This article explores the various aspects of managing supplier relationships, such as the importance of the customer being correct, the implications of you getting what you pay for, and building relationships with your suppliers. It is important to remember that from your suppliers' perspective, you are the customer and that you should expect them to live by the mantra "the customer is always right."

Remembering that you get what you pay for and that building relationships with your suppliers is essential for a successful business. Taking the time to make a trusting and mutually beneficial relationship with your suppliers will ensure that both of you can succeed.

Introduction

The Customer is Always Right

You Get What You Pay For

Building Relationships

Conclusion

Introduction: The customer-supplier relationship is one of the most important aspects of any business. Both parties must have a trusting and mutually beneficial relationship to achieve success. This article will explore the various aspects of managing supplier relationships, such as the importance of the correct customer, the implications of getting what you pay for, and building relationships with your suppliers.

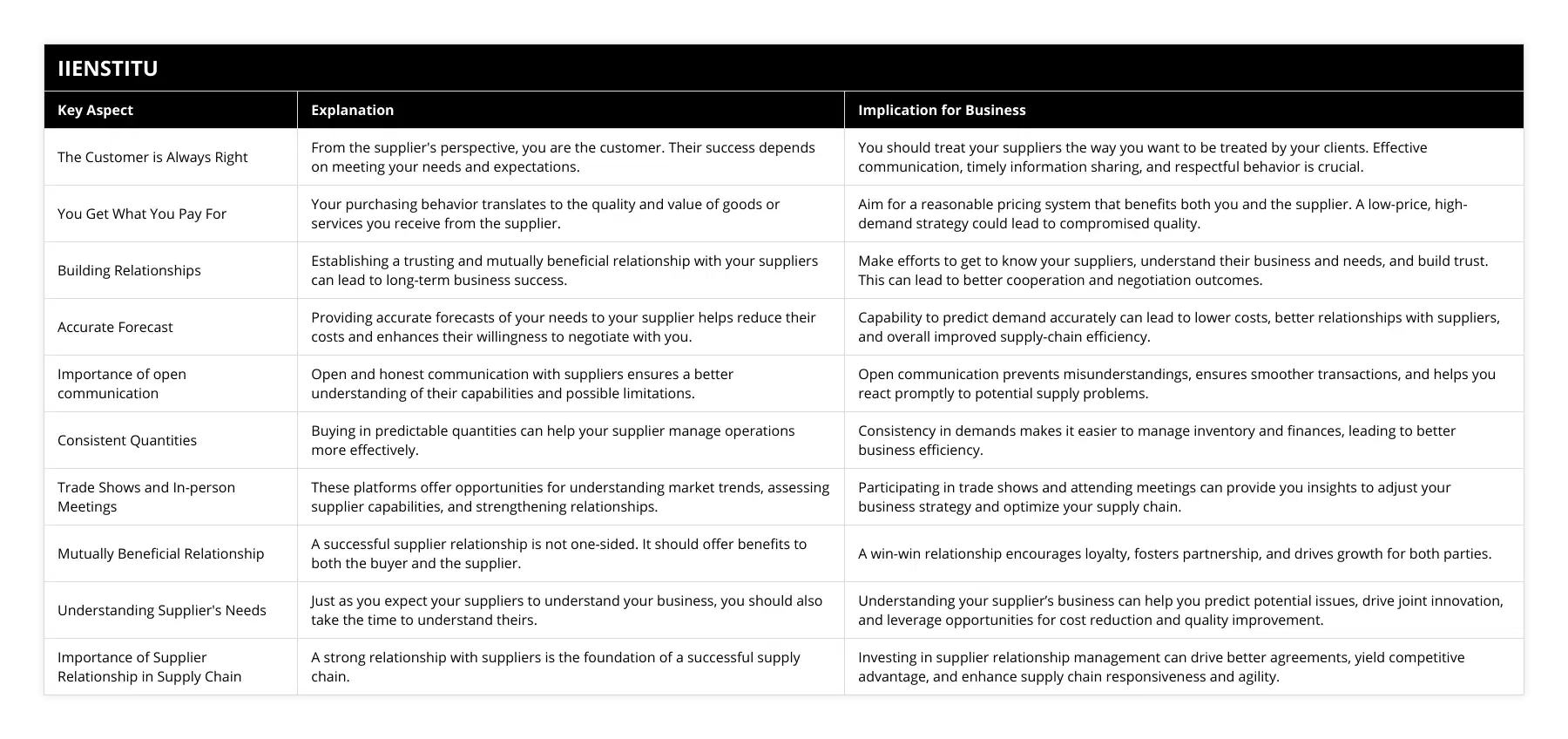

The Customer is Always Right

The customer is always right is a well-known phrase in the business world. However, it is essential to remember that you are the customer from your suppliers' perspective. This means that your suppliers will expect you to act the way you would expect your customers to work. This includes giving ample notice when you need something, buying in predictable quantities, and being willing to pay a reasonable amount.

You Get What You Pay For

When managing supplier relationships, it is essential to remember that you get what you pay for. This means that your purchasing behavior will affect both the costs your supplier has to pay and their willingness to negotiate with you. For example, suppose you can provide an accurate forecast of your needs to your supplier in advance. In that case, they can safely reduce the amount of stock they need to carry, reducing their costs and making them more willing to negotiate with you.

