The supply chain helps identify potential risk areas and improve customer service.

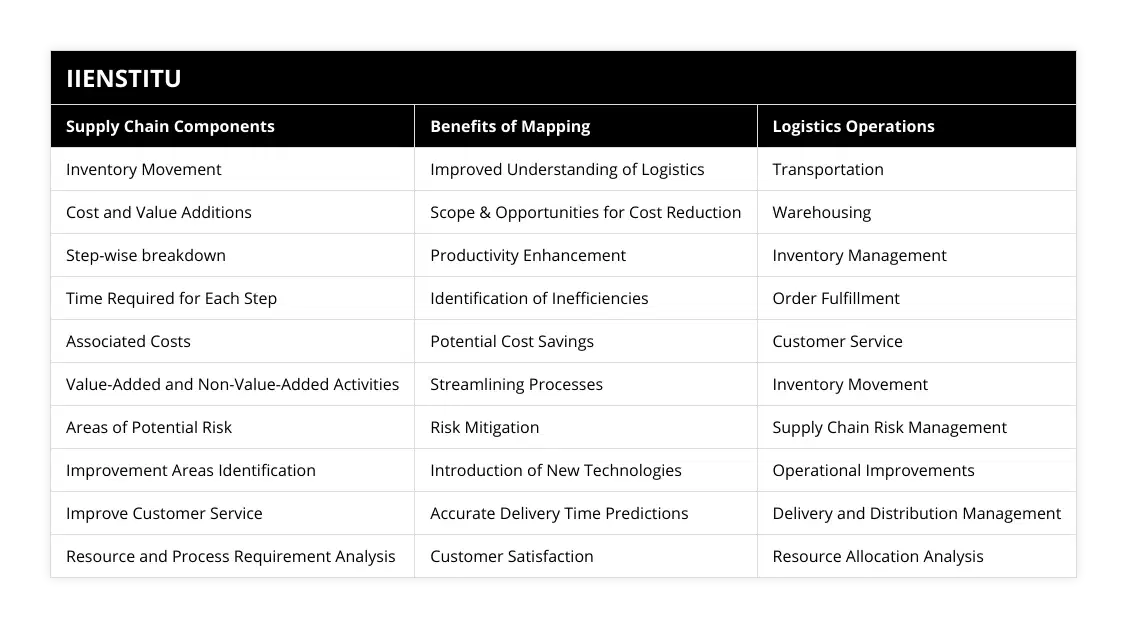

Introduction

Mapping the Supply Chain

Benefits of Mapping

Logistics Operations

Conclusion

Introduction: Mapping the supply chain is a process that helps to understand the implications of cost and value additions at the different stages of inventory movement in the supply chain. This process helps identify the scope and opportunities for cost reduction and productivity enhancement.

By mapping the supply chain, companies can better understand the logistics operations and their associated costs, value-added and non-value-added activities, time frames, and cost implications.

Mapping the Supply Chain

Mapping the supply chain involves breaking down the process into its various components and analyzing each. This includes identifying the steps, the time required to complete each step, the costs associated with each step, and the value-added or non-value-added activities that occur at each step.

This analysis helps to identify areas of inefficiency and potential cost savings. It also helps identify areas of improvement, such as streamlining processes or introducing new technologies.

Benefits of Mapping

Mapping the supply chain has several benefits.

First, it helps companies better understand logistics operations and associated costs. This helps to identify areas of inefficiency and potential cost savings.

Second, mapping the supply chain helps identify areas of improvement, such as streamlining processes or introducing new technologies.

Third, it helps to identify areas of potential risk, such as delays in delivery or inventory shortages.

Finally, mapping the supply chain can help improve customer service, enabling companies to more accurately predict delivery times and ensure that customers receive their orders on time.

Order Status İnformation For Customer Satisfaction İn Logistics Management

Optimizing Logistics Management Balancing Stock And Service Levels

Effective Warehousing And Logistics Management Tips And Strategies

Logistics Operations

Logistics operations are the activities that facilitate the movement of inventory across the supply chain. These operations include transportation, warehousing, inventory management, order fulfillment, and customer service.

Each of these operations requires different resources and processes and has its own associated costs. By mapping the supply chain, companies can better understand the logistics operations and their associated costs. This helps to identify areas of inefficiency and potential cost savings.

Conclusion: Mapping the supply chain is a process that helps to understand the implications of cost and value additions at the different stages of inventory movement in the supply chain.

This process helps identify the scope and opportunities for cost reduction and productivity enhancement. By mapping the supply chain, companies can better understand the logistics operations and their associated costs, value-added and non-value-added activities, time frames, and cost implications.

This helps identify areas of inefficiency and potential cost savings, as well as areas of improvement. Mapping the supply chain can also help to improve customer service, enabling companies to more accurately predict delivery times and ensure that customers receive their orders on time.

Unlock the power of Logistics Management by mapping the Supply Chain - the key to unlocking a successful future.

Related Course: Logistics Course

Frequently Asked Questions

What are the key benefits of mapping the supply chain?

Mapping the supply chain is creating a representation or model of the various elements and processes within the supply chain of a given business.

This process can identify and monitor the aspects that make up the supply chain, from the initial supplier to the end customer.

By mapping the supply chain, businesses can better understand their operations and how they can be improved to increase efficiency, reduce costs and improve customer satisfaction.

One of the critical benefits of mapping the supply chain is identifying potential improvement areas. By mapping the supply chain, businesses can better understand how their products move from supplier to customer and identify and monitor potential areas of inefficiency. This can result in improved operations and cost savings.

Additionally, by mapping the supply chain, businesses can identify and monitor the various stakeholders involved in the supply chain and can develop better relationships with them.

Another critical benefit of mapping the supply chain is monitoring and tracking performance. By mapping the supply chain, businesses can monitor the performance of various aspects of their supply chain, such as delivery times and costs.

This can help businesses to identify areas of inefficiency and develop strategies to improve them. Additionally, mapping the supply chain can enable businesses to identify potential risks and develop mitigation strategies.

Furthermore, mapping the supply chain can enable businesses to develop more effective strategies for responding to customer requests and demands.

By understanding the different supply chain elements, businesses can respond more quickly and effectively to customer demands, leading to improved customer satisfaction and loyalty. Additionally, mapping the supply chain can enable businesses to understand their products' potential markets better and develop strategies to target them more effectively.

In conclusion, mapping the supply chain can provide businesses with numerous benefits, from identifying and monitoring potential areas of improvement to monitoring performance, mitigating risks, and responding to customer demands.

Mapping the supply chain is an essential tool for businesses looking to improve their operations and remain competitive in today’s market.

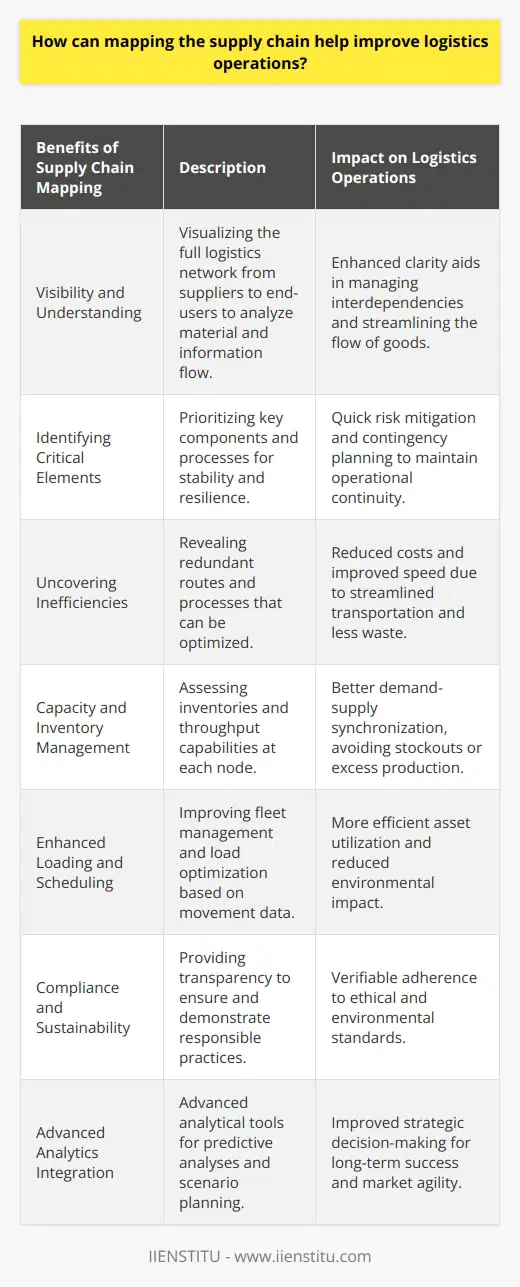

How can mapping the supply chain help improve logistics operations?

Logistics operations are a critical part of any business’s supply chain management. It is essential that these operations are efficient, cost-effective, and highly reliable. Mapping the supply chain can help improve logistics operations by clearly visualizing the supply chain network and its various components. This visualization can then identify areas for improvement, such as inefficiencies, cost savings, and process reengineering.

The supply chain can be mapped through various methods, such as GIS mapping, Process Flow Analysis, and Activity Network Diagrams. GIS mapping visually represents the physical locations of suppliers, customers, and other stakeholders in the supply chain.

Process Flow Analysis provides a detailed view of the processes and flow of materials through the supply chain. Activity Network Diagrams provide a high-level overview of the tasks and activities that make up the supply chain.

Using these mapping techniques can help identify inefficiencies and areas of improvement in the supply chain. For example, GIS mapping can be used to identify areas of over-utilization of resources or to identify potential bottlenecks. Process Flow Analysis can be used to analyze the cost and time associated with each supply chain step. Activity Network Diagrams can be used to identify areas of over-complexity or to identify potential automation opportunities.

Mapping the supply chain can also help identify cost savings opportunities. For instance, GIS mapping can help identify locations of suppliers that may offer lower prices than current suppliers. Process Flow Analysis can identify areas of over-utilization, which can be addressed by streamlining processes or introducing automation. Activity Network Diagrams can identify areas of over-complexity that can be addressed by simplifying processes or eliminating redundant tasks.

In summary, mapping the supply chain can help improve logistics operations by clearly visualizing the supply chain network and its various components. This visualization can then identify areas for improvement, such as inefficiencies, cost savings, and process reengineering. Additionally, mapping the supply chain can help identify cost savings opportunities. By utilizing these mapping techniques, businesses can make their supply chain operations more efficient, cost-effective, and reliable.

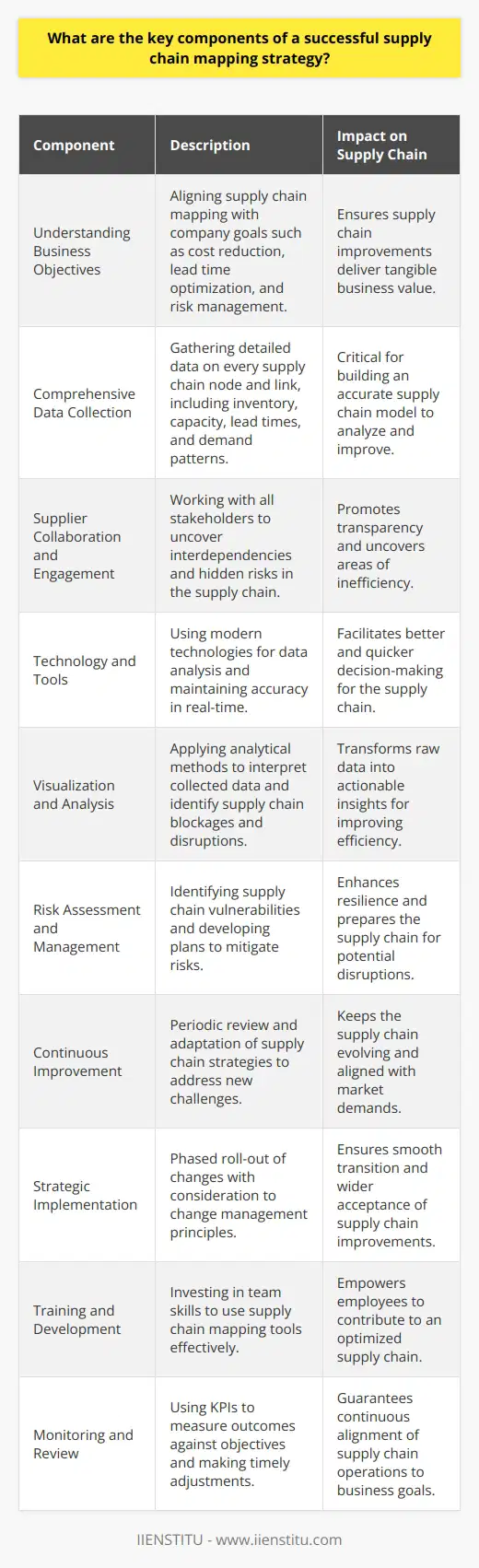

What are the key components of a successful supply chain mapping strategy?

