle yönetmeye olanak tanır.

Sonuç olarak, etkili bir bahçe yönetim sisteminin anahtar performans göstergeleri, verimlilik ve optimal kullanım, maliyet yönetimi, süreç kontrolü, entegrasyon ve otomasyon ve güvenlik ve izlenebilirlik olmak üzere beş ana başlık altında ele alınmalıdır. Tüm bu göstergelerin sürekli kontrol edilmesi ve gerekli iyileştirmelerin yapılması, sistem performansının ve işletme verimliliğinin sürekli artırılmasına katkı sağlayacaktır.

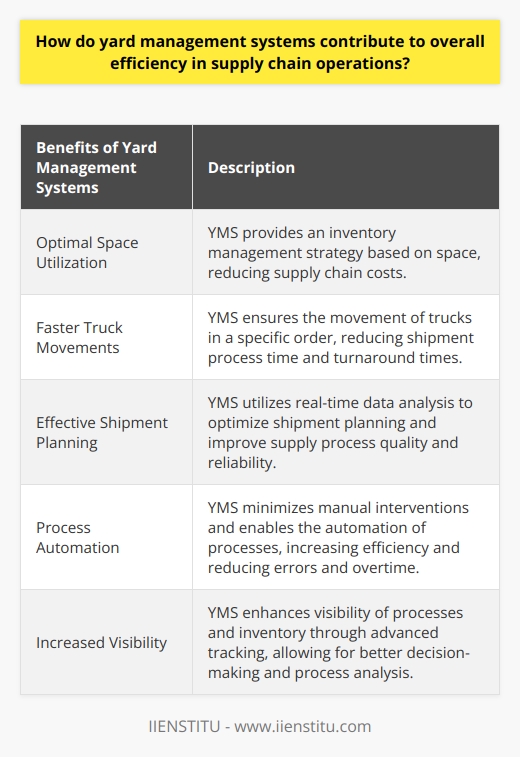

How do yard management systems contribute to overall efficiency in supply chain operations?

Tedarik Zinciri Operasyonlarındaki Etkinlik

Bahçe Yönetim Sistemleri (YMS) Nedir?

Yard Management System (YMS), tedarik zinciri operasyonlarının akıcılığını sağlamak ve maliyetleri düşürmek amacıyla lojistik merkezlerinde kullanılan bir araçtır. YMS, ambarlar, park alanları ve mevcut taşıtların kullanımını ve depolama alanlarının kullanılmasını içerir.

Yard Management Sistemlerinin Faydaları

Optimum Alan Kullanımı: YMS, alana dayalı envanter yönetimi stratejisi sağlar. Sistem, boş taşıma araçlarını ve boş konteynerlerin yerleştirilmesi için en uygun alanın belirlenmesine yardımcı olur. Bu doğrudan tedarik zinciri maliyetlerinin azalmasına yol açar.

Hızlı Kamyon Hareketleri: YMS, kamyonların belirli bir düzen içinde hareketini sağlayarak daha hızlı yüklemeye katkıda bulunur. Sistem, sevkiyat sürecinin zamanını azaltır ve termin sürelerini kısaltır.

Makul Sevkiyat Planlaması: YMS, sevkiyatın planlamasını ve tahsisini optimize etmek için gerçek zamanlı veri analizinden yararlanır. Bu etkin planlama sayesinde, tedarik süreçlerinin kalitesi ve güvenilirliği artar.

Süreçlerin Otomasyonu: YMS, süreçlerin otomatikleştirilmesini sağlar ve böylece hatalara ve fazla mesaiye yol açabilecek manuel müdahaleleri en aza indirir. Kullanıcılar, sistem sayesinde daha etkin ve sorunsuz amaçlarını gerçekleştirebilirler.

Artan Görünürlük: YMS, tüm süreçleri ve envanterleri gelişmiş izleme ile görünür hale getirir. Bu sayede lojistik yöneticiler, süreçleri daha iyi anlayarak ve analiz ederek verimliliği artırma yolunda önemli kararlar alabilirler.

Sonuç

Sonuç olarak, Yard Management Sistemlerinin kullanımı, tedarik zinciri operasyonlarında sürdürülebilir ve verimli bir yöntem sağlar. Bu sistemler; alan, zaman ve maliyet etkenlerinin optimize edilmesiyle iş süreçlerinde ve üretimde etkinliği artırır ve rekabet avantajı kazandırır. Dolayısıyla, YMS, tedarik zinciri yönetiminin önemli bir parçasıdır ve operasyonların genel verimliliğine önemli ölçüde katkı sağlar.

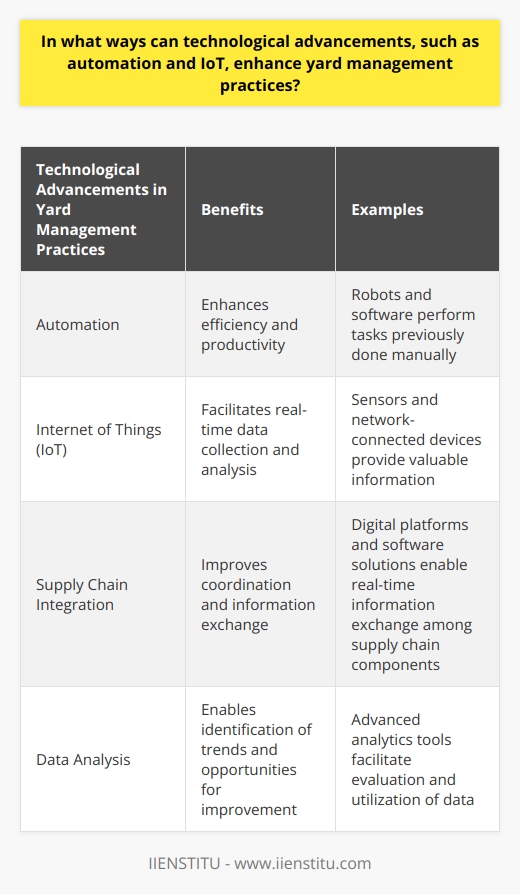

In what ways can technological advancements, such as automation and IoT, enhance yard management practices?

Yardım Yönetim Uygulamalarında Teknolojinin Rolü

Otomasyon Süreçleri:

Yardım yönetimi uygulamaları üzerinde teknolojinin önemli bir etkisi, otomasyon süreçlerinin gelişmesidir. Otomasyon, elle yapılan süreçlerin robotlar ve yazılım tarafından gerçekleştirilmesini sağlayarak alan yönetiminin etkinliğini ve verimliliğini önemli ölçüde artırabilir. Özellikle depo ve lojistik alanlarında, otomasyon, ürünlerin hızlı bir şekilde taşınmasına, istiflenmesine ve izlenmesine olanak tanıyarak stok kontrol süreçlerini daha kolay ve daha doğru hale getirir.

İnternet Nesneleri (IoT) Kullanımı:

Yardım yönetim uygulamalarında teknolojinin bir diğer önemli katkısı da İnternet Nesneleri (IoT) teknolojisinin kullanılmasıdır. IoT, sensörler ve ağ bağlantılı cihazlar sayesinde gerçek zamanlı veri toplama ve analiz imkanı sunarak yardım yönetim süreçlerinin optimize edilmesine yardımcı olur. Örneğin, IoT sayesinde, yardımların hareketine ve konumuna ilişkin değerli bilgiler sağlanarak lojistik sorunlarının belirlenmesinde ve meydana gelen aksaklıkların hızla giderilmesinde büyük kolaylıklar sağlanır.

Tedarik Zinciri Entegrasyonu:

Teknolojik gelişmeler, yardım yönetimi ile tedarik zinciri süreçlerinin daha iyi entegrasyonuna ve koordinasyonuna olanak sağlar. Dijital platformlar ve ileri yazılım çözümleri sayesinde farklı tedarik zinciri bileşenleri, gerçek zamanlı bilgi alışverişi yaparak daha etkili ve düşük maliyetli süreçler oluşturmaya yardımcı olabilir. Böylelikle yardımların lojistik süreçlerinin verimliliği artırılır ve zamanında teslimi sağlanır.