Technologies For Enhancing Supply Chain Visibility İnterview Strategies

Effective Procurement Management Strategies For Supply Chain Success

Building Relationships

Building relationships with your suppliers is essential for a successful business. It is important to be open and honest with your suppliers and to take the time to build a relationship with them. This can include attending trade shows, meeting with them in person, and having regular conversations about their needs and yours. Taking the time to build a relationship with your suppliers will ensure a mutually beneficial relationship that will help both of you succeed.

Conclusion: Managing supplier relationships is an integral part of any business. It is essential to remember that from your suppliers' perspective, you are the customer and that you should expect them to live by the mantra "the customer is always right." Remembering that you get what you pay for and that building relationships with your suppliers is essential for a successful business. Taking the time to make a trusting and mutually beneficial relationship with your suppliers will ensure that both of you can succeed.

A strong relationship with suppliers is the foundation of a successful supply chain.

The article emphasizes the need to manage supplier relationships as a core element of supply chain management. Recognizing oneself as the customer from the viewpoint of the supplier and expecting customer-centric treatment accordingly, understanding that the value of what you pay for impacts the costs and negotiation abilities of the supplier, along with building strong, open, and honest relationships with suppliers form the crux of effective

Frequently Asked Questions

What strategies can be used to build strong supplier relationships?

