I still remember the first time I walked into my family's warehouse as a child. It was a vast space filled with towering shelves and boxes stacked as high as the eye could see. To my young eyes, it was like a playground of endless adventures. Little did I know that behind that seemingly chaotic maze was a carefully orchestrated system designed to keep the wheels of our family business turning smoothly.

The Importance of Efficient Material Storage

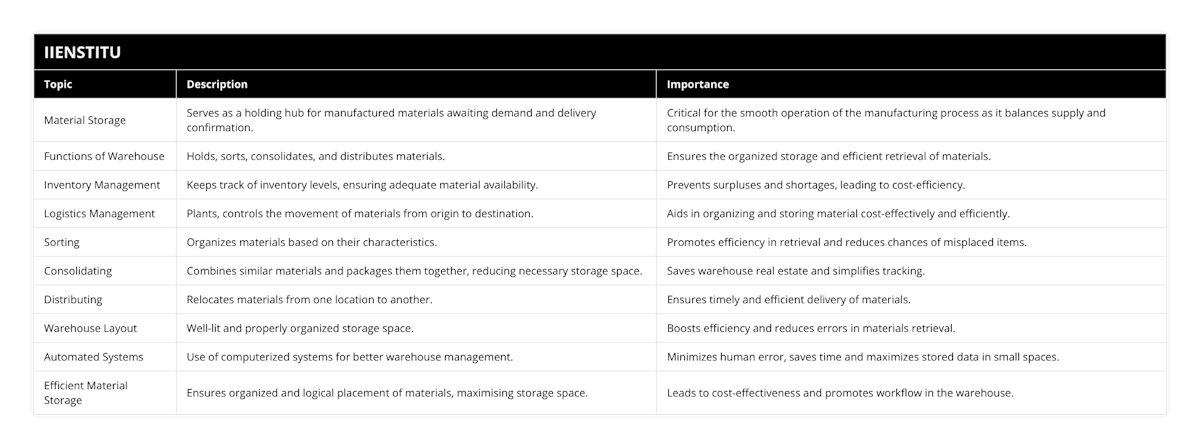

Material storage isn't just about putting things away until they're needed. It's the backbone of any manufacturing or distribution process. An organized warehouse is essential for ensuring that materials are available when needed, reducing costs, and improving overall efficiency.

Introduction

The Function of Material Storage

Logistics Management Strategies

Maximizing Material Storage

Conclusion

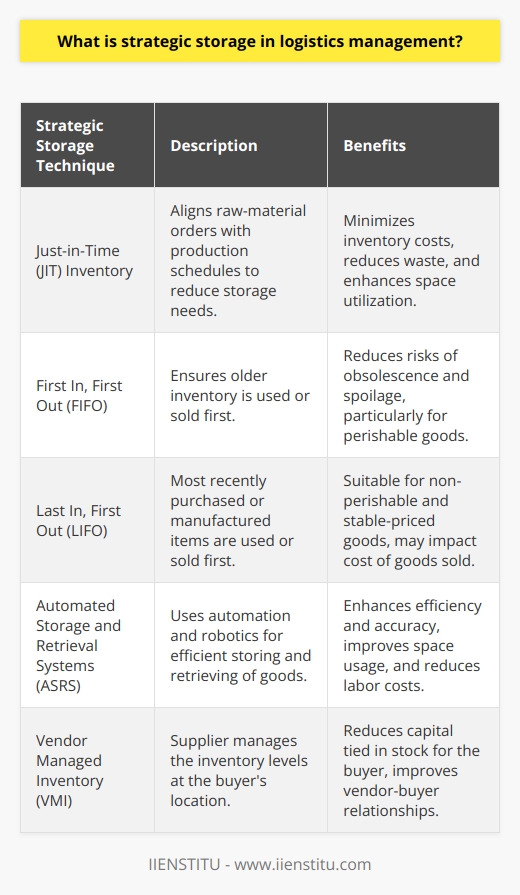

Holding: The Warehouse's Primary Function

At its core, a warehouse acts as a holding space for materials and products. Consider a time when a friend of mine, who runs a local manufacturing business, faced severe delays because his supplier couldn't deliver raw materials on time. He realized that by not maintaining adequate inventory levels, his entire production line could come to a grinding halt. By effectively holding materials, businesses can buffer against supply chain uncertainties.