Supply chain mapping is essential for businesses to increase efficiency and profitability. It provides visibility into supply chain operations, which helps identify areas of improvement, identify cost savings, and improve customer service.

A successful supply chain mapping strategy is critical to achieving these goals.

The first component of a successful supply chain mapping strategy is developing a clear understanding of the company’s goals and objectives. Companies should identify the desired outcomes they wish to achieve through the mapping exercise, such as reduced costs, improved customer service, or increased efficiency. This will ensure that the mapping exercise is focused and will provide a better understanding of the data needed and how it should be organized.

The second component is data collection. Companies should collect data from all relevant stakeholders in the mapping process, including suppliers, customers, logistics providers, and other key stakeholders. This data should include information about the sources and destinations of products, delivery times, order volumes, and costs. Having a comprehensive understanding of the supply chain is essential for successful mapping.

The third component is analysis. Once the data has been collected, it must then be analyzed to identify improvement areas and potential cost savings. Companies should use analytical tools such as big data analytics and artificial intelligence to identify patterns in the data and uncover insights.

The fourth component is implementation. Once the data has been analyzed and insights have been identified, the next step is implementing changes in the supply chain. These changes should be implemented promptly to ensure that they are effective. Companies should also consider the impact of these changes on the entire supply chain, as well as on the customer experience.

Finally, companies should monitor the results of their supply chain mapping strategy. Regular monitoring will ensure that changes are effective and that additional improvements can be made.

Monitoring should also help to identify any potential issues that may arise, such as supply chain delays or disruption.

Overall, supply chain mapping is essential for businesses to optimize their supply chains and increase efficiency. A successful supply chain mapping strategy requires careful planning, data collection, analysis, implementation, and monitoring.

By following these steps, companies can maximize the potential of their supply chain mapping strategy and achieve the desired outcomes.

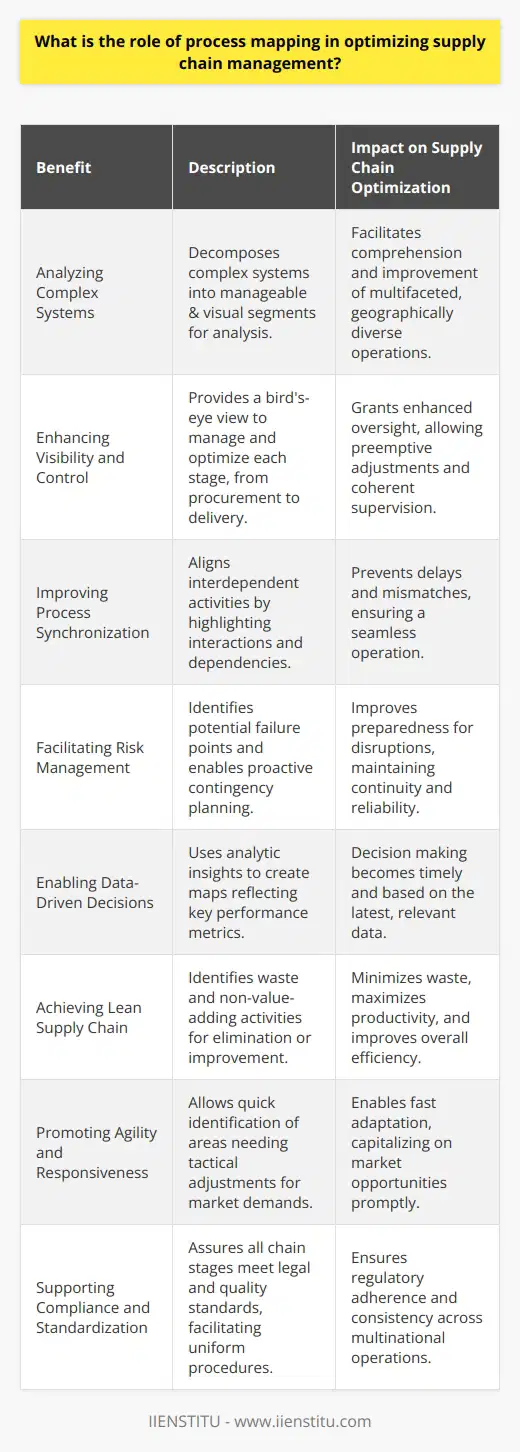

What is the role of process mapping in optimizing supply chain management?

Role of Process Mapping in Supply Chain Optimization

Understanding the Process

Process mapping plays a crucial role in optimizing supply chain management by providing a visual representation of the entire process, from suppliers to end customers. This illustration helps organizations identify inefficiencies, redundancies, and opportunities for improvement within their supply chains.

Facilitating Communication and Collaboration

Through the use of process maps, supply chain stakeholders can effectively communicate and collaborate, building a shared understanding of the current process. This consensus enables cross-functional teams to work together and develop strategies for streamlining operations, ultimately improving efficiency and reducing costs.

Identifying Bottlenecks and Inefficiencies

Process mapping allows supply chain managers to pinpoint bottlenecks and inefficiencies within the system. By identifying these problem areas, organizations can implement targeted solutions to alleviate constraints, resulting in improved operational performance and customer satisfaction.

Evaluating Performance Metrics

By comparing the current state process map to an ideal (or future state) process map, organizations can assess their progress towards supply chain optimization. This comparison highlights areas for improvement and helps identify key performance indicators (KPIs) to measure success. Monitoring these KPIs can ensure continuous improvement and sustained optimization throughout the supply chain.

Supporting Continuous Improvement

Process mapping fosters a culture of continuous improvement by encouraging regular reevaluation and updates to the map as organizational goals, technologies, and market conditions change. This iterative approach ensures that supply chain management practices evolve to stay aligned with the organization's strategic objectives and industry best practices.

In conclusion, process mapping is an essential tool for optimizing supply chain management, enabling organizations to identify inefficiencies, foster collaboration, evaluate performance metrics, and support continuous improvement. By leveraging the insights gained through process mapping, companies can develop more efficient, cost-effective, and customer-centric supply chains.

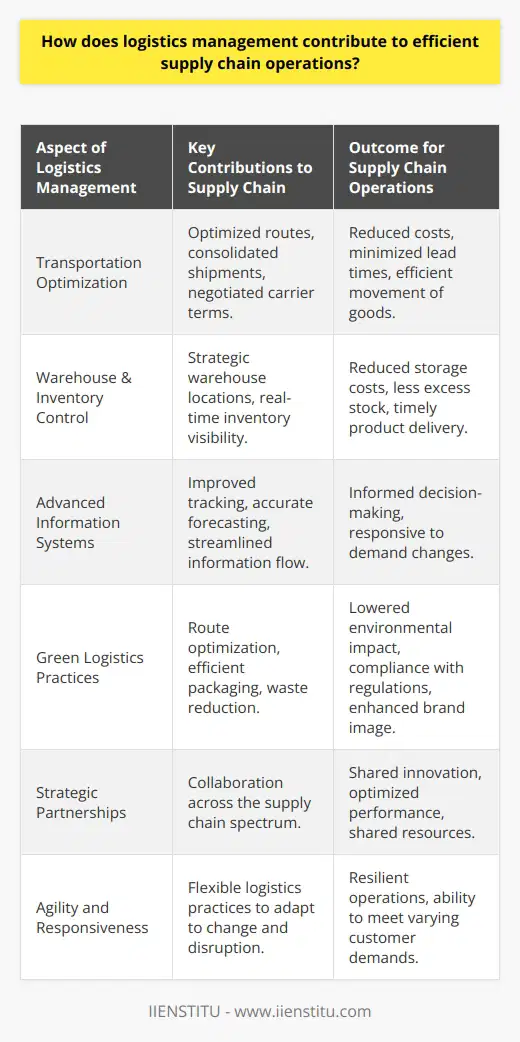

How does logistics management contribute to efficient supply chain operations?

Logistics Management and Supply Chain Efficiency

Logistics management is essential to the efficiency of the supply chain as it facilitates planning, implementation, and control of the movement and storage of goods, services, and related information. By efficiently managing logistics, companies can reduce overall costs, improve customer service, and increase competitiveness in the market.

Cost Reduction

One of the significant ways logistics management contributes to supply chain efficiency is by reducing costs. Efficient logistics planning ensures optimal transportation, warehousing and distribution, and inventory management minimizing expenses. Through careful coordination and decision making, logistics managers can identify and eliminate bottlenecks, redundancies, and wastage.

Improved Customer Service

Additionally, logistics management significantly impacts customer service levels. Efficient logistics ensure that the right products are delivered to the right place at the right time, ultimately contributing to customer satisfaction. A well-managed logistics system also helps companies to handle customer returns and address their needs and complaints quickly, securing long term loyalty.

Increased Competitiveness

Finally, efficient logistics management contributes to increased competitiveness. Streamlined logistics operations reduce lead times, enabling companies to respond swiftly to market changes and customer demands. With faster deliveries and better inventory management, companies can grab market opportunities and stay ahead of the competition.

In conclusion, logistics management plays a crucial role in the overall supply chain operations' efficiency. By reducing costs, improving customer service, and increasing competitiveness, logistics management allows companies to optimize their operations, ultimately contributing to higher profits, satisfied customers, and a competitive edge in the market.

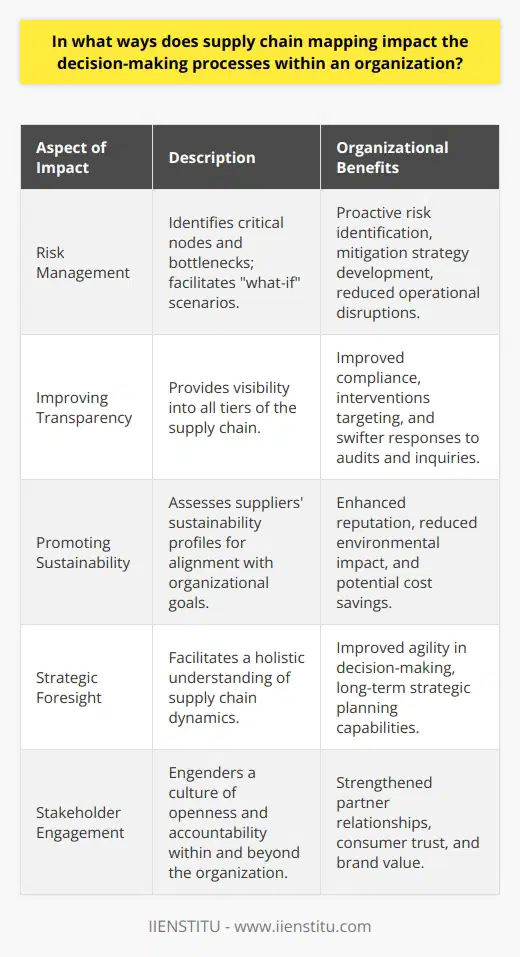

In what ways does supply chain mapping impact the decision-making processes within an organization?