Veri ve Analiz Yetenekleri:

Otomasyon ve IoT teknolojileri, yardım yönetim uygulamalarında büyük miktarda verinin toplanmasını ve işlenmesini sağlar. Bu verilerin analizi, önceden belirsiz olan eğilimlerin ve süreçlerinin iyileştirilmesine yönelik fırsatların keşfi için kullanılabilir. Gelişmiş analitik araçlar, verilerin değerlendirilmesini ve kullanılmasını kolaylaştırarak yardım yönetim süreçlerinin daha bilinçli ve stratejik planlamalarına imkan sağlar.

Sonuç olarak, teknolojik gelişmelerin yardım yönetim uygulamalarında sağladığı otomasyon, IoT kullanımı, tedarik zinciri entegrasyonu ve veri analizi gibi unsurlar, süreçlerin verimliliğini ve etkiliğini artırmanın yanı sıra belirsizlikleri azaltarak daha başarılı yardım yönetim uygulamalarının hayata geçirilmesine imkan sağlamaktadır.

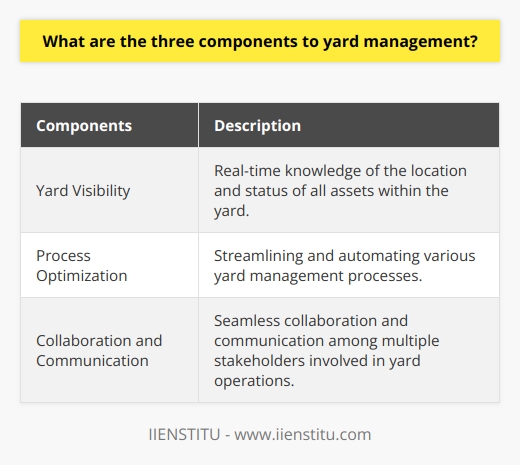

What are the three components to yard management?

Effective Yard Management: Three Key Components

Yard Visibility

The first component of yard management is maintaining comprehensive yard visibility. Complete yard management requires knowing the real-time location and status of all trailers, containers, assets, and resources within the yard. This visibility enables managers to track and monitor assets efficiently, improving the overall organization and productivity of the yard. With accurate data on the positions of trailers, containers, and other equipment, managers can optimize yard operations, such as vehicle movement and yard jockey assignments.

Process Optimization

The second component is continuous process optimization. Yard management entails streamlining and automating processes, such as checking in and out trailers, creating yard moves, and updating statuses, to eliminate redundancies and improve efficiency. This optimization aims to boost operational productivity and reduce labor costs. Implementing state-of-the-art yard management systems can assist managers in automating management tasks, providing real-time information on yard activities, and making more informed decisions.

Collaboration and Communication

The third component is effective collaboration and communication among all stakeholders. Yard management is a complex operation involving various departments, vendors, carriers, and customers who must work together seamlessly. As such, effective yard management requires the ability to communicate and collaborate with all involved parties, using integrated systems and platforms that ensure smooth information and data flow. These tools can help managers coordinate tasks, allocate resources, and resolve issues as they arise, ultimately leading to improved yard performance and customer satisfaction.

In summary, effective yard management hinges on three essential components: yard visibility, process optimization, and collaboration and communication among all stakeholders. By mastering and implementing these elements, organizations can enjoy a more streamlined and productive yard management operation, ultimately enhancing overall efficiency and customer satisfaction.

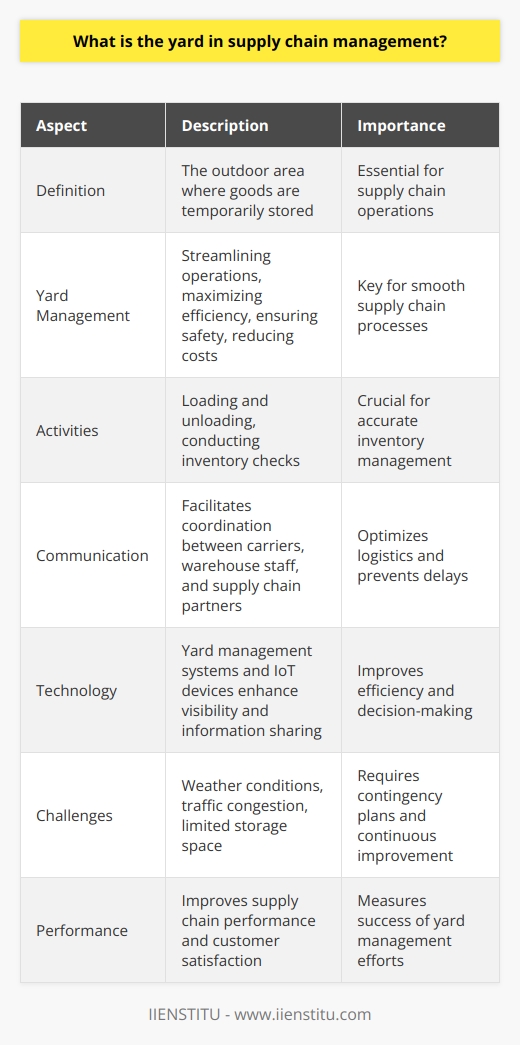

What is the yard in supply chain management?

Yard Management in Supply Chain

In supply chain management, the yard refers to the outdoor area where goods are temporarily stored, waiting for transportation or further processing. Yard management focuses on streamlining essential operations, such as the orderly flow of incoming and outgoing goods, to maximize efficiency, ensure safety, and reduce operational costs.

Role of Yard Management

A key aspect of yard management is coordinating the various activities occurring within the yard, including loading and unloading trucks, relocating goods, and conducting warehouse inventory checks. Effective yard management prioritizes smooth communication between freight carriers, warehouse staff, and supply chain partners. By doing so, it facilitates a seamless transfer of goods from one stage of the supply chain to the next.

Benefits of Effective Yard Management

Efficient yard management greatly contributes to the optimization of supply chain processes by minimizing delays, reducing labor and equipment usage costs, and lowering the risk of product damage or loss. Furthermore, it enables organizations to maintain visibility into their inventory levels and transportation schedules, ensuring the timely delivery of goods to customers and boosting overall customer satisfaction.

Use of Technology in Yard Management

Technology plays a vital role in modern yard management practices. It enhances the overall visibility of yard operations through real-time tracking of vehicles, goods, and staff. Various software solutions, such as yard management systems (YMS), track and monitor the movement of goods and vehicles within the yard. The integration of Internet of Things (IoT) devices, such as RFID tags and GPS systems, further improves accuracy and real-time information sharing among yard management stakeholders.

Challenges in Yard Management

Despite its importance within supply chain management, yard management often faces obstacles that can negatively impact efficiency, including unpredictable weather conditions, congested traffic, and limited availability of storage space. Companies must address these challenges by carefully balancing capacity with demand, implementing contingency plans for unforeseen disruptions, and regularly reviewing yard management processes to identify areas of improvement.

In conclusion, the yard is a crucial component of supply chain management. Effective yard management strategies must address the timely and orderly flow of goods, facilitate communication between stakeholders, and leverage technology for real-time visibility and coordination. By adopting a proactive and efficient approach to yard management, organizations can significantly improve the performance of their supply chains and drive greater value for their customers.

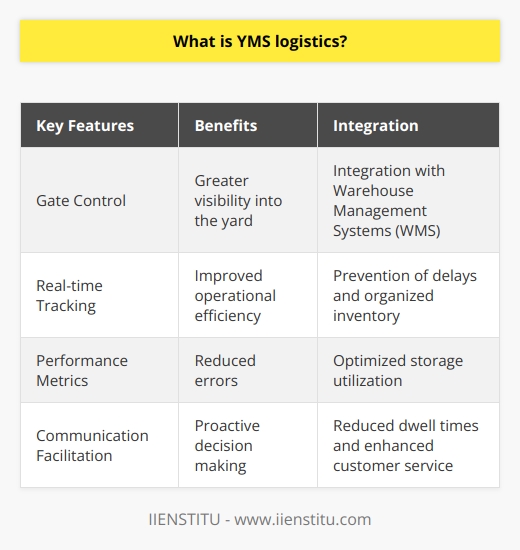

What is YMS logistics?

Overview of YMS Logistics

YMS Logistics is a comprehensive management system primarily designed to optimize and streamline the processes involved in yard operations. By effectively handling the movement and tracking of trailers and containers within a yard, the system ultimately enhances the efficiency of various logistics activities.

