I still remember the day when I was eagerly waiting for a package—a gift for my niece's birthday. It was supposed to arrive the day before her party, but due to some unforeseen logistics hiccups, it got delayed. That experience made me realize just how crucial effective logistics management is in our daily lives, not just for businesses but for individuals like you and me.

The Heartbeat of Business: Understanding Logistics Management

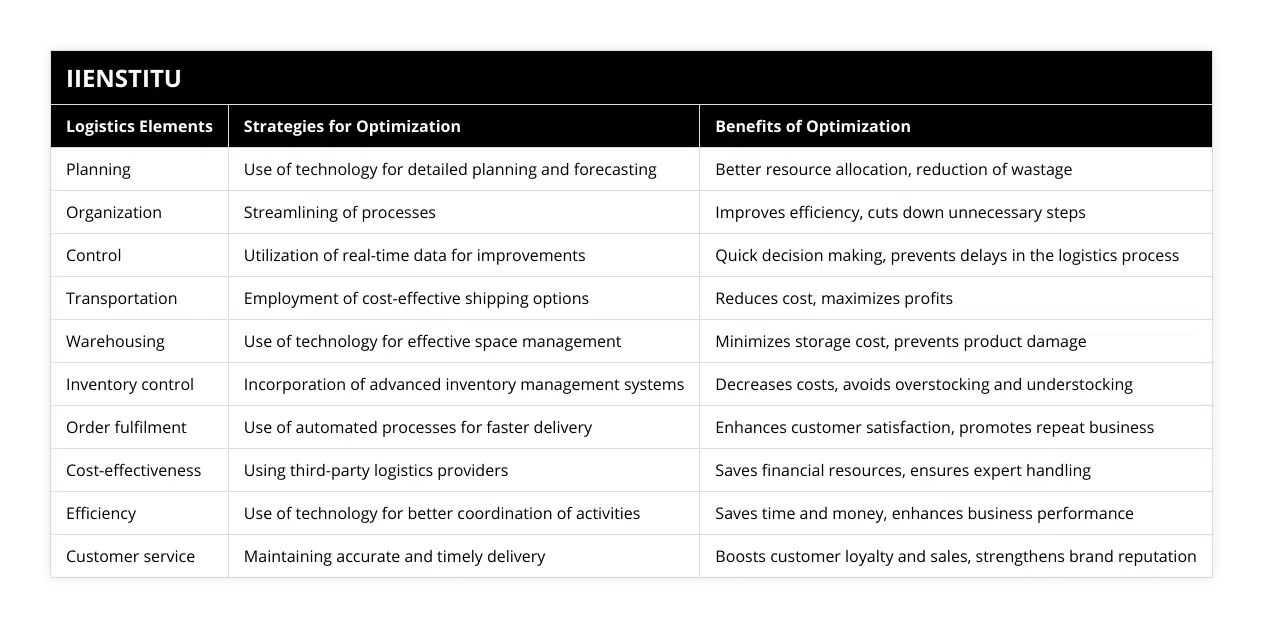

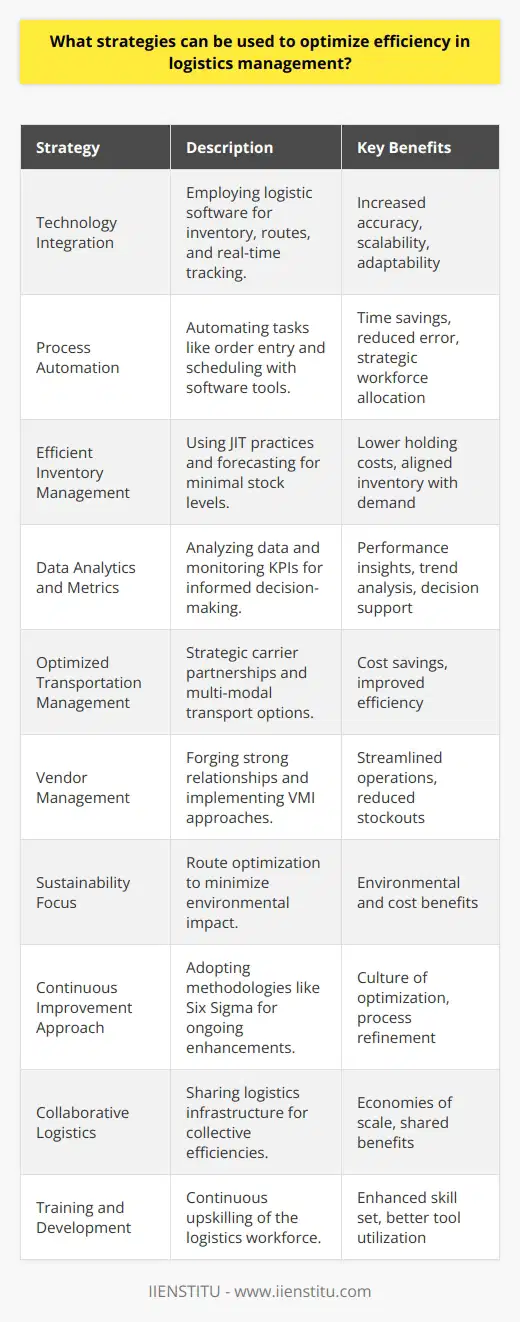

At its core, logistics management is all about planning, organizing, and controlling the movement of resources—be it products, services, or information—from one point to another. Think of it as the orchestra conductor of the supply chain, ensuring every instrument plays in harmony to create a beautiful symphony. Without proper logistics management, businesses can face delays, increased costs, and unhappy customers.

Introduction to Logistics Management

Benefits of Optimizing Logistics Management

Strategies for Optimizing Efficiency

Strategies for Optimizing Cost

Conclusion

I once spoke with a friend who runs a small artisan bakery. She shared how managing her supply chain, from sourcing organic ingredients to delivering fresh bread to local stores, was a daily challenge. By optimizing her logistics, she not only reduced waste and costs but also managed to deliver fresher products to her customers, enhancing their satisfaction.

Why Optimize Logistics? The Unseen Benefits

Optimizing logistics isn't just a buzzword; it's a necessity in today's fast-paced market. Here are some compelling reasons:

Cost Reduction: Streamlining logistics processes can significantly cut down operational costs. By minimizing unnecessary steps and optimizing routes, businesses can save on transportation and storage expenses.

Improved Customer Service: Fast and reliable delivery enhances customer satisfaction. Remember my niece's late gift? Companies that ensure timely deliveries build trust and loyalty with their customers.

Increased Efficiency: Efficient logistics mean that resources are used optimally. This can lead to faster turnaround times, better inventory management, and the ability to meet market demands promptly.

Competitive Advantage: Businesses that master their logistics can outperform competitors by offering better prices and services.

Strategies for Boosting Efficiency in Logistics

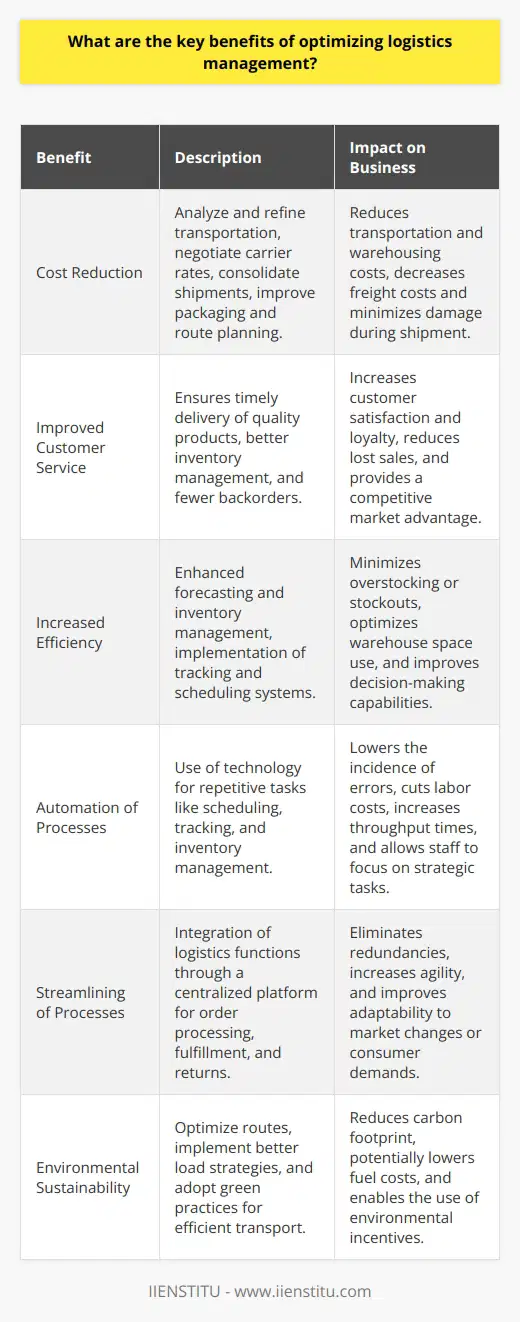

Enhancing logistics efficiency isn't a one-size-fits-all solution, but there are proven strategies that businesses can adopt:

Embracing Technology

In today's digital age, leveraging technology is a game-changer. For instance:

1- Automation: Implementing automated systems for order processing and inventory management reduces human error and speeds up operations.

2- Transportation Management Systems (TMS): These platforms help in planning, executing, and optimizing the movement of goods.

3- IoT and Real-Time Tracking: Internet of Things devices enable real-time tracking of shipments, providing transparency and allowing for proactive problem-solving.

I recall visiting a warehouse where they used automated guided vehicles (AGVs) to move goods around. It was fascinating to see how technology streamlined the workflow, reduced labor costs, and improved safety.

Streamlining Processes

Simplifying logistics processes can lead to significant efficiency gains:

Process Mapping: By visualizing each step in the logistics chain, businesses can identify bottlenecks and redundancies.

Lean Logistics: Adopting lean principles focuses on eliminating waste—be it time, resources, or effort.

Cross-Docking: This practice involves unloading materials from an incoming truck and loading them directly onto outbound trucks, minimizing storage time.

Optimizing Inventory Management

Effective inventory management ensures that businesses have the right amount of stock at the right time:

1- Just-In-Time (JIT) Inventory: This strategy reduces inventory costs by receiving goods only as they are needed in the production process.

2- Demand Forecasting: Using historical data and market analysis to predict future demand helps in maintaining optimal inventory levels.

Efficient logistics management is the key to reducing costs and increasing efficiency.

3- Safety Stock Management: Keeping a buffer stock to prevent stockouts during unexpected demand surges.

Cutting Costs Without Cutting Corners

Reducing logistics costs doesn't mean compromising on quality or service. Here are some ways to optimize expenses:

Negotiating with Suppliers and Carriers

Building strong relationships with suppliers and carriers can lead to better terms:

Bulk Purchasing: Buying in larger quantities can reduce costs per unit.

Long-Term Contracts: Committing to longer agreements may lead to discounted rates.

Freight Consolidation: Combining shipments can reduce transportation costs.

Utilizing Third-Party Logistics (3PL) Providers

Outsourcing logistics to specialized firms can offer:

Expertise: 3PL providers have industry knowledge and networks that can optimize logistics operations.

Scalability: They can adjust services based on business needs without the company investing in infrastructure.

Cost Savings: Economies of scale allow 3PLs to offer competitive pricing.

