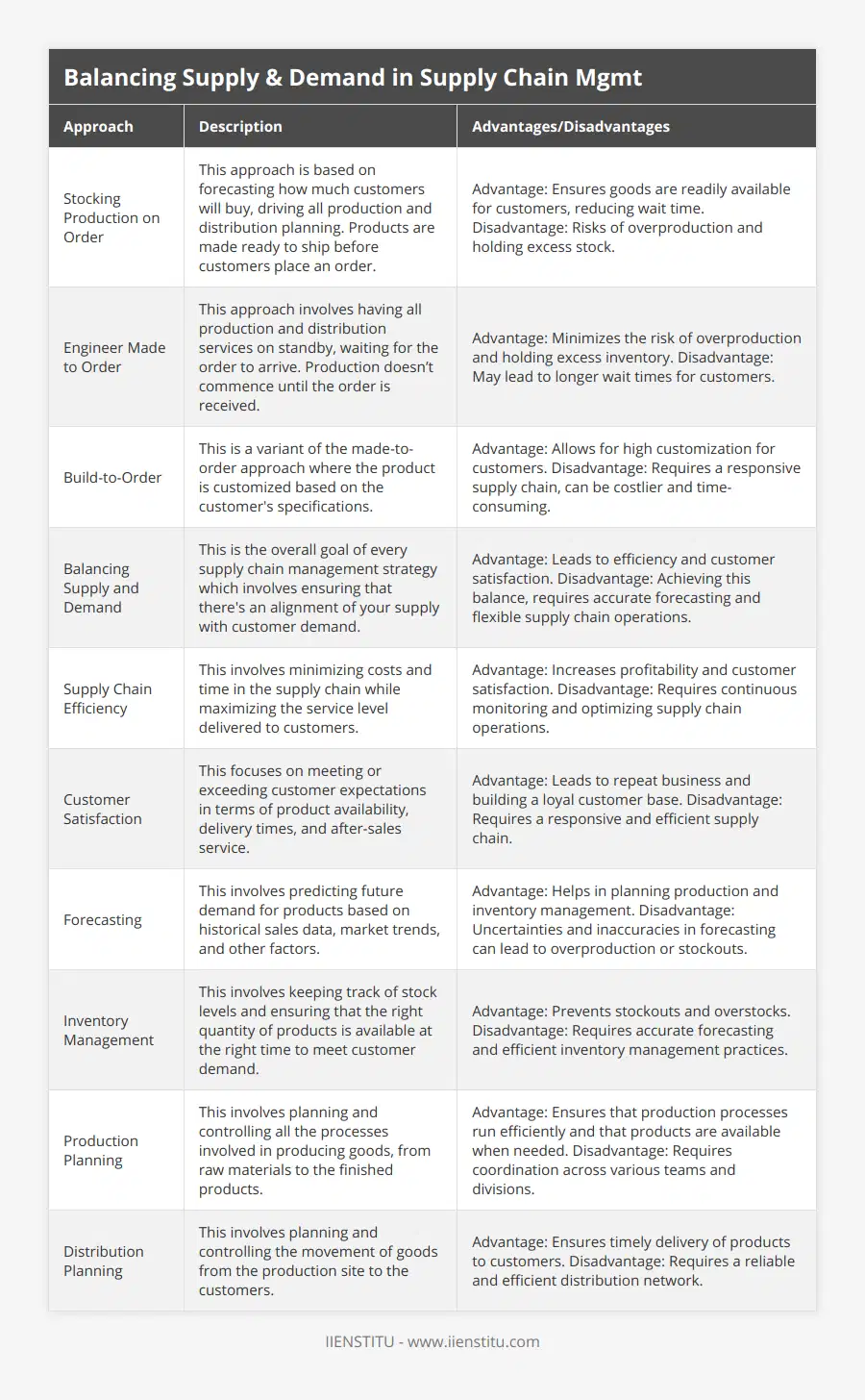

This article explains the three main approaches to balancing supply and demand in a supply chain plan. These approaches are stocking production on order, engineering made-to-order, and build-to-order. Each approach has its advantages and disadvantages and should be carefully considered when deciding which approach is best for a particular supply chain. Balancing supply and demand is essential to any supply chain plan and should be carefully considered.

Introduction

What is Balancing Supply and Demand?

Stocking Production on Order

Engineer Made to Order

Conclusion

Introduction: Balancing supply and demand is a fundamental question at the heart of every supply chain plan. It is essential to ensure that the correct goods are available to meet customer demand. This article will explore the three main approaches to balancing supply and demand, including stocking production on order, engineering made-to-order, and build-to-order.

What is Balancing Supply and Demand?

Balancing supply and demand ensures that the right amount of goods is available to meet customer demand. This process is critical to ensuring that customers are satisfied and that the supply chain runs efficiently.

Stocking Production on Order

The make-to-stock approach is based on forecasting how much customers will buy. This forecast drives all production and distribution planning. Before customers place an order, the work is done, and the products are ready to ship. This approach is sometimes called a push system, as products are pushed to customers even if they haven't ordered yet.

Engineer Made to Order

The build-to-order approach is based on having all production and distribution services on standby, waiting for the order to arrive. For this, production is done until the order is received. This approach is an example of a pull system, as an order needs to pull products through the supply chain.

Conclusion: Balancing supply and demand is critical to any supply chain plan. There are three main approaches to balancing supply and demand: stocking production on order, engineering made-to-order, and build-to-order. Each approach has its advantages and disadvantages and should be carefully considered when deciding which approach is best for a particular supply chain.

Successful supply chain management is the art of balancing supply and demand to ensure maximum efficiency.

This article delves into the essential aspect of balancing supply and demand in supply chain management, a topic vital to supply chain management classes, revealing three main approaches: stocking production on order, engineering made-to-order, and build-to-order, with each having its own strengths and weaknesses. Aimed at enabling maximum efficiency and customer satisfaction, these approaches represent the core of sound supply chain planning. Therefore, understanding and choosing the appropriate strategy based on individual supply chain characteristics are of paramount importance presented in

