Streamlining material handling and storage in any organization can feel like trying to solve a complex puzzle. I remember when I first started working in the logistics sector, the warehouse felt like a maze—products scattered, workers hustling without a clear direction, and delays becoming the norm rather than the exception. It was evident that without the right strategies in place, inefficiencies would continue to plague the supply chain. However, with careful planning and the implementation of effective systems, it's entirely possible to transform this chaos into a well-oiled machine.

Introduction

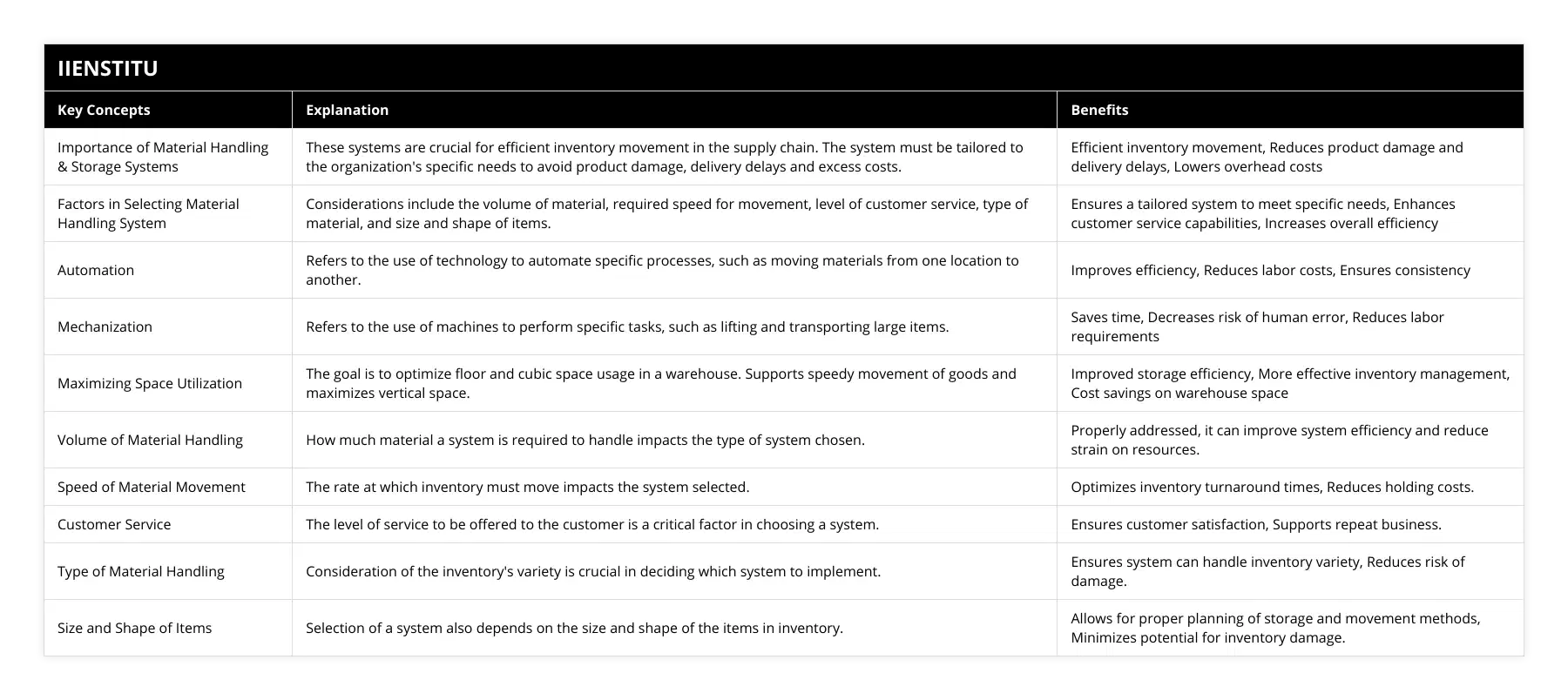

The Importance of Material Handling & Storage Systems

Factors to Consider When Selecting a Material Handling System

Benefits of Automation & Mechanization

Maximizing Space Utilization

The Heart of Logistics: Material Handling & Storage Systems

At the core of any successful supply chain management lies the efficiency of its material handling and storage systems. These systems are not just about moving goods from point A to point B; they're about ensuring that every product reaches its destination safely, promptly, and cost-effectively. I recall a time when our company's outdated handling system led to consistent delays and damaged goods. Customers were unhappy, and we knew something had to change.

Understanding Supply Chain Management

Before diving deeper, it's essential to grasp the meaning of logistics and how it intertwines with supply chain management. Logistics, in its simplest form, refers to the detailed coordination of complex operations involving people, facilities, and supplies. On the other hand, supply chain management (SCM) encompasses the entire production flow of goods or services—from the raw components to delivering the final product to the consumer.

In essence, SCM is like the backbone of any business that deals with products. It involves supply chain activities such as sourcing, procurement, conversion, and logistics management activities. Effective SCM management ensures that businesses can cut excess costs and deliver products faster to the consumer.

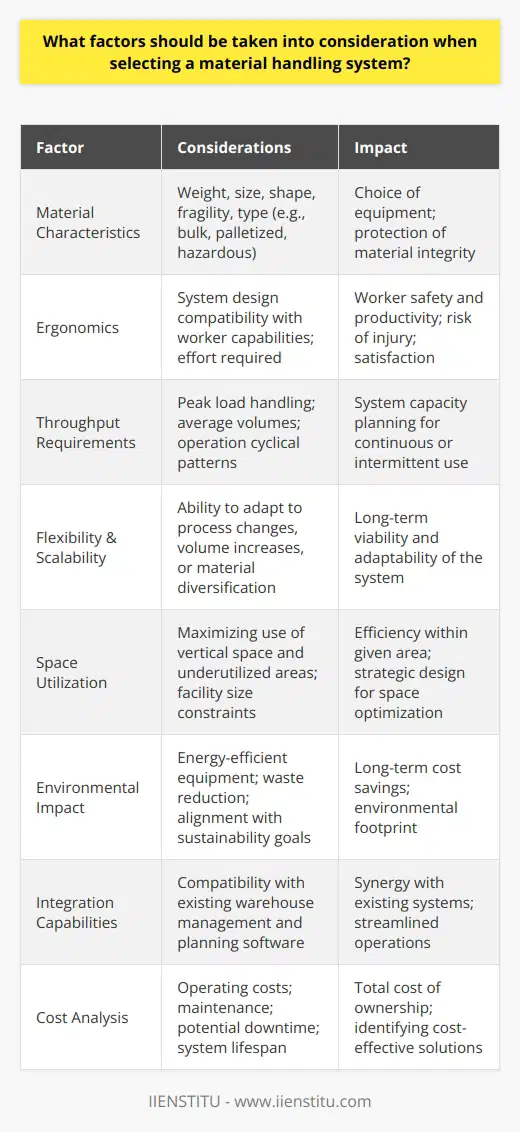

Factors to Consider When Selecting a Material Handling System

When we faced challenges in our warehouse, we realized that selecting the right material handling system wasn't just about picking the latest technology or the cheapest option. It was about understanding our specific needs and the unique demands of our operations.

