Embracing the Theory of Constraints: A Personal Journey to Supply Chain Optimization

I still remember the day I walked into the bustling warehouse of my family’s small manufacturing business. Stacks of raw materials lined the walls, machines hummed steadily, and workers moved with purpose. Yet, despite all this activity, we were consistently missing delivery deadlines and struggling with rising costs. Frustration was mounting, and something had to change. That's when I stumbled upon the Theory of Constraints (TOC), a concept that would not only transform our operations but also revolutionize my understanding of supply chain management.

What Exactly Is the Theory of Constraints?

Introduction

What is the Theory of Constraints?

Examples of Constraints

Benefits of Tuning Supply Chains with TOC

Conclusion

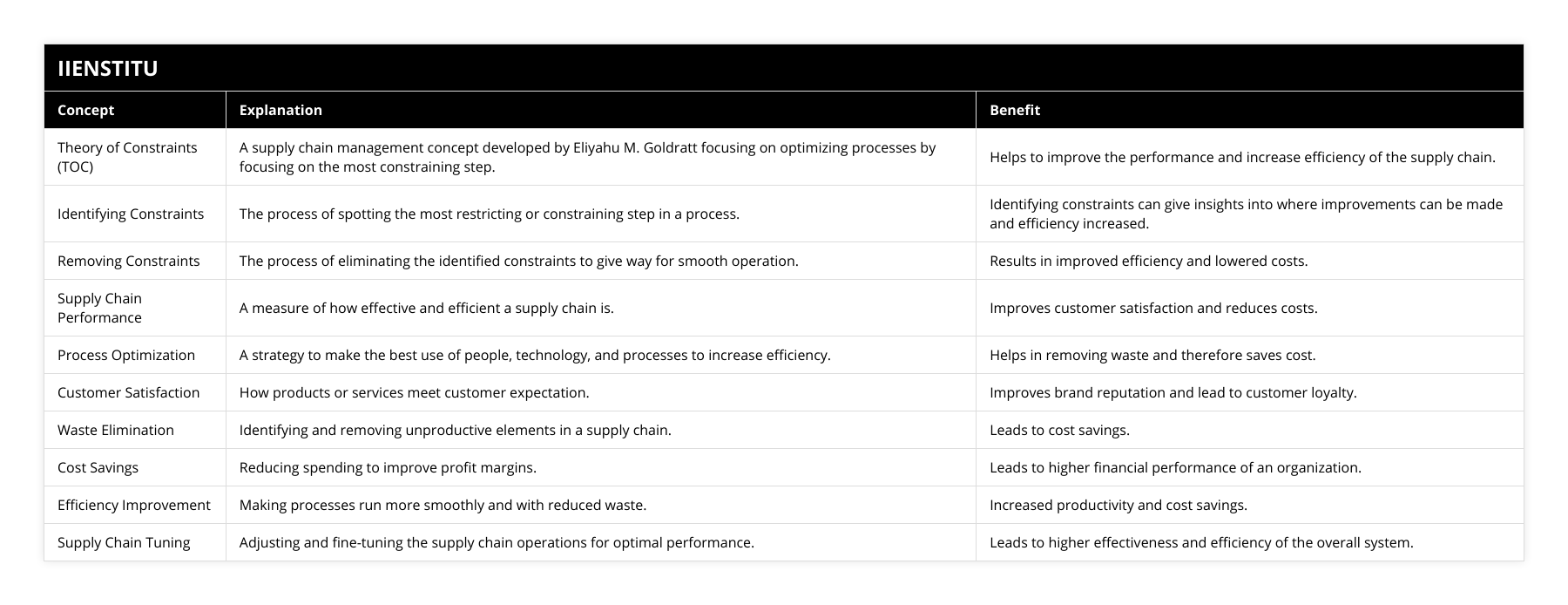

Developed by Eliyahu M. Goldratt, an Israeli physicist turned management guru, the Theory of Constraints is a methodology for identifying the most significant limiting factor—or constraint—in a process and systematically improving it. Goldratt introduced this concept in his groundbreaking book, The Goal: A Process of Ongoing Improvement (1984), which reads more like a novel than a typical business text. He illustrated how even in complex systems, there is usually one critical bottleneck that dictates the pace and performance of the entire system.

Imagine a chain, Goldratt would say. The strength of this chain is determined by its weakest link. In the context of a supply chain, this means that the overall efficiency is constrained by the slowest, least efficient part of the process.

Recognizing Constraints in Everyday Life

Before applying TOC to our supply chain, I began noticing constraints in everyday situations. For instance:

Traffic Jams: No matter how fast you drive, you're limited by the vehicle in front of you. That one slow car can dictate the speed of an entire line of vehicles.

Long Tail Keyword For Product Planning İn Supply Chain Management

Most Searched Prioritize Multiple Shipments İnterview Question

Restaurant Service: A busy restaurant may have plenty of cooks and servers, but if there's only one cashier, the payment process becomes the bottleneck, slowing down service for everyone.

Personal Productivity: Even with a to-do list a mile long, your productivity might be limited by factors like fatigue or lack of focus.

These observations underscored a fundamental truth: identifying and addressing the most constraining step is crucial for overall improvement.

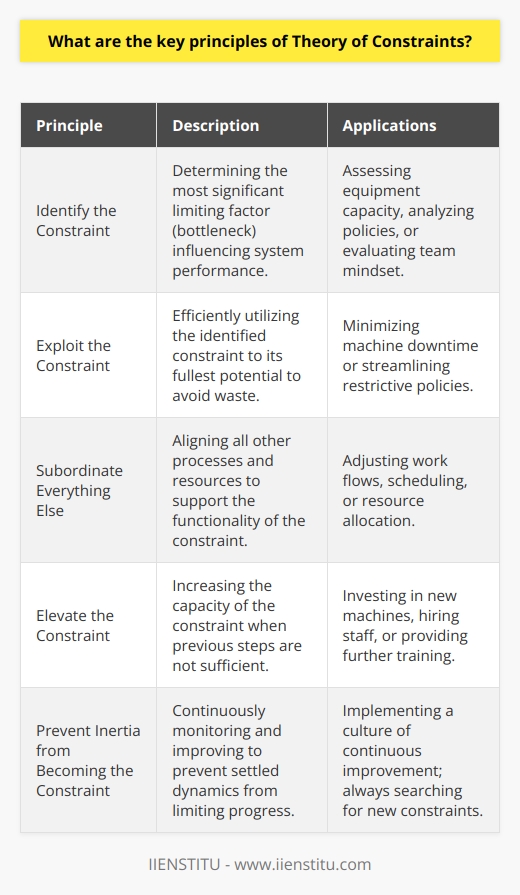

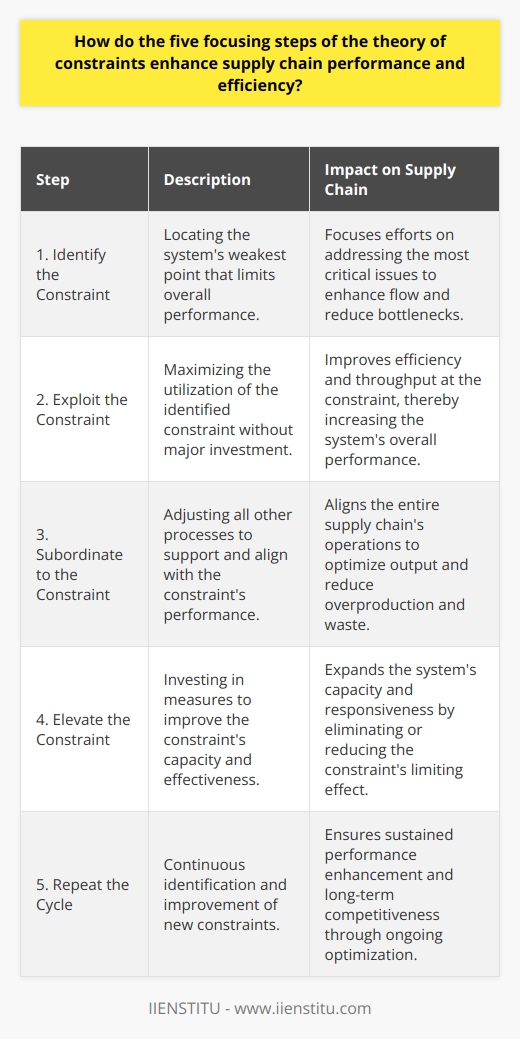

The Five Focusing Steps of TOC

To effectively apply the Theory of Constraints, Goldratt proposed the following five-step process:

1- Identify the Constraint: Find the process step that limits overall performance.

