As someone who has worked in supply chain management for over a decade, I can attest to the transformative power of collaboration. When I first started my career, the concept of collaborative planning, forecasting, and replenishment (CPFR) was still relatively new. However, as I witnessed the benefits of CPFR firsthand, it became clear that this approach was the future of supply chain management.

I remember one particular instance where our company was facing significant challenges with inventory management. We were constantly running out of stock on key products, which led to frustrated customers and lost sales. It wasn't until we implemented CPFR that we were able to turn things around.

Introduction

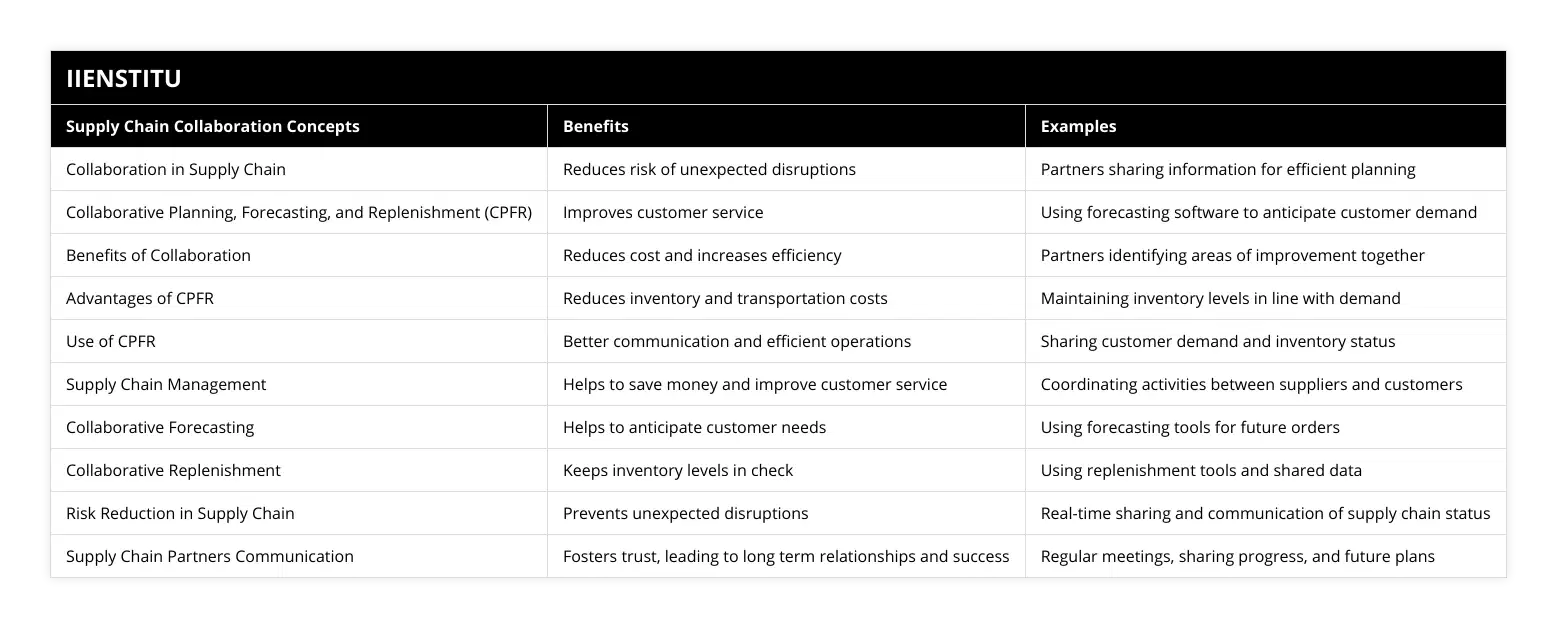

Benefits of Collaboration

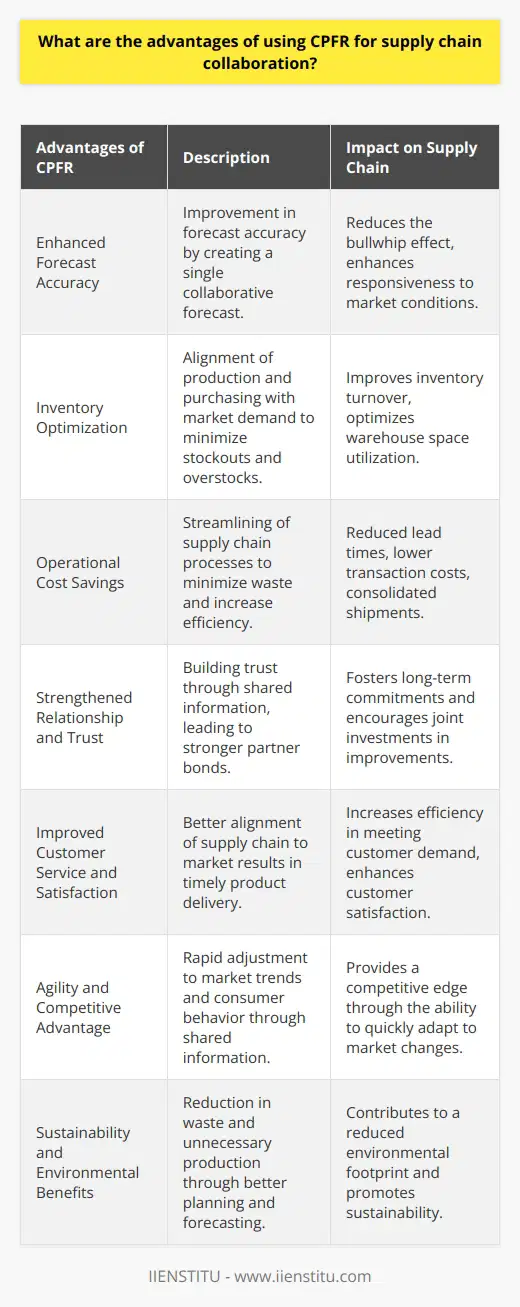

CPFR: Collaborative Planning, Forecasting, and Replenishment

Advantages of CPFR

Conclusion

By collaborating closely with our suppliers and sharing real-time data on inventory levels and customer demand, we were able to create a more accurate forecast and ensure that we always had the right products in stock. This not only improved our customer service levels but also helped us reduce our inventory carrying costs.

The benefits of CPFR extend far beyond just inventory management. When companies collaborate effectively, they can:

1- Reduce supply chain disruptions

2- Improve communication and coordination between partners

3- Increase efficiency and productivity

4- Enhance customer service levels

5- Drive cost savings and profitability

However, implementing CPFR is not without its challenges. It requires a significant investment in technology, as well as a willingness to share data and work closely with partners. Many companies struggle with the cultural shift required to embrace collaboration and break down silos between departments and organizations.

Despite these challenges, the advantages of collaboration in business are clear. In today's fast-paced, global economy, companies that can work together effectively are better positioned to succeed. As Johanna Rothman notes in her book Agile and Lean Program Management: Scaling Collaboration Across the Organization, "Collaboration is essential for any organization that wants to deliver value quickly and effectively" (Rothman, 2016, p. 23).

One of the key benefits of CPFR is its ability to improve inventory management. By sharing data on sales forecasts, production plans, and inventory levels, companies can ensure that they have the right products in the right place at the right time. This helps to reduce stockouts, overstocks, and obsolescence, which can have a significant impact on profitability.

According to a study by the Aberdeen Group, companies that have implemented CPFR have seen a 13% increase in inventory turns and a 5% increase in gross margin (Davis, 2018, p. 7). These improvements can have a significant impact on a company's bottom line and help to drive long-term success.

Collaboration is the key to unlocking Supply Chain Success with CPFR.

Another significant benefit of CPFR is its ability to enhance customer service levels. By collaborating closely with partners, companies can ensure that they are meeting customer needs and expectations. This can help to build stronger relationships with customers and drive loyalty and retention over time.

As Ritu Jain notes in her book Customer-Centric Supply Chains: Strategies for Improving Performance, "CPFR enables companies to respond quickly to changes in customer demand, which can help to improve customer satisfaction and drive revenue growth" (Jain, 2019, p. 112).

Of course, implementing CPFR is not without its challenges. One of the biggest obstacles is the need for effective communication and data sharing between partners. This requires a significant investment in technology and a willingness to work closely with suppliers and customers.

Another challenge is the need for cultural change within organizations. Many companies are used to working in silos and may resist the idea of sharing data and collaborating with partners. Overcoming these cultural barriers requires strong leadership and a commitment to change management.

Despite these challenges, the benefits of CPFR are clear. By collaborating effectively with partners, companies can drive significant improvements in inventory management, customer service, and overall supply chain performance.

As Mark Trowbridge notes in his book Supply Chain Disruption: Aligning Business Strategy and Supply Chain Tactics, "CPFR is not just a technology solution; it's a business strategy that requires a fundamental shift in the way companies think about their supply chain relationships" (Trowbridge, 2020, p. 89).

To be successful with CPFR, companies need to focus on developing strong partnerships with their suppliers and customers. This requires a willingness to share information, work together to solve problems, and continuously improve processes over time.

Effective CPFR strategies often involve the following key components:

Collaborative forecasting: Companies work together to develop accurate demand forecasts based on shared data and insights.

Joint planning: Partners collaborate to develop production and inventory plans that are aligned with customer needs and market trends.

