I still remember my early days working in the bustling world of supply chain management. It was my first big project, and I was eager to make a meaningful impact. One afternoon, as I sipped my coffee, my mentor leaned over and asked, "Have you ever heard of Just-In-Time and Safety Stock?" I blinked, realizing that while I had come across these terms in textbooks, I hadn't fully grasped their real-world applications. That conversation ignited a journey of discovery into the intricacies of inventory management, a journey I'd like to share with you.

Understanding the Essentials of Inventory Management

Before diving into the depths of Just-In-Time (JIT) and Safety Stock, it's essential to appreciate the pivotal role inventory management plays in the supply chain. Effective inventory management ensures that products are available when customers need them, without incurring unnecessary costs from overstocking. It's a delicate balancing act, one that can make or break a company's operational efficiency.

The Dance of Demand and Supply

In the dynamic dance between demand and supply, businesses strive to:

Smart Supply Chain Management Estimating Demand Optimization Strategies

How To Answer What's Your Top Problem-solving Method İnterview Question

Meet customer expectations promptly.

Minimize holding costs associated with excess inventory.

Avoid stockouts that can lead to lost sales and dissatisfied customers.

Optimize processes to enhance overall efficiency.

Achieving these goals requires a strategic approach to managing inventory, which brings us to the two prominent methodologies: Just-In-Time and Safety Stock.

Just-In-Time (JIT): A Symphony of Timeliness

Just-In-Time is more than just a strategy; it's a philosophy that revolutionized manufacturing and supply chain processes. Originating from Japan's Toyota Production System in the 1970s, JIT emphasizes producing and delivering goods exactly when they are needed, no sooner, no later.

The Core Principles of JIT

1- Elimination of Waste: JIT seeks to remove any non-value-adding activities, streamlining processes to enhance efficiency.

2- Continuous Improvement: It encourages ongoing evaluation and refinement of processes.

3- Integrated Systems: Collaboration across departments and suppliers ensures seamless operations.

4- Quality Management: Emphasizing high-quality production reduces defects and associated costs.

Advantages of JIT

Reduced Inventory Costs: By minimizing inventory levels, companies can significantly cut down on storage and handling expenses.

Improved Cash Flow: Less capital is tied up in stock, freeing resources for other investments.

Enhanced Supplier Relationships: JIT requires close coordination with suppliers, fostering stronger partnerships.

Greater Responsiveness: Companies can quickly adapt to changes in demand without the burden of excess stock.

I recall a project where we implemented JIT for a client producing electronic components. The results were astounding: inventory holding costs dropped by 35%, and the efficiency of the production line improved markedly. The synchronization of supply with production demand was like watching a well-rehearsed orchestra perform—every part played in harmony.

Challenges of Implementing JIT

However, JIT isn't without its challenges:

Supplier Reliability: Delays from suppliers can halt production.

Lack of Buffer: With minimal inventory, there's little room for error.

Demand Fluctuations: Sudden spikes in demand can be difficult to meet promptly.

Safety Stock: The Guardian Buffer

In contrast to JIT's lean approach, Safety Stock acts as a cushion against uncertainty. It's the extra inventory kept on hand to mitigate risks associated with supply chain disruptions and unpredictable demand.

The Rationale Behind Safety Stock

Unpredictable Demand: Even with forecasts, demand can vary due to market trends, seasonal factors, or unforeseen events.

Supply Chain Disruptions: Delays from suppliers, transportation issues, or production hiccups can lead to stockouts.

Lead Time Variability: Differences between expected and actual lead times necessitate a buffer.

Benefits of Safety Stock

Protection Against Stockouts: Ensures products are available, maintaining customer satisfaction.

Stabilizes Production: Aids in smoothing out the production schedule despite fluctuations.

Risk Mitigation: Acts as a safeguard against external uncertainties.

Can you compare and contrast the JIT and Safety Stock strategies in a supply chain approach?

How does JIT differ from Safety Stock in managing a supply chain?

Could you explain the difference between the JIT and safety stock in a supply chain approach?

What distinguishes JIT from Safety Stock in their approach to supply chain management?

Could you provide insights into the pros and cons of JIT and Safety Stock in the handling of supply chains?

In the context of supply chain strategy, can you outline the key differences between JIT and Safety Stock?

Is there an advantage of JIT over Safety Stock in supply chain management or vice versa?

How do the approaches of JIT and Safety Stock compare when faced with supply chain demands?

When it comes to a supply chain approach, how do you differentiate between JIT and Safety Stock?

Can you provide a comparative study on JIT and Safety Stock strategies in managing a supply chain?

On one occasion, a sudden snowstorm disrupted our supply routes. Thanks to the Safety Stock we had diligently maintained, operations continued without a hitch, and our customers were none the wiser. It was a lesson in the value of preparedness, one that underscored the importance of balancing efficiency with resilience.

Drawbacks of Safety Stock

Yet, maintaining Safety Stock comes with its own set of challenges:

Increased Holding Costs: Additional inventory means more capital tied up and higher storage expenses.

Potential Obsolescence: Risk of stock becoming outdated, especially in industries with rapid product cycles.

Reduced Cash Flow: Funds invested in excess inventory cannot be used elsewhere.

Comparing JIT and Safety Stock: Striking the Right Balance

Understanding the differences between JIT and Safety Stock is crucial for any supply chain professional. Both approaches offer unique advantages and come with inherent risks. The key lies in assessing which strategy aligns best with a company's operational goals and market conditions.

Key Differences

| Aspect | Just-In-Time (JIT) | Safety Stock |

|-------------------------|---------------------------------------------------------|--------------------------------------------------------|

| Inventory Levels | Minimal inventory, aligned with immediate needs | Additional inventory as a buffer |

| Cost Implications | Lower holding costs but relies heavily on supplier efficiency | Higher holding costs due to extra stock |

| Risk Management | Vulnerable to supply chain disruptions | Provides protection against uncertainties |

| Supplier Dependence | Requires reliable and responsive suppliers | Less immediate pressure on suppliers |

| Flexibility | Less flexible in responding to sudden demand spikes | More adaptable to demand fluctuations |

When to Use Each Approach

Opting for JIT When:

Supplier Reliability is High: Strong, dependable supplier relationships are in place.

Demand is Predictable: Stable market conditions with accurate demand forecasting.

Focus on Lean Operations: The company aims to streamline processes and reduce waste.

Choosing Safety Stock When:

Demand is Volatile: Industries with seasonal or unpredictable demand patterns.

Supply Chain Risks are Present: Potential for supplier delays or logistical challenges.

Customer Service is Paramount: Prioritizing product availability to maintain satisfaction.

Integrating JIT and Safety Stock: A Hybrid Approach

In practice, many companies find that a hybrid strategy serves them best. By combining elements of both JIT and Safety Stock, businesses can optimize their supply chain management process to suit their specific needs.

Tips for Balancing Both Strategies

1- Analyze Demand Patterns: Use data analytics to understand demand fluctuations.

2- Segment Inventory: Apply JIT to stable products and Safety Stock to volatile items.

3- Strengthen Supplier Relationships: Collaborate closely to improve reliability.

4- Invest in Technology: Implement systems for real-time tracking and forecasting.

5- Continuous Improvement: Regularly review and adjust strategies as conditions change.

In one of our supply chain optimization projects, we helped a manufacturer adopt this hybrid approach. By segmenting their product lines based on demand volatility, they could apply JIT principles to consistent sellers while maintaining Safety Stock for unpredictable items. This not only reduced overall costs but also improved their ability to meet customer demands swiftly.

Navigating the Risks: Mitigation Strategies

Understanding the risk factors associated with JIT and Safety Stock is essential. Here are some strategies to mitigate these risks:

For Just-In-Time

Diversify Suppliers: Avoid over-reliance on a single source.

Enhance Communication: Establish clear and constant communication channels.

Implement Contingency Plans: Prepare alternative solutions for potential disruptions.

For Safety Stock

Optimize Stock Levels: Use statistical models to determine optimal quantities.

Regularly Review Inventory: Monitor for obsolescence or slow-moving items.

Balance Costs and Benefits: Weigh the holding costs against the risk of stockouts.

Conclusion: Crafting the Right Strategy for Your Business

Reflecting on my journey through supply chain management, I've come to appreciate that there's no one-size-fits-all solution. Every business is unique, with its own set of challenges and objectives.

By understanding the fundamental differences between Just-In-Time and Safety Stock, and recognizing the circumstances under which each is most effective, companies can make informed decisions. Whether striving for lean operations or safeguarding against uncertainties, the ultimate goal remains the same: to deliver value to customers efficiently and effectively.

So, the next time you're evaluating your inventory management strategies, consider these insights. Perhaps, like me, you'll find that the key lies not just in choosing one approach over the other but in finding the perfect balance that aligns with your business goals.

References

1- Chopra, S., & Meindl, P. (2016). Supply Chain Management: Strategy, Planning, and Operation. Pearson.

2- Heizer, J., & Render, B. (2014). Operations Management: Sustainability and Supply Chain Management. Prentice Hall.

3- Christopher, M. (2016). Logistics & Supply Chain Management. Pearson UK.

Similar Interview Questions to Consider

How do you integrate both JIT and Safety Stock in a supply chain strategy?

Can you discuss the impact of demand forecasting on inventory management approaches?

How would you handle supply chain disruptions in a JIT environment?

What methods do you recommend to optimize supply chain management processes?

Could you explain the role of technology in managing Safety Stock levels?

Key Takeaways:

Just-In-Time (JIT) focuses on reducing inventory levels and requires high supplier reliability.

Safety Stock provides a buffer against uncertainties but increases holding costs.

A hybrid approach can offer the benefits of both strategies.

Understanding your company's specific needs is essential to optimize supply chain management processes.

Remember, the world of supply chain is ever-evolving. Staying informed and adaptable is key to success. Happy managing!