Here are some crucial factors we considered:

1- Volume of Material: The quantity of goods we handled daily significantly influenced the type of system we needed.

2- Speed Requirements: Fast-moving goods required systems that could keep up with the pace without causing bottlenecks.

3- Customer Service Needs: We had to ensure that the system could meet our promise to customers regarding delivery times and product availability.

4- Type and Nature of Materials: Handling delicate electronics is different from managing bulk raw materials.

5- Space Constraints: Our warehouse space was limited, so maximizing space utilization was paramount.

6- Labor Considerations: We needed to consider the availability and cost of labor—could automation be more efficient?

7- Flexibility and Scalability: The system had to adapt to changing demands and seasonal fluctuations.

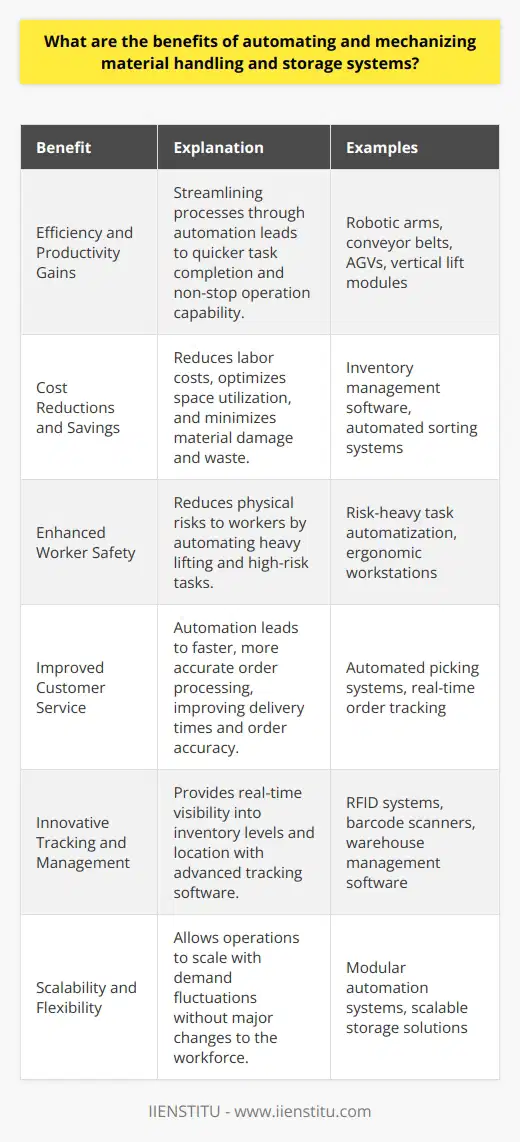

The Role of Automation & Mechanization

Embracing automation and mechanization was a game-changer for us. Initially, there was skepticism—would machines replace jobs? Would the cost of investment be justifiable? However, the benefits soon became evident.

Automation refers to using control systems and technology to manage processes with minimal human intervention. For instance, automated conveyor belts, robotic arms for picking and placing, and computerized tracking systems enhanced our efficiency.

Mechanization, on the other hand, involves using machinery to assist or replace human labor, especially in tasks that are repetitive or physically demanding. Equipment like forklifts, pallet jacks, and automated storage and retrieval systems (AS/RS) fall into this category.

The key to successful logistics is efficient material handling and storage.

Benefits We Experienced:

Increased Efficiency: Tasks were completed faster, reducing lead times.

Reduced Errors: Automation minimized human errors, especially in inventory management.

Improved Safety: Mechanization reduced the risk of injuries from manual handling.

Cost Savings: Over time, the reduction in labor costs and increased productivity led to significant savings.

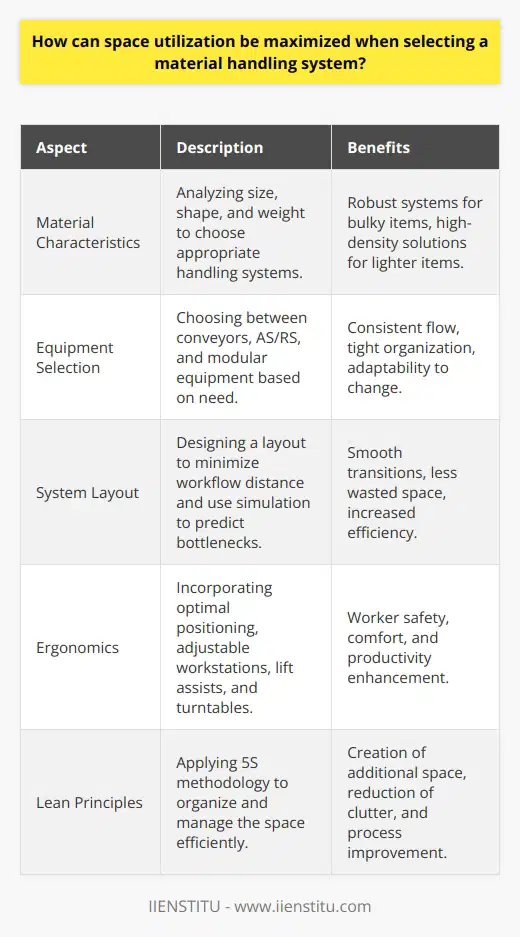

Maximizing Space Utilization: Making Every Square Foot Count

Space in a warehouse is like gold. Every unused or poorly used square foot is a missed opportunity. When we started focusing on supply and chain management, we realized that optimizing our space wasn't just about fitting more products but about enhancing the overall flow and accessibility.

Strategies We Implemented:

1- Vertical Storage Solutions: By utilizing vertical space with tall shelving units and mezzanines, we significantly increased our storage capacity.

2- Cross-Docking: This involved unloading materials from incoming trucks and loading them directly onto outbound trucks, reducing storage needs.

3- Inventory Management Systems: Implementing advanced SCM supply software helped us keep track of stock levels and reduce overstocking.

4- Aisle Optimization: Narrower aisles and efficient layout designs allowed more storage space without compromising accessibility.

5- Regular Audits: Periodically reviewing our storage usage helped identify areas of improvement.

