Overview of ERP and its Role in Supply Chain Management

Benefits of ERP in Supply Chain Management

Challenges and Risks of ERP in Supply Chain Management

Best Practices for Implementing ERP in Supply Chain Management

Future Trends and Opportunities for ERP in Supply Chain Management

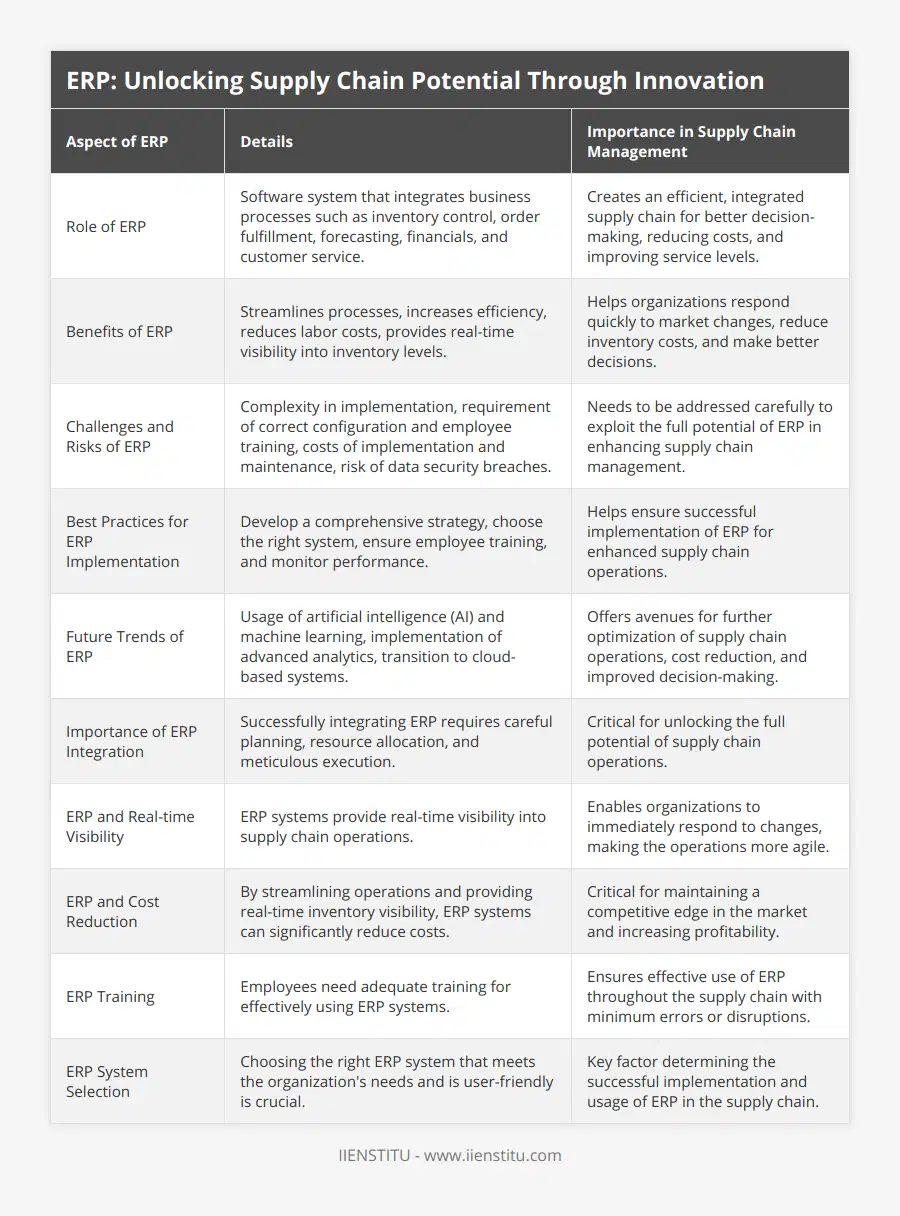

Enterprise resource planning (ERP) systems are a powerful tool for managing and optimizing supply chain operations. ERP systems enable organizations to gain real-time visibility into their supply chain operations, enabling them to make smarter decisions, reduce costs, and improve service levels. In this article, we discuss ERP's role in supply chain management, the benefits and challenges associated with ERP, best practices for implementing ERP in the supply chain, and future trends and opportunities.

Overview of ERP and Its Role in Supply Chain Management

ERP is a software system that helps organizations manage their business processes more efficiently. It integrates multiple systems: inventory control, order fulfillment, forecasting, financials, and customer service. As a result, organizations can create an efficient, integrated supply chain by integrating these functions. ERP also helps to reduce costs, improve customer service, and increase profitability.

Benefits of ERP in Supply Chain Management

There are numerous benefits to using ERP in supply chain management. First, ERP helps organizations to streamline processes and increase efficiency. By automating processes, organizations can reduce labor costs and eliminate manual errors. ERP also increases visibility into the supply chain, enabling organizations to make better decisions and respond quickly to changes in the market. In addition, ERP can help organizations to reduce inventory costs by providing real-time visibility into inventory levels.

Challenges and Risks of ERP in Supply Chain Management

Though ERP can provide significant benefits to organizations, challenges, and risks are associated with its implementation. One of the primary challenges is implementing a complex system. For example, organizations must ensure that the system is configured correctly and that employees are trained to use it. In addition, organizations must consider the costs of implementing and maintaining the system. There is also a risk of data security breaches, which can have serious consequences.

Best Practices for Implementing ERP in Supply Chain Management

When implementing ERP in the supply chain, organizations should consider the following best practices:

Develop a comprehensive strategy: Organizations should develop a comprehensive strategy for implementing ERP. This should include an analysis of current processes and an assessment of the organization's needs.

Choose the right system: Organizations should choose an ERP system that meets their needs and is easy to use.

Train employees: Organizations should ensure all employees are trained to use the system.

Monitor performance: Organizations should monitor their ERP system to identify areas for improvement.

Future Trends and Opportunities for ERP in Supply Chain Management

The use of ERP in supply chain management is expected to continue to grow in the coming years. Organizations are increasingly looking for ways to gain real-time visibility into their supply chain operations. One key trend is using artificial intelligence (AI) and machine learning to automate processes and improve decision-making. In addition, organizations are looking for ways to reduce costs and increase efficiency. This includes the use of cloud-based ERP systems and the implementation of advanced analytics.

Overall, ERP is an invaluable tool for optimizing supply chain operations. Organizations can reduce costs, improve customer service, and increase profitability by using ERP. However, organizations must take the necessary steps to ensure that the system is implemented correctly and that employees are adequately trained. In addition, organizations should look for ways to leverage ERP to gain a competitive edge as technology advances.

Innovative ERP solutions unlock the potential of any supply chain to reach new heights.

The given text extensively discusses the usage and effects of Enterprise Resource Planning (ERP) in Supply Chain Management, elaborating on its benefits, challenges, and future opportunities. ERP significantly aids in streamlining operations and boosting efficiency, yet its implementation can be complex and expensive. The article underscores the importance of developing a detailed strategy, choosing the right system, adequately training employees, and continuously monitoring for improvement when implementing an ERP system. With the evolution of technology, the role of ERP systems in supply chain management is set to grow, incorporating advanced analytics, AI, machine learning, and cloud systems. Overall, ERP's successful integration requires careful planning and execution, which could be achieved through advanced training mechanisms such as supply chain certification online. This allows for cost reduction, improved customer service, enhanced profitability, and a competitive edge in the market.

Frequently Asked Questions

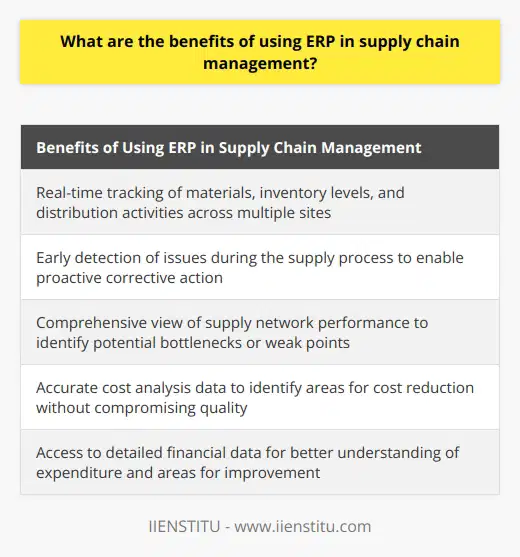

What are the benefits of using ERP in supply chain management?

Enterprise resource planning (ERP) systems are a powerful tool for supply chain management, allowing businesses to manage their inventory and resources better. ERP is an integrated system that provides information and tools to automate business processes across multiple locations, from purchasing and production to sales and customer service. By leveraging ERP capabilities, businesses can gain increased visibility into their supply chain operations, enabling them to make more informed decisions about optimizing their resources for maximum efficiency.

Using ERP in supply chain management offers several key benefits. First, it allows businesses to track materials, inventory levels, and distribution activities across multiple sites in real-time. This enables them to identify any issues that may arise during the supply process more quickly, allowing them to take corrective action before they become costly problems. Additionally, by having a comprehensive view of the supply network's performance at all times, businesses can detect potential bottlenecks or weak points before they become critical issues.

ERP also helps businesses manage their costs more effectively by providing accurate cost analysis data on raw materials and finished products throughout the entire production cycle. This allows organizations to identify areas where costs can be reduced or eliminated without compromising quality or performance standards. Additionally, it enables organizations to determine which suppliers offer the best value for money based on current market conditions so that they can select those more likely to meet their needs without breaking the budget. Finally, it provides access to detailed financial data on all aspects of production so businesses can better understand how much is being spent at each step in the process and where improvements can be made to maximize profitability over time.