Key Features of YMS Logistics

The system typically encompasses various features, such as gate control, real-time tracking, and performance metrics. These features not only save manual labor but also help deliver critical data for better decision making in supply chain operations. Furthermore, YMS Logistics enables seamless communication between different stakeholders, such as truck drivers, dispatchers, and warehouse managers.

Benefits of Using YMS Logistics

Implementing YMS Logistics in a facility offers numerous benefits, including greater visibility, increased efficiency, reduced delays, and improved inventory control. The increased visibility into the yard helps businesses predict and identify potential bottlenecks, allowing them to make proactive decisions to optimize operations. Besides, the real-time tracking feature facilitates accurate and timely data exchange, ultimately improving overall operational efficiency and minimizing errors.

YMS Logistics and Warehouse Management System Integration

Another significant advantage of YMS Logistics is its integration with Warehouse Management Systems (WMS), creating a holistic approach to managing logistics operations. By connecting both systems, businesses can streamline the movement of goods, prevent possible delays, and maintain an organized inventory. This integration helps optimize storage utilization, reduce dwell times, and enhance customer service.

Conclusion

In conclusion, YMS Logistics is a valuable tool that serves to transform and optimize yard management operations. By providing advanced features, seamless integration with WMS, and multiple benefits, the system has become an essential element in improving logistics efficiency and ultimately, increasing overall competitiveness within the industry.

What are the critical elements of an effective yard management system?

Critical Elements of an Effective Yard Management System

Yard Visibility and Real-time Data

An effective yard management system (YMS) must provide complete visibility of the yard operations, including real-time data on the location and status of trailers, containers, and other essential equipment. This information enables efficient resource allocation, reducing the time required for movement and preventing bottlenecks.

Integration with Warehouse and Transportation Systems

Seamless integration with warehouse management systems (WMS) and transportation management systems (TMS) is another critical element. This integration ensures smooth information flow between various supply chain operations, allowing accurate inventory tracking, dock door scheduling, and carrier coordination. Consequently, it reduces lead times and strengthens overall supply chain resilience.

Optimal Yard Flow and Space Utilization

An effective YMS must optimize yard flow and space, by intelligently organizing equipment and facility usage. Yard layout optimization and location assignment should be based on factors such as priority, cargo type, and carrier efficiency, preventing congestion and improving operational effectiveness.

Carrier and Appointment Management

A yard management system should include advanced carrier and appointment management capabilities, ensuring precise scheduling of pick-up and drop-off times. This feature helps to minimize wait times and reduce operational costs, as carriers are held accountable for adhering to their scheduled appointments. Moreover, it improves communication between carriers and the yard, allowing flexible responses to unexpected changes in demand or capacity.

Performance Measurement and Analysis

Lastly, a comprehensive performance measurement and analysis system is vital. The yard management system must provide key performance indicators (KPIs) and reports, based on which yard managers can strategically plan and implement improvements. Continuous monitoring of operations and benchmarking against industry best practices will further enhance yard performance and overall supply chain efficiency.

In summary, an effective yard management system should encompass yard visibility, real-time data, integration with WMS and TMS, optimal yard flow and space utilization, carrier and appointment management, and performance measurement and analysis. By incorporating these critical elements, a YMS can substantially improve yard operations and boost overall supply chain performance.

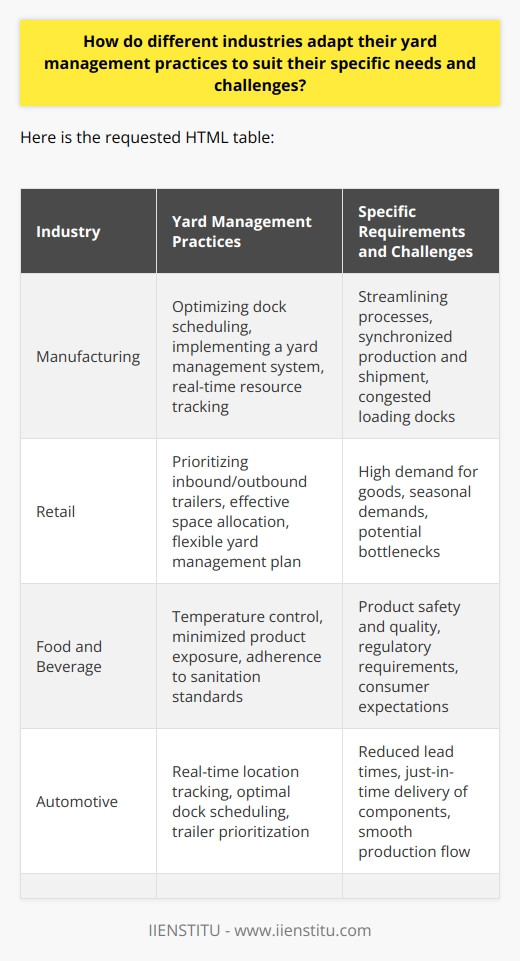

How do different industries adapt their yard management practices to suit their specific needs and challenges?

Yard Management in Various Industries

Customized Approach for Each Industry

Different industries have unique challenges that require tailor-made yard management practices. The ultimate goal is to align these practices with the specific needs of each industry while ensuring efficiency, speed, and cost-effectiveness. To realize this, industries need to adopt a customized approach that addresses their distinct challenges and maximizes the potential benefits of effective yard management.

Manufacturing Industry: Streamlining Processes

In the manufacturing sector, production and shipment should be in-sync to maintain a steady flow of goods. Yard management needs to tackle issues such as congested loading docks and timely shipment tracking. Solutions might include optimizing dock scheduling, implementing a yard management system, and ensuring easy access to real-time information on available resources.

Retail Industry: Optimizing Space Utilization

Retailers typically experience high demand for goods, resulting in increased yard activity. This creates the need for effective space utilization and prioritization of inbound and outbound trailers. Retailers should be adequately prepared for seasonal demands and potential peaks in yard usage. By having a flexible yard management plan, retailers can allocate space effectively and avoid bottlenecks.

Food and Beverage Industry: Ensuring Product Safety and Quality

The food and beverage industry faces the challenge of maintaining product quality and safety during storage and transportation. Yard management practices should facilitate temperature control, minimize product exposure, and adhere to strict sanitation standards. These measures can help ensure products arrive at their final destination in excellent condition, complying with regulatory requirements and consumer expectations.

Automotive Industry: Reducing Lead Times

In the automotive industry, assembly lines rely on just-in-time delivery of components to maintain production schedules. Yard management needs to ensure that suppliers can deliver parts promptly and accurately, facilitating the movement of trailers within the yard. This includes implementing real-time location tracking, optimal dock scheduling, and trailer prioritization to keep production running smoothly.

In conclusion, the yard management practices across various industries should be designed to cater to their specific needs and challenges. A customized approach can provide the flexibility, responsiveness, and cost-effectiveness companies require to succeed in today's competitive global landscape. By aligning management practices with each industry's unique requirements, organizations can enhance efficiency, improve customer satisfaction, and drive overall business performance.

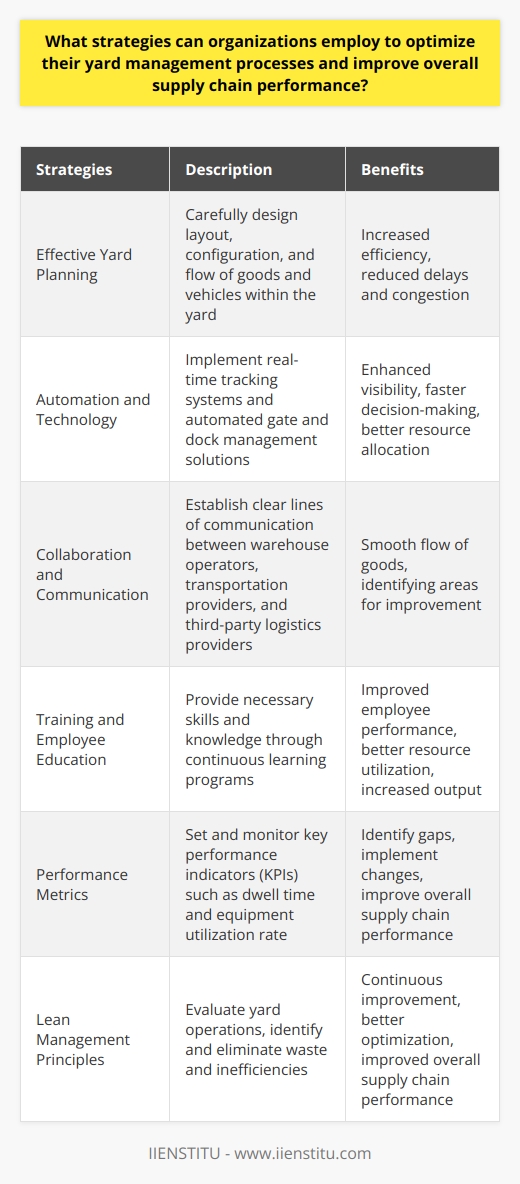

What strategies can organizations employ to optimize their yard management processes and improve overall supply chain performance?

