Inventory management—it's something that seems straightforward on the surface, yet when you dive into it, it can feel like untangling a ball of yarn. I remember visiting my grandfather's workshop as a kid. He had a small hardware store, and everything had its place. He knew exactly how many screws or nails were in each drawer. "You keep tabs on your stock, and it'll keep tabs on your business," he'd say with a wink.

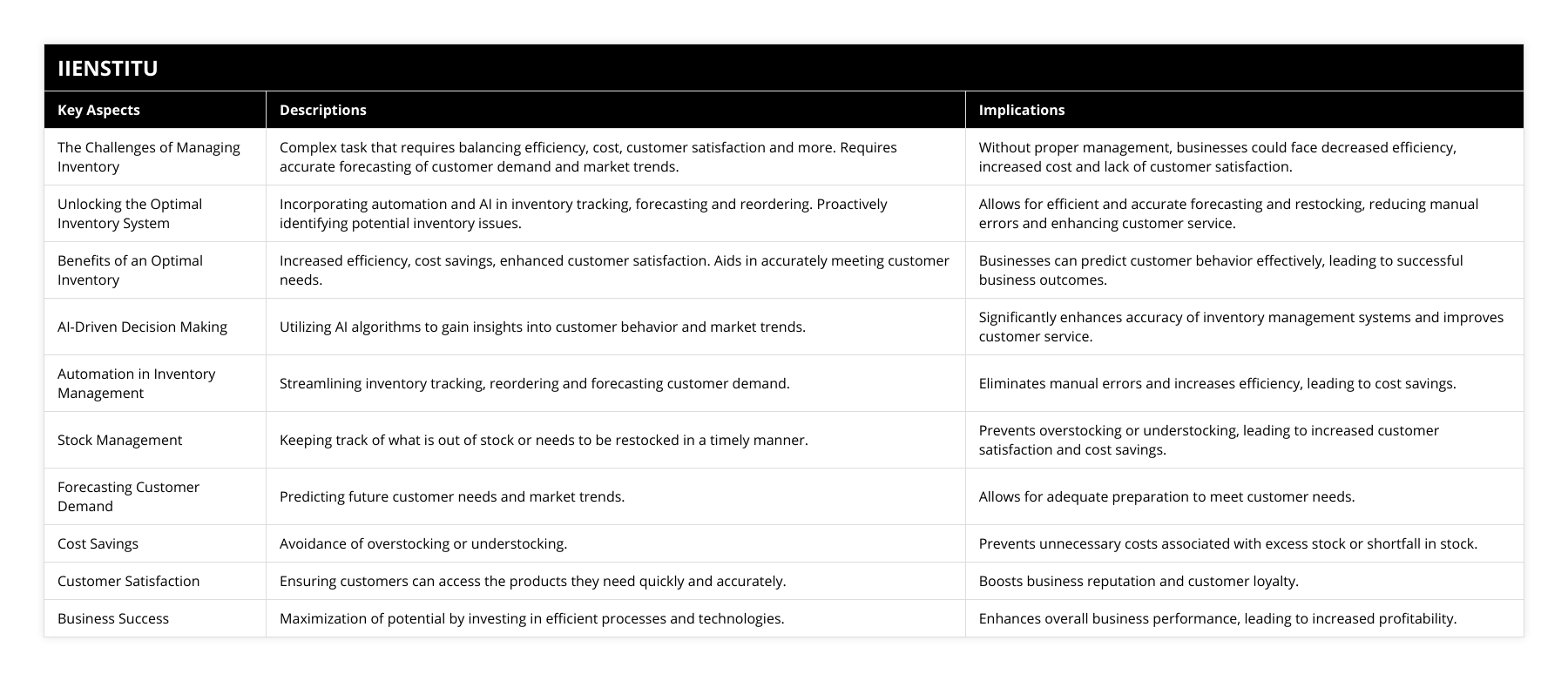

The Challenges of Managing Inventory

Unlocking the Optimal Inventory System

Benefits of an Optimal Inventory

Fast forward to today, and businesses are dealing with inventories that are infinitely more complex. The days of tallying items by hand are long gone, replaced by sophisticated systems that track, predict, and optimize every aspect of inventory management.

