In an increasingly complex economic landscape, businesses constantly seek ways to optimize their operations and stay competitive. This pursuit has led to the adoption of sophisticated methods within the domain of supply chain management, key among them being Advanced Planning and Scheduling (APS).

As we delve into the intricacies of APS, we discover how it emerges as a pivotal element in the orchestration of supply chain activities, harmonizing demands with enterprise resources. The integration of APS systems has become quintessential for entities aiming to achieve agility, precision, and efficiency. The following exposition aims to elucidate the concept of APS, its significance in modern commerce, and the myriad ways in which businesses can harness its full potential.

Understanding Advanced Planning and Scheduling (APS)

Definition and explanation of APS

APS stands as a technological marvel, a comprehensive toolset designed to refine and elevate supply chain management to its zenith. It amalgamates a sophisticated array of algorithms, heuristics, and simulations to enable businesses to formulate tactical and operational plans meticulously.

These systems help firms anticipate market requirements, align production capacities, and manage inventory levels with unprecedented precision. They serve as the digital backbone that synchronizes various supply chain components, transforming a wealth of data into actionable insights and strategic foresight.

The role of APS in supply chain management

In the supply chain arena, APS functions as a maestro, directing a symphony of interconnected processes toward a harmonious output. It empowers enterprises to visualize their supply chains holistically, optimizing the flow of goods from raw materials to finished products. An online courses with certificates in APS equips professionals with the acumen needed to navigate the dense and intricate pathways of supply chain networks.

For example, a company implementing APS can dynamically adjust its production schedules in response to real-time sales data, mitigating the risk of stockouts or overproduction.

Difference between traditional scheduling and APS

Comparing traditional scheduling to APS is akin to contrasting a manual typewriter with a modern computer — both achieve the end goal of producing text, but with markedly different levels of efficacy and finesomeness. Traditional scheduling operates on a static timeline with limited ability to adapt to shifts in demand or supply chain disruptions.

Conversely, APS boasts a dynamic and holistic approach, factoring in myriad variables and constraints to produce a plan that is both robust and flexible. To illustrate, while traditional methods might falter during unexpected spikes in demand, APS rapidly recalibrates, ensuring productivity remains unhampered.

Key Components of APS

Demand planning and forecasting

At the heart of APS lies demand planning and forecasting, a clairvoyant mechanism that discerns the shape of market demand in forthcoming periods. Intricate algorithms harness historical sales data and market trends, and are increasingly augmented by artificial intelligence to heighten the foresight they deliver.

For instance, a retailer utilizing AI-driven APS could accurately predict seasonal fluctuations, thereby aligning inventory levels with consumer appetite, thereby obviating both surpluses and shortages.

Master Production Scheduling (MPS)

Central to the APS framework is the Master Production Scheduling (MPS) module, a strategic component that determines what should be produced, in what quantities, and at which juncture. It acts as a pivotal link between strategic business plans and actual shop floor operations, ensuring that production targets are attainable and perfectly attuned to resource availability.

By extrapolating from MPS, APS intertwines various operational aspects such as workforce capacity, raw material procurement, and machinery utilization, to construct a coherent production blueprint.

Detailed Scheduling and Planning

Zooming in from the MPS, detailed scheduling and planning is where APS gets granular, determining the exact sequence and timing of production activities. It serves as a tactical instrument, capable of orchestrating complex manufacturing operations with multiple constraints.

Its significance is underscored in high-precision industries where operational efficiency is not just a goal, but a prerequisite. Through intricate scheduling algorithms, APS paves the way for a streamlined production process that meets tight deadlines without compromising quality.

Benefits of Implementing APS

Improved efficiency and productivity

The enactment of APS within an enterprise ushers in a new epoch of operational efficiency and enhanced productivity. Empirical studies showcase quantifiable enhancements in throughput and a palpable reduction in cycle times after APS adoption. Manufacturing entities, once plagued by the inertia of legacy planning methodologies, find rejuvenation in leaner, more responsive production schedules that align closely with actual demand.

Enhanced customer satisfaction

Consumers, the ultimate arbiters of business success, stand to gain markedly from an APS-enabled company. The agility afforded by APS systems means that customer orders can be fulfilled more swiftly and with greater accuracy, fostering brand loyalty and repeat business. A comprehensive logistics certificate course often emphasizes the pivotal role of customer satisfaction within supply chain metrics, an area where APS provides substantial leverage.

