The concept of cartonization refers to the process of selecting the most appropriate carton for packing items based on their dimensions, weight, and other attributes, which can significantly enhance operational efficiency within supply chain management. It is a critical step that ensures products are packaged in a way that minimizes empty spaces, reduces material usage, and optimizes shipping costs.

With an ever-accelerating demand for e-commerce and speedy deliveries, understanding the art and science behind cartonization is not just beneficial but necessary. This article navigates through the intricacies of cartonization, its evolution, and its profound impact on the logistics industry.

Historical Overview

The evolution of cartonization

Cartonization, as a practice, has originated from the necessity to improve the packing process, which has a direct impact on the cost and reliability of shipping goods. Initially, much of the carton selection was done manually, based on the experience and judgment of packing personnel. This presented numerous inefficiencies, leading to a transformation propelled by the need for more precise and cost-effective solutions.

Technological innovations that boosted its growth

With the rise of advanced technologies in supply chain management, cartonization has undergone significant advancements. Technological innovations, particularly in the form of software, have allowed for automated decision-making, enabling a more accurate and faster packing process. These innovations have not only streamlined operations but have also contributed to reducing the carbon footprint of shipping operations by minimizing waste.

In-Depth Understanding of Cartonization

How cartonization works

The cartonization process

The cartonization process involves determining the smallest box or carton size that can safely and securely accommodate a set of items. This optimization can substantially decrease freight costs and material usage. Advanced algorithms consider a multitude of factors including size, shape, and the fragility of items, to name a few. These algorithms are capable of making complex computations to ensure each item is packed in the most space-efficient and cost-effective manner possible.

Influencing factors in cartonization decisions

Various factors influence cartonization decisions, including the type of products, their compatibility, and destination. Fragile items, for instance, require more protective space and packaging material, whereas durable goods can be packed more compactly. The prioritization of these factors also depends on the objectives of the business, such as whether cost reduction, space efficiency, or product safety is the highest priority.

Different types of cartonization methods

Manual cartoning: Pros and Cons

Initially, cartonization was primarily a manual process driven by human experience and estimation. While manual cartoning allows for tailored decision-making and human supervision, it also introduces subjectivity and is prone to errors. Additionally, it is significantly slower and often less efficient than automated systems, paving the way for technological advancements to take center stage.

Automated cartoning: Pros and Cons

Automated cartoning has become the standard in larger operations due to its consistent accuracy and speed. Although the initial setup costs and maintenance of automated systems can be high, the long-term benefits in efficiency and cost savings are substantial. However, it is important to ensure that these systems are kept up to date with the latest software to maintain optimal performance.

Role of technology in cartonization

Cartonization software and its benefits

Cartonization software enables businesses to automate the decision-making process associated with choosing the right carton. By incorporating predefined rules and constraints, the software can make quick and cost-effective packing decisions. The benefits of implementing such systems include reduced manual labor, decreased material waste, and optimized use of transportation space.

Impact of AI and Machine learning in cartonization

The integration of AI and machine learning into cartonization software has revolutionized the process, making it more dynamic and intelligent. These technologies can learn from historical data, adapt to new packing scenarios, and continuously improve the efficiency of the cartonization process over time. The ability to anticipate and optimize packaging needs in real-time is a significant leap forward for the logistics industry.

Cartonization in Supply Chain Management

The efficiency of a supply chain is intricately linked to its cartonization strategy. Properly executed, it leads to cost savings, better space utilization, and a reduction in carbon emissions due to less unnecessary packaging and fewer trips necessary to move goods.

The importance of efficient cartonization in logistics

Efficient cartonization directly affects the bottom line of logistics operations. It enables companies to pack more effectively, reducing both shipping costs and the environmental impact of their operations. For businesses that depend heavily on logistics, such as those in the e-commerce sector, mastering cartonization techniques can be a significant competitive advantage.

Costs and benefits analysis of cartonization in a supply chain

Cost savings in terms of shipping and packaging

Adopting a more strategic approach to cartonization can lead to significant cost savings. Less material means lower expenses on packaging supplies, while optimized space utilization can reduce the number of trucks or containers needed to transport goods. Moreover, it can also translate into lower fuel costs and a reduction in greenhouse gas emissions.

Minimizing product damages during transportation

Cartonization also plays a crucial role in minimizing product damage during transportation. By ensuring that each product is securely packaged in an appropriately sized carton, the risk of damage from movement or compression is greatly reduced. This leads to higher customer satisfaction and lower return rates.

Case study of successful cartonization implementation in companies

Examining real-life applications of successful cartonization practices can offer valuable insights. Businesses who have leveraged these strategies often witness measurable improvements in their operational efficiency and profitability. It's not uncommon for companies to report a marked decrease in logistics-related expenses and improved delivery times post-implementation.