Sorting: Organizing for Efficiency

Imagine trying to find a needle in a haystack. Without proper sorting, that's precisely what retrieving materials from a warehouse can feel like. By organizing materials according to their characteristics—such as size, weight, or type—we make it easier to locate them when the time comes. I recall visiting a warehouse where items were sorted haphazardly. The staff spent more time searching for products than actually moving them. Implementing a proper sorting system transformed their operations overnight.

Consolidating: Making the Most of Space

Space is at a premium in any warehouse. Consolidating similar materials not only saves space but also streamlines operations. Think about stacking similar boxes together or grouping related products. A colleague once shared how they reduced their storage costs by 20% simply by consolidating their inventory more effectively.

Distributing: Getting Materials Where They Need to Be

Finally, the distribution function ensures that materials move from the warehouse to their next destination efficiently. Whether it's shipping products to customers or moving raw materials to the production line, effective distribution minimizes delays and keeps the entire supply chain flowing smoothly.

An In-depth Study of Lean Logistics: Excellence in Supply Chains

Exploring the Dynamics of Multi-modal Transportation in Supply Chain

Decoding the Process and Benefits of Return Merchandise Authorization (RMA)

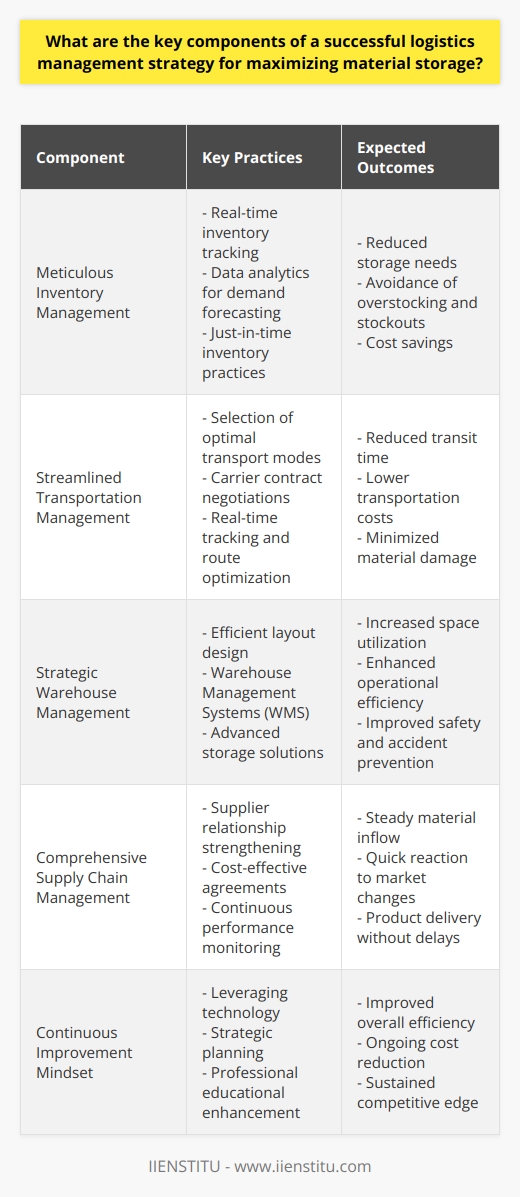

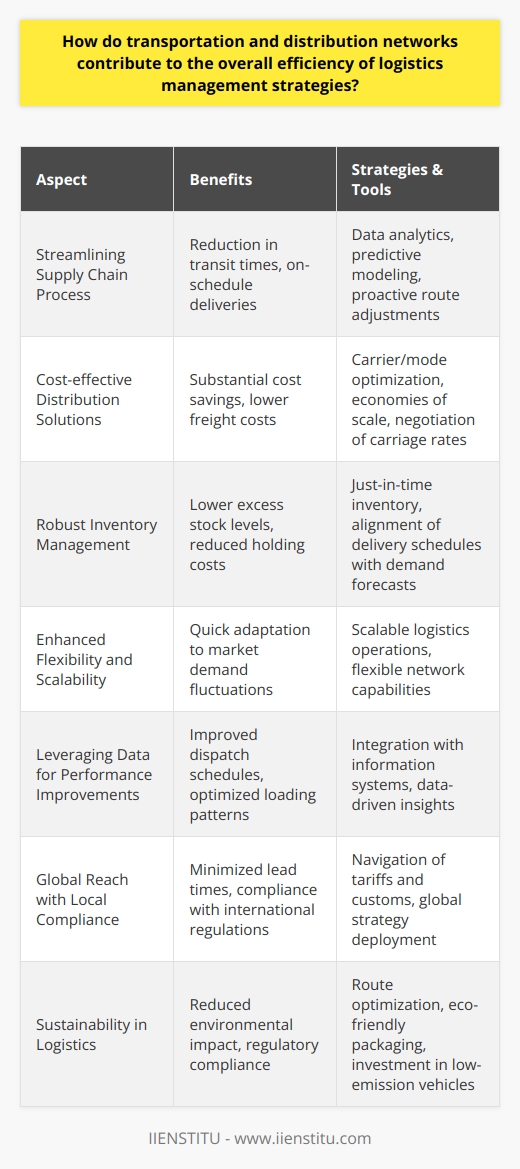

Logistics Management Strategies

In the world of logistics, order fulfillment reliability in logistics management is paramount. It's not enough to have materials stored; they must be moved and delivered reliably.

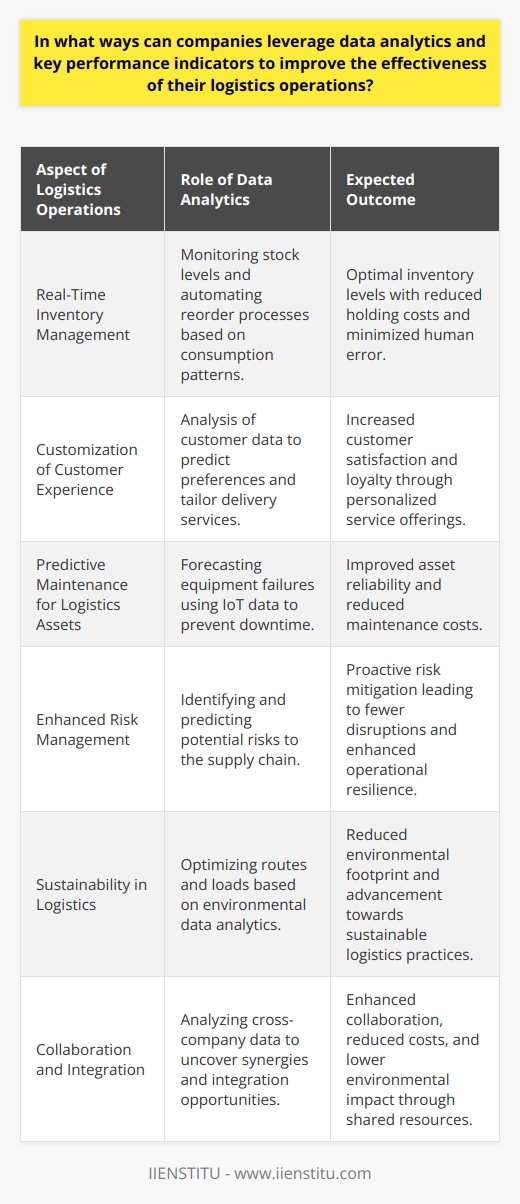

Inventory Management: Keeping Track of It All

Effective inventory management is like keeping a well-balanced checkbook. It's essential to know what's in stock, what's running low, and what's overstocked. By maintaining accurate inventory levels, businesses can avoid the pitfalls of stockouts or overstocking. I once assisted a small retailer who was losing money due to excess inventory gathering dust. By implementing a just-in-time inventory system, they freed up cash flow and reduced waste.

Order Processing: The Customer's Journey Begins

Every customer's journey starts with an order. Efficient order processing ensures that orders are accurate, processed quickly, and delivered on time. This enhances customer satisfaction and builds brand loyalty.

Transportation Management: The Road to Success

Transportation management involves planning and optimizing routes, selecting the right carriers, and ensuring timely deliveries. A friend in the logistics industry often emphasizes that "a product isn't sold until it's delivered." Efficient transportation can reduce costs and improve delivery times.