Supply Chain Mapping Significance

Supply chain mapping serves as a crucial tool in the decision-making processes of an organization. By providing a visual representation of the entire supply chain network, mapping enables organizations to identify and address inefficiencies and vulnerabilities effectively. The impacts of supply chain mapping on decision-making can be analyzed through its influence on risk management, improving transparency, and promoting sustainability.

Enhancing Risk Management

One of the primary benefits of supply chain mapping is its contribution to more effective risk management. By mapping the supply chain network, organizations gain a better understanding of their supplier base and can identify potential risks such as single-source dependencies or geographic concentrations. This information enables decision-makers to take proactive steps in reducing reliance on high-risk suppliers, diversifying their supplier base, and implementing contingency plans for potential disruptions.

Improving Transparency

Another significant impact of supply chain mapping on decision-making is the enhancement of transparency within the organization. A clear and accurate map allows for a comprehensive view of the entire supply chain, including the relationships between suppliers and product flows. Decision-makers can use this information to identify areas where more visibility is needed, implement traceability mechanisms, and ensure compliance with regulatory requirements. Furthermore, increased transparency can lead to more effective collaboration with suppliers and stakeholders, ultimately improving the efficiency and responsiveness of the supply chain.

Promoting Sustainability

Lastly, supply chain mapping supports organizations in adopting more sustainable practices. A detailed map highlights areas of the supply chain where environmental, social, and governance (ESG) performance can be improved, providing decision-makers with the data necessary to drive meaningful change. By identifying opportunities for sustainable sourcing, reducing waste, and minimizing carbon emissions, supply chain mapping can guide organizations in making more responsible and sustainable supply chain decisions.

In conclusion, supply chain mapping can significantly impact an organization's decision-making processes by enhancing risk management, improving transparency, and promoting sustainability. By harnessing the power of supply chain mapping, decision-makers can create more resilient, efficient, and sustainable supply chains, ultimately leading to increased long-term success for the organization.

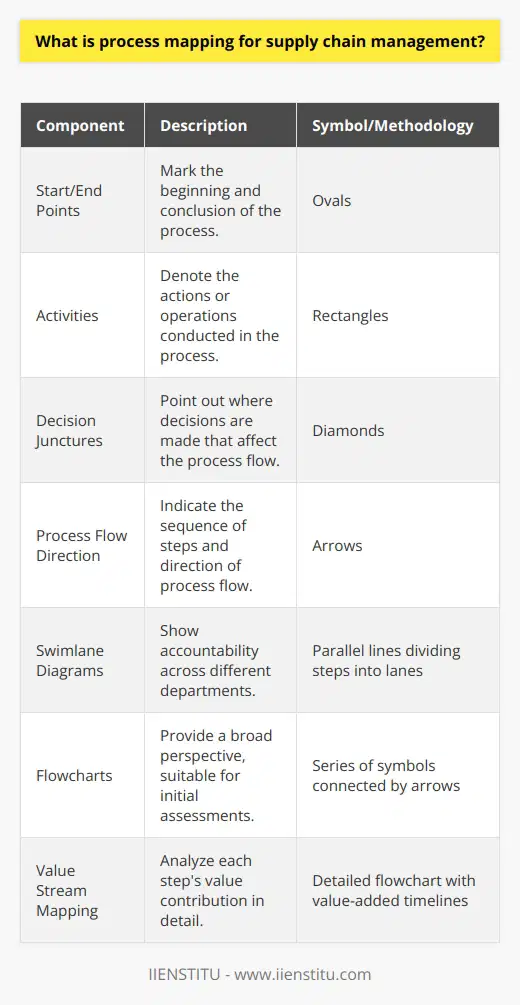

What is process mapping for supply chain management?

Introduction to Process Mapping

Process mapping for supply chain management involves creating a visual representation of various business operations, focusing on the flow of materials, information, and resources within a supply chain network. This systematic approach identifies and examines all the necessary steps and interdependencies within an organization, from suppliers to end customers.

Key Components of Process Mapping

The essential components of process mapping include identifying key activities, actors, and information flow within the supply chain. Specific elements such as inputs, outputs, resources, and stakeholders are crucial in creating an accurate overview of the entire system. Furthermore, process maps often use standardized symbols and notations to depict various elements and their relationships.

Purpose and Benefits of Process Mapping

The primary purpose of process mapping is to gain a comprehensive understanding of the supply chain, which allows organizations to identify inefficiencies, bottlenecks, and optimization opportunities. By visualizing the processes, decision-makers can analyze the interactions among multiple steps, actors, and resources, leading to improved strategy development and prioritization of initiatives. Consequently, an organization can achieve cost reduction, enhanced customer service, and accelerated time-to-market of products.

Process Mapping Techniques

Various process mapping techniques provide diverse levels of detail, complexity, and analysis for supply chain management. Examples include flowcharts, which represent a simplistic overview of the processes; value stream maps, which highlight critical steps adding value to customers; and swimlane diagrams, which emphasize the division of responsibilities among various departments or stakeholders. The choice of the method depends on the specific needs of an organization and its supply chain objectives.

Application in Supply Chain Management

When applied to supply chain management, process mapping can facilitate cross-functional communication, foster continuous improvement initiatives, and ensure compliance with industry standards or regulations. By incorporating metrics and key performance indicators into process maps, organizations can measure performance, benchmark against competitors, and track progress towards established goals. As a powerful analytical and communication tool, process mapping can contribute significantly to the overall success of supply chain management efforts.

In conclusion, process mapping for supply chain management is a valuable technique that allows organizations to visualize, analyze, and optimize their supply chain operations. By identifying areas for improvement and facilitating effective decision-making, process mapping can ultimately lead to enhanced organizational performance and competitive advantage.

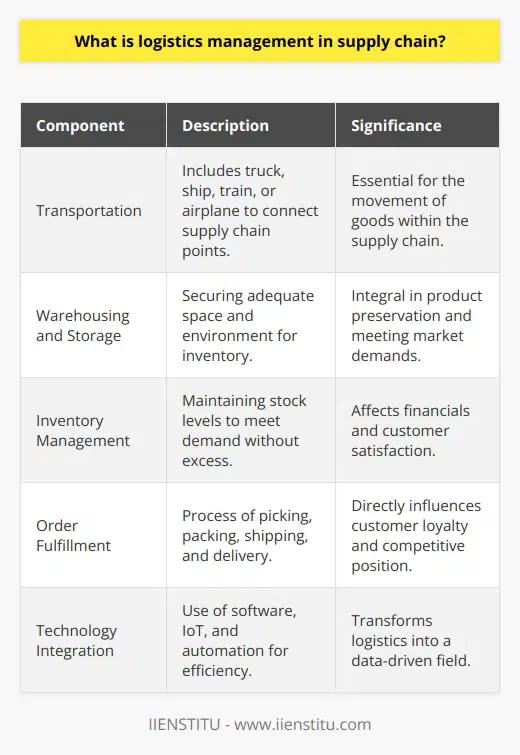

What is logistics management in supply chain?

Understanding Logistics Management

Logistics management can be defined as the strategic coordination and optimization of all activities involved in the movement and storage of materials, products, and information within a supply chain. This includes transportation, warehousing, inventory management, and order fulfillment, which are essential in ensuring that the right products arrive at the right place and at the right time.

Key Components

A well-functioning logistics management system comprises various interconnected components. Some of these vital elements are as follows:

Transportation: One of the most critical aspects of logistics management, transportation entails the physical movement of goods through various modes like air, road, rail, or sea. Efficient transportation systems ensure timely and cost-effective delivery of products.

Warehousing: Warehousing involves the storage of finished goods and raw materials, while also maintaining the optimal inventory levels to meet customer demands. Proper warehousing techniques can result in improved product availability and reduced costs.

Inventory management: This component helps to maintain the appropriate levels of stock, ensuring that there is no overstocking or stockouts. Effective inventory management leads to reduced holding costs and increased customer satisfaction.

Order fulfillment: This involves processing customer orders, their packing, and eventually shipping. By streamlining the order fulfillment process, an organization can enhance its operational efficiency and customer satisfaction.

The Role of Technology

Modern logistics management heavily relies on technology to improve efficiency and effectiveness. Advanced software systems, such as transportation management systems (TMS), warehouse management systems (WMS), and inventory management systems (IMS), facilitate automation, data analysis, and greater visibility throughout the supply chain. These technologies have vastly improved decision-making and coordination among different elements of the supply chain, ultimately leading to significant cost savings and enhanced customer service.

Challenges and Future Trends

Globalization, changing consumer preferences, and increased competition have brought forth numerous challenges for logistics management. One significant challenge is the need to continuously adapt and evolve to accommodate emerging technologies, such as automation, robotics, and artificial intelligence (AI). Additionally, there is an increasing focus on sustainability and reducing carbon emissions, necessitating the adoption of eco-friendly logistics practices.

In summary, logistics management plays a crucial role in optimizing the overall functioning of a supply chain. By effectively integrating transportation, warehousing, inventory management, and order fulfillment, successful logistics management can vastly improve an organization's operational efficiency and overall customer satisfaction. The continuous integration of technology and the need for sustainable practices will further shape logistics management's future, addressing some of the existing challenges in the field.

Why is mapping important in supply chain management?

Importance of Accurate Mapping

Mapping is crucial in supply chain management as it facilitates various aspects of decision-making, efficiency, and effectiveness. Establishing a clear and accurate map of the entire supply chain allows organizations to identify critical points and areas for improvement. This identification empowers managers to prioritize resources and strategically allocate them.

Enabling Visibility and Collaboration

One primary benefit of mapping in supply chain management is increased visibility into internal and external processes. When companies have a comprehensive understanding of their networks, they can easily track the flow of goods, resources, and information. In turn, they can collaborate more effectively with suppliers, manufacturers, and distributors to optimize operations and respond to fluctuations in demand more efficiently.

Risk Management and Mitigation

Supply chain mapping also plays a significant role in risk management. By visualizing the entire system, organizations can assess vulnerabilities and implement preventive measures before disruptions occur. The ability to anticipate and address potential risks allows for the development of contingency plans that can minimize the impact on productivity and customer satisfaction.

Enhancing Sustainability

Mapping out supply chains can also contribute to improved sustainability. By identifying the origin of all components and materials, companies can make informed decisions about selecting suppliers and products that align with their sustainability objectives. This strategic approach can support not only environmental goals but also ethical sourcing, fair labor practices, and other social concerns.

Streamlining Decision-Making

Lastly, accurate mapping provides essential data to support decision-making processes. By analyzing the flow of goods and resources, organizations can identify bottlenecks, inefficiencies, and other issues that may hinder progress. This information enables the development of targeted strategies to optimize performance and achieve a competitive advantage.

In conclusion, mapping is of paramount importance in supply chain management due to its impact on visibility, collaboration, risk management, sustainability, and decision-making. By creating a comprehensive map of their supply chain, organizations can streamline their operations, enhance efficiency, and ensure long-term success.