Balancing Multiple Factors for Seamless Movement

Creating efficient material handling and storage systems isn't just about individual components but about how they all come together. It's like orchestrating a symphony—each instrument (or in this case, each department) must be in harmony with the others.

Key Elements to Balance:

Coordination Between Departments: Ensuring smooth communication between procurement, production, storage, and delivery teams.

Technology Integration: Using integrated systems where data flows seamlessly between departments, enhancing visibility and decision-making.

Employee Training: Our staff needed to be adept at using new systems and understanding the importance of their roles in the bigger picture.

Real-Life Example: Transforming Challenges into Opportunities

At one point, we received a reassignment request letter from a key employee who felt that the inefficiencies were too frustrating to handle. This was a wake-up call. We took this feedback seriously and held open forums to understand the ground-level challenges better.

By involving our team in the problem-solving process, we not only found practical solutions but also boosted morale. Their insights led to simple yet effective changes, such as rearranging the storage layout and implementing suggestion boxes for continuous improvement.

The Broader Impact on Chain of Supply Management

Effective material handling and storage systems don't just benefit the warehouse—they have ripple effects throughout the entire management chain supply. When products move smoothly through the supply chain, customer satisfaction increases, company reputation improves, and profitability grows.

Benefits Beyond the Warehouse:

Enhanced Customer Experience: Timely deliveries and fewer errors lead to happier customers.

Competitive Advantage: Efficiency can set a company apart in a crowded market.

Sustainability Efforts: Efficient systems often reduce waste and energy consumption.

Tips for Organizations Looking to Improve

1- Assess Current Systems: Understand where inefficiencies lie. Is it in the handling, storage, or movement of goods?

2- Engage with Employees: They often have valuable insights into day-to-day operations.

3- Invest in Technology Wisely: Not all solutions require high-tech investments. Sometimes, simple mechanization can make a big difference.

4- Continuous Improvement: Regularly review and adjust systems as needed.

5- Educate Yourself: Understanding the intricacies of supply chain mgmt through courses or literature can provide fresh perspectives.

Conclusion: The Key to Successful Supply Chain Management

Streamlining material handling and storage is not just about reducing costs or speeding up processes; it's about creating a cohesive and efficient system that benefits everyone involved—from the supplier to the end customer.

Reflecting on our journey, I realize that the challenges we faced were stepping stones to building a more robust and resilient supply chain. By considering speed requirements, customer service needs, and space utilization techniques such as automation or mechanization, organizations can indeed optimize their operations for maximum efficiency.

Remember, the key to successful logistics is efficient material handling and storage. It's a continuous journey of balancing multiple factors to ensure seamless movement between departments—from production to delivery!

References

1- Christopher, M. (2016). Logistics & Supply Chain Management. Pearson UK.

2- Rushton, A., Croucher, P., & Baker, P. (2017). The Handbook of Logistics and Distribution Management. Kogan Page Publishers.

3- Arnold, J. R. T., Chapman, S. N., & Clive, L. M. (2018). Introduction to Materials Management. Pearson.

4- Johnson, J. C., & Wood, D. F. (2019). Contemporary Logistics. Prentice Hall.

5- Mangan, J., Lalwani, C., & Lalwani, C. L. (2016). Global Logistics and Supply Chain Management. John Wiley & Sons.

Note: This content is based on professional experiences and widely recognized publications in the field of logistics and supply chain management.

Frequently Asked Questions

What are the benefits of automating and mechanizing material handling and storage systems?

Automating and mechanizing material handling and storage systems has revolutionized warehouses, manufacturing facilities, and distribution centers. Automating these processes can increase efficiency, reduce costs, boost worker safety, and improve customer service.

By automating material handling and storage systems, warehouses and manufacturing facilities can reduce overhead costs. Automation reduces labor costs by eliminating the need for human labor to move and store materials. Automated systems can also reduce the time needed for order picking, inventory control, and restocking processes. Computerized systems can also reduce the amount of energy used for these tasks.

Automating material handling and storage systems can also improve worker safety. Manual handling of materials is associated with an increased risk of injuries, such as strains and sprains. Automated systems reduce the risk of injuries by eliminating the need for manual labor. Additionally, automated systems can reduce the risk of accidents and injuries by providing a safer work environment.

Finally, automating material handling and storage systems can improve customer service. Automated systems can reduce the time it takes to fulfill orders and process returns, resulting in faster order fulfillment times. Computerized systems can also reduce the number of errors associated with manual processes, resulting in fewer customer complaints.

In conclusion, automating and mechanizing material handling and storage systems offers a range of benefits, including cost savings, improved worker safety, and better customer service. Automated systems can reduce labor costs, reduce the risk of injuries, and improve customer service, making them an attractive option for warehouses, manufacturing facilities, and distribution centers.

How can space utilization be maximized when selecting a material handling system?

When selecting a material handling system, maximizing space utilization is a critical factor to consider. Proper space utilization can help increase efficiency, reduce costs, and improve safety and productivity.

One way to maximize space utilization when selecting a material handling system is to consider the material to handle. Different materials require different amounts of space, and choosing the right design for the job can help optimize the available space. Additionally, selecting the correct type of system can help ensure that the material is handled efficiently and safely.

Another way to optimize space utilization is to consider the system's layout. A well-designed material handling system should be able to use the available space in the most efficient way possible. The system's structure should be designed to reduce clutter, improve productivity, and maximize safety. Additionally, the layout should be prepared to use the available space in the most efficient way possible.

Finally, it is essential to consider the system's ergonomics when selecting a material handling system. Ergonomically designed systems are more efficient and safer, as they reduce the physical strain on employees and reduce the risk of injury. Additionally, ergonomically designed systems are more comfortable for employees, which leads to improved productivity and morale.

In conclusion, there are several ways to optimize space utilization when selecting a material handling system. By considering the type of material to be handled, designing an efficient layout, and establishing an ergonomically designed system, it is possible to maximize space utilization and improve efficiency, safety, and productivity.

What factors should be taken into consideration when selecting a material handling system?

Material handling systems are used in various industries to assist in the movement of materials, products, and goods. When selecting a material handling system, it is essential to consider several factors.

The first factor to consider is cost. Material handling systems come at various prices, and it is essential to ensure that the selected design will be within the budget constraints. Additionally, it is necessary to consider the cost of installation and ongoing system maintenance.

The second factor to consider is capacity. It is essential to ensure that the material handling system can handle the volume of materials, products, and goods that will be moved. It is also necessary to consider the speed of the system and its ability to handle the desired volume of materials in the required time frame.

The third factor to consider is safety. The material handling system must be designed to ensure the safety of personnel operating the system and those who may be in the vicinity of the system. It is essential to consider any potential hazards associated with the design and ensure proper safety protocols are in place.