Reduced operational costs

Cost-efficiency is another compelling argument for the assimilation of APS. By finetuning the production and distribution processes, businesses can substantially diminish inventory costs, minimize waste, and curtail excessive labor expenditures. Case studies frequently illuminate how the judicious application of APS can lead to a leaner, more cost-effective operation, delivering tangible savings to the bottom line.

Increased business competitiveness

Lastly, APS acts as a catalyst for competitive advantage in a fiercely contested market. Companies wielding the predictive power and operational dexterity afforded by APS find themselves ahead of the curve, swiftly adapting to market dynamics while their counterparts grapple with the inertia of outdated methods. Illustrations of this phenomenon are rife across industries, from automotive to electronics, where nimbleness and adaptability crown market leaders.

Challenges and Limitations of APS

Technological constraints

No advance in business methodologies comes devoid of challenges, and APS is no exception. The technological sophistication that underpins APS can also act as a barrier, as it necessitates robust IT infrastructure, which smaller firms may find daunting. Real-world examples highlight instances where businesses struggle with data integration and system compatibility issues during APS implementation.

Need for skilled professionals

Another impediment to the unfettered proliferation of APS is the scarcity of adept professionals. Mastery over APS systems requires a deep understanding of supply chain fundamentals, coupled with expertise in the software itself. There is a burgeoning demand for individuals who can bridge the gap between the theoretical framework of APS and its practical execution within business operations.

High setup costs

Furthermore, venturing into the APS landscape can entail considerable initial outlays. Companies often confront hefty investments in software licensing, infrastructure upgrades, and workforce training to lay the groundwork for an APS deployment. This substantial capital requirement can be prohibitive for smaller entities, though it is vital to consider such expenses as strategic investments that promise long-term dividends.

Adaptive Challenges

Even with all the right resources in place, the transition to an APS-centric operation is seldom frictionless. Firms must reckon with the inertia of established practices, as well as the resistance that often accompanies systemic change. Cultivating an organizational culture that embraces continuous improvement and adaptability is as much a part of APS success as the system's technical configuration.

Strategies for Successful APS Implementation

Selection of appropriate APS software

Embarking on the APS journey begins with the critical selection of software that aligns with the business's unique needs and constraints. Each APS solution presents its own suite of features, scalability options, and integration capabilities, thus demanding meticulous scrutiny.

Training and development of employees

Concomitant with software selection is the imperative of equipping the workforce with the skills necessary to harness APS to its full potential. Training programs should not be perfunctory; they need to instill not only technical know-how but also an understanding of how APS dovetails with broader business strategy.

Continuous monitoring and upgrading

APS is not a set-and-forget solution; it demands persistent monitoring and refinement. To stay attuned to the ever-evolving business landscape, firms must commit to regular reviews of their APS systems, updating parameters, and algorithms to reflect current realities.

Emphasizing on interdepartmental coordination

Lastly, APS's efficacy is contingent upon seamless cooperation among various business units. Siloed operations stand diametrically opposed to the integrative nature of APS. Therefore, fostering a culture of collaboration and transparency across departments is crucial for realizing the system's comprehensive benefits.

To encapsulate, Advanced Planning and Scheduling (APS) stands as a linchpin in the sophisticated machinery of contemporary supply chain management. Its relevance and utility in bolstering operational efficiency, customer satisfaction, cost-saving, and competitive fortitude cannot be overstated.

However, the journey to APS excellence is fraught with hurdles, ranging from technological requisites to organizational adaptability, which demand astute strategies and resolute commitment.

The businesses that navigate these waters successfully will emerge as paragons of supply chain innovation and examples to emulate in the 21st century. The future of APS awaits on the horizon, teeming with prospects as supply chains become more intricate and business environments continue to morph.

Those who invest in APS and its continuous refinement will likely find themselves ahead in the inexorable march toward operational excellence.