Warehouse Management: The Heart of Operations

At the heart of it all is warehouse management. This encompasses everything from the layout of the warehouse to the technology used to track inventory. By optimizing warehouse operations, businesses can increase efficiency, reduce errors, and improve safety.

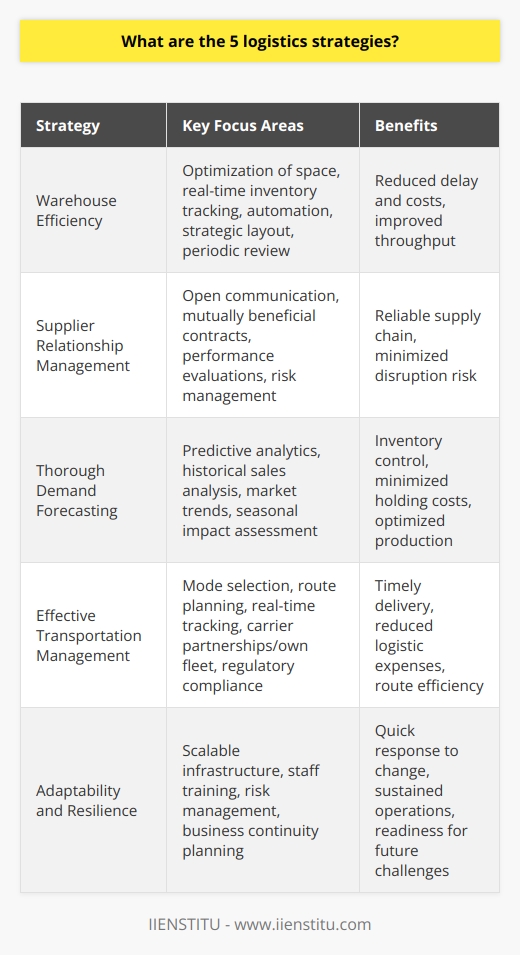

Maximizing Material Storage

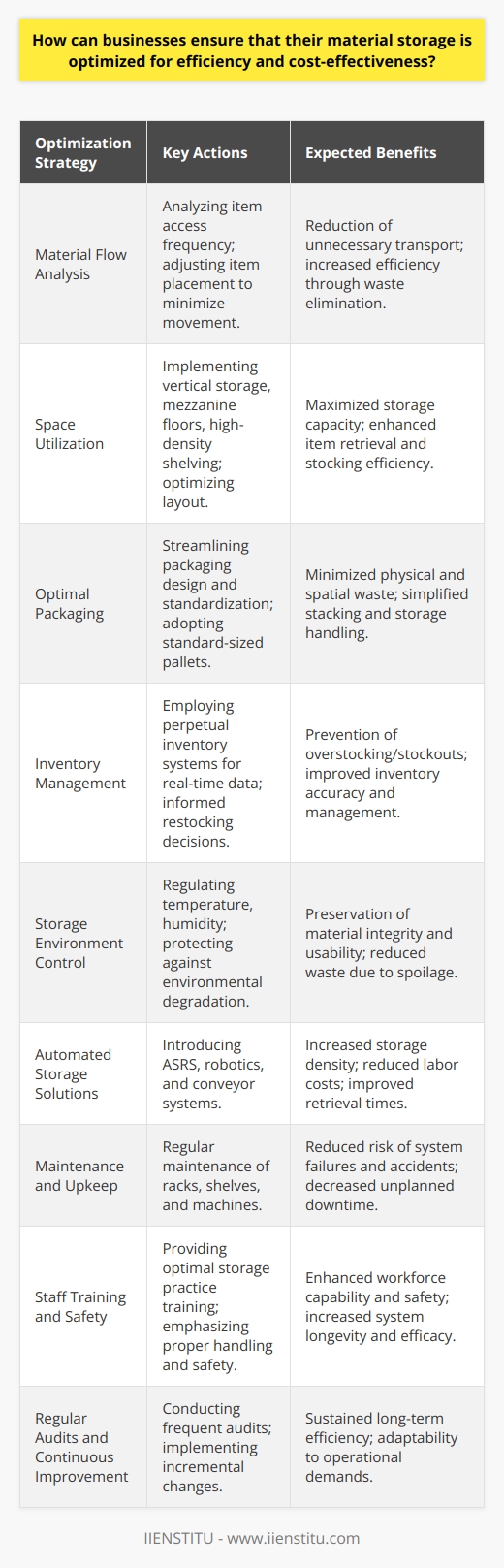

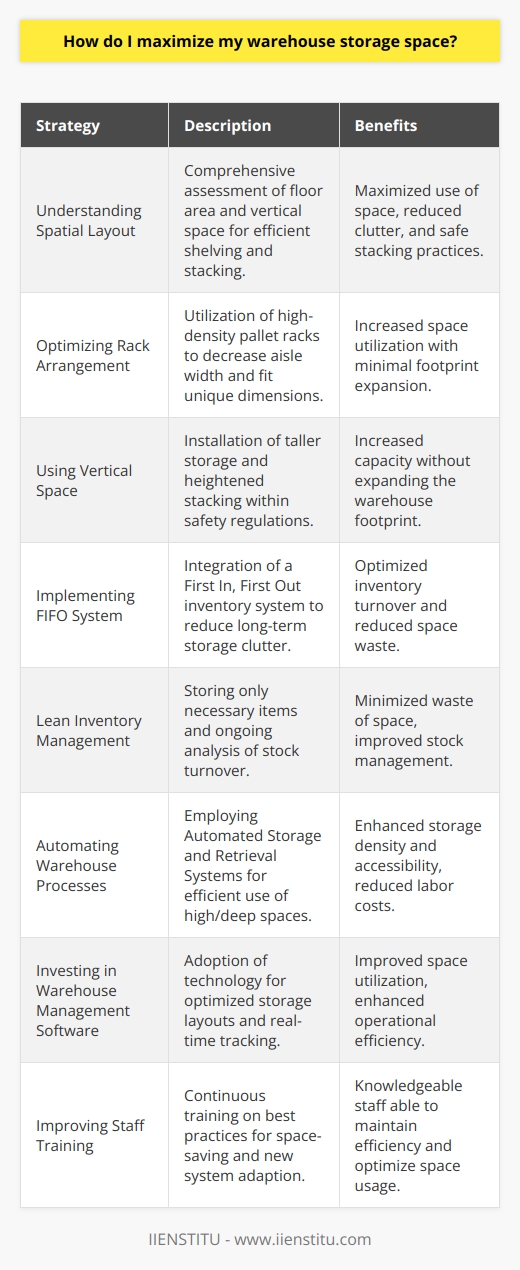