The Complexities of Modern Inventory Management

Managing inventory in the modern world isn't just about counting what's on the shelves. It's an intricate dance of ensuring products are where they need to be, when they need to be there, all while minimizing costs and maximizing efficiency. It's a juggling act between supply and demand, one that can make or break a business.

Take, for example, the implementation of just in time (JIT) inventory systems. The philosophy of JIT is to reduce lead time and eliminate excess inventory by receiving goods only as they are needed in the production process. It's brilliant in theory but challenging in practice. I recall working with a manufacturing company that tried to adopt JIT without proper planning. The result? Production halted because key components didn't arrive just and time, leading to frustrated customers and frantic phone calls to suppliers.

The Hidden Costs of Mismanaged Inventory

When inventory isn't managed properly, the consequences can be severe:

Increased holding costs due to overstocked items.

Lost sales from out-of-stock products.

Damaged customer relationships from unmet expectations.

Inefficiencies that ripple through the entire supply chain.

A friend of mine, Laura, owned a thriving online bookstore. She prided herself on her curated selection. However, without a robust inventory monitoring system, she struggled to keep popular titles in stock while slow-moving books gathered dust. Eventually, customers started shopping elsewhere, and her sales plummeted—a painful lesson in inventory mismanagement.

Unlocking the Path to Optimal Inventory Management

So, what's the secret sauce to mastering inventory? It's about leveraging technology, embracing data, and never underestimating the human touch.

Harnessing Technology and Automation

In today's fast-paced world, manual processes just don't cut it anymore. Automation is no longer a luxury; it's a necessity. By integrating systems that handle:

1- Real-time inventory tracking

2- Automated reordering processes

The key to excellent performance is making informed inventory decisions.

3- Predictive analytics for forecasting

Businesses can stay ahead of the curve. Consider inventory mgmt software that syncs with sales platforms, providing up-to-the-minute data on stock levels. This minimizes human error and frees up time for employees to focus on more strategic tasks.

The Power of AI and Data Analytics

Artificial Intelligence (AI) isn't about robots taking over; it's about enhancing our capabilities. AI can analyze massive amounts of data to:

Predict customer demand with uncanny accuracy.

Optimize reorder points to reduce inventory costs.

Identify trends that might be invisible to the human eye.

An e-commerce company I consulted for used AI to sift through their sales data. They discovered that certain products spiked in popularity during specific times of the year, something they hadn't noticed before. By adjusting their inventory accordingly, they boosted sales and reduced excess stock.

Streamlining the Supply Chain

Efficiency doesn't stop at the warehouse door. Optimizing the entire supply chain is crucial. Some tips to optimize supply chain management processes include:

Building strong relationships with reliable suppliers.

Implementing cross-docking to reduce storage time.

Utilizing jit management to synchronize production schedules.

The Human Element

While technology provides tools and data, it's people who make decisions. Training staff to understand and utilize these tools is essential. Empower your team to take ownership of inventory processes, and you'll foster a culture of continuous improvement.

The Tangible Benefits of Optimal Inventory Systems

Embracing optimal inventory and inventory management practices isn't just about avoiding pitfalls; it's about reaping rewards.

Cost Savings

By reducing excess inventory and minimizing stockouts, businesses can significantly cut costs. Holding inventory ties up capital and incurs storage expenses. Efficient management frees up resources that can be invested elsewhere.

Improved Customer Satisfaction

Nothing frustrates a customer more than a product being out of stock. By ensuring high-demand items are always available, businesses can enhance the customer experience, leading to repeat sales and positive word-of-mouth.

Better Decision Making

With accurate, real-time data at their fingertips, managers can make informed decisions that drive the business forward. Whether it's expanding product lines or entering new markets, solid inventory data provides the foundation for strategic planning.

Practical Steps to Enhance Inventory Management

Implementing an optimal inventory system doesn't happen overnight, but there are actionable steps businesses can take:

1- Assess Current Systems: Understand what's working and what's not.

2- Invest in Technology: Choose systems that align with business needs.

3- Train Staff: Ensure everyone knows how to use new tools effectively.

4- Monitor and Adjust: Regularly review performance and make necessary tweaks.

Avoiding Inventory Mismanagement

Preventing inventory mismanagement requires vigilance and proactive strategies:

Set Clear KPIs: Define metrics like turnover rates and fill rates.