Yard Management Improvement Strategies

Effective Yard Planning

One strategy to optimize yard management processes is to have effective yard planning in place, including the layout, configuration, and flow of goods and vehicles. This involves allocating designated areas for different activities, including parking, loading, and unloading of trucks, ensuring that these areas are easily accessible and are not congested.

Automation and Technology Implementation

Another strategy to improve overall supply chain performance is to implement automation and technology in everyday yard operations. Through the installation of real-time tracking systems and automated gate and dock management solutions, organizations can have a constant overview of their assets and resources, enhancing visibility and enabling faster decision-making.

Collaboration and Communication

Establishing clear lines of communication and fostering collaboration between various stakeholders, such as warehouse operators, transportation providers, and third-party logistics providers, is essential in optimizing yard management processes. Regular meetings, constant tracking of performance metrics, and identifying areas for improvement can contribute significantly to a streamlined supply chain.

Training and Employee Education

Focusing on training and employee education can lead to improved supply chain performance. A well-trained workforce, equipped with the right skills, is more likely to adhere to best practices, leading to better utilization of resources and increased output. Continuous learning can be established through workshops, seminars, and training sessions, with a focus on yard management protocols and safety standards.

Establish Performance Metrics

Setting performance metrics and monitoring them regularly can ensure that yard management processes are achieving the desired results. Key performance indicators (KPIs) such as dwell time, equipment utilization rate, and on-time delivery metrics can help organizations identify gaps and implement changes to improve supply chain performance.

Lean Management Principles

Incorporating lean management principles can lead to better optimization of yard management processes. These principles advocate the continuous improvement of a system by identifying and eliminating sources of waste and inefficiencies. By evaluating yard operations, organizations can pinpoint areas for improvement and take corrective measures, ultimately improving overall supply chain performance.

In conclusion, implementing these strategies and focusing on constant improvement can lead to significant gains in yard management processes and overall supply chain performance. With the right planning, communication, and technology in place, organizations can create a more efficient and effective yard operation, contributing to improved overall business outcomes.

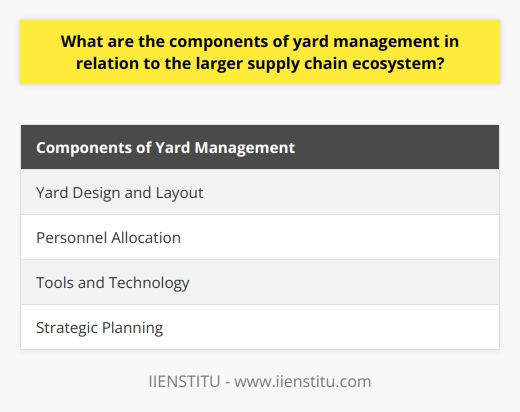

What are the components of yard management in relation to the larger supply chain ecosystem?

Components of Yard Management

Effective yard management is a critical aspect of supply chain optimization as it focuses on the organization, efficiency, and coordination of inbound and outbound logistical operations. The main components of yard management include yard design and layout, personnel allocation, tools and technology, and strategic planning.

Yard Design and Layout

A well-designed yard plays a crucial role in improving supply chain operations by enabling streamlined movement of goods and vehicles. Optimizing the yard layout, including the configuration of parking areas, docks, and gates, helps in reducing congestion and speeding up loading and unloading processes. Furthermore, proper yard design can prevent bottlenecks, safety hazards, and additional transportation costs.

Personnel Allocation

An effective yard management system ensures that the right mix of skilled personnel, such as loaders and unloaders, yard jockeys, and supervisors, is available at strategic points in the yard. This results in efficient vehicle handling, resource utilization, and error reduction. Additionally, appropriate training and safety measures can minimize workplace accidents and increase staff productivity in the yard.

Tools and Technology

The incorporation of advanced technology, such as yard management software, sensors, and real-time tracking systems, enhances visibility, control, and communication within yard operations. These tools enable real-time data-driven decision-making, reducing asset dwell time and eliminating the need for manual tracking. Moreover, technology allows for agile and responsive planning, enabling companies to quickly adapt to changes in supply chain dynamics.

Strategic Planning

Effective yard management strategies, including scheduling, inventory management, and carrier coordination, are essential to optimize supply chain operations. Establishing efficient scheduling practices for receiving, shipping, and cross-docking activities can considerably reduce yard congestion and transportation delays. Comprehensive inventory management, on the other hand, ensures that goods are accurately accounted for and can be quickly located in the yard, further improving logistics efficiency. Lastly, coordinating with carriers and streamlining communication can enhance load planning and reduce vehicle turnaround time.

Conclusion

In conclusion, yard management constitutes a vital component of the larger supply chain ecosystem. By optimizing yard design and layout, allocating skilled personnel, implementing advanced technology, and developing effective strategic plans, companies can significantly enhance their supply chain operations and achieve a competitive advantage in the market.

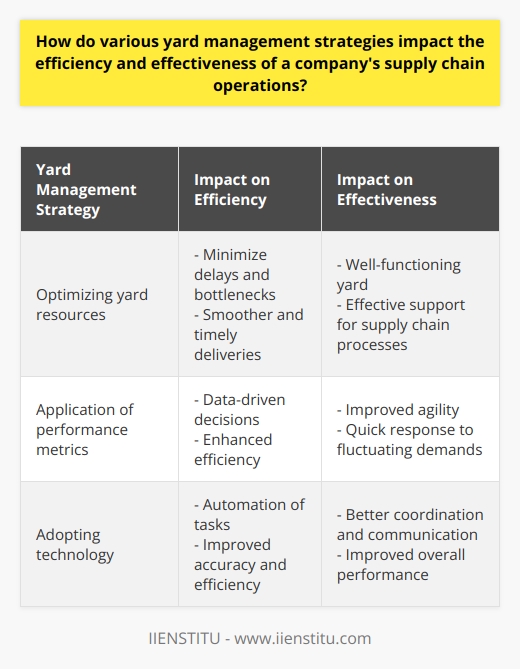

How do various yard management strategies impact the efficiency and effectiveness of a company's supply chain operations?

Yard Management Strategies and Supply Chain Operations

Yard management is a crucial aspect of any supply chain, influencing overall efficiency and effectiveness. Implementing proper strategies allows companies to improve yard operations and facilitate the transport of goods for smooth, timely deliveries. There are various yard management strategies that impact supply chain operations, including optimization of yard resources, application of performance metrics, and adoption of technology.

Optimization of Yard Resources

Efficient yard management requires utilization of resources, such as personnel, equipment, and physical space, in an optimal manner. By organizing the distribution of resources, businesses reduce time spent on transportation and inventory management, thereby increasing operational efficiency. Companies can also analyze their yard resources to identify areas where improvements are necessary, ensuring that they maintain a well-functioning yard that supports supply chain processes effectively.

Application of Performance Metrics

One yard management strategy that benefits supply chain operations is the use of performance metrics. Companies need to monitor key performance indicators, such as dwell times or equipment utilization rates, to evaluate the effectiveness of their yard operations. Letting these metrics guide decision-making enhances efficiency, streamlines processes, and helps companies develop more agile supply chain networks to meet fluctuating demands.

Adoption of Technology

Technological advancements have revolutionized yard management practices, impacting supply chain operations significantly. Implementing software solutions enables companies to automate tasks, such as inventory tracking and gate operations, improving accuracy and efficiency. Furthermore, technology, like radio-frequency identification (RFID) tracking, helps businesses better locate products and manage yard capacity, leading to more effective supply chain management.