Frequently Asked Questions

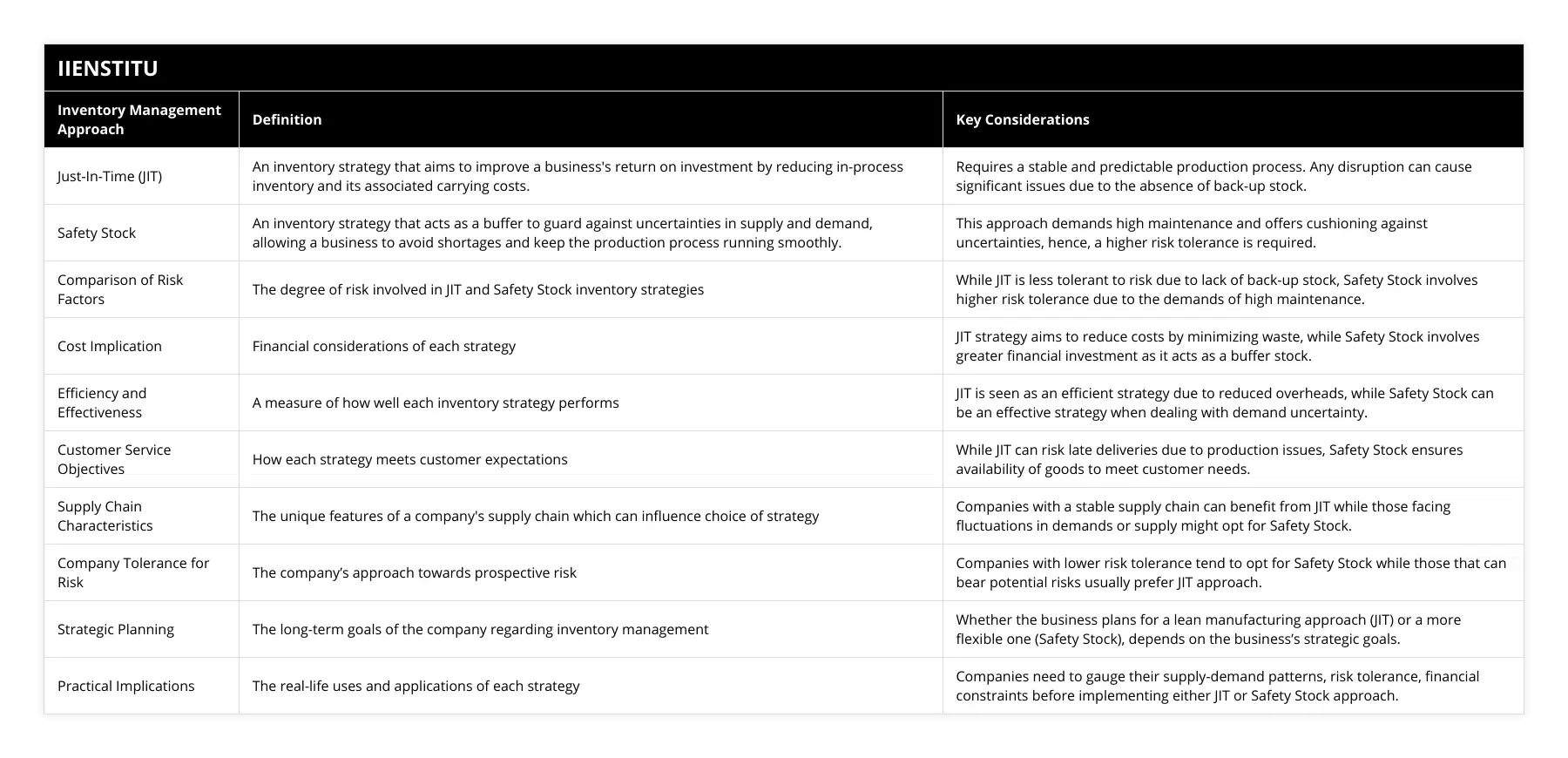

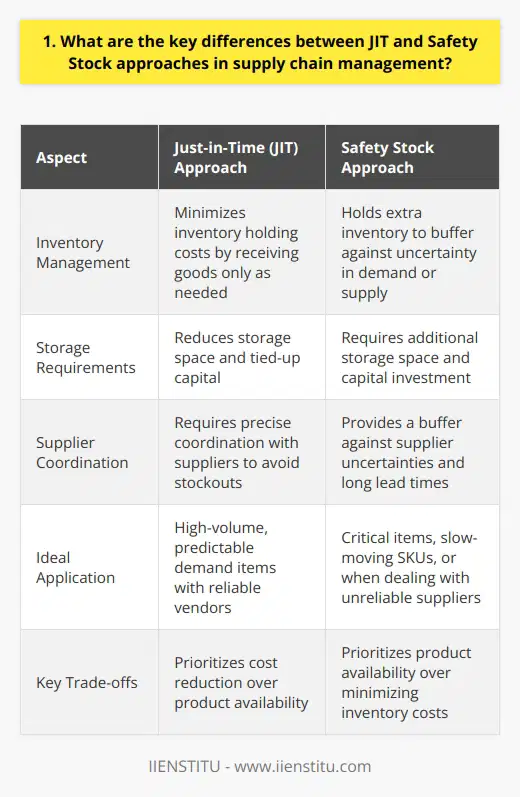

1. What are the key differences between JIT and Safety Stock approaches in supply chain management?

As a supply chain professional, I've worked with both JIT and safety stock approaches. The key differences lie in how inventory is managed.

Just-in-Time (JIT) Approach

JIT aims to minimize inventory holding costs by receiving goods only as they're needed for production or sales. This reduces storage requirements and tied-up capital, but requires precise coordination with suppliers to avoid stockouts. In my experience, JIT works best for high-volume, predictable demand items with reliable vendors.

Pros of JIT

Cons of JIT

Safety Stock Approach

In contrast, safety stock involves holding extra inventory to buffer against uncertainty in demand or supply. This approach prioritizes product availability over minimizing inventory costs. I think it's most suitable for critical items, slow-moving SKUs, or when dealing with long lead times and unreliable suppliers.

Pros of Safety Stock

Cons of Safety Stock

Ultimately, the right approach depends on carefully weighing the trade-offs for each product and supply chain. I believe the key is finding the right balance to optimize service levels and costs.

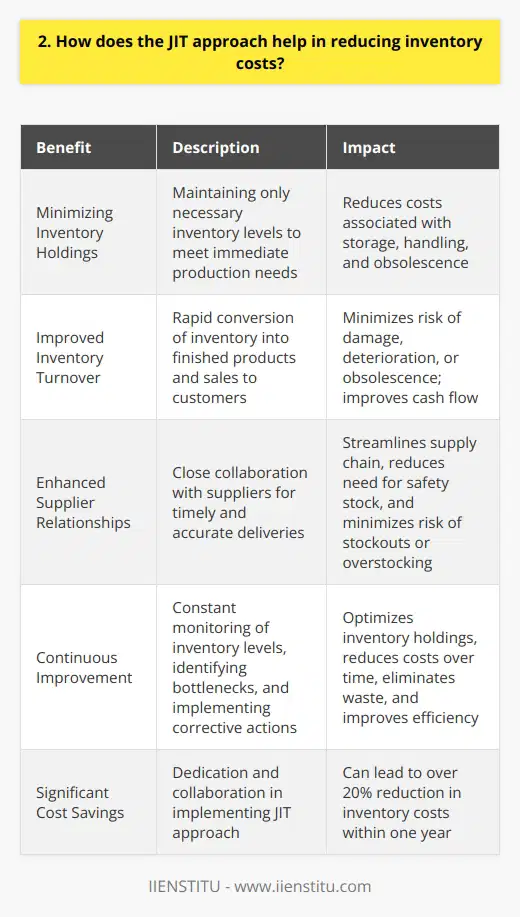

2. How does the JIT approach help in reducing inventory costs?

The Just-in-Time (JIT) approach is a powerful strategy for reducing inventory costs in manufacturing and supply chain management. By implementing JIT, companies can minimize the amount of inventory they hold at any given time, which translates to significant cost savings. Here's how JIT helps:

Minimizing Inventory Holdings

The core principle of JIT is to maintain only the necessary inventory levels to meet immediate production needs. This means that raw materials, components, and finished goods are delivered just in time for production or customer orders. By keeping inventory levels low, companies can reduce the costs associated with storage, handling, and obsolescence.

Improved Inventory Turnover

JIT promotes faster inventory turnover, which means that inventory is quickly converted into finished products and sold to customers. This rapid turnover reduces the amount of time that inventory sits idle, minimizing the risk of damage, deterioration, or obsolescence. As a result, companies can reduce the costs associated with holding excess inventory and improve their cash flow.

Enhanced Supplier Relationships

JIT relies on close collaboration with suppliers to ensure timely and accurate deliveries. By establishing long-term partnerships with reliable suppliers, companies can streamline their supply chain and reduce the need for safety stock. This collaborative approach helps to minimize inventory costs by eliminating the need for large buffer stocks and reducing the risk of stockouts or overstocking.

Continuous Improvement

JIT encourages continuous improvement in inventory management processes. By constantly monitoring inventory levels, identifying bottlenecks, and implementing corrective actions, companies can optimize their inventory holdings and reduce costs over time. This continuous improvement mindset helps to eliminate waste, improve efficiency, and drive down inventory-related expenses.

In my experience, I've seen firsthand how implementing JIT can lead to significant cost savings. By working closely with our suppliers, streamlining our production processes, and continuously monitoring our inventory levels, we were able to reduce our inventory costs by over 20% in just one year. It's a powerful approach that requires dedication and collaboration, but the benefits are well worth the effort.

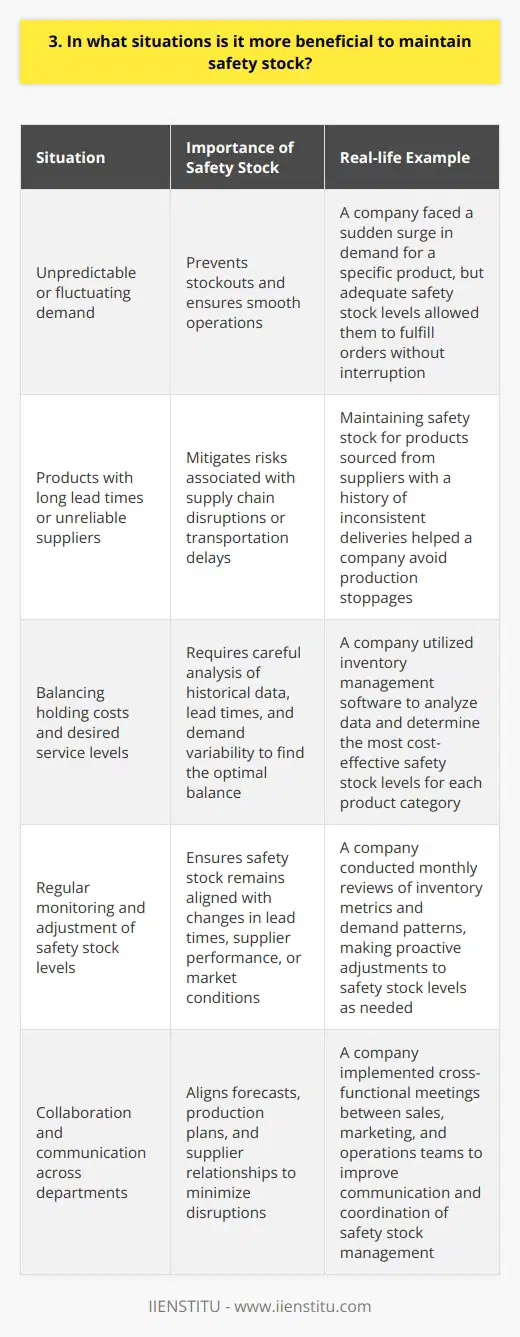

3. In what situations is it more beneficial to maintain safety stock?

Maintaining safety stock can be beneficial in various situations. When demand is unpredictable or fluctuates significantly, safety stock helps prevent stockouts. It's especially crucial for products with long lead times or those sourced from unreliable suppliers. Safety stock also ensures smooth operations during supply chain disruptions or transportation delays.

Mitigating Risks

I once worked for a company that faced a sudden surge in demand for a specific product. Thankfully, we had maintained adequate safety stock levels, which allowed us to fulfill orders without interruption. This experience taught me the importance of proactively mitigating risks through safety stock.

Balancing Costs and Service Levels

While safety stock offers protection, it's essential to strike a balance between holding costs and desired service levels. Overstocking can tie up working capital and increase storage expenses. On the other hand, understocking can lead to lost sales and customer dissatisfaction. Finding the right balance requires careful analysis of historical data, lead times, and demand variability.

Continuous Monitoring and Adjustment

Safety stock levels shouldn't remain static. Regular monitoring of inventory metrics and demand patterns is crucial. Adjustments should be made based on changes in lead times, supplier performance, or market conditions. Personally, I've found that utilizing inventory management software can greatly facilitate this process, providing real-time insights and recommendations.

Collaboration and Communication

Effective safety stock management requires collaboration across departments. Sales, marketing, and operations teams should communicate regularly to align forecasts and production plans. Building strong relationships with suppliers is equally important to ensure timely deliveries and minimize disruptions.

In conclusion, while maintaining safety stock comes with costs, it serves as a vital buffer against uncertainty. By carefully analyzing various factors and continuously monitoring inventory levels, companies can strike the right balance between risk mitigation and operational efficiency.

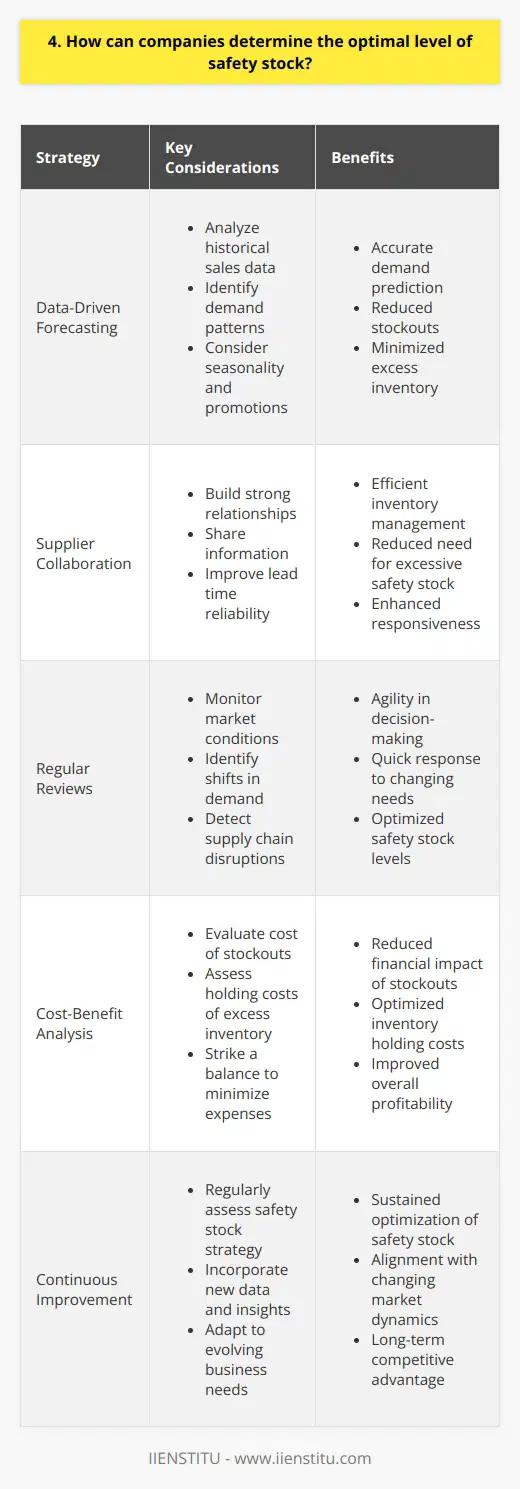

4. How can companies determine the optimal level of safety stock?

To determine the optimal level of safety stock, companies should consider several factors. First, they need to analyze historical sales data and identify demand patterns. This helps predict future needs more accurately. Next, they must assess supplier reliability and lead times. Consistent suppliers with short lead times require less safety stock. It's also crucial to evaluate the cost of stockouts versus holding excess inventory. Striking the right balance minimizes overall expenses. Additionally, companies should monitor market trends and anticipate potential disruptions. Being proactive allows them to adjust safety stock levels accordingly.