Future Trends in Cartonization

As businesses and technologies evolve, so do the methods of cartonization. The future of this field is likely to be shaped by sustainability demands and technological advancements that will push for further efficiencies and innovations.

Potential development and improvements for cartonization

Advancements in robotics and automation

The future of cartonization is expected to see an increased integration of robotics and automation. Robots equipped with AI can potentially handle the physical packing process, further reducing the need for human labor and increasing packing speed and precision.

Sustainability trends in packaging and cartonization

Sustainability trends are incentivizing companies to explore eco-friendly materials and practices in their cartonization strategies. This may include the use of biodegradable materials, recycling programs, and the development of reusable packaging that can withstand multiple shipments.

Challenges and opportunities

While the future is promising, there are challenges that must be tackled such as the balance between cost and sustainable practices, and the need for continuous investment in cutting-edge technologies. Nevertheless, the opportunities for improving efficiency, sustainability, and customer satisfaction make cartonization an exciting field to watch.

Throughout this article, the pivotal role of cartonization in supply chains has been underscored, from its definition and evolution to the technological advancements that have shaped its current state.

The future of cartonization, defined by its potential to contribute to more sustainable and efficient logistics, presents a landscape of opportunities marred only by the challenges of an ever-evolving industry. Packaged within these insights are the keywords of innovation and improvement, which will no doubt continue to drive the progress of cartonization strategies in supply chain management.

Frequently Asked Questions

What are the key benefits of relying on cartonization in supply chain processes?

Cartonization Enhances Efficiency

Supply chain experts strive for optimization. Cartonization represents a key method. It involves selecting the right carton before packing. This step, performed via specialized software, becomes critical. Businesses gain numerous benefits through cartonization.

Reduced Material Waste

Optimal carton selection minimizes material use. Fewer cartons and packing materials suffice. This approach directly reduces waste. Consequently, it supports sustainable practices.

Improved Space Utilization

Packing items in the right-sized cartons maximizes space. Both within cartons and during transport. Efficient space utilization decreases the number of shipments. It provides cost savings in logistics.

Cost Savings

Cartonization offers direct and indirect cost reductions. Using fewer materials cuts expenses. Optimizing truck loads saves on transportation costs. Furthermore, it reduces the labor required for packing.

Enhanced Product Protection

Accurate carton sizing improves product safety. Items fit snugly, reducing movement. This effort lowers the risk of damage during transit. Thus, it enhances customer satisfaction through intact deliveries.

Streamlined Order Fulfilment

Cartonization streamlines packing processes. Packers work with predefined carton sizes. This standardization expedites the packing process. Thus, it speeds up order fulfillment.

Better Customer Experience

Customers desire eco-friendly packaging. Cartonization leads to reduced packaging materials. The outcome is a more sustainable unpacking experience. Additionally, appropriate carton sizes ensure easy handling for customers.

Data Collection for Optimization

Cartonization software collects valuable data. This data reflects packing efficiency and trends. Businesses use this information for continuous improvement. It applies to packing strategies and supply chain optimization.

These benefits manifest in various supply chain aspects. Cartonization affects cost, efficiency, and sustainability. Through its implementation, companies gain a competitive advantage. They service customers better, with reliable and responsible deliveries.

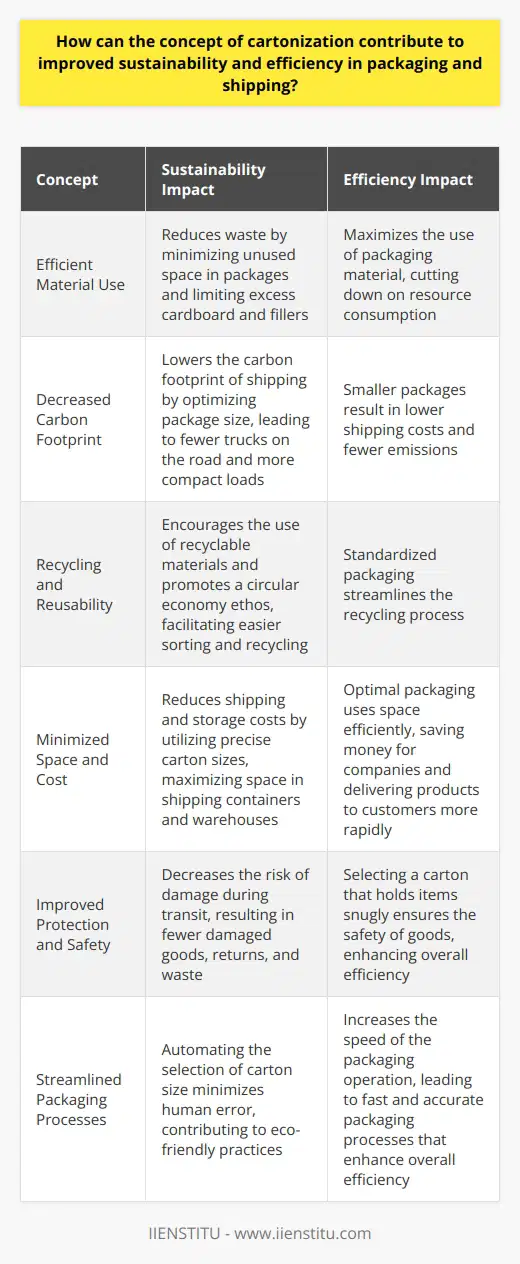

How can the concept of cartonization contribute to improved sustainability and efficiency in packaging and shipping?