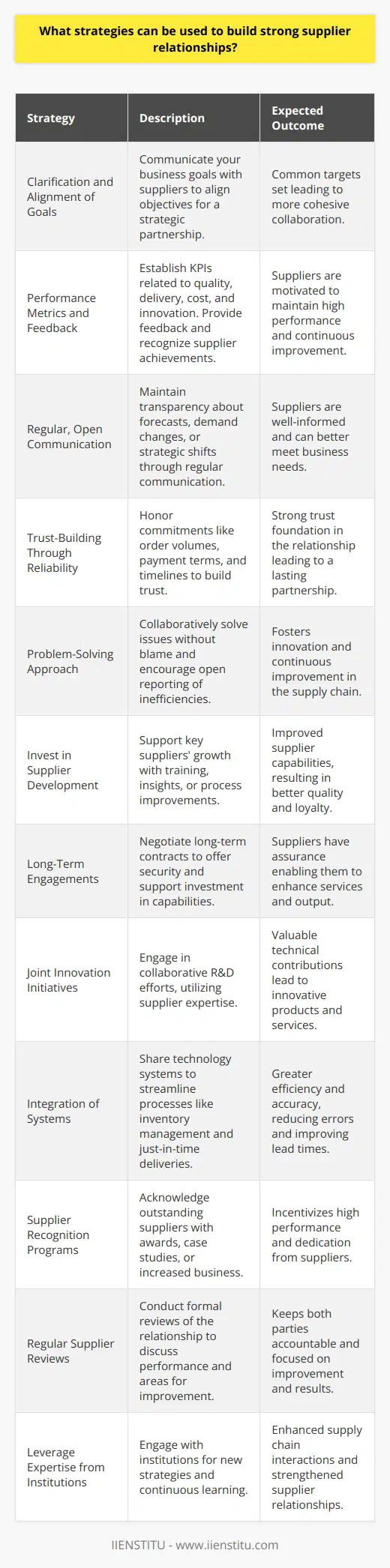

Developing strong supplier relationships is essential for any business looking to achieve long-term success. A successful supplier relationship requires both parties to understand goals, expectations, and communication styles. In this article, we will explore strategies that can be used to help build strong supplier relationships.

First, it is essential to establish clear and mutual expectations between the supplier and the business. This should include a thorough analysis of the supplier’s capabilities and the business’s needs. The supplier should clearly understand the expectations placed on them, as well as the timeline and budget for the project. Establishing and agreeing upon these expectations upfront will ensure that both parties are on the same page throughout the process.

Second, open and effective communication is critical. A designated contact person on both sides of the relationship should be responsible for communications. This will help ensure that both parties have the same understanding of any changes or updates to the project. Regular meetings should also be held in person or over the phone to discuss any potential issues or opportunities.

Third, building trust and respect between the supplier and the business is essential. This can be done by honoring commitments and having consistent follow-through. Suppliers should also be recognized and rewarded for their efforts, which will help build a strong relationship.

Finally, it is essential to foster a collaborative environment. This means that both parties should be willing to work together to devise solutions to any potential issues. Suppliers should be encouraged to ask questions and provide feedback to ensure the best possible outcome.

In conclusion, building strong supplier relationships is critical to achieving long-term success. Establishing clear and mutual expectations, open communication, trust and respect, and a collaborative environment are all essential strategies for achieving this goal. Following these strategies, businesses can create strong, long-term relationships with their suppliers.

How can customer feedback be used to improve supplier relationships?

Supplier relationships are essential for businesses to help ensure the quality and continuity of their supply chain. Customer feedback can improve these relationships by providing performance feedback, identifying improvement areas, and increasing customer satisfaction.

The use of customer feedback can help suppliers assess their performance in meeting customer expectations. By analyzing customer feedback, suppliers can identify areas for improvement and focus on those areas to better meet customer needs. This can include changes in product quality, delivery times, customer service, or any other site that customers deem as necessary.

Customer feedback can also inform supplier relationships regarding pricing, payment terms, and other contractual aspects. By understanding customer needs and expectations, suppliers can negotiate better terms with their customers and better align their services with customer needs.

Finally, customer feedback to improve supplier relationships can help increase customer satisfaction. By understanding customer needs, expectations, and preferences, suppliers can develop better products and services that meet those needs. This can help to build trust and loyalty between suppliers and customers, leading to long-term relationships.

In conclusion, customer feedback is an invaluable tool for improving supplier relationships. By understanding customer needs and preferences, suppliers can change their products and services to meet customer expectations better. This can help improve pricing, payment terms, and other contractual aspects and increase customer satisfaction.

What are the benefits of managing supplier relationships for supply chain success?

The success of a supply chain is often dependent on the quality of the relationships between the various stakeholders. Therefore, managing supplier relationships is critical to the success of a supply chain, as it is one of the primary methods used to ensure the timely and efficient delivery of goods and services. This article will discuss the various benefits of managing supplier relationships for supply chain success.

Firstly, managing supplier relationships can help to create greater transparency within the supply chain. This transparency is essential for ensuring that all stakeholders within the chain have access to the necessary information regarding the delivery of goods and services. This helps to ensure that all stakeholders are aware of their responsibilities and can act quickly to resolve any issues which may arise. This can help to improve overall efficiency and reduce the potential for disruption.