Perform Regular Audits: Catch discrepancies before they become problems.

Engage with Suppliers: Open communication can prevent delays.

The Road Ahead: Embracing the Future of Inventory Management

As industries evolve, so too must inventory practices. Emerging technologies like blockchain and IoT devices offer exciting possibilities for even greater efficiency and transparency.

The Role of Blockchain

Blockchain technology can enhance supply chain transparency, allowing all parties to track products from origin to destination. This can reduce fraud, improve compliance, and build trust with consumers.

Internet of Things (IoT)

IoT devices, such as smart shelves and sensors, can provide real-time data on inventory levels without manual intervention. Imagine a system where products communicate their status, ensuring that nothing slips through the cracks.

Conclusion

Optimal inventory management is more than just a business function; it's a competitive advantage. By blending technology with human insight, businesses can navigate the complexities of modern supply chains and set themselves up for long-term success.

As my grandfather wisely said, "Look after your stock, and your stock will look after you." In today's terms, that means investing in the right systems, processes, and people to ensure your inventory works for you, not against you.

References

1- Ballou, R. H. (2004). Business Logistics/Supply Chain Management. Pearson Education.

2- Christopher, M. (2016). Logistics & Supply Chain Management. Pearson UK.

3- Heizer, J., & Render, B. (2014). Operations Management. Pearson Education Limited.

4- Krajewski, L. J., Ritzman, L. P., & Malhotra, M. K. (2013). Operations Management: Processes and Supply Chains. Pearson.

5- Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (2008). Designing and Managing the Supply Chain: Concepts, Strategies, and Case Studies. McGraw-Hill.

Frequently Asked Questions

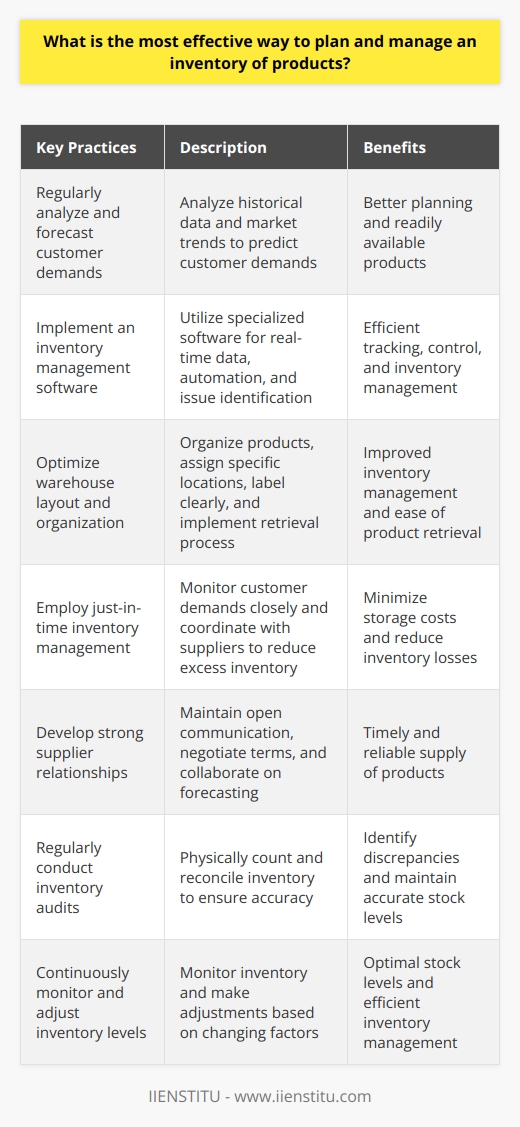

What is the most effective way to plan and manage an inventory of products?

Having an inventory management system is essential for a business to succeed. This system's effectiveness relies on the plan's quality, implementation, and continued management. Proper planning and management of an inventory are critical to driving economic, cost-effective operations.

Planning is the foundation of any successful inventory management system. The process entails identifying the right products to stock, predicting the right amounts, and identifying the correct locations. With appropriate planning, the inventory will ensure efficient operations while keeping overhead costs in check.

A crucial part of effective inventory planning is forecasting and demand management. Forecasting helps to identify how much inventory needs to be stocked and when allowing for efficient restocking practices. This can be done through trending customer demands and systematic data analysis. Knowing what customers need and when they need it can help to avoid over and understocking.