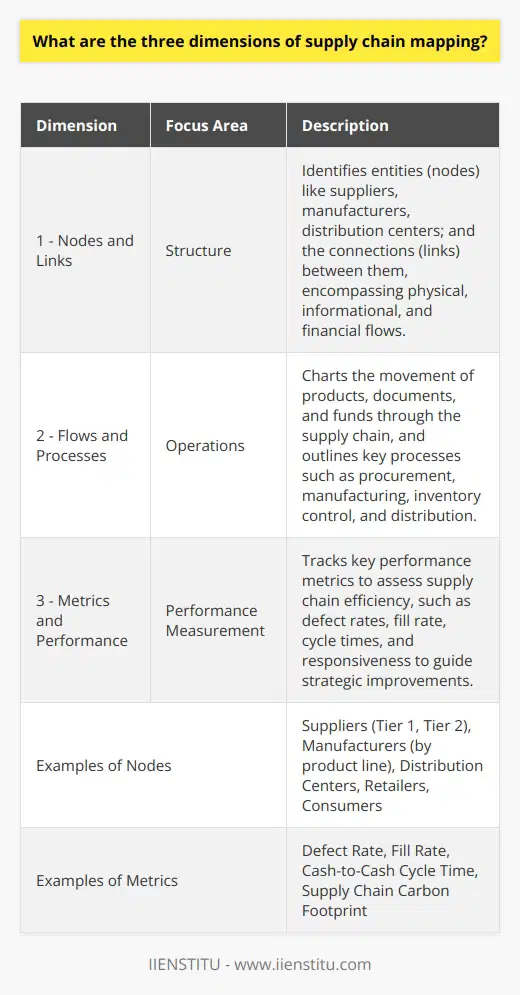

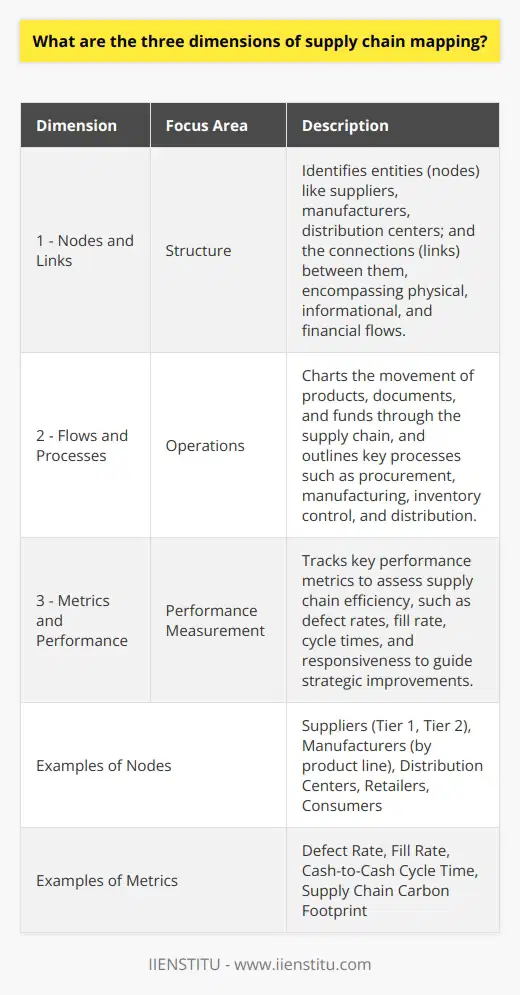

What are the three dimensions of supply chain mapping?

Dimension One: Nodes and Links

The first dimension of supply chain mapping focuses on identifying the nodes (i.e., the key players) and links (i.e., the relationships between these players) within the supply chain. Nodes typically include suppliers, manufacturers, distributors, retailers, and customers, while links represent the flow of goods, services, information, and resources between these entities. By visualizing these connections and understanding the roles and responsibilities of each participant, organizations can better manage and optimize their supply chain operations.

Dimension Two: Flows and Processes

The second dimension of supply chain mapping involves analyzing the flows and processes that occur within the interconnected network of nodes and links. This includes material flows (e.g., raw materials, components, and finished goods), information flows (e.g., data and knowledge), and financial flows (e.g., payments, credits, and investments). Additionally, managers should pay attention to the processes that govern these flows, such as procurement, production, logistics, and sales. Understanding the dynamics of these flows and processes is essential for a well-functioning and efficient supply chain.

Dimension Three: Metrics and Performance

The third dimension of supply chain mapping encompasses the use of metrics and performance indicators to evaluate and benchmark the efficiency, effectiveness, and overall health of the supply chain. These measurements may include key performance indicators (KPIs), such as on-time delivery, inventory turnover, and order cycle time, as well as other quantitative and qualitative metrics related to cost, quality, and customer satisfaction. By consistently monitoring and analyzing these metrics, supply chain managers can identify areas for improvement and drive continuous optimization efforts.

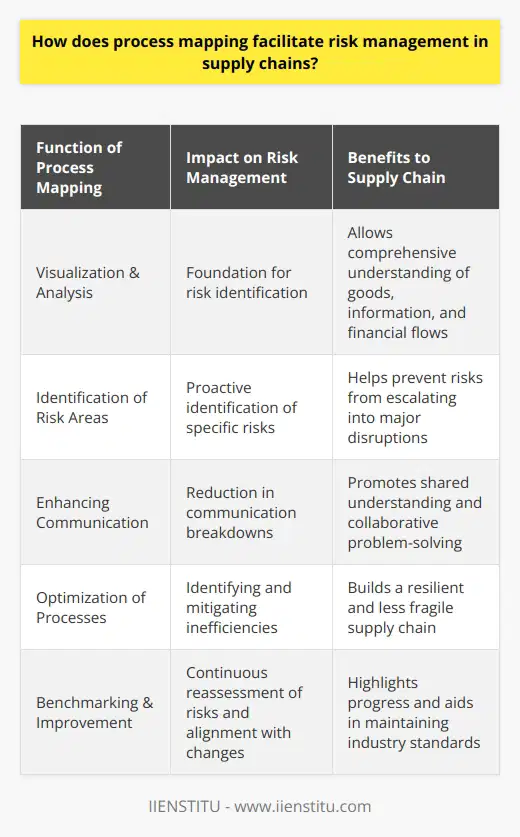

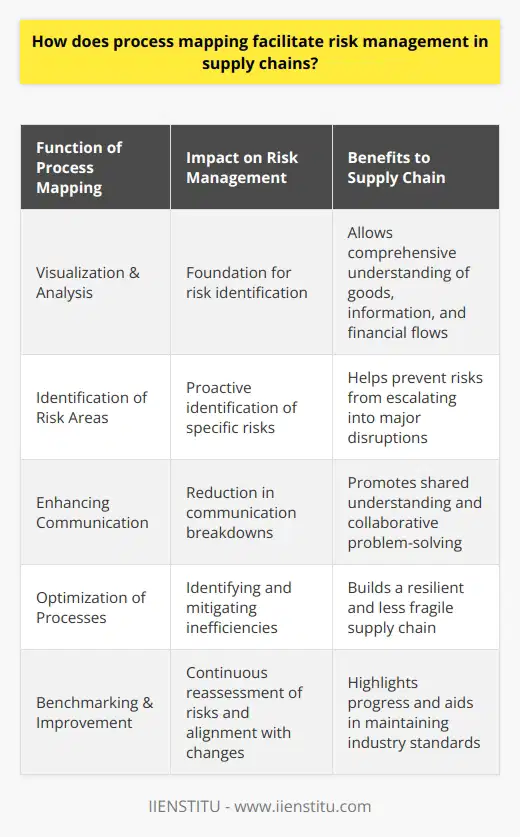

How does process mapping facilitate risk management in supply chains?

Process Mapping in Risk Management

Process mapping plays a crucial role in risk management within supply chains by providing a visual representation of a supply chain's processes, activities, and interactions. By outlining the entire process, organizations can identify and analyze potential risks and vulnerabilities more effectively.

Identification of Risk Areas

Through process mapping, businesses can pinpoint areas of risk in their supply chain. As the map details each step involved, it allows stakeholders to assess where problems such as bottlenecks, compliance issues and resource limitations might arise. This knowledge enables organizations to address risks proactively, reducing the likelihood of disruption.

Enhancing Communication and Collaboration

A process map also aids communication among supply chain stakeholders. By developing a shared understanding of the supply chain, team members across different departments can collaborate more effectively to address risk factors. This cross-functional approach encourages active engagement, fostering a more robust risk management culture.

Optimization of Supply Chain Processes

By identifying risks through process mapping, organizations can implement process enhancements to minimize vulnerabilities. Streamlining, automating, and optimizing workflows can lead to increased efficiency, reduced costs, and improved supply chain resilience. Consequently, robust process management can lower the probability and impact of potential risks.

Benchmarking Performance and Continuous Improvement

A process map can serve as a benchmark for performance. Businesses can use the map to compare current performance against established best practices and standards, helping them identify gaps and areas for improvement. In addition, process mapping facilitates continuous improvement, allowing organizations to monitor the effectiveness of risk management strategies and make iterative adjustments as necessary.

In conclusion, process mapping is an integral tool for risk management in supply chains. By identifying risk areas, enhancing communication, optimizing processes, and facilitating continuous improvement, it allows organizations to minimize potential disruptions and improve overall supply chain performance.

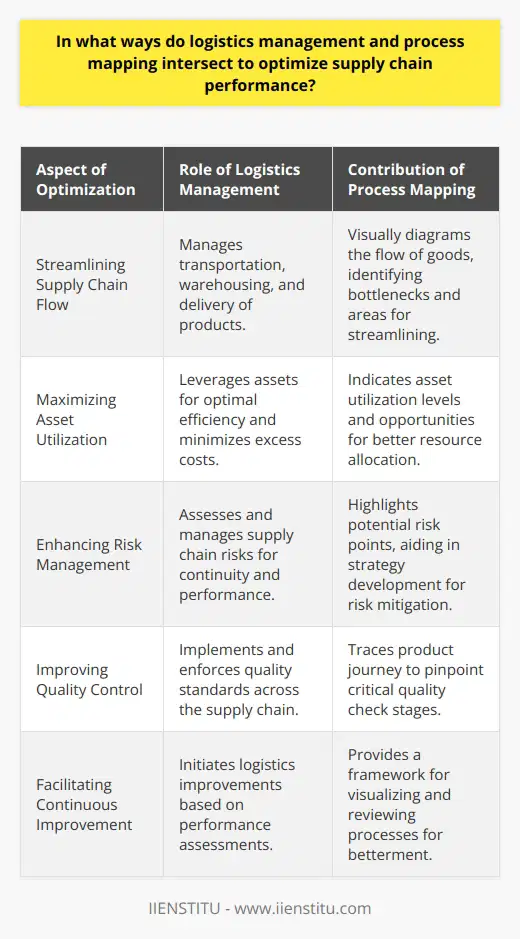

In what ways do logistics management and process mapping intersect to optimize supply chain performance?

Mapping Logistics Processes in Supply Chains

Logistics management and process mapping play significant roles in optimizing supply chain performance through seamless integration and analysis of interrelated activities. The synergistic approach of these essential components ensures a competitive advantage by addressing business challenges and enhancing performance metrics.

Coordination of Activities

One notable intersection is the coordination of diverse activities involved in the supply chain. Logistics management ensures the efficient flow of goods and information, while process mapping serves as a graphical representation of these activities. Thus, each process or task within the supply chain becomes easier to understand, manage, and improve.

Identification of Bottlenecks

Logistics management often encounters challenges with supply chain bottlenecks or points where delays occur. Process mapping facilitates bottleneck identification by visually displaying connections between activities and highlighting areas where congestion or delays might happen. Consequently, managers can implement targeted solutions to resolve these bottlenecks and optimize overall supply chain performance.

Reducing Operational Inefficiencies

Logistics management aims to reduce operational inefficiencies to streamline operations and drive higher customer satisfaction. Process mapping intersects with this objective by offering a comprehensive and visual overview of existing processes. It allows managers to pinpoint areas requiring improvement and develop more efficient logistics practices, ultimately leading to better supply chain performance.

Enhancing Collaboration and Communication

Collaboration and communication between departments, employees, and external partners are crucial for supply chain success. Logistics management establishes effective communication channels, while process mapping acts as a common language for all stakeholders to comprehend and visualize the supply chain structure. This harmonization contributes to organizational alignment and improved supply chain performance.

Data-Driven Decision Making

Finally, combining logistics management data and process mapping insights leads to data-driven decision making. This approach enables managers to make informed choices for process improvement, capacity planning, and resource allocation based on timely and accurate information. As a result, strategic decisions become more precise, intelligent, and profitable.

To conclude, logistics management and process mapping intersect to optimize supply chain performance by coordinating activities, identifying bottlenecks, reducing operational inefficiencies, enhancing collaboration, and facilitating data-driven decision making. Utilizing these practices in tandem not only streamlines processes but also fosters innovation and growth, ensuring long-term organizational success.