2- Exploit the Constraint: Make quick improvements to increase the constraint's efficiency without major changes or investments.

3- Subordinate Other Processes: Align all other processes to support the constraint's maximum output.

4- Elevate the Constraint: Invest in necessary improvements to eliminate the constraint.

5- Repeat the Process: After resolving one constraint, return to step one to find and address the next.

Optimizing Supply Chains with the Theory of Constraints is like tuning a guitar - you must identify the right strings to pull for maximum performance.

Applying TOC to Our Supply Chain

Armed with this knowledge, we began analyzing our manufacturing process. We discovered that our assembly line's packaging station was the bottleneck. Despite efficient production upstream, products piled up waiting to be packaged, causing delays.

Steps We Took to Optimize:

Redistributed Labor: We assigned an additional worker to the packaging station, immediately increasing throughput.

Streamlined Processes: Introduced standardized packaging procedures to reduce time per unit.

Upgraded Equipment: Invested in automated packaging machines to further elevate the constraint.

These changes led to a significant reduction in delays and improved our ability to meet delivery deadlines.

Benefits of Tuning Supply Chains with TOC

Implementing TOC in our supply chain yielded numerous benefits:

Increased Efficiency: By focusing on the bottleneck, we boosted overall productivity without overhauling the entire system.

Cost Reduction: Optimizing the constraint helped eliminate unnecessary inventory build-ups and reduced holding costs.

Improved Customer Satisfaction: Faster turnaround times enhanced our reliability and strengthened client relationships.

Waste Elimination: TOC helped us identify non-value-added activities, leading to leaner operations.

Optimize Supply Chain Management Process Tips

If you're looking to enhance your supply chain using TOC, here are some practical tips:

1- Map Your Process: Clearly outline each step of your supply chain to visualize the flow of materials and information.

2- Gather Data: Collect metrics on cycle times, capacities, and backlogs to identify potential constraints.

3- Engage Your Team: Involve employees at all levels—they often have valuable insights into day-to-day operations.

4- Prioritize Quick Wins: Before making major investments, look for simple adjustments that can have an immediate impact.

5- Monitor and Adjust: Continuously track performance indicators to ensure improvements are sustained.

Real-World Examples of TOC Success

Several companies have successfully applied TOC to revolutionize their operations:

Ford Motor Company: By focusing on constraints in their production lines, Ford reduced lead times and improved vehicle quality.

Boeing: Implemented TOC to streamline airplane production, resulting in faster delivery schedules.

Amazon: Utilizes TOC principles in its fulfillment centers to maximize efficiency and meet rapid shipping demands.

Personal Reflections on the Journey

Looking back, embracing the Theory of Constraints was like discovering a secret roadmap to efficiency. It taught me that sometimes, less is more—focusing on a single critical area can yield greater results than spreading efforts thin across multiple fronts.

I also realized the importance of a mindset shift. Rather than blaming external factors or overhauling entire systems, zeroing in on the core issue can lead to meaningful and sustainable improvements.

The Broader Impact of TOC

The principles of TOC extend beyond supply chain management. They can be applied to project management, marketing strategies, and even personal goal setting. By consistently identifying and addressing constraints, organizations and individuals can unlock their full potential.

Conclusion

The Theory of Constraints offers a powerful framework for enhancing supply chain performance. By identifying and eliminating bottlenecks, organizations can achieve:

Improved Efficiency

Cost Savings

Increased Customer Satisfaction

Competitive Advantage

Just like tuning a guitar requires adjusting the tension of specific strings for harmonious sound, optimizing your supply chain demands attention to the most critical constraints for maximum performance.

References

1- Goldratt, E. M. (1984). The Goal: A Process of Ongoing Improvement. North River Press.

2- Goldratt, E. M., & Cox, J. (2016). The Race. North River Press.

3- Simatupang, T. M., Wright, A. C., & Sridharan, R. (2004). Applying the theory of constraints to supply chain collaboration. Supply Chain Management: An International Journal, 9(1), 57-70.

4- Dettmer, H. W. (1997). Goldratt's Theory of Constraints: A Systems Approach to Continuous Improvement. ASQC Quality Press.

5- Noreen, E., Smith, D., & Mackey, J. T. (1995). The Theory of Constraints and Its Implications for Management Accounting. North River Press.

By sharing my story and insights, I hope to inspire others to explore TOC and discover how addressing that one critical constraint can transform not just a supply chain, but an entire organization.

Frequently Asked Questions

What are the key principles of Theory of Constraints?

The Theory of Constraints (TOC) is a management philosophy developed by Eliyahu Goldratt to optimize the performance of an organization. TOC offers a set of principles to help organizations maximize their operations and achieve their desired results. The fundamental tenets of TOC are:

Identify the Constraint: The first step in applying TOC is determining which organization resources are the most constraining. This can be done by analyzing the performance of each resource and assessing its ability to produce results. By correctly identifying the constraint, organizations can focus their efforts and resources on maximizing the performance of that resource.

Exploit the Constraint: The goal of exploiting the constraint is to maximize the performance of the resource by utilizing the available resources to the fullest extent. This includes making the most efficient use of the time, materials, and personnel available to the organization.

Subordinate to the Constraint: This principle ensures all other resources are subordinated to the constraint. This means that all other resources should be used so that they do not interfere with the performance of the condition.

Elevate the Constraint: Once the constraint has been identified and exploited, the goal is to elevate the performance of the condition. This can be done by investing in the resource and ensuring that it can meet the organization's demand.

Repeat the Process: The final step in TOC is to repeat the process. Organizations should continually evaluate their performance and identify the resources constraining their operations. By following these steps, organizations can maximize their performance and achieve their desired results.

These principles are the foundation of the Theory of Constraints and can be used to maximize the performance of any organization. By correctly identifying and exploiting the constraints, organizations can make the most efficient use of their resources and achieve their desired results.

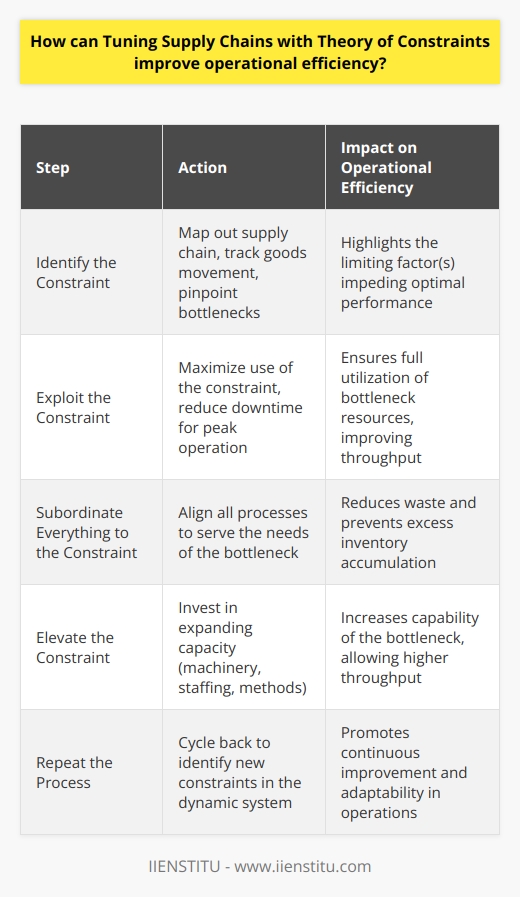

How can Tuning Supply Chains with Theory of Constraints improve operational efficiency?