In addition, proper inventory management requires control of stock levels in all locations. An inventory control system can track and manage the inventory of different internal and external warehouses. An inventory control system makes monitoring and adjusting stocking levels easier to ensure the correct items are available in suitable locations at the right time.

The most effective way to manage an inventory of products is to implement a comprehensive inventory management system that combines planning, forecasting, demand management, and inventory control. This system should be based on customer demands, previous trends, market forecasts, and inventory control software. By implementing this system, businesses can ensure that the right products are available, in the right quantities, in the suitable locations, and at the right time. This can help drive down costs and increase efficiency.

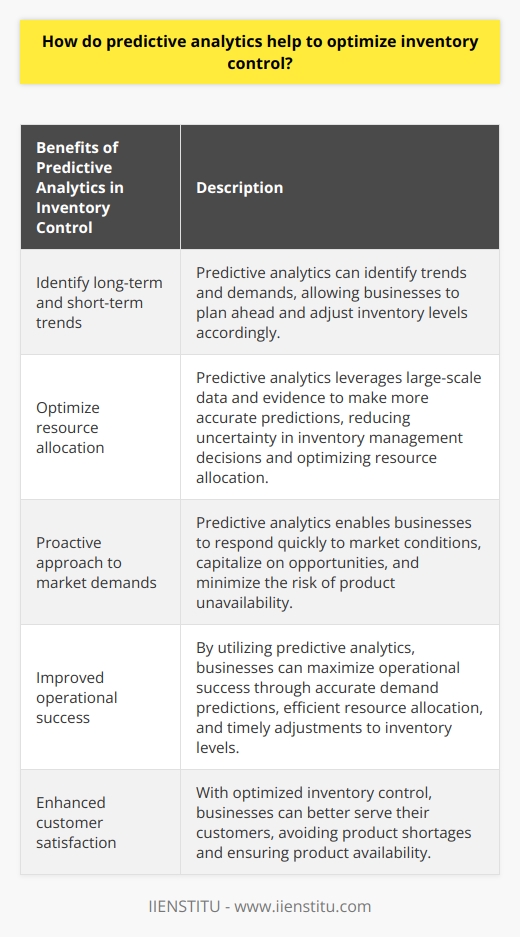

How do predictive analytics help to optimize inventory control?

Data is rapidly becoming the cornerstone of informed decision-making in the modern market. Predictive analytics, which has evolved from increasingly efficient data collection and analysis, can maximize potential outcomes, often through optimizing inventory control. By leveraging the insights derived from predictive analytics, businesses can more accurately assess the optimal inventory levels to meet the demands of the marketplace.

Predictive analytics requires the collection of data, often through the use of intelligent software programs and databases. This data can include operational factors such as sales histories and supply chain data, as well as external factors such as market conditions and customer preferences and behaviors. Through analyzing this data, predictive analytics helps identify the likely future demand for products, allowing for fine-tuned decisions relating to inventory control.

Inventory control should be adjusted based on long-term and short-term trends and demands for maximum benefit. Predictive analytics is ideally suited for this due to its ability to differentiate between regular and unique needs, and predict and anticipate potential problems, thus allowing businesses to plan accordingly. Additionally, companies can more efficiently purchase and distributes resources, helping to manage cash flow and working capital more effectively.

Predictions are more reliable and accurate as predictive analytics leverages high-volume and large-scale evidence and data points. This decrease in uncertainty allows businesses to allocate resources under their expected needs rather than invoking a strategy of guesswork.

Overall, predictive analytics represents a significant advancement in the capacity for understanding the marketplace and, ultimately, for making sound inventory control decisions. By taking a proactive stance on inventory control, businesses can respond quickly, capitalize on opportunities, and minimize the risk of product unavailability, thus maximizing their operational success.