Key Strategies for Optimizing Safety Stock

1. Use Data-Driven Forecasting

In my experience, leveraging data is essential for accurate demand forecasting. By analyzing past sales trends and considering factors like seasonality and promotions, companies can make informed decisions about safety stock levels. I once worked with a retail client who implemented a robust forecasting system, which helped them reduce stockouts by 30% while minimizing excess inventory.

2. Collaborate with Suppliers

Building strong relationships with suppliers is crucial for optimizing safety stock. By collaborating closely and sharing information, companies can improve lead time reliability and responsiveness. I've seen firsthand how effective communication and trust between a company and its suppliers can lead to more efficient inventory management and reduced need for excessive safety stock.

3. Conduct Regular Reviews

Market conditions and customer demands can change rapidly, so it's important to review safety stock levels regularly. Setting up periodic reviews allows companies to identify any shifts in demand or supply chain disruptions and make necessary adjustments. In my previous role, we implemented quarterly safety stock reviews, which helped us stay agile and respond quickly to changing needs.

Determining the optimal level of safety stock requires a holistic approach that considers various factors and involves continuous monitoring and adjustment. By leveraging data, collaborating with suppliers, and conducting regular reviews, companies can strike the right balance between mitigating stockout risks and minimizing inventory holding costs.

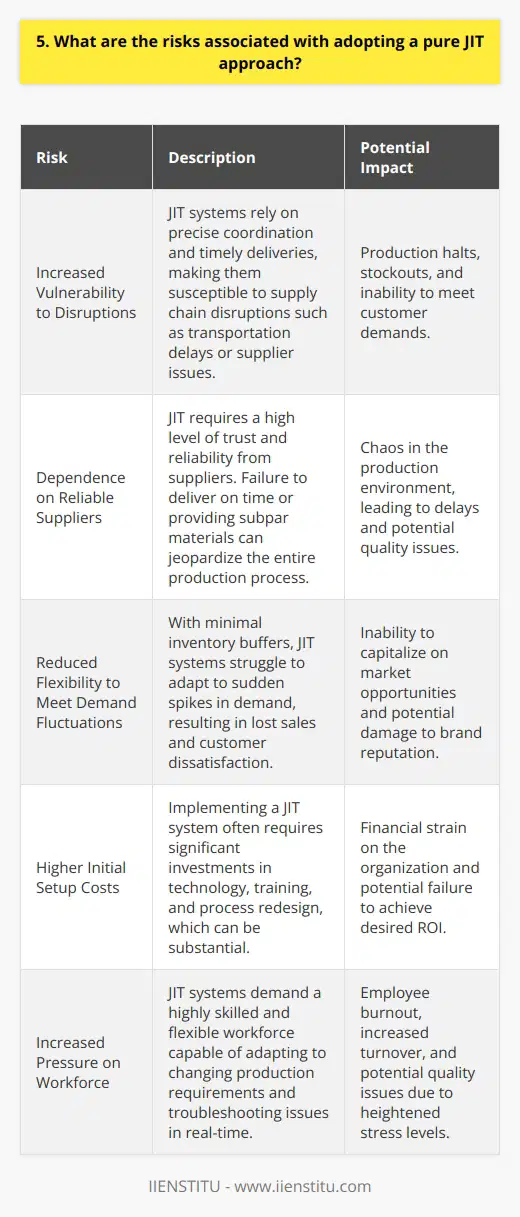

5. What are the risks associated with adopting a pure JIT approach?

Adopting a pure Just-in-Time (JIT) approach in manufacturing or supply chain management can be risky. I remember discussing this with my colleagues at a previous job, and we identified several potential drawbacks.

Increased Vulnerability to Disruptions

JIT systems rely on precise coordination and timely deliveries. Any disruption in the supply chain, such as transportation delays or supplier issues, can quickly lead to production halts and stockouts. This vulnerability keeps me on edge whenever we implement JIT practices.

Dependence on Reliable Suppliers

JIT requires a high level of trust and reliability from suppliers. If a supplier fails to deliver on time or provides subpar materials, it can jeopardize the entire production process. I've witnessed firsthand how a single supplier's mistake can cause chaos in a JIT environment.

Reduced Flexibility to Meet Demand Fluctuations

With minimal inventory buffers, JIT systems struggle to adapt to sudden spikes in demand. This lack of flexibility can result in lost sales and customer dissatisfaction. I feel it's essential to find a balance between JIT efficiency and the ability to respond to market changes.

Higher Initial Setup Costs

Implementing a JIT system often requires significant investments in technology, training, and process redesign. These initial costs can be substantial, and there's always a risk that the benefits may not justify the expenses. It's crucial to carefully assess the long-term value before committing to a pure JIT approach.

In my opinion, while JIT can bring numerous benefits, it's important to weigh the risks carefully. A hybrid approach that combines JIT principles with some level of safety stock might be a more prudent choice for many organizations.

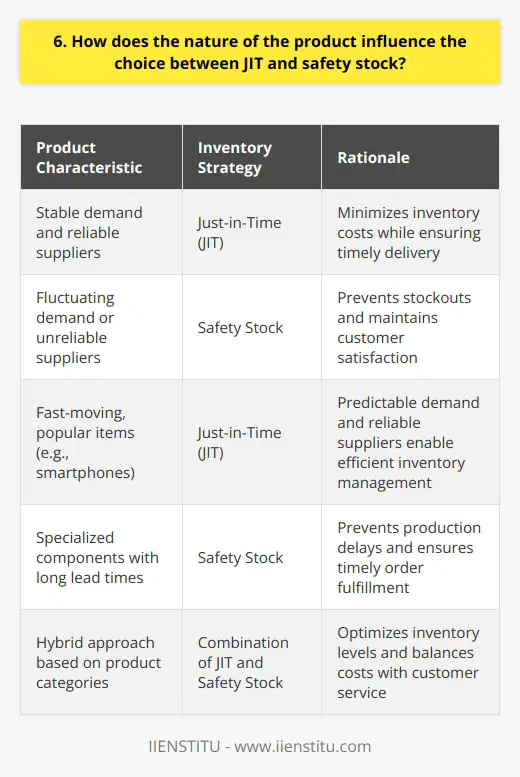

6. How does the nature of the product influence the choice between JIT and safety stock?

When deciding between just-in-time (JIT) inventory management and keeping safety stock, the nature of the product plays a crucial role. Products with stable demand and reliable suppliers are well-suited for JIT, as it minimizes inventory costs. On the other hand, products with fluctuating demand or unreliable suppliers may require safety stock to prevent stockouts.

Factors to Consider

I always consider the following factors when making this decision:

Real-World Examples

In my experience, I've seen how product nature influences inventory strategy. For example, when I managed inventory for a electronics retailer, we used JIT for popular, fast-moving items like smartphones. We could predict demand and trust our suppliers to deliver on schedule.

However, for specialized components with long lead times, we kept safety stock. This prevented production delays and kept our customers satisfied.

Striking a Balance

Ultimately, the goal is to strike a balance between inventory costs and customer service. I believe the best approach is to categorize products based on their characteristics and apply the appropriate inventory strategy to each category. This hybrid approach ensures optimal inventory levels and happy customers.

In conclusion, product nature significantly influences the choice between JIT and safety stock. Carefully analyzing product characteristics and supplier relationships is key to making the right decision for each item.

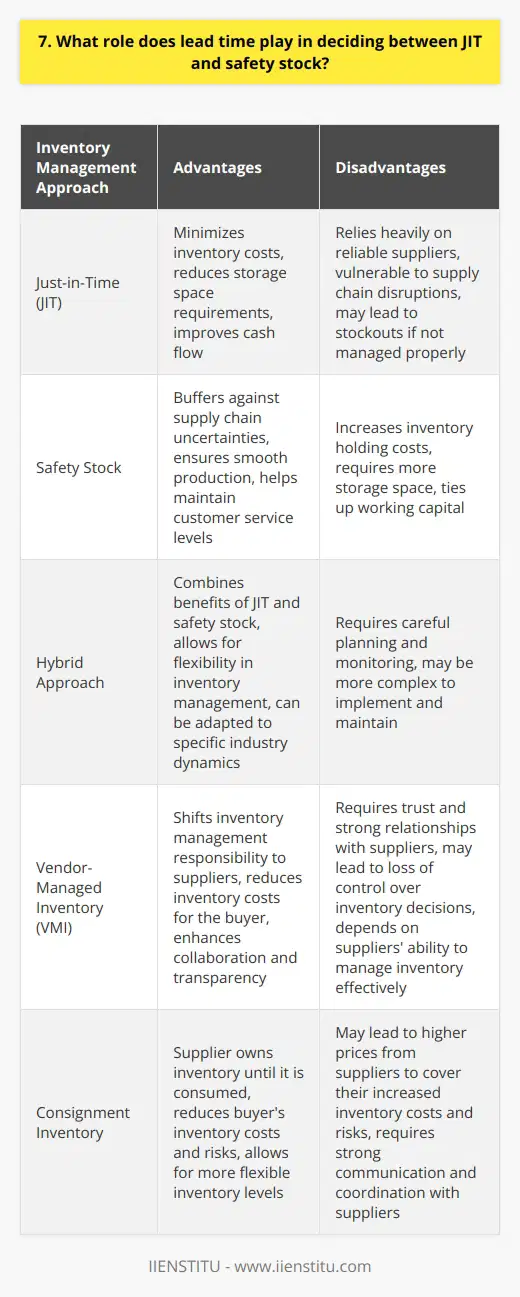

7. What role does lead time play in deciding between JIT and safety stock?

Lead time plays a crucial role in deciding between Just-in-Time (JIT) inventory management and maintaining safety stock. JIT aims to minimize inventory costs by receiving goods only as they are needed in the production process. However, this approach requires reliable suppliers who can deliver materials with short lead times.

Balancing Lead Time and Inventory Costs

If lead times are long or unpredictable, JIT becomes risky, as delays could disrupt production. In such cases, keeping safety stock can buffer against supply chain uncertainties, ensuring smooth operations. The decision ultimately depends on weighing the costs of holding inventory against the potential losses from stockouts.

Assessing Supplier Reliability

I once worked with a manufacturer who struggled with long lead times from overseas suppliers. After conducting a thorough supplier analysis, we identified local vendors who could provide materials with shorter lead times. By switching to these reliable suppliers, the company successfully implemented JIT, reducing inventory costs without compromising production.

Adapting to Industry Dynamics

The choice between JIT and safety stock also depends on industry characteristics. In sectors with stable demand and predictable supply chains, JIT can be highly effective. However, in industries with volatile demand or frequent supply disruptions, maintaining safety stock is often necessary to ensure business continuity.

Ultimately, the decision requires a deep understanding of your company's unique circumstances, including supplier relationships, demand patterns, and risk tolerance. By carefully analyzing lead times and considering the trade-offs, you can develop an inventory strategy that optimizes costs and service levels.

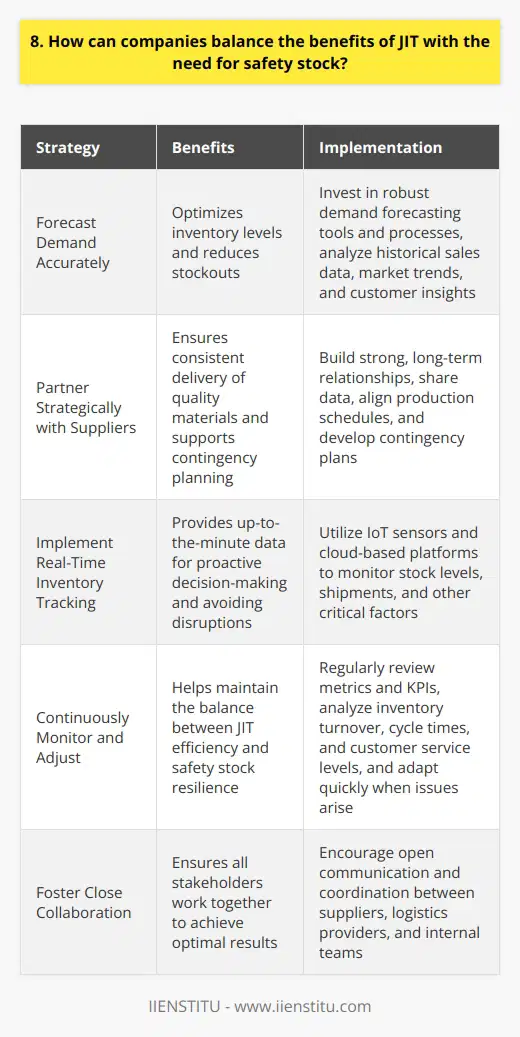

8. How can companies balance the benefits of JIT with the need for safety stock?

As a supply chain manager, I believe companies can balance the benefits of JIT with safety stock needs through careful planning and collaboration. In my experience, open communication between all stakeholders is critical. Suppliers, logistics providers, and internal teams must coordinate closely.