Shared metrics: Companies agree on key performance indicators (KPIs) and share data to track progress and identify areas for improvement.

Continuous improvement: Partners work together to identify opportunities for process improvement and drive ongoing optimization of the supply chain.

By focusing on these key areas, companies can drive significant improvements in supply chain performance and build stronger, more resilient partnerships with their suppliers and customers.

In conclusion, collaborative planning in supply chain management is no longer a nice-to-have; it's a necessity for companies that want to compete in today's fast-paced, global marketplace. By embracing CPFR and working closely with partners to drive continuous improvement, companies can achieve significant benefits, including:

1- Reduced supply chain disruptions

2- Improved inventory management

3- Enhanced customer service levels

4- Increased efficiency and productivity

5- Cost savings and profitability

While implementing CPFR can be challenging, the benefits are clear. As companies continue to face increasing pressure to optimize their supply chains and drive growth, collaboration will only become more important. Those that embrace this approach and build strong partnerships with their suppliers and customers will be well-positioned for success in the years to come.

References:

Davis, D. (2018). The Power of CPFR: How Collaborative Planning, Forecasting, and Replenishment Can Transform Your Supply Chain. London: Kogan Page.

Jain, R. (2019). Customer-Centric Supply Chains: Strategies for Improving Performance. New York: Springer.

Rothman, J. (2016). Agile and Lean Program Management: Scaling Collaboration Across the Organization. New York: Addison-Wesley Professional.

Trowbridge, M. (2020). Supply Chain Disruption: Aligning Business Strategy and Supply Chain Tactics. Boston: Harvard Business Press.

Frequently Asked Questions

What are the benefits of collaborating for supply chain success?

Collaboration is essential for supply chain success in today’s increasingly complex and globalized business environment. Collaboration between supply chain partners allows for greater visibility, improved communication, and better decision-making. It is essential to understand the benefits of collaborating for supply chain success.

The first benefit of collaborating for supply chain success is increased visibility. Collaboration between supply chain partners enables greater visibility into each other’s operations, allowing organizations to understand their partners’ strengths and weaknesses better. As a result, organizations can better identify and address any potential problems in the supply chain, leading to improved efficiency and cost savings.

The second benefit of collaborating for supply chain success is improved communication. Collaboration between supply chain partners allows for a greater understanding of each other’s needs and strategies, leading to more effective internal and external communication. Organizations can better anticipate potential problems and respond more quickly and efficiently by having a more comprehensive understanding of the supply chain.

The third benefit of collaborating for supply chain success is better decision-making. By better understanding the supply chain, organizations can make better-informed decisions that are more aligned with the organization's overall objectives. This leads to improved efficiency, cost savings, and customer satisfaction.

In conclusion, collaboration is essential for supply chain success. By increasing visibility, improving communication, and enabling better decision-making, a collaboration between supply chain partners can improve efficiency, cost savings, and customer satisfaction. It is essential to understand the benefits of collaborating for supply chain success.

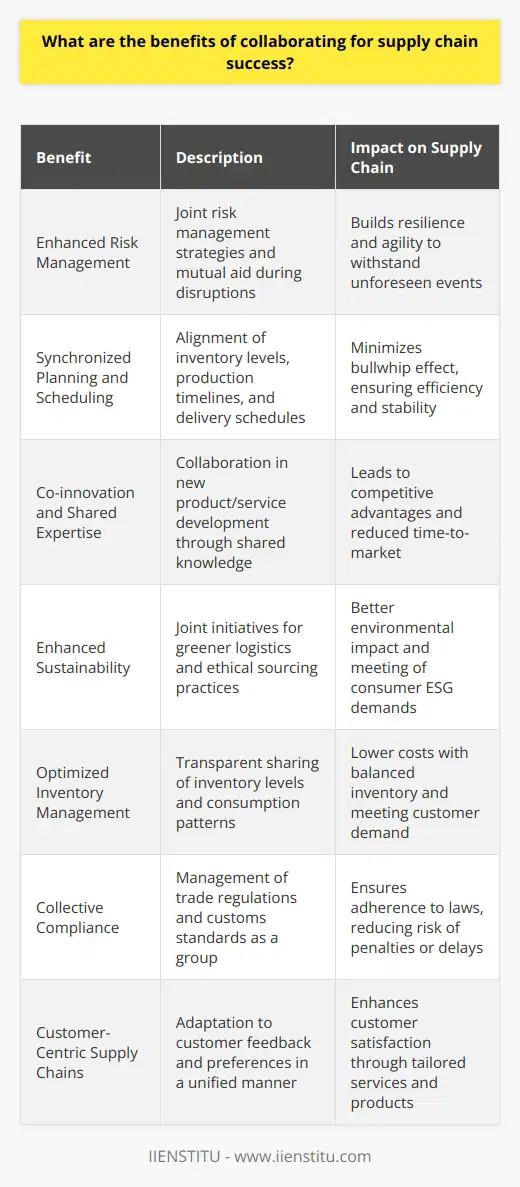

How does CPFR (Collaborative Planning, Forecasting and Replenishment) help to improve supply chain success?

In recent years, the importance of Collaborative Planning, Forecasting, and Replenishment (CPFR) in supply chain success has become increasingly apparent. CPFR is a process that allows businesses to coordinate the planning, forecasting, and replenishment of products by involving multiple partners in the supply chain. This process facilitates the flow of information and enables each partner to have visibility into their supply chain and make informed decisions.

This article will explore how CPFR helps improve supply chain success. We will discuss the benefits of CPFR, such as improved communication, accuracy, and collaboration. We will also discuss how CPFR can help reduce costs and increase customer satisfaction. Finally, we will discuss the challenges of implementing CPFR and recommend best practices for successful adoption.

One of the primary benefits of CPFR is improved communication. CPFR enables partners to share information more quickly and accurately, which leads to better visibility into the supply chain. Improved communication also leads to better collaboration between supply chain partners, allowing them to quickly resolve any issues and prevent them from becoming costly problems.

The accuracy of CPFR also helps to improve supply chain success. With CPFR, supply chain partners can more quickly and accurately forecast demand, allowing them to better plan for inventory and order fulfillment. This helps to reduce the risk of overstocking, understocking, and stock-outs, which can lead to lost sales and customer dissatisfaction. Additionally, CPFR can improve collaboration between partners, leading to better collaboration and more accurate demand forecasts.

Another benefit of CPFR is that it can help to reduce costs. CPFR allows partners to reduce lead times and inventory costs by improving the accuracy of their demand forecasts. Additionally, CPFR can reduce the need for manual data entry and the associated costs. Finally, CPFR can help to reduce the number of returns, which can help to reduce costs associated with returns processing.

Finally, CPFR can also help to increase customer satisfaction by improving communication and collaboration between supply chain partners. This can lead to faster delivery and better order fulfillment, resulting in higher customer satisfaction.

While CPFR can offer many benefits, successful implementation can be challenging. To ensure successful adoption, it is essential to ensure that all supply chain partners are on board and that data is accurate and up to date. Additionally, it is essential to ensure that all partners are comfortable with the process and that it is well-documented. Finally, it is essential to monitor and adjust the process as needed.

In conclusion, CPFR can help to improve supply chain success by enabling better communication, accuracy, and collaboration between partners. Additionally, CPFR can help to reduce costs and increase customer satisfaction. However, the successful implementation of CPFR requires careful planning and monitoring. With careful planning and monitoring, CPFR can be a valuable tool for improving supply chain success.

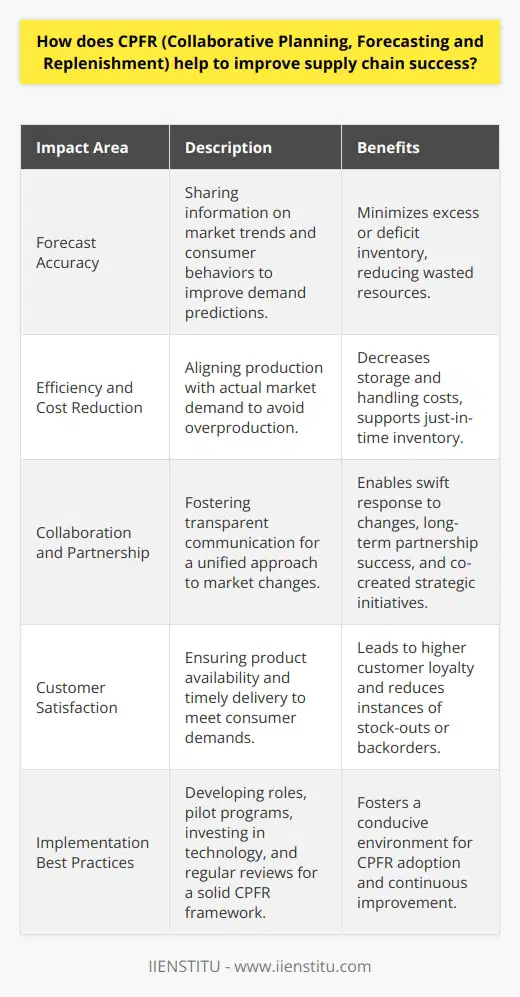

What are the advantages of using CPFR for supply chain collaboration?