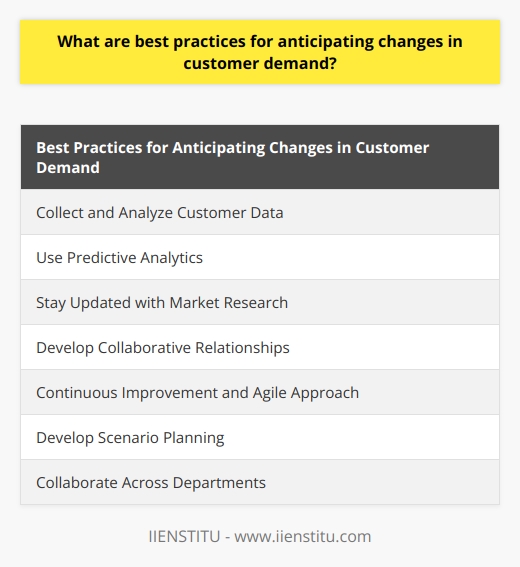

What are best practices for anticipating changes in customer demand?

Anticipating changes in customer demand is a critical skill for any business. Accurately predicting customer needs and wants can help companies to stay ahead of the competition, maximize profits, and provide better customer service. The following are some best practices for forecasting customer demand:

Understand the customer: Businesses should be aware of the needs and preferences of the customer, the competitive landscape, the current and future market trends, and how their customers may react in the future. By understanding the customer and their needs, businesses can be better prepared to meet changing customer demands.

Analyze internal data: An analysis of internal data can provide valuable insights and information about customers, their spending habits, and their preferences. Leveraging this data can help businesses create a detailed understanding of their customer base and anticipate changes in customer demand.

Monitor external factors: Businesses should also be aware of external trends, such as industry news, customer feedback, and new product introductions. Monitoring these external factors can help businesses forecast changes in the market and remain competitive.

Leverage predictive analytics: Predictive analytics allows businesses to capture, integrate and analyze large amounts of data to improve their forecasting capability. By leveraging predictive analytics, companies can anticipate changes in customer demand and ensure that they are meeting the needs of their customers.

Test and refine forecasts: Businesses should also regularly test their predictions to remain accurate and current. By testing and refining the estimates, businesses can quickly adapt to changing customer demands and stay competitive.

By following these best practices, businesses can stay ahead of the competition and ensure they are meeting the needs of their customers. In addition, through understanding the customer and leveraging data, predictive analytics, and refining forecasts, businesses can anticipate changes in customer demand and remain competitive in the marketplace.

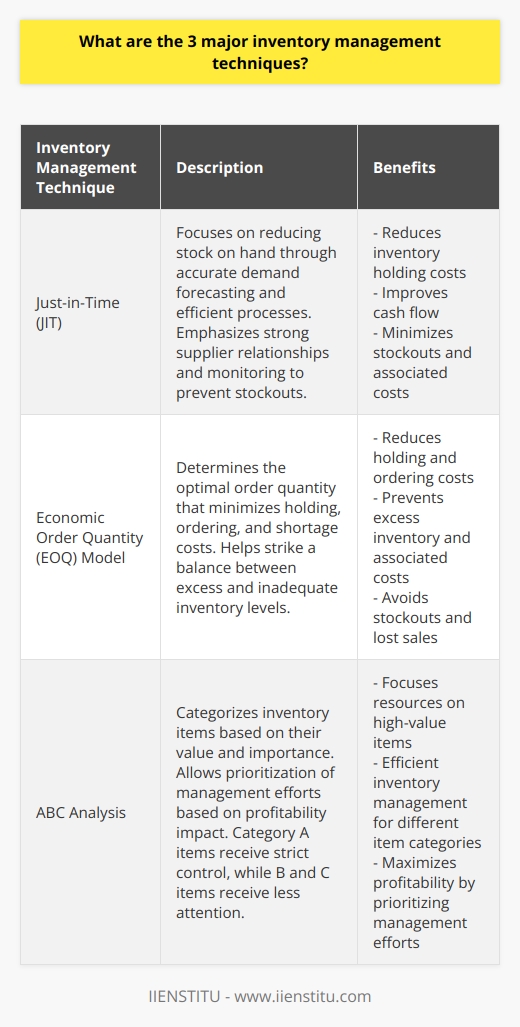

What are the 3 major inventory management techniques?

Three Major Inventory Management Techniques

Just-in-Time Inventory Management

The Just-in-Time (JIT) inventory management technique is a lean approach that aims to reduce the amount of stock held on hand and minimize carrying costs. This method is based on accurately forecasting demand and implementing efficient, streamlined processes to fulfill orders as they arrive. JIT emphasizes the need for strong supplier relationships and communication to ensure quick turnaround times, as well as continuous monitoring and improvement of stock levels to prevent stockouts.