Overall, using ERP in supply chain management offers numerous advantages for businesses of all sizes by providing them with greater visibility into their operations and reducing costs associated with inventory management and production cycles. In addition, with its ability to integrate multiple systems into one unified platform, an ERP system is invaluable for optimizing a business's overall efficiency while helping them succeed in today's competitive marketplace.

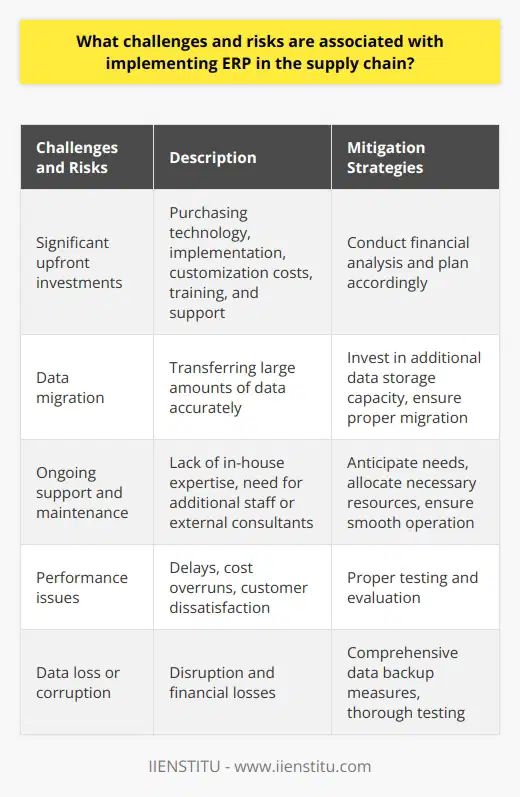

What challenges and risks are associated with implementing ERP in the supply chain?

Implementing an Enterprise Resource Planning (ERP) system in the supply chain can bring many benefits, including increased efficiency, greater accuracy, and improved customer service. However, the implementation process can be complex and costly and comes with various challenges and risks. This article will discuss the potential challenges and risks associated with ERP implementation in the supply chain.

Firstly, ERP systems require significant upfront investments. Companies typically must purchase the technology, pay for implementation and customization costs, and invest in training and support. This can be a challenging expense for many companies and lead to budget overruns. Additionally, the implementation process can be complex and time-consuming, requiring significant resources and expertise. Therefore, companies must invest in the right resources, such as experienced consultants, to implement the system correctly.

Another major challenge is data migration. ERP systems require large amounts of data to be migrated from existing systems to the new system. This process can be complicated and time-consuming; errors occur if data is not migrated correctly. Companies may also need additional data storage capacity to ensure the ERP system can handle the data.

In addition, ERP systems require ongoing support and maintenance. This can be a challenge for companies that need more in-house expertise. As a result, companies may need to invest in additional staff or engage external consultants to provide support and maintenance.

Finally, there are potential risks that come with implementing an ERP system. For example, the system may perform differently than expected, leading to delays, cost overruns, and dissatisfied customers. Additionally, there is a risk that data may be lost or corrupted during the migration process, resulting in significant disruption and financial losses.

In conclusion, although ERP systems can bring various benefits to the supply chain, they can also come with challenges and risks. Therefore, companies must consider these potential issues carefully before embarking on the implementation process.

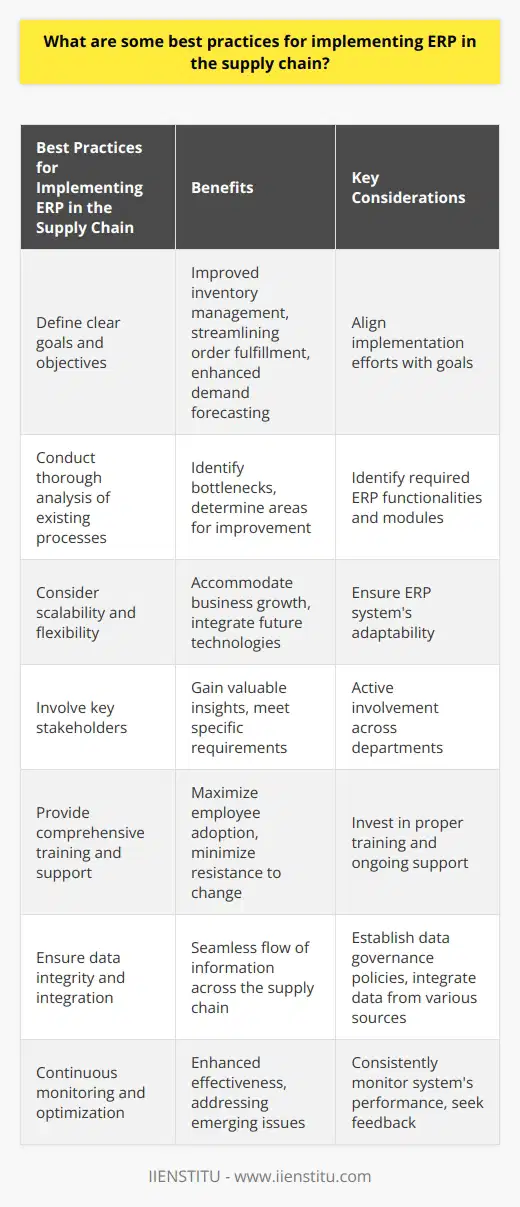

What are some best practices for implementing ERP in the supply chain?

In recent years, implementing Enterprise Resource Planning (ERP) in the supply chain has become increasingly crucial for businesses to remain competitive. Effective utilization of ERP in the supply chain can provide several benefits, such as improved customer service, increased efficiency, and cost savings. However, due to the complexity of ERP systems and their integration with existing processes and technology, successful implementation requires careful planning and execution. Below are some best practices that should be considered when implementing ERP in the supply chain:

Establish clear objectives: It is essential to establish clear objectives before beginning an ERP project. This includes identifying key performance indicators such as cost savings, customer service levels, inventory management, or performance metrics. These should be documented and communicated throughout the organization, so everyone understands why these goals are being set.

Evaluate existing processes: Before implementing an ERP solution, it is essential to evaluate your current processes to identify areas where improvements can be made. This evaluation should include internal processes such as inventory management and external processes such as supplier relationships or customer service levels. This will help ensure that any new system effectively integrates into existing processes and helps improve overall performance.

Develop a comprehensive plan: Once objectives have been established, it is essential to develop a comprehensive plan outlining all steps required for successful implementation, including budgeting, timeline, resources, etc. This plan should also include data migration plans, user training plans, and other vital elements necessary for the system's successful deployment.

Choose the right vendor/solution: Choosing a vendor or solution that fits your specific needs is essential for effectively utilizing an ERP system within your organization's supply chain network. In addition, selecting a vendor with experience working with similar enterprises is essential so they can best understand your needs and provide tailored solutions that meet those needs while being cost-effective.

Test & Monitor Performance: Once implemented, it is important to regularly test & monitor the performance of your new system to ensure it meets expectations set forth at the outset of the project. Regular testing & monitoring will help identify areas where further improvements may be needed, which will ensure optimal utilization & return on investment over time.

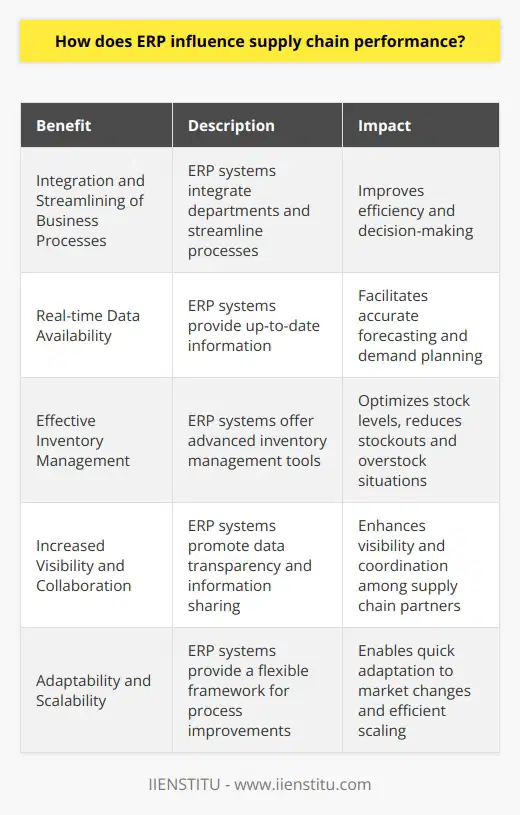

How does ERP influence supply chain performance?

Impact of ERP on Supply Chain Efficiency

Enterprise Resource Planning (ERP) systems play a pivotal role in enhancing supply chain performance by integrating and streamlining business processes. Through centralized data management, ERP systems offer improved information sharing, enabling organizations to make informed decisions.

Process Integration and Automation

ERP systems integrate all aspects of a business, such as procurement, production, sales, and logistics, to ensure seamless communication among departments. This integration leads to reduced lead times, increased efficiency in operations, and overall improved supply chain performance.

Real-Time Data Availability

Access to real-time data is critical for accurate forecasting and demand planning. ERP systems provide organizations with up-to-date information, which facilitates accurate decision-making and enhanced responsiveness to market changes.

Inventory Management and Optimization

Effective inventory management is a key contributor to an efficient supply chain. ERP systems offer advanced inventory management tools that help monitor stock levels, track inventory, and maintain optimum stock levels, leading to reduced stockouts and overstock situations.

Increased Visibility and Collaboration

ERP systems enable organizations to achieve greater visibility across all tiers of the supply chain. By breaking down information silos and promoting data transparency, they encourage information sharing, collaboration, and better coordination among supply chain partners.

Enhanced Adaptability and Scalability

ERP systems allow organizations to quickly adapt to changes in the marketplace and efficiently scale their operations. By providing a flexible framework that supports continuous process improvements, ERP systems facilitate supply chain optimization and long-term competitiveness.