So, how can businesses make the most of their warehouse space?

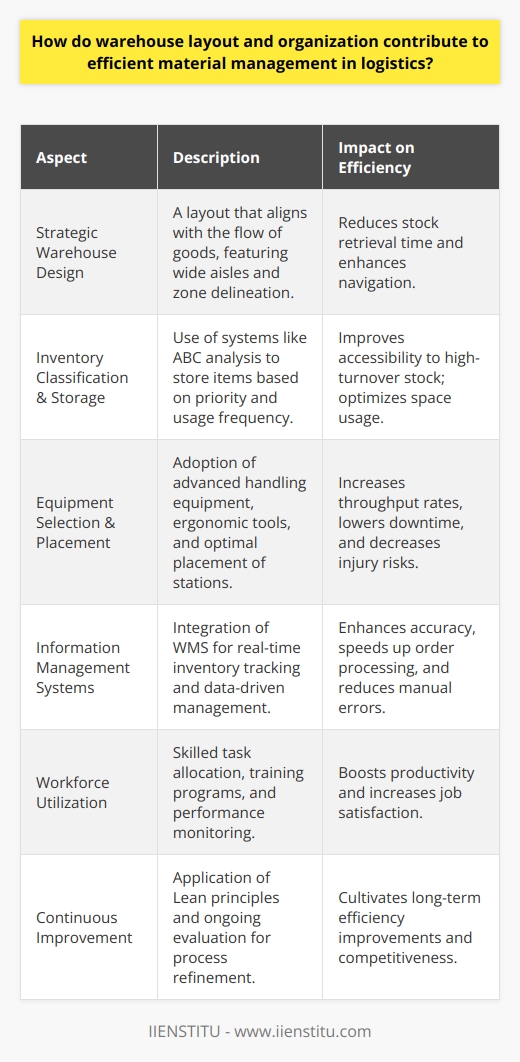

Optimizing Warehouse Layout

An efficient warehouse layout minimizes movement and maximizes space utilization. By arranging aisles, shelves, and storage areas strategically, workers can navigate the warehouse more efficiently. I recall helping a company reconfigure their warehouse layout, which reduced their picking time by 30%.