Collaborative Planning, Forecasting, and Replenishment (CPFR) have become increasingly popular in supply chain collaborations between companies. CPFR is a business practice that enables companies to share information and collaborate to improve supply chain performance. It enables companies to plan, forecast, and replenish their respective inventory in a synchronized manner, leveraging the power of collaboration to optimize their inventory levels. This article will discuss the benefits of CPFR for supply chain collaboration.

One of the primary advantages of CPFR for supply chain collaboration is that it allows for improved inventory management. Through CPFR, companies can understand their inventory needs better, match them with sales forecasts, and adjust inventory levels accordingly. This helps to ensure that companies have the right amount of stock to meet customer demand while also avoiding overstocking, which can lead to costly inventory write-offs.

CPFR also helps to reduce costs associated with supply chain collaboration. By leveraging CPFR, companies can better coordinate their respective inventory and supply chain activities, allowing them to reduce the costs associated with managing their supply chain operations. This can result in cost savings regarding labor, transportation, and other related expenses.

In addition, CPFR helps to improve customer service. Companies can respond to customer demand more quickly and accurately by having a better understanding of their inventory needs. This helps to reduce customer wait times, leading to improved customer satisfaction.

Finally, CPFR helps to create a more efficient supply chain. By leveraging CPFR, companies can share data, develop better forecasts, and identify gaps or opportunities in their supply chain processes. This helps ensure that the supply chain runs as efficiently as possible, leading to improved performance overall.

In conclusion, CPFR has become a widely-adopted business practice for supply chain collaborations between companies. It enables companies to manage their inventory, reduce costs, improve customer service, and create a more efficient supply chain. As such, CPFR has become an invaluable tool for optimizing supply chain collaboration between companies.

What are the 4 phases of CPFR in supply chain collaboration?

CPFR Phases Overview

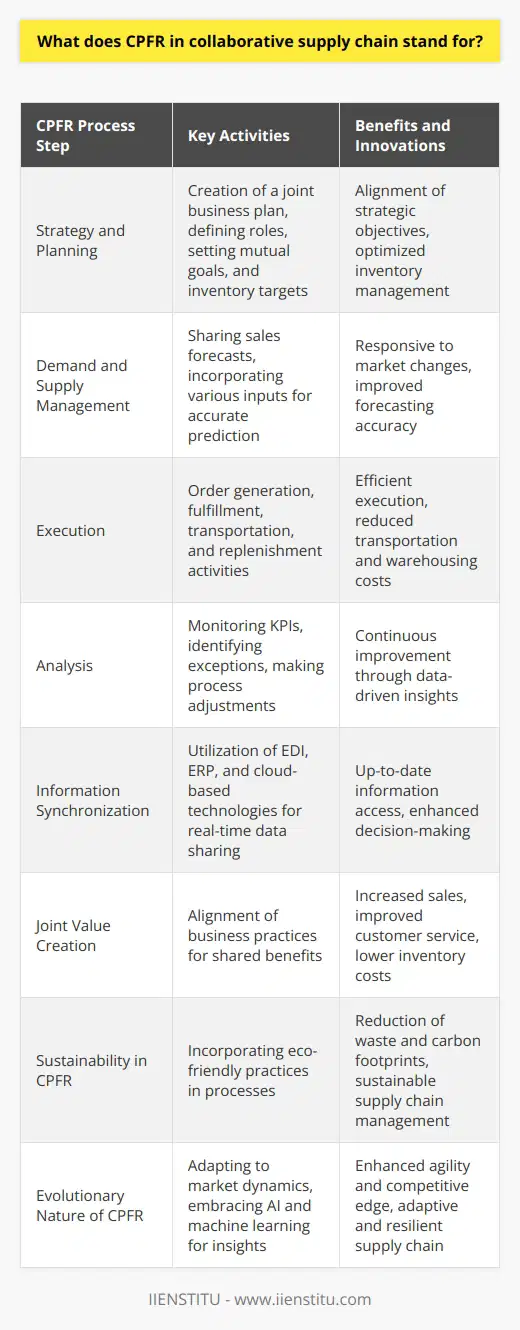

The Collaborative Planning, Forecasting, and Replenishment (CPFR) model is a strategic collaboration methodology aiming to harmonize processes and streamline the supply chain for mutual benefit. This approach is divided into four distinct phases: Strategy and Planning, Demand and Supply Management, Execution, and Analysis.

Strategy and Planning Phase

The first phase of CPFR is dedicated to establishing a mutual understanding of objectives and forming agreements. This involves identifying potential partners, defining the scope of collaboration, and negotiating terms that govern data sharing, confidentiality, and dispute resolution.

Demand and Supply Management Phase

The second phase deals with demand forecasting and supply planning. Both collaborating parties share crucial information about inventory levels, sales data, and promotional activities to create a single, unified demand forecast. This fosters alignment between supply chain partners and better anticipates fluctuations in product demand.

Execution Phase

During the execution phase, the agreed-upon forecast is transformed into specific orders and deliveries. This involves coordinating production, sourcing, and transportation activities to achieve optimal synchronization. Effective communication plays a central role in avoiding delays and ensuring a seamless flow of products from manufacturers to end-users.

Analysis Phase

Finally, the analysis phase focuses on monitoring the collaborative process to identify areas for improvement. Key performance indicators (KPIs) are defined and analyzed to measure the success of the collaboration. Regular performance reviews uncover inefficiencies, enable corrective actions, and foster continuous improvement.

In conclusion, the CPFR model promotes supply chain efficiency through well-structured collaboration, demand forecasting, and continuous evaluation. The four interconnected phases ensure that supply chain partners work together in harmony, maximizing their chances of achieving shared objectives and enhancing their competitiveness in the long run.

What does CPFR in collaborative supply chain stand for?

CPFR: Collaborative Planning, Forecasting, and Replenishment

In the context of collaborative supply chain management, CPFR stands for Collaborative Planning, Forecasting, and Replenishment. This business strategy involves the exchange of information and collaboration between suppliers, manufacturers, distributors, and retailers. The primary goal of CPFR is to enhance supply chain efficiency, increase visibility, and streamline processes across all participating companies.

Key Elements of CPFR

The implementation of CPFR consists of several essential components. These include the establishment of transparent communication channels, collaborative planning to predict demand and align production, and responsive replenishment strategies to maintain optimal inventory levels.

Communication Channels: Participants in the supply chain must establish transparent communication channels. These channels enable partners to share critical information, such as forecasts, sales data, and inventory levels. This data sharing promotes trust among partners and improves overall accuracy of information throughout the supply chain.

Collaborative Planning: To achieve effective collaboration, partners must employ a unified approach to demand planning. This process involves analyzing historical sales data, forecasting future demand, and adjusting production schedules accordingly. By collaborating on predicting and understanding market trends, supply chain partners can better anticipate customer needs and allocate resources more efficiently.

Demand Forecasting: Leveraging the insights gleaned from collaborative planning, partners can develop more accurate demand forecasts. These forecasts serve as crucial inputs for inventory management and replenishment strategies. Improved accuracy in demand forecasts ultimately results in reduced instances of stockouts and overstocking, enhancing customer satisfaction and supply chain efficiency.

Replenishment Strategies: A key component of CPFR lies in devising effective replenishment strategies. These strategies aim to keep inventory levels at their optimal state, reducing costs associated with stockouts or excess stock. By maintaining a balance between demand and supply, supply chain partners can better manage resources while improving customer service.

Benefits of CPFR Implementation

Implementing CPFR in a supply chain results in various benefits for all parties involved. First and foremost, the improved information sharing leads to a more accurate understanding of demand patterns. This knowledge allows companies to better coordinate production, reduce lead times, and minimize instances of stockouts, ultimately enhancing customer satisfaction. Additionally, the increased visibility and transparency throughout the supply chain foster strong relationships between partners, promoting an environment of trust and a proactive approach to problem-solving. In summary, CPFR is a valuable strategy for companies aiming to achieve more efficient, cohesive, and responsive supply chain operations.

What are the 4 primary activities in CPFR?

Introduction to CPFR Activities

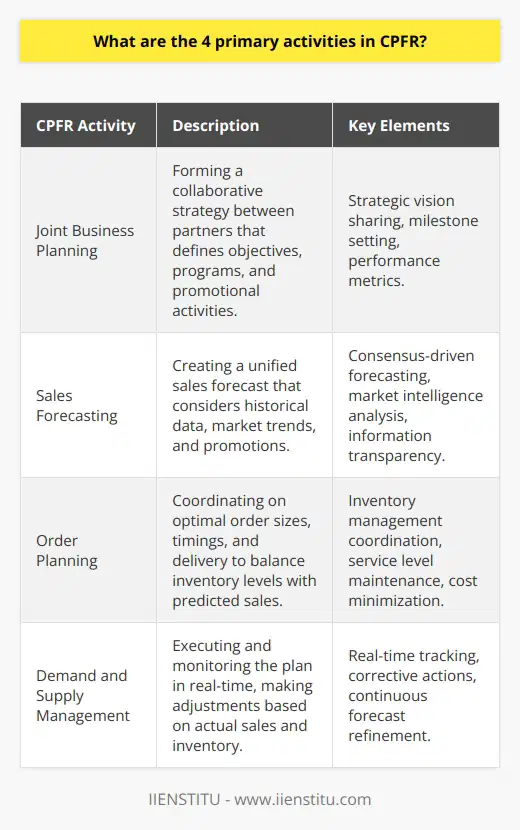

Collaborative Planning, Forecasting, and Replenishment (CPFR) is an essential practice within supply chain management, aimed at improving efficiency and collaboration between retailers and manufacturers. The four primary activities in CPFR include joint business planning, sales forecasting, order planning, and demand and supply management.