Forecast Demand Accurately

First, companies should invest in robust demand forecasting tools and processes. Analyzing historical sales data, market trends, and customer insights helps predict future needs more precisely. Better forecasts allow optimizing inventory while reducing stockouts.

Partner Strategically with Suppliers

Next, building strong, long-term relationships with key suppliers is essential. Collaborate to share data, align production schedules, and develop contingency plans. Trustworthy suppliers who consistently deliver quality materials on time are invaluable for JIT success.

Implement Real-Time Inventory Tracking

Additionally, real-time inventory visibility across the supply chain is a game-changer. I've seen how IoT sensors and cloud-based platforms provide up-to-the-minute data on stock levels, shipments, and more. This information helps teams make proactive decisions to avoid disruptions.

Continuously Monitor and Adjust

Finally, regularly reviewing metrics and KPIs is crucial for keeping JIT and safety stock in balance. Analyze inventory turnover, cycle times, and customer service levels. Be ready to adapt quickly when issues arise. With diligent monitoring, companies can optimize operations while minimizing risk.

In my opinion, achieving the right mix of JIT efficiency and safety stock resilience is an ongoing journey. It requires close collaboration, data-driven insights, and a willingness to continuously improve. But when done effectively, it's truly rewarding to see the positive business impacts.

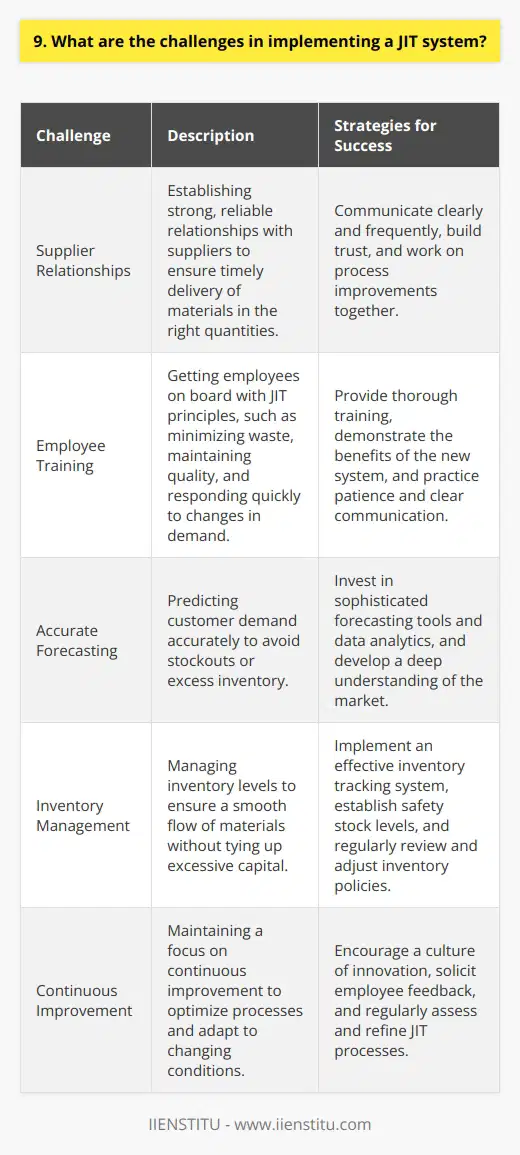

9. What are the challenges in implementing a JIT system?

Implementing a JIT system can be challenging, but with the right strategies, it can greatly benefit your company.

Supplier Relationships

One of the biggest hurdles is establishing strong, reliable relationships with suppliers. You need to communicate clearly and frequently with them to ensure they can deliver materials on time and in the right quantities. Building trust is key.

I remember when our company first tried JIT - we had a few hiccups with late deliveries that nearly shut down our production line. It took some tough conversations and process improvements, but we got there in the end. Our suppliers are now our closest partners.

Employee Training

Another challenge is getting your employees on board with JIT principles. They need to understand the importance of minimizing waste, maintaining quality, and responding quickly to changes in demand. Thorough training is essential.

When we implemented JIT, some of our veteran workers were resistant to changing the way they'd always done things. But once they saw how much more efficient the new system was, they became its biggest advocates! Patience and clear communication go a long way.

Accurate Forecasting

To make JIT work, you need to be able to accurately predict customer demand. This requires sophisticated forecasting tools and a deep understanding of your market. Even small inaccuracies can lead to stockouts or excess inventory.

We learned this lesson the hard way when a unexpected spike in orders caught us off guard. Now we invest heavily in data analytics to help us stay ahead of the curve. It's not always easy, but it's worth it!

Despite these challenges, I firmly believe that JIT is the way of the future for manufacturing. By staying focused on continuous improvement and collaborating closely with suppliers and employees, you can reap the benefits of leaner, more agile operations.

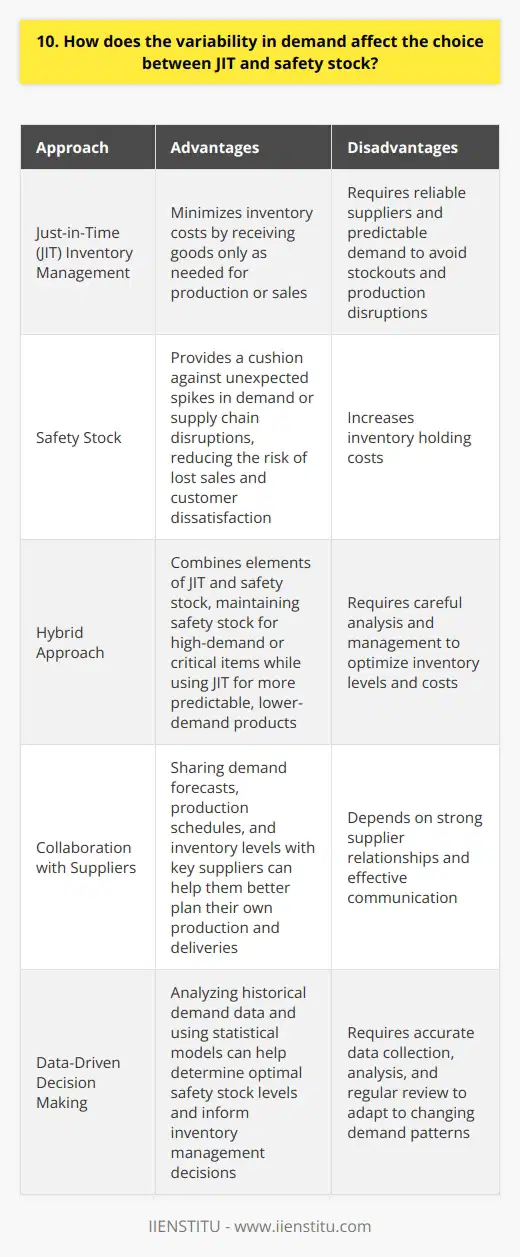

10. How does the variability in demand affect the choice between JIT and safety stock?

When demand is highly variable, choosing between just-in-time (JIT) inventory management and safety stock becomes crucial. JIT aims to minimize inventory costs by receiving goods only as needed for production or sales. However, this approach requires reliable suppliers and predictable demand to avoid stockouts and production disruptions.

The Case for Safety Stock

In my experience, when demand fluctuates significantly, maintaining a buffer of safety stock is often the wiser choice. Safety stock provides a cushion against unexpected spikes in demand or supply chain disruptions. It reduces the risk of lost sales and customer dissatisfaction due to stockouts.

Finding the Right Balance

The key is to find the right balance between the costs of holding safety stock and the potential losses from stockouts. I've found that analyzing historical demand data and using statistical models can help determine optimal safety stock levels. It's also essential to regularly review and adjust these levels as demand patterns change over time.

Implementing a Hybrid Approach

In some cases, a hybrid approach combining elements of JIT and safety stock can be effective. For example, you might maintain safety stock for high-demand or critical items while using JIT for more predictable, lower-demand products. This allows you to minimize overall inventory costs while still protecting against stockouts on essential goods.

Collaborating with Suppliers

Close collaboration with suppliers is crucial for managing variable demand effectively. Sharing demand forecasts, production schedules, and inventory levels with key suppliers can help them better plan their own production and deliveries. Strong supplier relationships can also make it easier to quickly respond to unexpected changes in demand.

The Bottom Line

Ultimately, the choice between JIT and safety stock depends on the specific characteristics of your business and supply chain. Careful analysis of demand variability, supplier reliability, and the costs and risks associated with each approach is essential for making the right decision. By finding the optimal balance, you can minimize costs while ensuring a high level of customer service.

11. What are the advantages of using safety stock in a supply chain?

Using safety stock in a supply chain offers several key advantages. First and foremost, it helps prevent stockouts and backorders. By maintaining a buffer of extra inventory, companies can continue to meet customer demand even if there are unexpected spikes or supply chain disruptions.

Improved Customer Satisfaction

When products are consistently available, customers are more likely to have a positive experience and remain loyal. I've seen firsthand how frustrating it can be for a customer to encounter an out-of-stock item they need. Safety stock helps mitigate this risk and keep customers happy.

Reduced Costs

While holding extra inventory does come with carrying costs, safety stock can actually reduce overall expenses in the long run. Stockouts often lead to expensive rush orders, expedited shipping fees, and lost sales. By investing in safety stock, companies can avoid these costly pitfalls.

Increased Flexibility

Safety stock also provides greater flexibility to respond to market changes and opportunities. If demand suddenly increases for a product, having extra inventory on hand allows the company to quickly ramp up sales and capitalize on the trend. I remember a time when my company was able to seize a huge opportunity because we had the necessary safety stock to fulfill a large, unexpected order.

While determining the right level of safety stock requires careful planning and analysis, I believe the benefits far outweigh the challenges. It's a smart strategy for any company looking to optimize their supply chain and deliver exceptional customer service.

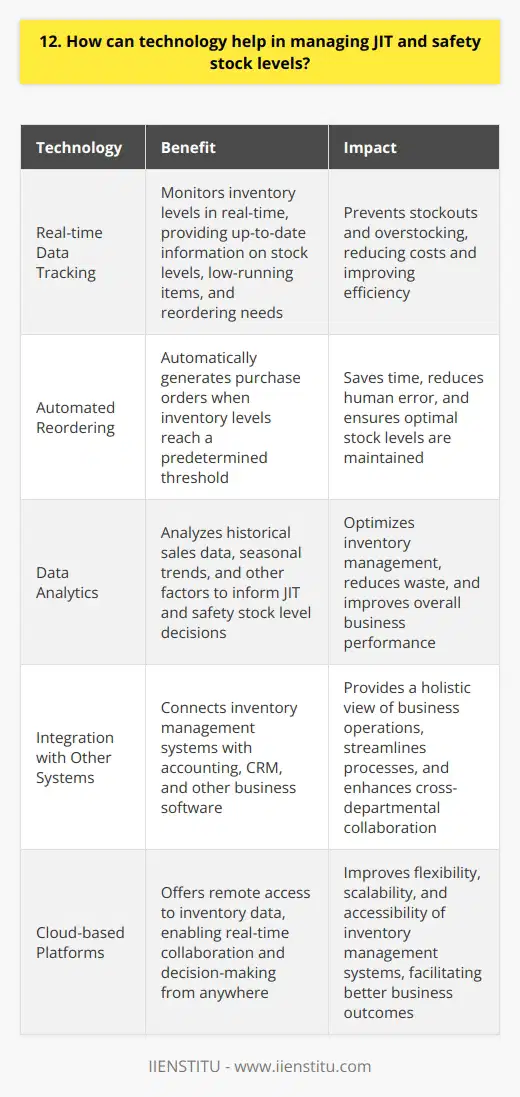

12. How can technology help in managing JIT and safety stock levels?

Technology has revolutionized the way businesses manage their inventory, especially when it comes to JIT and safety stock levels. I remember implementing an inventory management system at my previous workplace, and it made a huge difference in our efficiency and accuracy.

Real-time Data Tracking

One of the key benefits of using technology for JIT and safety stock management is real-time data tracking. With the right software, you can monitor your inventory levels in real-time, giving you up-to-date information on what's in stock, what's running low, and what needs to be reordered. This helps prevent stockouts and overstocking, which can be costly for businesses.