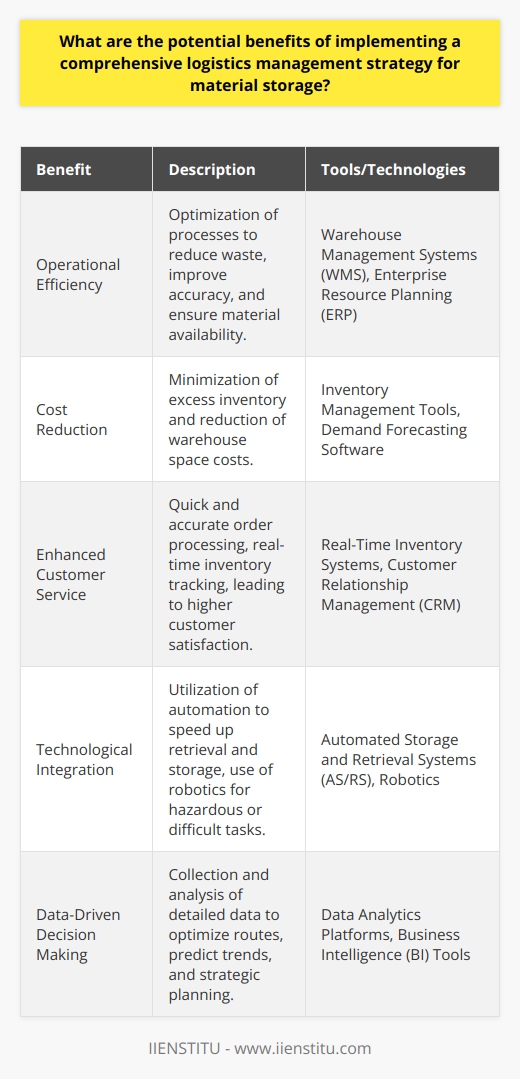

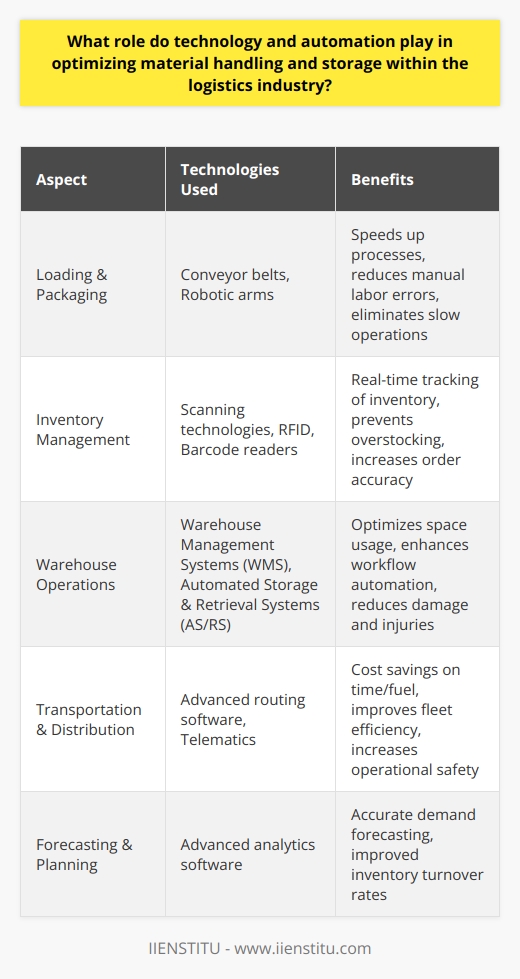

Implementing Automated Systems

Technology is a game-changer in warehouse management. Automated systems, such as Warehouse Management Systems (WMS) and barcode scanning, can significantly reduce errors and improve efficiency. Automated storage and retrieval systems (AS/RS) can handle materials faster and more accurately than manual methods.