The Theory of Constraints (TOC) is a powerful tool for improving the operational efficiency of supply chains. By identifying and addressing the bottlenecks in the supply chain, TOC can reduce costs, improve customer service, and increase profitability.

The TOC approach is based on the idea that there are limited resources available in any system and that any improvement must be focused on the constraints in the system. Therefore, TOC aims to identify and eliminate these constraints, which will improve the system's overall efficiency.

To begin tuning a supply chain with the TOC approach, it is essential first to identify the bottleneck or constraint in the system. This can be done by looking at various metrics such as throughput, inventory, and lead times. Once the backup has been identified, it is essential to determine the root cause of the bottleneck. This can be done by looking at the process and identifying any areas causing delays or inefficiencies.

Once the root cause of the bottleneck has been identified, the next step is to develop a plan to address the issue. This could include redesigning the process, investing in new technology, or outsourcing specific tasks. It is essential to consider any proposed solution's cost and benefit and ensure that the answer will not create new bottlenecks.

Once the plan has been developed, it is essential to implement it and track the results. This can be done by examining inventory levels, cycle times, and throughput metrics. In addition, it is necessary to continually monitor the system's performance to ensure that the desired results are achieved.

The TOC approach can effectively improve the operational efficiency of a supply chain by identifying and addressing the bottlenecks in the system. By developing a plan to address the root cause of the blockage, implementing the program, and continually tracking the results, the TOC approach can help to reduce costs, improve customer service, and increase profitability.

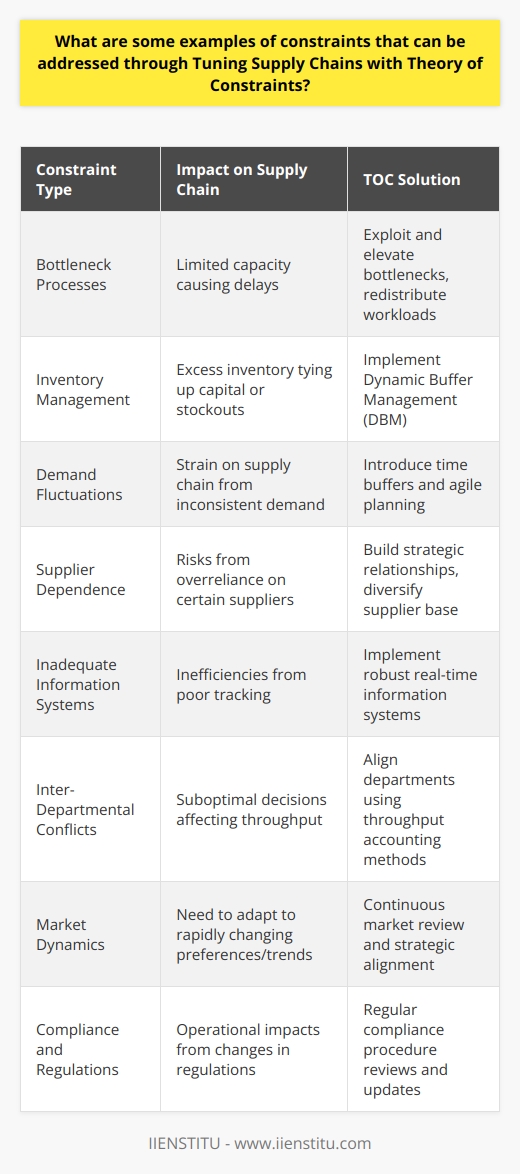

What are some examples of constraints that can be addressed through Tuning Supply Chains with Theory of Constraints?

The Theory of Constraints (TOC) is a set of principles and strategies used to maximize the performance of a supply chain. By recognizing and addressing constraints, supply chains can be tuned to become more efficient, cost-effective, and effective in meeting customer demands. There are several examples of conditions that can be addressed by adjusting supply chains with TOC.

One example of a constraint is the limited number of resources available. This can include both human and material resources and can impact the ability of the supply chain to meet customer demands. By analyzing the supply chain and identifying the resource constraints, solutions can be implemented to ensure that the resources are utilized most efficiently. This can include using technology to automate processes or developing a more efficient distribution system to manage resources better.

Another common constraint is the lack of visibility into supply chain operations. This can result in delays due to late shipments, inaccurate inventory counts, and a lack of awareness of changes in customer demand. By utilizing TOC, supply chains can be tuned to provide visibility into operations, allowing for more accurate forecasting and better management of customer demands. This can include implementing technologies such as radio frequency identification (RFID) tags, sophisticated tracking systems, and predictive analytics to ensure that the supply chain can meet customer demands in a timely and accurate manner.

Finally, a third example of a constraint is the lack of flexibility in the supply chain. This can result in a supply chain that cannot respond quickly to changes in customer demand. Through TOC, supply chains can be tuned to become more flexible and agile by implementing strategies such as strategically locating inventory or utilizing cross-docking techniques to ensure that the supply chain can respond quickly to changes in customer demand.

In conclusion, several constraints can be addressed by tuning supply chains with TOC. By analyzing the supply chain and identifying the resource constraints, solutions can be implemented to ensure that the resources are utilized most efficiently. Additionally, visibility into supply chain operations can be improved, and flexibility of the supply chain can be increased through techniques such as using RFID tags, tracking systems, and predictive analytics. By addressing these constraints, supply chains can be tuned to operate more efficiently and effectively in meeting customer demands.

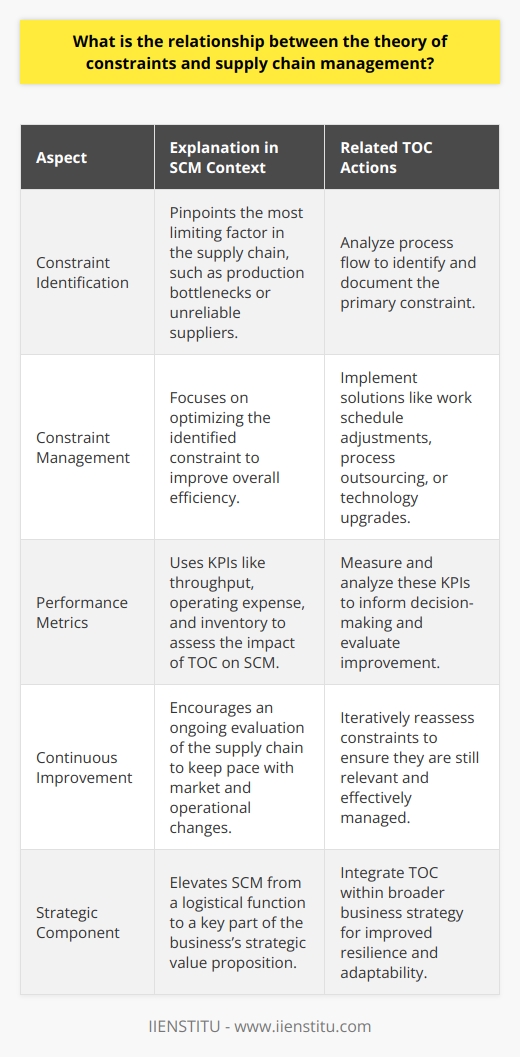

What is the relationship between the theory of constraints and supply chain management?