Frequently Asked Questions

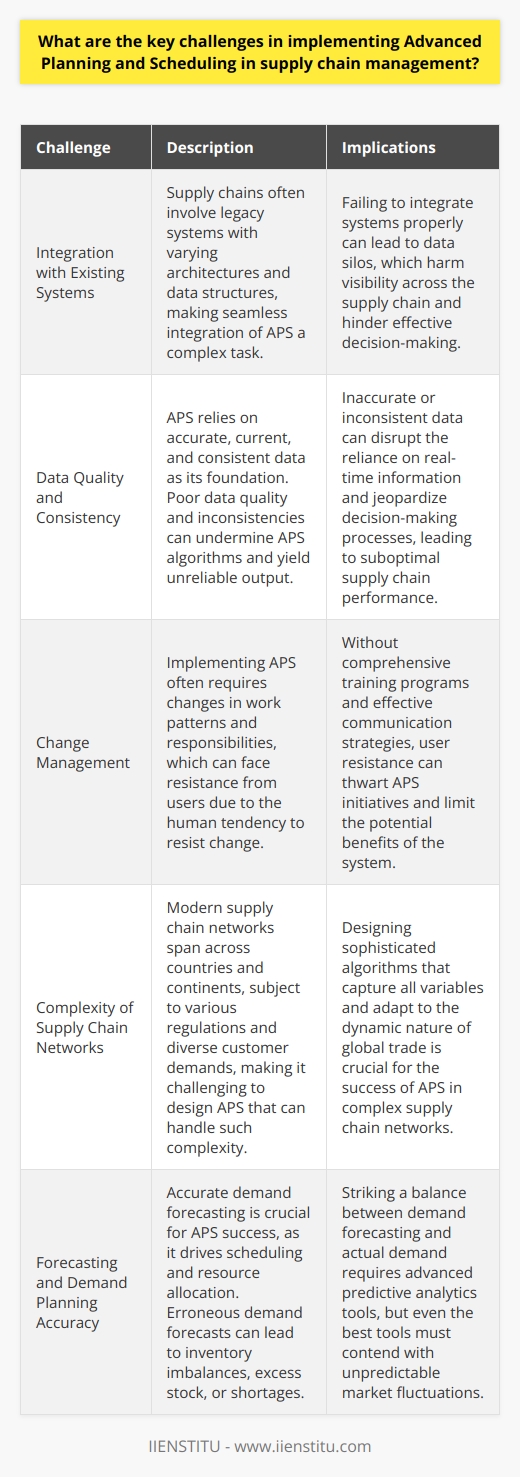

What are the key challenges in implementing Advanced Planning and Scheduling in supply chain management?

Understanding Advanced Planning and Scheduling

Advanced Planning and Scheduling (APS) systems represent a key solution. They aim to optimize supply chain management. This involves multiple complex processes. APS balances demand and supply. It plans resources effectively. Yet, implementing APS poses significant challenges.

Integration with Existing Systems

A notable challenge lies in system integration. Supply chains often involve legacy systems. These systems vary in architecture. They contain diverse data structures. Seamless integration of APS with these systems becomes crucial. It demands meticulous planning. It also requires robust data exchange protocols. Failing to integrate systems leads to data silos. These silos harm the visibility across the supply chain.

Data Quality and Consistency

Data serves as APS's foundation. The data must be accurate. It must be current. Moreover, data consistency is essential. Poor data quality undermines APS algorithms. It yields unreliable output. APS relies on real-time information. Inconsistencies disrupt this reliance. They jeopardize decision-making processes.

Change Management

Change management stands as another obstacle. APS implementation changes work patterns. It alters responsibilities. Resistance to change remains a human tendency. Encouraging user adoption thus becomes critical. This requires comprehensive training programs. It also requires effective communication strategies. Without these strategies, user resistance can thwart APS initiatives.

Complexity of Supply Chain Networks

Supply chain networks have grown in complexity. They span across countries and continents. They are subject to various regulations. Diverse customer demands also play a role. Designing APS to handle such complexity is not trivial. It demands sophisticated algorithms. These algorithms must capture all variables. They must also adapt to the dynamic nature of global trade.

Forecasting and Demand Planning Accuracy

Accurate demand planning is vital. It is core to APS success. Forecasts drive scheduling and resources allocation. Erroneous demand forecasts lead to inventory imbalances. They cause either excess stock or shortages. Striking a balance between demand forecasting and actual demand is challenging. It requires advanced predictive analytics tools. Yet, even the best tools must contend with unpredictable market fluctuations.

Managing Expectations of Stakeholders

Stakeholders expect tangible benefits. They look for cost savings. They want increased efficiency. Ensuring these stakeholders understand APS's value is tough. Setting realistic expectations is key. This involves clear communication. It also involves setting achievable timelines. It helps prevent disillusionment if initial results fall short of the promise.

Scaling with Business Growth

An APS system must be scalable. It must grow with the business. As companies evolve, so does their supply chain complexity. An APS must handle increased data volumes. It must manage more complex decision-making scenarios. This scalability requires flexible system architecture. It also requires continuous updates and enhancements.

Handling Variability and Uncertainty

Uncertainty is inherent in supply chains. Disruptions occur. These can be natural disasters. They can also be economic shifts. Variability in supplier performance exists. Managing this variability is critical. APS must be resilient. It must be able to adjust plans swiftly. It requires robust scenario planning capabilities. These capabilities allow for quick responses to unforeseen events.