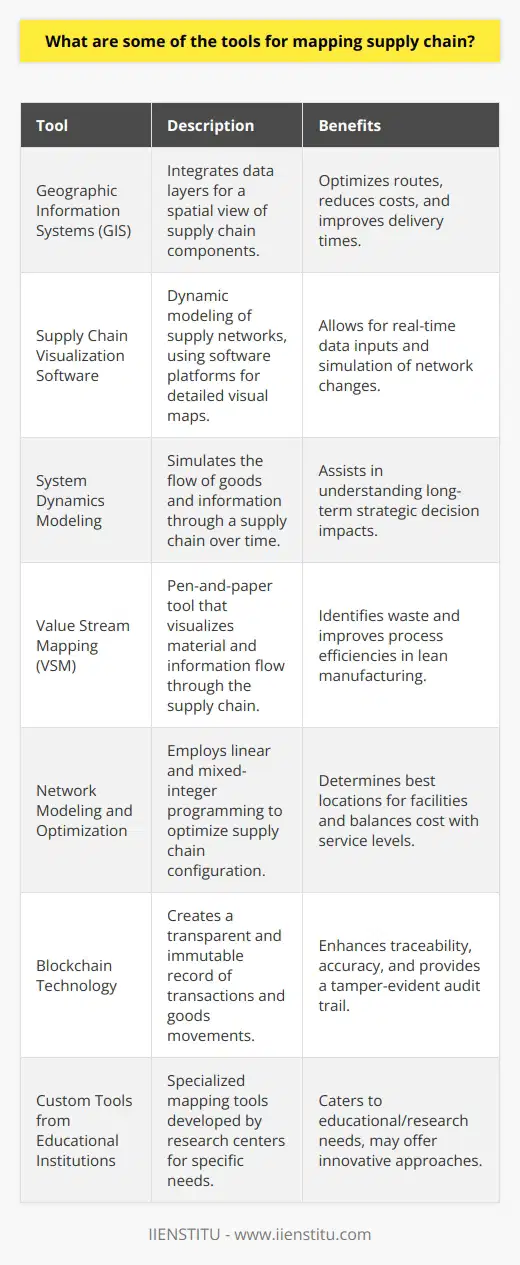

What are some of the tools for mapping supply chain?

Supply Chain Mapping Tools

Various tools can facilitate efficient mapping, visualization, and analysis of supply chains. These tools enable businesses to gain insights into their operations and make data-driven decisions to optimize overall performance.

Geographic Information Systems (GIS)

One prevalent tool for visualizing and analyzing supply chain networks is the Geographic Information Systems (GIS). GIS allows the integration of geospatial data with other information (e.g., suppliers, customers, and transport routes) to create visual representations of entire supply chain systems.

Supply Chain Visualization Software

Numerous software applications provide supply chain visualization capabilities. Some notable examples include LLamasoft Supply Chain Guru, IBM Watson Supply Chain Insights, and AnyLogistix. These tools enable businesses to model, optimize, and simulate their supply chains with the goal of reducing costs and ensuring timely delivery of products.

System Dynamics Modeling

System dynamics modeling, a simulation technique that assists decision-makers in understanding complex systems and their behavior over time, can be employed in supply chain mapping. This approach helps analyze various scenarios, identifying potential bottlenecks and areas for improvement within the supply chain.

Network Modeling and Optimization

Network modeling and optimization tools are used to design efficient supply chain networks by considering factors such as production costs, transportation costs, and demand patterns. These tools, such as GAMS and CPLEX, aid in determining the optimal locations for production facilities, warehouses, and distribution centers.

Blockchain Technology

Blockchain technology, by allowing the secure and transparent sharing of information, can enhance supply chain mapping. Companies can track product movements and transactions along the supply chain, ensuring the accuracy of information and reducing the risk of fraud.

In conclusion, successful supply chain mapping requires employing various tools and methodologies. By leveraging the power of GIS, supply chain visualization software, system dynamics modeling, network modeling and optimization, and blockchain technology, businesses can obtain a comprehensive understanding of their supply chain operations and make informed decisions to improve efficiency and effectiveness.

What are the five major management processes within the supply chain operation?

Five Key Management Processes in Supply Chain Operations

**1. Supply Chain Planning**

The supply chain planning process involves determining the best strategies and approaches for effectively meeting consumer demands. This includes demand forecasting, inventory management, and coordinating production, distribution, and transportation activities to optimize resources and ensure a seamless flow of goods throughout the supply chain.

**2. Sourcing and Procurement**

Sourcing and procurement activities focus on obtaining the necessary raw materials, goods, and services from suppliers to support a company's operations. This includes identifying potential suppliers, negotiating contracts, managing supplier relationships, and controlling costs through strategic purchasing and risk management.

**3. Manufacturing and Production**

Manufacturing and production activities encompass the transformation of raw materials into finished products or services. This process includes the planning and execution of operations, such as product design, assembly, quality control, and maintenance to meet customer expectations regarding product quality, cost, and delivery.

**4. Logistics and Distribution**

Logistics and distribution activities manage the transportation, warehousing, and delivery of finished products to customers, ensuring timely and efficient delivery. This process includes managing transportation modes and carriers, inventory control, warehouse management, order processing, and tracking shipments to improve customer satisfaction and minimize transportation costs.

**5. Reverse Logistics**

Reverse logistics addresses the management of product returns, repairs, and recycling, as well as the disposal of waste or obsolete products. This process aims to minimize costs and environmental impact by effectively managing product lifecycles, recovering value from returns or waste, and ensuring regulatory compliance.

How does process mapping facilitate risk management in supply chains?

Mapping Supply Chain Processes

Process mapping facilitates risk management in supply chains by providing a comprehensive visual representation of a supply chain's various activities, resources, and entities. This representation enables organizations to identify potential risks and vulnerabilities, making it easier to implement mitigation strategies.

Identifying Potential Risks

Through process mapping, organizations can systematically assess the different stages of their supply chain to pinpoint potential hazards. A thorough understanding of activities, infrastructure, and the inter-relationships between various entities helps in uncovering potential areas of concern, such as suppliers' reliability, transportation delays, or geopolitical issues affecting raw materials sourcing.

Enhancing Visibility and Collaboration

Process maps offer a transparent view of the complete supply chain, supporting communication and collaboration between stakeholders. Enhanced visibility enables organizations to share critical information related to risks and vulnerabilities. Consequently, supply chain partners can effectively work together to prevent disruptions, ensure the stability of the supply chain, and minimize the impact of unforeseen events.

Developing Robust Risk Mitigation Plans

A process map serves as a foundation for designing risk mitigation strategies by enabling organizations to proactively identify potential threats to supply chain continuity. With a clear understanding of the cause-and-effect relationships between various activities, organizations can prioritize risks and allocate resources to address those with the highest potential impact. As a result, companies can develop comprehensive risk management plans that address potential vulnerabilities and improve supply chain resilience.

Continuous Improvement and Monitoring

Process mapping also allows organizations to continuously monitor their supply chain and assess the effectiveness of their risk management strategies. By regularly updating the process map, companies can track changes in their supply chain environment and respond promptly to emerging risks. Moreover, a process map can serve as a valuable tool for continuous improvement, helping organizations identify areas for optimization and develop new strategies to further enhance supply chain risk management.

In conclusion, process mapping is an effective tool for facilitating risk management in supply chains. By providing a comprehensive, visual representation of supply chain activities, organizations can systematically identify risks, improve collaboration, develop robust risk mitigation strategies, and continuously monitor and improve their supply chain operations.

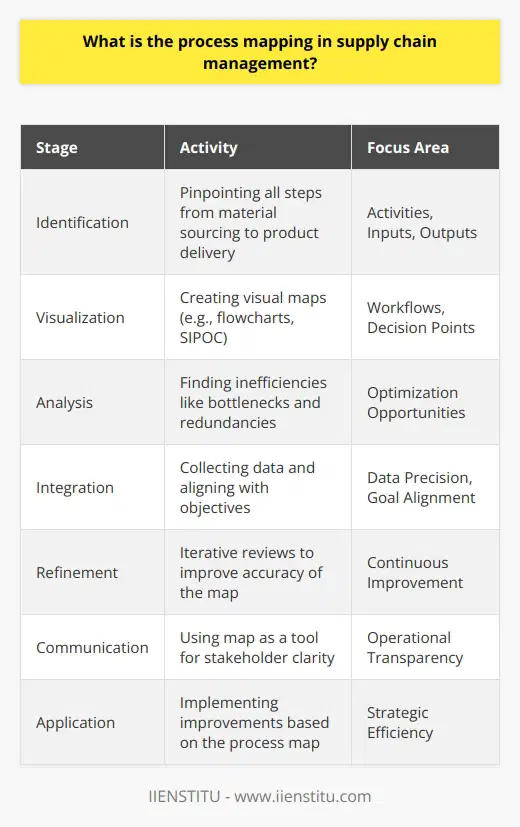

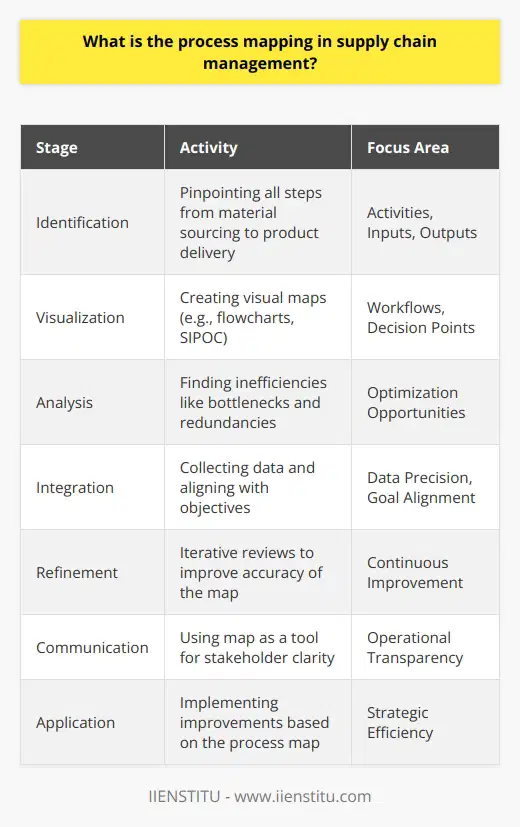

What is the process mapping in supply chain management?

Understanding Process Mapping in Supply Chain Management

Process mapping plays a crucial role in supply chain management (SCM) as it defines and visualizes the activities involved in the overall supply chain process. It attempts to create a clear understanding of the workflow, uncover any inefficiencies, and establish areas for improvement. Essentially, process mapping facilitates more streamlined decision-making by enabling supply chain professionals to analyze every aspect of their operations.

Components of Process Mapping

The components of process mapping can be broadly categorized into activities, inputs, and outputs. Activities refer to the tasks performed throughout the supply chain, such as procurement, production, warehousing, and distribution. Inputs include the materials, resources, or information required to execute these activities. Outputs represent the outcomes or results of the activities, such as finished goods, invoices, or delivery notices.

Types of Process Maps

There are several types of process maps used in SCM, each with varying levels of detail and complexity. Some of the most common include the flowchart, SIPOC (suppliers, inputs, process, outputs, customers) diagram, and value stream map. Flowcharts are relatively simple representations of the activities and decision points in a process. SIPOC diagrams provide a high-level overview of the entire system, identifying suppliers, inputs, processes, outputs, and customers in a single visual. Value stream maps, on the other hand, offer a more comprehensive analysis of process flows, incorporating metrics like lead time, value-added activities, and waste identification.

Benefits of Process Mapping in SCM

The main advantage of process mapping in SCM is its ability to identify inefficiencies and areas for potential improvement. By visually representing the activities, inputs, and outputs of a supply chain, managers can more easily identify bottlenecks, unnecessary steps, and redundant processes. They can also pinpoint any inconsistencies, such as input/output mismatches or duplicate activities, that may be contributing to operational inefficiencies. Furthermore, process mapping can help identify opportunities for cost reduction, better allocation of resources, and improved customer service.