In conclusion, ERP systems significantly influence supply chain performance by providing an integrated platform for decision-making, increased visibility, and collaboration among partners. By optimizing inventory management and enhancing adaptability, these systems empower organizations to achieve improved supply chain efficiency and competitiveness.

In what ways could we use technology to improve an organization's supply chain management with ERP?

Enhancing Inventory Management

One way to use technology to improve an organization's supply chain management with ERP is by enhancing inventory management. This can be achieved through real-time tracking of inventory levels, maintaining accurate stock information, and automating restocking processes. This not only reduces human error but also improves efficiency and reduces stockouts or overstocking issues.

Streamlining Warehouse Operations

Another application of technology in supply chain management is streamlining warehouse operations. By using advanced automation tools, such as robotics and AI-controlled systems, warehouse tasks like product picking, packing, and shipping can be performed more efficiently. This results in reduced labor costs and lower overall operational expenses. These systems also increase accuracy, leading to fewer customer complaints due to shipping errors.

Optimizing Supplier Relationship Management

Improving supplier relationship management is another critical aspect of supply chain optimization. Technology enables organizations to maintain real-time communication with suppliers, making it easier to exchange information, negotiate contracts, and resolve issues more efficiently. Electronic data interchange (EDI) and cloud-based platforms facilitate better collaboration between supply-chain partners, leading to lower lead times and better order fulfillment.

Managing Transportation and Logistics

Technology advancements in transportation and logistics management can significantly impact an organization's supply chain efficiency. GPS tracking, route optimization software, and Internet of Things (IoT) devices enable organizations to monitor shipments and delivery vehicles in real-time. This results in better control, improved visibility, and reduced transportation costs. Moreover, data collected from these technologies can be analyzed to identify patterns and trends, leading to better decision-making and predictive analytics.

Facilitating Collaborative Planning and Forecasting

Effective supply chain management relies on accurate planning and forecasting. Technology solutions, such as advanced analytics tools, can help organizations predict customer demand, plan production schedules, and optimize resource allocation more accurately. By integrating data from multiple sources and applying advanced algorithms, organizations can make more informed decisions and anticipate changes in the market.

In conclusion, technology plays a crucial role in improving an organization's supply chain management with ERP. By leveraging tools and solutions for inventory management, warehouse operations, supplier relationship management, transportation and logistics, and collaborative planning and forecasting, organizations can enhance their supply chain performance, reduce costs, and ultimately increase competitive advantage.

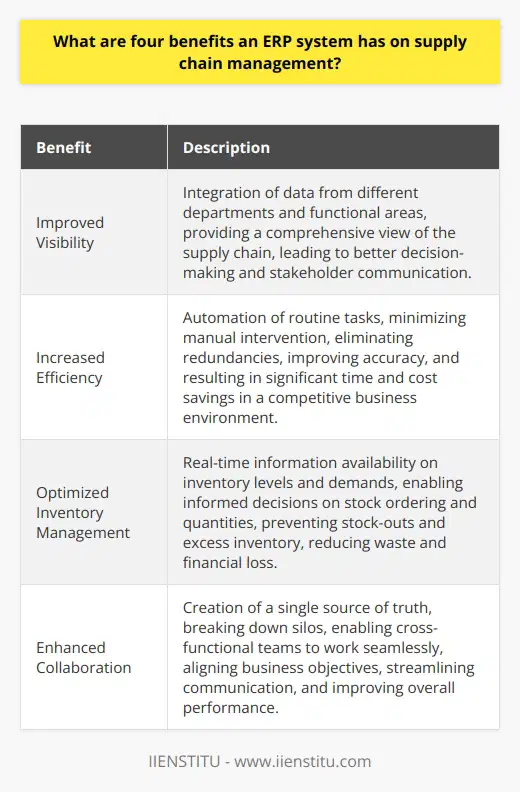

What are four benefits an ERP system has on supply chain management?

**Improved Visibility**

One significant advantage of an ERP system within supply chain management is the enhanced visibility it provides. By integrating data from different departments and functional areas, ERP systems enable businesses to gain a comprehensive view of the supply chain. This promotes better decision-making and ensures all relevant stakeholders are kept in the loop.

**Increased Efficiency**

ERP systems also play a crucial role in streamlining operations and increasing efficiency. By automating routine tasks, businesses can minimize manual intervention, eliminate redundancies, and improve accuracy. This leads to significant time and cost savings, which are often crucial in a competitive business environment.

**Optimized Inventory Management**

Another benefit of implementing an ERP system is the optimization of inventory management. ERP systems provide real-time information about inventory levels and demands, allowing businesses to make informed decisions about when to order stock and in what quantities. This prevents stock-outs and excess inventory, which can often lead to waste and financial loss.

**Enhanced Collaboration**

Finally, an ERP system fosters collaboration among different departments and external partners. By creating a single source of truth, the ERP system breaks down silos and enables cross-functional teams to work together seamlessly. This ultimately leads to better alignment of business objectives, streamlined communication, and improved overall performance.

In summary, ERP systems provide a range of benefits to supply chain management, including improved visibility, increased efficiency, optimized inventory management, and enhanced collaboration. By leveraging these advantages, businesses can achieve a more robust and agile supply chain, allowing them to better meet customer demands and stay ahead of the competition.

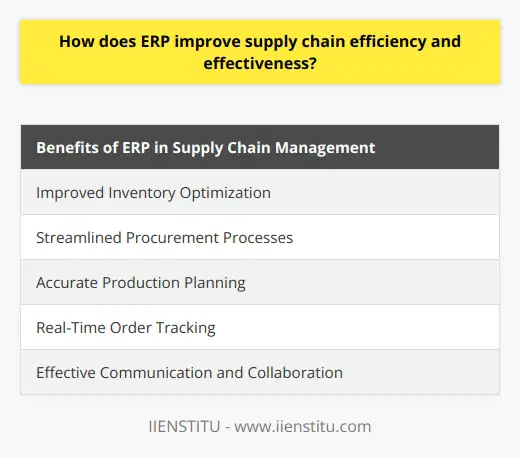

How does ERP improve supply chain efficiency and effectiveness?

ERP Integration in Supply Chain Management

Enterprise Resource Planning (ERP) systems play a pivotal role in enhancing supply chain efficiency and effectiveness by integrating various business functions through real-time information exchange. By providing a centralized platform for data sharing, ERP systems significantly reduce the chances of information asymmetry, delays, and errors that may arise in supply chain management.

Inventory Optimization

One of the main ways ERP systems contribute to supply chain efficiency is by optimizing inventory levels. They allow demand planning and forecasting by analyzing historical sales data and market trends. This crucial insight helps companies to make informed decisions on inventory replenishment, reducing stockouts, and avoiding overstock situations.

Streamlining Procurement Processes

ERP systems streamline procurement processes by automating purchasing activities, generating purchase orders, and tracking vendor performance. This increased visibility into procurement activities enables companies to optimize their supplier relationships, negotiate better pricing terms, and decrease lead times, ultimately enhancing the overall efficiency of the supply chain.

Improved Production Planning

Accurate production planning is essential for meeting customer demands and avoiding production bottlenecks. The integration of production scheduling and capacity planning tools within ERP systems provides an accurate view of the production process, considering factors such as labor, materials, and equipment availability. This helps companies to allocate resources more effectively and increase the overall efficiency of production processes, which in turn reduces overall supply chain costs.

Real-Time Order Tracking

ERP systems offer real-time order tracking capabilities, enabling companies to monitor the progress of orders and shipments throughout the entire supply chain. This increased visibility provides business owners with the information necessary to make timely decisions and promptly address any issues that can impact the efficiency and effectiveness of the supply chain.

Enhanced Collaboration and Communication

Effective communication and collaboration between various departments, suppliers, and customers are essential for an efficient supply chain. ERP systems contribute to this by offering a centralized platform for sharing relevant information, improving interdepartmental communication, and creating a single source of truth for critical decision-making.

In conclusion, ERP systems significantly improve supply chain efficiency and effectiveness by optimizing inventory levels, streamlining procurement processes, enabling better production planning, facilitating real-time order tracking, and enhancing collaboration and communication between stakeholders. As a result, businesses can achieve increased responsiveness and flexibility, reduced lead times, and minimized operational costs, which ultimately leads to higher customer satisfaction and competitive advantage.

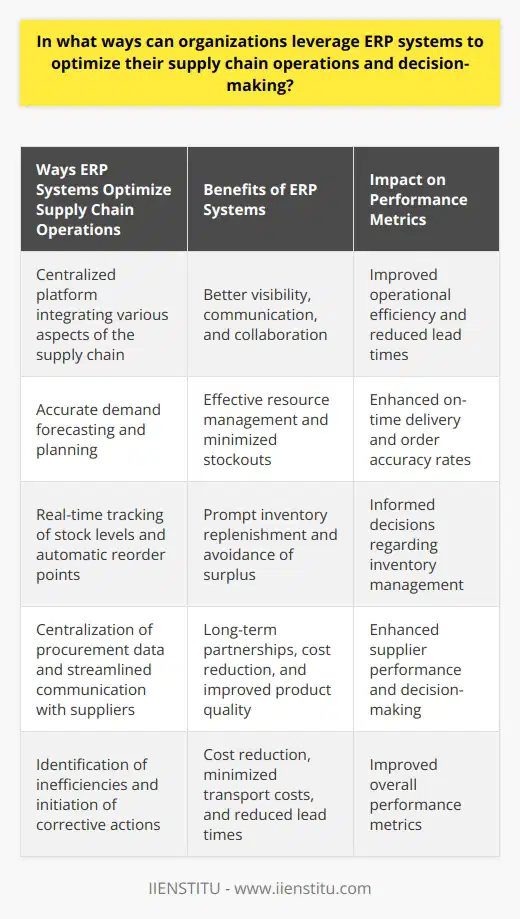

In what ways can organizations leverage ERP systems to optimize their supply chain operations and decision-making?