Energy and Fuel Efficiency

Transportation is a major cost in logistics. Improving fuel efficiency can lead to significant savings:

1- Route Optimization: Using software to find the most efficient routes reduces fuel consumption and delivery times.

2- Eco-Friendly Vehicles: Investing in vehicles with better fuel efficiency or alternative energy sources.

3- Driver Training: Educating drivers on fuel-efficient driving practices.

Real-Life Example: A Tale of Two Companies

Let me share a story about two companies I consulted for—both in the same industry, but with vastly different logistics approaches.

Company A struggled with frequent delays, high shipping costs, and inventory pile-ups. They relied on outdated manual processes and had little visibility into their supply chain.

Company B, on the other hand, invested in technology, streamlined their processes, and regularly trained their staff on best practices. They utilized demand forecasting and maintained optimal inventory levels.

The result? Company B not only saved costs but also increased their market share due to higher customer satisfaction. Meanwhile, Company A faced declining sales and customer complaints.

This example highlights how critical efficient logistics management is to a company's success.

The Human Element in Logistics

While technology and processes are vital, we shouldn't overlook the human aspect. Effective communication, training, and a culture of continuous improvement are essential.

Employee Training: Regular training ensures staff are up-to-date with the latest tools and practices.

Open Communication: Encouraging feedback and ideas from employees can lead to innovation and improvements.

Customer Feedback: Listening to customers can provide insights into areas needing improvement.

I recall a logistics manager who held monthly meetings with his team to discuss challenges and brainstorm solutions. This not only fostered a sense of teamwork but also led to innovative ideas that improved their operations.

Incorporating Sustainability into Logistics

Sustainability is becoming increasingly important:

Green Logistics: Implementing eco-friendly practices, such as reducing emissions and using recyclable packaging.

Sustainable Sourcing: Working with suppliers who prioritize ethical and sustainable practices.

Corporate Social Responsibility (CSR): Demonstrating commitment to the environment and society can enhance brand image and customer loyalty.

Navigating Challenges in Logistics Management

Like any field, logistics management comes with its set of challenges:

Globalization: Managing international shipments involves navigating customs, tariffs, and cultural differences.

Technology Integration: Adopting new technologies can be costly and require training.

Market Fluctuations: Changes in demand can lead to overstocking or stockouts.

However, with careful planning and a proactive approach, these challenges can be mitigated.

Reassignment Request Letter Tips and Information

If you ever find yourself needing a change within your company—perhaps moving to a different department or location—writing a reassignment request letter is a professional way to initiate that process. Drawing parallels to logistics, just as resources are moved efficiently with proper planning, so too can your career shift be smooth with the right approach.

Tips for Writing a Reassignment Request Letter:

1- Be Clear and Concise: Clearly state your request and the reasons behind it.

2- Highlight Benefits: Explain how the reassignment will benefit both you and the company.

3- Professional Tone: Maintain respect and professionalism throughout the letter.

4- Provide Supporting Information: If applicable, include any relevant experience or qualifications.

5- Express Gratitude: Thank your employer for considering your request.

Understanding the logistics of your own career path can be just as important as managing physical goods.

Conclusion: The Road Ahead

Optimizing logistics management is not just about cutting costs or speeding up processes; it's about creating a seamless experience for everyone involved—from suppliers to customers. By embracing technology, streamlining processes, and keeping the human element at the heart of operations, businesses can navigate the complex world of logistics with confidence.

Just like waiting eagerly for that special package to arrive on time, businesses thrive when they can deliver on their promises promptly and efficiently. Whether you're a small bakery owner or a manager in a multinational company, investing in logistics management is investing in your success.

Remember, the journey of a thousand miles begins with a single step—or in logistics terms, a single, well-planned shipment.

References

Christopher, M. (2016). Logistics & Supply Chain Management. Pearson Education Limited.

Rushton, A., Croucher, P., & Baker, P. (2017). The Handbook of Logistics and Distribution Management. Kogan Page Publishers.

Ballou, R. H. (2004). Business Logistics/Supply Chain Management. Pearson Education.

Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (2008). Designing and Managing the Supply Chain. McGraw-Hill.

Lambert, D. M., Stock, J. R., & Ellram, L. M. (1998). Fundamentals of Logistics Management. McGraw-Hill/Irwin.

Frequently Asked Questions

What are the key benefits of optimizing logistics management?

The key benefits of optimizing logistics management include reducing costs, improving customer service, and increasing efficiency. Additionally, optimizing logistics management can help businesses automate processes, streamline processes, and reduce the amount of time and money spent on managing inventory. This can ultimately lead to increased customer satisfaction and improved profitability for businesses.

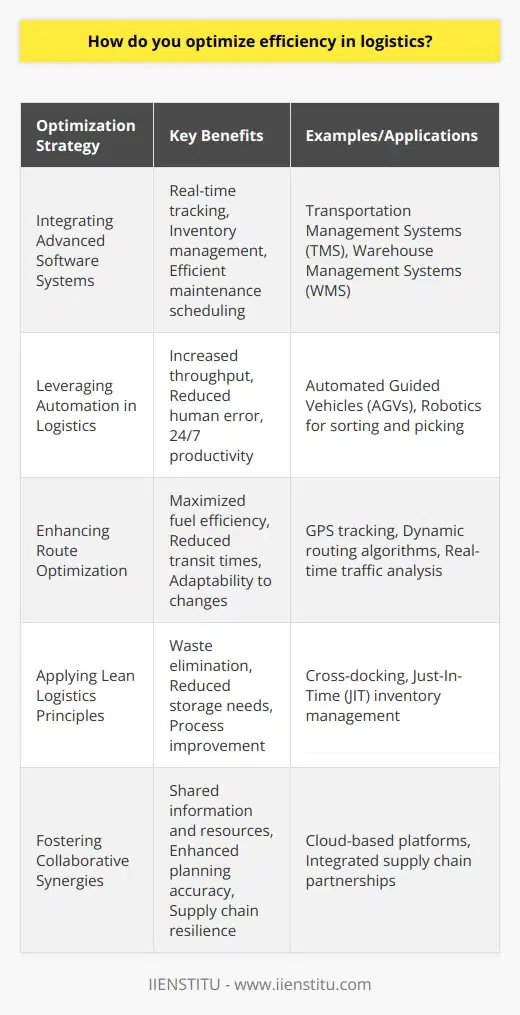

What strategies can be used to optimize efficiency in logistics management?

Strategies for optimizing efficiency in logistics management include leveraging technology to automate processes, streamlining existing processes, and reducing the amount of time and money spent on managing inventory. By implementing these strategies, businesses can optimize their logistics management, reduce costs, improve customer service, and increase efficiency. Additionally, businesses should strive to be proactive in their approach to logistics management, anticipating potential problems and taking steps to prevent them from occurring. By taking a proactive approach, businesses can ensure that their logistics management is optimized for maximum efficiency and cost savings.

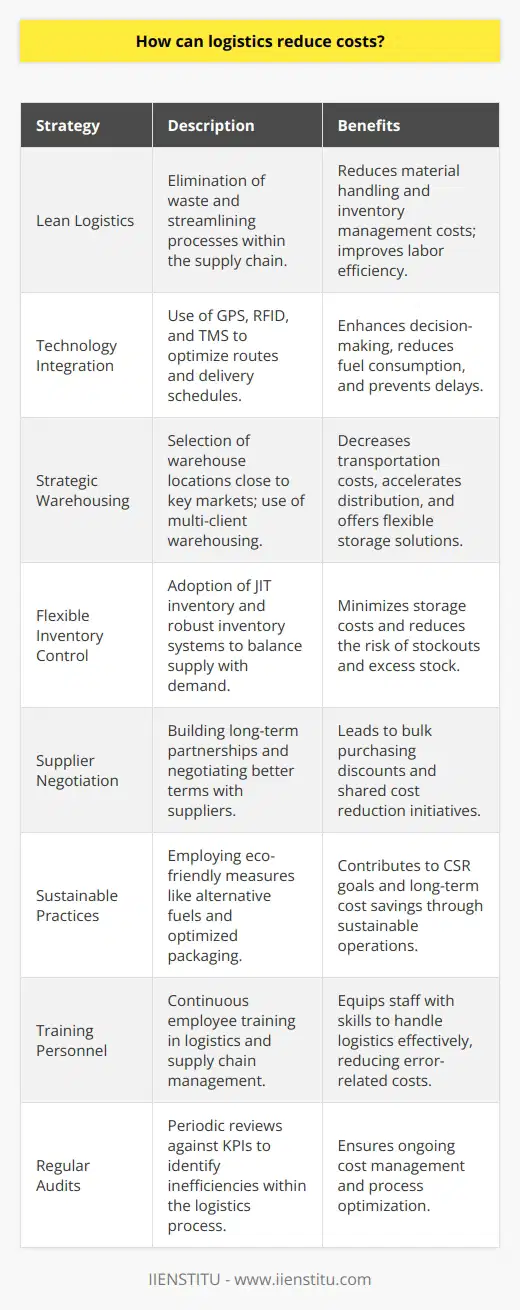

What strategies can be used to optimize cost in logistics management?

To optimize cost in logistics management, businesses should consider utilizing technology to automate processes, streamlining processes, and reducing the amount of time and money spent on managing inventory. Automating processes can help businesses save time, money, and resources, while streamlining processes can help to reduce the complexity of managing logistics. Reducing the amount of time and money spent on managing inventory can also help to keep costs down. By leveraging these strategies, businesses can optimize their logistics management and improve customer satisfaction.

How do you optimize efficiency in logistics?

Optimizing Efficiency through Technology

One strategy to optimize efficiency in logistics involves leveraging technology solutions. For instance, through the implementation of advanced software, organizations can facilitate more effective communication, better route planning, and enhanced inventory management. This ultimately leads to reduced bottlenecks and increased productivity.

Automating Processes and Tasks

Automation also plays a significant role in improving efficiency. By streamlining repetitive tasks, such as data entry and document management, companies can save time and resources. This frees up employees to focus on more strategic aspects of the supply chain, ultimately contributing to greater efficiency.

Improving Route Planning and Delivery Scheduling

Efficient route planning and delivery scheduling are crucial components of logistics optimization. Utilizing sophisticated algorithms and real-time data, organizations can optimize delivery routes, taking into account factors such as traffic, weather conditions, and fuel costs. This minimizes the time and resources required to complete deliveries, leading to improved operational efficiency and customer satisfaction.

Adopting Lean Practices

Embracing lean practices focused on continuous improvement can also contribute to enhanced logistics efficiency. By systematically identifying and eliminating waste and inefficiencies in the supply chain, organizations can streamline their operations and boost overall performance. Examples of lean practices include just-in-time inventory management and root-cause analysis, which target key areas for improvement within logistics processes.

Enhancing Collaboration and Visibility

Strong collaboration and increased visibility across the entire supply chain are essential to optimizing logistics efficiency. Collaborative platforms that enable real-time communication and data-sharing among partners, suppliers, and customers can significantly improve decision-making and resource allocation. This, in turn, leads to a more responsive and efficient supply chain that is better equipped to deal with challenges and disruptions.

In conclusion, optimizing efficiency in logistics requires a multi-faceted approach that encompasses technology, automation, route planning, lean practices, and strong collaboration. By combining these elements, organizations can effectively streamline their logistics processes, resulting in improved operational performance and a more competitive advantage.

What are the 7 R's for better logistics management?