The fourth factor to consider is scalability. It is essential to ensure that the material handling system can be easily expanded or modified to meet the changing needs of the business. Additionally, it is necessary to consider the potential for integration with existing systems and the ease of adding or removing components as needed.

Finally, it is essential to consider the type of materials the system will handle. Different materials require different handling systems, and it is necessary to ensure that the selected method can handle the materials used. Additionally, it is essential to consider the materials' size, shape, and weight.

In conclusion, several factors should be considered when selecting a material handling system. It is essential to consider cost, capacity, safety, scalability, and the type of materials that will be handled. By considering these factors, businesses can ensure that they select the most suitable system for their needs.

What is material handling and storage in logistics?

Material Handling and Storage: Definition and Importance

Material handling in logistics refers to the process of managing and moving materials, goods, or products within manufacturing operations, warehouses, distribution centers, and other logistics environments. It includes activities such as loading, unloading, lifting, transferring, and transporting materials via different equipment and technologies. Material handling plays a crucial role in ensuring the safe, efficient, and cost-effective transportation of goods throughout the supply chain.

Significance of Material Handling Systems

Well-designed material handling systems help companies achieve optimized operations, reduced labor costs, increased productivity, and improved workplace safety. By implementing effective material handling strategies, organizations can minimize the risk of damaged or lost materials, while also reducing operational costs and delivery time. In addition, proper material handling leads to a better utilization of space, resulting in more effective storage and distribution.

Key Equipment and Technologies

Various types of equipment and technologies are used in material handling processes, including forklifts, pallet jacks, conveyors, automated guided vehicles (AGVs), and robotics. These tools and systems enable efficient movement, storage, and tracking of materials throughout the logistics process. The choice of equipment depends on factors such as the nature of the materials, the layout of the logistics facility, and the specific handling requirements of the operation.

Storage Solutions in Logistics

Storage in logistics is concerned with the efficient and systematic organization of materials within a facility. Effective storage systems not only optimize the available space but also ensure the easy retrieval, timely delivery, and proper protection of goods. Various types of storage solutions exist, such as pallet racking, mezzanines, shelving, and modular drawer cabinets. The right storage system can improve inventory management, reduce errors, and enhance overall operational efficiency.

Role of Material Handling and Storage in Supply Chain Management

Material handling and storage are critical components of the supply chain management process. They help ensure that products are moved and stored effectively throughout the entire logistics operation, from raw materials acquisition to finished goods distribution. Efficient material handling and storage systems can lead to reduced lead times, increased customer satisfaction, and a greater competitive advantage in the market. Therefore, ongoing innovation, investment, and improvement in these areas are essential for companies aiming to maintain a robust and responsive supply chain.

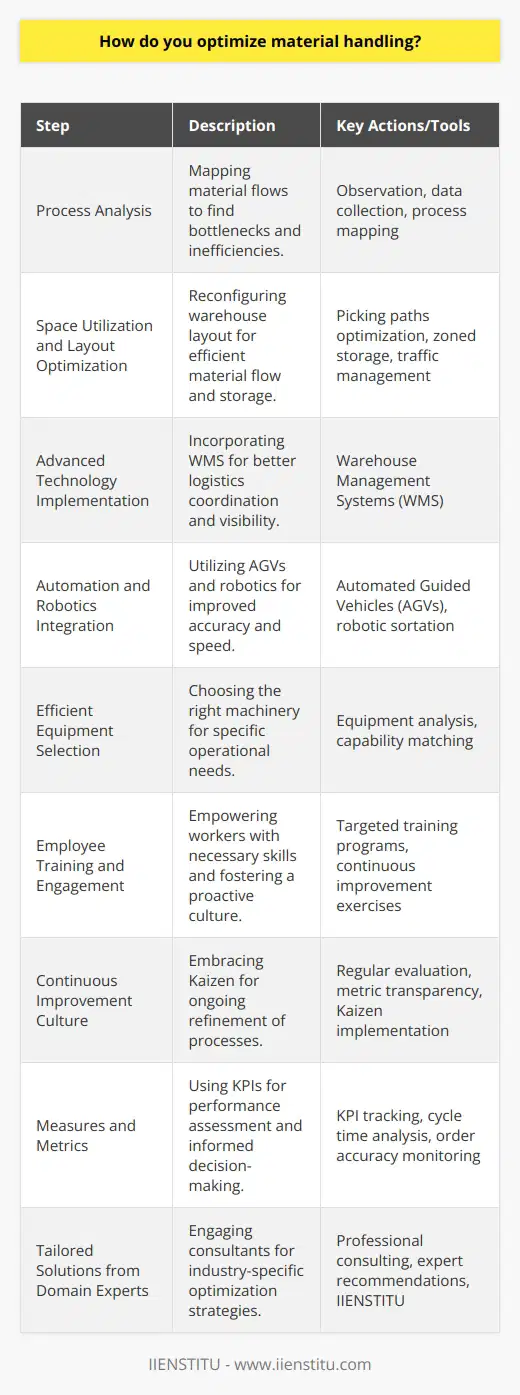

How do you optimize material handling?

Understanding Material Handling Optimization

Optimizing material handling involves a thorough analysis of the entire distribution process. It starts with evaluating the organization's production and distribution networks while identifying bottlenecks and operational inefficiencies. By studying various factors like resource allocation, inventory levels, and equipment utilization, one can develop data-driven strategies to maximize efficiency and minimize costs in the supply chain.

Implementing Warehouse Management Systems

A key factor in optimizing material handling is the implementation of warehouse management systems (WMS). These systems enable real-time data access and provide visibility into inventory levels and warehouse operations. WMS enhances decision-making capabilities, improves inventory tracking and control while reducing human error.

Automation and Robotics Integration

Integrating automation and robotics in material handling processes can lead to significant cost savings and enhanced productivity. Automated guided vehicles (AGVs) and robotic palletizers, for example, can reduce manual labor, boost efficiency, and improve accuracy. As a result, businesses can achieve higher throughput rates and lower operational costs.

Investing in Efficient Equipment

Investing in high-quality, efficient equipment can have a profound impact on optimizing material handling. Equipment like conveyors, lift trucks, and storage solutions should be selected based on specific industry requirements and warehouse layouts. Proper equipment selection not only enhances productivity but also minimizes maintenance costs and downtime.

Regular Employee Training

Regular employee training is essential for maintaining an optimized material handling operation. Training sessions should focus on equipment operation, maintenance, safety, and best practices. Well-trained employees are less likely to make errors and can contribute significantly to the overall efficiency of the system.

Continuous Improvement Initiatives

Lastly, adopting continuous improvement initiatives such as Lean or Six Sigma methodologies can help organizations in achieving long-term material handling optimization goals. This involves consistent analysis of processes, regular evaluation of key performance indicators (KPIs), and employee engagement in problem-solving and continuous improvement efforts. Ultimately, this fosters a culture of optimization and encourages constant growth and development.