Secondly, managing supplier relationships can help to create a greater level of trust between the various stakeholders. This trust is essential for the successful delivery of goods and services. For example, a trusting relationship between suppliers and customers can help to ensure that deliveries are made on time and that any issues are quickly resolved. This trust can also help to reduce the potential for disputes and disagreements between stakeholders, as they are more likely to communicate effectively and work together to resolve any issues.

Thirdly, managing supplier relationships can help to ensure that goods and services are delivered cost-effectively. This is because suppliers are more likely to provide competitive prices when they have a trusting relationship with their customers. This can help reduce the supply chain's overall cost, as suppliers are more likely to provide the best quality goods and services at the lowest prices.

Finally, managing supplier relationships can help ensure that all stakeholders within the supply chain work together to achieve the same goals. This is because suppliers are more likely to collaborate on projects as they have a trusting relationship with their customers. This can help create a more efficient and effective supply chain, as all stakeholders work together towards a common goal.

In conclusion, managing supplier relationships is essential for the success of a supply chain. By creating greater transparency and trust between stakeholders, managing supplier relationships can help to ensure that goods and services are delivered cost-effectively. Furthermore, managing supplier relationships can help ensure that all stakeholders work together to achieve the same goals.

What is key supplier relationship management in supply chains and why is it important?

Understanding Key Supplier Relationship Management

Key supplier relationship management (KSRM) encompasses the strategies and practices that businesses employ to engage with their most important suppliers. These suppliers are typically selected based on their critical contribution to the organization's operations or value creation.

Significance of KSRM in Supply Chains

The importance of KSRM in supply chains cannot be overstated, as it directly impacts the efficiency, performance, and resilience of these networks. By fostering strong and collaborative relationships with key suppliers, companies can reap several benefits:

Cost Reduction and Efficiency Improvement: An effective KSRM helps businesses identify opportunities to lower costs through joint initiatives, streamlined processes, and better coordination. Implementing these measures results in leaner and more efficient supply chains.

Enhanced Innovation and Competitive Advantage: Collaborative relationships with key suppliers can drive innovation by combining shared resources, knowledge, and expertise. This synergy can lead to the development of better products, services, and solutions, ultimately increasing a company's competitive advantage.

Increased Supply Chain Resilience: Strong relationships with key suppliers help organizations mitigate the risk of disruptions in their supply chains. By developing a better understanding of their suppliers' capabilities and limitations, businesses can create contingency plans that prepare them for unforeseen events.

Improved Supplier Performance and Quality: KSRM involves continuous communication and feedback, which enables companies to hold their suppliers accountable, monitor performance, and ensure product and service quality. This proactive approach can prevent potential issues, leading to more reliable and consistent outputs.

Strengthened Sustainability Efforts: Developing a close partnership with key suppliers can help organizations improve their sustainability by working together on various environmental and ethical initiatives. Engaging suppliers in the sustainability journey can lead to a more socially responsible and environmentally friendly supply chain.

Overall, key supplier relationship management is essential for maintaining effective supply chains. By focusing on KSRM, organizations can reduce costs, foster innovation, enhance resilience, improve performance and quality, and strengthen sustainability efforts. This approach ensures that supply chains remain agile, efficient, and responsive, ultimately boosting the long-term success and growth of an organization.

What key factors contribute to the success of supplier relationships, and how do these affect overall supply chain performance?

Key Factors in Supplier Relationships Success

Effective supplier relationships are crucial to businesses seeking to achieve supply chain performance, maintain competitive advantage, and enhance profits. Several factors contribute to the success of supplier relationships, impacting overall supply chain efficiency.

Open and Clear Communication:

Clear, open, and transparent communication between supply chain participants is essential for maintaining productive and agile relationships. Open channels of communication enable the quick resolution of problems, foster effective coordination, and facilitate the sharing of information.

Trust and Long-Term Orientation:

Trust and long-term orientation are vital considerations to ensure the stability and resilience of supply chain networks. The development and maintenance of trustworthy relationships improve supplier adaptability, increase scalability, and result in stronger connections for sustained growth.