Implementing Process Mapping in SCM

To implement process mapping effectively in SCM, organizations should follow a systematic approach that includes identifying the goals and scope of the mapping exercise, selecting the most appropriate mapping tools, and gathering relevant data. Once these steps are completed, the actual mapping process can commence, involving the creation of the map, analysis, and improvement recommendations. Finally, the process map should be validated and revised as necessary to ensure optimal accuracy and value.

In conclusion, process mapping is a vital component of supply chain management, which helps to visualize and understand the activities within a supply chain. By using process mapping tools and techniques, supply chain professionals can identify inefficiencies, remove waste, and ultimately achieve a more efficient and cost-effective supply chain operation.

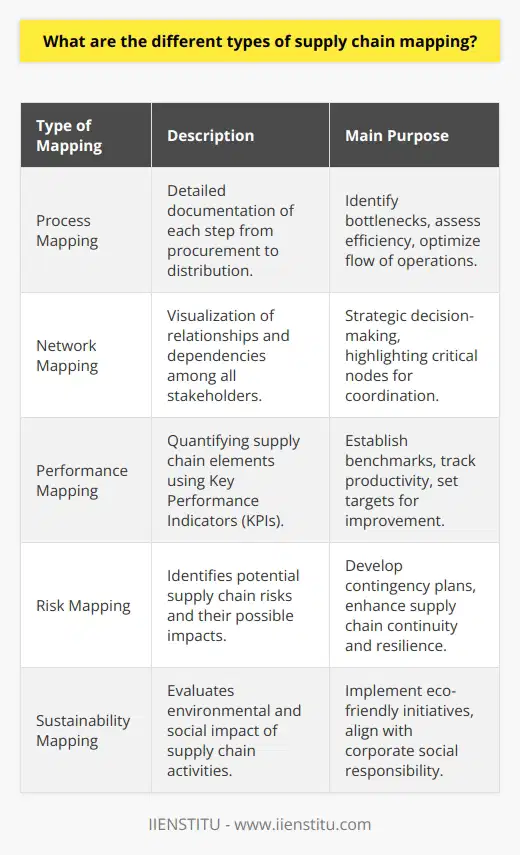

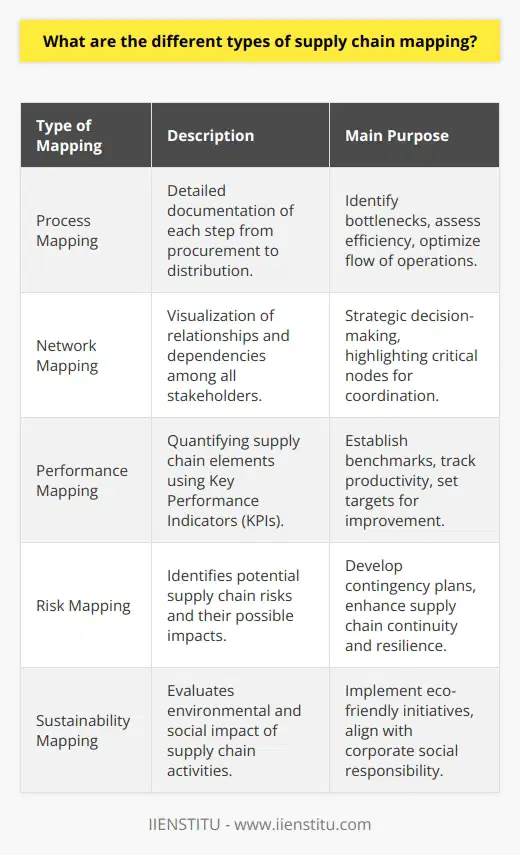

What are the different types of supply chain mapping?

Types of Supply Chain Mapping

First category: Process Mapping

Within the broad domain of supply chain management, process mapping stands out as a critical method. This approach involves the systematic documentation of every step in a specific supply chain process, from raw material sourcing to end-user delivery. Process maps graphically represent the sequence of tasks, often employing flowcharts, to generate a clear understanding of the chain's structure, enabling organizations to identify inefficiencies, redundancies, and improvement opportunities.

Second category: Network Mapping

Network mapping operates at a higher, more strategic level than process mapping. This method examines the relationships and interconnectivity among different entities within the supply chain, such as suppliers, manufacturers, distributors, and customers. Analysts create maps to visualize the entire network, illustrating the flow of materials, information, and finances throughout the system. Network mapping thus enables better decision-making, robust risk management, and enhanced collaboration among supply chain partners.

Third category: Performance Mapping

The third prominent type of supply chain mapping is performance mapping, which focuses on evaluating and measuring the performance of various supply chain components. Performance maps utilize key performance indicators (KPIs) to identify areas of strength and weakness within the network. By consistently tracking and analyzing these metrics, organizations can enhance their operational efficiency, cost effectiveness, and overall competitiveness in the marketplace.

Fourth category: Risk Mapping

Risk mapping is another essential tool for supply chain managers, as it exposes potential vulnerabilities within the system. This method entails systematically assessing and categorizing potential risks or disruptions to the supply chain, such as natural disasters, political unrest, or supplier failures. By plotting these risks on a visual map, organizations can prioritize and implement appropriate mitigation strategies to minimize potential impacts on their operations.

Fifth category: Sustainability Mapping

Lastly, sustainability mapping has gained significant traction in recent years, as concerns about environmental, social, and economic issues continue to grow. This approach involves evaluating the sustainability performance of various supply chain actors and processes. By identifying areas of concern and opportunity, organizations can work towards implementing responsible sourcing, green manufacturing, and environmentally friendly distribution practices, ultimately contributing to a more sustainable future.

In conclusion, there are five principal types of supply chain mapping: process mapping, network mapping, performance mapping, risk mapping, and sustainability mapping. Each method serves distinct purposes and offers unique insights, ultimately contributing to more efficient and effective supply chain management. By employing these tools, organizations can optimize their operations, reduce costs, enhance performance, manage risks, and promote sustainability in today's ever-changing global landscape.

What are the three dimensions of supply chain mapping?

Dimension One: Geographical Mapping

Geographical Mapping is the first dimension of supply chain mapping, which illustrates the spatial distribution of suppliers, production sites, and customers. This involves visually representing the physical locations, transportation routes, and logistics infrastructures that relate to a business's supply chain. Geographical mapping enhances the comprehension of risks, dependencies, and potential bottlenecks in the supply chain network. Furthermore, understanding the locations of various supply chain nodes enables a business to plan for, adapt to, and respond to various challenges in the supply chain efficiently.

Dimension Two: Process Mapping

The second dimension, Process Mapping, is the analysis of the different stages and procedures involved in the supply chain. It entails describing the flow of goods, information, and transactions among the suppliers, manufactures, and customers. Process mapping involves scrutinizing the movement of raw materials, semi-finished goods, and final products throughout the supply chain, from sourcing to delivery. By identifying key processes and their interdependencies, companies gain a better understanding of value-creating activities, reducing inefficiencies, and optimizing their operational performance.

Dimension Three: Information Mapping

The final dimension, Information Mapping, revolves around the flow of data, communication, and connectivity between the various actors involved in a supply chain. Such information includes details on product specifications, inventories, delivery schedules, and costs, which are essential for effective planning, coordination, and decision-making. Information mapping helps to identify gaps, redundancies, and weak links in the communication channels and the flow of data, which may crucially impact the overall functioning of a supply chain. This dimension aids in enhancing transparency, traceability, and the capacity to quickly respond to fluctuations in demand or supply.

In conclusion, the three dimensions of supply chain mapping—Geographical Mapping, Process Mapping, and Information Mapping—are essential aspects of supply chain analysis and management. Each dimension focuses on different components of the supply chain, providing insight into the spatial relationships, the efficiency of processes, and the effectiveness of information flow. By interconnecting these dimensions, businesses can gain a comprehensive understanding of their supply chain networks, enabling them to identify areas for improvement, mitigate risks, and optimize performance.

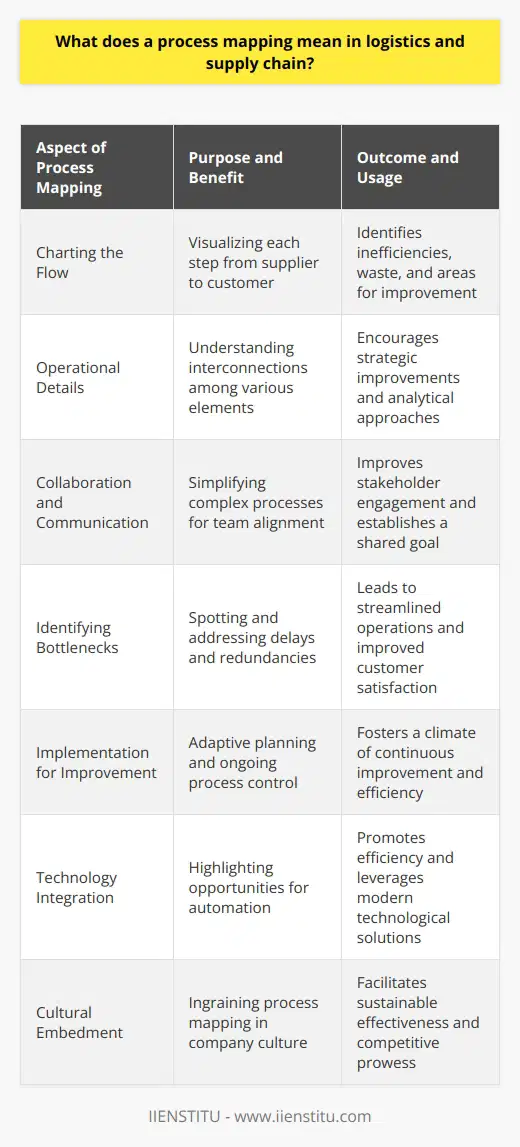

What does a process mapping mean in logistics and supply chain?

Understanding Process Mapping in Logistics and Supply Chain

Process mapping, as a technique, has emerged as an essential tool for organizations to analyze and understand the steps involved in logistics and supply chains. It entails the visualization of a series of activities and decisions that occur from the starting point to the end of a specific procedure. Particularly, process mapping involves creating a visual representation, usually in the form of a flowchart or diagram, to provide a comprehensive view of an organization's logistical and supply chain processes.

Role of Process Mapping

The primary objective of process mapping in logistics is to eliminate any inefficiencies and streamline the entire system effectively. It achieves this by revealing bottlenecks, redundancies, and unnecessary steps in the process while suggesting improvements and helping organizations make more informed decisions regarding their operations. In addition, it renders a holistic perspective on the overall logistics and supply chain strategy, allowing organizations to revise their techniques accordingly.

Benefits for Supply Chain Management

Process mapping plays a decisive role in supply chain management by offering several advantages. First, it enhances visibility and transparency within the organization, enabling better collaboration among different departments. This in turn leads to a unified workflow, resulting in improved efficiency and accuracy in supply chain operations. Secondly, it facilitates better communication and understanding among supply chain stakeholders, promoting smoother coordination to combat potential challenges and capitalize on emerging opportunities. Finally, process mapping facilitates continuous performance optimization through regular monitoring and evaluation of processes, thus driving organizations towards perpetual improvement.

Improving Logistics Processes

Employing process mapping in logistics leads to various improvements, including shorter cycle times, reduced costs, and enhanced customer satisfaction. With a clear understanding of the existing processes through mapping, companies can identify opportunities for automation, optimization, and digitization of their logistics procedures. Ultimately, optimizing logistics processes results in streamlined operations that necessitate fewer resources and time to execute, enabling companies to deliver better services at lower costs.

Final Considerations

In conclusion, process mapping is a vital tool in logistics and supply chain management, providing valuable insights into an organization's existing processes. By creating visual representations of these processes, businesses can identify inefficiencies, improve collaboration, and continually optimize their performance, leading to overall operational excellence. Embracing process mapping as a part of their strategic initiatives can unquestionably help organizations stay ahead in the competitive landscape of logistics and supply chain management.

