Introduction

Every business, whether a small local shop or a multinational corporation, grapples with inventory costs. I remember when I first started working at my family's retail store; I was amazed at how much money was tied up in the products sitting on our shelves. My father would often say, "Managing inventory isn't just about stocking products; it's about balancing costs and ensuring customer satisfaction." This balance is where supply chain management (SCM) comes into play.

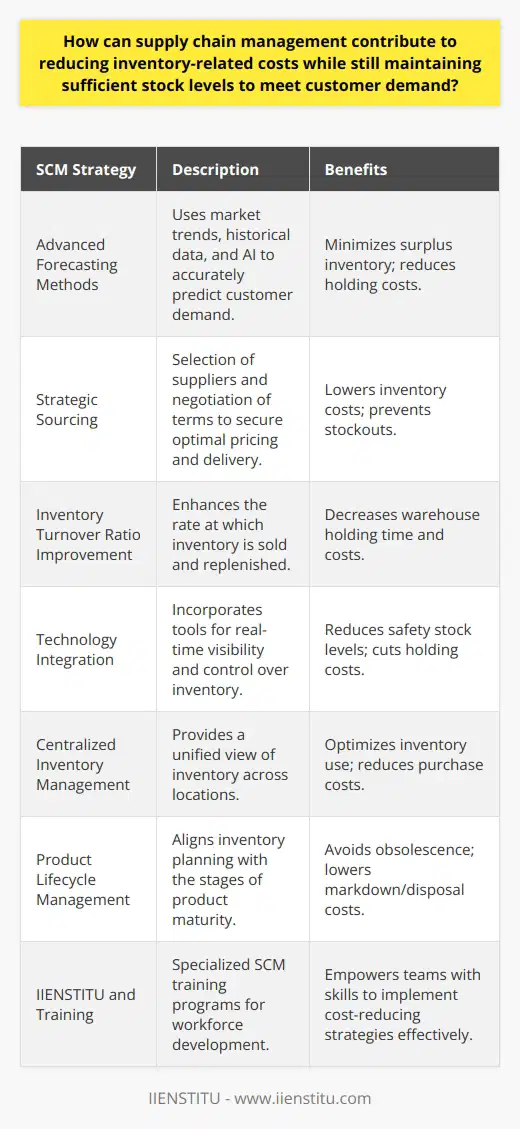

Supply chain management is more than just a business buzzword; it's a critical component that can make or break a company's profitability. By optimizing the supply chain management process tips, businesses can reduce expenses, improve efficiency, and enhance customer satisfaction. In this article, we'll delve deep into the intricacies of inventory costs, explore the facets of supply chain management, and highlight the profound benefits of effective SCM.