In summary, optimizing material handling is a comprehensive approach that entails process analysis, implementing warehouse management systems, integrating automation, using efficient equipment, conducting regular employee training, and fostering a culture of continuous improvement. By adopting these strategies, organizations can streamline their supply chain processes, realize cost savings, and enhance overall productivity.

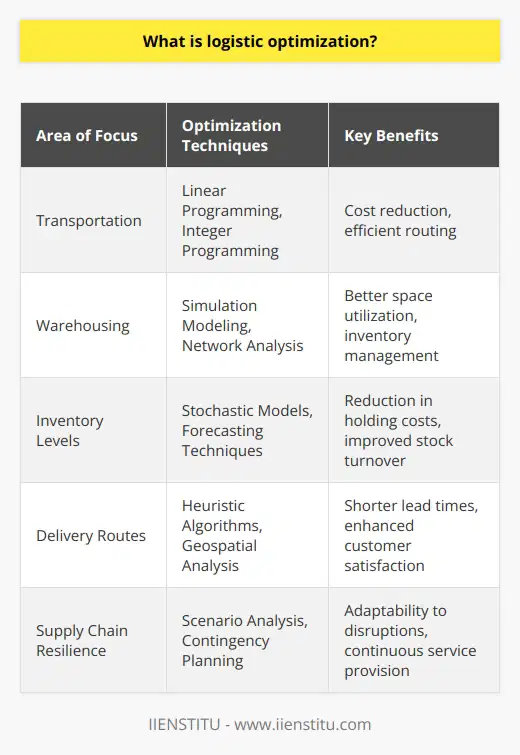

What is logistic optimization?

Logistic Optimization: Definition and Goals

Logistic optimization is a process that attempts to improve the efficiency and effectiveness of a logistics system. It revolves around the planning, organization, and control of various activities in a supply chain, with the aim of minimizing costs while maintaining high service levels. This is achieved by analyzing the transportation, warehousing, and distribution of goods to determine the best strategies and solutions for each aspect.

Importance of Logistic Optimization

Optimizing logistics minimizes operating expenses, reduces inventory costs, and ensures timely delivery services. As global competition increases, the need for an efficient and cost-effective logistics system becomes essential. In this context, logistic optimization plays a crucial role in strengthening a company's competitive advantage. Furthermore, effective logistic management contributes significantly to reducing a business's carbon footprint and promoting sustainable practices.

Methods and Techniques

Several techniques can be applied in logistic optimization. The methods vary, ranging from simple to highly sophisticated algorithms. These techniques include linear programming, integer programming, network analysis, and simulation modeling. Depending on the intricacies of a particular logistic problem, one or more of these methodologies can be employed to achieve optimal solutions.

Overcoming Challenges in Logistic Optimization

Determining the optimal logistics solutions can be complex due to the need to balance cost and service quality. Moreover, each element of the supply chain contributes to the overall efficiency and effectiveness of the system. When addressing logistic optimization, it is crucial to consider the interdependencies between various components. This may include accounting for factors such as demand fluctuations, supplier reliability, transportation disruptions, and changing regulations.

Conclusion

Logistic optimization is essential to streamline supply chain operations, minimize costs, and maintain a competitive edge in the market. By leveraging various techniques and methods, businesses can optimize their logistics processes and improve overall performance. With the increasing focus on sustainability and environmental concerns, logistic optimization also contributes to reducing the negative impact of business operations on our planet.

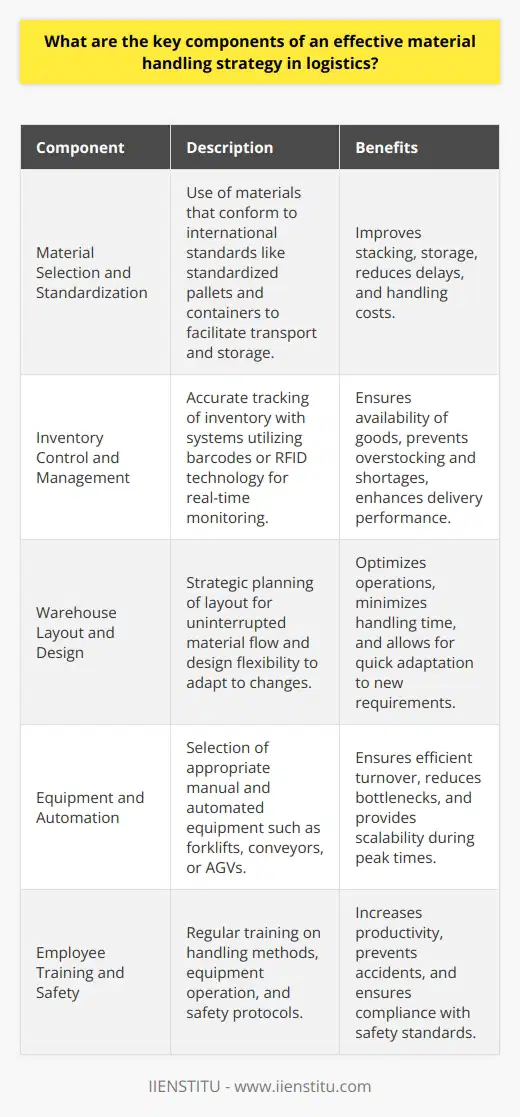

What are the key components of an effective material handling strategy in logistics?

Material Selection and Standardization

The first component of an effective material handling strategy in logistics is material selection and standardization. This involves selecting the appropriate materials for handling various types of products, including choosing the right type of pallet, container, or packaging that meets established industry standards. Standardizing material handling processes can lead to reduced costs, increased efficiency, and improved safety in the logistics chain.

Inventory Control and Management

Another key component of material handling strategy is inventory control and management. An efficient inventory management system helps to track the location, quantity, and movement of materials within a warehouse or storage facility. Implementing barcode or RFID scanning technology can greatly enhance inventory accuracy, reduce the risk of stockouts, and avoid excess inventory, ultimately optimizing material flow and minimizing costs associated with warehouse storage.

Warehouse Layout and Design

The warehouse layout and design play a crucial role in effective material handling. A well-planned layout can improve the overall flow of materials within the warehouse, minimizing unnecessary handling and optimizing the use of space. Considering factors such as aisle widths, storage rack dimensions, and equipment accessibility are essential in designing a layout that maximizes efficiency and minimizes the risk of accidents.