ERP System Benefits

Organizations can leverage enterprise resource planning (ERP) systems to optimize their supply chain operations and decision-making in numerous ways. First, ERP systems provide a centralized platform that allows organizations to integrate and coordinate multiple facets of their supply chain, such as inventory management, procurement, manufacturing, distribution, and demand planning. This facilitates better visibility, communication, and collaboration among all stakeholders, which can lead to improved operational efficiency and reduced lead times.

Demand Forecasting and Planning

Second, ERP systems facilitate accurate demand forecasting and planning. By analyzing historical data and factoring in external variables like market trends and seasonality, these systems can predict future demand with greater accuracy. This enables organizations to manage resources effectively, adjust production schedules as needed, and ultimately, minimize stockouts and overstock situations.

Inventory Management

Third, ERP systems can help organizations maintain optimal inventory levels. With real-time tracking of stock levels, these systems can trigger automatic reorder points, ensuring the organization effectively replenishes inventory while avoiding surplus. In addition, real-time visibility of inventory data can help identify slow-moving or obsolete items, enabling better decisions regarding their future management.

Supplier Relationship Management

Fourth, ERP systems can enhance supplier relationship management by centralizing procurement data and streamlining communication with suppliers. This helps build long-term partnerships, reduce costs, and improve product quality. By maintaining updated supplier performance data, organizations can make informed decisions when selecting and evaluating suppliers.

Cost Reduction and Improved Efficiency

Fifth, ERP systems can identify inefficiencies in the supply chain, enabling organizations to initiate corrective actions. For instance, these systems can assist organizations in identifying areas for cost reduction, such as minimizing transport costs and reducing procurement lead times. Consequently, these improvements contribute to better overall performance metrics, such as on-time delivery and order accuracy rates.

In summary, ERP systems can provide organizations with a competitive edge by enabling better visibility, collaboration, and communication within the supply chain. With accurate demand forecasting, optimally managed inventory levels, strong supplier relationships, and streamlining of all aspects of the supply chain, organizations can enhance their operational efficiency and decision-making capabilities, ultimately leading to improved profitability and customer satisfaction.

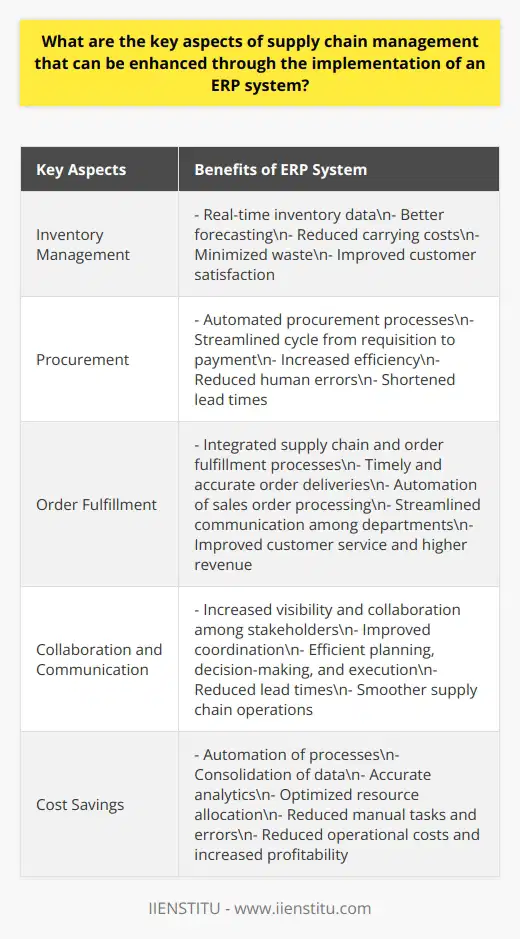

What are the key aspects of supply chain management that can be enhanced through the implementation of an ERP system?

Enhancing Inventory Management

One key aspect of supply chain management that can be enhanced through implementing an ERP system is inventory management. ERP systems provide real-time data on inventory levels, allowing for better forecasting and reduction of overstocking or stock shortages. This results in lower carrying costs, less waste, and improved customer satisfaction.

Optimizing Procurement Processes

ERP systems facilitate automation of procurement processes. This increases efficiency, reduces human errors, and shortens lead times. Moreover, ERP systems enable better supplier management through tracking performance, negotiating terms, and monitoring compliance. This helps companies to build strong relationships with reliable suppliers, ensuring consistent product quality and timely deliveries.

Improving Order Fulfillment

By integrating supply chain and order fulfillment processes, ERP systems help ensure timely and accurate order deliveries. This includes automating sales order processing, tracking shipments, and facilitating communication among warehouse, distribution, and customer service teams. All these features lead to a streamlined order-to-cash cycle, resulting in better customer service and higher revenue.

Enhancing Collaboration and Communication

ERP systems serve as a central hub for supply chain data, providing increased visibility and collaboration among various stakeholders. This improves coordination between departments, resulting in more efficient planning, decision-making, and execution. The elimination of data silos and real-time information sharing helps reduce lead times, ensures players are always informed, and makes for smoother supply chain operations.

Reducing Operational Costs

Efficient supply chain management through ERP systems improves the company's bottom line by reducing operational costs. By automating processes, consolidating data, and providing accurate analytics, ERP systems help companies optimize resource allocation, minimize manual tasks, and reduce the risk of costly errors. Improved efficiency ultimately leads to cost savings and increased profitability.

In conclusion, implementing an ERP system in supply chain management enhances inventory management, optimizes procurement processes, improves order fulfillment, establishes better collaboration and communication, and reduces operational costs. By streamlining these key aspects of supply chain management, businesses can improve their overall efficiency, customer satisfaction, and profitability.

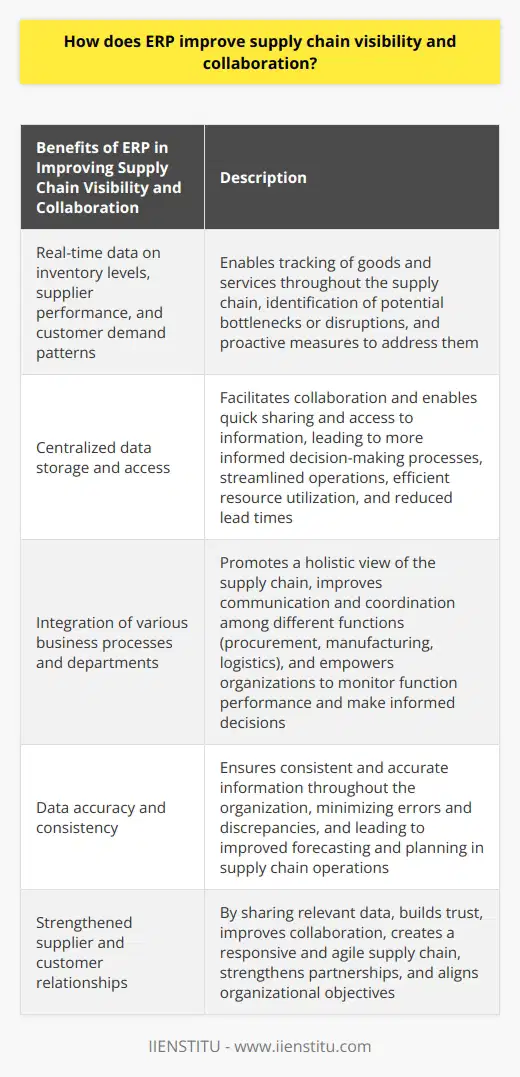

How does ERP improve supply chain visibility and collaboration?

Supply Chain Visibility Enhancement through ERP

Enterprise resource planning (ERP) systems contribute significantly to enhancing supply chain visibility by providing real-time data on inventory levels, supplier performance, and customer demand patterns. This information allows stakeholders to track the movement of goods and service delivery throughout the supply chain, enabling companies to identify potential bottlenecks or disruptions and implement proactive measures to address them.

Collaboration Facilitation

By fostering collaboration, ERP systems play a pivotal role in improving the overall performance and efficiency of the supply chain. By centralizing data storage and access, these systems enable all parties involved in the supply chain to share and access information quickly, leading to more informed decision-making processes. Consequently, this results in streamlined operations, better utilization of resources, and a reduction in lead times.

Integration of Business Processes

ERP systems are designed to integrate various business processes and departments in an organization, leading to a holistic view of the supply chain. This integration facilitates communication and coordination among different departments, such as procurement, manufacturing, and logistics, which is essential for efficient supply chain operations. As a result, organizations can monitor the performance of each function and make informed decisions based on the available data.

Data Accuracy and Consistency

Data accuracy and consistency are critical for effective supply chain management, as this enables organizations to make data-driven decisions. ERP systems offer a single platform for data input and management, ensuring that the information is consistent and accurate throughout the organization. This consistency helps minimize errors and discrepancies, leading to improved forecasting and planning in the supply chain operations.

Improved Supplier and Customer Relationships

The use of ERP systems can improve supplier and customer relationships by offering a transparent view of the supply chain's performance. By sharing relevant data with suppliers and customers, organizations can build trust and improve collaboration, leading to a more responsive and agile supply chain. This contributes to stronger partnerships and better alignment of organizational objectives, generating long-term benefits for all parties involved.

In conclusion, ERP systems significantly enhance supply chain visibility and collaboration by centralizing data, integrating business processes, and promoting better communication among stakeholders. This, in turn, leads to more efficient operations, improved supplier and customer relationships, and a more competitive and resilient supply chain.