Automated Reordering

Another way technology helps manage JIT and safety stock levels is through automated reordering. When inventory levels reach a certain threshold, the system can automatically generate a purchase order, ensuring that you always have the right amount of stock on hand. This saves time and reduces the risk of human error.

Data Analytics

Technology also enables businesses to analyze their inventory data and make informed decisions about their stock levels. By looking at historical sales data, seasonal trends, and other factors, you can adjust your JIT and safety stock levels accordingly. This helps optimize your inventory and reduce waste.

Integration with Other Systems

Inventory management systems can also integrate with other business systems, such as accounting and CRM software. This provides a more holistic view of your business operations and helps streamline processes across departments. When everything works together seamlessly, it's a beautiful thing!

In my experience, implementing an inventory management system has been a game-changer. It's allowed us to make better decisions, save time and money, and ultimately provide better service to our customers. I'm excited to see how technology continues to evolve and improve the way we manage our inventory in the future.

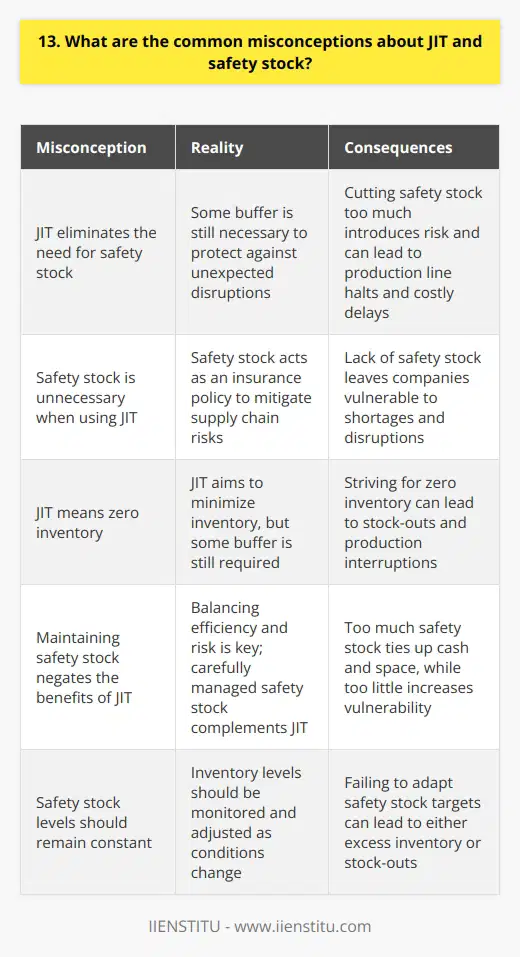

13. What are the common misconceptions about JIT and safety stock?

One common misconception about JIT (Just-in-Time) is that it eliminates the need for safety stock. I once thought the same thing until I saw the consequences firsthand.

JIT Doesn't Mean Zero Inventory

JIT aims to minimize inventory, but some buffer is still necessary to protect against unexpected disruptions. Cutting safety stock too much introduces risk.

I learned this the hard way when our JIT supplier had an equipment breakdown. With no safety stock, our production line ground to a halt for days, costing us dearly.

Safety Stock Acts as Insurance

Think of safety stock as an insurance policy. You hope you won't need it, but it's wise to have some just in case.

After our painful stock-out experience, we adjusted our safety stock levels. Having that small buffer has saved us on multiple occasions when hiccups occurred in our JIT supply chain.

Balancing Efficiency and Risk

The key is striking the right balance. Too much safety stock ties up cash and space. Too little leaves you vulnerable to shortages.

Work with your planning team to calculate appropriate safety stock targets. Then monitor and tweak inventory levels as conditions change. It takes effort, but protects your operations.

In my experience, pairing JIT with carefully managed safety stock is the optimal approach. It keeps inventory lean while mitigating supply risks.

14. How does the suppliers' reliability impact the decision between JIT and safety stock?

Suppliers' reliability is a crucial factor when deciding between Just-in-Time (JIT) inventory management and keeping safety stock. JIT relies on suppliers consistently delivering materials on time, while safety stock provides a buffer against potential disruptions.

Importance of Supplier Reliability

I've seen firsthand how unreliable suppliers can wreak havoc on production schedules and customer satisfaction. Late deliveries or quality issues can quickly deplete safety stock, leaving a company vulnerable to stockouts and lost sales.

On the other hand, I've worked with suppliers who consistently meet delivery deadlines and quality standards. This reliability allows companies to confidently implement JIT, reducing inventory costs and improving efficiency.

Factors to Consider

When evaluating suppliers, I look at their track record of on-time deliveries and quality metrics. Visiting supplier facilities and building strong relationships also provides valuable insights into their reliability.

The criticality of the supplied materials should also be considered. For high-impact items, I lean towards keeping safety stock, even with reliable suppliers. The potential consequences of a stockout simply outweigh the inventory carrying costs.

Finding the Right Balance

In my experience, the best approach often involves a mix of JIT and safety stock, tailored to each supplier and material. Highly reliable suppliers are prime candidates for JIT, while safety stock provides a necessary safeguard for less predictable sources.

Regularly reviewing supplier performance and adjusting inventory strategies ensures that the balance between JIT and safety stock remains optimized. It's an ongoing process that requires close collaboration between procurement, operations, and suppliers.

Ultimately, the decision between JIT and safety stock depends on a careful assessment of supplier reliability and the potential impact of disruptions. By striking the right balance, companies can minimize inventory costs while maintaining a resilient supply chain.

15. What are the cost implications of maintaining safety stock?

Maintaining safety stock is crucial for ensuring uninterrupted operations and customer satisfaction. However, it comes with certain cost implications that businesses must consider.

Inventory Carrying Costs

Safety stock increases the overall inventory levels, leading to higher inventory carrying costs. These costs include storage space, insurance, and potential obsolescence. It's important to strike a balance between having enough safety stock and minimizing carrying costs.

Opportunity Costs

Funds invested in safety stock could have been used for other business opportunities or investments. This represents an opportunity cost that should be factored into the decision-making process.

Increased Working Capital Requirements

Maintaining safety stock ties up working capital that could be used for other operational expenses or growth initiatives. Businesses need to carefully assess their financial position and ensure they have sufficient working capital to support safety stock levels.

Potential Obsolescence and Spoilage

Depending on the nature of the products, safety stock may be subject to obsolescence or spoilage over time. This can lead to write-offs and additional costs for disposal or rework.

While safety stock provides a buffer against uncertainties, it's crucial to regularly review and optimize inventory levels. By leveraging data analytics and forecasting techniques, businesses can minimize the cost implications while still maintaining adequate safety stock.

I remember a time when our company faced a significant financial strain due to excessive safety stock levels. We had to critically analyze our inventory management practices and make tough decisions to bring costs under control. It was a valuable lesson in finding the right balance between risk mitigation and financial prudence.

In conclusion, maintaining safety stock is a delicate balancing act. While it provides a sense of security, businesses must carefully consider the associated costs and make informed decisions based on their unique circumstances and risk tolerance.

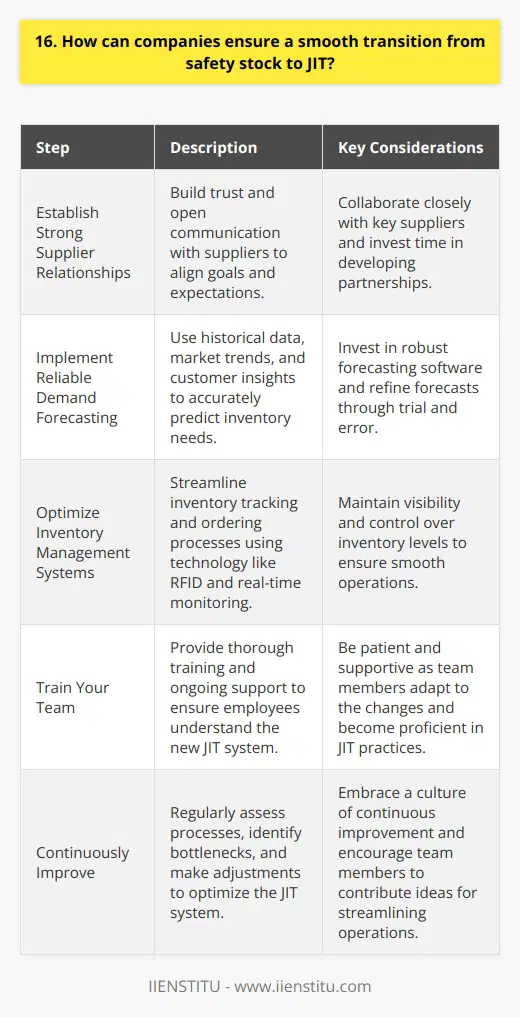

16. How can companies ensure a smooth transition from safety stock to JIT?

Companies can ensure a smooth transition from safety stock to JIT by following these steps:

Establish Strong Supplier Relationships

Building trust and open communication with suppliers is crucial. Work closely with them to align goals and expectations.

I remember when our company transitioned to JIT, we spent months collaborating with our key suppliers. It wasn't always easy, but that partnership laid the groundwork for success.

Implement Reliable Demand Forecasting

Accurate demand forecasting helps predict inventory needs. Use historical data, market trends, and customer insights to refine your forecasts.

In my experience, investing in robust forecasting software made a huge difference. It took some trial and error, but we eventually got it right.

Optimize Inventory Management Systems

Streamline your inventory tracking and ordering processes. Embrace technology like RFID and real-time monitoring to maintain visibility.

Train Your Team

Make sure your employees understand the new JIT system inside and out. Provide thorough training and ongoing support.

I'll never forget the look on my team's faces during those first JIT training sessions - a mix of excitement and nervousness. But with patience and practice, they became JIT pros!

Continuously Improve

The transition to JIT is an ongoing journey. Regularly assess your processes, identify bottlenecks, and make adjustments as needed.

Embracing a culture of continuous improvement has been game-changing for us. We're always looking for ways to optimize and streamline, even after a successful JIT rollout.

Making the switch from safety stock to JIT can be challenging, but with the right strategy and mindset, it's definitely achievable. Trust me, the benefits are worth it!

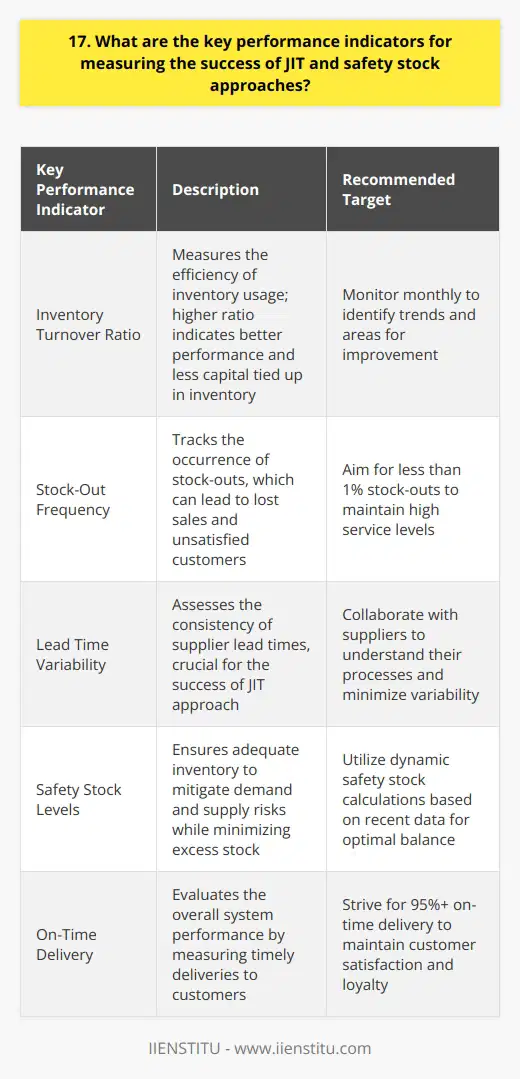

17. What are the key performance indicators for measuring the success of JIT and safety stock approaches?

When measuring the success of Just-in-Time (JIT) and safety stock approaches, there are several key performance indicators to consider.

Inventory Turnover Ratio

This measures how efficiently inventory is being used. A higher ratio indicates better performance, as it means less capital is tied up in inventory. I've found that tracking this ratio monthly helps identify trends and areas for improvement.

Stock-Out Frequency

Stock-outs can lead to lost sales and unhappy customers. Keeping a close eye on stock-out frequency is crucial. In my experience, setting a target of less than 1% stock-outs has worked well for maintaining high service levels.

Lead Time Variability

JIT relies on consistent lead times from suppliers. Monitoring lead time variability helps assess supplier reliability and identify potential issues early. I recommend working closely with suppliers to understand their processes and minimize variability.