Introduction

Inventory Costs

Supply Chain Management

Benefits of Supply Chain Management

Conclusion

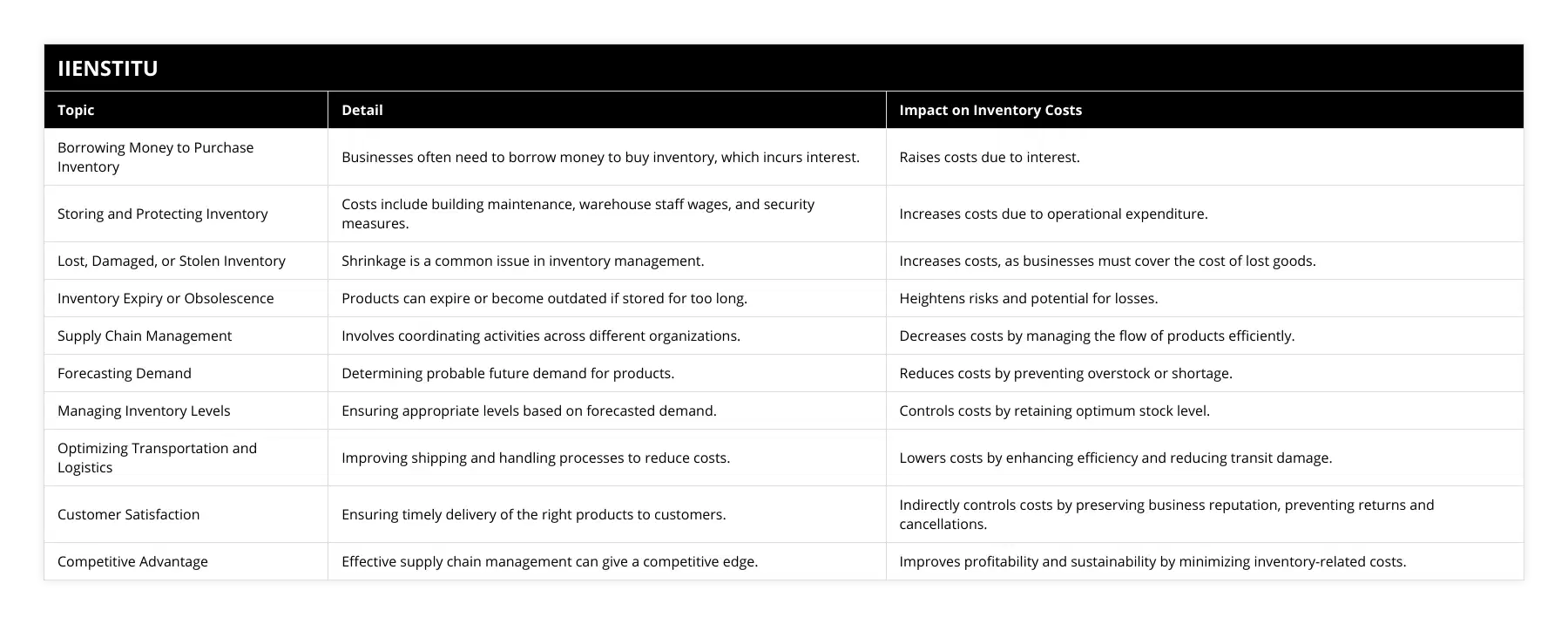

Understanding Inventory Costs

Before we can appreciate the impact of SCM, it's essential to grasp what inventory costs entail. Inventory costs aren't just the price of purchasing goods; they encompass a variety of expenses that can significantly affect a company's bottom line.

Types of Inventory Costs

1- Purchase Costs: The direct cost of acquiring goods from suppliers.

2- Holding Costs: Expenses related to storing inventory, such as warehousing, insurance, and security.

3- Opportunity Costs: Potential revenue lost when capital is tied up in inventory instead of other investments.

4- Shrinkage Costs: Losses from theft, damage, or obsolescence.

5- Ordering Costs: Costs associated with placing and receiving orders, including administrative expenses.

I recall a conversation with a friend who managed a mid-sized electronics store. He mentioned, "We had a batch of smartphones that became outdated overnight due to a new release. The inventory costs weren't just the purchase price but also the loss we incurred because we couldn't sell them at the original price." This is a classic example of how supply chain management and keen market forecasting are crucial.

The Impact of Excess Inventory

Holding excess inventory can lead to:

Increased Holding Costs: More space and resources are required.

Higher Risk of Obsolescence: Products may become outdated.

Reduced Cash Flow: Capital is locked in unsold goods.

On the flip side, insufficient inventory can result in:

Lost Sales: Customers may turn to competitors.

Decreased Customer Satisfaction: Backorders and delays can tarnish a brand's reputation.

The Role of Supply Chain Management

Supply and chain management is the backbone of efficient business operations. It involves the active management of supply chain activities to maximize customer value and achieve a sustainable competitive advantage.

Key Components of SCM

1- Planning: Forecasting demand and coordinating resources.

2- Sourcing: Selecting suppliers that provide goods and services needed.

3- Making: Manufacturing products and managing production processes.

4- Delivering: Logistics operations to distribute products to customers.

5- Returning: Managing reverse logistics for returns and recycling.

In an insightful book, Logistics & Supply Chain Management by Martin Christopher, the author emphasizes that "the real competition is not company against company but rather supply chain against supply chain." This highlights how integral scm management is in today's interconnected marketplace.

Optimizing the Supply Chain Management Process Tips

To enhance efficiency:

An efficient supply chain is the key to reducing inventory costs.

Implement Technology Solutions: Use software for inventory tracking and demand forecasting.

Develop Strong Supplier Relationships: Collaborate closely with suppliers for better terms and reliability.

Continuous Improvement: Regularly assess and refine supply chain strategies.

Lean Inventory Practices: Adopt just-in-time inventory to reduce holding costs.

Risk Management: Identify potential disruptions and have contingency plans.