Collaboration and Strategic Alignment:

Effective strategic planning, collaborative product development, and customizable operational processes lead to stronger overall supply chain performance. Collaborative partnerships enable businesses to remain competitive by ensuring that suppliers understand and support their strategic goals and direction.

Performance and Quality Management:

Continuous monitoring, assessment, and improvement of supplier performance and quality standards are crucial for ensuring supply chain performance. Businesses must establish clear performance expectations and work closely with suppliers to promote the ongoing alignment of desired product performance, industry standards, and consumer demands.

Adequate Risk Management:

Effective risk management mitigates supply chain disruptions and minimizes potential losses. Businesses must develop robust risk management strategies to identify and address potential risks proactively, such as geopolitical instability, economic downturns, and supplier bankruptcies.

By focusing on these key factors, businesses can foster strong supplier relationships that enable improved supply chain performance, ultimately leading to increased responsiveness, lower production costs, and higher customer satisfaction levels.

How can organizations effectively manage relationships with suppliers to maximize supply chain efficiency and resilience?

**Effective Communication and Collaboration**

Organizations can effectively manage relationships with suppliers by ensuring clear and consistent communication channels. Sharing information on demand forecasts, inventory levels, and market trends allow suppliers to better anticipate organizational needs, thereby contributing to efficient supply chain operations. Timely and accurate feedback fosters collaboration in decision-making, critical to aligning expectations and minimizing potential disruptions.

**Supplier Integration and Performance Monitoring**

To maximize supply chain efficiency, organizations should integrate suppliers into their internal processes and systems. Providing suppliers with access to relevant data and resources enables them to make informed decisions, enhancing their ability to adjust to changing requirements. Moreover, establishing key performance indicators (KPIs) to track and evaluate supplier performance helps organizations identify areas for improvement, fostering continuous learning and optimization within the supply chain.

**Vendor Risk Management**

In order to build a resilient supply chain, organizations must implement a comprehensive vendor risk management strategy. This includes monitoring suppliers' financial stability and operational performance, as well as conducting regular audits and assessing their compliance with industry standards and regulations. By identifying potential risks, organizations can proactively address these issues and mitigate any negative impact on the supply chain.

**Supplier Development and Training Programs**

Organizations can strengthen supplier relationships and improve supply chain performance by investing in supplier development and training programs. Offering tailored workshops and training sessions on topics such as cost reduction, process improvement, and sustainability practices can enhance suppliers' capabilities and better align them with organizational objectives. Additionally, facilitating knowledge-sharing events and ongoing educational resources further encourages suppliers' commitment to continuous improvement.

**Strategic Supplier Partnerships**

Cultivating strategic supplier partnerships is essential to increase supply chain resilience. By developing long-term relationships with key suppliers that demonstrate a shared vision and commitment to customer success, organizations can jointly develop innovative solutions to complex challenges. Such partnerships enable collaborative problem-solving, pooling of resources, and continuous enhancement of products and services. Ultimately, strong supplier partnerships contribute to supply chain reliability and stability, ensuring high performance even in the face of uncertainties and disruptions.

Why is key supplier relationship management important in supply chains?

Significance of Supplier Relationship Management

Key supplier relationship management (KSRM) is a critical aspect of supply chain management, playing a vital role in optimizing business operations. There are several reasons for its importance, including cost reduction, risk mitigation, innovation facilitation, and improved collaboration.

Cost Reduction

One crucial advantage of KSRM is its potential to reduce costs by streamlining procurement processes and identifying strategic sourcing opportunities. Through improved communication and understanding of the supplier's capabilities, organizations can make better-informed decisions, negotiate more favorable pricing, and establish long-term cost-saving strategies.

Risk Mitigation

Another aspect of KSRM is its role in mitigating supply chain risks. Establishing solid relationships with key suppliers allows organizations to identify and manage potential disruptions, such as shortages, quality problems, and delivery delays. By closely monitoring suppliers and maintaining open lines of communication, companies can quickly respond to emerging risks before they escalate into more significant issues.