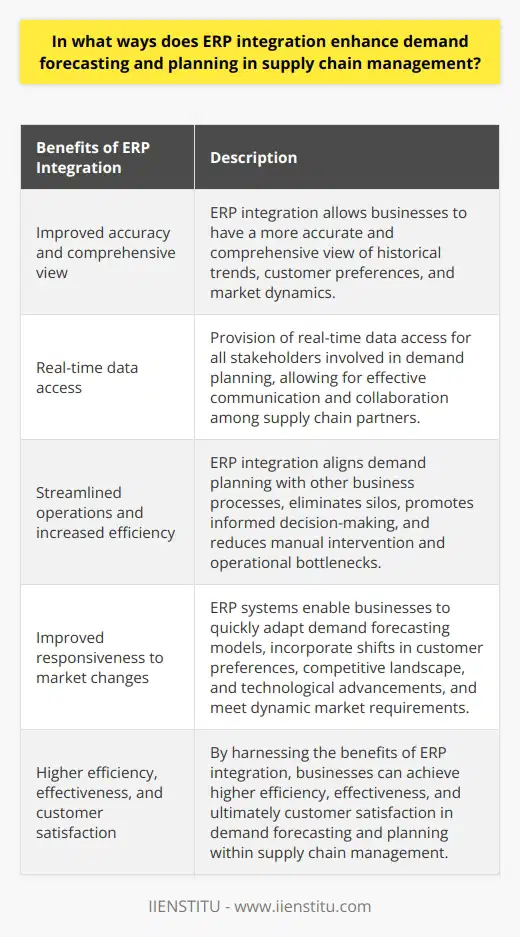

In what ways does ERP integration enhance demand forecasting and planning in supply chain management?

ERP Integration and Demand Forecasting Accuracy

Enterprise Resource Planning (ERP) integration significantly enhances demand forecasting and planning in supply chain management through improved accuracy. By integrating various data sources, ERP systems enable businesses to gain better visibility into historical trends, customer preferences, and market dynamics. This comprehensive view supports more accurate and timely forecasts, reducing the risk of errors in demand estimation and minimizing the bullwhip effect, which can lead to costly consequences, such as excess inventory or stockouts.

Real-time Data Access for Collaborative Planning

Another critical benefit of ERP integration is the provision of real-time data access to all stakeholders involved in demand planning. This aspect facilitates more effective communication and collaboration among supply chain partners, such as suppliers, manufacturers, distributors, and retailers. As a result, organizations can proactively address potential challenges, synchronize production and distribution processes, and optimize their response to fluctuations in demand.

Streamlined Operations and Increased Efficiency

ERP integration also streamlines supply chain operations and increases overall efficiency. The alignment of demand planning with other business processes, such as inventory management, procurement, production, and sales, eliminates silos and promotes more informed decision-making. Moreover, automated workflows and standardized procedures fueled by ERP systems reduce manual intervention and the risk of human errors, thus minimizing operational bottlenecks and enhancing process efficiency.

Improved Responsiveness to Market Changes

With ERP integration, businesses can achieve greater responsiveness to market changes and customer demands. It allows organizations to quickly adapt their demand forecasting models to incorporate shifts in customer preferences, competitive landscape, and technological advancements. This proactive approach enables businesses to stay ahead of the curve and meet dynamic market requirements while maximizing their profit margins.

In conclusion, ERP integration plays a crucial role in enhancing demand forecasting and planning in supply chain management. By improving forecasting accuracy, facilitating collaborative planning through real-time data access, streamlining operations, and increasing responsiveness to market changes, ERP systems empower organizations to achieve higher efficiency, effectiveness, and customer satisfaction.

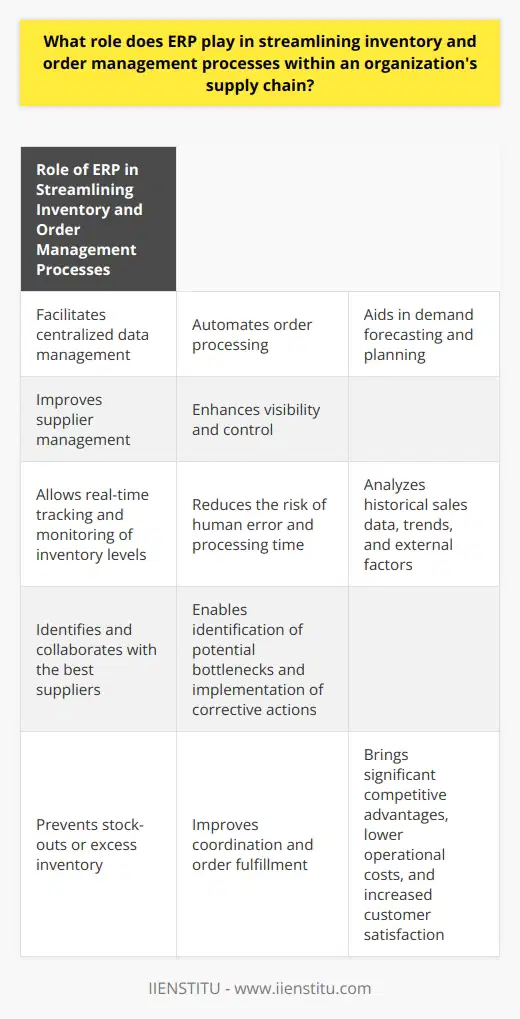

What role does ERP play in streamlining inventory and order management processes within an organization's supply chain?

Role of ERP in Inventory and Order Management

Efficient inventory and order management are crucial for the success of an organization's supply chain. Enterprise Resource Planning (ERP) systems play a significant role in streamlining these processes by providing an integrated platform to manage various aspects of an organization's operations.

Centralized Data Management

ERP systems enable centralized data management, allowing organizations to track and monitor inventory levels in real-time. This facilitates timely decision-making and prevents stock-outs or excess inventory, leading to reduced carrying costs and improved customer satisfaction.

Automated Order Processing

Through the automation of order processing, ERP solutions significantly reduce the risk of human error, decrease order processing time, and increase overall efficiency. This automation ensures accurate information flow between sales, production, and logistics departments, allowing for better coordination and improved order fulfillment.

Demand Forecasting and Planning

ERP systems aid in demand forecasting and planning by analyzing historical sales data, trends, and external factors. This information helps organizations proactively manage their inventory and optimize order quantities, ultimately balancing the trade-off between inventory holding costs and customer service levels.

Improved Supplier Management

By incorporating supplier information and performance metrics, ERP systems enable organizations to identify and collaborate with the best suppliers for their specific needs. This strategic supplier management approach results in improved order accuracy, reduced lead times, and minimized risk of supply disruptions.

Enhanced Visibility and Control

Through real-time data visualization and reporting, ERP systems provide better visibility and control over inventory and order management processes. This increased transparency enables organizations to identify potential bottlenecks, implement corrective actions, and continuously improve their supply chain operations.

In conclusion, ERP systems play a vital role in streamlining inventory and order management processes within an organization's supply chain. They facilitate centralized data management, automate order processing, aid in demand forecasting and planning, improve supplier management, and enhance overall visibility and control. As a result, organizations that adopt ERP systems can achieve significant competitive advantages, lower operational costs, and increased customer satisfaction levels.

How does ERP improve supply chain planning and demand forecasting?

Enhanced Collaboration through ERP

Enterprise Resource Planning (ERP) systems play a crucial role in improving supply chain planning and demand forecasting by streamlining processes and enhancing collaboration among different departments. These integrated software solutions facilitate communication and information exchange, enabling organizations to make informed decisions based on real-time data.

Improved Data Accuracy and Consistency

ERP systems improve data accuracy and consistency by centralizing information from various departments, such as sales, production, and finance. This centralization reduces the need for manual data entry and duplicate efforts, leading to increased data quality and more reliable demand forecasts. Accurate demand forecasts are essential for organizations to plan production schedules, inventory levels, and resource allocation effectively.

Enhanced Visibility and Tracking

With increased visibility and tracking capabilities provided by ERP systems, organizations can easily monitor and control their supply chains. ERP solutions offer real-time updates on inventory levels, demand trends, and production schedules, allowing decision-makers to assess potential risks and make timely adjustments. This responsiveness promotes smoother operations and results in a more efficient supply chain.

Optimized Inventory Management

ERP systems provide organizations with real-time insights into their inventory levels, helping them maintain optimal stockpiles and avoid overstocking or stockouts. Through better inventory management, organizations can improve cash flow, reduce holding costs, and enhance customer satisfaction. Furthermore, ERP solutions can help identify patterns in demand and seasonality, enabling organizations to make better buy and replenish decisions.

Streamlined Planning and Scheduling

By consolidating data from multiple sources, ERP systems enable organizations to develop more accurate plans for production and delivery. Through a comprehensive view of resources, capacity, lead times, and customer demand, ERP solutions allow for efficient scheduling and allocation of resources. This streamlined planning process results in reduced production costs and improved overall supply chain performance.

Increased Flexibility and Adaptability

ERP systems provide organizations with the tools necessary to quickly adapt to changes in the market and customer needs. With improved demand forecasting, organizations can respond to fluctuations in demand more effectively and adjust their supply chain strategies accordingly. This adaptability allows organizations to maintain a competitive edge and meet customer expectations more consistently.

In conclusion, ERP systems play a critical role in enhancing supply chain planning and demand forecasting by providing a comprehensive view of an organization's operations and enabling data-driven decision-making. Organizations that adopt and effectively utilize ERP solutions can significantly improve their supply chain efficiency, responsiveness, and overall performance.

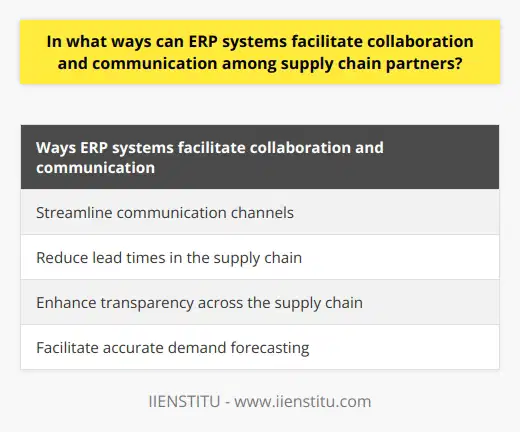

In what ways can ERP systems facilitate collaboration and communication among supply chain partners?