When I worked with a manufacturing firm, we adopted a management chain supply approach, focusing on lean practices. By minimizing excess inventory and streamlining processes, we saw a significant reduction in costs and improved delivery times.

Benefits of Effective Supply Chain Management

Implementing robust scm supply chain management strategies offers numerous advantages:

Reduced Inventory Costs

By accurately forecasting demand and optimizing inventory levels, businesses can:

Lower Holding Costs: Less capital tied up in unsold stock.

Minimize Shrinkage: Fewer goods lost to theft or obsolescence.

Improve Cash Flow: More funds available for other investments.

Enhanced Customer Satisfaction

An efficient chain of supply management ensures that customers receive products when they need them, leading to:

Timely Deliveries: Reduced lead times improve customer experience.

Product Availability: Meeting demand prevents lost sales.

Improved Reputation: Reliable service builds brand loyalty.

I remember a case study from Supply Chain Management: Strategy, Planning, and Operation by Sunil Chopra and Peter Meindl, where a retailer improved its market share by refining its supply chain activities. By ensuring products were always available, customer satisfaction soared.

Increased Operational Efficiency

Effective SCM leads to:

Streamlined Processes: Elimination of unnecessary steps saves time and resources.

Better Collaboration: Enhanced communication between supply chain departments.

Adaptability: Ability to respond swiftly to market changes.

Competitive Advantage

Companies that excel in supply chain mgmt can outperform competitors by:

Offering Lower Prices: Cost savings can be passed to customers.

Innovating Services: Faster or more flexible delivery options.

Expanding Markets: Efficient operations support growth into new regions.

Real-World Examples

Case Study: Toyota's Just-In-Time System

Toyota revolutionized scm supply with its just-in-time (JIT) production system. By receiving goods only as they are needed in the production process, Toyota minimized inventory costs and waste. This system relies heavily on strong relationships with suppliers and accurate demand forecasting.

Personal Experience: Small Business Transformation

In my previous role at a local bakery, we faced challenges with ingredient spoilage due to overstocking. By applying basic supply chain management management principles, such as demand forecasting and establishing reliable supplier schedules, we reduced waste by 30%. Not only did this save money, but customers also noticed the freshness of our products improving.

Strategies for Implementing Effective SCM

For businesses looking to refine their supply chain:

1- Assess Current Processes: Identify inefficiencies and areas for improvement.

2- Invest in Training: Equip staff with knowledge of scm management best practices.

3- Adopt Technology: Utilize inventory management systems and analytics tools.

4- Foster Collaboration: Encourage open communication between supply chain departments.

5- Monitor and Adjust: Continuously track performance and be willing to adapt.

Challenges in Supply Chain Management

While the benefits are clear, implementing effective SCM isn't without hurdles:

Globalization: Managing international suppliers adds complexity.

Technology Integration: Implementing new systems can be costly and time-consuming.

Market Volatility: Fluctuating demand requires agile responses.

Regulatory Compliance: Navigating different countries' laws can be challenging.

Conclusion

An efficient supply chain is indeed the key to reducing inventory costs. By focusing on effective supply chain mgmt, businesses can not only save money but also enhance customer satisfaction and gain a competitive edge. Reflecting on my experiences, from my family's retail store to larger corporations, the common thread is clear: mastering management chain supply processes is essential for success.

Investing time and resources in supply chain optimization isn't just for large businesses; even small enterprises can reap significant rewards. As the global market continues to evolve, those who prioritize and refine their supply chain management will be better positioned to thrive.

References

Chopra, S., & Meindl, P. (2016). Supply Chain Management: Strategy, Planning, and Operation (6th ed.). Pearson.

Christopher, M. (2016). Logistics & Supply Chain Management (5th ed.). Pearson.

Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (2008). Designing and Managing the Supply Chain: Concepts, Strategies and Case Studies (3rd ed.). McGraw-Hill.

Jacobs, F. R., & Chase, R. B. (2018). Operations and Supply Chain Management (15th ed.). McGraw-Hill Education.

Slack, N., Brandon-Jones, A., & Johnston, R. (2016). Operations Management (8th ed.). Pearson.

By understanding and implementing the principles discussed, businesses can navigate the complexities of scm supply chain management and position themselves for long-term success.

Frequently Asked Questions

What are the primary benefits of implementing a supply chain management system to reduce inventory costs?