Innovation Facilitation

KSRM also fosters a collaborative environment that encourages innovation and drives continuous improvement. By establishing close ties with suppliers, organizations can access new ideas, technologies, and best practices that can enhance their products, services, and operational efficiencies. As a result, businesses can stay ahead of the competition and facilitate long-term growth.

Improved Collaboration

Lastly, KSRM is essential for enhancing collaboration with suppliers by identifying common goals, aligning expectations, and fostering trust. Active collaboration can lead to supply chain synergies, enabling organizations to reduce lead times, improve responsiveness, and increase the overall efficiency of their operations. Effective supplier relationship management encourages an environment of mutual benefit and shared success, leading to more resilient and sustainable supply chains.

In conclusion, key supplier relationship management is a vital component of supply chain management, contributing to cost reduction, risk mitigation, innovation facilitation, and improved collaboration. By forging strong relationships with suppliers, organizations can optimize their operations, fortify their supply chains, and position themselves for long-term success.

How do supplier relationships contribute to supply chain performance?

**Significance of Supplier Relationships**

Supplier relationships play a crucial role in enhancing supply chain performance. When an organization establishes strong relationships with suppliers, it can access essential resources more effortlessly. These resources include raw materials, labor, and knowledge, which are vital in meeting customer demands. By engaging in close collaborations with suppliers, an organization can also gain a competitive edge within the industry.

**Reducing Costs and Risks**

One significant contribution of supplier relationships to supply chain performance is cost reduction. When a firm maintains healthy relationships with suppliers, it secures better deals on cost, payment terms, and discounts, resulting in lower operational costs. Moreover, strong supplier relationships allow businesses to mitigate potential risks, such as supply disruptions and fluctuations in availability or quality of materials, by enhancing communication and responsiveness to changing market conditions.

**Continuous Improvement and Innovation**

Long-term supplier relationships foster a culture of continuous improvement and innovation. Suppliers, when engaged in collaborative relationships, are more inclined to share their expertise and knowledge, leading to enhanced product quality and process efficiency. Besides, suppliers with strong customer ties are more likely to invest in research and development resulting in more innovative products, which would ultimately benefit the supply chain performance by meeting or exceeding customer expectations.

**Enhanced Agility and Responsiveness**

Strong supplier relationships contribute to increased supply chain agility and responsiveness. Collaboration with suppliers enables organizations to better anticipate demand changes and respond to market fluctuations promptly. Additionally, a mutually beneficial relationship with suppliers allows organizations to tap into suppliers' industry expertise to implement lean and just-in-time inventory practices, leading to reduced lead times and improved time-to-market.

**Trust and Collaboration**

Trust and collaboration are cornerstones of supplier relationships that contribute to supply chain performance. When trust exists between a firm and its suppliers, it enables open communication, better coordination, and greater willingness to share information. This in turn leads to more proactive problem-solving and closer alignment of objectives, facilitating an improved supply chain management process.

In conclusion, supplier relationships are essential for an organization to achieve optimal supply chain performance. By building strong connections with suppliers, firms can reduce costs and risks, foster continuous improvement and innovation, enhance agility and responsiveness, and establish trust and collaborate effectively. This critical aspect of supply chain management helps businesses to deliver exceptional value to customers and maintain a competitive edge in the market.

How do you manage supplier relationships effectively?

Establishing Trust

Managing supplier relationships effectively requires establishing trust between both parties. Open communication and transparent information exchange are crucial in building this trust. Sharing accurate and realistic forecasts, as well as clearly stating expectations, can facilitate a strong foundation for a long-lasting, productive partnership.

Regular Evaluations

Regular evaluation of supplier performance is essential in maintaining a healthy relationship. Assessing and providing feedback on aspects such as promptness, quality, and overall satisfaction can promote continuous improvement. Furthermore, it encourages suppliers to meet or exceed expectations, ensuring a consistently high level of service.

Mutual Commitment

Demonstrating a mutual commitment to the partnership further strengthens supplier relationships. This can be achieved by involving suppliers in decision-making processes or strategic collaborations. Providing opportunities for joint innovation, for example, encourages both parties to work together towards a common goal and fosters a sense of shared responsibility.