Frequently Asked Questions

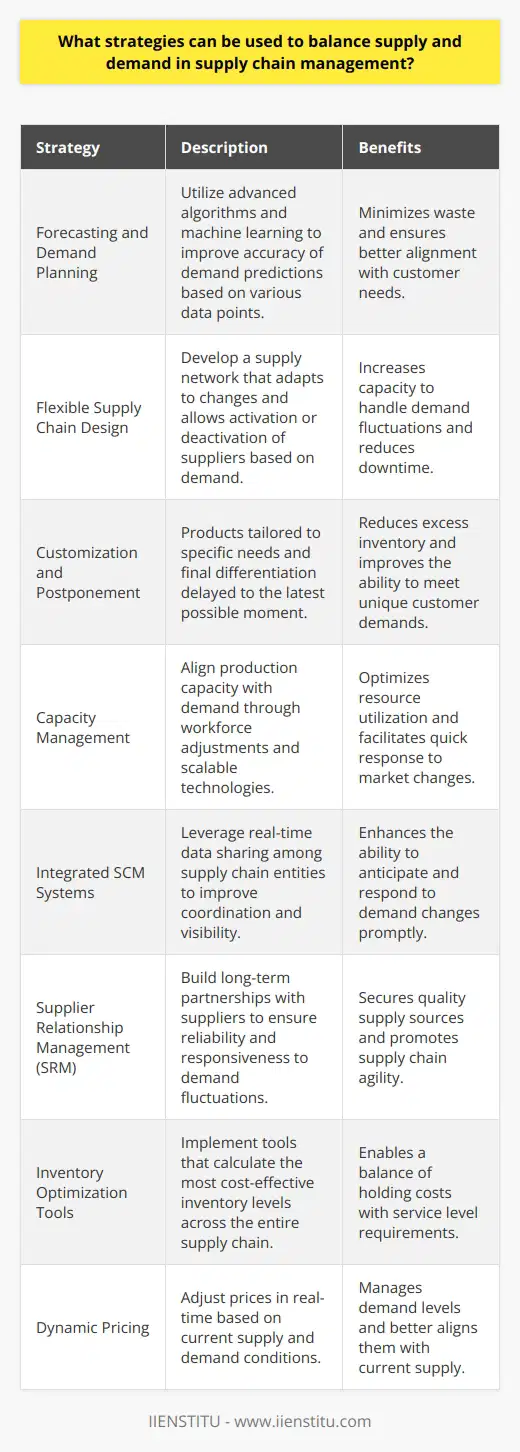

What strategies can be used to balance supply and demand in supply chain management?

Supply chain management (SCM) manages and coordinates the flow of goods, services, and information from the point of origin to the point of consumption. SCM is an integral part of any business and is essential for ensuring that products and services reach their intended customers in a timely, cost-efficient manner. Balancing supply and demand is one of the most critical aspects of effective SCM. In this article, we will discuss strategies that can be used to balance supply and demand in SCM.

One strategy for balancing supply and demand is to optimize inventory levels. This involves determining the optimal inventory to maintain to meet customer demands. This can be done through forecasting techniques such as trend, regression, and time-series analysis. These techniques can help identify customer demand patterns, enabling businesses to adjust their inventory levels accordingly.

Another strategy for balancing supply and demand is to use just-in-time (JIT) inventory management. JIT inventory management only replenishes inventory when needed rather than keeping large amounts of inventory in stock. This allows businesses to reduce inventory costs while ensuring that they have enough products to meet customer demand.

Thirdly, businesses can use supply chain collaboration to balance supply and demand. Supply chain collaboration involves working closely with suppliers, distributors, and other stakeholders in the supply chain to ensure that all stakeholders have a shared understanding of customer demand and can work together to meet it. This can help reduce the costs associated with managing the supply chain and provide more accurate and timely information about customer demand.

Finally, businesses can use technology to balance supply and demand. Technology can automate and streamline many processes involved in SCM, including inventory management, order fulfillment, and distribution. This can help reduce costs associated with managing the supply chain and provide more accurate information about customer demand.

In conclusion, several strategies can be used to balance supply and demand in SCM. These strategies include optimizing inventory levels, using just-in-time inventory management, collaborating with supply chain partners, and leveraging technology. By using these strategies, businesses can ensure that they have enough products to meet customer demand while minimizing the costs associated with managing the supply chain.

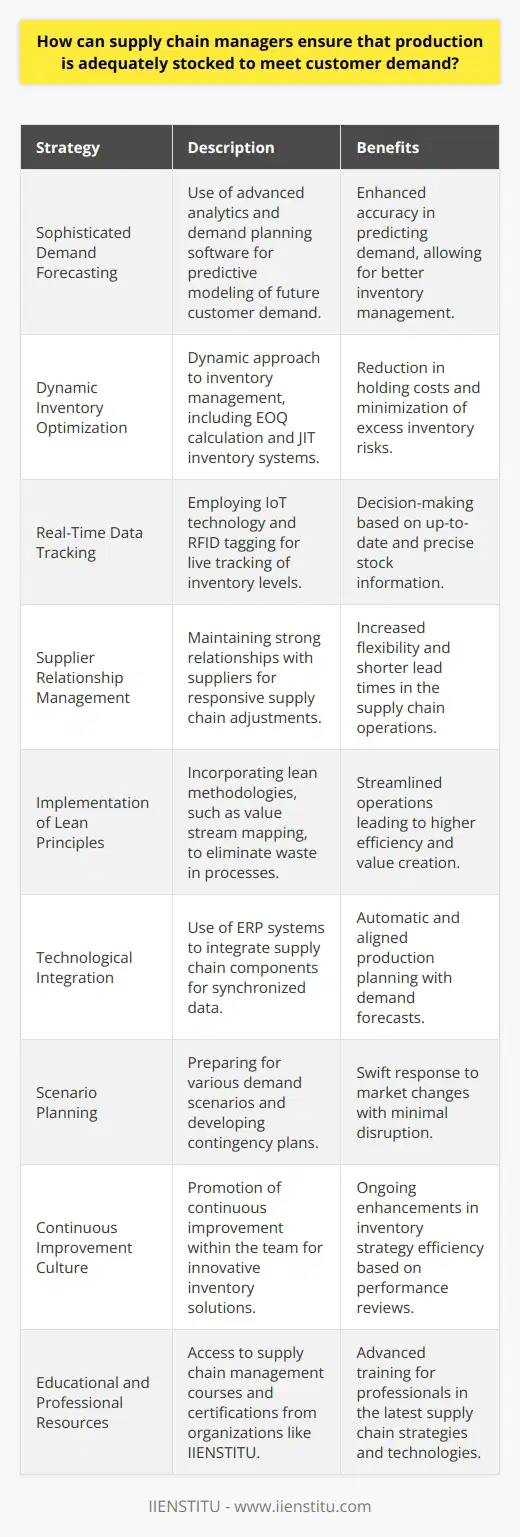

How can supply chain managers ensure that production is adequately stocked to meet customer demand?

Supply chain management is integral to any business, ensuring that production meets customer demands efficiently and effectively. Supply chain managers should employ various strategies and tools to ensure that production is adequately stocked to meet customer demand.

One of the most critical aspects of supply chain management is forecasting. Forecasting involves predicting customer demand and using that information to plan production and inventory levels. Forecasting can be done manually, using historical data and intuition, or using sophisticated software programs that employ algorithms to predict future demand. Forecasting can help supply chain managers identify potential risk areas and adjust production levels accordingly.

In addition to forecasting, supply chain managers should also focus on inventory optimization. This involves ensuring that inventory levels are sufficient to meet customer demand while avoiding overstocking, which can lead to inventory costs and waste. Inventory optimization can be done using various techniques such as inventory control, tracking, and planning.

Finally, supply chain managers should also employ lean techniques to ensure that production is adequately stocked to meet customer demand. Lean techniques focus on eliminating waste and improving efficiency by streamlining processes and workflow. Lean techniques can help reduce costs and improve customer service by ensuring that production is done promptly and efficiently.

By employing forecasting, inventory optimization, and lean techniques, supply chain managers can ensure that production is adequately stocked to meet customer demand. With the right strategy and tools in place, supply chain managers can ensure that production is done promptly and efficiently, while minimizing costs and inventory waste.