Equipment and Automation

Investing in the right equipment and automation technology can greatly improve material handling efficiency. From simple tools such as hand trucks and pallet jacks to more advanced automated systems like conveyors and automated guided vehicles (AGVs), the choice of equipment should be based on the specific needs of the logistics operation. Automation technologies can help to reduce manual labor, increase throughput, and enhance the overall efficiency of material handling processes.

Employee Training and Safety

Lastly, employee training and safety are critical components of an effective material handling strategy. Providing ongoing training for workers on proper material handling techniques and the use of equipment can reduce the risk of injuries and increase productivity. Additionally, implementing safety measures such as clear signage, well-maintained equipment, and regular inspections can contribute to a safe working environment and a more efficient logistics operation.

In conclusion, effective material handling strategies in logistics consist of several key components, including material selection and standardization, inventory control, warehouse layout and design, equipment automation, and employee training and safety. By focusing on these factors, businesses can enhance efficiency, minimize costs, and reduce the risk of accidents in their material handling processes.

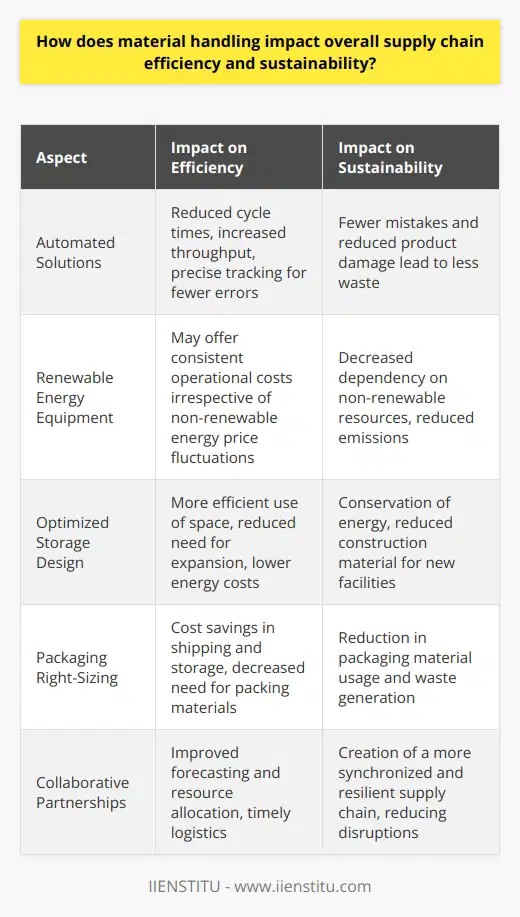

How does material handling impact overall supply chain efficiency and sustainability?

Material Handling's Effect on Efficiency

Material handling plays a crucial role in improving overall supply chain efficiency, directly affecting the speed, accuracy, and cost-effectiveness of various processes. These include the movement, storage, control, and protection of materials and products throughout manufacturing, warehousing, distribution, and disposal processes. By implementing advanced material handling solutions, such as automated storage and retrieval systems, businesses can significantly enhance their supply chain performance. This results in faster production rates, reduced errors, lower labor costs, and improved customer satisfaction.

Sustainability in Material Handling

Moreover, companies are increasingly focusing on the sustainability aspect of material handling in supply chain management. This involves minimizing the environmental impact of material handling activities, particularly through the utilization of eco-friendly equipment and energy-efficient practices. For instance, the deployment of electric-powered forklifts and conveyors replacing traditional fossil fuel-driven machines contributes to reduced greenhouse gas emissions. Additionally, optimizing material flow and inventory management reduces the need for excessive transportation and warehousing requirements, thereby lessening energy consumption and carbon footprint.

Addressing Challenges

Implementing sustainable material handling practices in the supply chain faces several challenges, including high initial investment costs for advanced equipment and the need to train workforce members in adopting new techniques. However, organizations can overcome these hurdles by focusing on long-term benefits and incorporating cost-effective, scalable solutions tailored to their specific operational requirements. This may involve investing in modular and recyclable material handling equipment, utilizing energy management systems, and prioritizing regular maintenance to maximize the lifespan of assets.

Enhancing Supply Chain Collaboration

The effectiveness of material handling strategies in increasing supply chain efficiency and sustainability depends on strong collaboration and communication among various stakeholders. Supply chain partners, from suppliers and manufacturers to logistics providers and customers, must collaborate in information-sharing and decision-making processes. This allows for better forecasting, planning, and execution of material handling activities, aligning them with overarching supply chain objectives. A robust collaboration framework minimizes risks associated with disruptions, redundancies, and inefficiencies across the entire supply chain.

Conclusion

In conclusion, material handling serves as an indispensable element in shaping overall supply chain efficiency and sustainability. The integration of efficient and eco-friendly practices in material handling processes not only drives cost savings and enhances customer satisfaction but also minimizes the environmental footprint of businesses. By addressing challenges and fostering collaboration, organizations can maximize the potential of their material handling operations and, in turn, ensure a more reliable and sustainable supply chain.

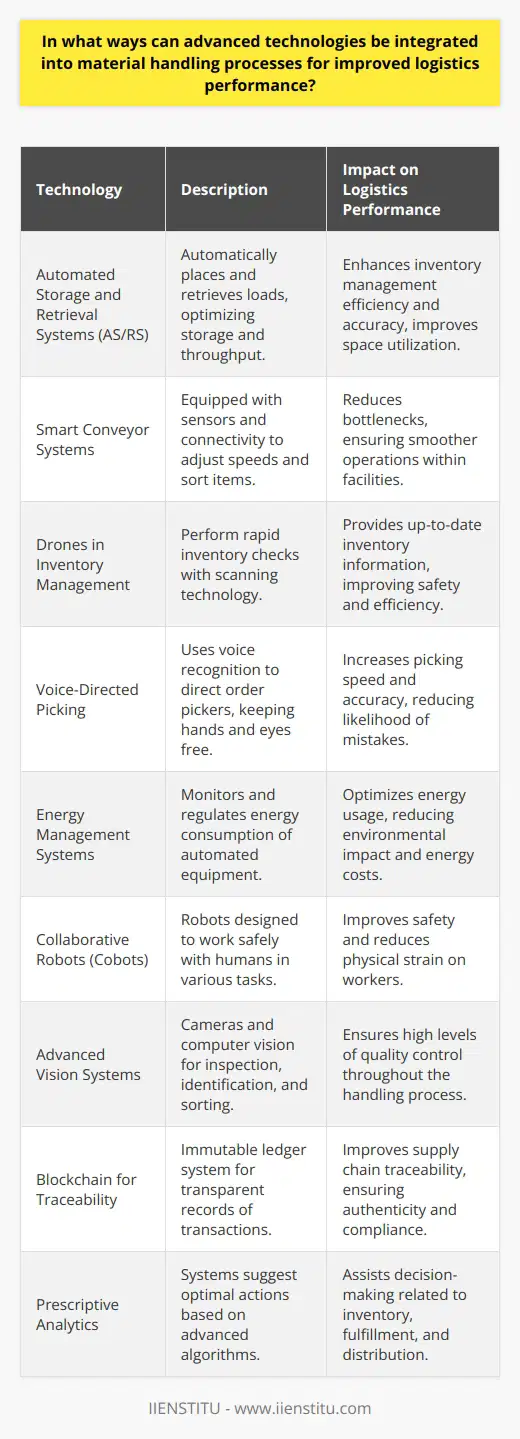

In what ways can advanced technologies be integrated into material handling processes for improved logistics performance?