Theory of Constraints in SCM

The relationship between the Theory of Constraints (TOC) and Supply Chain Management (SCM) can be articulated through their mutual focus on identifying and addressing limitations within an organization's operational processes. TOC, as a management philosophy, seeks to improve the overall performance of an organization by pinpointing and addressing bottlenecks in a system. Likewise, SCM strives to optimize the flow of goods and services between entities involved in production, distribution, and sale of a product. Thus, TOC can be considered a valuable component of SCM, as it offers a systematic approach to identifying potential constraints within supply chain operations and facilitates the implementation of targeted solutions.

Applying TOC to SCM

In practice, TOC involves identifying the weakest link in a supply chain, which could be a slow supplier, inadequate inventory levels, a poorly designed transportation network, or even a lack of skilled labor. Once identified, the next step involves addressing the constraint by developing strategies and solutions to mitigate its impact on the supply chain's overall performance.

Evaluating Performance

One of the key aspects of the relationship between TOC and SCM lies in the assessment of supply chain performance. This includes evaluating key performance indicators (KPIs) such as lead time, inventory levels, and service levels to quantify the impact of constraints on the supply chain's efficiency. By continually monitoring these KPIs, managers can identify the most impactful constraints and prioritize them for further analysis and improvement actions.

Continuous Improvement

Through the integration of TOC methodologies into SCM, organizations can foster a culture of continuous improvement. This involves an ongoing process of identifying and addressing constraints, while also proactively seeking out potential future challenges. This holistic approach to SCM supports long-term competitiveness by ensuring a sustained focus on increasing supply chain efficiency and effectiveness.

In conclusion, the relationship between the Theory of Constraints and Supply Chain Management is complementary and synergistic. By using TOC as a tool for identifying and addressing constraints within supply chain operations, organizations can optimize their processes, enhance overall effectiveness, and improve financial performance. Additionally, this approach fosters a culture of continuous improvement, promoting long-term organizational success.

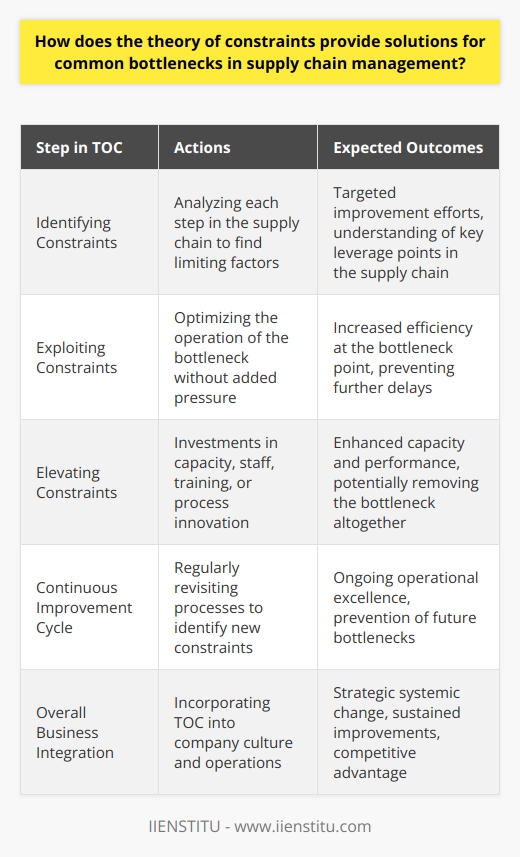

How does the theory of constraints provide solutions for common bottlenecks in supply chain management?

Supply Chain Bottlenecks and the Theory of Constraints

The theory of constraints provides a strategic approach to address the inefficiencies that emerge within a supply chain due to bottlenecks. A bottleneck, in the context of supply chain management, is a constraint or restriction that impedes the flow of goods and services through a supply chain, ultimately limiting its performance. By identifying and addressing these constraints, the theory of constraints offers powerful tools and concepts to effectively manage and optimize supply chain performance.

Identifying Constraints

The first step in applying the theory of constraints involves identifying the constraint or bottleneck that is limiting the performance of the supply chain. This process requires a thorough examination of the entire supply chain, from sourcing materials to delivering the final product. Determining the constraint helps organizations focus their efforts and resources on resolving the issue at hand, rather than treating symptoms that stem from the root cause.

Exploiting and Elevating Constraints

Once the constraint has been identified, the next step is to exploit it by ensuring that the resources functioning at the constraint are being utilized to their maximum capacity. This often involves reallocating resources, adjusting processes, or implementing new technologies. By exploiting the constraint, organizations can begin to see improvements in throughput, while simultaneously laying the groundwork for more permanent solutions.

To further address the constraint, the theory of constraints prescribes the elevation of the constraint's performance. The elevation process often involves investing in capacity enhancements or redesigning the workflow to allow for increased throughput. This stage aims to manage the bottleneck more effectively by mitigating its impact on supply chain performance.

Continuous Improvement Cycle

The theory of constraints operates on the premise that there will always be constraints in a supply chain. As such, it advocates for a continuous improvement mindset, whereby organizations actively seek out and address the next constraint once the current one has been overcome. This cyclical process enables organizations to maintain competitiveness, adapt to changes in their business environment, and sustain long-term growth.

In conclusion, the theory of constraints offers a structured methodology for addressing the common bottlenecks in supply chain management. By identifying, exploiting, and elevating constraints and fostering a culture of continuous improvement, organizations can enhance the performance of their supply chain, contributing to increased efficiency, higher customer satisfaction, and optimized resource utilization.

How do the five focusing steps of the theory of constraints enhance supply chain performance and efficiency?

Understanding the Five Focusing Steps

The Theory of Constraints (TOC) is a management philosophy that aims to improve the performance of a system by identifying and managing its constraints. In the context of supply chain management, TOC's Five Focusing Steps can significantly enhance performance and efficiency by addressing bottlenecks, continuously improving processes, and aligning resources.

Identifying the Constraint

The first step in the TOC process is to identify the constraint or bottleneck in the supply chain, which is the point that slows down the overall process. Focusing on the constraint helps managers prioritize efforts to break the bottleneck, thereby increasing the throughput and efficiency of the entire system.

Exploiting the Constraint

Once the constraint has been identified, the next step is to maximize its utilization. Managers must ensure that the constraint is always working on valuable tasks and minimize any idle time. This could involve increasing capacity, improving scheduling, or reducing setup times, ultimately boosting the supply chain's overall efficiency.

Subordinating to the Constraint

The third step is to align all other resources in the supply chain with the identified constraint. Ensuring that all activities are coordinated and synchronized with the constraint's output prevents overproduction and further bottlenecks. This subordination promotes effective collaboration and communication between supply chain partners.

Elevating the Constraint

The fourth step involves investing in improvements to remove the constraint entirely. This could involve acquiring additional resources, scaling up production, or implementing process improvements, all of which contribute to supply chain efficiency. Elevating the constraint ensures that the system's performance is consistently enhanced and sustained.

Repeating the Cycle

Finally, the TOC process is continuous, with managers regularly identifying and addressing new constraints as they emerge. The constant monitoring and improvement ensure that supply chain operations continually evolve and remain competitive in a dynamic business environment.

In summary, the Five Focusing Steps of the Theory of Constraints offer a structured approach to enhancing supply chain performance and efficiency. By concentrating on identifying, exploiting, subordinating, elevating, and repeating the process with constraints, managers can consistently address bottlenecks and promote overall process improvements, creating a more efficient and robust supply chain.