In conclusion, yard management strategies play a fundamental role in ensuring the efficiency and effectiveness of supply chain operations. By optimizing resources such as personnel and equipment, applying performance metrics, and harnessing new technology, businesses can achieve a well-organized, functional yard that bolsters their overall supply chain performance.

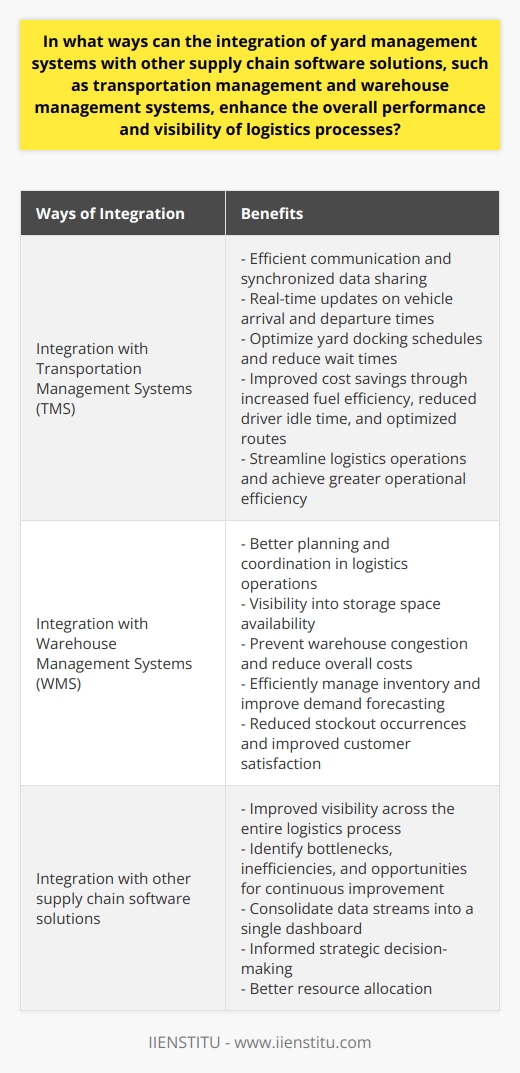

In what ways can the integration of yard management systems with other supply chain software solutions, such as transportation management and warehouse management systems, enhance the overall performance and visibility of logistics processes?

Integration with Transportation Management Systems

The integration of yard management systems (YMS) with transportation management systems (TMS) can significantly improve logistics processes by enabling efficient communication between the two systems. Synchronized data sharing allows for real-time updates on vehicle arrival and departure times, optimizing yard docking schedules and reducing wait times. Additionally, streamlined transport operations lead to improved cost savings through increased fuel efficiency, reduced driver idle time, and optimized routes.

Enhanced Warehouse Management System Connectivity

By connecting YMS to warehouse management systems (WMS), organizations can further optimize their logistics operations. Integrated software solutions enable better planning and coordination by providing visibility into the availability of storage spaces, helping to prevent warehouse congestion, and reducing overall costs. Furthermore, enhanced data analytics capabilities facilitate efficient inventory management and improved demand forecasting, which can lead to reduced stockout occurrences and improved customer satisfaction.

Improved Visibility and Performance

Integration between YMS and other supply chain software presents an opportunity to enhance visibility across the entire logistics process. Real-time data helps stakeholders identify bottlenecks, inefficiencies and opportunities for continuous improvement. By consolidating various data streams into a single dashboard, decision-makers can gain a comprehensive view of their supply chain operations, enabling informed strategic decision-making and better resource allocation.

In conclusion, integrating yard management systems with other supply chain software solutions such as transportation management and warehouse management systems has the potential to significantly enhance the overall performance and visibility of logistics processes. This integration leads to more efficient communication, better planning, and improved cost savings. Ultimately, these advantages enable organizations to deliver better services to their customers while minimizing operational complexities and costs.

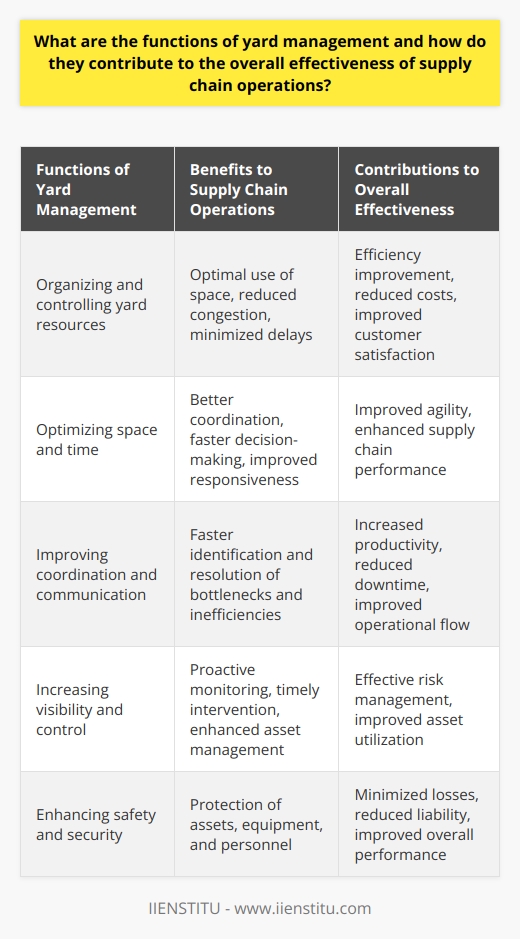

What are the functions of yard management and how do they contribute to the overall effectiveness of supply chain operations?

Function of Yard Management

Yard management facilitates the efficient movement of goods within a company's premises, playing a crucial role in supply chain operations. The primary function of yard management involves the organization and control of the yard resources, such as trailers, containers, workforce, and equipment. This is achieved through the monitoring, tracking, and scheduling of inbound and outbound transportation as well as allocating appropriate parking spaces and maintaining yard security.

Optimization of Space and Time

An effective yard management system ensures optimal use of available space, providing visibility of assets and equipment within the yard. This helps in reducing congestion, minimizing delays, and lowering dwell times. Consequently, an efficient yard management system contributes to decreasing cycle time for assets, reducing operational costs, and improving overall profitability for businesses.

Improved Coordination and Communication

Another crucial function of yard management is to foster better coordination and communication among supply chain stakeholders, such as carriers, shippers, and warehouse personnel. This is achieved by streamlining the flow of information and eliminating communication barriers. As a result, supply chain operations become more proactive, with faster and more accurate decision-making, ultimately enhancing supply chain responsiveness and agility.

Increased Visibility and Control

Yard management systems provide real-time visibility of assets and operations within the yard. This increased transparency enables companies to have better control over their assets, which in turn contributes to improved inventory management and resource allocation. Additionally, enhanced visibility allows for the proactive identification and resolution of potential bottlenecks and inefficiencies, ensuring seamless supply chain operations.

Enhanced Safety and Security

A well-managed yard ensures enhanced safety and security of assets, equipment, and personnel. This is achieved through enforcing access control, monitoring truck movements, and ensuring compliance with safety regulations. A safe and secure yard environment not only minimizes damage and losses but also reduces the likelihood of accidents, thus positively impacting overall supply chain performance.

In conclusion, yard management is a vital aspect of supply chain operations, with functions that contribute significantly to the overall effectiveness of supply chain operations. By optimizing space and time, improving coordination and communication, increasing visibility and control, and enhancing safety and security, yard management systems enable businesses to achieve greater efficiency, responsiveness, and profitability.