Technology Integration in Material Handling

Advanced technologies can significantly improve logistics performance through their integration into material handling processes. These technologies can streamline operations, support decision-making, and enhance overall efficiency. The following sections highlight a few prominent examples.

Automated Guided Vehicles

Automated Guided Vehicles (AGVs) are autonomous vehicles employed in warehouses and distribution centers to transport materials. AGVs can enhance productivity and minimize manual labor, thereby reducing human error and ensuring accurate product handling.

Robotics and Automation

Robots can perform various material handling tasks, such as picking, packing, and palletizing. These automation systems can reduce human intervention, increase throughput, and enable organizations to respond swiftly to changing market demands.

Internet of Things (IoT)

Implementing IoT devices in material handling systems can enable real-time tracking and monitoring. This capability allows decision-makers to identify operational inefficiencies and optimize the logistics process, resulting in improved performance.

Warehouse Management Systems

Advanced Warehouse Management Systems (WMS) integrate various technologies to provide better visibility, control, and optimization in material handling processes. These tools can improve inventory management, enhance order fulfillment accuracy and speed, and facilitate better utilization of resources.

Machine Learning and Artificial Intelligence

Machine learning algorithms and artificial intelligence can be used to analyze vast amounts of data generated by material handling systems. This analysis can drive better decision-making by identifying patterns, predicting demand, and optimizing routes for maximum efficiency.

Augmented Reality

Employing augmented reality (AR) tools, such as smart glasses or mobile applications, in material handling processes can improve precision and reduce errors. AR can equip workers with overlaying contextual information on their physical environment, enabling faster and more accurate execution of tasks.

Monitoring and Analytics

Advanced technologies can provide real-time monitoring and analytics capabilities, ensuring proper functioning of material handling processes. These analytical tools can offer insights into operational efficiency, machine health, and overall performance, enabling organizations to optimize their logistics processes.

In conclusion, the integration of advanced technologies into material handling processes can enhance logistical performance by automating tasks, improving decision-making, and optimizing resource utilization. These solutions promote operational efficiency, reduce human error, and support the overall success of organizations in the highly competitive logistics market.

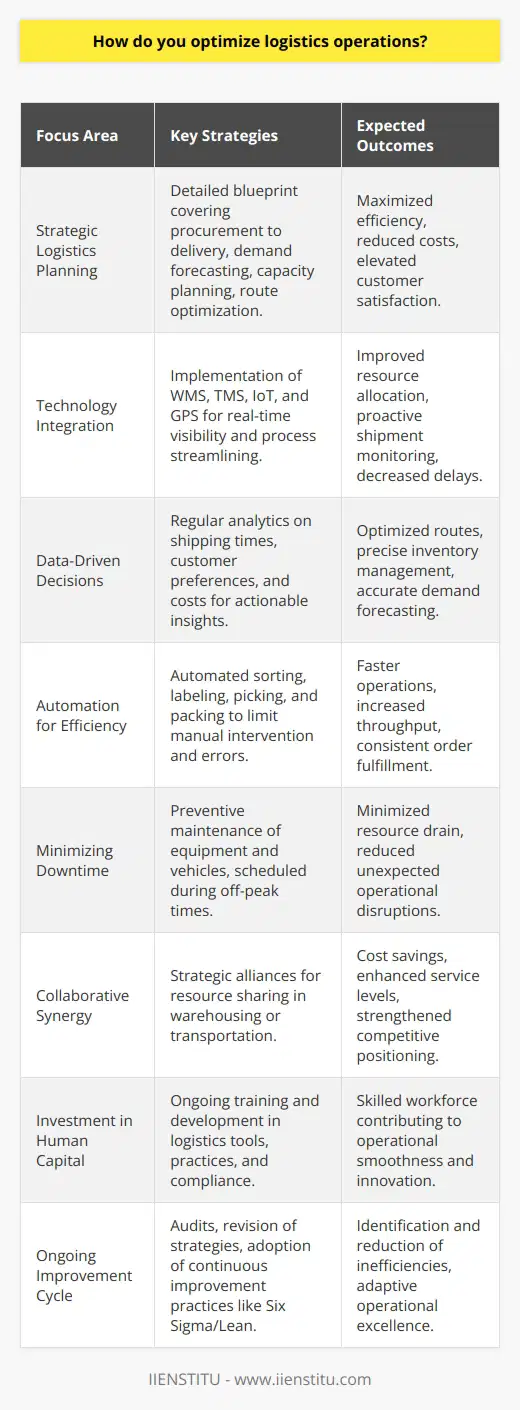

How do you optimize logistics operations?

Logistics Planning

Firstly, to optimize logistics operations, extensive logistics planning becomes essential. This involves having a comprehensive strategy for procurement, production, and distribution.

Use of Technology

Adapting to changes in technology is crucial. Utilization of advances such as real-time tracking, Warehouse Management Systems (WMS), and Transportation Management Systems (TMS) proves beneficial.

Data Analysis

Additionally, gathering and analyzing data on a regular basis is key. It helps in predicting demand, managing inventory, and identifying areas for improvement.

Automation

Automation of regular tasks can also improve logistics operations. It eliminates manual errors, saves precious time, and enhances customers' service.

Reducing Downtime

Reducing downtime is another essential aspect. Efficient preventive maintenance systems can keep equipment running smoothly, reducing unexpected breakdowns.

Collaborative Approach

Establishing strategic partnerships and alliances also helps in optimization. A collaborative approach often leads to shared resources and capabilities, enhancing overall efficiency.

Training and Development

Conducting regular training programs for the workforce contributes to optimization as well. Keeping the team updated with the latest trends and techniques in logistics is beneficial.

Check and Revise

Eventually, there should be a system to check and revise the logistics strategies. Regular audits and revisions enable companies to stay competitive and ensure their logistics operations are optimized.