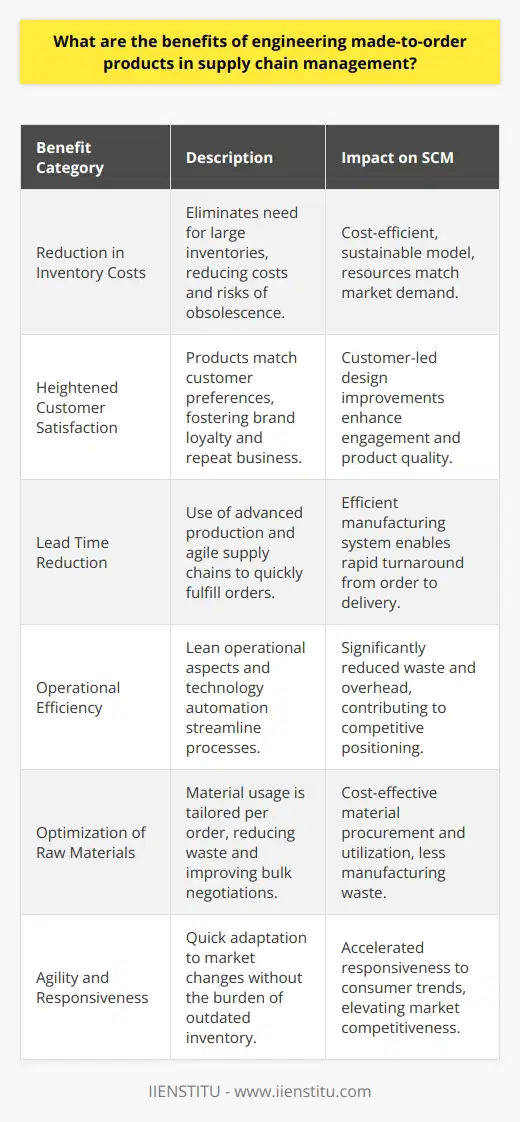

What are the benefits of engineering made-to-order products in supply chain management?

The introduction of engineering made-to-order (MTO) products in supply chain management has provided several unique benefits that are not available through traditional methods. In particular, the ability to customize products to meet exact customer requirements can provide a competitive edge in the marketplace while also streamlining the supply chain process. This article will explore the benefits of engineering MTO products in supply chain management, including cost savings, improved customer satisfaction, and improved operational efficiency.

One of the primary benefits of engineering MTO products is the cost savings associated with the process. By customizing products to meet exact customer requirements, companies can reduce their inventory costs as they do not need to carry large quantities of stock. This also reduces the risk of obsolescence and wasted resources, as the products can be adjusted to meet changing customer needs. Additionally, companies can reduce their manufacturing costs, as the customization process allows them to use raw materials efficiently.

Furthermore, engineering MTO products can also provide improved customer satisfaction. By customizing products to meet individual customer needs, companies can ensure that they deliver exactly what their customers want. This can lead to improved customer loyalty, as customers are more likely to return to a company that can provide them with the exact product they need. Additionally, companies can reduce their lead time as they do not need to wait for materials to be manufactured from scratch.

Finally, engineering MTO products can also improve operational efficiency. Companies can streamline their operations and reduce overhead costs by eliminating the need for manual processes, such as product design and testing. Additionally, the engineering process can be automated, reducing the time and resources needed to customize a product.

In conclusion, engineering made-to-order products can provide several unique benefits in supply chain management, including cost savings, improved customer satisfaction, and improved operational efficiency. By leveraging the advantages of this process, companies can remain competitive in the marketplace while optimizing their operations.

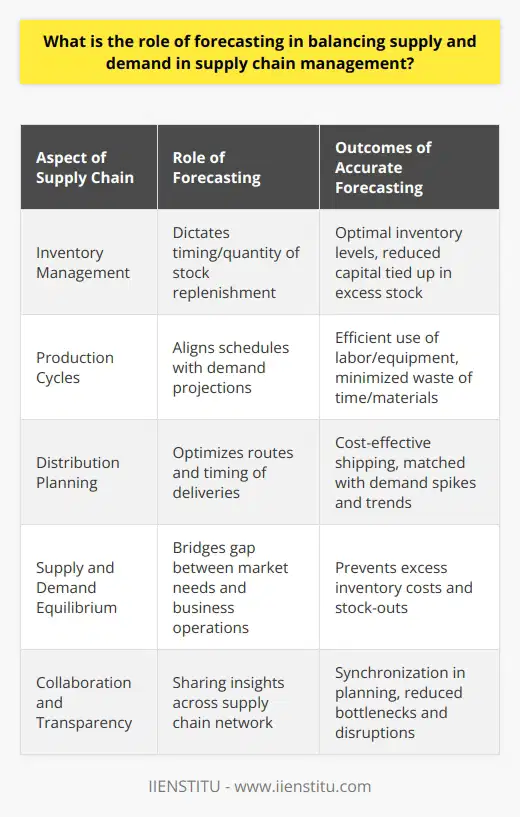

What is the role of forecasting in balancing supply and demand in supply chain management?

Role of Forecasting in Supply Chain Management

Significance of Accurate Forecasting

Forecasting enables supply chain managers to predict the demands of customers for a specific product or service accurately. This critical process assists in making informed decisions for ordering raw materials, scheduling production, managing inventory, and optimizing transportation facilities, ultimately striking a perfect balance between demand and supply.

Incorporating Advanced Technologies

Advanced technologies, such as artificial intelligence, machine learning, and big data analytics, are becoming increasingly vital in honing the forecasting process. Implementing these technologies enables businesses to analyze large volumes of data swiftly, assessing trends and patterns to predict the future. Consequently, supply chain managers can make well-informed decisions, optimize resources, and reduce operating costs, ultimately improving overall efficiency.

Demand Prediction and Inventory Management

Effective demand forecasting is crucial for inventory management, helping businesses avoid overstocking or understocking of products. An accurate prediction of demand allows for better purchasing and production decisions, reducing the risk of stockouts and improving customer satisfaction. By maintaining appropriate inventory levels, companies can achieve operational efficiency while maximizing profits.

Optimizing Resource Allocation

Forecasting in supply chain management ensures the optimum use of manufacturing and distribution resources. An accurate forecast allows supply chain managers to align manufacturing capacity with demand, reduce lead times, and minimize stock obsolescence. This synchronization can lead to significant cost savings and increased customer satisfaction as businesses can ensure the timely fulfillment of orders.

Facilitating Collaboration

Effective forecasting fosters collaboration among stakeholders involved in the supply chain process. By sharing demand forecasts with suppliers, manufacturers, and retailers, businesses can improve collaboration and enhance transparency throughout the supply chain. This cooperative approach helps in identifying potential issues, developing suitable strategies, and reducing the risk of disruptions in the supply chain.

In conclusion, accurate demand forecasting is critical for balancing supply and demand in supply chain management, promoting optimal resource allocation, effective inventory management, and enhanced collaboration among stakeholders. Therefore, integrating advanced technologies and predictive analytics into the forecasting process is imperative for supply chain managers to achieve operational efficiency and maintain a competitive edge.