An organized warehouse is the foundation of efficient material storage management.

Leveraging Vertical Space

Often, warehouses only utilize floor space, neglecting the vertical space above. By installing taller shelving units and utilizing equipment like forklifts, businesses can maximize the use of vertical space.

Regular Training and Safety Protocols

An organized warehouse isn't just about storage; it's also about the people who work there. Regular training ensures that staff are aware of the best practices and safety protocols, reducing accidents and improving efficiency.

Periodic Inventory Audits

Conducting regular inventory audits helps maintain accurate records, identify discrepancies, and prevent losses. This practice keeps the material storage system running smoothly.

Personal Experiences in Warehouse Management

Over the years, I've had the opportunity to work with various businesses to improve their warehouse operations.

Case Study: Transforming a Chaotic Warehouse

A local electronics distributor was struggling with delayed shipments and lost inventory. Their warehouse was disorganized, with items scattered randomly. Customers were complaining about late deliveries and incorrect orders.

We started by implementing a proper sorting system, organizing products by category and frequency of order. High-demand items were placed closer to the shipping area, reducing the time it took to fulfill orders. We also introduced a basic inventory management system to track stock levels in real-time.

The result? Order accuracy improved by 50%, and order fulfillment reliability in logistics management increased significantly. Customers noticed the difference, and the company saw a boost in repeat business.

Lessons Learned

From these experiences, I've learned that:

1- Organization is key: A well-organized warehouse improves efficiency and reduces errors.

2- Technology aids efficiency: Even simple automation can have a significant impact.

3- Training empowers staff: Knowledgeable staff are more efficient and make fewer mistakes.

4- Safety shouldn't be overlooked: A safe warehouse is a productive warehouse.

5- Continuous improvement is essential: Regular reviews help identify areas for improvement.

The Role of Technology in Modern Warehousing

In today's fast-paced world, technology plays an integral role in optimizing warehouse operations.

Warehouse Management Systems (WMS)

A Warehouse Management System helps manage and control day-to-day operations. It guides inventory receiving and put-away, optimizes picking and shipping orders, and advises on inventory replenishment.

Radio-Frequency Identification (RFID)

RFID tags allow for real-time tracking of inventory without the need for manual scanning. This technology increases accuracy and efficiency in inventory management.

Automated Guided Vehicles (AGVs)

AGVs are robotic vehicles used to transport materials around the warehouse. They reduce the need for manual labor, lower the risk of accidents, and increase productivity.

Environmental Considerations in Material Storage

Sustainability is becoming increasingly important in all aspects of business, including warehousing.

Energy Efficiency

Implementing energy-efficient lighting and climate control systems can reduce the warehouse's environmental footprint and lower operating costs.

Sustainable Materials

Using sustainable packaging materials and recycling programs minimizes waste and supports environmental initiatives.

Optimized Transportation

By planning efficient transportation routes and consolidating shipments, businesses can reduce fuel consumption and emissions.

Conclusion

Material storage is more than just stacking boxes in a warehouse. It's a complex system that requires careful planning, organization, and management. By focusing on key functions like holding, sorting, consolidating, and distributing, and by implementing effective logistics management strategies, businesses can enhance their warehouse operations.

The journey towards an efficient warehouse is ongoing. It involves embracing new technologies, training staff, and continually seeking ways to improve. But the rewards—improved efficiency, reduced costs, and increased customer satisfaction—are well worth the effort.

An organized warehouse is the foundation of efficient material storage management. It's not just about space; it's about creating a system that supports the entire supply chain, from raw materials to the customer's hands.

References

1- Bowersox, D. J., Closs, D. J., & Cooper, M. B. (2013). Supply Chain Logistics Management (4th ed.). McGraw-Hill Education.

2- Richards, G. (2017). Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse (3rd ed.). Kogan Page Publishers.

3- Frazelle, E. (2002). World-Class Warehousing and Material Handling. McGraw-Hill.

4- Tompkins, J. A., & Smith, J. D. (1998). The Warehouse Management Handbook (2nd ed.). Tompkins Press.