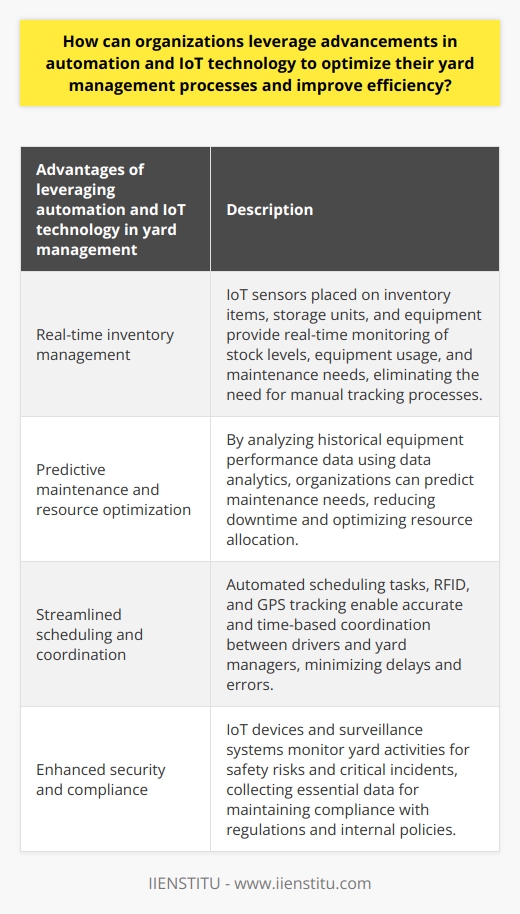

How can organizations leverage advancements in automation and IoT technology to optimize their yard management processes and improve efficiency?

Leveraging Automation and IoT for Yard Management

Benefits of Integration

Organizations can optimize their yard management processes and improve efficiency by leveraging advancements in automation and the Internet of Things (IoT) technology. This involves integrating sensors, devices, and software systems to streamline routine tasks, such as tracking inventory, monitoring equipment, and scheduling deliveries.

Real-time Inventory Management

A key advantage of embracing automation and IoT in yard management is real-time inventory management. More specifically, IoT sensors can be placed on inventory items, storage units, and equipment, enabling organizations to monitor stock levels, equipment usage, and maintenance needs. This real-time monitoring not only eliminates manual tracking processes but also enhances decision-making by providing accurate and up-to-date information.

Predictive Maintenance and Resource Optimization

Automation and IoT technology can also lead to efficient resource allocation and predictive maintenance. For instance, organizations can use data analytics to examine historical equipment performance, allowing them to predict when machinery might require maintenance. This leads to reduced downtime and improved equipment longevity. Moreover, IoT devices can facilitate the prioritization of resources, ensuring the smooth functioning of yard operations.

Streamlining Scheduling and Coordination

In addition to inventory and equipment management, automation and IoT can significantly improve scheduling and coordination processes. For example, Radio Frequency Identification (RFID) and GPS tracking can be employed to coordinate deliveries and pickups. These technologies automate scheduling processes and ensure accurate and time-based coordination between drivers and yard managers, minimizing delays and errors.

Enhancing Security and Compliance

One unique aspect of incorporating automation and IoT into yard management is the reinforcement of security and compliance. IoT devices and surveillance systems can be deployed to monitor yard activities for safety risks and possible critical incidents. Moreover, these devices can collect essential data to help organizations maintain compliance with regulations or internal policies.

In conclusion, employing automation and IoT technology in yard management provides organizations with a plethora of benefits. From real-time inventory management to streamlined scheduling, these advancements allow businesses to optimize their yard operations and maximize efficiency. Furthermore, they also enhance security and compliance, presenting a holistic approach to modernizing yard management processes.

What factors should be considered when integrating yard management systems with other supply chain software solutions, such as transportation and warehouse management, for enhanced visibility and performance?

Integration Considerations

When integrating yard management systems with other supply chain software solutions such as transportation and warehouse management, several factors must be considered for enhanced visibility and performance. These factors include compatibility, scalability, data accuracy, and real-time information exchange.

Compatibility and Integration

A crucial factor to consider is the compatibility of different software systems. The yard management system should seamlessly integrate with existing transportation and warehouse management software to avoid data inconsistencies and ensure smooth end-to-end supply chain operations. This requires evaluating the application programming interfaces (APIs) and data formats supported by the systems to ensure easy data exchange.

Scalability of Systems

Another essential factor is the scalability of the software systems. A scalable solution can cater to the evolving needs of a business as it expands, grows, and faces fluctuating market demands. This means that the yard management system, as well as the transportation and warehouse management systems, should be robust and flexible enough to accommodate growth and handle increased operational complexities without affecting performance.

Data Accuracy and Quality

The quality and accuracy of data exchanged between the systems play a pivotal role in the overall effectiveness of supply chain operations. Accurate, consistent, and up-to-date data is vital for making informed and timely business decisions. Therefore, organizations must ensure that their software systems support accurate and efficient data sharing to prevent errors and discrepancies that may negatively impact supply chain performance.

Real-time Information Exchange

Lastly, it is crucial to consider the ability of the systems to exchange information in real-time. Real-time information sharing enables better visibility across the entire supply chain. It allows organizations to make more informed and timely decisions, optimize resource allocation, and improve overall operational efficiency. This can be achieved by ensuring that the yard management system provides real-time data to transportation and warehouse management systems through seamless integration and effective communication protocols.

In conclusion, to enhance visibility and performance across the supply chain, organizations must consider factors such as compatibility, scalability, data accuracy, and real-time information exchange when integrating yard management systems with transportation and warehouse management software. Considering these factors allows businesses to optimize their supply chain operations effectively, leading to increased efficiency and improved decision-making processes.

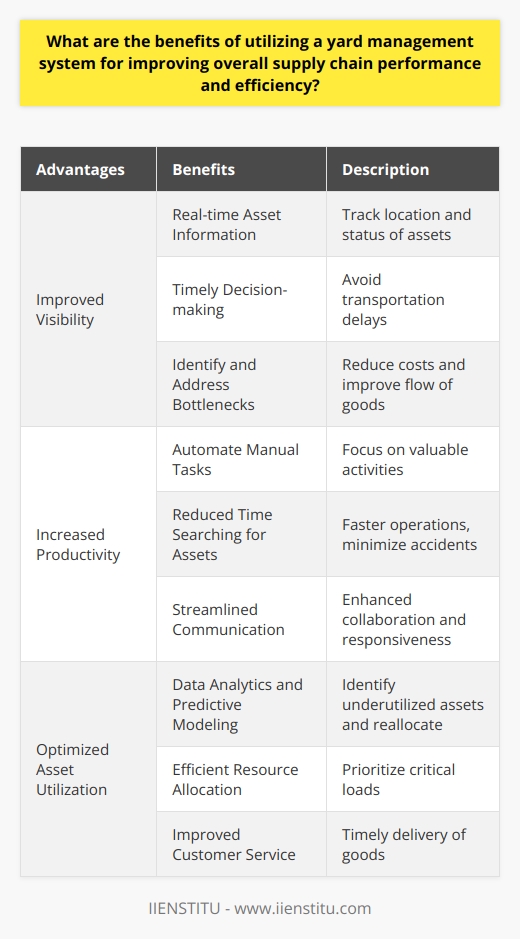

What are the benefits of utilizing a yard management system for improving overall supply chain performance and efficiency?

**Yard Management System Advantages**

Yard management systems (YMS) provide numerous benefits that contribute to enhancing the overall performance and efficiency of the supply chain. These advantages can be grouped into three main areas: improved visibility, increased productivity, and optimized asset utilization.

**Improved Visibility**

A significant benefit of using a YMS is the enhanced visibility it offers into the location and status of assets within the yard, such as trailers, containers, and equipment. This real-time information allows for timely decision-making and prevents delays in the transportation process. By monitoring asset movements, businesses can identify and address bottlenecks, ultimately reducing costs and improving the flow of goods through the supply chain.

**Increased Productivity**

Effective yard management systems also help to improve labor productivity. By automating manual tasks, such as yard checks and data entry, employees can focus on higher-value activities. A YMS also reduces the time spent by drivers searching for trailers or containers, which not only speeds up operations but also minimizes the risk of accidents. Furthermore, streamlined communication features within a YMS facilitate collaboration between departments, resulting in a more agile and responsive workforce.

**Optimized Asset Utilization**

Lastly, a yard management system allows organizations to optimize the use of their assets, including trailers, containers, and equipment. Through data analytics and predictive modeling, businesses can identify underutilized assets and reallocate them as needed. Additionally, a YMS can help in enhancing resource allocation by identifying and prioritizing critical loads. This ability to prioritize shipments supports a more efficient use of assets and leads to improved customer service through timely delivery of goods.