Transparent Negotiations

Engaging in transparent negotiations is critical in managing supplier relationships. Both parties should approach discussions openly, presenting their respective viewpoints, challenges, and constraints. Through candid negotiations, both the buyer and supplier can reach mutually beneficial agreements, resulting in a more stable and long-term partnership.

Maintaining Responsiveness

Responsiveness and adaptability are key components in effective supplier relationship management. Addressing issues or concerns in a timely manner fosters trust and demonstrates a proactive approach. Likewise, being open to changes in order parameters and other unforeseen circumstances promote problem-solving and flexibility in the partnership.

Continuous Improvement

Lastly, driving continuous improvement within the relationship leads to enhanced performance and stronger collaboration. Encouraging suppliers to adopt industry best practices or improve operational efficiency can benefit both parties. This collaborative improvement effort often results in higher regional and global competitiveness, ensuring sustainable growth.

In conclusion, managing supplier relationships effectively involves several interdependent factors, including trust, mutual commitment, evaluation, negotiation, responsiveness, and continuous improvement. By nurturing these elements in a partnership, organizations can enjoy more reliable and successful supplier relationships, ultimately contributing to their overall business performance.

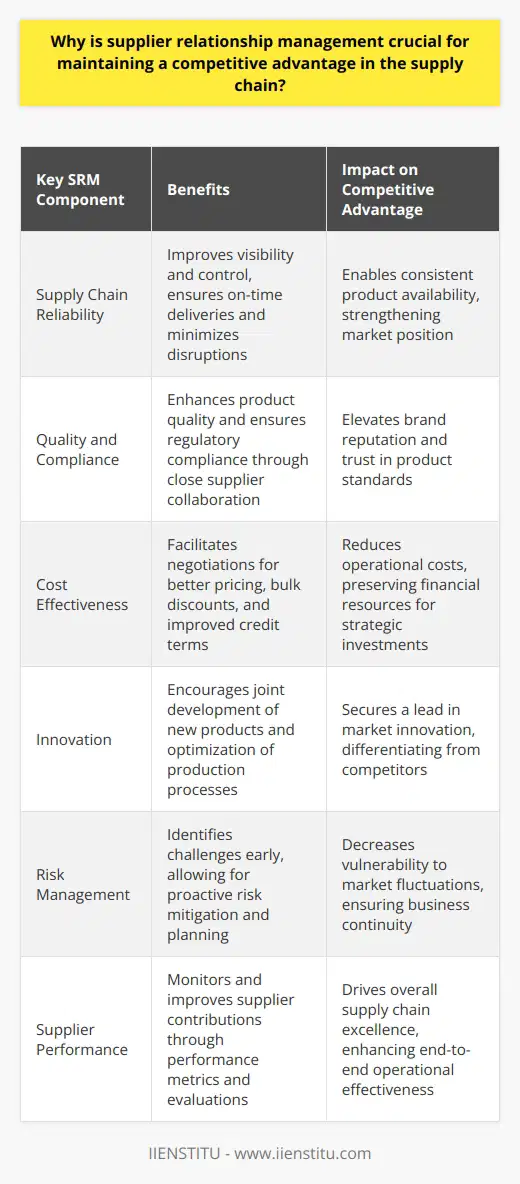

Why is supplier relationship management crucial for maintaining a competitive advantage in the supply chain?

Supplier Relationship Management: A Competitive Edge

Maintaining healthy supplier relationships is crucial for several reasons. Firstly, effective relationship management aids in ensuring the continuous supply of goods and services. Without a stable supply, companies might find it challenging to meet customer demand promptly.

Enhancing Quality Control

Supplier relationship management significantly contributes to quality control. Active engagement with suppliers might result in better product or service quality. A strong supplier relationship can allow companies to influence or control the supplier’s production practices ensuring adherence to set quality standards.

Enabling Cost-Efficiencies

Cost-efficiencies can also be realized through active supplier relationship management. Good relationships tend to result in more advantageous pricing, credit terms and bulk-purchase discounts. These factors translate into substantial cost savings, contributing positively to the bottom line.