Economic Order Quantity Model

Another widely used technique is the Economic Order Quantity (EOQ) model, which focuses on determining the optimal order quantity that minimizes the total costs of holding, ordering, and shortage expenses. The EOQ model involves calculating the ideal size and frequency of orders to optimize cost efficiency, based on factors such as demand, order costs, and holding costs. Implementing the EOQ model allows businesses to strike a balance between the costs associated with having too much or too little inventory on hand, ultimately helping to improve overall profitability.

ABC Analysis

The third major inventory management technique is ABC analysis, which involves categorizing inventory items based on their value and importance to the organization. This method assigns items to one of three categories; A, B, or C. Category A items are considered high value, with significant impact on overall profitability, and therefore require close monitoring and strict control. Category B items hold medium importance with moderate profit impact, while Category C items are low-value items with minimal effect on business performance. By prioritizing inventory management efforts and resources according to the ABC classification, organizations can ensure that high-impact items receive the necessary attention, while optimizing overall inventory management efficiency.

In conclusion, the three major inventory management techniques - Just-in-Time inventory management, Economic Order Quantity model, and ABC analysis - each provide businesses with valuable frameworks to optimize their stock levels, minimize costs, and maintain strong relationships with suppliers. Implementing one or a combination of these techniques can greatly improve an organization's inventory management practices and contribute to better performance and profitability.

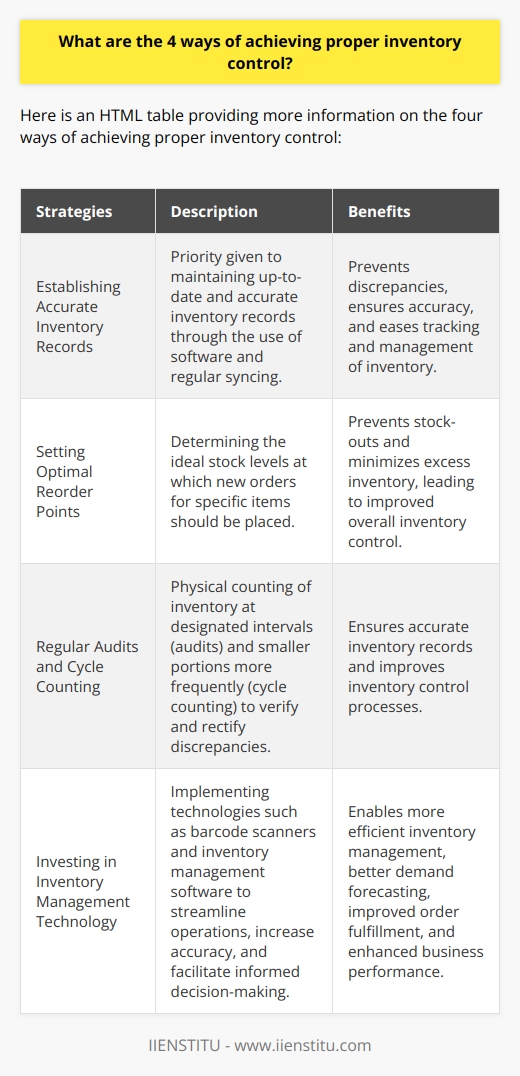

What are the 4 ways of achieving proper inventory control?

Establishing Accurate Inventory Records

One crucial way to achieve proper inventory control is by establishing accurate inventory records. Regularly updating and syncing these records prevents discrepancies, allowing businesses to maintain an up-to-date view of their stock levels. Incorporating inventory management software can also enhance accuracy and automate record-keeping processes.

Setting Optimal Reorder Points

The second essential way to achieve proper inventory control is to set optimal reorder points. This method involves determining the stock levels at which new orders for specific items should be placed. Calculating reorder points helps prevent stock-outs while also minimizing excess inventory. Factors to consider when determining reorder points include lead time, sales velocity, and desired safety stock levels.

Regular Audits and Cycle Counting

To ensure proper inventory control, it is vital to conduct regular audits and engage in cycle counting. Regular audits involve physically counting the inventory at designated intervals, such as quarterly or annually, to verify its accuracy. In comparison, cycle counting involves counting smaller portions of the inventory more frequently. This approach reduces the disruption caused by a full inventory count while enabling businesses to identify and correct discrepancies promptly.