Understanding Cartonization

Cartonization refers to the process of selecting the most appropriate carton for shipping a set of items. This concept leverages software and algorithms to determine the best box size. It ensures items fit perfectly for shipping. Cartonization aids in optimizing how items package for transport.

The Role of Cartonization in Sustainability

Efficient Material Use

Cartonization reduces waste. It does so by minimizing unused space in packages. It maximizes the use of packaging material. By doing so, it limits the excess cardboard and fillers needed. This efficiency in material use is crucial for sustainability. It cuts down on resource consumption.

Decreased Carbon Footprint

Smaller packages mean lower shipping costs. They also mean fewer emissions. By optimizing package size, cartonization can lower the carbon footprint of shipping. It leads to fewer trucks on the road. It also results in more compact loads. This efficiency is key to a greener supply chain.

Recycling and Reusability

Cartonization encourages the use of recyclable materials. It promotes a circular economy ethos. By carefully selecting the carton size, it facilitates recycling. Smaller, standardized packaging becomes easier to sort and recycle.

Cartonization Enhancing Efficiency

Minimized Space and Cost

Optimal packaging uses space efficiently. It reduces shipping and storage costs. By utilizing the precise carton size, cartonization helps to maximize space in shipping containers and warehouses. It saves money for companies. It also delivers products to customers more rapidly.

Improved Protection and Safety

Cartonization ensures the safety of goods. It selects a carton that holds the items snugly. This method decreases the risk of damage during transit. Fewer damaged goods translate to fewer returns and wastes. This protection is essential for both sustainability and efficiency.

Streamlined Packaging Processes

Automation speeds up the packaging process. Cartonization makes use of this by automating the selection of carton size. It increases the speed of the packaging operation. It also minimizes human error. Fast and accurate packaging operations enhance overall efficiency.

Cartonization plays a critical role in sustainable and efficient packaging and shipping practices. It minimizes waste, reduces emissions and advocates for recyclability. It also lowers costs, speeds up delivery, and secures item safety. By implementing cartonization, companies can take significant strides towards eco-friendly and streamlined logistics.

What determining factors affect the effectiveness of a cartonization strategy in optimizing storage and transportation costs?

Cartonization Strategy Effectiveness

Factors Determining Cartonization Efficiency

When optimizing cartonization strategies, many factors come into play. Some factors affect storage, while others influence transportation costs.

Product Dimensions and Weight

Product dimensions hold significant weight. They dictate the carton size required. This factor remains crucial for optimization. Heavy or bulky items need sturdy, larger cartons. These requirements alter space utilization and shipping costs.

Carton Variety

A diverse carton size inventory aids flexibility. It allows shippers to select the most fitting carton for each item. Too many varieties, however, can increase complexity. This surplus may lead to inefficiency and wasted space in both warehousing and transportation.

Packaging Material

The type of packaging material greatly impacts cartonization. Some materials offer strength without added weight. Others might be lightweight but less durable. The balance between protection and weight is key to optimizing cost.

Order Profiles

Different order profiles present unique challenges. Single-item orders versus multi-item orders require different strategies. Aligning your approach to common order configurations is vital.

Shipping Destinations

Long-distance shipping changes the equation. Durable packaging becomes more important. It must withstand longer transit times and multiple handling.

Automation Level

Automation level determines speed and consistency. Automated cartonization systems can select optimal carton sizes. They can adapt quickly to inventory changes. Manual systems fail to keep pace with these changes.

Inventory Diversity

High inventory diversity disrupts cartonization. A wide variety of product sizes complicates the selection of standard carton sizes. It may necessitate a more dynamic strategy.

Analytical Tools Used

Strong analytical tools enhance cartonization strategies. Data-driven decisions on carton size and packaging materials can outline a more efficient process.

Environmental Factors

Environmental factors push for sustainable practices. Recyclable materials and minimal packaging can reduce costs. They can also meet green logistics demands.

In conclusion, optimizing a cartonization strategy demands a multifaceted approach. Consideration of physical characteristics, automation, and analytical prowess form the cornerstone of a cost-effective cartonization strategy. Effectiveness hinges on how well one adapts to these determining factors. This balance optimizes both storage and transportation costs.