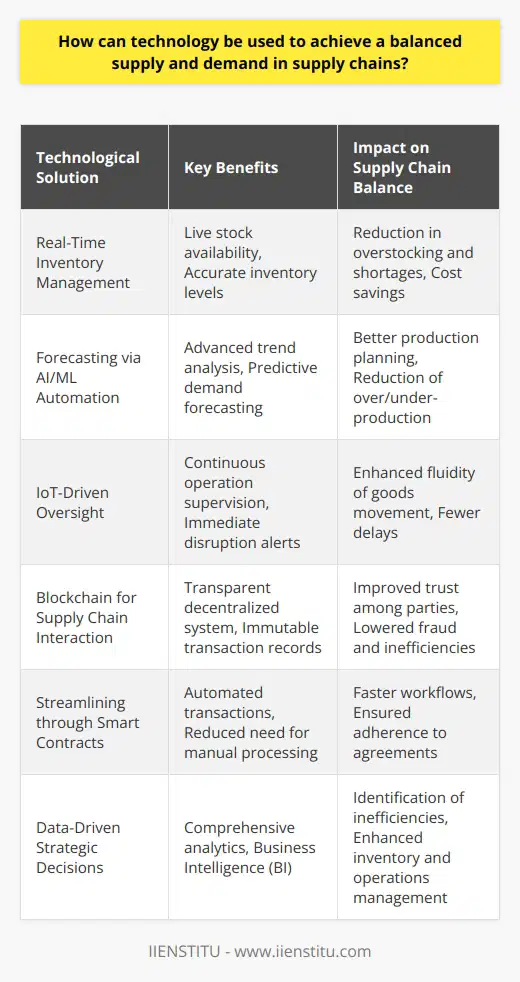

How can technology be used to achieve a balanced supply and demand in supply chains?

Technology Integration in Supply Chain Management

Achieving a balanced supply and demand relies on efficient supply chain management. Technology plays a crucial role in enhancing coordination, communication, and connectivity among various stakeholders.

Real-Time Inventory Management

Real-time inventory management systems provide instant visibility of inventory levels at each stage of the supply chain. These systems help suppliers, manufacturers, and retailers track the movement of goods and respond proactively to minimize stockouts or excess inventory.

Automation in Forecasting and Planning

Advanced technologies, such as artificial intelligence (AI) and machine learning (ML), enable more accurate demand forecasting and production planning. These tools analyze historical sales data, trending patterns, and market variables to predict future demand, allowing companies to optimize production schedules and resource allocation.

IoT-Enabled Tracking and Monitoring

The Internet of Things (IoT) connects physical devices and sensors within the supply chain, enabling real-time tracking and monitoring of goods. This connectivity helps to prevent delays, bottlenecks, or disruptions by identifying issues early and offering actionable insights for agile decision-making.

Blockchain for Transparency and Collaboration

Blockchain platforms facilitate increased transparency and collaboration among supply chain participants. By providing an immutable record of transactions, blockchain technology promotes trust and traceability, allowing for seamless sharing of information, reduced costs, and improved efficiency.

Smart Contracts for Streamlined Processes

Smart contracts, powered by blockchain technology, can automate and streamline various supply chain processes. These digital contracts automatically execute predefined rules and conditions, reducing the need for manual intervention and minimizing errors or discrepancies.

Data-Driven Decision Making

Data-driven decision making involves analyzing vast amounts of supply chain data to identify patterns, trends, and opportunities for improvement. Business intelligence (BI) and analytics tools enable managers to make informed decisions that balance supply and demand, optimize production plans, and allocate resources efficiently.

In conclusion, technology integration is essential for achieving a balanced supply and demand in supply chains. Real-time inventory management, automation in forecasting and planning, IoT-enabled tracking and monitoring, blockchain platforms, smart contracts, and data-driven decision making are vital components that contribute to an efficient, resilient, and responsive supply chain.

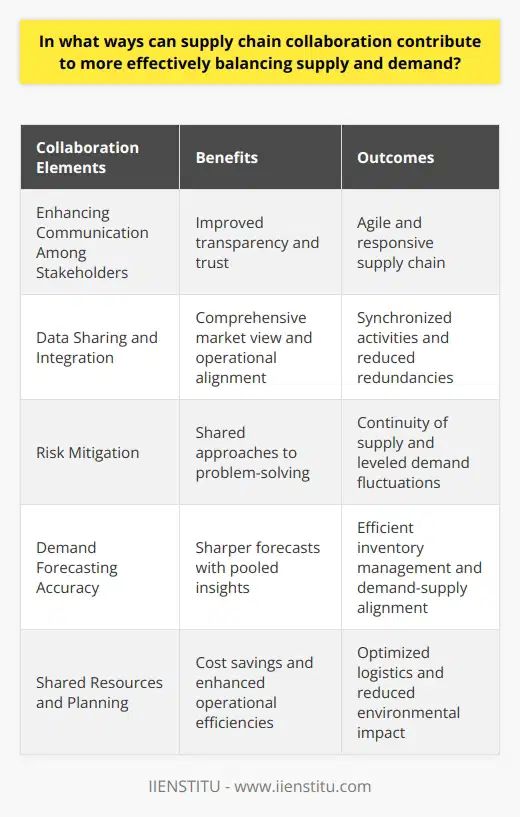

In what ways can supply chain collaboration contribute to more effectively balancing supply and demand?

Enhancing Communication Among Stakeholders

Supply chain collaboration can make a significant impact on effectively balancing supply and demand through improved communication among stakeholders. By fostering open and transparent relationships among suppliers, manufacturers, distributors, and retailers, a collaborative supply chain enables smoother coordination and streamlined decision-making processes.

Data Sharing and Integration

This collaboration further encourages sharing and integration of data such as forecasts, inventory levels, production schedules, and order statuses. This comprehensive visibility of real-time information enables stakeholders to make informed decisions and promptly respond to shifts in demand or supply, ultimately leading to better synchronization between supply and demand.

Risk Mitigation

Supply chain collaboration also aids in risk mitigation efforts, as stakeholders actively cooperate to identify potential disruptions early on and develop contingency plans together. Proactively addressing the risks in the supply chain ensures a more stable and predictable demand-supply balance, reducing the possibility of stockouts or excess inventory.

Demand Forecasting Accuracy

Another crucial advantage of supply chain collaboration is the enhancement of demand forecasting accuracy. With increased access to collective intelligence and the latest market trends, stakeholders can better anticipate fluctuations in demand and adjust their plans accordingly. Accurate demand forecasting subsequently helps organizations to maintain optimal inventory levels and avoid costly holding or stockout expenses.

Shared Resources and Planning

Lastly, supply chain collaboration allows companies to share resources and plan joint strategies, resulting in increased efficiency and cost reduction. By synchronizing production, warehousing, and transportation activities, stakeholders can optimize resource allocation and reduce waste, thereby ensuring a better balance of supply and demand.

In conclusion, supply chain collaboration proves essential in maintaining the delicate balance between supply and demand. Through enhanced communication, data sharing, risk mitigation, demand forecasting, and shared resources, organizations can work together to create a more efficient and resilient supply chain that caters to the needs of the ever-changing market environment.