Implementing APS in supply chain management is complex. It requires a clear strategy. It demands attention to integration and data quality. Change management plays a crucial role. Addressing the nuances of complex supply networks is vital. Accurate forecasting is a non-negotiable need. Transparency with stakeholders is mandatory. Scalability is to be kept in mind. Handling variability and uncertainty is indispensable. Overcoming these challenges paves the way for an efficient supply chain. It also allows for leveraging the full potential of APS systems.

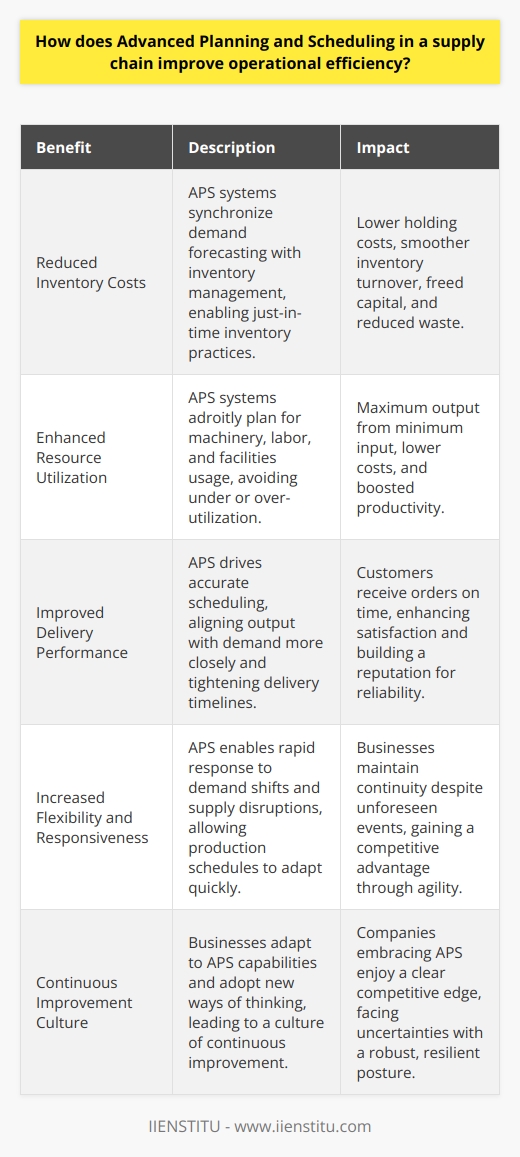

How does Advanced Planning and Scheduling in a supply chain improve operational efficiency?

Advanced Planning and Scheduling: A Pillar of Efficiency

Supply chain complexities demand precise coordination. Advanced Planning and Scheduling (APS) systems tackle this complexity head-on. They provide a sophisticated framework for decision-making. APS ensures that supply chain components align optimally. This alignment boosts operational efficiency significantly.

Core Benefits of APS

Reduced Inventory Costs

APS systems synchronize demand forecasting with inventory management. They enable just-in-time inventory practices. This synchronization leads to lower holding costs. Smoother inventory turnover emerges. Companies benefit from freed capital and reduced waste.

Enhanced Resource Utilization

Resource allocation gains sharp focus under APS. These systems adroitly plan for machinery, labor, and facilities usage. Companies avoid under or over-utilization. Maximum output from minimum input becomes attainable. This lean approach lowers costs and boosts productivity.

Improved Delivery Performance

APS drives accurate scheduling. Output aligns with demand more closely. Delivery timelines tighten. Customers receive orders on time, enhancing satisfaction. The company builds a reputation for reliability. Repeat business often follows.

Increased Flexibility and Responsiveness

Supply chains must react swiftly to changes. APS enables rapid response to demand shifts and supply disruptions. Production schedules adapt quickly. Businesses maintain continuity despite unforeseen events. Such agility underpins competitive advantage.

Strategic Integration

APS does not stand alone. It integrates with other systems like ERP (Enterprise Resource Planning). This integration forms a cohesive infrastructure. Strategy and operations proceed from a unified base. It leads to informed, strategic decision-making across the business.

Data-Driven Decision Making

APS relies heavily on real-time data. This data guides operational choices. Managers harness this data for insights. They improve forecasting and respond proactively to market trends. The entire supply chain benefits from intelligent, data-backed adjustments.

Streamlined Communication

Communication channels also undergo streamlining. APS platforms facilitate information flow among departments. This transparent communication reduces errors. Coordination issues diminish. Teams share a unified view of the supply landscape, promoting harmony and synchronicity.