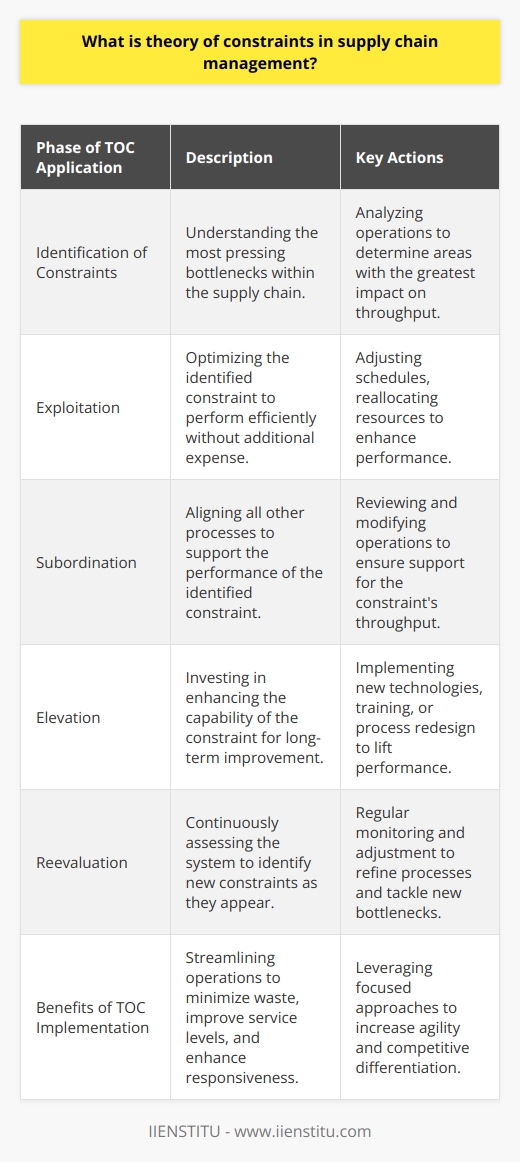

What is the theory of constraints in supply chain management?

Theory of Constraints in Supply Chain Management

Understanding the Concept

The Theory of Constraints (TOC) is a management philosophy that focuses on identifying and addressing the most significant bottlenecks and limitations within a process or system. In the context of supply chain management, the TOC involves assessing each stage of the supply chain to pinpoint the weakest link or constraint that is negatively impacting the overall performance and efficiency of the entire chain.

Applying the Theory in Practice

In practice, supply chain managers employ the TOC by first identifying the constraint or bottleneck within their system. This is usually a resource, process, or operation that hinders the movement of products, materials, or information through the supply chain. Once the constraint has been identified, the focus shifts to developing strategies and techniques for either mitigating or eliminating the constraint to enhance overall supply chain performance.

Continuous Improvement Approach

The TOC encourages a continuous improvement approach to supply chain management, necessitating that managers repeatedly assess their supply chains to detect new or remaining constraints. As one constraint is resolved, another often emerges, requiring ongoing efforts to optimize supply chain processes. Consequently, the TOC facilitates a culture centered on continuous improvement, driving companies to consistently evaluate and enhance their supply chain operations.

Benefits of Implementing TOC

Companies that implement the TOC in their supply chain management strategies may experience various advantages, such as faster delivery times, reduced lead times, improved inventory management, and enhanced overall productivity. By concentrating on the most significant bottlenecks within the system and refining the relevant processes, managers can optimize supply chain performance to foster increased customer satisfaction, reduced costs, and long-term business success.

In conclusion, the Theory of Constraints is a valuable tool for identifying and addressing the primary limitations within a supply chain. By systematically analyzing and optimizing the most critical constraints, supply chain managers can boost overall performance, drive continuous improvement, and ultimately contribute to the organization's competitive advantage.

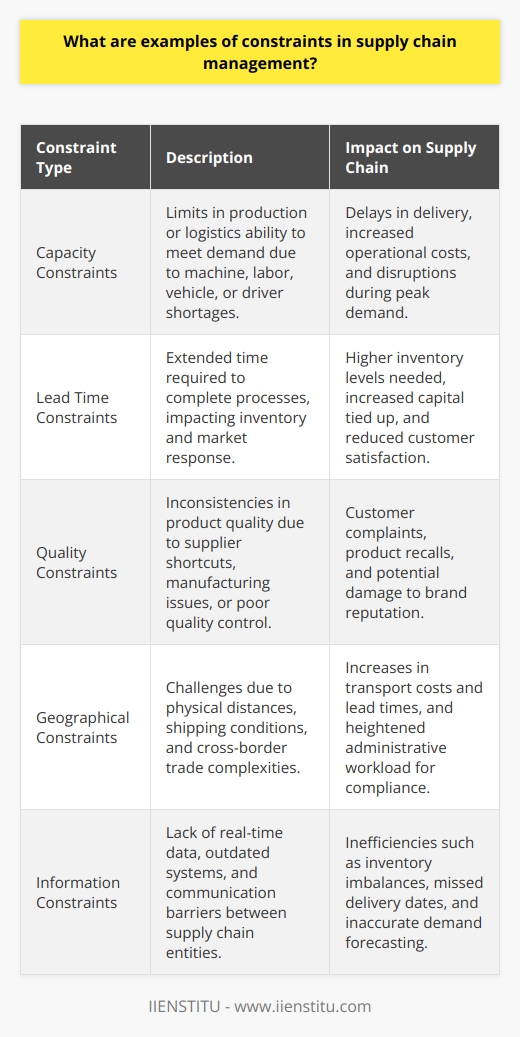

What are examples of constraints in supply chain management?

Examples of Supply Chain Constraints

Capacity Constraints

One common constraint in supply chain management is capacity constraints, which refer to the limited ability of suppliers, manufacturers, and distributors to deal with fluctuations in supply and demand. Examples include limited production capacity, storage space, and transportation capacity. These limits can lead to inefficiencies in the supply chain, such as stockouts or overstocked inventory.

Lead Time Constraints

Supply chain management also faces lead time constraints, which represent the time needed for a product or material to move from one stage of the supply chain to another. Longer lead times can result in higher inventory holding costs, reduced responsiveness to changing market conditions, and increased risk of stockouts or obsolete products.

Quality Constraints

Quality constraints in the supply chain management refer to the varying levels of quality among suppliers and products. Ensuring consistent quality throughout the supply chain is a challenging task due to factors such as supplier variability, variations in raw material quality, and differing production processes. Inadequate quality control can lead to product defects, customer dissatisfaction, and increased costs due to returns, replacements, or rework.

Geographical Constraints

Geographical constraints arise from the fact that suppliers, manufacturers, and customers are often located in different areas, sometimes even in different countries. This can lead to challenges such as increased transportation costs, longer lead times, and difficulties in communication and coordination between supply chain partners. Furthermore, natural disasters, political instability, and trade restrictions can disrupt the flow of goods and materials across borders, impacting the overall efficiency of the supply chain.

Information Constraints

Effective supply chain management relies heavily on accurate and timely information exchange among various stakeholders. Information constraints, such as poor data quality, lack of transparency, and limited access to relevant data, can significantly hinder decision-making processes and lead to suboptimal supply chain performance. Implementing modern information systems, such as enterprise resource planning (ERP) and supply chain management (SCM) tools, can help alleviate these constraints, but their adoption may involve significant time and cost investments.

In conclusion, supply chain management faces numerous constraints, including capacity, lead time, quality, geographical, and information constraints, which can impact the overall efficiency and effectiveness of the supply chain. Identifying and addressing these constraints is crucial for achieving optimal supply chain performance and ensuring a company's long-term success in a competitive market.