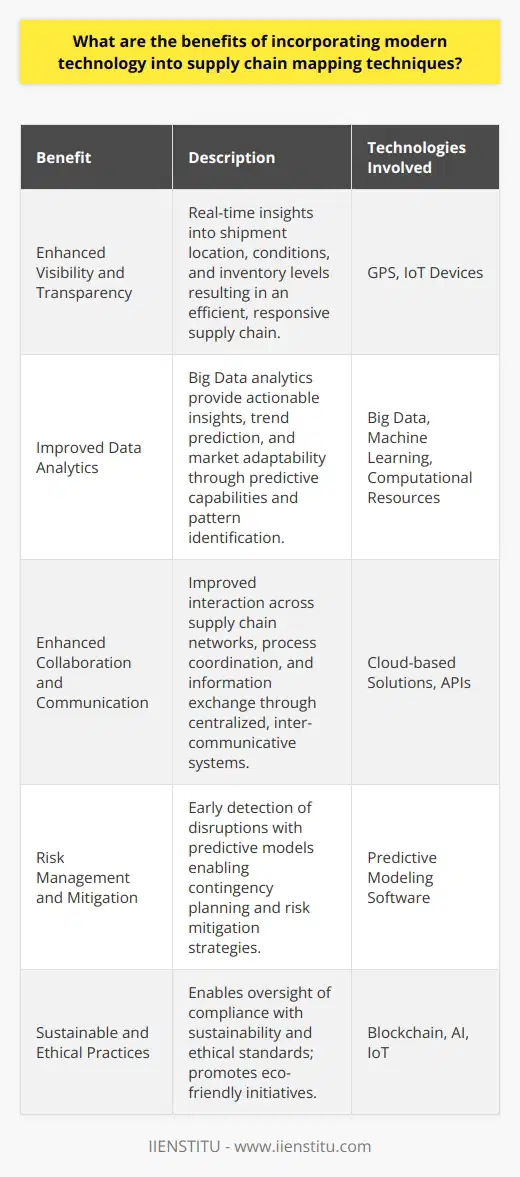

What are the benefits of incorporating modern technology into supply chain mapping techniques?

Enhanced Visibility and Transparency

One significant advantage of integrating modern technology in supply chain mapping techniques is the increased visibility and transparency throughout the entire supply chain process. Advanced tools such as Global Positioning System (GPS) tracking and Internet of Things (IoT) devices allow supply chain professionals to monitor the location and status of a shipment in real-time, enabling them to manage potential risks proactively, minimize delays, and optimize overall efficiency.

Improved Data Analytics

Modern technology facilitates the collection, storage, and analysis of copious amounts of data generated within supply chains. Big Data analytics and Machine Learning algorithms can identify trends, patterns, and correlations that were once impossible to comprehend. This newfound knowledge empowers businesses to make data-driven decisions, streamline operations, and uncover innovative solutions to existing problems.

Enhanced Collaboration and Communication

Digitizing the supply chain encourages collaboration between various stakeholders, including suppliers, manufacturers, distributors, and customers. Cloud-based platforms and application programming interfaces (APIs) facilitate communication and data sharing, fostering a collaborative environment that ensures alignment in goals, strategies, and decision-making. Improved collaboration translates to better decision-making, effective allocation of resources, and overall enhancement in supply chain agility.

Risk Management and Mitigation

Incorporating technology into supply chain mapping techniques plays a crucial role in identifying, assessing, and managing potential risks. Advanced tools such as predictive analytics enable businesses to foresee potential risks, quantify their impact, and implement proactive measures to mitigate them. In addition, these risk management techniques provide a foundation for businesses to ensure continuity and adapt to changing market conditions.

Sustainable and Ethical Practices

Lastly, modern technology supports businesses in establishing sustainable and ethical practices in their supply chains. Technologies such as blockchain can facilitate secure and transparent transactions, ensuring that materials and products adhere to specific environmental and social standards. Moreover, advanced tools such as artificial intelligence (AI) and IoT can aid in monitoring resource consumption, reducing waste, and optimizing energy use. These advancements ultimately contribute to a more sustainable and socially responsible supply chain.

In conclusion, the incorporation of modern technology in supply chain mapping techniques offers numerous benefits, including enhanced visibility, improved data analytics, increased collaboration, effective risk management, and sustainable practices. By embracing these advanced tools, businesses can optimize their supply chains, make more informed decisions, and ultimately thrive in an increasingly complex and competitive global market.

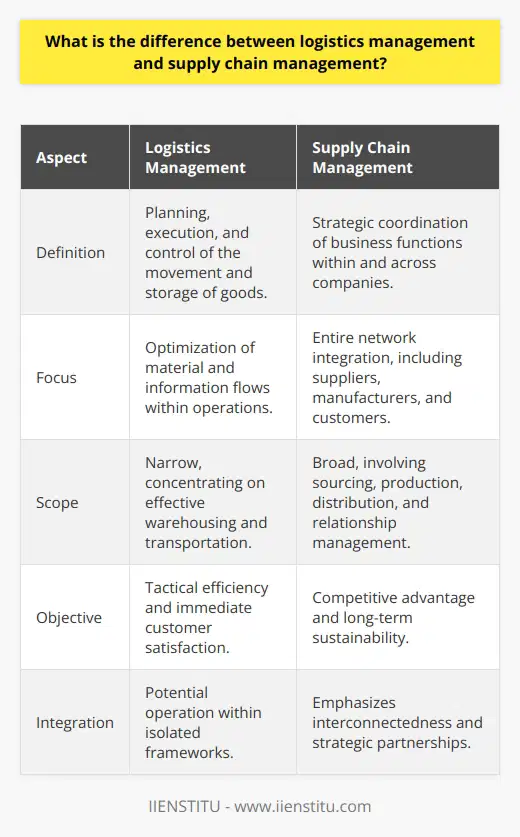

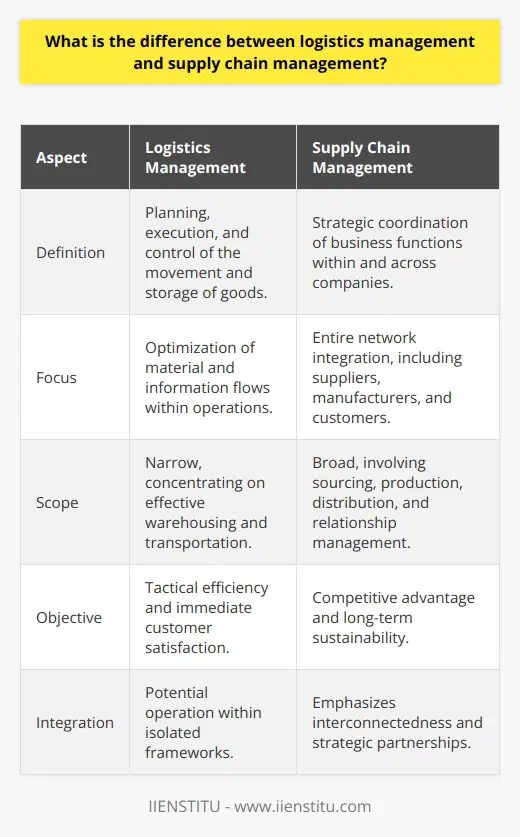

What is the difference between logistics management and supply chain management?

Understanding the Concepts

Logistics management and supply chain management are interrelated concepts; however, they possess distinct differences in terms of their scope and objectives. Logistics management primarily focuses on the efficient and effective movement and storage of goods and related information throughout an organization, from suppliers to end consumers. On the other hand, supply chain management encompasses a broader range of activities, covering the entire process of sourcing, production, transportation, storage, and distribution of products, services, and information across a network of interconnected businesses.

Role of Logistics Management

In an organization, the role of logistics management is crucial to ensure the efficient flow of goods and information. This involves planning, implementing, and controlling the movement and storage of raw materials, work-in-process inventory, finished goods, and related data within the organizational boundaries. It includes tasks such as material handling, inventory management, transportation management, warehousing, and order fulfillment. In essence, logistics management is responsible for managing and optimizing the internal movement of goods and information to achieve cost-effective and timely delivery of products to customers.

Scope of Supply Chain Management

While logistics management is focused on the internal processes of an organization, supply chain management has a broader perspective, addressing external factors that influence the overall supply chain performance. Supply chain management involves aligning the organization's strategies, processes, and relationships with its suppliers and customers to optimize the entire value chain. This includes strategic sourcing, supplier relationship management, demand forecasting, inventory planning, production scheduling, quality management, and customer service. By integrating and coordinating these diverse functions, supply chain management aims to enhance organizational competitiveness, maximize customer value, and achieve sustainable business growth.

Key Differences

The primary difference between logistics management and supply chain management lies in their respective scopes and objectives. While logistics management is concerned with the effective and efficient movement and storage of goods within an organization, supply chain management focuses on the entire network of businesses and stakeholder relationships that contribute to the creation and delivery of a product or service. Essentially, logistics management serves as an essential component of the broader supply chain management process.

In conclusion, although logistics management and supply chain management share some common goals – such as improving the flow of goods and information – they differ in their scope, objectives, and focus areas. Logistics management is predominantly concerned with the internal operations of an organization, whereas supply chain management adopts a more holistic approach, addressing both internal and external factors that impact the overall performance of the supply chain network.

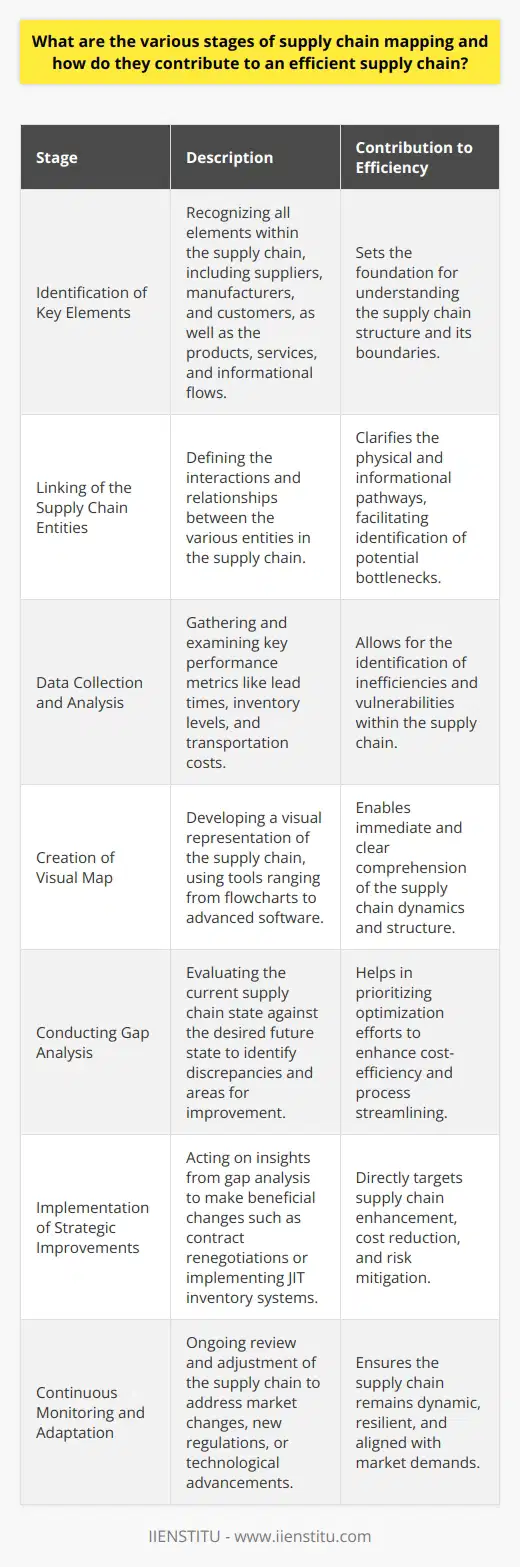

What are the various stages of supply chain mapping and how do they contribute to an efficient supply chain?