Enhancing Collaboration

Enterprise resource planning (ERP) systems, through their integrated nature, enable supply chain partners to access and share vital information in real-time, enhancing collaboration. This seamless flow of information across organizational borders facilitates coordination, ensures resource optimization, and reduces waste or duplication of efforts. By offering a centralized platform to manage business processes, an ERP system streamlines communication channels, enabling informed decision-making and improved collaboration among supply chain partners.

Reducing Lead Times

The reduction of lead times is another way in which ERP systems facilitate collaboration among supply chain partners. By integrating procurement, production, and distribution processes within a single system, these software solutions help partners to foresee potential disruptions, adjust production schedules as needed, and respond more efficiently to changes in demand. Consequently, this proactive approach allows organizations to better align their supply chain strategies and improve overall performance.

Increasing Transparency

ERP systems also foster transparency across the supply chain by providing real-time updates on inventory, production, and distribution statuses. This increased visibility allows partners to monitor activities and make necessary adjustments to maintain operational efficiency. In this way, ERP systems support proactive decision-making as well as enhance the trust between supply chain partners. With improved collaboration and communication, partners can avoid potential bottlenecks and minimize the risk of stock-outs or excess inventory.

Improving Forecast Accuracy

Accurate demand forecasting is crucial for supply chain management, and ERP systems can improve the process by consolidating historical data, customer information, and market trends. By leveraging these insights, organizations can more accurately predict future demand patterns and plan their production and distribution activities accordingly. This improved forecast accuracy enables supply chain partners to coordinate their activities more effectively, reduce excess inventory, and ultimately, deliver better customer service.

In conclusion, ERP systems play a critical role in facilitating collaboration and communication among supply chain partners, leading to enhanced operational efficiency, reduced lead times, increased transparency, and improved forecast accuracy. By leveraging these advantages, companies can not only improve their overall performance but also achieve a more sustainable, competitive edge in today's dynamic global market.

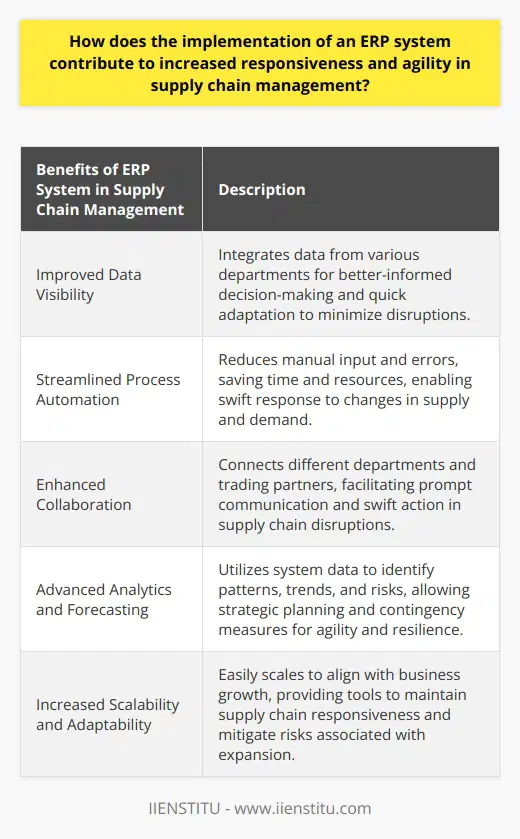

How does the implementation of an ERP system contribute to increased responsiveness and agility in supply chain management?

ERP System's Role in Supply Chain Management

An essential aspect of managing a supply chain is the ability to respond quickly and effectively to changes in demand, new market conditions or disruptive events such as unexpected supply chain bottlenecks. This capability, often referred to as responsiveness and agility, is greatly enhanced by the implementation of an Enterprise Resource Planning (ERP) system.

Improved Data Visibility

To begin with, ERP systems provide comprehensive data visibility throughout the supply chain. Integrated data from procurement, production, warehousing, and distribution allows businesses to make better-informed decisions. As a result, organizations can quickly adapt their operations to minimize disruptions and maintain optimal performance.

Streamlined Process Automation

In addition, ERP systems automate many supply chain processes, reducing manual input and errors. By automating these processes, businesses can save time and resources, enabling them to swiftly respond to any changes in supply and demand. Moreover, process automation allows for proactive decision-making, as companies can leverage real-time data to anticipate potential issues and implement adjustments promptly.

Enhanced Collaboration and Communication

Another benefit of implementing an ERP system is improved collaboration and communication among supply chain stakeholders. ERP systems connect different departments and trading partners, facilitating seamless information exchange. This connectivity fosters prompt communication and enables companies to act swiftly in the face of any supply chain disruptions, providing them with a competitive edge.

Advanced Analytics and Forecasting

Furthermore, ERP systems house a wealth of data that supports advanced analytics and forecasting capabilities. Utilizing this data, organizations can identify patterns, trends and potential risks, allowing them to formulate strategic plans and contingency measures. Consequently, businesses can become more agile and resilient, as they can quickly adapt their supply chain operations to accommodate market fluctuations and disruptions.

Increased Scalability and Adaptability

Finally, ERP systems offer scalability and adaptability to growing enterprises. As companies expand, they need flexible infrastructure to accommodate their evolving needs. ERP systems can be easily scaled to align with business growth, providing organizations with the necessary tools to maintain their supply chain's responsiveness and agility while mitigating risks associated with expansion.

In conclusion, implementing an ERP system significantly contributes to increased responsiveness and agility in supply chain management. By offering improved data visibility, streamlined process automation, enhanced collaboration, analytics capabilities, and scalability, ERP systems allow organizations to thrive in dynamic market conditions and minimize the effects of disruptions. Ultimately, adopting an ERP system is vital for businesses seeking to optimize their supply chain performance and maintain a competitive edge.

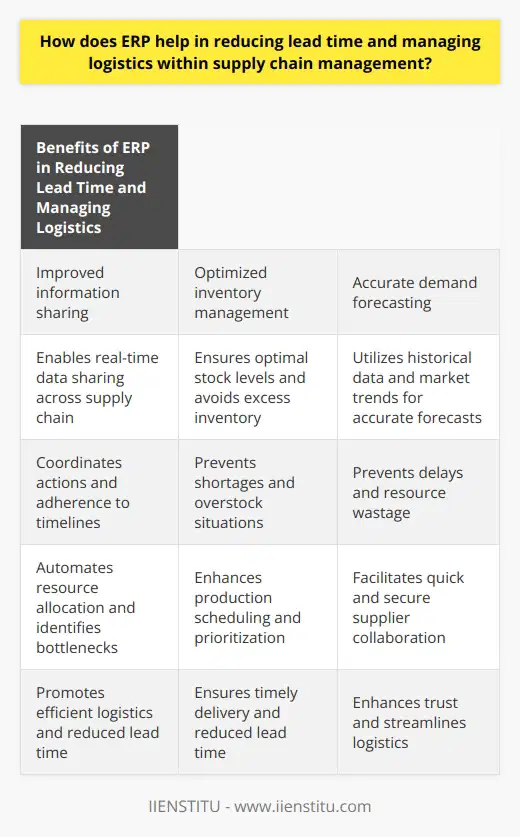

How does ERP help in reducing lead time and managing logistics within supply chain management?

Impact of ERP on Lead Time Reduction

Enterprise Resource Planning (ERP) systems significantly contribute to reducing lead time within supply chain management by streamlining information sharing and enhancing operational efficiency. Lead time refers to the duration between the initiation of a process and its completion, a critical factor determining the overall efficiency of a supply chain.

Improved Information Sharing

ERP systems facilitate informed decision-making by providing real-time data across the entire supply chain, allowing organizations to monitor performance indicators and resolve bottlenecks before they escalate. Seamless communication between different departments, such as procurement, production, and distribution, promotes efficient coordination of actions and adherence to established timelines.

Optimized Inventory Management

An ERP system offers superior inventory management capabilities, ensuring optimal stock levels and avoiding excess or obsolete inventory. It enables organizations to accurately forecast demand, execute timely procurement or production, and promptly deliver finished goods, significantly reducing lead time. Effective inventory control reduces storage costs and enhances customer satisfaction by ensuring product availability.

Accurate Demand Forecasting

Accurate demand forecasting is essential for reducing lead time and improving supply chain responsiveness. ERP systems offer sophisticated analytics tools that consider historical data, consumer preferences, and market trends to create accurate sales forecasts. Such forecasts prevent stockouts or overstock situations, thus minimizing lead time delays and resource wastage.

Enhanced Production Scheduling

Within the manufacturing sector, ERP systems support efficient production scheduling by automating resource allocation and providing up-to-date information on the progress of current projects. Consequently, organizations can identify and resolve production bottlenecks, eliminate idle time or underutilization of resources, and prioritize urgent orders to ensure timely delivery.

Better Supplier Collaboration

Efficient collaboration with suppliers becomes possible through ERP systems, as they facilitate quick and secure data exchange regarding order specifications, delivery schedules, and quality requirements. Such collaboration promotes trust, reduces lead time, and ensures that suppliers meet delivery deadlines as per organizations' expectations.

In conclusion, ERP systems play a vital role in reducing lead time and optimizing logistics in supply chain management through enhanced information sharing, better inventory control, more accurate demand forecasting, efficient production scheduling, and improved supplier collaboration. The integration of these processes under an ERP system results in a more coordinated and responsive supply chain, ultimately leading to increased customer satisfaction and long-term business success.