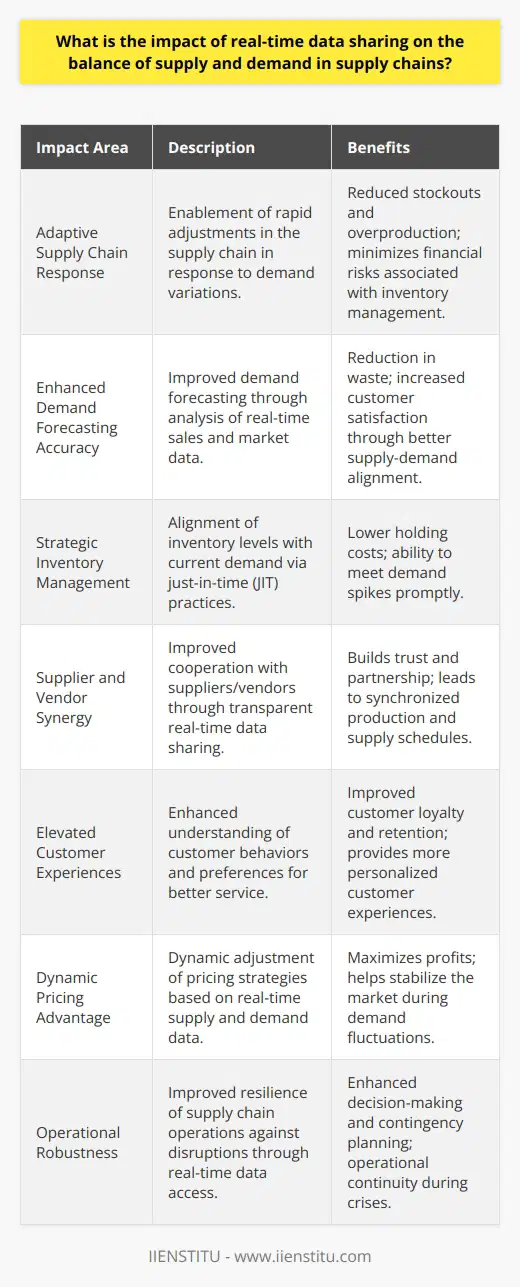

What is the impact of real-time data sharing on the balance of supply and demand in supply chains?

Impact on Supply Chain Efficiency

Real-time data sharing significantly impacts the balance of supply and demand in supply chains by enhancing overall efficiency. It enables businesses to monitor inventory levels, production status, and other critical factors contributing to supply chain effectiveness. With instant access to such information, companies can take proactive measures to prevent shortages or excess supplies.

Improved Demand Forecasting

One primary benefit of real-time data sharing is the improvement in demand forecasting. Accurate demand forecasts allow businesses to make informed decisions about production and distribution schedules, ensuring that the right amount of goods is manufactured and available to meet customer needs. Consequently, this reduces the operational costs associated with overstocking or understocking products.

Increased Supplier Collaboration

Sharing real-time data with suppliers fosters collaboration and coordination in the supply chain. This collaboration enables suppliers to understand fluctuations in demand promptly, leading to timely adjustments in their production and distribution processes. As a result, suppliers can make more accurate and responsive decisions, further enhancing the balance between supply and demand.

Facilitating Dynamic Pricing

Real-time data sharing also facilitates dynamic pricing strategies. As businesses have access to up-to-date information about market trends and competitor pricing, they can quickly adapt their pricing models to meet fluctuations in demand. This flexibility in pricing can prevent situations where excess supply or demand causes disruptions in the supply chain.

Enabling Capacity Planning

Finally, real-time data sharing allows companies to optimize their capacity planning. By continuously monitoring key performance indicators (KPIs) such as warehouse space, transportation availability, and production levels, businesses can better align their operations to meet varying customer requirements. In turn, this effective capacity planning translates into a balanced supply and demand situation across the supply chain.

In conclusion, real-time data sharing has a profound impact on balancing supply and demand within supply chains. By improving forecasting, enhancing collaboration with suppliers, facilitating dynamic pricing, and enabling effective capacity planning, real-time data sharing contributes to a more efficient and resilient supply chain landscape.

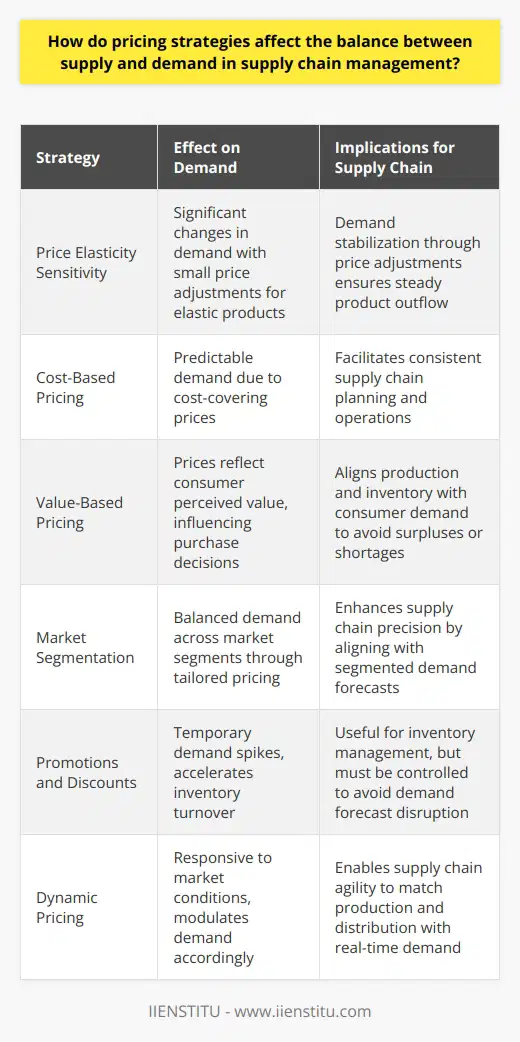

How do pricing strategies affect the balance between supply and demand in supply chain management?

Impact on Supply and Demand

Effective implementation of pricing strategies in supply chain management can help maintain an optimum balance between supply and demand. A major factor influencing the balance is the degree of price sensitivity of the target market. When consumers respond to even slight price changes, companies need to adapt their pricing strategies accordingly to maintain profitability.

Cost-based and Value-based Strategies

Cost-based pricing strategies focus on covering production and logistical costs, while value-based pricing strategies emphasize the perceived value of the product or service to the consumer. These approaches are critical for aligning the prices with the actual costs of production and the subsequent supply chain operations, affecting the overall balance between supply and demand. By understanding the relationship between customers' willingness to pay and product value, businesses can effectively adjust their pricing, which in turn makes supply chain management more efficient.

Role of Market Segmentation

Market segmentation is another crucial aspect to consider in designing pricing strategies, as it significantly impacts the level of demand. By segmenting the market based on variables such as geography, income levels, or demographic factors, firms can better understand different customer groups' price sensitivity levels. This understanding enables businesses to implement pricing strategies that cater to specific segments, leading to better management of supply and demand.

Influence of Promotions and Discounts

Promotions and discount strategies are powerful tools to stimulate demand and maximize revenues. For instance, offering time-sensitive discounts or special promotions can speed up product turnovers, leading to better inventory management and higher cash flow. Timely implementation of these strategies contributes to a balanced supply chain by aligning production levels with actual demand.

Dynamic Pricing Approach

Adopting dynamic pricing strategies that fluctuate based on market conditions can also impact the supply and demand balance in supply chain management. For instance, during periods of high demand, companies can increase prices to benefit from scarcity, thus reducing the strain on the supply chain. Conversely, during periods of low demand, lowering prices can enhance sales and minimize the risk of excess inventory, thereby optimizing the supply chain operations.

In conclusion, successful implementation of pricing strategies can directly affect the balance between supply and demand in supply chain management. By tailoring these strategies to customer price sensitivity, market segmentation, and promotions, companies can optimize their supply chain operations and achieve sustainable profitability.

What role do inventory management systems play in maintaining a balance between supply and demand within a supply chain?

**Role of Inventory Management Systems**

Inventory management systems play a critical role in maintaining a balance between supply and demand within a supply chain. These systems ensure that businesses have the right amount of products at the right time. They help organizations avoid stockouts and overstocks that can disrupt the flow of goods and services. As a result, supply chains can respond more effectively to changes in demand patterns.