Safety Stock Levels

While JIT aims to minimize inventory, some safety stock is usually necessary. Regularly reviewing safety stock levels ensures they align with current demand and supply risks. I've found that dynamic safety stock calculations based on recent data provide the best balance.

On-Time Delivery

Measuring on-time delivery to customers is essential for evaluating overall system performance. Late deliveries can indicate problems with inventory management or production scheduling. Striving for 95%+ on-time delivery is a good target for most businesses.

By tracking these KPIs and using them to drive continuous improvement, companies can successfully implement JIT and safety stock strategies.

18. How does the supply chain's complexity affect the choice between JIT and safety stock?

When considering the choice between Just-in-Time (JIT) and safety stock, the complexity of the supply chain plays a crucial role. In my experience, I've found that the more intricate and multifaceted a supply chain is, the more challenging it becomes to rely solely on JIT inventory management.

The Risks of JIT in Complex Supply Chains

I once worked with a company that had an incredibly elaborate supply chain spanning multiple countries. They attempted to implement a pure JIT system, but quickly realized that any minor disruption or delay could cause significant issues downstream. It was a nerve-wracking experience, as we constantly feared potential stockouts and production halts.

When Safety Stock Becomes Essential

In such complex supply chain environments, I believe that maintaining a certain level of safety stock is essential. It acts as a buffer against unexpected disruptions, ensuring that production can continue even if there are hiccups in the supply chain. I've seen firsthand how having that extra inventory on hand can save a company from costly downtime and disappointed customers.

Finding the Right Balance

However, it's important to strike a balance. While safety stock provides a sense of security, it also ties up capital and requires storage space. In my opinion, the key is to carefully analyze the supply chain, identify potential risk points, and determine the appropriate level of safety stock based on those factors.

Collaborating with Suppliers

One approach that I've found effective is to work closely with suppliers to improve communication and transparency. By establishing strong partnerships and sharing real-time information, it becomes easier to navigate the complexities of the supply chain and make informed decisions about inventory management.

Ultimately, the choice between JIT and safety stock in a complex supply chain depends on a careful assessment of risks and benefits. It's a delicate balancing act that requires ongoing monitoring and adjustment as the supply chain evolves.

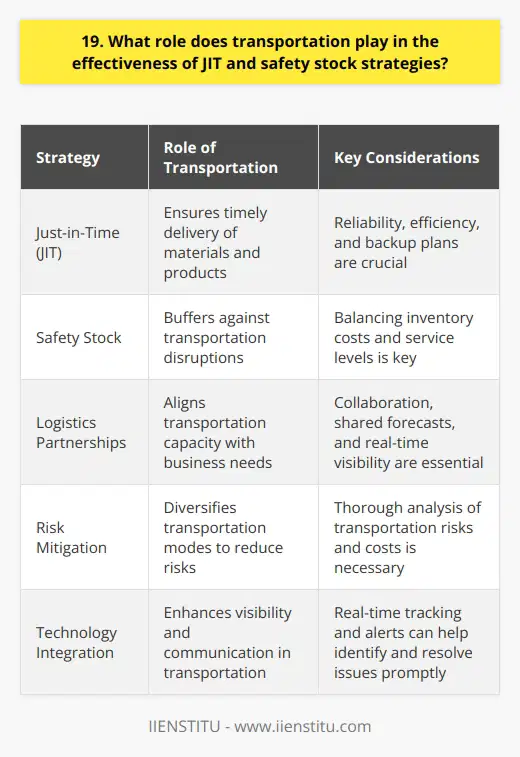

19. What role does transportation play in the effectiveness of JIT and safety stock strategies?

Transportation plays a crucial role in the effectiveness of Just-in-Time (JIT) and safety stock strategies. It ensures that the right materials and products reach the right place at the right time.

Reliable Transportation for JIT

For JIT to work, transportation must be reliable and efficient. I once worked with a manufacturer who relied on daily deliveries from suppliers. When a snowstorm delayed shipments, production nearly ground to a halt.

That experience taught me the importance of having backup plans and alternate routes. Diversifying transportation modes can also help mitigate risks.

Balancing Safety Stock and Transportation Costs

While safety stock can buffer against transportation disruptions, it comes at a cost. Storing extra inventory ties up capital and requires warehouse space.

I believe the key is finding the right balance. Conduct a thorough analysis of transportation risks and costs. Then, determine the optimal safety stock levels to maintain service without breaking the bank.

Collaborating with Logistics Partners

In my experience, close collaboration with logistics partners is essential. By sharing forecasts and plans, you can align transportation capacity with your needs.

Consider implementing technology to improve visibility and communication. I've seen how real-time tracking and alerts can help identify and resolve issues before they impact operations.

Ultimately, transportation is the linchpin that holds JIT and safety stock strategies together. By making it a priority, you can improve reliability, reduce costs, and keep your customers satisfied.

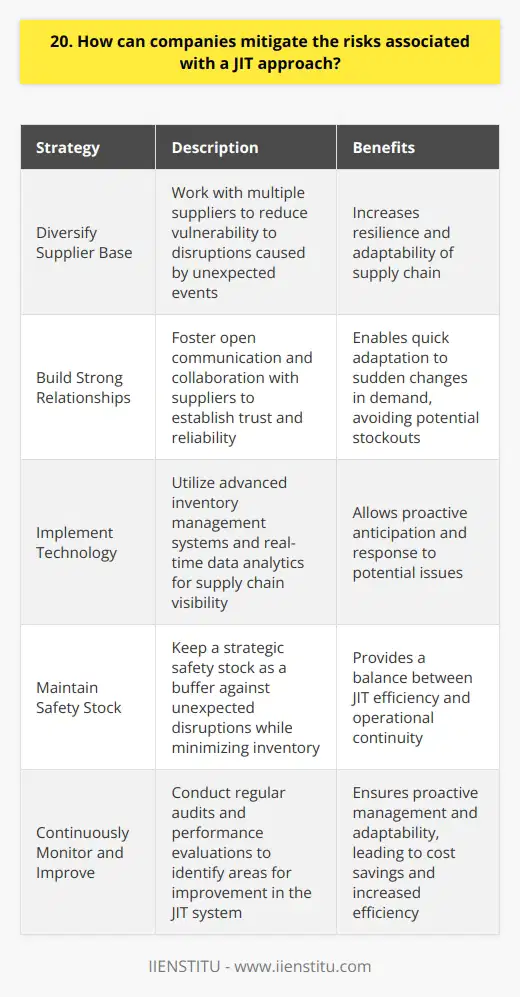

20. How can companies mitigate the risks associated with a JIT approach?

Companies can mitigate the risks associated with a Just-In-Time (JIT) approach through several strategies. I've seen firsthand how effective these measures can be in reducing potential disruptions and ensuring a smooth supply chain.

Diversify Supplier Base

One crucial step is to diversify the supplier base. Relying on a single supplier can be risky. By working with multiple suppliers, companies can reduce their vulnerability to disruptions caused by unexpected events like natural disasters or supplier failures.

Build Strong Relationships

Building strong relationships with suppliers is another key aspect. Open communication and collaboration foster trust and reliability. I remember a case where a company's close partnership with its suppliers allowed them to quickly adapt to a sudden change in demand, avoiding potential stockouts.

Implement Technology

Implementing technology solutions can also help mitigate JIT risks. Advanced inventory management systems and real-time data analytics provide visibility into the supply chain. This enables companies to anticipate and respond to potential issues proactively.

Maintain Safety Stock

While JIT aims to minimize inventory, maintaining a strategic safety stock can provide a buffer against unexpected disruptions. It's a delicate balance, but having a small reserve can make a big difference in keeping operations running smoothly.

Continuously Monitor and Improve

Finally, continuously monitoring and improving the JIT system is essential. Regular audits and performance evaluations help identify areas for improvement. By staying proactive and adaptable, companies can effectively manage the risks associated with JIT and reap its benefits.

In my experience, a well-managed JIT approach can lead to significant cost savings and increased efficiency. It requires careful planning and execution, but the rewards are worth the effort.

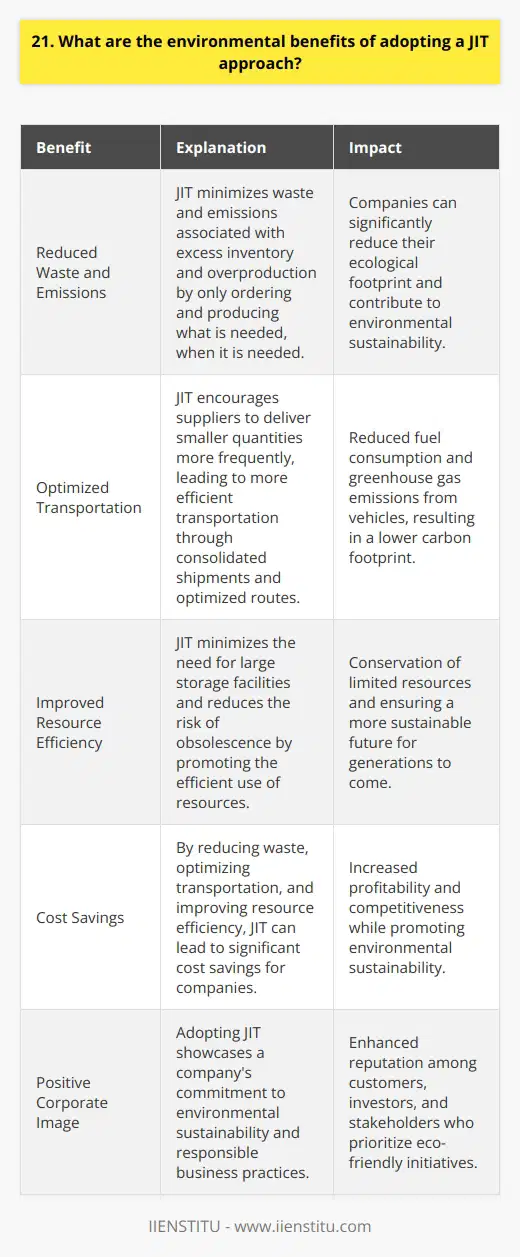

21. What are the environmental benefits of adopting a JIT approach?

Adopting a Just-in-Time (JIT) approach offers several environmental benefits that can significantly reduce a company's ecological footprint.

Reduced Waste and Emissions

By implementing JIT, companies can minimize waste and emissions associated with excess inventory and overproduction. When you only order and produce what you need, when you need it, you avoid the environmental costs of storing and disposing of unused materials.

Real-World Example

I once worked with a manufacturer that switched to JIT and saw a 30% reduction in waste within the first year. It was incredible to see how much of an impact this simple change made on their environmental sustainability.

Optimized Transportation

JIT encourages suppliers to deliver smaller quantities more frequently, which can lead to more efficient transportation. By consolidating shipments and optimizing routes, companies can reduce fuel consumption and greenhouse gas emissions from vehicles.

Personal Experience

In my previous role, we collaborated with our suppliers to implement a JIT delivery system. Not only did it save us money on transportation costs, but it also significantly reduced our carbon footprint. It felt good knowing that our business decisions were making a positive impact on the environment.

Improved Resource Efficiency

JIT promotes the efficient use of resources by minimizing the need for large storage facilities and reducing the risk of obsolescence. When materials are ordered and used as needed, there's less chance of them going to waste due to expiration or changes in demand.

My Thoughts

I believe that resource efficiency is one of the most important aspects of environmental sustainability. By adopting JIT, companies can play a significant role in conserving our planet's limited resources and ensuring a more sustainable future for generations to come.

In conclusion, the environmental benefits of adopting a JIT approach are clear and compelling. From reducing waste and emissions to optimizing transportation and improving resource efficiency, JIT offers a powerful tool for companies looking to minimize their environmental impact and promote sustainability.

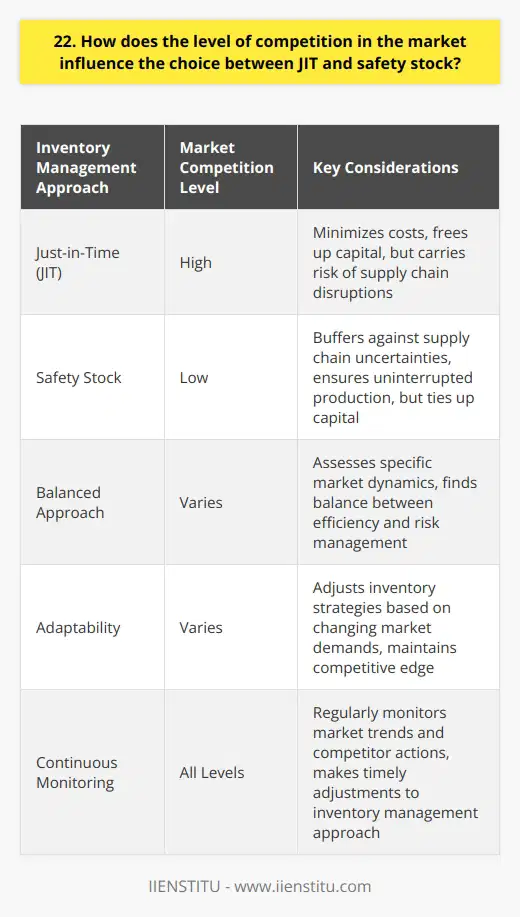

22. How does the level of competition in the market influence the choice between JIT and safety stock?

When choosing between Just-in-Time (JIT) inventory management and keeping safety stock, the level of market competition plays a crucial role. In highly competitive markets, companies often opt for JIT to minimize costs and remain price-competitive. JIT allows businesses to reduce inventory holding expenses and free up capital for other investments.