Investing in Inventory Management Technology

Finally, investing in inventory management technology is an effective way to achieve proper inventory control. Utilizing technology, such as barcode scanners and inventory management software, enables businesses to streamline operations, increase accuracy, and make more informed decisions regarding inventory levels. Additionally, integrating technology into the inventory control process can lead to better demand forecasting, improved order fulfillment, and enhanced overall business performance.

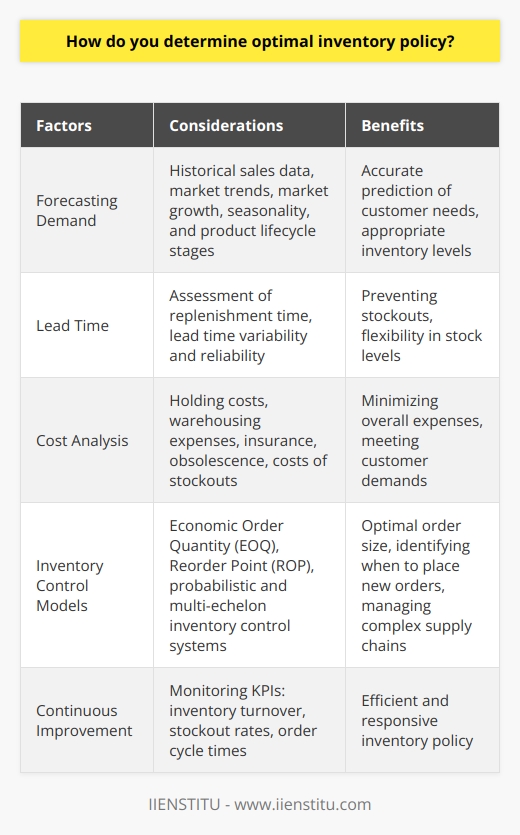

How do you determine optimal inventory policy?

**Determining Optimal Inventory Policy Factors**

The optimal inventory policy aims to balance the costs and benefits of holding inventory to minimize total costs while meeting customer demand. Determining an efficient inventory policy involves considering several factors such as demand, lead time, and holding costs.

**Demand Forecasting and Analysis**

An essential element in establishing an optimal inventory policy is accurately forecasting product demand. Utilizing historical sales data and analyzing market trends helps anticipate customer needs, allowing for appropriate inventory levels to be maintained. Additionally, considering factors like market growth, seasonality, and product lifecycle stages further fine-tunes demand forecasts.

**Lead Time Considerations**

Another crucial factor in determining an inventory policy is the lead time required to replenish stock. Longer lead times may necessitate carrying more inventory to prevent stockouts, while shorter lead times enable greater flexibility and lower stock levels. Moreover, considering the variability and reliability of lead times ensures a consistent buffer stock is maintained to mitigate unforeseen delays.

**Cost Analysis**

A comprehensive cost analysis is integral in devising an optimal inventory policy. This involves examining the costs associated with holding inventory, such as warehousing expenses, insurance, and obsolescence, and comparing them against the costs of stockouts, such as lost sales and customer dissatisfaction. Balancing these costs assists in establishing an inventory policy that minimizes overall expenses while fulfilling customer demand.

**Inventory Control Models**

Employing inventory control models further refines optimal inventory policy. Techniques like the Economic Order Quantity (EOQ) model calculate the optimal order size by minimizing holding and ordering costs, while the Reorder Point (ROP) model identifies when to place a new order based on demand and lead time. Additionally, using more advanced models like the probabilistic and multi-echelon inventory control systems can manage varying demand patterns and complex supply chains.

**Continuous Improvement**

Lastly, maintaining an optimal inventory policy requires continuous improvement and regular evaluation. Monitoring and analyzing key performance indicators such as inventory turnover, stockout rates, and order cycle times enables adjustments to be made as market conditions evolve, ensuring the inventory policy remains efficient and responsive.

In conclusion, determining an optimal inventory policy involves accurate demand forecasting, lead time considerations, comprehensive cost analysis, implementation of inventory control models, and a commitment to continuous improvement. Adopting a holistic approach that takes these factors into account ensures an inventory policy that minimizes costs and maintains customer satisfaction.