7 R's for Better Logistics Management

Right Product

Effective logistics management begins with identifying the right product for the supply chain. This often entails accurate demand forecasting and understanding customer needs to ensure timely and efficient product delivery.

Right Quantity

Inventory control is crucial for optimal logistics management. Striking a balance between holding excess inventory and maintaining customer service levels requires careful assessment of demand fluctuations and lead times.

Right Condition

To guarantee customer satisfaction, products must be in excellent condition upon arrival. Therefore, implementing comprehensive quality assurance processes and investing in proper packaging and storage will prevent product damage during transportation and handling.

Right Place

Strategically positioning warehouses and distribution centers can reduce transportation costs and expedite delivery times. By considering factors such as market locations, transportation infrastructure, and accessibility, companies can optimize their network and maximize efficiency.

Right Time

Timely delivery contributes significantly to customer satisfaction. Implementing robust transportation management systems (TMS) and leveraging real-time tracking technology can help companies monitor shipments, adjust routes as needed, and increase supply chain visibility.

Right Cost

Cost-effective logistics management seeks to minimize expenses and maximize profits. Potential cost reduction strategies may include supply chain optimization, negotiation of transportation rates, and introducing lean principles to improve operations.

Right Customer

Even with tailored products and efficient supply chain operations, success depends on reliably delivering to the correct customer. Ensuring accurate customer information throughout the order management process, as well as proper address verification, can mitigate potential delivery issues and prevent costly returns.

In conclusion, the 7 R's for better logistics management - right product, right quantity, right condition, right place, right time, right cost, and right customer - form the foundation of a cohesive and efficient logistics strategy. By embracing these principles, companies can enhance their supply chain performance, reduce costs, and ultimately increase customer satisfaction.

How can logistics reduce costs?

Logistics Cost Reduction Strategies

Efficient Routing and Load Optimization

Logistics can reduce costs through the implementation of efficient routing and load optimization strategies. By selecting the most direct and cost-effective transportation routes, companies can save on fuel, labor, and vehicle maintenance expenses. Additionally, maximizing load capacities can lead to a reduction in the number of vehicles needed for transport, further decreasing costs.

Inventory Management and Demand Forecasting

Effective inventory management and demand forecasting can also contribute to cost reduction in logistics. By accurately predicting customer needs, companies can reduce excess stock and limit warehouse expenses. This can be achieved through the employment of advanced demand forecasting tools and technologies, in conjunction with a strong understanding of market trends.

Consolidation and Collaboration

Logistics costs can be reduced by consolidating shipments and fostering collaboration among supply chain partners. Consolidation helps in streamlining transportation and warehousing operations while reducing the overall number of shipments. Likewise, collaboration can lead to the sharing of resources and expertise among partners, consequently generating economies of scale and improving cost efficiencies.

Outsourcing and Third-Party Logistics

Companies can reduce logistics costs by outsourcing certain aspects of their supply chain operations to specialized third-party logistics providers (3PLs). By leveraging the expertise of 3PLs, businesses can increase supply chain efficiency and minimize overhead costs related to storage, transportation, and logistics management tasks.

Continuous Improvement and Technology

Continuous improvement processes, such as Lean or Six Sigma, can result in significant cost reduction in logistics operations by identifying and eliminating inefficiencies. By adopting these methodologies, companies can streamline workflow, reduce waste, and improve overall supply chain performance. Furthermore, embracing modern technology, such as warehouse automation and real-time tracking systems, enables businesses to effectively manage their logistics processes, resulting in cost savings.

In conclusion, logistics play a crucial role in reducing costs across the supply chain. By focusing on efficient routing, inventory management, consolidation, outsourcing, and continuous improvement, companies can significantly minimize their logistics-related expenses and improve their overall profitability.

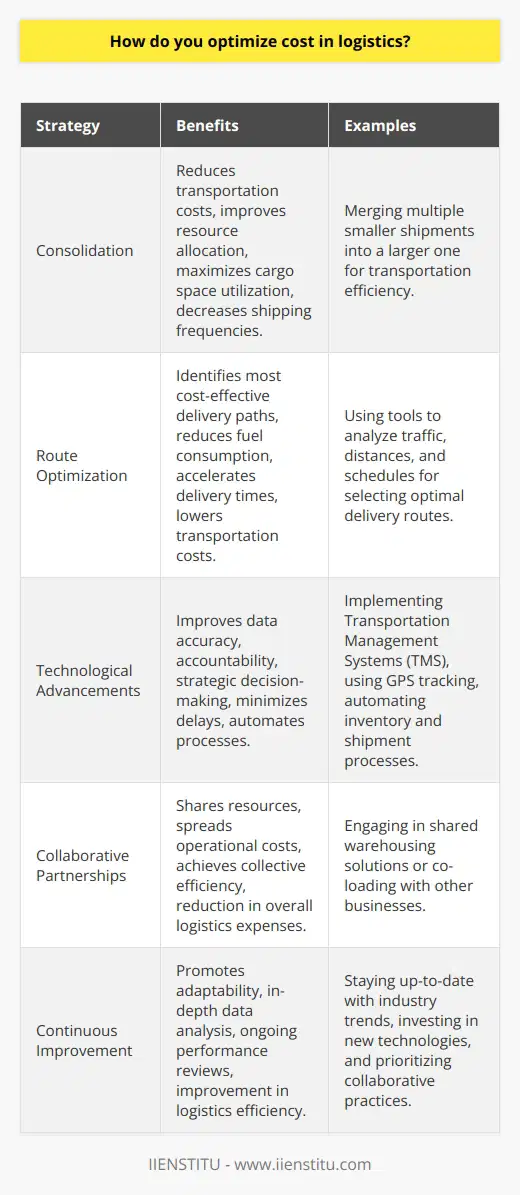

How do you optimize cost in logistics?

Cost Optimization Strategies in Logistics

To optimize cost in logistics, businesses should focus on implementing a range of strategies that can help reduce costs and enhance efficiencies within their supply chain operations. These strategies include consolidation, route optimization, technological investment, and partnership development.

Consolidation of Shipments

Combining shipments into one larger load can significantly lower logistics costs. By consolidating several smaller shipments into a single larger one, companies can decrease transportation costs and maximize the allocation of resources.

Route Optimization

Choosing the most efficient and cost-effective routes for transportation can substantially reduce costs. By continuously reevaluating existing routes and exploring new ones, businesses can cut down on fuel consumption and travel time, ultimately resulting in lower transportation expenses.

Technological Investment

Investing in advanced supply chain management technology can streamline logistics processes, enhance visibility, and support decision-making. Utilizing modern technology like GPS tracking and transportation management software allows businesses to make better-informed decisions, improving supply chain operations and reducing overhead expenses.

Partnership Development

Building strategic partnerships with other businesses can lead to cost savings and operational efficiencies. Working cooperatively with other companies, like sharing warehouse space or collaborating on transportation routes, can help businesses minimize costs while improving overall productivity.

In conclusion, optimizing cost in logistics is a critical consideration for many businesses as it can significantly impact overall success and profitability. By focusing on consolidation, route optimization, investments in technology, and establishing effective partnerships, businesses can expect to see substantial improvements in their supply chain operations, ultimately resulting in reduced costs and improved efficiency.

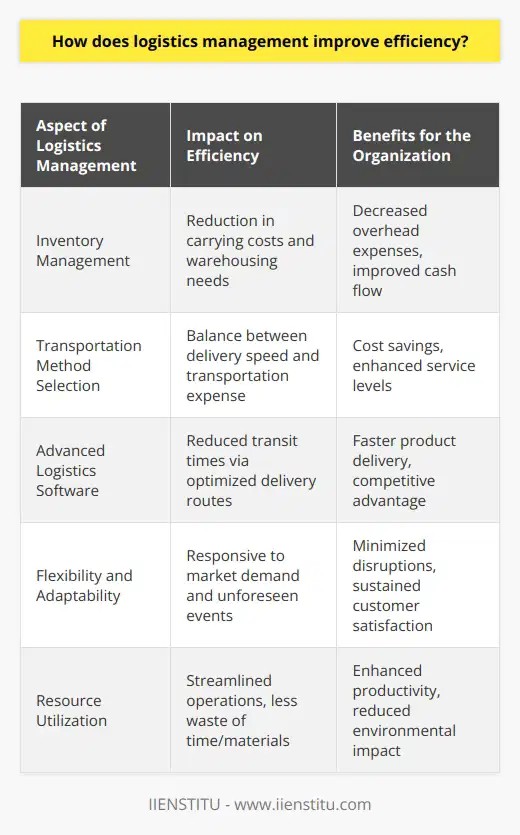

How does logistics management improve efficiency?

Logistics Management and Efficiency

Logistics management plays a vital role in the efficient functioning of organizations across diverse industries. By coordinating and optimizing various aspects involved in the supply chain, it improves overall efficiency in several ways.

Reduced Costs

Firstly, an effective logistics management system helps in reducing transportation and inventory costs. This can be achieved through strategic selection of transportation modes, consolidation of shipments, and effective warehouse management. By minimizing these costs, businesses can allocate resources more efficiently and ultimately offer their end-customers better value.

Improved Delivery Speeds

Secondly, efficient logistics management can lead to faster delivery times. By streamlining processes, integrating technology, and implementing real-time tracking, organizations can speed up their transit times and improve their overall time-to-market. Faster delivery times contribute to increased customer satisfaction, which in turn builds brand loyalty and enhances business performance.

Increased Flexibility

Thirdly, logistics management enables organizations to be more responsive to changing market demands. By leveraging advanced analytics to monitor market trends and make better demand forecasts, businesses can adapt their supply chain operations to consistently meet customer expectations. Flexible supply chain strategies allow firms to navigate through volatile markets and always stay ahead of competitors.

Optimized Resource Utilization

Lastly, logistics management allows for more efficient resource utilization through streamlined processes, automation, and the elimination of redundant tasks. By implementing efficient technologies, such as automated warehousing and inventory management systems, businesses can minimize manual errors and enhance productivity. Furthermore, efficient resource utilization contributes to a sustainable supply chain, thereby reducing environmental impact and promoting long-term growth.

In conclusion, logistics management significantly improves efficiency by reducing costs, enhancing delivery speeds, increasing flexibility, and optimizing resource utilization. Organizations seeking a competitive edge must continue to explore and adopt innovative logistics management strategies to stay ahead in the intensely competitive business landscape.

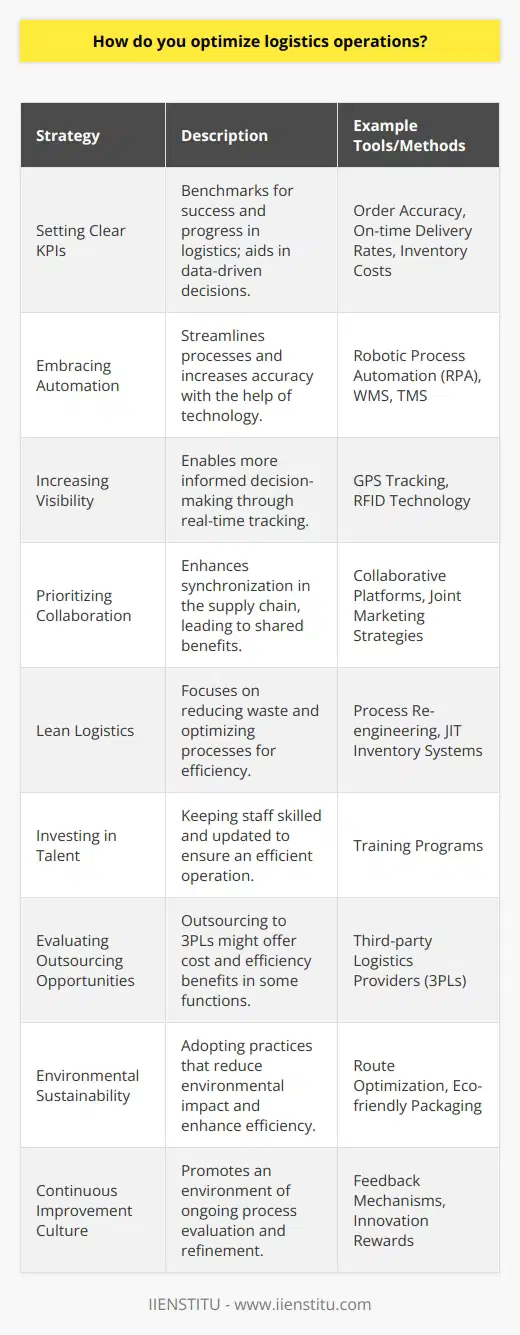

How do you optimize logistics operations?