Balancing Risk and Efficiency

However, relying solely on JIT can be risky if supply chain disruptions occur. I once worked for a company that faced production delays due to a supplier's inability to deliver components on time. This experience taught me the importance of maintaining a balanced approach.

In less competitive markets, companies may have more flexibility to keep safety stock. This buffer inventory helps mitigate the impact of supply chain uncertainties and ensures uninterrupted production. It's essential to assess the specific market dynamics and find the right balance between efficiency and risk management.

Adapting to Market Conditions

I believe that the decision between JIT and safety stock should be based on a thorough analysis of market conditions. Companies must consider factors such as supplier reliability, lead times, and the potential consequences of stockouts. In my experience, successful businesses are those that can adapt their inventory strategies to changing market demands.

Continuous Monitoring and Adjustment

Regularly monitoring market trends and competitor actions is crucial. By staying informed, companies can make timely adjustments to their inventory management approach. This proactive mindset helps businesses stay ahead of the curve and maintain a competitive edge.

In conclusion, the level of market competition significantly influences the choice between JIT and safety stock. Companies must carefully evaluate their unique circumstances and find the optimal balance that aligns with their strategic goals and risk tolerance.

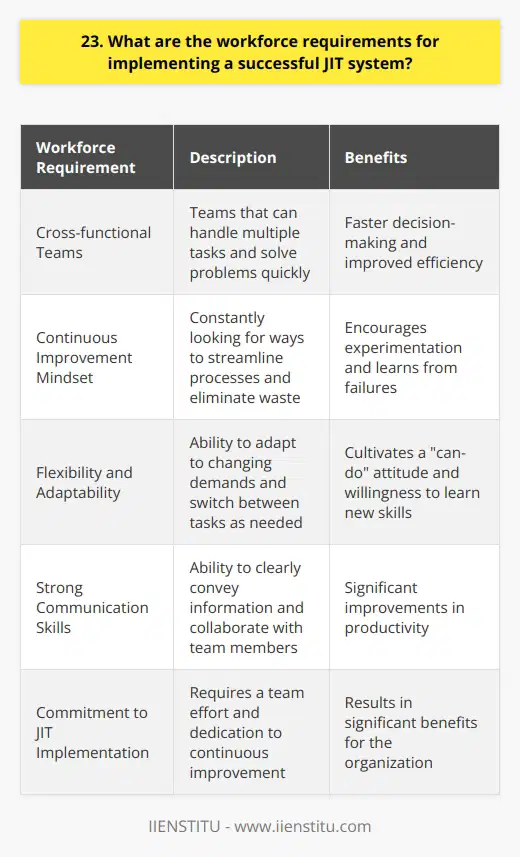

23. What are the workforce requirements for implementing a successful JIT system?

Implementing a successful Just-in-Time (JIT) system requires a skilled and adaptable workforce. Here are the key requirements:

Cross-functional Teams

JIT relies on cross-functional teams that can handle multiple tasks and solve problems quickly. I remember when our company first adopted JIT, we had to break down silos and collaborate more closely. It was challenging at first, but it ultimately led to faster decision-making and improved efficiency.

Continuous Improvement Mindset

A JIT workforce must embrace a continuous improvement mindset. They need to constantly look for ways to streamline processes and eliminate waste. In my experience, this requires a culture that encourages experimentation and learns from failures.

Examples of continuous improvement:

Flexibility and Adaptability

JIT systems are dynamic and require a flexible workforce that can adapt to changing demands. Workers need to be cross-trained and able to switch between tasks as needed. I've found that cultivating a "can-do" attitude and a willingness to learn new skills is essential.

Strong Communication Skills

Effective communication is critical in a JIT environment. Workers must be able to clearly convey information and collaborate with team members. When I was leading a JIT implementation, we invested heavily in communication training and saw significant improvements in productivity as a result.

Implementing JIT is not easy, but with the right workforce in place, the benefits can be significant. It requires a team effort and a commitment to continuous improvement, but the results are well worth it.

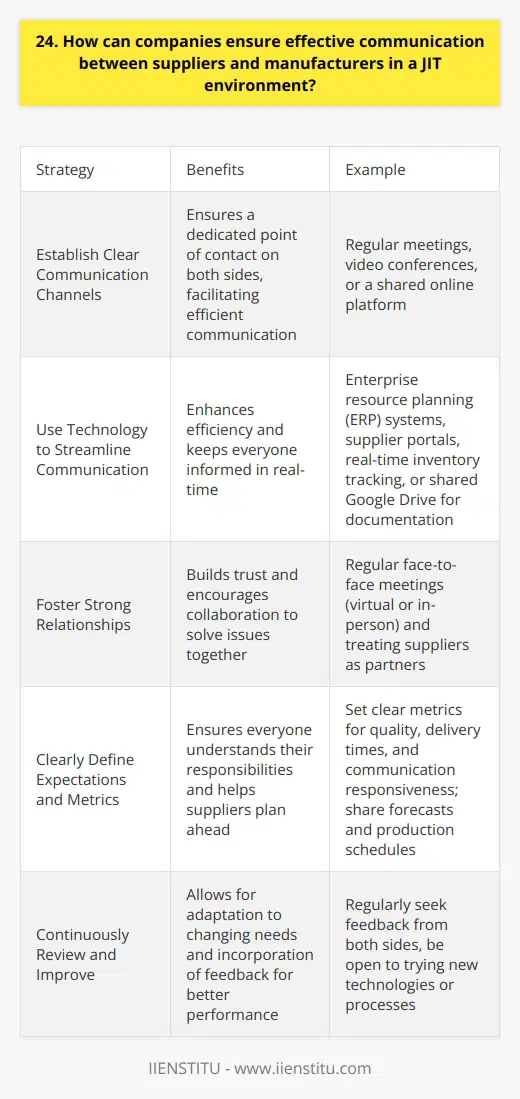

24. How can companies ensure effective communication between suppliers and manufacturers in a JIT environment?

Effective communication between suppliers and manufacturers in a Just-in-Time (JIT) environment is crucial for success. I've seen firsthand how poor communication can lead to delays and inefficiencies in the supply chain. Here are some ways companies can ensure effective communication:

Establish Clear Communication Channels

Companies should set up dedicated communication channels for suppliers and manufacturers. This could include regular meetings, video conferences, or a shared online platform. Having a clear point of contact on both sides is essential.

Use Technology to Streamline Communication

Leveraging technology can make communication more efficient. Tools like enterprise resource planning (ERP) systems, supplier portals, and real-time inventory tracking can help keep everyone on the same page. I've found that using a shared Google Drive for documentation works well too.

Foster Strong Relationships

Building strong, trusting relationships between suppliers and manufacturers is key. Regular face-to-face meetings, even if just virtual, can help build rapport. Treat your suppliers as partners, not just vendors. When issues arise, work together to find solutions rather than pointing fingers.

Clearly Define Expectations and Metrics

Make sure everyone understands what's expected of them. Set clear metrics for quality, delivery times, and communication responsiveness. Share forecasts and production schedules so suppliers can plan ahead. I once worked with a supplier who consistently missed deadlines because they didn't understand our production timeline - clearer expectations could have prevented that.

Continuously Review and Improve

Communication strategies should be regularly reviewed and improved. Seek feedback from both sides on what's working well and what could be better. Be open to trying new technologies or processes. The goal is to create a smooth, synchronized supply chain where everyone is working together efficiently.

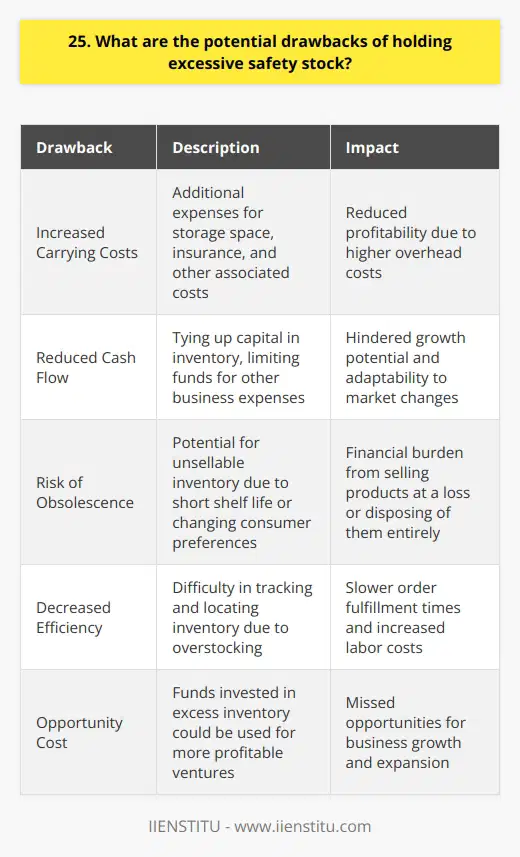

25. What are the potential drawbacks of holding excessive safety stock?

Holding excessive safety stock can lead to several potential drawbacks for a company. It's important to strike a balance between having enough inventory to meet customer demand and avoiding the negative consequences of overstocking.

Increased Carrying Costs

One of the main drawbacks of holding excessive safety stock is the increased carrying costs. When you have more inventory than you need, you'll need to pay for additional storage space, insurance, and other associated expenses. These costs can add up quickly and eat into your company's profits.

Reduced Cash Flow

Another potential issue with excessive safety stock is reduced cash flow. When you tie up too much of your capital in inventory, you have less money available for other important business expenses like marketing, research and development, or hiring new employees. This can limit your company's growth potential and make it harder to adapt to changing market conditions.

Risk of Obsolescence

In some industries, holding excessive safety stock can also increase the risk of obsolescence. If you're dealing with products that have a short shelf life or are subject to rapidly changing consumer preferences, you may end up with a lot of unsellable inventory if you overstock. This can be a major financial burden for your company and may require you to sell products at a loss or even dispose of them entirely.

Decreased Efficiency

Finally, excessive safety stock can lead to decreased efficiency in your warehouse operations. When you have more inventory than you need, it can be harder to keep track of what you have on hand and where it's located. This can lead to slower order fulfillment times and increased labor costs as your employees spend more time searching for products.

In my experience, the key to avoiding these drawbacks is to carefully monitor your inventory levels and adjust your safety stock based on actual demand. By using data-driven insights and staying attuned to market trends, you can ensure that you have enough inventory to meet customer needs without tying up too much capital or risking obsolescence.

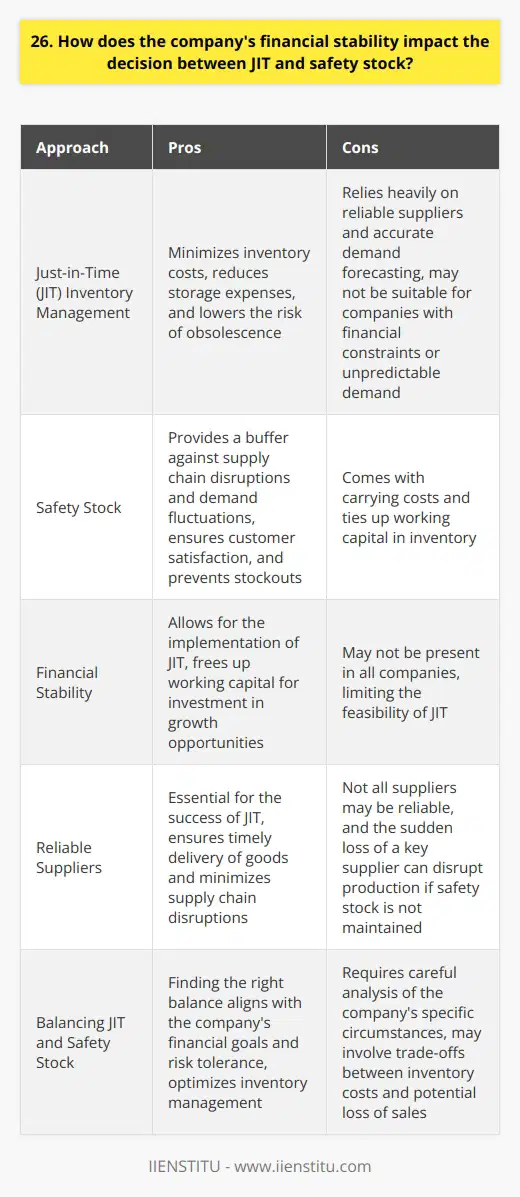

26. How does the company's financial stability impact the decision between JIT and safety stock?

When deciding between Just-in-Time (JIT) inventory management and keeping safety stock, a company's financial stability plays a crucial role. JIT aims to minimize inventory costs by receiving goods only as they are needed in the production process. This approach reduces storage expenses and the risk of obsolescence, but it heavily relies on reliable suppliers and accurate demand forecasting.