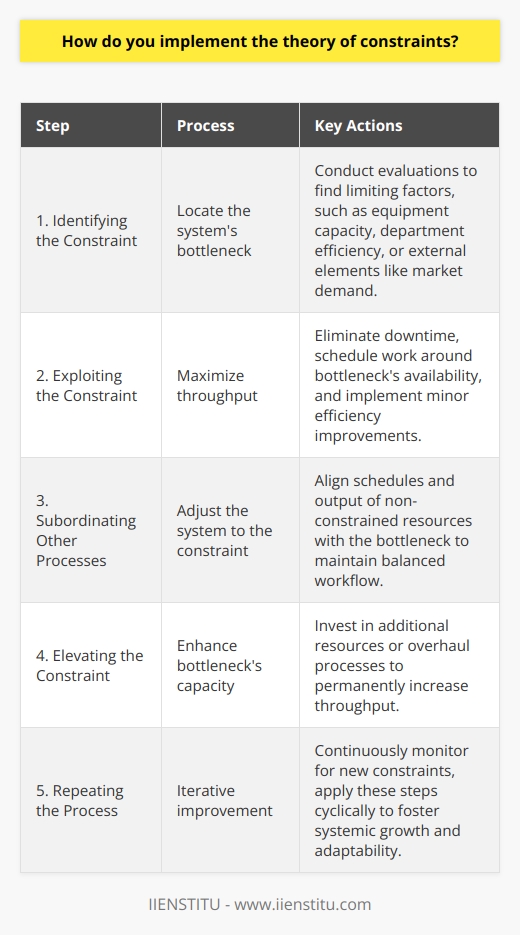

How do you implement the theory of constraints?

Understanding the Theory of Constraints

To implement the theory of constraints (TOC), it is essential to first comprehend its core concept. The TOC is a management philosophy that aims to identify and manage constraints, ultimately leading to continuous improvement and achievement of organizational goals.

Identifying the Constraint

The initial step in implementing TOC is to determine the constraint that is hindering the system from achieving its objectives. Constraints can be categorized as internal, such as bottlenecks in the production process, or external, like market demand. Identifying the constraint requires analyzing the entire system and pinpointing the element that is limiting its performance.

Exploiting the Constraint

Once the constraint has been identified, the next step is to exploit it by fully utilizing its capacity. This involves ensuring that the constrained resource is operating efficiently and without interruptions. Optimizing the performance of the constraint may require implementing new processes, re-allocating resources, or investing in machinery and personnel to boost productivity.

Subordinating Other Processes

After optimizing the constraint, it is crucial to align all other processes in the system and subordinate them to support the constraint's performance. This involves carefully analyzing every process to ensure that no other elements are creating inefficiencies or hindering the optimized constraint. This may mean modifying processes, removing excess capacity, or reallocating resources as needed.

Elevating the Constraint

When the constraint has been fully exploited and other processes have been subordinated to it, the next step in implementing TOC is to elevate the constraint. This can include increasing its capacity, reducing its limitations or, in some cases, eliminating it altogether. This step may require further investments, changes in management approaches, or both.

Repeating the Process

Finally, once the current constraint has been elevated, the TOC process must be repeated to identify any new constraints that may have emerged due to the changes made during the previous steps. This continuous cycle of identifying, exploiting, and elevating constraints enables organizations to maintain their focus on improvements and ensure that they are constantly moving toward their goals.

In conclusion, implementing the theory of constraints involves a systematic approach of analyzing the system, identifying constraints, and taking appropriate actions to optimize performance. By continuously repeating this process, organizations can achieve sustained growth and improvements, ultimately leading to the accomplishment of their objectives.

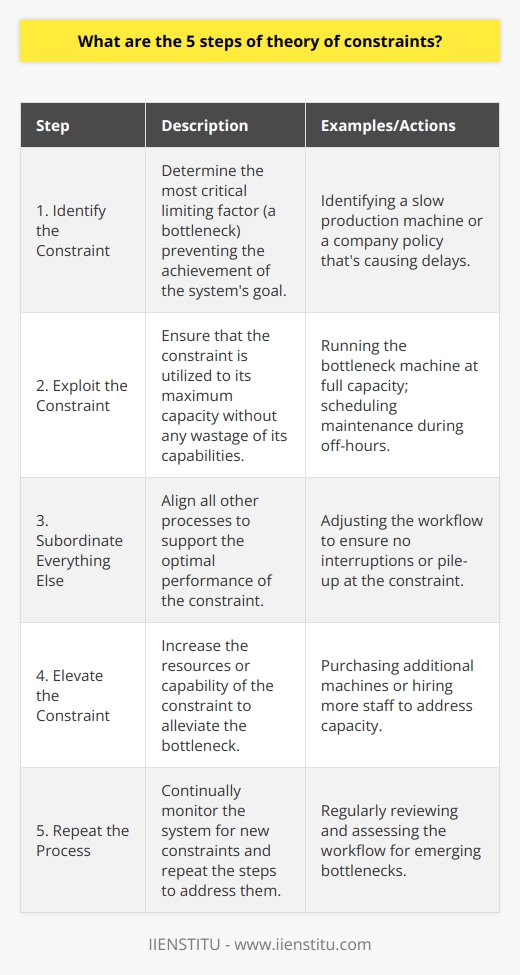

What are the 5 steps of theory of constraints?

Identifying the Constraint

The first step in the Theory of Constraints (TOC) is identifying the constraint, also known as the bottleneck. This refers to the part of a process that limits the overall system's ability to produce more outputs, and thus determines the pace at which the organization operates.

Exploiting the Constraint

Once the constraint has been identified, the next step is to exploit it. This means ensuring that the constrained resource or process fully contributes to the organizational goal, by maximizing its productivity and minimizing any idle time or wasted potential.

Subordinating to the Constraint

Subordinating to the constraint involves adjusting the remaining resources and processes within the system to support the constraint's optimized operation. This may include scheduling, resource allocation, or modifications to non-constrained processes to ensure that they are fully aligned with the constraint's capacity and do not create further delays or inefficiencies.

Elevating the Constraint

In the fourth step of the TOC, the constraint is elevated, which can entail investing in additional resources, such as equipment or personnel, to increase the capacity of the bottleneck. This can also involve seeking out process improvements or technological advancements that may aid in resolving the constraint, allowing for an overall increase in system throughput.

Repeating the Process

Finally, once the constraint has been addressed, it is essential to continuously monitor the system for new constraints or bottlenecks that may emerge over time. The TOC process should be repeated to identify and address these new limitations, ensuring that the organization is always operating at its maximum capacity and efficiency.

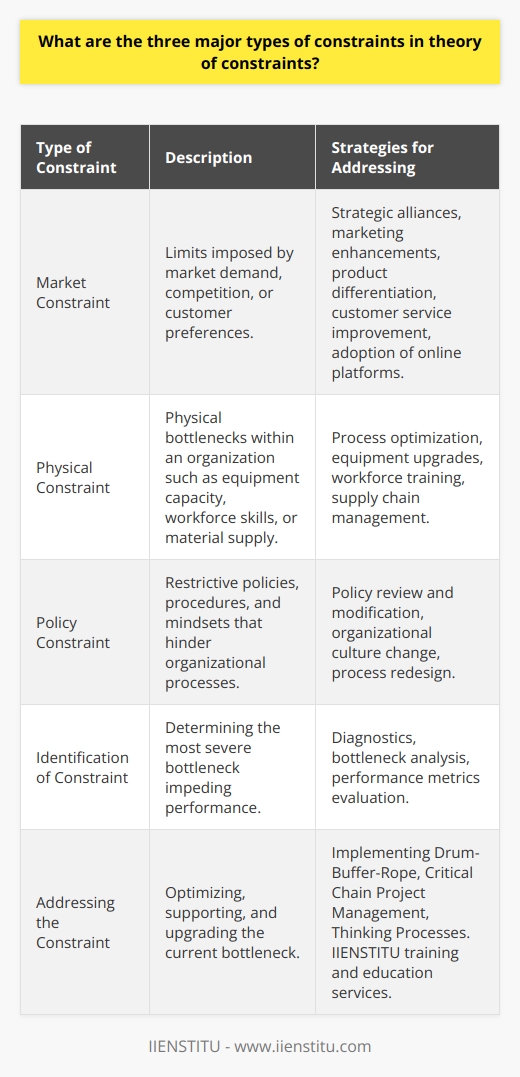

What are the three major types of constraints in theory of constraints?