Stages of Supply Chain Mapping

Supply chain mapping involves representing a detailed vision of the entire supply chain, from procurement to final distribution, in a graphical manner. This process entails several stages to ensure an efficient supply chain management system.

Identifying Key Elements

The first stage involves identifying key elements, including suppliers, manufacturers, distribution centers, and customers. Categorizing these components according to their functions helps in comprehending the overall structure and helps in identifying potential bottlenecks.

Establishing Relationships

Once the key elements are identified, the next stage is to establish relationships among them. Linking suppliers with manufacturers, manufacturers with distributors, and distributors with customers helps visualize the flow of goods and information throughout the supply chain. This interconnectivity can facilitate better coordination and collaboration between different entities.

Gathering Data

Data collection is vital for effective supply chain management. In this stage, relevant information such as lead times, transportation costs, order quantities, and production capacities is gathered. This data enables organizations to make informed decisions, identify areas for improvement, and respond quickly to changes in market demand.

Creating a Visual Representation

With the necessary information in hand, a visual representation of the supply chain is created, either manually or using specialized software. This detailed map provides a comprehensive view of the entire supply chain and its complexity. It helps identify potential vulnerabilities, inefficiencies, or dependencies that need to be addressed.

Performing Gap Analysis

Once the supply chain map is complete, a gap analysis is performed to compare the current state to the desired state and identify areas requiring improvement. This evaluation is essential for highlighting inefficiencies or vulnerabilities that could impact the overall effectiveness of the supply chain.

Implementing Improvements

Based on the gap analysis, organizations can implement strategies and improvements to optimize supply chain performance. This may involve adopting new technologies, reorganizing processes, or building stronger relationships with suppliers and customers. Continuous monitoring of the supply chain's performance ensures that improvements are sustainable over time.

In conclusion, thorough supply chain mapping involves identifying key elements, establishing relationships, gathering data, creating a visual representation, performing a gap analysis, and implementing improvements. Each stage contributes to the development of an efficient supply chain, promoting increased productivity and profitability for organizations involved.

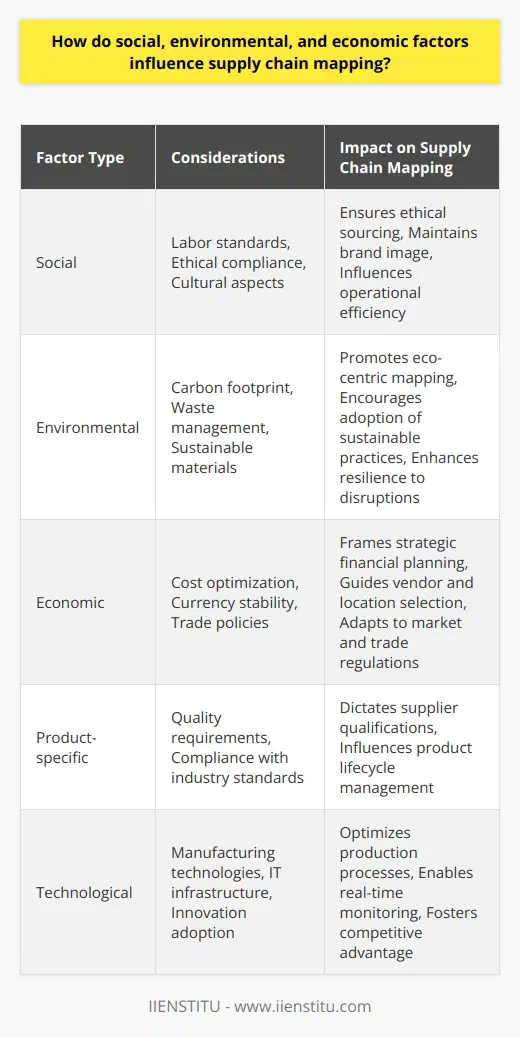

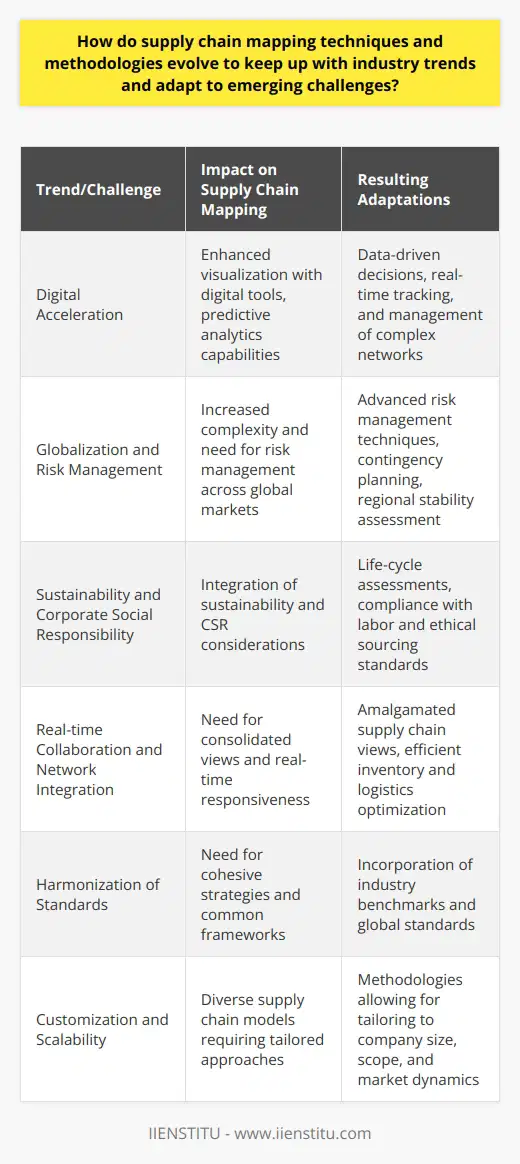

How do supply chain mapping techniques and methodologies evolve to keep up with industry trends and adapt to emerging challenges?

Utilizing Modern Technologies

Supply chain mapping techniques and methodologies have evolved over time to keep pace with the dynamic nature of industry trends while adapting to emerging challenges. One significant advancement is the integration of modern technologies such as digital tools, data analytics, and cloud-based platforms, which enable greater visibility, efficiency, and faster decision-making within supply chains.

Adapting to Globalization and Risk Management

The rapid globalization of markets and heightened risk associated with supply chain disruptions have prompted the development of more robust risk management approaches. Techniques focused on identifying vulnerabilities, monitoring the likelihood of disruptions, and building resilience in the supply chain are now vital elements in contemporary mapping methodologies.

Sustainability and Corporate Social Responsibility

As organizations increasingly prioritize environmental and social concerns, supply chain mapping techniques now incorporate considerations related to sustainability and corporate social responsibility. This includes the assessment of a company's environmental impact, social standard compliance, and circular economy principles to ensure ethical sourcing and better overall performance.

Real-time Collaboration and Network Integration

Another important aspect of supply chain mapping evolution lies in fostering real-time collaboration and network integration amongst stakeholders. Combining various data sources from different actors in the supply chain offers a more accurate representation of the entire network, aiding in identifying bottlenecks, inefficiencies, and better vendor strategies.

Harmonization of Standards

In recent years, various global organizations and industry groups have been working towards harmonizing standards and best practices in supply chain management. This harmonization process encourages the adoption of universal guidelines and techniques, fostering the development of widely applicable mapping methodologies.

Customization and Scalability

Finally, supply chain mapping techniques and methodologies have adapted to include customization and scalability. This allows organizations of varying sizes and sectors to tailor their mapping approaches to suit their specific requirements and objectives. Such flexibility enables supply chain strategies to grow and evolve in tandem with the organization's needs.

In conclusion, the evolution of supply chain mapping techniques and methodologies has kept pace with industry trends and emerging challenges by embracing advanced technologies, prioritizing risk management, focusing on sustainability and corporate social responsibility, encouraging real-time collaboration, promoting harmonized standards, and accommodating customization and scalability. These developments help ensure that supply chains remain agile, transparent, and efficient in an ever-changing global landscape.

What is the process mapping in supply chain management?

Understanding Process Mapping in Supply Chain Management

Process mapping represents a critical tool in supply chain management. It involves creating a visual representation of a process flow. This map assists in ascertaining the sequence of events or activities that a product or service undergoes to reach its final consumer.

Steps in Process Mapping

The first step in process mapping is identifying and specifying the starting and ending points of a specific process in the supply chain. Next, all steps in-between get detailed, forming a sequential order. This stepwise approach helps in understanding the flow of activities, presenting a clear picture of all steps, their interactions, and possible areas of improvements.

Importance of Process Mapping

Process mapping is paramount in analysing, improving, and configuring business processes. Its systematic approach allows managers to identify pitfalls and bottlenecks. Consequently, it aids in designing improvement strategies, cutting unnecessary costs, and saving time.

Benefits of Process Mapping

Process mapping can lead to minimized errors, meeting customer demands more effectively and streamlined workflow. Additionally, it fosters clear communication, thereby enhancing understanding among staff, reducing confusion and contributing to the overall company's efficiency.

Tools for Process Mapping

Several software tools are available to aid in process mapping. These tools facilitate a systematic and easy-to-understand pictorial representation of the entire process. Examples of these tools include MS Visio, Lucidchart, and SmartDraw.

In conclusion, process mapping plays an instrumental role in effective supply chain management. It fosters clarity, improves efficiency, reduces cost, and directly contributes to a competitive advantage for any organization.

What are the different types of supply chain mapping?

Supply Chain Mapping: A Brief Overview

Supply chain mapping is a critical tool in business. There are three major types: process mapping, network mapping, and system mapping.

Process Mapping

Process mapping involves recording each step in a supply chain in a visual manner. This includes understanding the entire journey of a product, from where it originates to where it finally ends up. Through this mapping style, managers can track material flows and identify possible bottlenecks and inefficiencies.

Network Mapping

Network mapping involves creating a visual diagram of all the entities in a supply chain and their interactions. It provides a macro-level view of the supply chain, encompassing the physical location of suppliers, distributors, and retailers. Network mapping also includes transportation routes and information flows, which helps in understanding global footprint and potential risks.

System Mapping

System mapping is the most complex form. It incorporates both process and network aspects. Additionally, it includes external influences like market forces or regulatory requirements. System mapping supports in identifying root causes of systemic issues and in devising comprehensive solutions.

In conclusion, supply chain mapping types vary based on the level of detail and scope. Each type aims to offer visibility and transparency. This assists managers to make informed decisions and improve overall supply chain performance. Understanding these different mapping types is key for success in any supply chain management strategy.

What is the difference between logistics management and supply chain management?

Defining Logistics Management

Logistics management refers to the administration of activities involved in the storage and transportation of goods. These procedures can include warehousing, inventory management, transportation, and interlinking these tasks to ensure effective movement of goods.

Defining Supply Chain Management

On the other hand, supply chain management (SCM) encompasses a wider range of activities designed to improve the overall efficiency and profitability of a business. This can involve sourcing raw materials, manufacturing processes, distribution of finished goods to consumers, and even reverse logistics such as returns and refunds.

Key Distinctions

While logistics management primarily focuses on storage and transportation, supply chain management is more comprehensive, integrating end-to-end processes to improve organizational efficiency. Logistics is essentially a component of the larger supply chain. The importance of coordination within and amongst organizations to achieve optimal outputs is a fundamental concern in SCM, but not as emphasized in logistics management.

Impact of Technology

Technology plays a profound role in both fields. In logistics, technology facilitates tracking and optimization of transport and storage processes. In supply chain management, technology enhances transparency, propelling collaboration among different links in the chain. This includes manufacturers, wholesalers, retailers, and customers.

In conclusion, the degree of complexity distinguishes logistics management from supply chain management. While the former focuses on managing specific operations, the latter involves strategic coordination of processes from raw material sourcing to the consumer's hands.