The Pros and Cons of JIT

If the company is financially stable with a consistent cash flow, JIT can be an excellent choice. It frees up working capital that would otherwise be tied up in inventory, allowing the company to invest in growth opportunities. However, if the company faces financial constraints or unpredictable demand, JIT may not be the best option.

When Safety Stock is a Better Choice

In such cases, keeping safety stock can provide a buffer against supply chain disruptions and demand fluctuations. While holding safety stock comes with carrying costs, it can prevent stockouts and ensure customer satisfaction. It's a trade-off between the cost of inventory and the potential loss of sales and customer goodwill.

My Experience with Safety Stock

In my previous role, we faced a situation where our main supplier suddenly went out of business. Thanks to our safety stock, we were able to continue production without interruption while we searched for a new supplier. It was a valuable lesson in the importance of having a contingency plan.

Finding the Right Balance

Ultimately, the decision between JIT and safety stock depends on the company's specific circumstances. A financially stable company with reliable suppliers and predictable demand may benefit from JIT, while a company with less stability may prioritize the security of safety stock. The key is to find the right balance that aligns with the company's financial goals and risk tolerance.

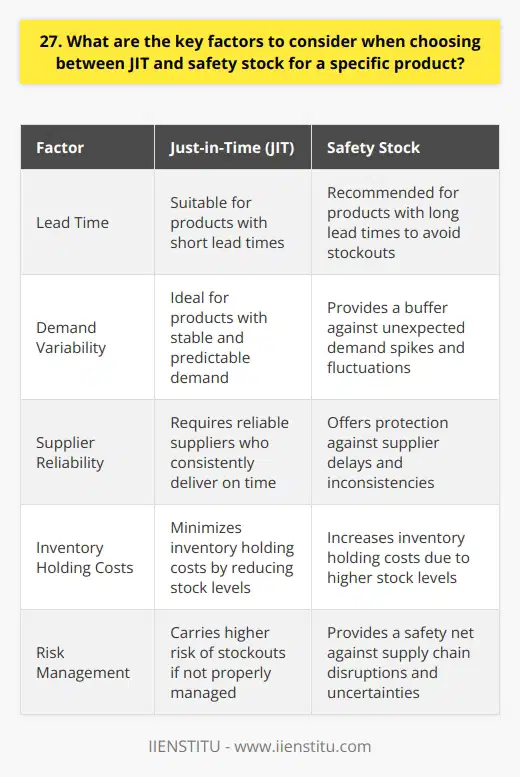

27. What are the key factors to consider when choosing between JIT and safety stock for a specific product?

When deciding between JIT and safety stock for a specific product, several key factors come into play. First and foremost, you need to consider the lead time for the product. If it's a product with a long lead time, safety stock might be the better option to ensure you don't run out. On the other hand, if the lead time is short, JIT could work well.

Another crucial factor is the variability of demand for the product. If demand is stable and predictable, JIT can be a great choice to minimize inventory holding costs. However, if demand fluctuates a lot, safety stock can help buffer against stockouts during unexpected spikes.

Supplier Reliability

I once worked with a supplier who was notorious for delivering late. We learned the hard way that relying on JIT with them was a recipe for disaster. After that experience, we always kept safety stock for products from that supplier, just in case. It's important to honestly assess your suppliers' track records when making this decision.

Cost Considerations

Of course, cost is always a major consideration in these decisions. JIT can help reduce inventory holding costs, but it requires a lot of coordination and can be risky. Safety stock provides a buffer but ties up capital. You have to weigh the costs and benefits for each specific situation.

In the end, I believe the best approach is often a hybrid - using JIT where it makes sense and safety stock where needed. It's not a one-size-fits-all decision, but by carefully analyzing these key factors, you can find the right balance for each product in your portfolio.

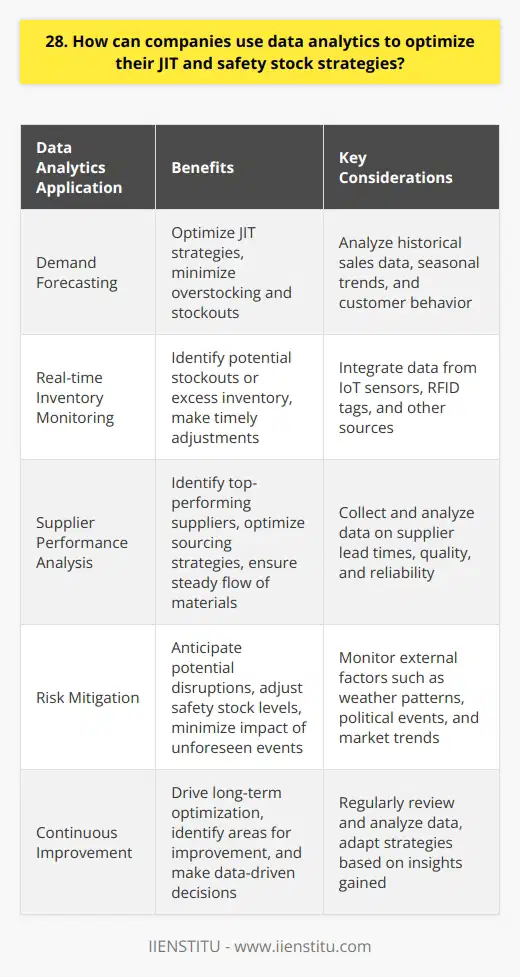

28. How can companies use data analytics to optimize their JIT and safety stock strategies?

As a data analyst with experience in supply chain optimization, I've seen firsthand how data analytics can revolutionize just-in-time (JIT) and safety stock strategies. By leveraging the power of data, companies can make informed decisions that minimize waste, reduce costs, and improve overall efficiency.

Demand Forecasting

One key area where data analytics shines is demand forecasting. By analyzing historical sales data, seasonal trends, and customer behavior, companies can predict future demand with greater accuracy. This allows them to optimize their JIT strategies, ensuring that the right products are available at the right time, without overstocking or running out of inventory.

Real-time Inventory Monitoring

Data analytics also enables real-time inventory monitoring. By integrating data from various sources, such as IoT sensors and RFID tags, companies can track inventory levels in real-time. This helps them identify potential stockouts or excess inventory, allowing them to make timely adjustments to their JIT and safety stock levels.

Supplier Performance Analysis

Another crucial aspect is supplier performance analysis. By collecting and analyzing data on supplier lead times, quality, and reliability, companies can identify top-performing suppliers and optimize their sourcing strategies. This ensures a steady flow of raw materials and components, reducing the need for excessive safety stock.

Risk Mitigation

Data analytics can also help companies mitigate supply chain risks. By monitoring external factors, such as weather patterns, political events, and market trends, companies can anticipate potential disruptions and adjust their safety stock levels accordingly. This proactive approach minimizes the impact of unforeseen events and ensures business continuity.

In my experience, implementing data analytics has led to significant improvements in JIT and safety stock management. By making data-driven decisions, companies can strike the perfect balance between efficiency and risk mitigation, ultimately driving business success.

29. What are the implications of global supply chain disruptions on JIT and safety stock approaches?

The disruptions in global supply chains have significant implications for Just-in-Time (JIT) and safety stock approaches. Companies relying on JIT manufacturing are particularly vulnerable to supply chain disruptions.

Challenges for JIT Manufacturing

JIT manufacturing aims to minimize inventory and produce goods only as needed. This approach requires a stable and predictable supply chain. Disruptions can quickly lead to production delays and stockouts.

I've seen firsthand how supply chain issues can derail JIT operations. Last year, my company faced a shortage of critical components due to a supplier's production halt. Our JIT system couldn't cope, forcing us to idle production lines.

The Case for Safety Stock

In light of supply chain uncertainties, many companies are reconsidering their inventory strategies. Holding extra safety stock can provide a buffer against disruptions.

While safety stock ties up capital, it can help maintain production and fulfill customer orders during supply chain hiccups. I believe finding the right balance between JIT efficiency and safety stock resilience is key.

Diversifying Suppliers

Another strategy is diversifying the supplier base. Relying on a single supplier or region is risky. Having multiple suppliers in different locations can mitigate the impact of localized disruptions.

My company is actively exploring new suppliers in various countries. It's not easy, but it's necessary to build a more resilient supply chain.

Adapting to the New Normal

Global supply chain disruptions are likely to persist in the near future. Companies must adapt their inventory management approaches accordingly.

While JIT remains valuable for efficiency, integrating safety stock and supplier diversification is crucial for navigating uncertainties. Flexibility and agility will be key success factors in this new normal.

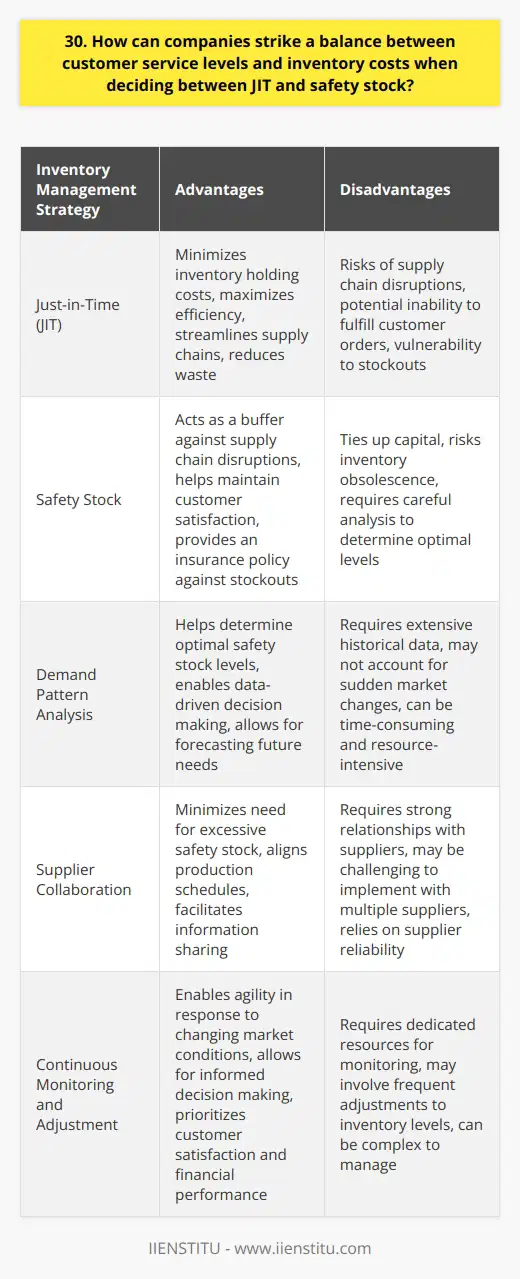

30. How can companies strike a balance between customer service levels and inventory costs when deciding between JIT and safety stock?

Striking a balance between customer service levels and inventory costs is a delicate juggling act for companies. They must carefully consider the trade-offs between Just-in-Time (JIT) inventory management and maintaining safety stock.

The Allure of Just-in-Time

JIT is a seductive strategy, promising minimal inventory holding costs and maximum efficiency. I've seen it work wonders in streamlining supply chains and reducing waste. However, it's not without risks.

When JIT Goes Wrong

I remember a case where a company's over-reliance on JIT left them high and dry when a key supplier faced disruptions. They couldn't fulfill customer orders, leading to frustration and lost business.

The Safety Net of Safety Stock

That's where safety stock comes in - it's like an insurance policy against supply chain hiccups. By maintaining a buffer of inventory, companies can weather short-term disruptions and keep customers happy.

Finding the Sweet Spot

The key is finding the right balance. Too much safety stock ties up capital and risks obsolescence. Too little leaves you vulnerable to stockouts and disappointed customers.

Analyzing Demand Patterns

Companies should carefully analyze historical demand patterns and forecast future needs. This helps determine optimal safety stock levels for each product.

Collaborating with Suppliers

Close collaboration with suppliers is also crucial. Sharing information and aligning production schedules can help minimize the need for excessive safety stock.

Continuously Monitoring and Adjusting

Finally, it's important to continuously monitor inventory levels and adjust as needed. Market conditions and customer demands can change quickly, so staying agile is essential.

In my experience, the companies that strike the right balance are those that take a holistic, data-driven approach. They don't just rely on gut instinct or rigid formulas. Instead, they constantly assess the trade-offs and make informed decisions that prioritize both customer satisfaction and financial performance.