Joint Business Planning

Joint business planning is a collaborative process between trading partners, focused on establishing strategic goals, identifying mutual opportunities, and addressing potential challenges. This phase involves open communication and agreement on business objectives, metrics, and review cycles. Successful joint business planning leads to improved alignment between retailers and manufacturers, enabling maximized sales and minimized costs.

Sales Forecasting

In the sales forecasting phase, partners work together to develop a single, shared forecast based on sales data, market insights, and promotional plans. This collaborative forecast aims to reduce errors caused by individual assumptions or biases, enhancing the accuracy of demand predictions. By sharing information and conducting joint analyses, both parties can better understand the factors that impact demand and make more informed decisions regarding product offerings, inventory levels, and merchandising strategies.

Order Planning

During order planning, partners collaborate on inventory management, determining the ideal order quantities, delivery schedules, and stock levels that will ensure product availability while minimizing costs. The goal is to balance supply and demand by aligning production, logistics, and warehousing capabilities with the anticipated demand. Working together in this stage minimizes stockouts and excess inventory, ultimately leading to more efficient supply chain operations and optimized working capital.

Demand and Supply Management

Lastly, demand and supply management focuses on monitoring actual sales data, inventory levels, and order execution. This phase involves identifying potential discrepancies and taking corrective actions to address shortfalls or excesses. By managing the demand and supply fluctuations in real-time, partners can quickly adapt to varying market conditions, avoid disruptions, and improve customer satisfaction.

Conclusion

Overall, the four primary activities in CPFR foster an environment of cooperation and transparency among supply chain partners. By collaborating on strategic planning, forecasting, order management, and demand and supply tracking, retailers and manufacturers can better respond to customer needs, optimize inventory levels, and ultimately achieve a more efficient and effective supply chain.

What are the key factors for a successful CPFR implementation in supply chain operations?

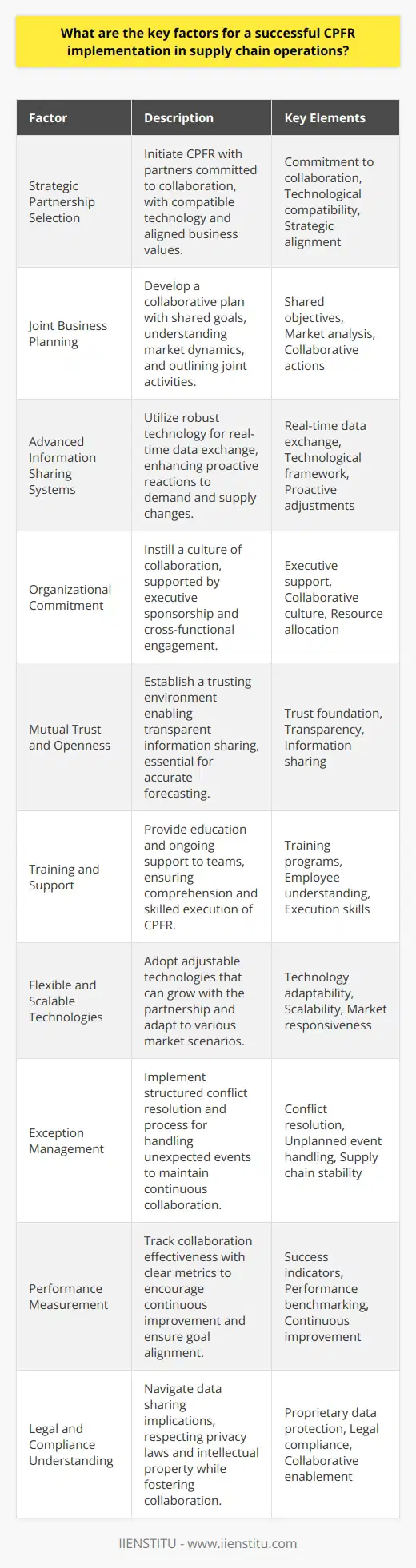

Key Factors for Successful CPFR Implementation

Collaborative Planning, Forecasting, and Replenishment (CPFR) is a strategic approach to enhance supply chain efficiency through joint planning and information sharing between trading partners. The success of CPFR initiatives in supply chain operations depends on several critical factors.

Effective Communication and Trust Building

One of the primary factors for successful CPFR implementation is effective communication and trust-building among stakeholders. It is crucial that participants share timely and accurate information to improve forecasting accuracy, decrease lead times, and reduce stockouts.

Technological Integration

Another critical factor in CPFR initiatives is the integration of technology for data exchange and analytics. Companies should deploy advanced technological platforms such as Electronic Data Interchange (EDI), Enterprise Resource Planning (ERP), and other software tools to facilitate seamless information sharing, improve visibility of supply chain activities, and enable more accurate demand predictions.

Identification of Metrics and Performance Indicators

Establishing clear performance metrics and key performance indicators (KPIs) is essential for the successful implementation of CPFR initiatives. By setting measurable goals and tracking progress regularly, organizations can identify areas for improvement, modify strategies, and continuously refine the process to optimize supply chain collaboration.

Alignment of Processes and Strategies

For an effective CPFR initiative, it is crucial to align supply chain processes and strategies across all participating organizations. This harmonization enables better cooperation, reduces the risk of miscommunication, and ensures that all partners are working towards common goals.

Training and Competency Development

Developing a skilled and competent workforce is essential for the successful implementation of CPFR initiatives. Providing proper training for employees to understand and implement CPFR processes ensures the seamless functioning of collaborative planning, forecasting, and replenishment activities.

Continuous Improvement and Adaptability

Finally, continuous improvement and adaptability are critical for the long-term success of CPFR initiatives. Companies must be open to change, adapt to new market conditions, and embrace new business models to maintain a competitive edge in the ever-evolving supply chain landscape.

How does CPFR contribute to enhancing overall supply chain visibility and synchronization?

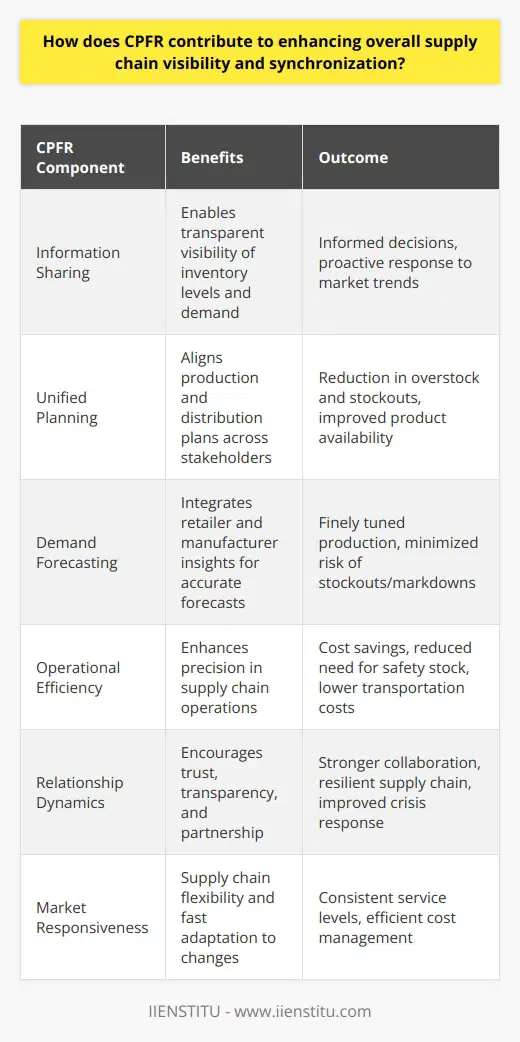

CPFR's Role in Increasing Supply Chain Visibility and Synchronization

The implementation of Collaborative Planning, Forecasting, and Replenishment (CPFR) extensively enhances overall supply chain visibility and synchronization. By systematically sharing critical information among various stakeholders, CPFR helps businesses to predict demand accurately, streamline inventory management, and improve operational efficiency.

Enhancing Information Exchange

CPFR plays a significant role in improving communication and data sharing, as it facilitates seamless information exchange among manufacturers, wholesalers, and retailers. The timely and reliable sharing of sales data, demand forecasts, and inventory levels allows for better anticipation of market needs, promoting more effective supply chain planning.

Aligning Supply Chain Processes

The synchronization feature of CPFR enables companies to align their supply chain processes, reducing discrepancies and minimizing stockouts or excess stock occurrences. By incorporating data from all levels of the supply chain, CPFR promotes a coordinated approach toward aligning production levels, delivery schedules, and warehouse replenishment activities. This level of coordination ensures an efficient and well-tuned supply chain.

Minimizing Uncertainties and Risks

CPFR significantly contributes to reducing uncertainties and risks associated with supply chain management. Through collaborative demand and supply forecasting, it provides stakeholders with better visibility into demand and allows businesses to proactively manage the supply chain. By collectively identifying and addressing potential risks, the overall performance and resilience of the supply chain are improved.

Optimizing Inventory Management

With better visibility and synchronization, the supply chain becomes more agile and responsive to fluctuations in demand. CPFR enables companies to monitor inventory levels in real-time, ensuring a balanced inventory at all times. This optimization of inventory management directly results in cost savings, increased customer satisfaction, and improved competitiveness.