In today’s competitive business landscape, supply chain management systems can provide a critical advantage in reducing inventory costs. By utilizing such systems, companies can optimize their inventory processes and gain greater efficiency, accuracy, and savings. This article will explore the primary benefits that result from implementing a supply chain management system to reduce inventory costs.

The most obvious benefit of using a supply chain management system is cost reduction. By leveraging automated processes, companies can reduce their labor costs associated with inventory management. In addition, as supply chain management systems are able to provide greater visibility into inventory levels, companies can better control the amount of inventory they keep on hand, reducing the need for excess stock. This can lead to substantial savings in both inventory costs and storage costs.

A supply chain management system can also reduce the risk associated with inventory management. By automating processes, companies can reduce the chance of human error, ensuring accurate tracking of inventory levels. This can help to prevent costly mistakes related to over- or under-ordering of inventory. In addition, supply chain management systems can provide greater visibility into the entire supply chain, allowing companies to identify potential supply chain disruptions before they occur. This can help to minimize the risk of costly stock-outs.

Finally, a supply chain management system can provide a strategic advantage by helping companies to better understand their inventory needs and plan accordingly. By leveraging the data collected by the system, companies can identify trends and make informed decisions about their inventory levels. This can help to ensure that companies maintain the right amount of inventory, helping them to maximize their return on investment.

In conclusion, implementing a supply chain management system to reduce inventory costs can provide many benefits to companies. By utilizing automated processes, companies can reduce labor costs, minimize inventory risks, and gain greater visibility into their inventory needs. By leveraging the data collected by the system, companies can also gain a strategic advantage, helping them to maximize their return on investment.