Optimizing Logistics Operations

Identify Key Performance Indicators

Firstly, to optimize logistics operations, it is essential to identify key performance indicators (KPIs). These are critical data points, reflecting operational efficiency and effectiveness, such as on-time delivery performance, warehousing costs, and inventory turnover rates. Monitoring and evaluating KPIs provide the foundation for measuring improvement and ensuring optimization efforts are effective.

Implement Automation and Technology

Next, automation and technology play a crucial role in optimizing logistics processes. For example, warehouse management systems streamline inventory tracking, shipment scheduling, and order processing. Similarly, transportation management systems help in route planning and carrier selection, minimizing both costs and transit time. Adopting these technologies can lead to increased efficiency and cost savings, contributing to overall optimization.

Enhance Visibility and Collaboration

Visibility and collaboration among supply chain stakeholders are also vital optimization elements. By providing real-time information on inventory levels, delivery tracking, and supplier performance, organizations can make better decisions and respond more quickly to changes in demand. Additionally, investing in collaborative platforms allows companies to work more closely with suppliers and customers, ensuring effective communication and reducing errors or miscommunications.

Establish Lean Practices

Optimizing logistics operations also involves eliminating inefficiencies and waste throughout the supply chain. This can be achieved through the implementation of lean practices, which focus on continuous improvement, process standardization, and the reduction of unnecessary steps or redundancies in operations. By establishing lean practices, organizations can improve both service levels and cost efficiency.

Invest in Employee Training and Development

Lastly, well-trained and competent staff contribute to effectively optimized logistics operations. Investing in employee training and development programs ensures that personnel are knowledgeable about best practices, technologies, and industry trends. Moreover, developing a culture of continuous learning and improvement can lead to a more engaged and agile workforce, capable of driving and sustaining optimization initiatives.

In conclusion, optimizing logistics operations requires a multifaceted approach, focusing on identifying KPIs, embracing technology, promoting visibility and collaboration, implementing lean practices, and investing in employees. By addressing these areas, organizations can continuously refine their supply chain processes and reap the benefits of higher efficiency and cost savings.

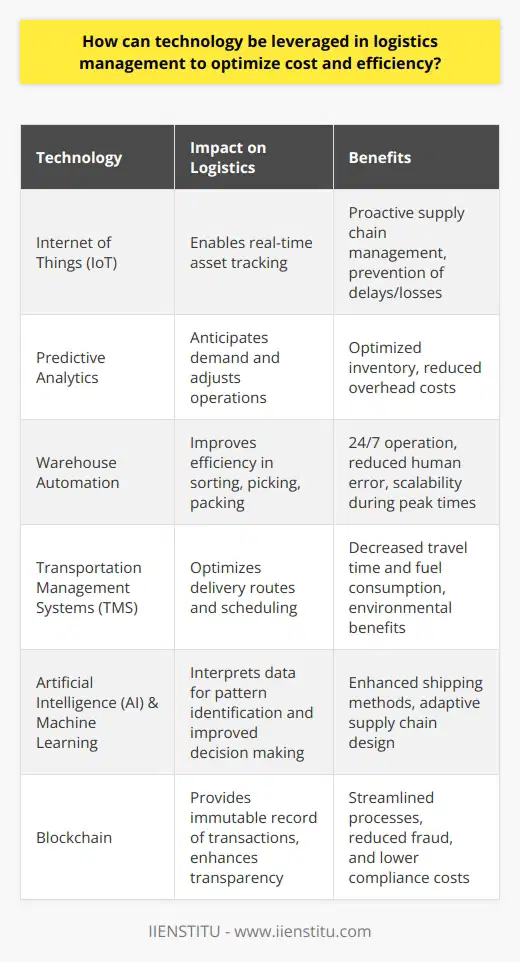

How can technology be leveraged in logistics management to optimize cost and efficiency?

Technology Integration in Logistics Management

The rise of digital innovation has opened up new opportunities for optimizing cost and efficiency in logistics management. Technology can play a crucial role in streamlining operations, improving customer service, and increasing profitability in this sector.

IoT and Real-Time Visibility

One way to optimize logistics operations is through the Internet of Things (IoT). IoT devices provide real-time visibility into the location and status of goods, enabling better tracking and monitoring. This allows for more informed decision-making, faster response times to issues, and reduced operational costs.

Predictive Analytics

Predictive analytics enables logistics managers to forecast demand, ensuring proper resource allocation and reducing wastage. This technology uses historical data to predict future needs, enabling companies to prepare in advance and avoid unnecessary expenses.

Automated Warehouse Management

The adoption of automation within warehouses can greatly enhance efficiency and reduce labor costs. Robotics and automated systems perform tasks such as sorting, loading, and unloading products, reducing human error, and providing faster, more accurate solutions.

Route Optimization

Technology can also improve logistic operations through more efficient route planning. Transportation Management Systems (TMS) utilize GPS data, traffic patterns, and weather conditions to provide drivers with the most efficient routes, ultimately reducing fuel consumption and delivery times.

Artificial Intelligence and Machine Learning

AI-driven solutions provide logistics managers with valuable insights to optimize processes, from demand forecasting to inventory management. Machine learning algorithms analyze patterns in data, identifying inefficiencies and recommending adjustments to achieve cost savings and improved performance.

Blockchain for Supply Chain Transparency

Blockchain technology offers increased transparency and traceability, enabling a seamless communication flow between suppliers, manufacturers, and distributors. By recording transactions and providing real-time data, blockchain can reduce administrative costs, improve trust between stakeholders, and streamline the supply chain process.

In conclusion, the integration of technology in logistics management is paramount to achieving cost optimization and increased efficiency. Technologies such as IoT, predictive analytics, automation, route optimization, artificial intelligence, and blockchain provide companies with invaluable tools necessary to remain competitive in a fast-paced, evolving industry.

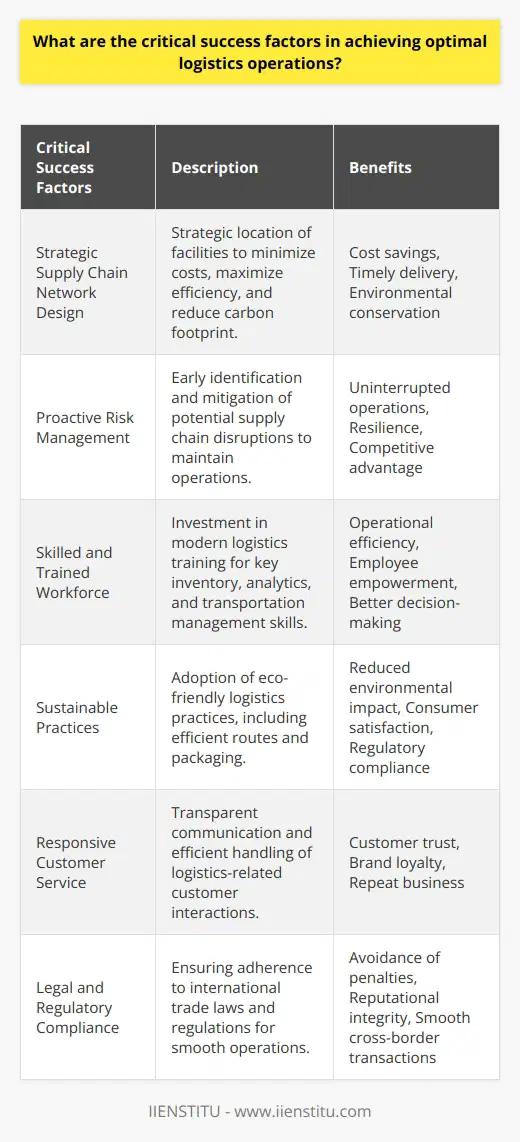

What are the critical success factors in achieving optimal logistics operations?

**Efficient Supply Chain Management**

Critical success factors in achieving optimal logistics operations include efficient supply chain management, which entails strategic planning to streamline the movement of goods and services from suppliers to end users. Aligning supply chain functions with business objectives ensures that resources are deployed effectively to minimize costs, maintain product quality, and improve customer satisfaction.

**Adoption of Advanced Technologies**

Incorporating advanced technology into logistics operations is essential for optimal performance. Utilizing innovative tools, such as artificial intelligence, robotics, and the Internet of Things (IoT), enhances transport and warehousing capabilities, enables real-time tracking of inventory, and facilitates data sharing among stakeholders. Integrating cutting-edge solutions into logistics processes boosts efficiency and creates competitive advantages in the marketplace.

**Collaboration and Partnerships**

Working together and establishing partnerships with key stakeholders (e.g., suppliers, manufacturers, carriers, and customers) is imperative for logistics optimization. Coordination and information sharing ensure seamless coordination of goods flow, reduce lead times, and minimize instances of stockouts or overstocks. Strong relationships with logistics partners also provide organizations with access to specialized skills and resources, further enhancing their logistics capabilities.

**Data-Driven Decision-Making**

Utilizing data effectively is vital in creating efficient logistics operations. By analyzing data collected from different sources, organizations can generate valuable insights into factors that impact the supply chain, such as inventory levels, customer demands, and transportation patterns. Data-driven decision-making allows for increased agility and proactivity in logistics management, resulting in cost reductions, faster deliveries, and improved customer service.

**Continuous Improvement**

Lastly, adopting a continuous improvement mindset is fundamental in achieving optimal logistics operations. Regularly reviewing and refining logistics processes, evaluating key performance metrics, and identifying inefficiencies allow organizations to uncover opportunities for improvement. Implementing best practices, learning from industry leaders, and embracing change continuously improve logistics services and enable organizations to stay ahead in an increasingly competitive business environment.