Strengthening Supplier Relationships

CPFR fosters a collaborative environment throughout the supply chain, encouraging stakeholders to work together and address shared challenges. This enhanced collaboration strengthens supplier relationships and improves the overall performance of the supply chain. As all parties work together to meet the needs of the end customer, companies can create a more resilient, efficient, and harmonious supply chain.

In conclusion, CPFR offers numerous benefits to supply chain management by improving visibility and synchronization. By facilitating information exchange, aligning processes, minimizing uncertainties, optimizing inventory management, and strengthening supplier relationships, CPFR contributes to a more efficient and resilient supply chain that can better adapt to changing market demands.

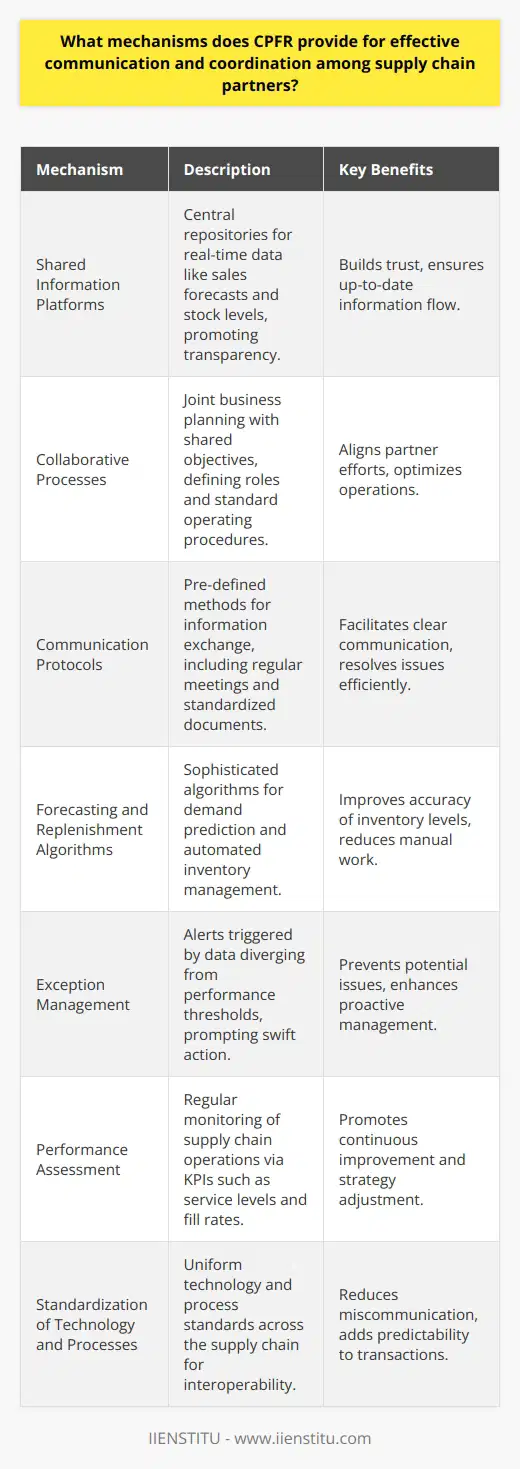

What mechanisms does CPFR provide for effective communication and coordination among supply chain partners?

Collaborative Planning, Forecasting, and Replenishment (CPFR)

CPFR is a business practice that enables supply chain partners to collaboratively plan and execute processes. It is a strategic approach to improving communication and coordination among supply chain partners to achieve better results in terms of replenishment, demand forecasting, and inventory management.

Enhanced Information Sharing

An essential aspect of CPFR is the sharing of information between supply chain partners. This entails exchanging data on sales figures, consumer trends, demand forecasts, and inventory levels. By making this information accessible, all involved partners gain better insights into market trends and consumer preferences, enabling them to make informed decisions and minimize errors in forecasting.

Collaborative Decision-Making Process

With the availability of shared information, CPFR facilitates a collaborative decision-making process among the partners. This involves harnessing the collective wisdom of all parties to create accurate demand forecasts and agree on replenishment plans. By engaging in regular communication, partners improve alignment, reduce uncertainty, and enhance overall supply chain performance.

Joint Performance Monitoring

CPFR provides a framework for joint performance monitoring, which entails tracking key performance indicators (KPIs) to ensure desired outcomes are achieved. By evaluating the progress of supply chain operations based on agreed-upon metrics, partners can identify areas for improvement and take corrective actions. This continuous monitoring ensures the supply chain remains agile and responsive to changes in market conditions.

Vendor-Managed Inventory (VMI)

One of the specific implementations of CPFR is Vendor-Managed Inventory (VMI), a practice in which the supplier takes the responsibility for managing the inventory levels of its customers. This mechanism enables suppliers to monitor stock levels, anticipate replenishment needs, and optimize order quantities, leading to significant improvements in inventory management and reduced stock-outs.

In conclusion, CPFR offers several mechanisms for effective communication and coordination among supply chain partners, including enhanced information sharing, collaborative decision-making processes, joint performance monitoring, and Vendor-Managed Inventory. By leveraging these mechanisms, supply chain partners can improve their operational efficiency, reduce costs, and adapt to changing market conditions.

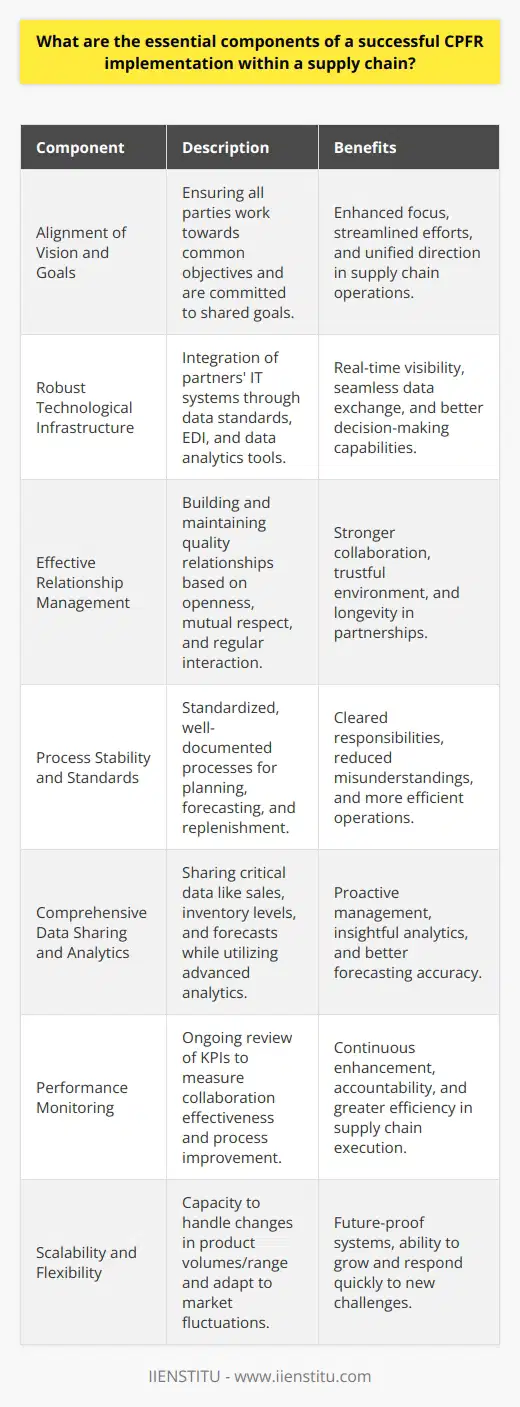

What are the essential components of a successful CPFR implementation within a supply chain?

Essential Components for CPFR Implementation

Successful Collaborative Planning, Forecasting, and Replenishment (CPFR) implementation within a supply chain hinges on several critical components. To optimize the benefits of CPFR, organizations must pay attention to key factors such as shared objectives, communication channels, data sharing, trust, and performance measurement.

Shared Objectives and Strategy

A mutual understanding of strategic goals and objectives among supply chain partners is vital for a successful CPFR implementation. By aligning their aims, all parties can work collectively to reduce costs, improve service levels, and ultimately enhance the overall performance of their supply chain.

Effective Communication Channels

Clear, open, and consistent communication is the backbone of any successful CPFR initiative. Efficient information exchange between stakeholders, such as sales, marketing, and logistics teams, effectively addresses fluctuations in consumer demand and ensures accurate forecasting and replenishment processes.

Data Sharing and Visibility

Real-time data sharing and visibility are crucial for CPFR implementation. This enhanced access to information enables supply chain partners to quickly respond to demand changes, identify potential risks or bottlenecks, and drive informed decision-making processes that ultimately eradicate inefficiencies in the supply chain.

Trust and Commitment

Establishing a foundation of trust and commitment among supply chain partners is essential. Trust fosters collaboration, encourages open dialogue, and nurtures strong relationships, all of which are necessary for the effective implementation of CPFR. Partners who trust one another are more likely to be open to mutually beneficial initiatives, ultimately driving the success of their collective endeavor.

Performance Measurement and Continuous Improvement

Finally, regular measurement of CPFR implementation is vital to evaluate progress, identify areas for improvement, and ensure the initiative is delivering tangible benefits. By implementing key performance indicators (KPIs) and continually monitoring their progress, organizations can refine their processes, adjust strategies when necessary, and move towards achieving a more streamlined and effective supply chain.