Promoting Innovations

Furthermore, strong supplier relationships can stimulate innovations. Companies can leverage strong ties with suppliers to gain access to the latest materials or technologies ahead of competitors. This ability to achieve first-mover advantage can be an important differentiating factor in the marketplace.

Bolstering Risk Management

Moreover, effective supplier relationship management can fortify risk management. Knowing suppliers well enables a company to anticipate plausible risk situations and prepare accordingly. This comprehensive understanding of the supplier’s circumstances can provide early warning signals, enabling more effective risk mitigation.

In conclusion, supplier relationship management is critical for maintaining a competitive edge in a supply chain. Benefits such as enhanced quality control, cost efficiencies, fostering innovation and improved risk management, derive from it. These benefits ultimately contribute to a strengthened competitive position. Therefore, supplier relationship management should be a strategic priority for companies striving for supply chain excellence.

What are the essential elements of effective communication and collaboration in supplier relationship management?

Effective Communication

Effective communication forms the backbone of supplier relationship management (SRM). It constitutes clarity, consistency, and transparency. Clarity includes precise conveyance of objectives and expectations. Equipping suppliers with a better understanding of a company's vision fosters effective decision making. Consistent communication on advancements, issues, and feedback ensures an updated, informed relationship. Transparency facilitates trust, vital for robust supplier relationships.

Collaboration

Collaboration is another essential element. It requires active involvement, mutual goals, and problem-solving strategies. Active involvement connotes recognition and respect towards suppliers' expertise. Collaborative achievements are maximized by setting mutual goals, leading to a highly committed relationship. Problem-solving strategies, such as regular meetings and supplier development initiatives, assist in overcoming challenges.

Trust and Respect

Trust and respect constitute the emotional component of SRM. Trust encourages honesty, reduces risk, and trims transaction costs. Respect paves the way for long-term relationships, developing a productive partnership based on mutual benefits.

Technology

Technology plays a significant role in SRM. It enhances communication speed, accessibility, and accuracy. Implementing technology promotes efficient sharing of real-time data and analytics. It streamlines processes, thereby reducing costs and improving supplier relationship experience.

In Conclusion

Overall, effective supplier relationship management requires an amalgamation of clear communication, mutual collaboration, trust, respect, and technology. Balancing these components can significantly enhance the quality of supplier relationships, leading to sustainable growth.

How can companies leverage technology to strengthen and streamline supplier relationships in the supply chain?

Improving Communication with Suppliers

Companies can use technology to enhance correspondence with suppliers. For instance, by adopting advanced communication platforms, businesses can create a shared workspace. This fosters direct, real-time communication and resolves queries instantly.

Harnessing Big Data for Decision Making

Big data analytics can further strengthen supplier relationships. This approach provides insights into supplier performance and potential supply chain vulnerabilities. By identifying under-performing suppliers, companies can facilitate proper support mechanisms and address potential hiccups before they become problematic.

Embracing Automation for Order Management

Automation of order management is another key aspect. Automated systems streamline order placement and tracking, reducing manual errors and increasing efficiency. Companies can update their suppliers in real-time regarding their inventory needs, leading to foreseeable production plans and fewer disruptions in the supply chain.

Embedding AI for Proactive Approach

Deploying AI tools can also be instrumental. AI helps in predictive analysis and notifies companies about potential hitches beforehand. Companies can then notify suppliers much in advance, promoting a proactive rather than reactive approach to issues that may surface.

Adopting Blockchain for Transparency

Lastly, blockchain technology can promote transparency and reliability. This tool provides a decentralized ledger system that records each transaction in a traceable, permanent and unalterable way. Such transparency builds trust and increases visibility of transactions, bolstering supplier confidence further.

Thus, leveraging technology in various forms aids in strengthening and streamlining supplier relationships. It roots out inefficiencies, reduces lag and ambiguity, promotes transparent transactions, and ultimately fosters a sustainable supply chain.