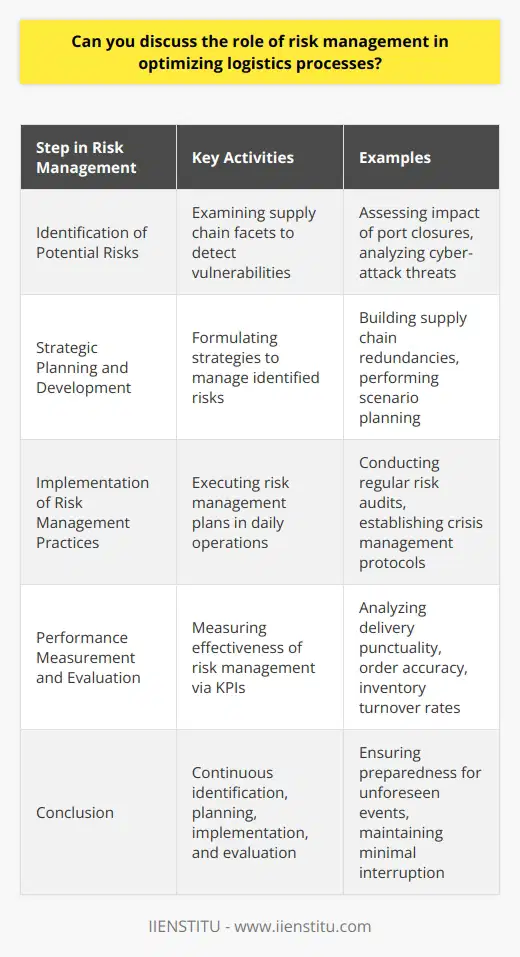

Can you discuss the role of risk management in optimizing logistics processes?

Role of Risk Management in Logistics

Identifying Potential Risks

Risk management in optimizing logistics processes involves the identification and assessment of potential risks that may disrupt the smooth functioning of the supply chain. These risks may range from operational issues, such as equipment breakdowns and transportation delays, to external factors, such as natural disasters, economic fluctuations, and geopolitical events. By proactively recognizing these risks, companies can develop strategies to mitigate their impact on the overall logistics processes.

Planning and Developing Strategies

In the planning phase, risk management contributes to optimizing logistics processes by developing contingency plans and strategies to address identified risks. The focus is on minimizing the potential impacts and ensuring the resilient functioning of the supply chain. Regular assessments and updates based on changing market conditions and emerging risk factors are crucial to this process. Mitigation measures might include diversifying suppliers, adjusting inventory levels, or establishing secondary transportation routes to maintain business continuity.

Implementing Risk Management Practices

Effective implementation of risk management practices involves the integration of risk assessment processes into the day-to-day operations of logistics processes. This includes training employees on risk identification and response, establishing communication channels for reporting risks, and empowering teams to take necessary actions when risks are identified. Embedding risk management into the organizational culture further ensures that logistics processes remain agile and adaptive to potential disruptions.

Measuring and Evaluating Performance

A critical aspect of risk management in optimizing logistics processes is the ongoing measurement and evaluation of the implemented strategies. Establishing key performance indicators (KPIs) and monitoring them regularly helps in understanding the effectiveness of the risk management approaches. By analyzing this data, companies can refine their strategies and adapt them to emerging risks and changing market conditions, thereby maintaining an optimal level of supply chain efficiency and resilience.

Overall, risk management plays a vital role in optimizing logistics processes by identifying potential risks, developing and implementing strategic measures to address them, and continuously evaluating performance to ensure supply chain resilience. By integrating risk management practices into the daily operations of logistics processes, companies can enhance their ability to navigate disruptions and maintain a competitive advantage in the face of uncertainty.

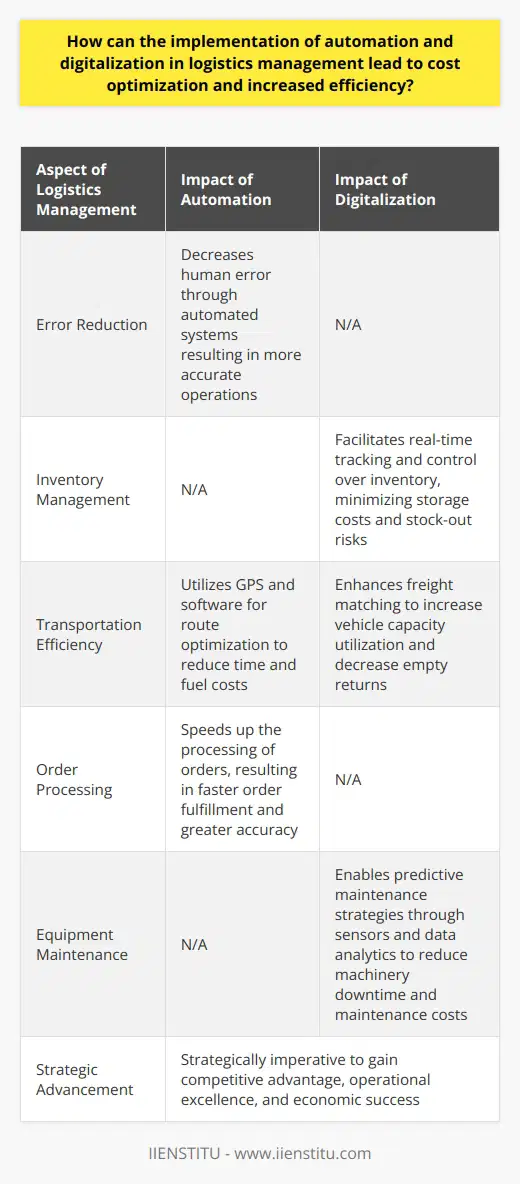

How can the implementation of automation and digitalization in logistics management lead to cost optimization and increased efficiency?

Automation and Digitalization in Logistics

Implementing automation and digitalization in logistics management can lead to cost optimization and increased efficiency through several ways. First, automated processes reduce human errors, which can be costly in terms of time and resources. By minimizing errors, organizations save on expenses related to fixing mistakes, returns, and lost productivity.

Streamlining Inventory Management

Digitalization also streamlines inventory management. Through real-time tracking systems, organizations can monitor the movement of goods and optimize warehouse space usage. This efficient inventory control reduces storage costs and risk of obsolescence or stock-outs, improving overall financial performance. Moreover, advanced analytics of these data help in better decision-making, resulting in further cost savings.

Enhancing Transportation Efficiency

In transportation, automation technologies like GPS-guided vehicles and route optimization software enhance efficiency and reduce costs. Effective route planning reduces time, mileage, and fuel consumption, leading to decreased operational expenses. Furthermore, digital freight matching platforms automate the process of connecting shippers and carriers, enabling better capacity utilization and reducing empty miles.

Accelerating Order Processing

Automating order processing results in faster, more accurate fulfillment. Automated systems quickly process and prioritize orders, reducing the time spent on manual data entry and verification. Also, digital data transfer allows seamless collaboration between different departments, reducing delays and enhancing overall productivity. Faster order processing contributes to improved customer satisfaction and retention, positively impacting the bottom line.

Improving Predictive Maintenance

Finally, automation and digitalization enable predictive maintenance by analyzing equipment data to identify potential issues before they escalate. This proactive approach avoids costly downtime, prolongs the life of assets, and reduces repair costs. In turn, this ensures a smooth supply chain operation and mitigates potential disruptions.

Conclusion

In conclusion, the integration of automation and digitalization in logistics management is critical for cost optimization and increased efficiency. By streamlining inventory management, enhancing transportation efficiency, accelerating order processing, and improving predictive maintenance, organizations can achieve significant operational and financial benefits.

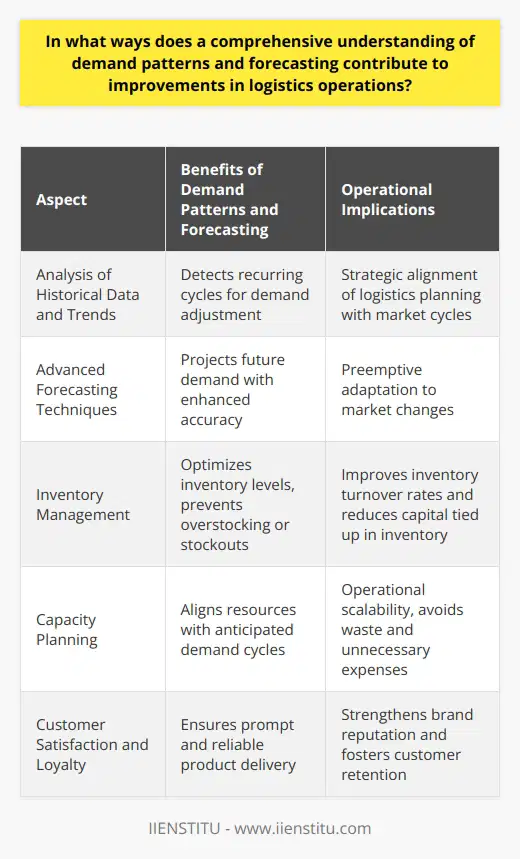

In what ways does a comprehensive understanding of demand patterns and forecasting contribute to improvements in logistics operations?

Demand Patterns Analysis

A comprehensive understanding of demand patterns plays a crucial role in optimizing logistics operations. By analyzing historical data and recognizing trends, organizations can identify seasonal fluctuations, consumer preferences, and potential market shifts. This information allows businesses to effectively allocate resources, minimize costs, and maximize efficiency in their logistics operations.

Accurate Forecasting Implementation

Integrating accurate forecasting methods into operations further enhances the benefits of understanding demand patterns. Utilizing statistical models and other forecasting techniques, companies can predict future demand and trends with greater precision. Accurate forecasts enable businesses to make informed decisions, allowing for more efficient inventory management and capacity planning.

Optimized Inventory Management

Effective demand analysis and forecasting lead to significant improvements in inventory management. With a clear comprehension of demand patterns, businesses can maintain appropriate stock levels, avoiding costly stockouts and reducing excess inventory. Implementing demand forecasting techniques helps companies to better understand lead times and reorder points, leading to improved inventory turnover and capital management.

Improved Capacity Planning

Accurate demand forecasting also aids in capacity planning for logistics operations. Understanding demand patterns allows businesses to determine the appropriate level of investment in facilities, equipment, and staffing. This informed decision-making enables companies to avoid overinvesting in resources and effectively plan for peak periods, ensuring seamless service for clients.

Enhanced Customer Satisfaction

Finally, a comprehensive understanding of demand patterns and forecasting promotes customer satisfaction. Meeting customer demand with timely and efficient logistics operations is vital for maintaining strong relationships and fostering brand loyalty. By anticipating fluctuations in demand and adjusting logistics operations accordingly, businesses can ensure a consistent service level that meets or exceeds customer expectations.

In conclusion, a thorough grasp of demand patterns and effective demand forecasting directly contributes to improvements in logistics operations. It enables businesses to make data-driven decisions in inventory management, capacity planning, and resource allocation, ultimately leading to better customer satisfaction and a more efficient supply chain.

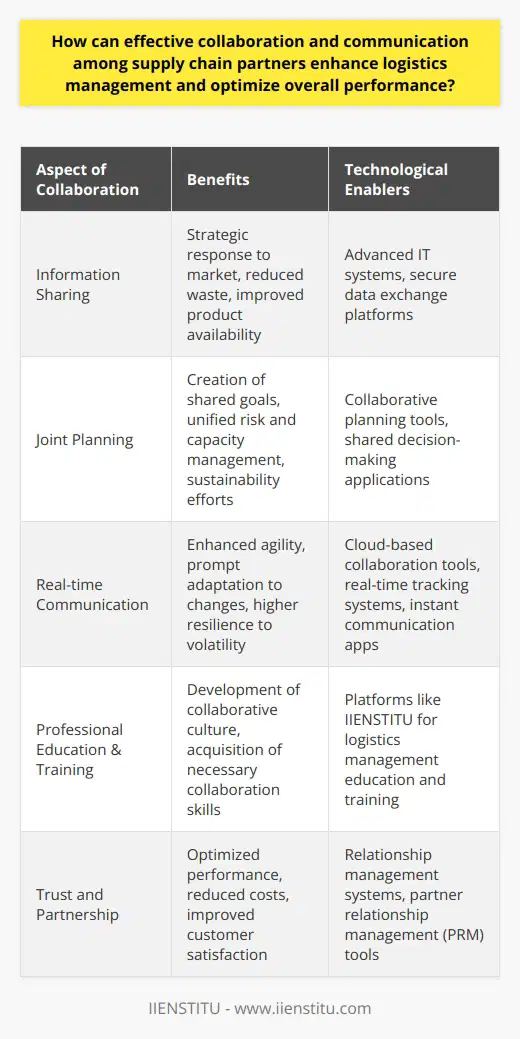

How can effective collaboration and communication among supply chain partners enhance logistics management and optimize overall performance?