In conclusion, a successful CPFR implementation hinges on shared objectives and strategies, effective communication channels, real-time data sharing, trust among partners, and continuous measurement for improvement. By incorporating these essential components, organizations can derive maximum benefit from their CPFR initiatives, ultimately driving supply chain efficiency and effectiveness.

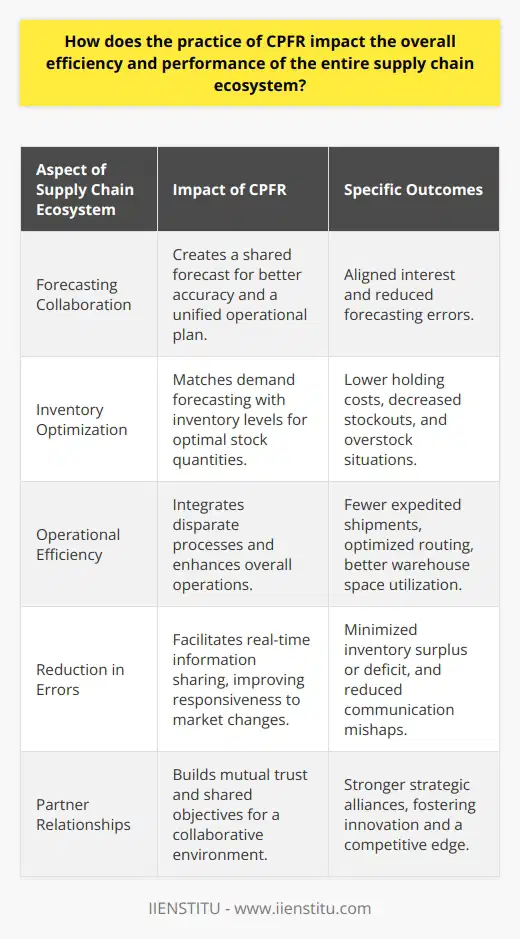

How does the practice of CPFR impact the overall efficiency and performance of the entire supply chain ecosystem?

Impact on Efficiency and Performance

The practice of Collaborative Planning, Forecasting, and Replenishment (CPFR) significantly impacts the overall efficiency and performance of the entire supply chain ecosystem. It promotes enhanced communication, transparency, and coordination among supply chain partners, which lead to several benefits.

Improved Forecast Accuracy

By collaboratively sharing information on demand forecasts, inventory planning and replenishment strategies, CPFR helps in reducing forecast errors. This improvement in forecast accuracy enables supply chain partners to optimize production, distribution, and inventory management processes, ultimately reducing stockouts and excess inventory.

Increased On-Time Deliveries

With improved forecast accuracy comes the ability to fulfill orders in a more timely manner. Since all partners are aligned in terms of demand and supply expectations, an effective CPFR process ensures the right products are manufactured and delivered at the right time. This results in increased on-time deliveries and reduced lead times, enhancing customer satisfaction.

Reduced Supply Chain Costs

CPFR contributes to cost reduction throughout the supply chain by streamlining planning and replenishment activities. Improved visibility and accuracy of data enable supply chain partners to reduce stock levels, minimize stock obsolescence, and optimize transportation and warehousing costs. These cost savings lead to increased profitability for all partners involved in the supply chain.

Enhanced Collaboration

In a CPFR model, open communication and information sharing between partners are prioritized. This fosters an environment of trust and cooperation, ultimately enabling better decision-making across the supply chain. With all parties working together to achieve common objectives, the entire supply chain ecosystem benefits from enhanced collaboration.

In conclusion, the practice of CPFR can significantly elevate the overall efficiency and performance of the supply chain ecosystem by improving forecast accuracy, increasing on-time deliveries, reducing supply chain costs, and promoting collaboration among partners. By adopting CPFR, supply chain stakeholders can enhance their ability to meet customers' needs while optimizing their operations for maximum effectiveness and profitability.

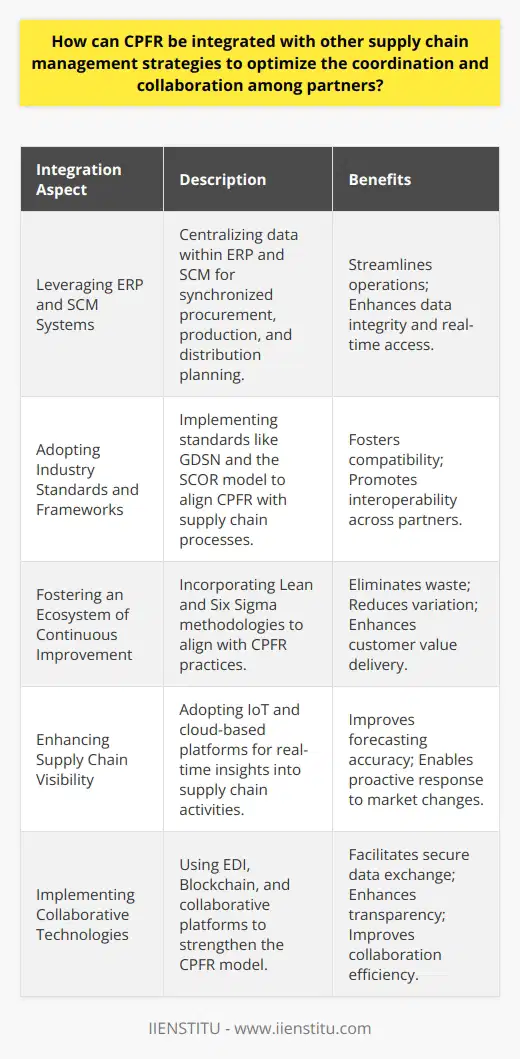

How can CPFR be integrated with other supply chain management strategies to optimize the coordination and collaboration among partners?

Integration of CPFR with Other Strategies

In order to optimize the coordination and collaboration among partners, it is crucial to integrate Collaborative Planning, Forecasting and Replenishment (CPFR) with other supply chain management strategies. This can be achieved by leveraging various integration approaches and technologies that work synergistically to enhance the overall supply chain effectiveness.

Utilizing a Centralized Information System

A centralized information system can be employed to share data and information seamlessly between the CPFR and other supply chain processes. This promotes transparency, real-time data exchange and ensures that all the partners are working with the same set of information. Consequently, decision-making and strategic planning become more coherent, reducing errors and inconsistencies across the supply chain.

Incorporating Advanced Analytics and Forecasting Tools

The integration of advanced analytics and forecasting tools allows for the synchronization of the CPFR with other supply chain strategies such as Demand-Driven Material Requirements Planning (DDMRP) and Vendor Managed Inventory (VMI). This enables all parties to anticipate fluctuations in consumer demands or capacity constraints proactively. As a result, the partners can adjust their production, distribution, and procurement plans dynamically to maintain an optimal inventory level and enhance cost-efficiency.

Standardizing Processes and Metrics

Establishing standardized processes and metrics throughout the supply chain ensures that all partners are following the same principles and guidelines during the integration of the CPFR strategy. This harmonization fosters operational efficiency, as it eliminates redundancies and friction points in communication and collaboration between partners. Moreover, shared performance indicators enable businesses to track their progress toward goals and continuously improve their supply chain management practices.

Promoting Collaborative Business Relationships

Establishing strong, trust-based relationships among supply chain partners is essential for the successful integration of the CPFR strategy. This is because CPFR inherently relies on information-sharing, collective decision-making, and mutual benefits. By nurturing a collaborative culture, businesses can foster an environment conducive to the sharing of knowledge, expertise, and best practices, which paves the way for continuous improvement and supply chain excellence.

In conclusion, integrating CPFR with other supply chain management strategies benefits businesses by enhancing coordination, collaboration, and ultimately, overall supply chain performance. By employing a centralized information system, incorporating advanced analytics and forecasting tools, standardizing processes and metrics, and promoting collaborative business relationships, organizations can achieve optimized supply chain operations and drive sustainable competitive advantage.

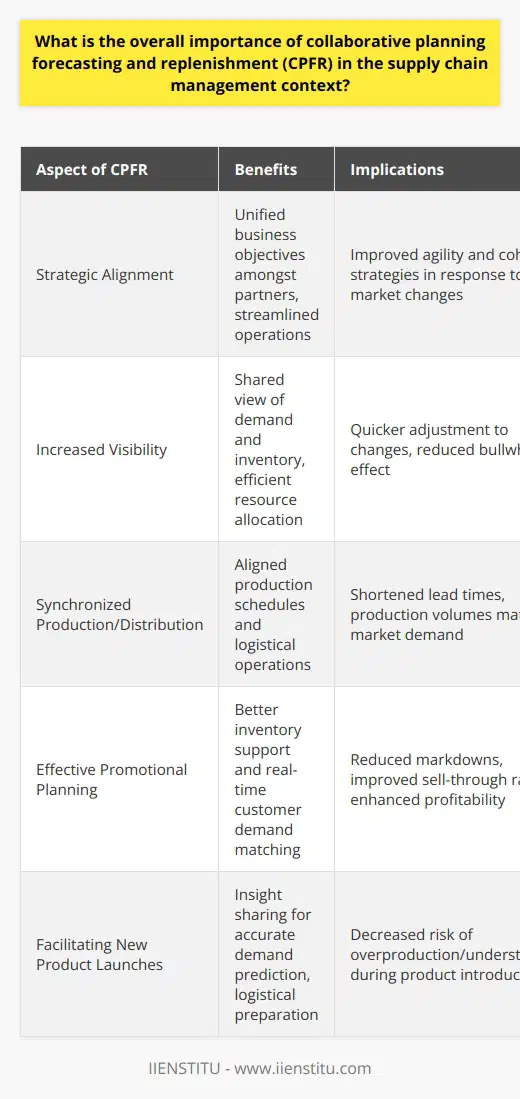

What is the overall importance of collaborative planning forecasting and replenishment (CPFR) in the supply chain management context?