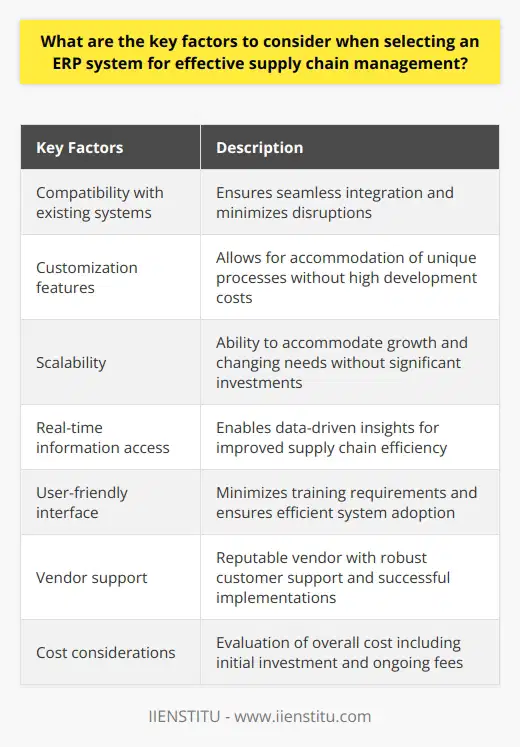

What are the key factors to consider when selecting an ERP system for effective supply chain management?

System Compatibility

One of the key factors when selecting an ERP system for effective supply chain management (SCM) is ensuring compatibility with existing systems. The chosen ERP software should integrate seamlessly with others, minimizing disruptions and providing a smooth transition for users.

Customization Features

Another crucial factor is the flexibility and adaptability of the ERP system to meet the specific needs of the organization. The chosen software should allow customization to accommodate unique organizational processes, procedures, and requirements without incurring high development costs or long implementation times.

Scalability

The ERP software should capabilities for scalability, as the success of a business may lead to growth and expansion. The selected system must have the capacity to accommodate this growth and changing needs, without significant additional investments in time, resources, or support services.

Real-Time Information Access

Modern SCM requires access to real-time information to facilitate effective decision-making processes. The ERP software should support data-driven insights by enabling users to access and analyze pertinent data for timely and accurate decision-making, improving supply chain efficiency and overall organizational performance.

User-Friendly Interface

The usability and user-friendliness of the ERP system are of vital importance. Supply chain managers and other users must easily navigate through the software to maximize the system's value. A user-friendly interface will minimize training requirements and ensure that system adoption is quick and efficient.

Vendor Support

The level of vendor support and their industry expertise are key factors when selecting an ERP system. A reputable vendor with robust customer support services and a proven track record of successful software implementations can be a significant asset in ensuring the ERP system is effectively integrated and optimized within the organization.

Cost Considerations

Lastly, organizations must evaluate the overall cost of implementing and using the ERP system. This includes initial investment, ongoing maintenance fees, user training costs, and any additional customizations needed. The selected ERP system should provide adequate corporate value and return on investment while fitting within the organization's budget constraints.

In conclusion, considering factors such as system compatibility, customization features, scalability, real-time information access, user-friendliness, vendor support, and cost are essential when selecting an ERP system for effective supply chain management. By choosing the right ERP software, organizations will be positioned to optimize their supply chain operations and facilitate continued growth and success.

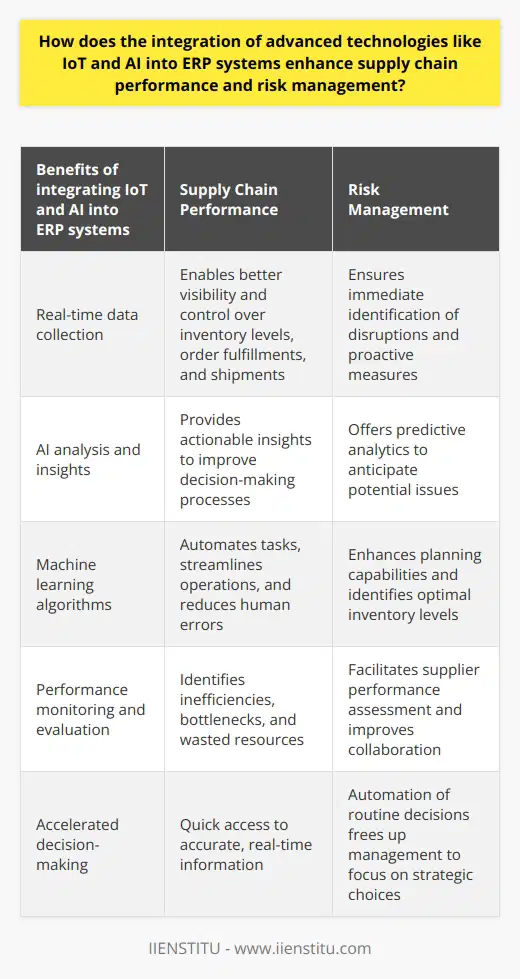

How does the integration of advanced technologies like IoT and AI into ERP systems enhance supply chain performance and risk management?

Improving Supply Chain Performance

The integration of advanced technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) into Enterprise Resource Planning (ERP) systems significantly enhances supply chain performance. IoT allows the collection of real-time data from various sources, including sensors and devices, throughout the entire supply chain. This data enables better visibility, monitoring, and control of inventory levels, order fulfillments, and shipments, ultimately reducing lead times and improving customer service.

Leveraging AI Capabilities

AI, when integrated into ERP systems, can analyze the collected data, predict demand patterns, and provide actionable insights that improve decision-making processes. Machine learning algorithms enable a higher level of automation in executing tasks, streamlining operations, and reducing human errors. AI can also enhance planning capabilities by identifying the best suppliers, optimal inventory levels, and the most efficient transportation routes.

Enhancing Risk Management

The combined power of IoT and AI drives more effective risk management in the supply chain. Real-time tracking enabled by IoT ensures immediate identification of disruptions, while AI provides predictive analytics to anticipate potential issues. This foresight enables businesses to take proactive measures, mitigating the impact of unexpected events, such as equipment failures, product defects, or supplier delays.

Optimizing Performance Monitoring

The integration of IoT and AI also enhances performance monitoring and evaluation in supply chain management. Constant data collection and analysis pinpoint inefficiencies, bottlenecks, and wasted resources, helping businesses adjust their strategies and processes to optimize performance. Additionally, advanced analytics tools facilitate the assessment of supplier performance and identify areas to improve collaboration and communication.

Accelerating Decision-Making

Integrating IoT and AI with ERP systems accelerates the decision-making process by providing quick access to accurate, real-time information. Enhanced analytics capabilities identify trends, opportunities, and threats, enabling faster, data-driven decisions that maximize performance and profitability. Additionally, the use of AI algorithms allows the automation of routine decisions, freeing up management to focus on strategic choices.

In conclusion, the integration of IoT and AI into ERP systems plays a crucial role in enhancing supply chain performance and risk management. Businesses can improve inventory management, optimize operations, better manage risks, monitor supplier performance, and accelerate decision-making processes, ultimately resulting in increased efficiency and profitability. Embracing these technologies positions companies to stay ahead of the curve in a constantly evolving global market.

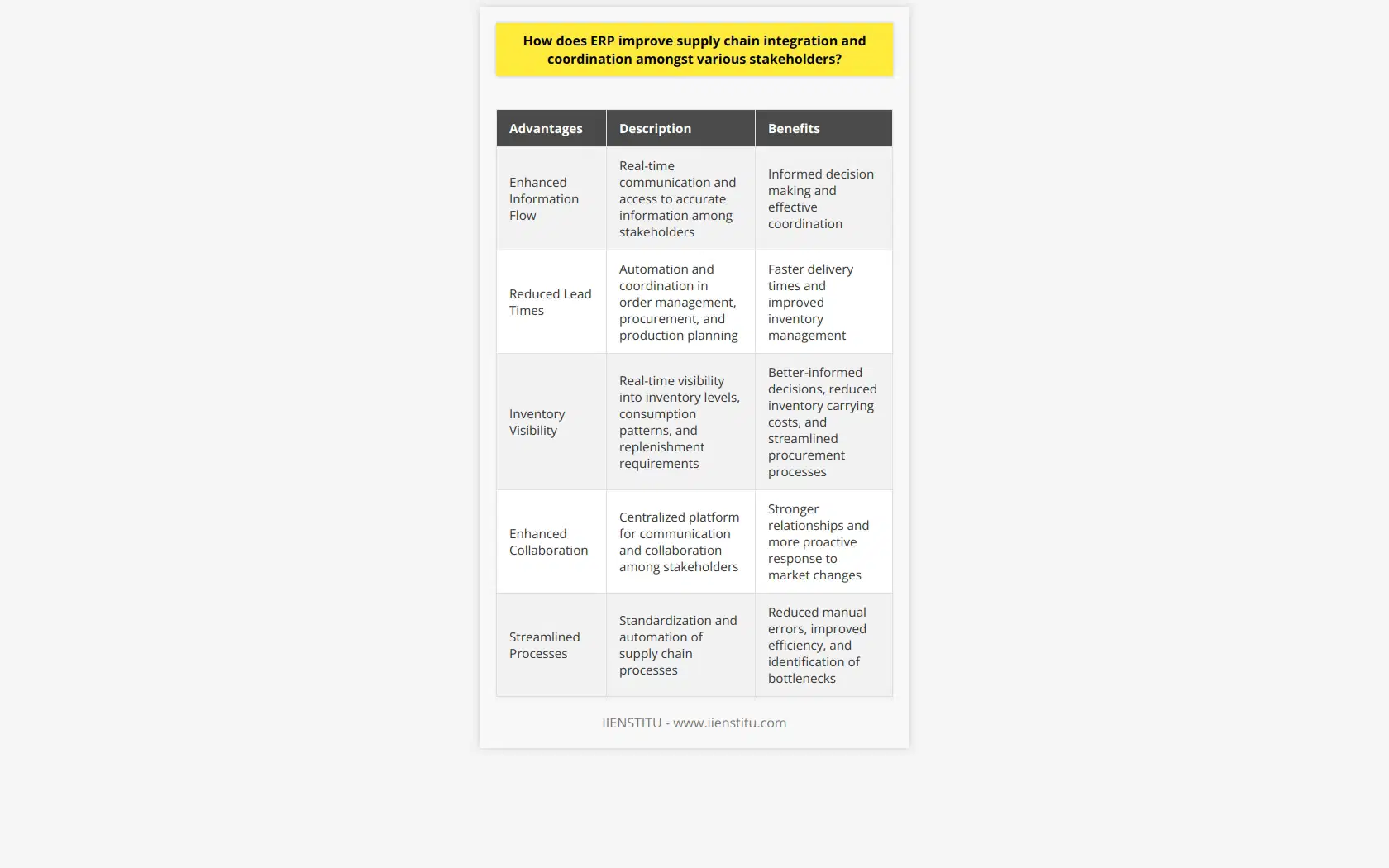

How does ERP improve supply chain integration and coordination amongst various stakeholders?