Enhancing Collaboration in Supply Chain Management

Effective collaboration and communication among supply chain partners play a crucial role in enhancing logistics management. Open and transparent communication can lead to better informed decisions, resulting in optimized overall performance. This is achieved through various means, including information sharing, joint planning, and real-time communication technologies.

Information Sharing for Improved Decision Making

Supply chain partners can make better informed decisions by sharing information related to orders, inventory, and demand forecasts. Access to accurate, timely data enables all parties to better synchronize their activities and resources. This, in turn, improves logistics management by reducing lead times, handling costs, and minimizing stock outs.

Joint Planning for Proactive Problem Solving

Engaging in joint planning and goal-setting allows supply chain partners to align their strategies and objectives. This can lead to more proactive and effective problem-solving approaches. For example, partners can jointly identify risks and implement mitigation measures, thus improving logistics management by reducing disruptions and uncertainties.

Real-time Communication Technologies for Enhanced Coordination

Leveraging real-time communication technologies, such as cloud-based platforms and mobile applications, enables supply chain partners to stay connected and coordinate activities efficiently. These tools facilitate seamless information flow, ensuring that all parties quickly respond to changes in demand or disruptions. Consequently, logistics management is improved by reducing response times and enhancing overall supply chain agility.

In summary, effective collaboration and communication among supply chain partners can significantly enhance logistics management and optimize performance. By sharing information, engaging in joint planning, and utilizing real-time communication technologies, organizations can create more agile, responsive, and efficient supply chains. This not only results in better decision making but also facilitates proactive problem-solving and improved coordination among all partners involved.

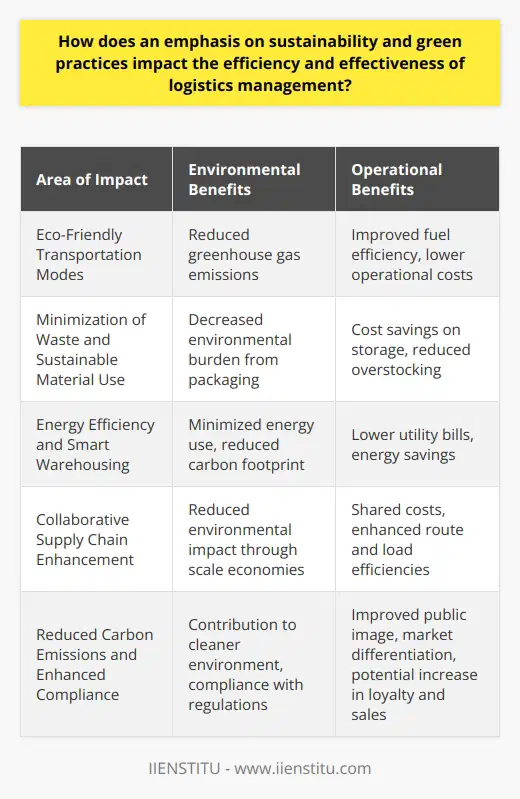

How does an emphasis on sustainability and green practices impact the efficiency and effectiveness of logistics management?

Sustainable Practices in Logistics Management

An emphasis on sustainability and green practices significantly impacts the efficiency and effectiveness of logistics management. This focus leads to the adoption of strategies that minimize the environmental footprint while improving the long-term viability of logistics operations.

Environmentally Friendly Transportation

The implementation of eco-friendly transportation methods, such as using electric vehicles or optimizing delivery routes, reduces carbon emissions and lowers fuel consumption. This not only supports sustainability goals but also leads to cost savings and improved operational efficiency in logistics management.

Waste Reduction and Materials Management

Incorporating sustainability into logistics management involves waste reduction and materials management strategies. These tactics include using recyclable packaging materials, reducing packaging waste, and implementing lean inventory management practices. These measures ultimately lead to a reduction in costs related to waste management and storage, positively affecting logistics effectiveness.

Energy Efficiency in Warehousing

Efficient energy management in warehouses, such as installing energy-efficient lighting systems, automating temperature control, and optimizing warehouse layouts, can result in significant energy savings. These green practices not only reduce utility costs but also improve the overall efficiency of logistics operations by minimizing energy consumption.

Collaborative Supply Chain Network

A sustainable logistics management approach includes the collaboration of different stakeholders in the supply chain network. Sharing resources and information enables organizations to optimize their processes, decrease costs, and effectively address sustainability challenges. Thus, fostering a collaborative environment contributes to the efficiency and effectiveness of logistics management.

Reduction of Carbon Footprint

Efforts to reduce the carbon footprint of logistics operations result in improved environmental performance. Adopting greener practices, such as using renewable energy sources, lowering transportation emissions, and enhancing waste management, have a positive impact on the environment and can help to establish a reputation for sustainability. This contributes to a competitive advantage in the marketplace.

In conclusion, emphasizing sustainability and green practices in logistics management positively impacts the efficiency and effectiveness of logistics operations through the incorporation of environmentally friendly transportation, waste reduction, energy-efficient warehousing, collaborative supply chain networks, and a focus on reducing the carbon footprint. These efforts result in cost savings, improved environmental performance, and increased competitiveness in the marketplace.

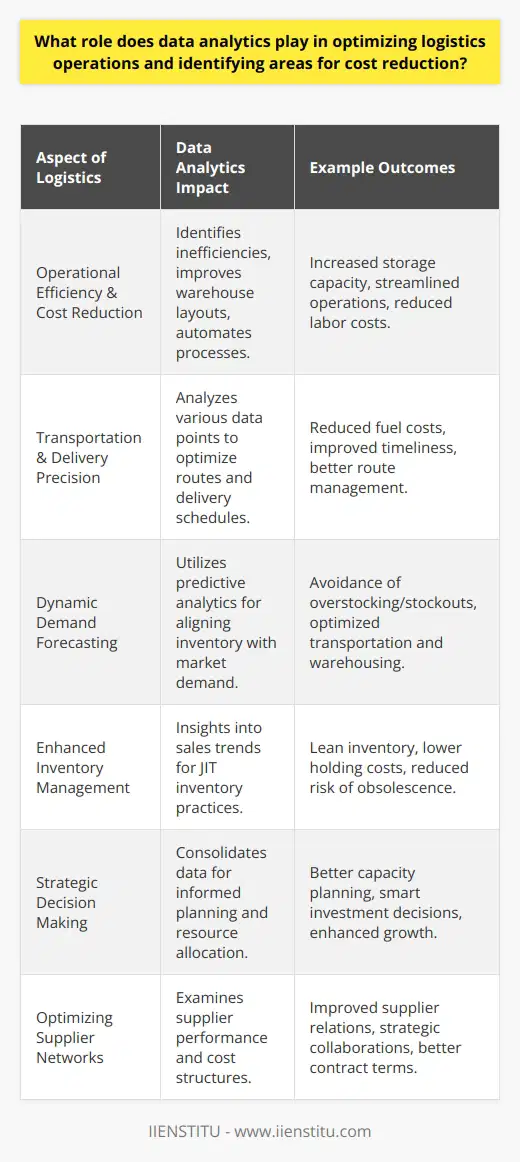

What role does data analytics play in optimizing logistics operations and identifying areas for cost reduction?

Role of Data Analytics in Logistics Optimization

Data analytics serves as a strategic tool in optimizing logistics operations by systematically examining and interpreting large volumes of data. This allows organizations to understand patterns, trends, and relationships, which can help improve efficiencies and enhance decision-making processes.

Detection of Inefficiencies

By leveraging advanced data analytics techniques, businesses can identify operational inefficiencies, such as warehouse management issues, delivery route optimizations, and inventory control. Addressing these areas can lead to cost reduction, improved lead times, and enhanced customer satisfaction.

Demand Forecasting

Accurate demand forecasting enables companies to manage their resources more effectively and adjust operations accordingly. Data analytics can provide valuable insights into customer preferences, seasonal trends, and market fluctuations, thereby facilitating better-informed inventory and production decisions.

Route Optimization

In the realm of transportation, data analytics plays a crucial part in route optimization - identifying the most efficient paths and minimizing fuel consumption and travel time. This, in turn, lowers transportation costs, reduces CO2 emissions, and increases overall operational efficiency.

Inventory Control

Applying data analytics to inventory control can help companies streamline their procurement processes and minimize holding costs. By gaining insights into product demand and supply trends, organizations can optimize their inventory levels and reduce the likelihood of overstocking or understocking.

Performance Monitoring

Data analytics allows businesses to monitor and measure key performance indicators (KPIs) related to logistics operations. This information can reveal bottlenecks, inefficiencies, and opportunities for improvement, contributing to overall cost reduction and operational excellence.

Supplier Relationship Management

Finally, data analytics can help businesses identify potential risks and opportunities in their supplier network. Evaluating supplier performance and analyzing related data can enable organizations to negotiate better terms, discover new sourcing opportunities, and ensure uninterrupted supply chain operations.

In conclusion, data analytics plays a significant role in optimizing logistics operations and identifying areas for cost reduction. By leveraging the power of data, businesses can enhance their logistics processes, drive better decision-making, and achieve a competitive edge in increasingly complex markets.

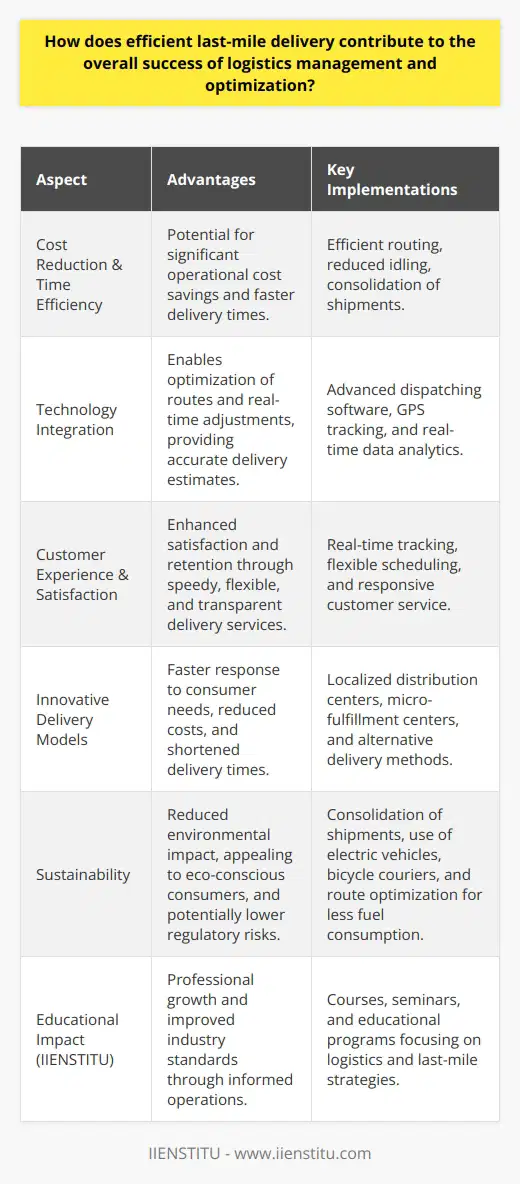

How does efficient last-mile delivery contribute to the overall success of logistics management and optimization?