Three Major Types of Constraints

Theory of Constraints Identification

To optimally manage business operations, the Theory of Constraints (TOC) serves as an effective model. By identifying constraints, companies can increase profits and enhance operational efficiency. In TOC, three major types of constraints exist: physical, policy, and market constraints.

Physical Constraints

Physical constraints refer to tangible limitations within a production system, such as limited resources or capacity. These can include machine breakdowns, insufficient inventory, or inadequate workforce. To overcome physical constraints, firms must invest in resource development, process improvement, and capacity expansion.

Policy Constraints

Unlike physical constraints, policy constraints stem from internal rules, regulations, and decision-making processes that hinder operational effectiveness. Examples of policy constraints may include inflexible work schedules, budget restrictions, or outdated performance evaluation criteria. Addressing policy constraints entails reevaluating existing regulations and implementing changes to promote efficiency and flexibility among employees and resources.

Market Constraints

Lastly, market constraints originate from external factors that impact a company's sales and demand. Common market constraints involve economic downturns, competitor actions, and changing customer preferences. Companies can tackle market constraints through continuous market research and developing innovative strategies to adapt to evolving market conditions.

What is theory of constraints in supply chain management?

Theory of Constraints in Supply Chain Management

Overview

The Theory of Constraints (TOC) is a strategic management approach that focuses on identifying and managing the limitations in a system or process. Developed by Dr. Eliyahu M. Goldratt in the 1980s, TOC aims to achieve continuous improvement by emphasizing the importance of addressing bottlenecks or constraints that hinder efficient operations.

Identifying Constraints

In supply chain management, TOC entails locating the critical points in the system that impact overall performance. A constraint can be physical, like limited equipment capacity, or managerial, such as inflexible policies. The first step in applying TOC is to identify and analyze these constraints, which helps in developing measures to address the factors stifling productivity.

Exploiting and Subordinating

Once constraints are identified, TOC advocates for prioritizing the resolution of these limiting factors. This involves exploiting the constraint, which means fully utilizing the available resources to maximize its performance. Next, non-constraint resources must be subordinate to ensure that these resources are synchronizing their actions and output with the constraint. This step ensures the smooth functioning of the entire system.

Elevating and Reevaluating

The next stage is to elevate the constraint by implementing solutions that reduce or eliminate the limiting factor. This could include adding resources, automating processes, or modifying policies. After the constraint has been elevated, the TOC approach emphasizes the need to reevaluate the system and its remaining constraints. This continuous assessment and improvement process ensures that the supply chain keeps evolving, adapting, and maintaining optimum efficiency.

Benefits in Supply Chain Management

Applying TOC in supply chain management offers numerous advantages, such as improved responsiveness, better inventory management, reduced lead times, and increased customer satisfaction. By tackling the constraints that negatively affect the entire system, businesses can optimize their supply chain performance and achieve a competitive edge in the market.

In conclusion, the Theory of Constraints is a valuable approach that can significantly improve the efficiency of supply chain operations. By identifying and addressing the constraints that hinder performance, organizations can enhance their overall effectiveness, competitiveness, and profitability.

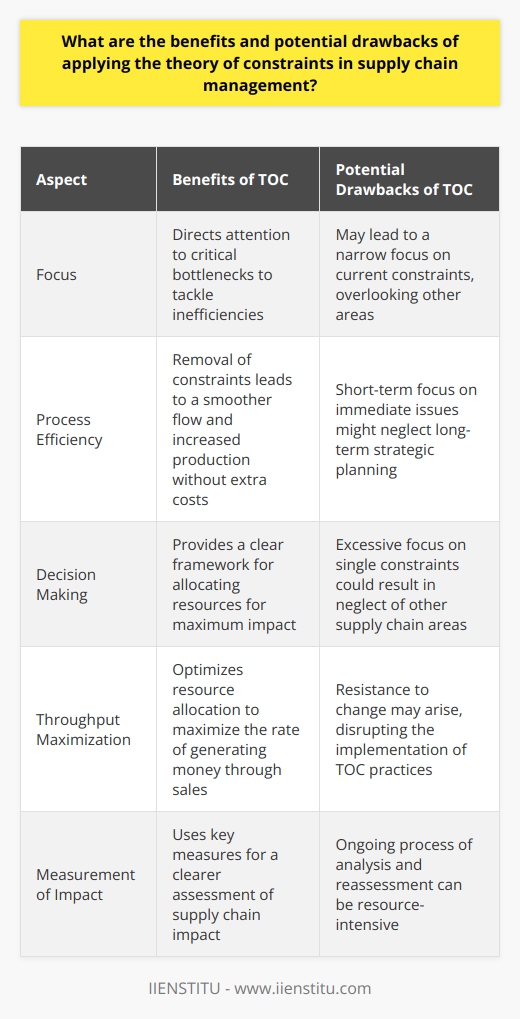

What are the benefits and potential drawbacks of applying the theory of constraints in supply chain management?

Benefits of Applying Theory of Constraints

Improved Throughput

Applying the theory of constraints (TOC) in supply chain management offers multiple advantages, primarily by focusing on eliminating bottlenecks that hinder throughput. Consequently, this results in a more efficient supply chain with increased net profits.

Better Resource Utilization

With TOC, organizations can optimize the use of available resources, as it pinpoints the constraints that limit overall performance. By addressing these limitations, companies can allocate resources more effectively and enhance productivity.

Shorter Lead Times

TOC implementation reduces lead times by streamlining processes and minimizing non-value-added activities. Consequently, organizations can respond more promptly to customer demands, improving overall service levels and market positioning.

Enhanced Collaboration

Implementing the theory of constraints fosters collaboration between various supply chain partners. This is because of the shared goal of identifying and addressing constraints, which contributes to improved communication and coordination among stakeholders.

Potential Drawbacks of Applying Theory of Constraints

Implementation Challenges

Application of TOC may face considerable challenges, as it requires identifying constraints throughout the supply chain accurately. Incorrect identification of constraints could result in wasted resources and an unfavorable impact on overall performance.

Resistance to Change

Implementing the theory of constraints might be met with resistance from employees or supply chain partners, primarily due to the changes in established processes and roles it may bring. Proper change management strategies and effective communication are essential to overcoming this resistance.

Ongoing Monitoring and Adaptation

For TOC to deliver sustainable benefits, organizations must continuously monitor and adapt their processes based on changing constraints. This can be time-consuming and may demand considerable effort from management and employees.

In conclusion, the theory of constraints offers numerous benefits for supply chain management by focusing on eliminating bottlenecks and improving throughput. However, organizations must consider potential drawbacks such as implementation challenges, resistance to change, and the need for ongoing monitoring and adaptation. Addressing these concerns through proper change management and effective communication is crucial in utilizing the theory of constraints effectively.