**Effective Demand Forecasting**

A key function of an inventory management system is demand forecasting. By analyzing historical sales data and trends, these systems can predict future customer demand. Through accurate demand forecasting, businesses can make informed decisions regarding procurement, production, and distribution. Consequently, they can better anticipate and respond to fluctuations in consumer needs and preferences.

**Optimizing Replenishment Rates**

An inventory management system can also determine optimal replenishment rates for different products. It considers factors like lead time, demand variability, and desired service levels. With this information, organizations can define the best reorder point and order quantity for each product line. Therefore, businesses can avoid excessive inventory levels while still meeting customer demand.

**Enhancing Coordination within Supply Chain**

Inventory management systems facilitate communication and coordination among various stakeholders in the supply chain. By sharing real-time data on stock levels, demand forecasts, and replenishment plans, these systems foster collaboration among suppliers, manufacturers, and retailers. As a result, supply chain partners can better align their operations and jointly address potential imbalances between supply and demand.

**Managing Obsolete and Slow-Moving Inventory**

Effective inventory management can also help businesses identify and manage obsolete or slow-moving products. By monitoring inventory turnover and shelf life, these systems can flag potential issues early. Businesses can then take appropriate actions, such as offering discounts, bundling products, or discontinuing a slow-selling item. This proactive approach can help companies prevent inventory obsolescence and maintain a healthy balance between supply and demand.

In conclusion, inventory management systems play a vital role in balancing supply and demand within a supply chain. They enable accurate demand forecasting, optimize replenishment, enhance coordination among supply chain partners, and manage obsolete and slow-moving inventory. By implementing efficient inventory management practices, businesses can improve their responsiveness to market shifts, reduce costs, and ultimately enhance their overall competitiveness.

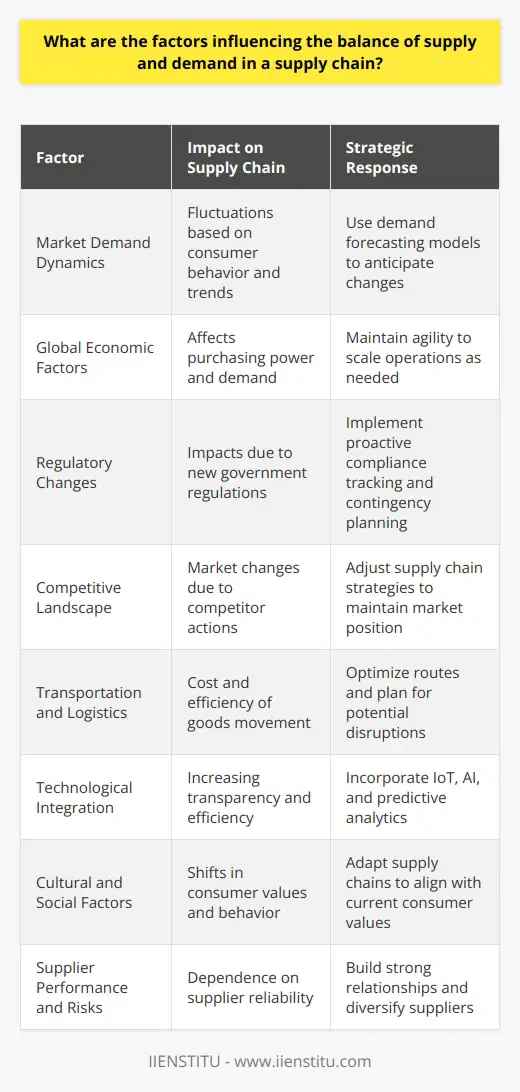

What are the factors influencing the balance of supply and demand in a supply chain?

Factors Affecting Supply Chain Balance

**Demand Fluctuations**

One significant factor influencing the balance of supply and demand in a supply chain is the fluctuation in customer demand. Rapid changes in market trends, preferences, and economic conditions can lead to shifts in demand patterns. These variations require suppliers to adapt their production levels to match the evolving market requirements, impacting the overall balance of supply and demand.

**Supplier Reliability**

Reliability of suppliers is another critical component contributing to the balance of supply and demand. Unpredictable suppliers with inconsistent delivery schedules, varying product quality, or frequent stockouts make it challenging for organizations to maintain the right balance in their supply chains. A stable network of trustworthy suppliers allows organizations to manage inventory levels more effectively and respond to market fluctuations promptly.

**Technological Advancements**

The role of technology cannot be downplayed when it comes to influencing the balance of supply and demand. Implementing advanced technologies such as automation, artificial intelligence, machine learning, and data analytics can help organizations optimize their supply chain processes. An efficient supply chain becomes more responsive to changes in demand, ensuring an appropriate balance between supply and demand at all times.

**Inventory Management**

Effective inventory management practices play a key role in maintaining the balance of supply and demand in a supply chain. Organizations that accurately forecast their inventory needs, optimally allocate resources, and monitor stock levels can better serve their customers and meet their changing demands. By having the right products available in the right amounts at the right times, organizations can prevent stockouts, overstocked items, and disrupted supply chain balance.

**Government Regulations and Policies**

Finally, government regulations and policies can significantly impact the balance of supply and demand. Trade restrictions, tariff changes, and environmental regulations are prime examples of factors that potentially alter the flow of goods and services within a supply chain. Organizations need to adapt to these regulatory changes, adjust their operations and procurement strategies, and maintain the delicate balance between supply and demand.

In conclusion, various factors influence the balance of supply and demand in a supply chain, highlighting the complexity of managing this equilibrium. Recognizing these factors and implementing effective strategies can help organizations enhance their supply chain resilience, optimize inventory levels, and cater to the dynamic nature of global markets.

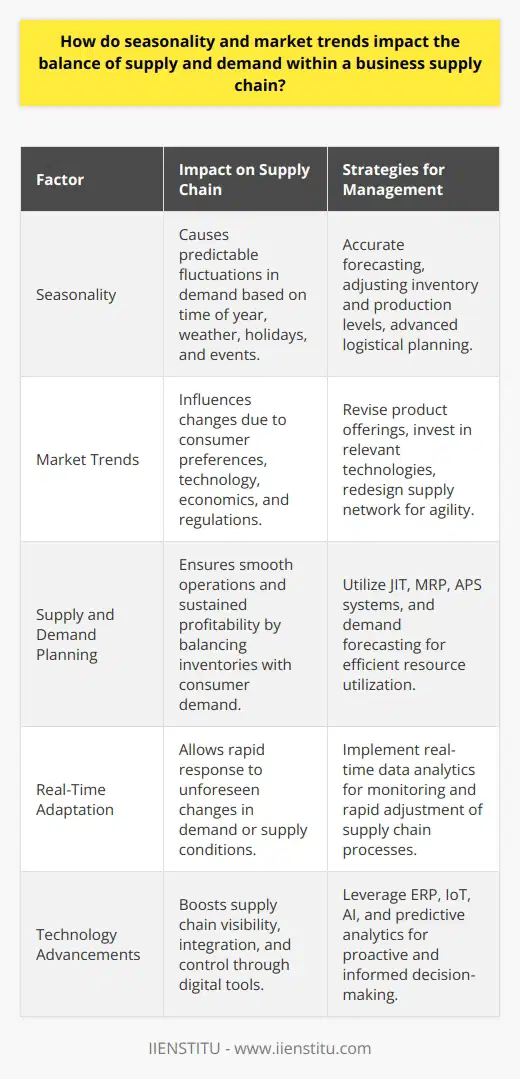

How do seasonality and market trends impact the balance of supply and demand within a business supply chain?