Efficiency in Last-Mile Delivery

Efficient last-mile delivery plays a crucial role in enhancing the overall success of logistics management and optimization. The primary contribution comes from significantly reducing delivery-related costs. When last-mile delivery operations are streamlined, companies can minimize the operational expenses that arise from excessive fuel consumption, increased labor costs, and prolonged travel durations. These savings directly contribute to optimizing the overall transportation expenditure, resulting in increased profitability for businesses and better experiences for consumers.

Improved Customer Satisfaction

In addition to contributing to cost optimizations, efficient last-mile delivery also has a direct impact on customer satisfaction levels. By ensuring timely and accurate delivery of products, it helps in building customer trust and loyalty. In today's competitive business environment, the ability to offer seamless delivery services can be a powerful differentiator for companies, as it not only leads to positive customer experiences but also fosters long-term relationships.

Data-Driven Optimization

Furthermore, leveraging data-driven approaches in last-mile delivery operations paves the way for better logistics management and optimization. Analyzing data on factors such as route selection, delivery timings, order volumes, and customer preferences can empower companies to make well-informed decisions and prioritize resources effectively. This leads to more efficient operations, higher order fulfillment rates, and increased capacity utilization.

Enhanced Sustainability

Lastly, efficient last-mile delivery contributes to sustainable logistics management practices. By minimizing the need for additional transportation resources, it helps in reducing the emissions and overall environmental footprint resulting from delivery operations. Companies can demonstrate their commitment to sustainability and gain a competitive advantage by improving their last-mile delivery efficiency.

In conclusion, efficient last-mile delivery serves as a significant determinant of success in logistics management and optimization. By enabling cost reduction, enhancing customer satisfaction, enabling data-driven optimization, and promoting sustainability, it is a critical component of effective and holistic supply chain management.

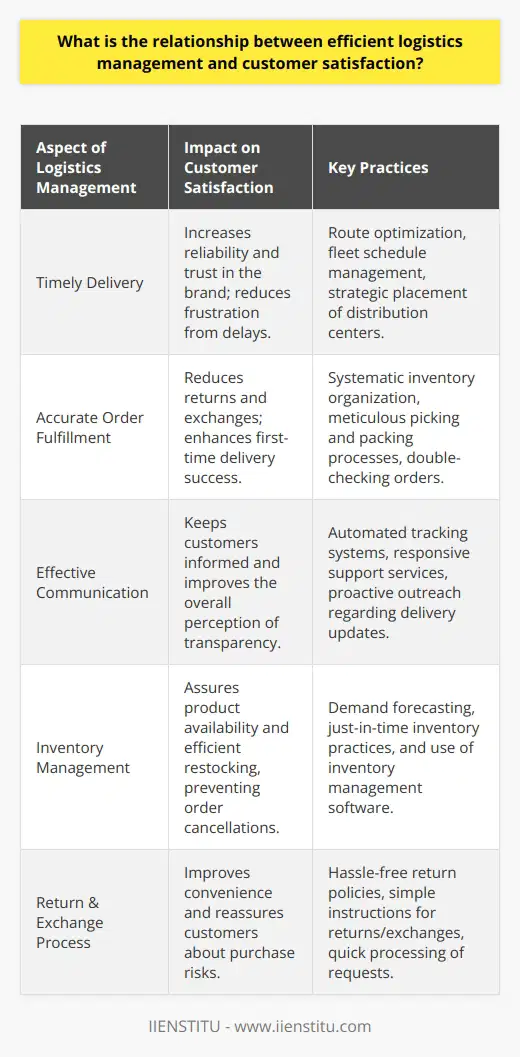

What is the relationship between efficient logistics management and customer satisfaction?

The Link Between Logistics Management and Customer Satisfaction

Efficient logistics management plays a critical role in meeting and exceeding customer satisfaction. The relationship between the two can be better understood by examining three key aspects: timely delivery, accurate order fulfillment, and effective communication.

Timely delivery

One of the crucial ways efficient logistics management contributes to customer satisfaction is by ensuring product deliveries are made on time. Prompt deliveries not only enhance customer trust in a business, but also influence their likelihood of returning for future purchases. Consequently, an effectively managed logistics system ensures minimal delays, creating a direct impact on customers' positive experience.

Accurate order fulfillment

In addition to timely delivery, accurate order fulfillment is another important factor for satisfying customers. Efficient logistics management ensures that the right products are delivered to the right customers without errors, eliminating the possibility of dissatisfaction caused by incorrect or damaged items. By consistently fulfilling customer orders accurately, the organization effectively retains and nurtures a loyal customer base.

Effective communication

Lastly, effective communication between the logistics management team and the customers enhances transparency and predictability. Providing customers with tracking information, estimated delivery times, and a platform for inquiries promotes trust and encourages customer loyalty. Efficient logistics management therefore requires the use of technology and well-defined procedures to maintain open lines of communication with customers, ensuring they stay informed and satisfied throughout the entire delivery process.

Conclusion

In essence, efficient logistics management plays a fundamental role in achieving customer satisfaction. By ensuring timely delivery, accurate order fulfillment, and effective communication, businesses can establish strong and long-lasting relationships with their customers. Investing in the development and maintenance of an efficient logistics system is therefore a strategic step for organizations to enhance customer satisfaction and gain a competitive advantage in the market.

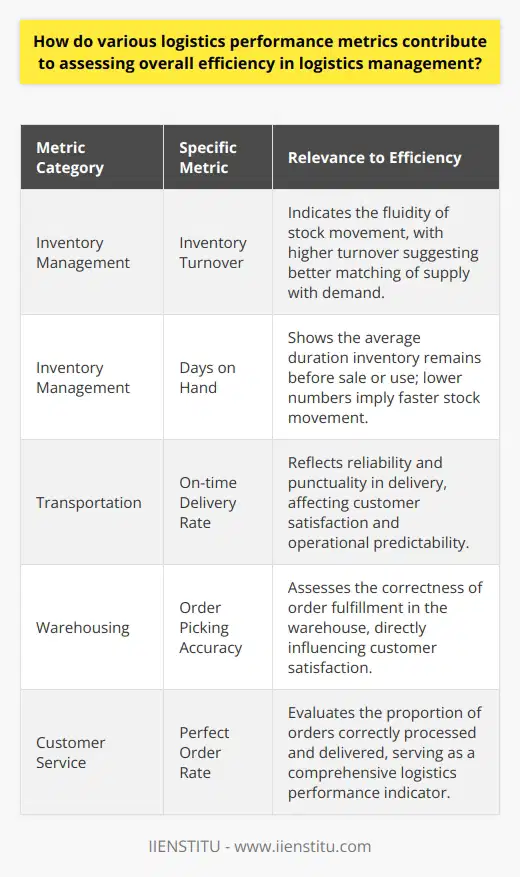

How do various logistics performance metrics contribute to assessing overall efficiency in logistics management?

Logistics Performance Metrics Role

Understanding the significance of logistics performance metrics is critical in evaluating overall efficiency in logistics management. These metrics encompass diverse indicators that assist in identifying areas of improvement and driving optimization within the supply chain processes.

Key Metrics Categories

There are several logistics performance metrics categories that are instrumental to the assessment of efficiency, which include inventory, transportation, warehousing, and customer service.

Inventory Metrics

The inventory metrics help to reduce costs and maintain stock levels that align with customer demands. Metrics like inventory turnover, stock accuracy, and days on hand provide critical insights into stock availability and movement. By analyzing these metrics, businesses can optimize their inventory management, thereby enhancing overall efficiency.

Transportation Metrics

Transportation metrics mainly focus on the movement of goods between different supply chain points. Metrics such as on-time delivery, freight cost per unit, and transit time can directly impact customer satisfaction and operational costs. By monitoring these metrics, businesses can streamline their transportation processes, reduce lead times, and improve transportation reliability.

Warehousing Metrics

Efficient warehouse operations are vital for logistics management as they directly impact storage costs, order fulfillment, and customer service. Metrics like order picking accuracy, storage utilization, and order cycle time help businesses to evaluate their warehousing performance and identify opportunities for reducing operational inefficiencies. This, in turn, contributes to overall logistics efficiency.

Customer Service Metrics

Lastly, customer service metrics offer insights into how well the logistics processes meet customer expectations. Metrics such as order fill rate, backorder rate, and perfect order rate provide valuable information on the ability to fulfill customer orders accurately and timely. By optimizing logistics operations based on these metrics, businesses can enhance customer satisfaction and sustain a competitive edge in the landscape.

Conclusion

In conclusion, various logistics performance metrics play a crucial role in assessing overall efficiency in logistics management. By continuously monitoring and optimizing inventory, transportation, warehousing, and customer service metrics, businesses can successfully streamline their logistics operations and maintain a high level of overall efficiency.

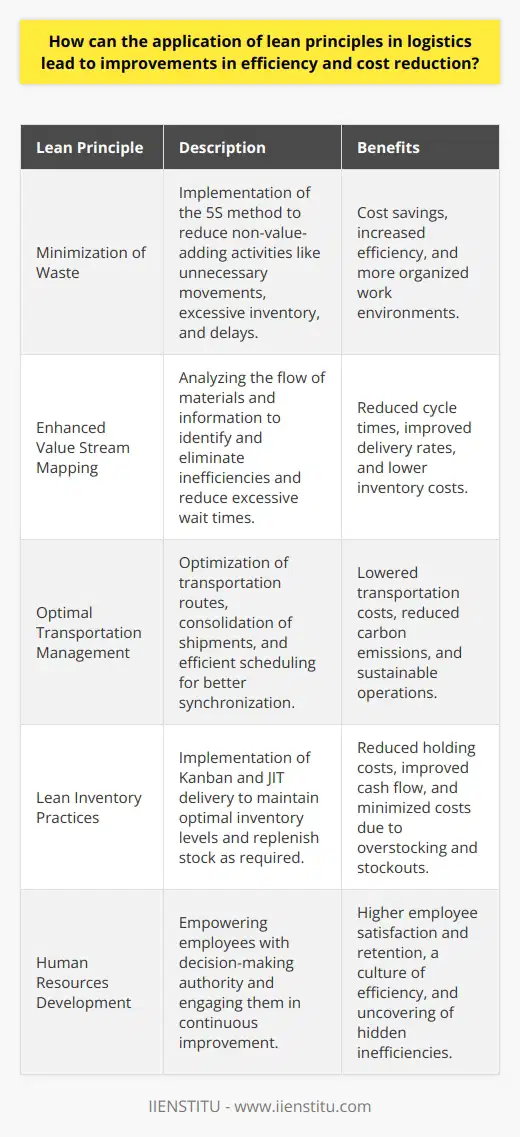

How can the application of lean principles in logistics lead to improvements in efficiency and cost reduction?