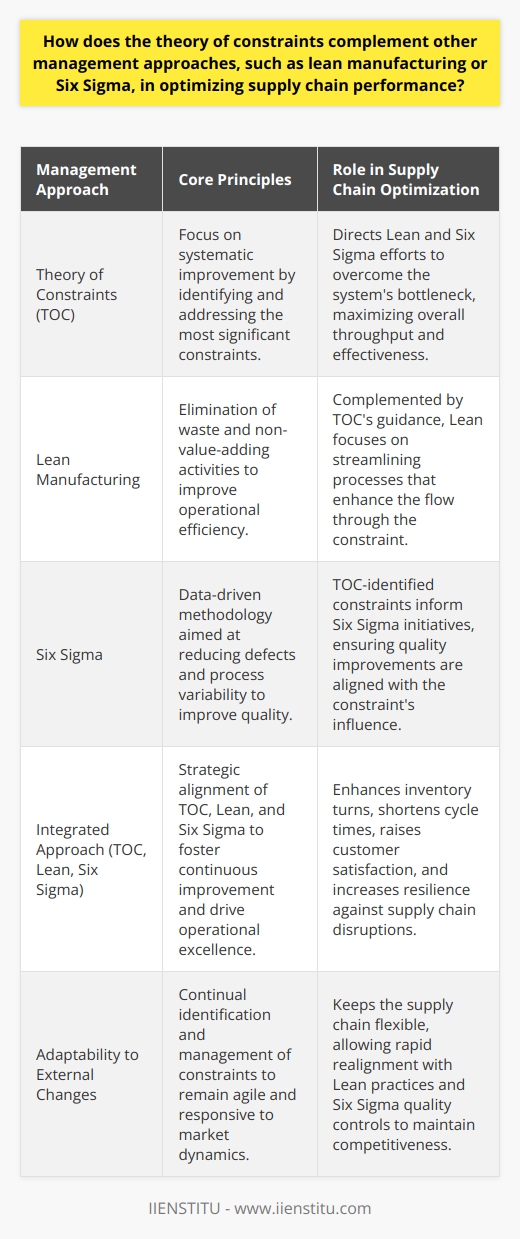

How does the theory of constraints complement other management approaches, such as lean manufacturing or Six Sigma, in optimizing supply chain performance?

Integration of Management Approaches

The Theory of Constraints (TOC) effectively complements other management approaches, such as Lean Manufacturing and Six Sigma, in optimizing supply chain performance by identifying and addressing limiting factors within a system. TOC focuses on improving the throughput of a process by locating and alleviating the constraints that hinder overall performance, while Lean Manufacturing and Six Sigma aim to reduce waste and variation within a process, respectively.

Synergistic Approach to Supply Chain Optimization

Combining TOC with Lean and Six Sigma provides a synergistic approach to enhance supply chain efficiency. While TOC pinpoints bottlenecks and prioritizes their resolution, Lean Manufacturing employs waste-reduction techniques, and Six Sigma utilizes statistical tools to reduce process variation, together resulting in a streamlined and robust supply chain system.

Holistic View of Supply Chain Performance

By considering supply chain performance in a holistic manner, incorporating TOC along with Lean and Six Sigma provides a comprehensive improvement strategy. TOC identifies global optimization opportunities, ensuring that constraints are eliminated without negatively impacting other parts of the supply chain. In contrast, Lean and Six Sigma focus on specific process improvements, effectively addressing localized optimization needs.

Increased Adaptability and Responsiveness

Incorporating TOC, Lean, and Six Sigma together also enhances the adaptability and responsiveness of the supply chain. TOC facilitates better decisions based on the identification and prioritization of constraints; Lean fosters a culture of continuous improvement focused on waste elimination, and Six Sigma promotes a data-driven decision-making approach. As a result, the combined use of these management approaches enables organizations to proactively address changes in market demands and customer needs.

In conclusion, the Theory of Constraints, when integrated with Lean Manufacturing and Six Sigma, offers a robust and comprehensive framework to optimize supply chain performance. This combined approach allows organizations to address both global and localized optimization needs, fostering increased efficiency, adaptability, and responsiveness in a dynamic business environment. Overall, the synthesis of these management approaches provides a powerful tool for organizations striving to achieve and maintain a competitive edge in their respective industries.

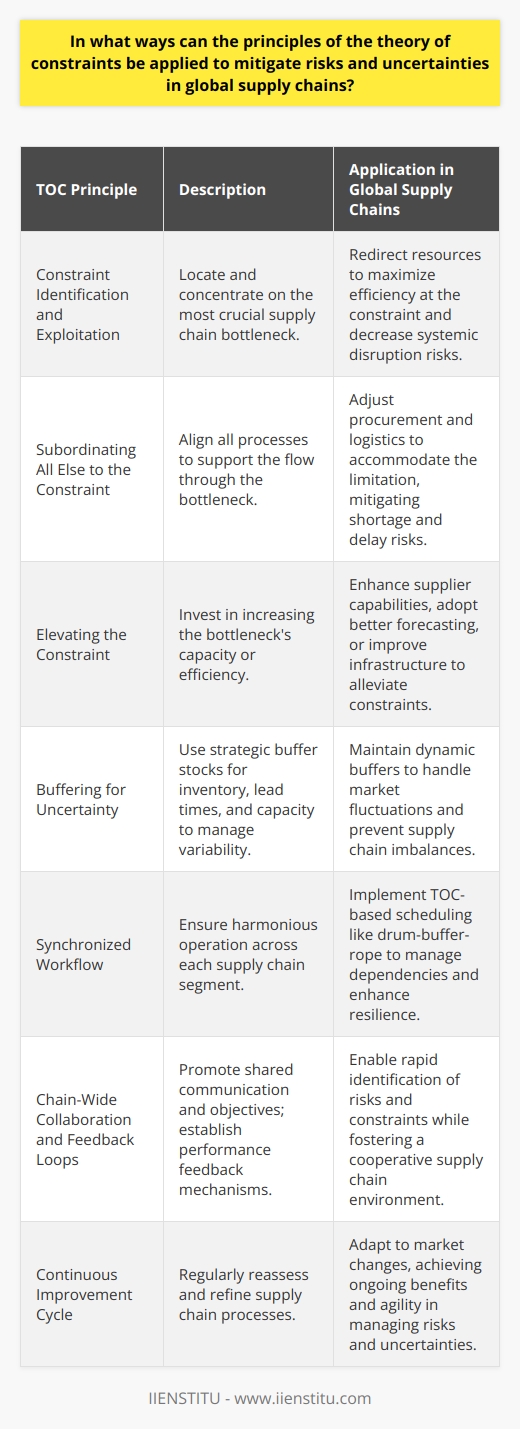

In what ways can the principles of the theory of constraints be applied to mitigate risks and uncertainties in global supply chains?

Application of TOC Principles

To mitigate risks and uncertainties in global supply chains, the Theory of Constraints (TOC) can be applied in various ways. One significant method is through identifying supply chain constraints, which could be demand-related, capacity-driven, regulatory, or technological. Recognizing these constraints enables organizations to address them directly and develop effective strategies.

Prioritizing Constraint Management

Firstly, companies can prioritize constraint management by narrowing their focus. Rather than tackling multiple risks simultaneously, they can address the most binding constraint. This targeted approach allows for efficient resource allocation and improved performance, as it helps eliminate waste and redundancy while achieving the desired outcome.

Utilizing Buffer Management

Secondly, buffer management is another pivotal TOC principle that can aid in risk mitigation. Appropriate buffer positioning and sizing ensure the smooth flow of materials, information, and finances along the supply chain. By closely monitoring these buffers, organizations can respond quickly to unexpected events, thus reducing the impact of uncertainties.

Adopting Continuous Improvement

Lastly, continuous improvement is a core tenet of TOC, emphasizing that organizations should regularly evaluate their processes and adjust them to address current and potential constraints. Companies can systematically identify weak points in their supply chains, anticipate potential disruptions, and implement measures to prevent or minimize risks.

In summary, applying the principles of the Theory of Constraints in global supply chains contributes to risk mitigation by focusing on the most critical constraints, managing buffers effectively, and continually refining processes. By doing so, organizations can adapt to uncertainties and maintain a competitive advantage in the dynamic global marketplace.