Seasonality and Market Trends in Supply Chain Management

The Influence of Seasonality

Seasonality plays a crucial role in determining the balance of supply and demand within a business supply chain. Seasonal fluctuations in consumer demand occur due to holidays, weather changes, or industry-specific trends. These fluctuations can lead to stretch and shrink in inventory levels, production schedules, and delivery timelines. Consequently, businesses need to forecast and adjust their supply chain operations to meet the expected demand efficiently.

The Effects of Market Trends

Market trends also significantly impact the business supply chain. Changes in consumer preferences, technological advancements, or economic conditions create shifts in the market demands. Businesses have to be responsive and adapt to these changes in order to maintain a balanced supply chain. This need for adaptation may result in altering product offerings, adjusting production capacities, or updating logistical strategies.

Efficient Supply Chain Planning

In order to ensure an effective balance of supply and demand, businesses must anticipate seasonal changes and market trends. This can be achieved through proper supply chain planning that includes demand forecasting, inventory management, and production scheduling. Accurate demand forecasting empowers businesses to adjust inventory levels and production schedules in response to changes in the market environment.

Adapting to Changes in Real-Time

Moreover, the ability to adapt to changes in real-time is pivotal for maintaining an efficient supply chain. By leveraging real-time data analysis and adopting agile operational strategies, businesses can quickly respond to unpredictable fluctuations of supply and demand. This ensures an optimized supply chain management that minimizes costs and maximizes customer satisfaction.

In conclusion, seasonality and market trends substantially impact the balance of supply and demand within a business supply chain. Through efficient supply chain planning and the quick adaptation to changes in real-time, businesses can address these challenges and maintain a stable and successful operation.

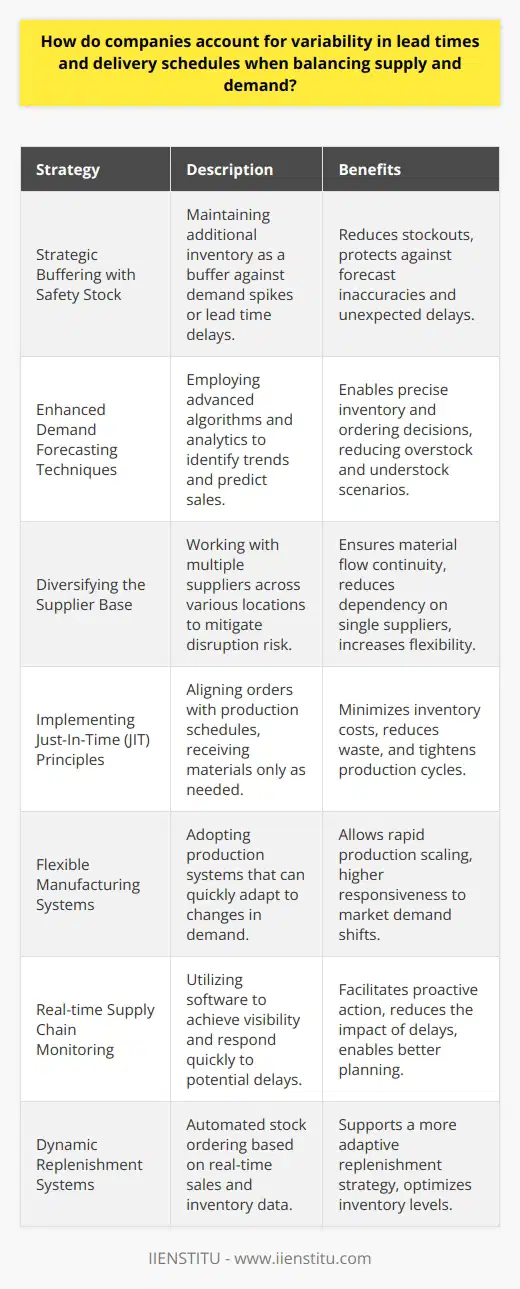

How do companies account for variability in lead times and delivery schedules when balancing supply and demand?

Lead Time Variability

Companies accommodate variability in lead times and delivery schedules to maintain a balance between supply and demand. Various strategies help in managing these uncertainties, ensuring smooth operations and customer satisfaction.

Demand Forecasting

Accurate demand forecasting plays a crucial role in addressing lead time variability. By predicting future sales and analyzing historical data, companies can effectively plan and organize their delivery schedules and supply chain processes.

Safety Stock Levels

To handle fluctuations in lead times, businesses maintain safety stock levels. This buffer inventory ensures continuous product availability even when suppliers face delays, thus meeting customer demands and preventing stockouts.

Supplier Management

Effective supplier management is essential for addressing supply chain variability. Companies collaborate with multiple suppliers, reducing dependency on single sources and minimizing the risk of delivery delays or disruptions in production processes.

Just-In-Time (JIT) Inventory System

Adopting the Just-in-Time inventory system allows firms to handle the lead time variation in supply chain management. This approach focuses on producing and delivering goods based on real-time customer demand, thus avoiding excessive inventory and reducing lead time uncertainties.

Flexible Production Planning

Incorporating flexibility in production planning facilitates adaptability to changes in demand and lead times. Companies using flexible production techniques can quickly adjust their production schedules in response to changing delivery times, ensuring constant product availability.

Real-time Data Analysis

Utilizing real-time data analysis enables businesses to monitor their supply chains effectively, identifying potential delays or disruptions. By assessing this data, companies can make informed decisions and take appropriate actions to manage lead time variability.

In conclusion, companies adopt various strategies to account for variability in lead times and delivery schedules. Accurate demand forecasting, maintaining safety stock levels, effective supplier management, adopting JIT inventory systems, flexible production planning, and real-time data analysis all contribute to strike a balance between supply and demand, even amid uncertainties.

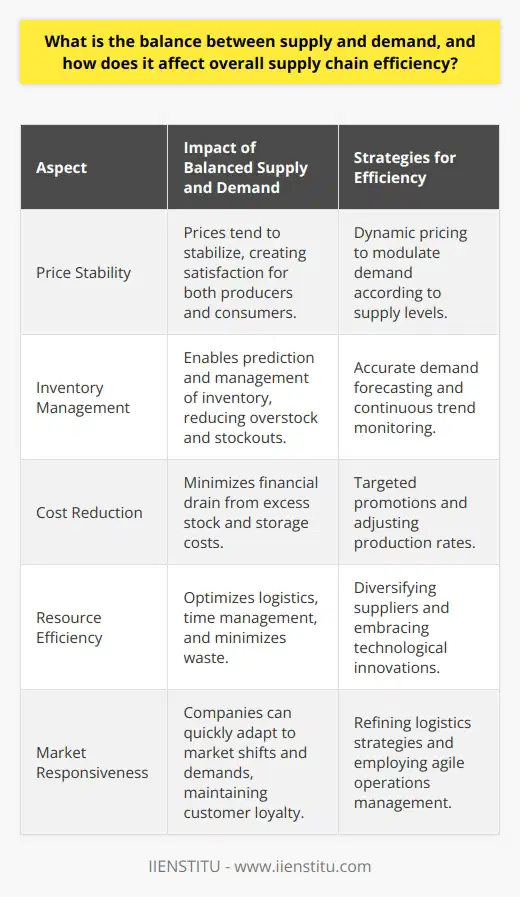

What is the balance between supply and demand, and how does it affect overall supply chain efficiency?