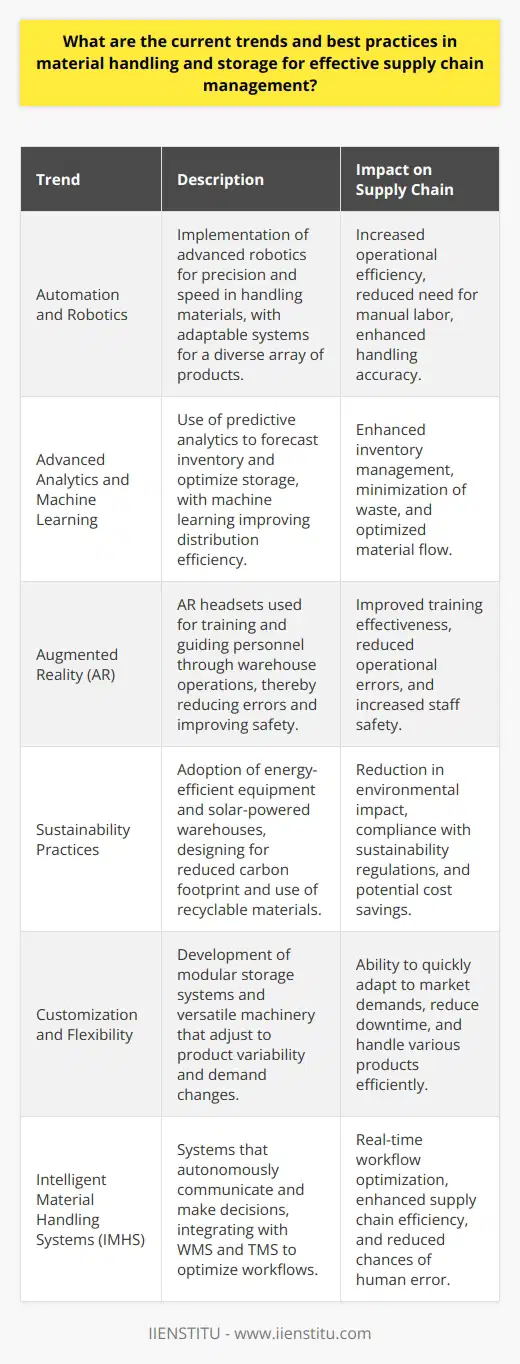

What are the current trends and best practices in material handling and storage for effective supply chain management?

Automation in Material Handling Systems

Nowadays, automation is a prominent trend in material handling and storage. It involves incorporating technologies such as robotics, artificial intelligence, and machine learning. Automated systems ensure accuracy, efficiency, and increased productivity, thus contributing significantly to successful supply chain management.

Improvement in Inventory Management

Inventory management has also witnessed noticeable changes. RFID (Radio Frequency Identification) and IoT (Internet of Things) technologies have become standard in tracking and controlling inventory items. These technologies help in real-time monitoring and provide accurate inventory data, preventing overstocking and stock-outs.

Adoption of Green Practices

Sustainability also features as a contemporary trend in material handling and storage. Companies focus on reducing waste, using recyclable packaging materials, and adopting energy-efficient technologies. These green practices not only minimize the environmental footprint but also lead to cost savings in the long run.

Safety Measures in Storage Facilities

In terms of best practices, safety remains a critical point in material handling and storage. Regular maintenance of facilities, proper staff training, and use of protective gear can significantly reduce workplace accidents. These practices enhance overall productivity and employee satisfaction levels.

Integration of Supply Chain Processes

Finally, integration of supply chain processes has become imperative for a well-functional supply chain. Firms are now investing in advanced software systems that allow consolidation of data. This integration enables easy retrieval and analysis, enhancing decision-making efficiency.

In conclusion, current trends involve leveraging automation, technological advancements and sustainability, while best practices focus on safety and process integration in material handling and storage for efficient supply chain management.

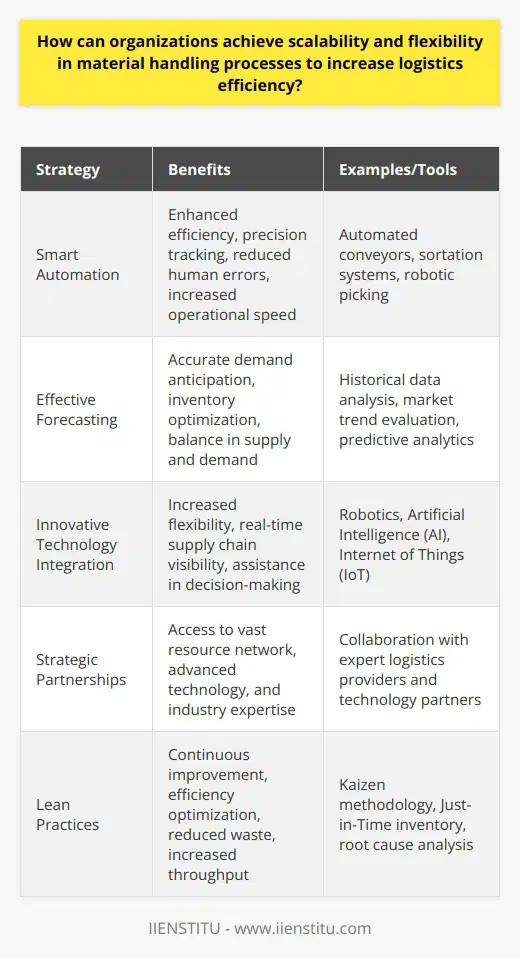

How can organizations achieve scalability and flexibility in material handling processes to increase logistics efficiency?

Smart Automation

Organizations can achieve scalability and flexibility in materials handling processes through smart automation. Automated systems allow for real-time tracking and management of materials. This enhances process efficiency, reduces errors, and streamlines operations.

Effective Forecasting

Effective forecasting is also critical in achieving scalability. Through in-depth analysis and predictive modeling, organizations can anticipate demand fluctuations. This reduces the risk of over or under-stocking, leading to notable cost savings.

Innovative Technology Integration

Incorporating innovative technologies, like robotics, AI, and IoT, can bring about increased flexibility in material handling processes. These technologies provide data-driven insights, aiding in planning, decision-making, and operational efficiency. They also ease the adaptation to changes in volume, variety, and velocity, ensuring continuous flow of operations.

Strategic Partnerships

Strategic partnerships with logistical service providers can help organizations to gain access to their competence and reach. This can improve resource allocation and increase overall efficiency of the supply chain.

Lean Practices

Lastly, the implementation of lean practices can lead to significant efficiency gains. These practices can reduce waste, streamline procedures, and balance workload. They focus on continuous improvement, enhancing the productivity and thereby the scalability and flexibility of the operations.

In conclusion, combining smart automation, effective forecasting, innovative technology integration, strategic partnerships, and lean practices can help organizations achieve scalability and flexibility. These measures can significantly elevate the efficiency and effectiveness of their logistical operations.