Enhanced Information Flow

Enterprise Resource Planning (ERP) systems facilitate real-time communication between departments, suppliers, and customers, streamlining supply chain processes. By consolidating data from various sources, ERP software breaks information silos and enhances information flow throughout the supply chain, enabling stakeholders to access accurate and updated information.

Reduced Lead Times

ERP systems empower businesses to respond effectively to customer demands by reducing lead times. By automating processes such as order management, procurement, and production planning, these systems allow for greater supply chain coordination with suppliers and customers, enabling faster delivery and better management of replenishment activities. Consequently, businesses can optimize inventory levels and improve customer satisfaction.

Inventory Visibility

ERP software provides real-time visibility into inventory levels, consumption patterns, and replenishment requirements, allowing businesses to manage both supply and demand fluctuations effectively. This increased visibility enables stakeholders to make better-informed decisions regarding inventory management and supply chain planning. As a result, businesses can minimize inventory carrying costs, reduce stockouts, and streamline procurement processes.

Enhanced Collaboration

The integration of all supply chain partners, including suppliers, manufacturers, and distributors, is one of the core objectives of ERP systems. By providing a centralized platform for communication, ERP applications foster collaboration amongst stakeholders, strengthening relationships and driving operational efficiency. Enhanced collaboration also allows organizations to align their supply chain strategies with their business objectives and to respond more proactively to changes in market dynamics.

Streamlined Processes

ERP software standardizes and automates various supply chain processes, allowing for seamless execution and monitoring of tasks such as order processing, transportation management, and purchasing. This standardization and automation result in reduced manual errors, improved efficiency, and increased information accuracy. Additionally, the consolidated data provided by ERP applications helps businesses identify bottlenecks and inefficiencies, enabling them to optimize their supply chain processes.

In conclusion, ERP systems play a critical role in improving supply chain integration and coordination by streamlining information flow, reducing lead times, enhancing inventory visibility, fostering collaboration, and standardizing processes. Consequently, businesses can better manage their supply chains, align them with their overall corporate strategy, and stay competitive in the global marketplace.

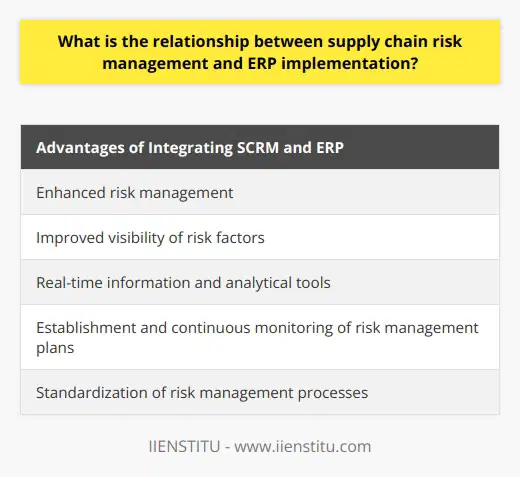

What is the relationship between supply chain risk management and ERP implementation?

Subheadings:

Supply Chain Risk Management

ERP Implementation

Integration of SCRM and ERP

Supply Chain Risk Management

Supply chain risk management (SCRM) is a systematic process of identifying, analyzing, and mitigating risks in the supply chain. It focuses on anticipating disruptions and ensuring the continuous flow of materials, information, and finances. Practicing a robust SCRM strategy is crucial, as failure to address risks can lead to operational breakdowns, financial losses and even damage to a company's reputation.

ERP Implementation

Enterprise resource planning (ERP) refers to the integrated management of core business processes using software and technology. ERP systems provide a unified platform for streamlining operations, enabling efficient data sharing and improving decision-making among departments. Its successful implementation can alleviate operational challenges and contribute to enhanced productivity and profitability.

Integration of SCRM and ERP

The relationship between SCRM and ERP implementation resides in their ability to work harmoniously for optimal management of supply chain activities. Integrating SCRM with ERP systems allows companies to better manage risks by providing real-time information and analytical tools to make informed decisions.

A well-integrated system enables better visibility of risk factors across the supply chain by combining data from various sources, such as suppliers, logistics providers, and customers. Through this integration, businesses gain improved situational awareness, enabling them to adapt quickly to changes and mitigate potential disruptors before they cause irreversible damage.

Another advantage of integrating SCRM and ERP is the combined efforts to establish risk management plans and monitor their effectiveness continuously. The ERP system can support in designing contingency plans, allocating resources, and tracking performance indicators, ensuring the supply chain is resilient to potential disruptions. It also aids in standardizing risk management processes across the organization, fostering accountability and creating a culture of risk awareness.

In conclusion, the relationship between supply chain risk management and ERP implementation is complementary, with both disciplines working in unison to ensure effective management of supply chain risks. By integrating SCRM and ERP, companies can achieve greater visibility, increased agility, and more informed decision-making in the face of supply chain challenges, ultimately enhancing business performance and competitiveness.

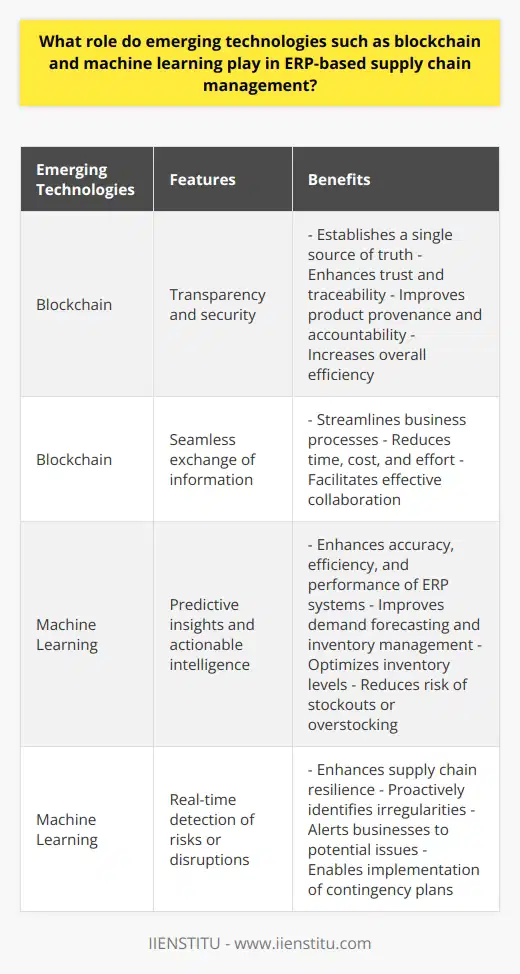

What role do emerging technologies such as blockchain and machine learning play in ERP-based supply chain management?

Role of Blockchain in Supply Chain Management

Blockchain technology plays an increasingly significant role in the realm of enterprise resource planning (ERP) for supply chain management. Essentially, blockchain serves as a distributed digital ledger, known for its transparency, security, and immutability. This technology provides a shared, consensus-driven method of recording and tracking transactions, enabling supply chain stakeholders to establish a single source of truth throughout the entire process.

Trust and Traceability Enhancement

One of the key benefits of integrating blockchain into an ERP-based supply chain process is the enhancement of trust and traceability. Blockchain's transparency ensures that all stakeholders can easily verify and authenticate various stages of the supply chain. This results in improved product provenance, accountability, and overall efficiency.

Optimizing the Flow of Data and Goods

Additionally, blockchain facilitates the flow of accurate data and goods within a supply chain, ultimately streamlining business processes. This seamless exchange of information eliminates bottlenecks and reduces the time, cost, and effort associated with traditional supply chain management methods. In turn, this fosters greater innovation and collaboration between stakeholders, leading to better decision-making and resource allocation.

Machine Learning's Impact on ERP Supply Chain Solutions

Machine learning, a subset of artificial intelligence, is transforming ERP-based supply chain management by providing predictive insights and actionable intelligence. The technology leverages data generated throughout the supply chain process to enhance the accuracy, efficiency, and overall performance of ERP systems.

Demand Forecasting and Inventory Management

Through sophisticated algorithms and pattern recognition, machine learning techniques can help businesses better anticipate customer demand and optimize their inventory management. This ultimately improves operational efficiency and reduces the risk of stockouts or overstocking, allowing organizations to more accurately meet customer needs and expectations.

Enhancing Supply Chain Resilience

Additionally, machine learning tools can improve supply chain resilience by identifying potential risks or disruptions in real-time. By monitoring and analyzing data from various sources within the supply chain, these technologies can proactively detect irregularities and alert businesses to potential issues before they escalate, enabling organizations to implement contingency plans and mitigate the impact of disruptions.

Conclusion

In summary, emerging technologies such as blockchain and machine learning are revolutionizing ERP-based supply chain management. By enhancing trust, traceability, operational efficiency, and resilience, these technologies equip businesses with powerful tools to succeed in an increasingly competitive and dynamic global marketplace.