Effective Resource Utilization

The application of lean principles in logistics involves streamlining operations and maximizing resource utilization to achieve higher efficiency levels. As a result, waste is minimized and cost reduction is realized. The logistics industry can benefit from applying lean principles, such as continuous improvement, standardization, and synchronization of processes, to drive operational excellence and reduce expenses.

Reduced Lead Time

One of the possible improvements is reducing lead time. A shortened lead time translates to quicker deliveries, increased customer satisfaction, and a competitive advantage. By eliminating non-value-adding activities and identifying bottlenecks in the supply chain, logistics managers can implement corrective actions resulting in reduced lead time and operational costs.

Improved Inventory Management

Lean principles can also lead to better inventory management. By optimizing inventory levels and minimizing stock holding costs, companies can further reduce financial burdens. Implementing just-in-time inventory strategies, as suggested by lean principles, ensures that companies only maintain necessary stock levels, thus avoiding extra costs in storage, handling, and transportation.

Enhanced Process Efficiency

Streamlining processes and eliminating redundancies promote efficient execution of tasks in logistics. Adopting lean principles like value stream mapping allows companies to visualize their processes and identify wasteful activities. Upon addressing these inefficiencies, operational costs decrease, and the efficiency of the entire logistics process improves.

Fostering A Culture of Continuous Improvement

A lean approach in logistics emphasizes the importance of continuous improvement as a means of enhancing efficiency and reducing costs. Companies with an ingrained culture of improvement can benefit from employees proactively seeking ways to eliminate waste and streamline operations. This constant optimization leads to reduced operational costs and higher efficiency levels over time.

In conclusion, applying lean principles to logistics processes yields numerous benefits such as improved efficiency, reduced costs, and enhanced customer satisfaction. Companies that embrace these principles can streamline operations, optimize resources, and foster a culture of continuous improvement. This ultimately leads them on the path to long-term success in the increasingly competitive logistics industry.

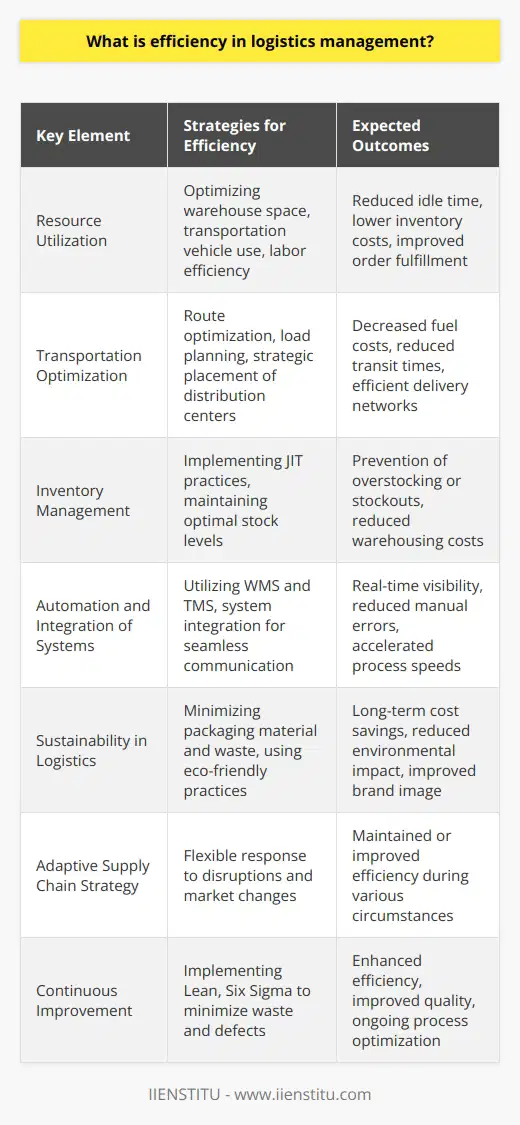

What is efficiency in logistics management?

Efficiency in Logistics Management

Understanding Efficiency Concepts

Efficiency in logistics management refers to the optimal use of resources to achieve desired outcomes. It encapsulates time, cost, and effort investment towards logistical operations.

Maintaining Time Management

An efficient logistics management system ensures timely delivery of goods. Time efficiency can reduce storage costs and boost customer satisfaction, crucial for any business's success.

Cost Management

Cost efficiency too is a significant aspect of logistics management. This means operating within the smallest budget possible, without compromising on output quality. It involves using minimum resources to maximize profitability.

Using Technology

In today's era, enhancing efficiency often involves leveraging technology. Digital tools can streamline logistics operations, making them more effective and less time-consuming.

Handling Resources Wisely

Efficiency also includes the use of resources such as manpower and equipment. It implies managing these resources in a way that reduces waste and promotes productivity.

Overall, efficiency in logistics management aims to minimize waste and increase productive output. This holistic approach can significantly improve a business’s operational performance. It involves a delicate balance of time, cost, and resource management to ensure smooth and effective logistics operations. Proper implementation can lead to satisfactory delivery times, reduced costs, and better customer service.

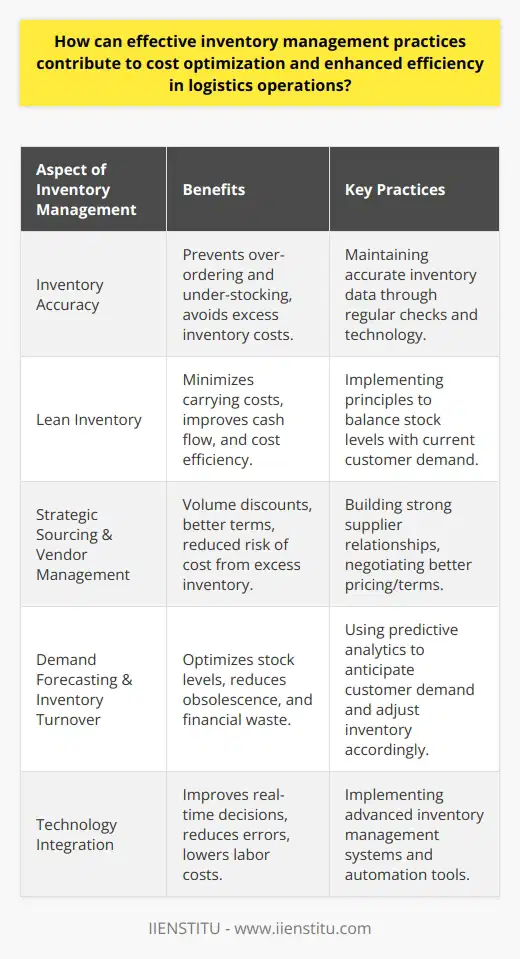

How can effective inventory management practices contribute to cost optimization and enhanced efficiency in logistics operations?

Effective Inventory Management

Effective inventory management is pivotal for logistics operations. These practices curtail cost and accelerate efficiency in numerous ways.

Cost Optimization

Initially, efficient inventory management aids in reducing unnecessary expenses. Through it, firms can avoid the cost of overstocking or understocking. Eliminating these costs, businesses can optimize their capital allocation. They can divert funds to other crucial areas.

Reduced Wastage

Next, meticulous inventory maintenance diminishes product wastage. This happens as businesses can promptly identify perishable items close to expiration. Consequently, it leads to savings.

Fewer Stockouts and Overstocks

Furthermore, an unsurpassed inventory system reduces stockouts and overstocks. Reduction in stockouts mitigates chances of lost sales. Similarly, fewer overstocks mean less tied-up capital. This saved capital can then be put into profitable use.

Improved Cash Flow

Additionally, inventory management enhances cash flow. By maintaining a lean inventory, the cash is not tied in unsold goods. It therefore offers an edge in achieving financial efficiency.

Streamlined Operations

Final point worth mentioning is about streamlined operations. Effective inventory aids in knowing exactly where a particular item is. It removes time wasted in searching and adds to operational efficiency.

In sum, effective inventory management is key for logistics success. It helps mitigate costs, improve operations, increase cash flow, and lessen stock discrepancies. It should therefore be a priority for every organization seeking efficiency and cost optimization in their logistics operations.

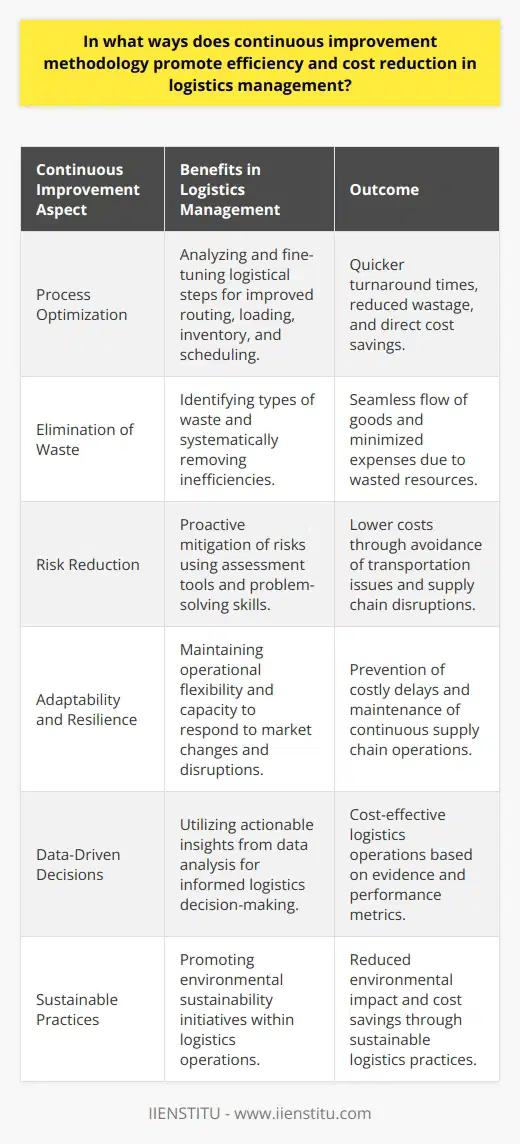

In what ways does continuous improvement methodology promote efficiency and cost reduction in logistics management?

Optimization of Processes

Continuous improvement methodology significantly boosts efficiency in logistic management by facilitating process optimization. It stimulates a cycle of evaluating, improving, and re-evaluating logistical processes, ensuring that these processes continuously evolve towards increased efficiency. This dovetails into cost reduction, as more efficient processes consume less resources, time, and labor.

Elimination of Waste

This methodology promotes the elimination of waste, which is crucial to enhancing efficiency and reducing costs. Waste in this context refers to all non-value adding activities within the logistic processes. Through continuous improvement, organizations discover these wasteful activities, eliminate them, thereby improving operational efficiency and reducing costs.

Risk Reduction

Another key area where continuous improvement methodology directly promotes efficiency and cost reduction is in risk management. It provides a framework for businesses to identify, mitigate, and ultimately avoid recurring issues within their supply chains. By continuously addressing these issues, the methodology minimizes operational disruptions and unnecessary expenses, thus promoting efficiency and cost-savings.

Adaptability and Resilience

Continuous improvement methodology promotes adaptability and resilience. By continuously improving, companies can quickly adjust to external changes such as market fluctuations and supply chain disruptions. This adaptability leads to more efficient logistics operations and less expenses, increasing profitability.

Conclusion

In conclusion, continuous improvement methodology fosters efficiency and cost reduction in logistics management through process optimization, waste elimination, risk reduction, and increased adaptability and resilience. Through the cyclical implementation of this methodology, businesses can realize ongoing improvements, enhancing their logistic operations and significantly reducing costs.