In summary, the employment of a yard management system offers significant advantages in improving overall supply chain performance and efficiency. Improved visibility, increased productivity, and optimized asset utilization are just a few of the key benefits businesses can achieve through the adoption of a YMS. By leveraging these technologies, organizations can streamline their operations and enhance the overall effectiveness of their supply chain management strategy.

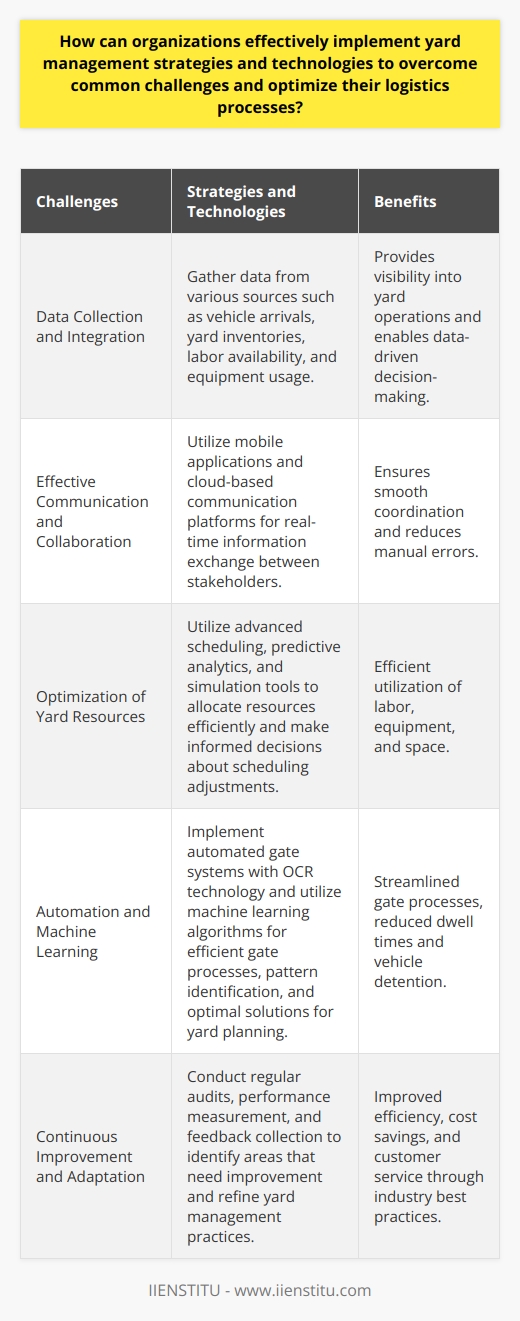

How can organizations effectively implement yard management strategies and technologies to overcome common challenges and optimize their logistics processes?

Yard Management Strategies and Technologies

To effectively implement yard management strategies and technologies, organizations should address key challenges and optimize their logistics processes. A comprehensive yard management system (YMS) can play a vital role in achieving greater efficiency, visibility, and control over yard operations.

Data Collection and Integration

The first step towards implementing a YMS is the collection and integration of data from various internal and external sources. Incorporating reliable data on vehicle arrivals, real-time yard inventories, labor availability, and equipment usage can enable organizations to have full visibility over their yard operations and make data-driven decisions.

Effective Communication and Collaboration

Effective communication and collaboration between various stakeholders, such as drivers, yard managers, and warehouse personnel, are crucial for successful yard management. Technologies such as mobile applications and cloud-based communication platforms can help facilitate real-time information exchange, ensuring smooth coordination and reducing manual errors.

Optimization of Yard Resources

Yard management strategies should also involve the optimization of yard resources, such as labor, equipment, and space. Utilizing advanced scheduling, predictive analytics, and simulation tools can help allocators and yard managers in making informed decisions related to yard resource allocation and schedule adjustments.

Automation and Machine Learning

To address common challenges such as dwell times and vehicle detention, organizations can leverage automation and machine learning (ML) technologies. Automated gate systems equipped with optical character recognition (OCR) can fast-track gate processes, while machine learning algorithms can identify patterns and propose optimal solutions for yard planning and execution.

Continuous Improvement and Adaptation

Finally, organizations should continuously monitor and improve their yard management strategies and technologies to adapt to changing conditions, such as increased demand, seasonal fluctuations, or the introduction of new transportation regulations. Regular audits, performance measurement, and feedback collection can help organizations in identifying areas that require improvement and refining their yard management practices in accordance with best industry standards.

In conclusion, an effective yard management system encompasses data collection and integration, communication and collaboration, optimization of yard resources, automation and machine learning, and continuous improvement and adaptation. By actively addressing these aspects, organizations can overcome common challenges and optimize their logistics processes, ultimately leading to increased efficiency, cost savings, and better customer service.

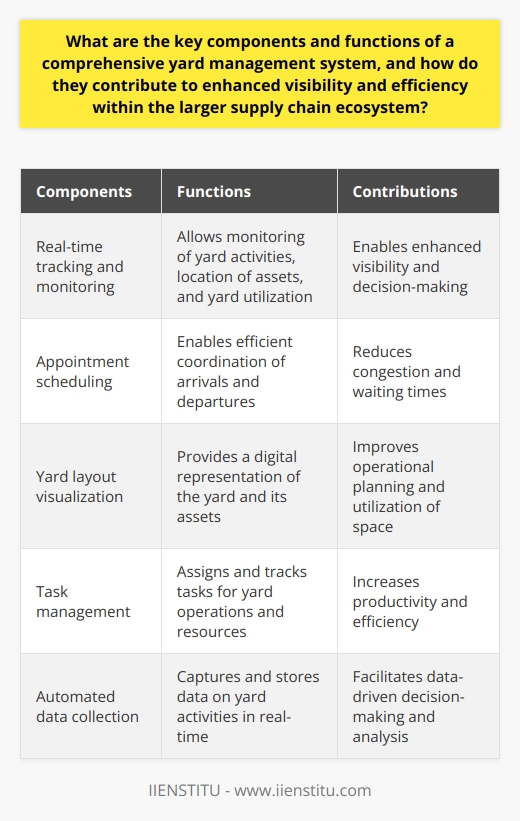

What are the key components and functions of a comprehensive yard management system, and how do they contribute to enhanced visibility and efficiency within the larger supply chain ecosystem?

Yard Management System Components

A comprehensive yard management system (YMS) comprises of various key components that are crucial for maintaining visibility and efficiency throughout the larger supply chain ecosystem. These components include real-time yard visibility, asset tracking and identification, optimized yard operations, and seamless integration with other supply chain systems.

Real-time Yard Visibility

Real-time yard visibility is a crucial component of a comprehensive YMS, enabling constant monitoring and tracking of assets within the yard. This ensures that supply chain stakeholders have up-to-date information on inventory levels, container locations, and vehicle movements, thus reducing the chances of misplacement or delays in shipments.

Asset Tracking and Identification

Efficient asset tracking and identification is essential for managing yard operations and maintaining adequate inventory control. A comprehensive YMS employs advanced technologies such as radio frequency identification (RFID) and global positioning systems (GPS) for accurately locating and identifying assets. This eliminates manual tracking processes, thereby reducing human error, labor costs, and improving overall operational efficiency.

Optimized Yard Operations

A comprehensive YMS is designed to streamline yard operations by automating routine tasks and facilitating informed decision-making. This includes optimizing asset movements, scheduling activities, and allocating resources based on real-time data. Enhanced visibility of yard operations allows managers to identify bottlenecks and implement proactive measures to mitigate potential issues, leading to improved efficiency and reduced turnaround times.

Seamless Integration with Supply Chain Systems

To maximize its potential, a comprehensive YMS must integrate seamlessly with other supply chain systems such as warehouse management systems (WMS) and transportation management systems (TMS). This integration enables the flow of real-time data across various stages of the supply chain, leading to informed decisions and enhanced visibility. Moreover, a well-integrated YMS contributes to the overall agility of the supply chain, allowing companies to adapt to evolving market demands and maintain a competitive edge.

In conclusion, the key components of a comprehensive yard management system work in unison to enhance visibility and operational efficiency within the larger supply chain ecosystem. By implementing a robust YMS, companies can optimize their yard operations, reduce costs, and improve overall supply chain performance.