Role of CPFR in Enhancing Supply Chain Performance

Collaborative planning, forecasting, and replenishment (CPFR) plays a vital role in streamlining operations within the supply chain management context. By adopting this approach, organizations can collectively design and execute strategies to optimize overall performance, maximize profit margins, and strengthen customer relationships. The collaborative nature of CPFR allows for a transparent and efficient data exchange between supply chain partners, building trust and fostering long-term partnerships.

Improved Forecast Accuracy

A key benefit of CPFR lies in enhancing forecast accuracy by leveraging the collective intelligence of supply chain partners. Accurate forecasting prevents stockouts and surplus inventory, contributing to better customer service levels. More precise predictions allow organizations to make informed decisions about procurement, production, and distribution schedules, reducing lead times and minimizing risks.

Optimized Inventory Management

Effective inventory management is paramount in supply chain management. By implementing CPFR, organizations can reduce the safety stock levels, capitalizing on the freed resources for other strategic initiatives. Additionally, the planned replenishments based on solid forecasts enable organizations to maintain optimal stock levels, striking a balance between inventory costs and customer expectations.

Reduction in Operating Costs

The integration of planning, forecasting, and replenishment processes eliminates redundancies and fosters efficient decision-making. Organizations can better allocate human and capital resources, resulting in lower operating costs. Furthermore, the improved forecast accuracy reduces the need for expediting shipments or holding excess inventory, eventually resulting in cost savings across the supply chain.

Enhanced Customer Satisfaction

By implementing CPFR strategies, organizations can efficiently adapt to fluctuating consumer demands. Timely and effective replenishment ensures the availability of products, directly impacting customer satisfaction. Additionally, the accurate forecasts empower organizations to plan promotions and new product introductions strategically, further enhancing the customer experience.

In conclusion, CPFR presents numerous advantages in the supply chain management context. It significantly contributes to better forecast accuracy, optimized inventory management, reduced operating costs, and enhanced customer satisfaction. Moreover, the collaborative nature of CPFR fosters trust and builds durable partnerships, ultimately improving the overall resilience and competitiveness of the supply chain.

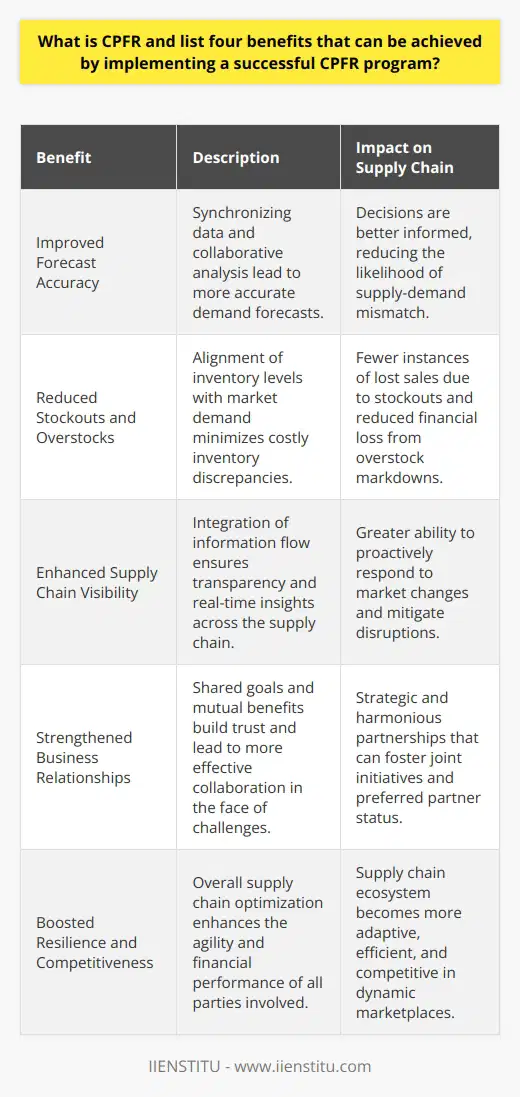

What is CPFR and list four benefits that can be achieved by implementing a successful CPFR program?

Defining CPFR

Collaborative Planning, Forecasting, and Replenishment (CPFR) is a supply chain management approach that facilitates collaboration among multiple stakeholders, including suppliers, manufacturers, and retailers. The goal is to improve demand forecasting, inventory management, and order fulfilment processes, resulting in enhanced efficiency and profitability for all the parties involved.

Benefit 1: Improved Forecast Accuracy

One of the primary benefits of a successful CPFR program is the enhancement of forecast accuracy. By sharing information and working together, supply chain partners can make more informed predictions about future demand patterns, resulting in better decision-making and reduced fluctuations in inventory levels.

Benefit 2: Reduced Stockouts and Overstocks

A well-implemented CPFR program helps in minimizing stockouts and overstocks by allowing all parties to collectively monitor and adjust inventory levels based on real-time demand information. This prevents costly situations where products are either unavailable for eager customers or overstocked, leading to wasted resources and potential markdowns.

Benefit 3: Enhanced Supply Chain Visibility

CPFR promotes greater supply chain visibility through its collaborative nature. By sharing information on sales, inventory, and production, stakeholders develop a more comprehensive understanding of their supply chain status. This increased visibility allows for better decision-making and improved responsiveness to demand fluctuations, ultimately resulting in higher customer satisfaction.

Benefit 4: Strengthened Business Relationships

Lastly, CPFR fosters stronger business relationships among suppliers, manufacturers, and retailers by creating a collaborative environment. Through open communication, parties develop trust and establish long-lasting, mutually beneficial relationships. This collaborative mindset can extend beyond supply chain management, leading to the potential for new partnerships, joint ventures, or other cooperative business initiatives.

In conclusion, implementing a successful CPFR program can offer an array of benefits, including improved forecast accuracy, reduction of stockouts and overstocks, increased supply chain visibility, and strengthened business relationships. By leveraging this strategy, companies can achieve greater efficiencies, enhance profitability, and foster better relationships among supply chain partners.

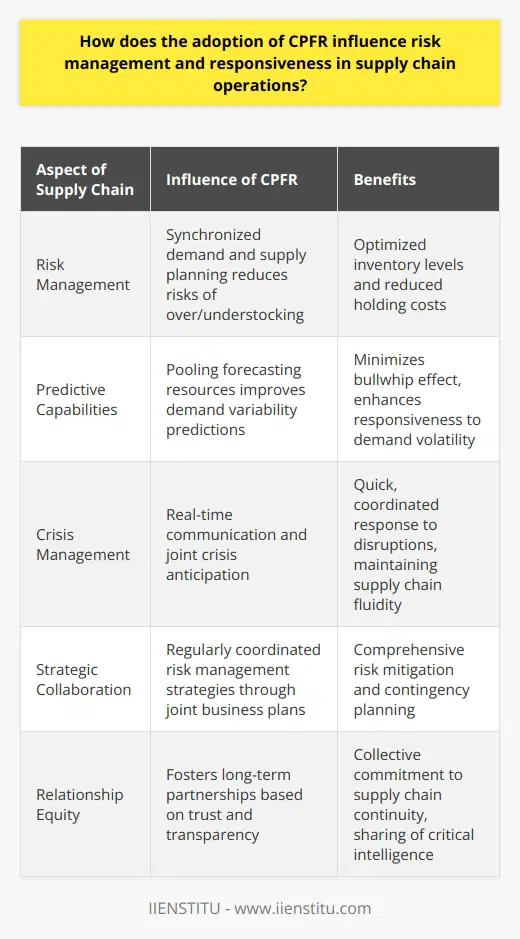

How does the adoption of CPFR influence risk management and responsiveness in supply chain operations?

Risk Reduction through CPFR Adoption

The adoption of Collaborative Planning, Forecasting, and Replenishment (CPFR) significantly influences risk management and responsiveness within supply chain operations. CPFR facilitates enhanced collaboration and visibility among supply chain stakeholders, leading to improved demand and supply planning. By sharing the forecasting and replenishment data, supply chain partners can effectively reduce inventory-related risks, such as stock-outs or excess inventory, enhancing the overall efficiency of the supply chain.

Increased Agility and Responsiveness

One notable impact of CPFR on supply chains is the increased agility and responsiveness. By enabling the real-time exchange of information among trading partners, businesses can quickly adjust production and distribution plans in response to fluctuating market conditions. Better communication and decision-making contribute to minimized lead times and expedited responses to shifting demand patterns. As a result, supply chain participants are better equipped to address potential disruptions and respond to customer needs promptly.