Facing Challenges With Advanced Planning and Scheduling

Even with APS, challenges remain. Implementation poses its own hurdles. Companies must align APS with their existing infrastructure. Personnel require training. Processes need reevaluation. All these steps require investment. But in the long run, this investment pays off handsomely.

Adoption and adaptation mark the path forward. Businesses adapt to the APS's capabilities. They also adopt new ways of thinking. This shift leads to a culture of continuous improvement.

APS shapes the future of supply chains. It heralds an era of streamlined operations. Companies embracing APS enjoy a clear competitive edge. They face uncertainties with a robust, resilient posture. Operational efficiency thus ceases to be a challenge. It becomes a hallmark.

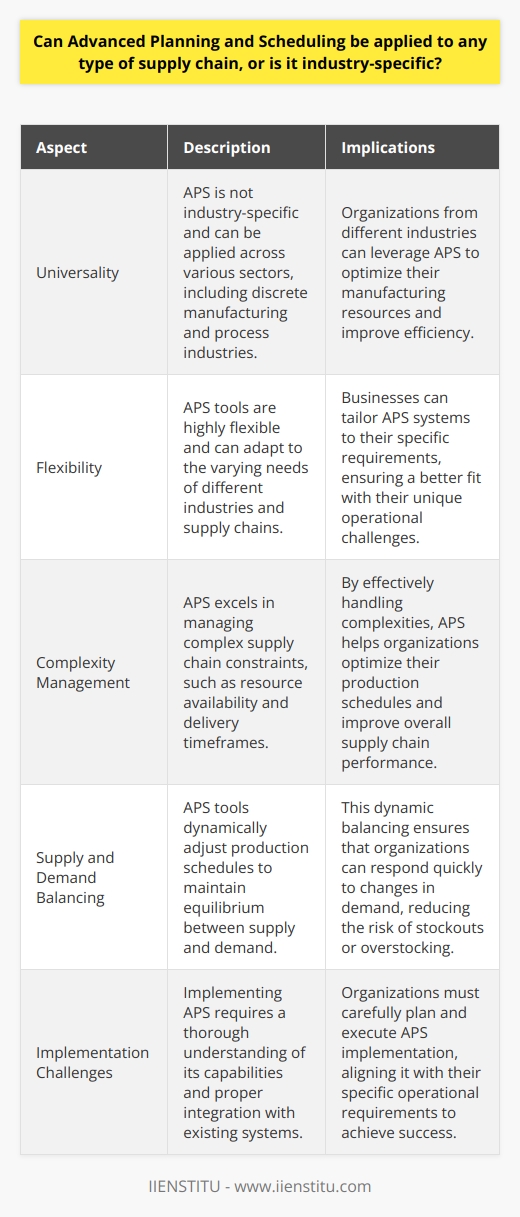

Can Advanced Planning and Scheduling be applied to any type of supply chain, or is it industry-specific?

Understanding Advanced Planning and Scheduling (APS)

Advanced Planning and Scheduling (APS) encompasses complex tools. These tools optimize the use of manufacturing resources. Businesses aim for efficiency and effectiveness. APS systems facilitate these goals.

APS Universality in Supply Chains

APS is not industry-specific. Organizations across sectors find these systems beneficial. The flexibility of APS tools is key. They serve discrete manufacturing and process industries alike. APS benefits sectors with varying needs.

Complexity and Variation Management

APS systems excel in managing complexity. They deal with various types of constraints. For instance, resource availability and delivery timeframes.

Discrete manufacturing benefits greatly.

In sectors like automotive, precision is vital.

Process industries such as pharmaceuticals also gain.

Here, formulas and recipes demand exact execution.

Balancing Supply and Demand

APS tools effectively balance supply with demand. They adjust production schedules dynamically. Thus, they maintain equilibrium.

Production fluctuations don't upset the balance.

Customer requirements drive adjustments.

Inventories remain optimal.

sStock-outs and overstocks decrease.

Key Challenges in APS Application

Implementation poses several challenges. APS requires thorough understanding. Enterprises must grasp its capabilities fully. Integration with existing systems is crucial. Inadequate integration hinders effective use.

Data integrity becomes critical.

Accurate data fuels precise scheduling.

Employees need comprehensive training.

A steep learning curve often presents itself.

APS is versatile across industries. It brings distinct advantages to varied supply chains. The approach needs careful tailoring. Understanding inherent supply chain complexities matters. APS implementation must be meticulous. Align it with specific operational requirements. Success then becomes more attainable.