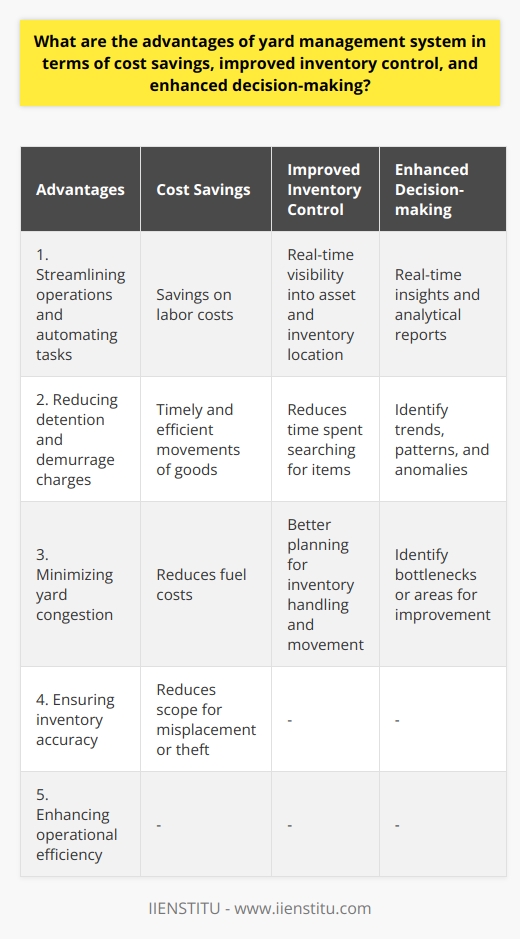

What are the advantages of yard management system in terms of cost savings, improved inventory control, and enhanced decision-making?

Advantages of Yard Management System

Cost Savings

Yard management systems (YMS) can significantly contribute to cost savings. These systems streamline operations, reducing the necessity for manual work. The yield is notable savings on labor costs. Further, they minimize detention and demurrage charges as efficient operations mean fewer delayed shipments. Lastly, by minimizing yard congestion, they decrease fuel costs resulting from idle vehicles.

Improved Inventory Control

Efficient inventory management remains a crucial aspect of logistics. YMS plays a pivotal role in enhancing inventory control, providing real-time visibility into the location of assets and inventories within the yard. This feature reduces the time spent searching for items. The system also enables real-time tracking, ensuring inventory accuracy and limiting scope for misplacement or theft.

Enhanced Decision-making

YMS contributes significantly to improving decision-making. By providing real-time insights and analytical reports, it allows managers to make better-informed decisions. They can easily identify trends, patterns, and anomalies within the yard operations. All these insights enable them to make data-driven decisions to enhance operational efficiency.

In conclusion, a yard management system is fundamental for logistics operations. Its benefits, including cost savings, improved inventory control, and enhanced decision-making cannot be underestimated. Investing in a robust YMS is thereby a strategic decision towards efficient, cost-effective operations.

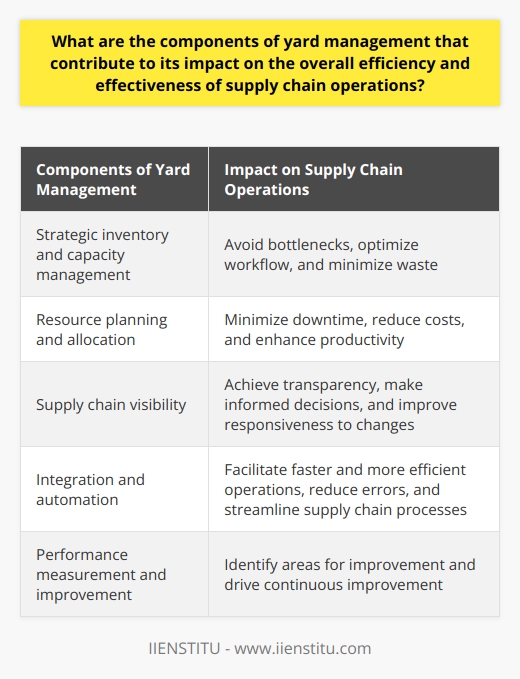

What are the components of yard management that contribute to its impact on the overall efficiency and effectiveness of supply chain operations?

Inventory and Capacity Management

Effective yard management encompasses inventory and capacity management. It involves regulating stock and available space in a swift and proficient manner. Through it, organizations avoid bottlenecks, optimize workflow, and minimize waste.

Resource Planning and Allocation

Resource planning and allocation form the backbone of efficient and agile supply chain operations. Yard management ensures resource readiness, availability, and optimal use. Thus, it minimizes downtime, reduces costs, and enhances productivity.

Supply Chain Visibility

Visibility over the entire supply chain process significantly impacts overall efficiency and effectiveness. Yard management systems facilitate real-time visibility into supply chain operations. This allows for transparency, informed decision-making, and improved responsiveness to changes.

Integration and Automation

Integration with other supply chain components and automation plays a crucial role in yard management. Seamless integration ensures smooth transitions between stages, facilitating faster and more efficient operations. At the same time, automation eliminates manual processes, reducing errors and improving speed.

Performance Measurement and Improvement

Performance measurement and continuous improvement are integral parts of yard management. Supply chain efficiency and effectiveness rely on robust metric systems that gauge performance. Consequently, yard management incorporates these measures, highlights areas needing change, and drives continuous improvement.

In conclusion, yard management impacts supply chain operations through strategic inventory and capacity management, careful resource planning and allocation, enabling supply chain visibility, ensuring integration and automation, and facilitating performance measurement and improvement. By focusing on these components, organizations can enhance the efficiency and effectiveness of their supply chain operations.

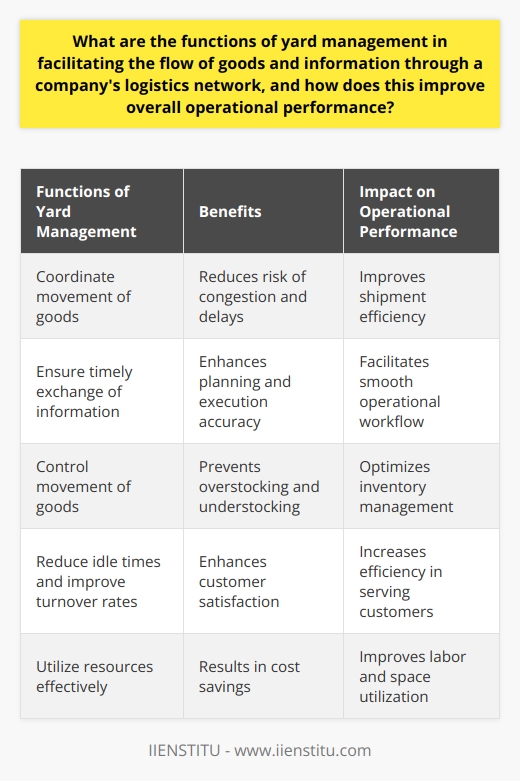

What are the functions of yard management in facilitating the flow of goods and information through a company's logistics network, and how does this improve overall operational performance?

Effective Coordination of Goods

One pivotal function of yard management is orchestrating the efficient movement of goods. Through careful organization and oversight, yard management ensures a smooth flow of shipments from arrival to departure. The deployment of assets like trailers, efficiently, mitigates the risk of congestion and delays.

Timely Exchange of Information

Another critical role played by yard management is ensuring timely information exchange. This covers communicating accurate arrival and departure times, shipment contents and destinations to all relevant stakeholders. As a result, operational departments are always abreast with the latest updates, enhancing their ability to plan and execute tasks accurately.

Accurate Inventory Management

Yard management also significantly contributes to accurate inventory management. By controlling the movement of goods, yard management helps in maintaining an accurate tally of available stock. It thus prevents overstacking and understocking situations, leading to customer satisfaction and minimizing losses due to expired or obsolete inventory.

Improvements in Operational Performance

In terms of enhancing operational performance, yard management helps in reducing idle times and improving turnover rates. Efficient stock flow and accurate information exchange enable the company to serve customers faster, improving customer satisfaction as well as the company's credibility. Moreover, with reduced congestion, resources such as labor and space are utilized more effectively, leading to cost savings.

Therefore, yard management plays an instrumental role in enabling an optimized flow of goods and information. Its benefits are reflected in a company's improved operational performance, customer service, and ultimately, its bottom line.