Balance between Supply and Demand

The balance between supply and demand refers to the equilibrium achieved when the quantity of a product or service desired by consumers equals the amount produced or available from suppliers. This balance plays a critical role in determining the overall efficiency of supply chains.

Impact on Supply Chain Efficiency

Efficient supply chain management is vital for businesses to optimize their operations, reduce costs, and improve customer satisfaction. When supply and demand are balanced, companies can better forecast their production and inventory levels, leading to more effective resource allocation.

Preventing Stockouts and Overstock

A balanced supply-demand scenario mitigates the risks of stockouts or overstock. Stockouts lead to lost sales, unsatisfied customers, and potential long-term brand damage. On the other hand, overstock results in increased holding costs and tied-up capital, ultimately impacting profitability. By maintaining equilibrium, organizations can avoid these negative outcomes and ensure efficient supply chain operations.

Dynamic Pricing and Promotions

Understanding how supply and demand interact allows businesses to develop and implement dynamic pricing and promotional strategies. Pricing directly impacts demand; thus, adjusting prices based on demand fluctuations can drive sales and profitability. Similarly, targeted promotions can help manage demand, ensuring smooth supply chain performance.

Adapting to Market Conditions

It is essential for companies to continuously monitor the balance between supply and demand to adapt to changing market conditions effectively. Global economic factors, technological innovations, and consumer preferences are constantly evolving, which could lead to sudden shifts in demand. By staying agile and adapting their supply chain processes to cater to such changes, organizations can maintain overall efficiency.

In conclusion, the balance between supply and demand is the foundation of well-functioning supply chains. By ensuring this equilibrium, businesses can optimize their operations, improve customer satisfaction and adapt their strategies to thrive in an ever-changing market.

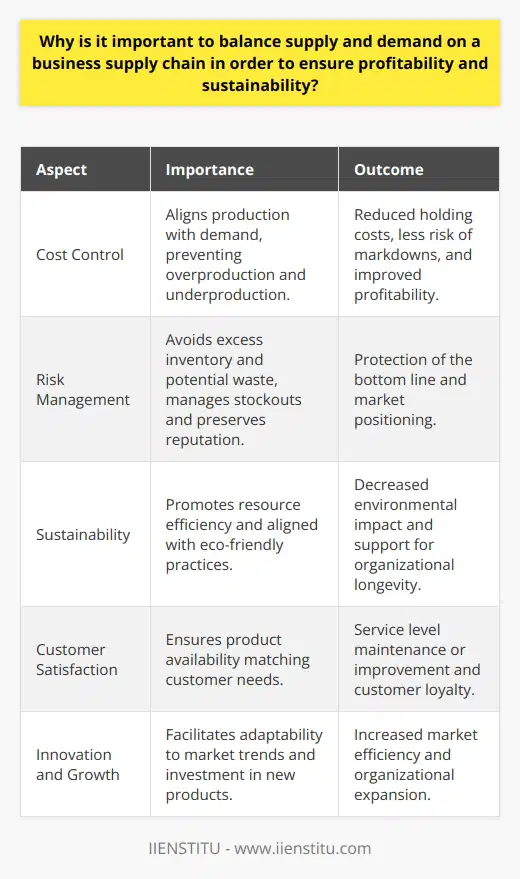

Why is it important to balance supply and demand on a business supply chain in order to ensure profitability and sustainability?

Balancing Supply and Demand

Achieving equilibrium between supply and demand is crucial for businesses to maintain profitability and sustainability. Optimizing the supply chain ensures that resources and capabilities are strategically aligned to match the needs of the market. This enables firms to respond quickly to fluctuations in demand, compete effectively in the industry, and create a favorable customer experience.

Cost Effectiveness

An efficient supply chain enables companies to minimize production, storage, and transportation costs. When supply and demand are in balance, businesses can produce and deliver goods more effectively while eliminating excess inventory. This results in reduced operational costs and higher profit margins. In turn, these savings can be passed on to customers, rendering the business more competitive within their market.

Reduced Risk

The balanced supply chain reduces financial risks associated with overproduction and stock obsolescence. These risks can lead to significant losses if unsold inventory requires steep discounts or becomes obsolete. Proactive supply chain management enables organizations to make informed decisions to manage and mitigate these risks and maintain financial stability.

Sustainability

In the context of environmental concerns and resource limitations, ensuring a balanced supply chain significantly contributes to sustainable business practices. By optimizing supply chain processes, companies can limit wastage, minimize greenhouse gas emissions, and conserve scarce resources. This demonstrates commitment to corporate social responsibility and maintains long-term business viability.

Customer Satisfaction

Understanding and fulfilling customer demands is critical to business success. A well-balanced supply chain ensures that products are readily available to meet consumers' desires, avoiding stockouts or unfulfilled orders. This enhances customer satisfaction, fosters loyalty, and contributes to a positive brand reputation.

Innovation and Growth

Lastly, the balance between supply and demand is essential for fostering innovation and growth within a business. When companies are responsive to shifting market trends, they can invest in product development, explore new markets, and capitalize on emerging opportunities. This adaptability ensures consistent growth and a competitive edge in the market.

In conclusion, achieving supply chain equilibrium is vital for businesses to remain profitable, sustainable, and competitive in today's continuously evolving economy. By proactively managing their supply chains, companies can mitigate risk, minimize expenses, promote sustainability, enhance customer satisfaction, and drive innovation within their industry.

What is the concept of balance and demand in the context of managing available resources and meeting customer needs in the supply chain?

Concept of Balance in Supply Chain Management

The concept of balance in supply chain management is rooted in aligning the available resources with the needs and expectations of customers. Achieving balance ensures that the resources are fully utilized, and customer satisfaction is maximized. This involves carefully planning and coordinating the procurement, production, and distribution activities to avoid shortages and overstocks, with the ultimate goal of meeting customer demands in a timely and cost-effective manner.

Demand and Resource Management

Successful supply chain management necessitates understanding and anticipating customer demand. This involves analyzing historical sales data, monitoring market trends, and forecasting future consumption patterns. Furthermore, an effective demand planning strategy helps businesses optimize inventory levels, prioritize replenishment decisions, and streamline operations to meet customer expectations while minimizing costs.

Resource optimization, on the other hand, is focused on identifying and managing the input factors, such as human resources, material, and financial resources, required to fulfill customer demands. Efficient resource management implies employing the right mix of resources, at the right time, to maximize output and ensure a consistent supply for the customers.

Supply Chain Collaboration and Flexibility

Collaboration among various stakeholders, including suppliers, manufacturers, and distributors, is essential for maintaining a balanced supply chain. Sharing critical information, such as demand forecasts, production schedules, and inventory levels, enables businesses to make informed decisions, respond to fluctuations in demand, and coordinate efforts to maximize customer satisfaction.

Flexibility is another crucial factor for supply chain balance, which can be achieved through implementing agile processes, investing in advanced technology, and cultivating a responsive organizational culture. Adaptable supply chains can quickly respond to changes in demand, mitigate potential risks, and capitalize on new market opportunities.

Conclusion

In summary, the concept of balance and demand in supply chain management revolves around efficiently managing resources to meet customer needs. Through effective demand planning, resource optimization, collaboration, and flexibility, businesses can enhance their supply chain performance, minimize costs, and, ultimately, improve customer satisfaction.