Improved Adaptability to Uncertainty

Another benefit of adopting CPFR is the adaptability it provides to external uncertainties like economic fluctuations, geopolitical instability, or natural disasters. Collaborative networks promote the development of contingencies and alternative strategies to cope with unexpected events. Through data sharing, organizations can conduct risk assessments and develop preventive measures to mitigate adverse impacts on their supply chains. Consequently, CPFR helps build resilient and adaptable supply chains that can withstand varying levels of risk and volatility.

Strengthened Supplier Relationships

CPFR also fosters stronger relationships among supply chain partners by establishing mutual trust, understanding, and commitment to joint objectives. Such robust relationships serve as a foundation for improved risk-sharing mechanisms, leading to better risk mitigation strategies. Supply chain partners work together in addressing potential issues and allocating resources to tackle potential threats. By collaborating effectively, they create a more robust and risk-resilient supply chain network.

In conclusion, the adoption of CPFR enhances risk management and responsiveness in supply chain operations through better collaboration and information exchange, increased agility, improved adaptability to external uncertainties, and strengthened supplier relationships. These factors contribute to the development of resilient supply chain networks capable of tackling risks, uncertainties, and disruptions while ensuring efficient and timely delivery of products to end customers.

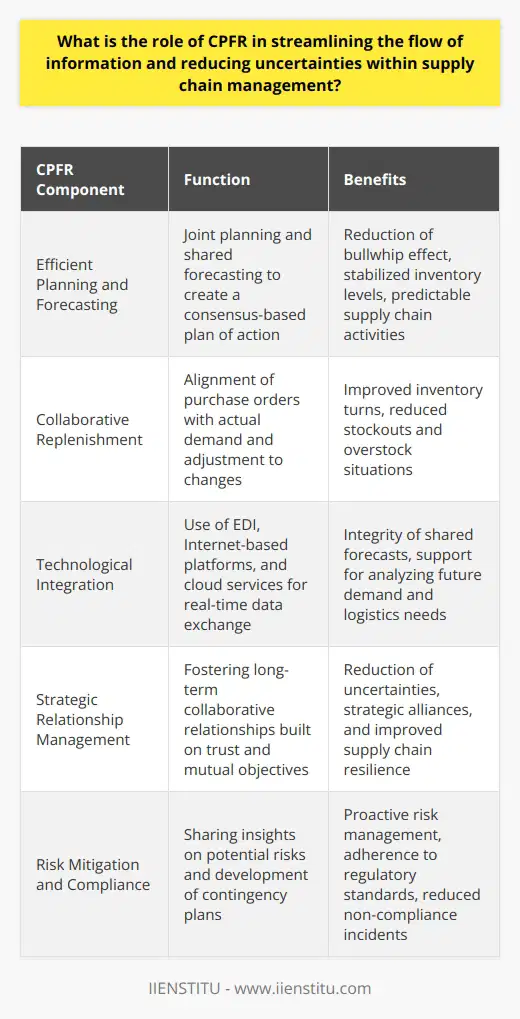

What is the role of CPFR in streamlining the flow of information and reducing uncertainties within supply chain management?

CPFR's Impact on Information Flow and Uncertainty Reduction

The Collaborative Planning, Forecasting, and Replenishment (CPFR) model serves a significant role in streamlining the flow of information and reducing uncertainties within supply chain management. By fostering collaborative relationships between partners in the supply chain, CPFR aims to enhance communication, transparency, and data sharing.

Improved Communication and Coordination

One of the primary roles of CPFR is promoting open communication and coordination among supply chain members. Through sharing real-time sales and inventory data, demand forecasts, and production plans, organizations can better align their operations and rapidly respond to changing market conditions. The synchronization of information enables better decision-making, resulting in improved efficiency and reduced lead times in the supply chain.

Increased Transparency

In addition to enhancing communication, CPFR contributes to increased transparency by creating a shared view of the supply chain network. This visibility allows all involved parties to easily identify potential bottlenecks, capacity constraints, and other disruptions in the supply chain. Consequently, companies can take proactive measures to manage risks and mitigate the impact of uncertainties, ensuring smooth and uninterrupted operations.

Data Sharing and Analysis

As a collaborative approach, CPFR encourages data sharing and analysis among partners, enabling enhanced understanding of customer behavior and market trends. This shared knowledge base allows organizations to better forecast demand, reduce stockouts and overstocks, and fine-tune their operations to maintain optimal inventory levels. The joint use of predictive analytics drives continuous improvement and the adoption of best practices that minimize uncertainties within the supply chain.

Conclusion

In summary, the CPFR model plays a vital role in streamlining the flow of information and reducing uncertainties within supply chain management. By fostering collaboration, improving communication, promoting transparency, and encouraging data sharing, CPFR enables organizations to enhance their overall operational efficiency and respond to rapidly evolving market conditions.

How can applying CPFR principles lead to more accurate demand forecasting and improved inventory management?

**Introduction to CPFR**

Collaborative Planning, Forecasting, and Replenishment (CPFR) is a supply chain management strategy aimed at improving the efficiency of inventory management and demand forecasting. By implementing CPFR, organizations can experience better communication and coordination among all stakeholders involved in the supply chain, resulting in enhanced business performance.

**Accurate Demand Forecasting through CPFR**

CPFR enables more accurate demand forecasting by fostering collaboration among suppliers, retailers, and other supply chain partners. Stakeholders share their demand forecasts and inventory plans to create a consensus forecast based on broader market insights. This joint effort reduces the likelihood of information discrepancies and the bullwhip effect, leading to improved demand predictability. In turn, accurate demand forecasts facilitate better decision-making regarding production, distribution, and inventory management.

**Optimizing Inventory Management with CPFR**

Effective inventory management is crucial for maintaining the balance between stocking too much, which leads to increased costs, and stocking too little, resulting in stockouts and lost sales. CPFR's collaborative approach enables organizations to optimize inventory levels across the supply chain. By sharing information on customer demand, sales promotions, and seasonal trends, retailers and suppliers can better synchronize their production and inventory management plans. Consequently, this collaboration minimizes stock discrepancies, inventory holding costs, and the risk of stockouts.

**Streamlining Operations and Reducing Costs**

In addition to enhancing demand forecasting and inventory management, CPFR supports overall business performance improvement by streamlining supply chain processes, promoting operational efficiency, and reducing costs. By fostering communication and alignment of supply chain activities, CPFR minimizes potential conflicts between supply chain partners and encourages faster resolution of any issues that may arise. This improved collaboration can reduce lead times, facilitate better resource utilization, and minimize waste, ultimately leading to significant cost savings.

**Conclusion: CPFR as a Key Enabler for Supply Chain Success**

In conclusion, applying CPFR principles can significantly improve demand forecasting accuracy and inventory management by promoting collaboration among supply chain partners. This joint effort encourages the creation of consensus forecasts, optimized inventory levels, and streamlined operations, which ultimately leads to reduced costs and enhanced business performance. As customer preferences and market conditions continue to evolve rapidly, adopting efficient supply chain management strategies like CPFR will be increasingly important for organizations to maintain a competitive edge.

What are the critical success factors and potential challenges when implementing a CPFR program in a complex supply chain network?

Critical Success Factors in CPFR Implementation

A critical success factor (CSF) in implementing a Collaborative Planning, Forecasting, and Replenishment (CPFR) program is establishing mutual trust and commitment among supply chain partners. Without effective collaboration and transparent communication, the risk of disjointed operations and unmet objectives significantly increases. Additionally, supply chain partners must possess adequate technological infrastructure and competence to support the seamless exchange and analysis of data in real-time. Effective change management is also vital, ensuring a smooth transition and buy-in from all personnel in adopting the new program.

Challenges in Implementing a CPFR Program

Conflict Resolution Mechanisms

One of the potential challenges in implementing a CPFR program is the absence of well-defined conflict resolution mechanisms among supply chain partners. Disagreements on forecasted demands or replenishment plans could lead to disruptions in the supply chain, negatively affecting overall performance and customer satisfaction. Establishing fair and transparent conflict resolution processes is crucial for maintaining trust and encouraging open communication among all parties.

Data Accuracy and Integrity

Ensuring data accuracy and integrity presents another challenge in implementing a CPFR program. The program's success depends on the quality of information shared among supply chain partners. Inaccurate or inconsistent data can result in ineffective planning, forecasting, and replenishment processes, ultimately compromising the supply chain's responsiveness and efficiency. Establishing robust data validation procedures and systems to monitor and maintain data quality is essential for the success of a CPFR program.

Organizational Culture and Resistance to Change

Implementing a CPFR program may be met with resistance from some employees due to the change's organizational culture and practices. Staff members may be apprehensive about their roles and responsibilities, or even their job security, in the new setup. Providing adequate training and support, communicating the benefits of CPFR, and involving employees in the program's implementation can help mitigate these concerns and ensure a smoother adoption process.

Scalability and Flexibility

Finally, scalability and flexibility may prove challenging when implementing a CPFR program in complex supply chain networks. As the number of partners increases and the network becomes more intricate, maintaining the program's efficiency and effectiveness can be daunting. Adapting the CPFR model to account for varying levels of complexity and adapting to changes in the supply chain environment requires regular reassessment and continuous improvement.

In conclusion, addressing these critical success factors and overcoming potential challenges in implementing a CPFR program is essential for ensuring the supply chain's overall success in a complex network. With mutual trust, commitment, technological capabilities, and effective change management in place, businesses can capitalize on the benefits of the CPFR model, ultimately enhancing their competitive edge in the market.