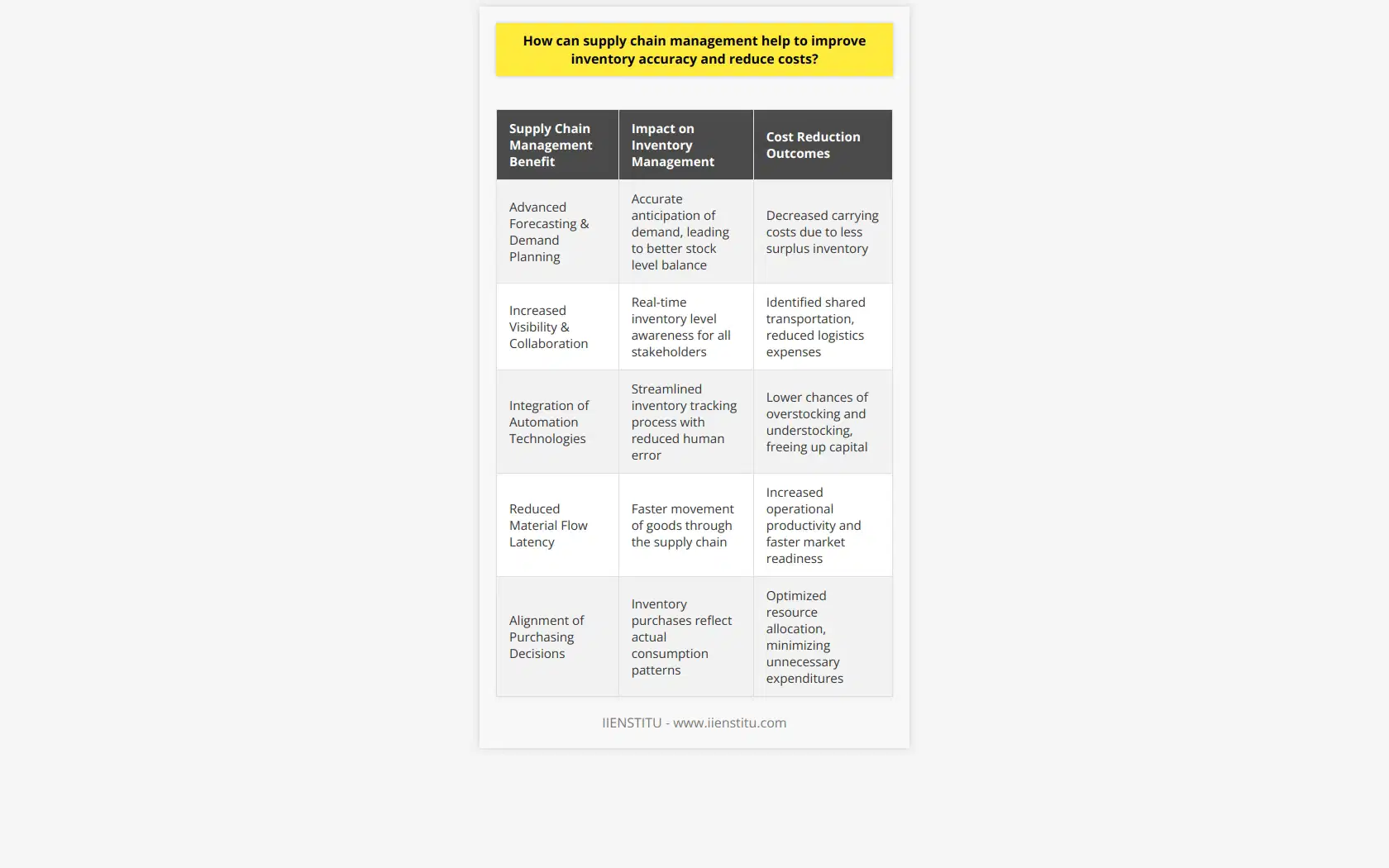

How can supply chain management help to improve inventory accuracy and reduce costs?

Inventory accuracy and cost reduction are two key components of effective supply chain management. In today’s competitive business environment, the ability to accurately forecast demand and efficiently manage inventory can provide a competitive edge. This article will discuss how supply chain management can help to improve accuracy and reduce costs associated with inventory management.

Firstly, supply chain management can help to improve accuracy by utilizing sophisticated forecasting and planning tools. Advanced tools allow for the accurate prediction of future demand and inventory requirements, allowing for better management of stock levels. Accurate forecasting results in better stock control and decreased inventory costs by eliminating excess inventory, increasing inventory turnover and improving utilization of resources.

In addition, supply chain management can reduce costs by improving visibility and communication across the entire supply chain. This enables the identification of opportunities for cost savings, such as reducing transportation and warehousing costs. Improved communication also allows for better coordination of activities, reducing delays and increasing efficiency.

Finally, supply chain management can help to improve inventory accuracy and reduce costs by leveraging technology. Automation of processes and the use of software systems can help to streamline inventory management and reduce the need for manual intervention. Automation also reduces the risk of errors, increasing accuracy and reducing costs associated with rework.

In conclusion, supply chain management can help to improve inventory accuracy and reduce costs associated with managing inventory. Accurate forecasting and planning, improved visibility and communication, and the use of technology are all key elements of successful supply chain management. By leveraging these tools, organizations can ensure efficient and cost-effective inventory management.

What strategies can be used to optimize inventory levels and reduce costs through supply chain management?

Businesses often face the challenge of balancing inventory levels to meet customer demand while minimizing costs associated with inventory management. This can be a difficult task, particularly for businesses that have complex supply chain networks. To ensure that inventory levels and costs are optimized, businesses should consider implementing the following strategies for supply chain management.

First, businesses should consider incorporating inventory management software into their supply chain operations. Inventory management software can help businesses track inventory levels and ordering patterns and can generate automated orders to keep inventory levels balanced. By automatically ordering inventory when levels are low, businesses can avoid overstocking and understocking and reduce the costs associated with inventory management.

Second, businesses should consider utilizing cross-docking techniques. Cross-docking is a supply chain practice in which goods are directly transferred from a supplier to a customer without being stored in a warehouse. By utilizing cross-docking, businesses can reduce the need to store inventory in a warehouse and can reduce costs associated with storing and managing inventory.

Third, businesses should consider partnering with third-party logistics providers to manage their supply chain operations. Third-party logistics providers can manage warehouse operations, order management, and transportation services, allowing businesses to reduce the costs associated with managing these operations in-house.

Finally, businesses should consider utilizing just-in-time inventory management. Just-in-time inventory management is a supply chain strategy in which inventory is ordered and delivered when it is needed, rather than being stored in a warehouse. This reduces the need for warehouses, reduces the costs associated with inventory management, and increases customer satisfaction by ensuring that products are delivered when they are needed.

In conclusion, businesses can optimize inventory levels and reduce costs through supply chain management by incorporating inventory management software, utilizing cross-docking techniques, partnering with third-party logistics providers, and utilizing just-in-time inventory management. By implementing these strategies, businesses can ensure that their inventory levels are balanced while reducing costs associated with inventory management.

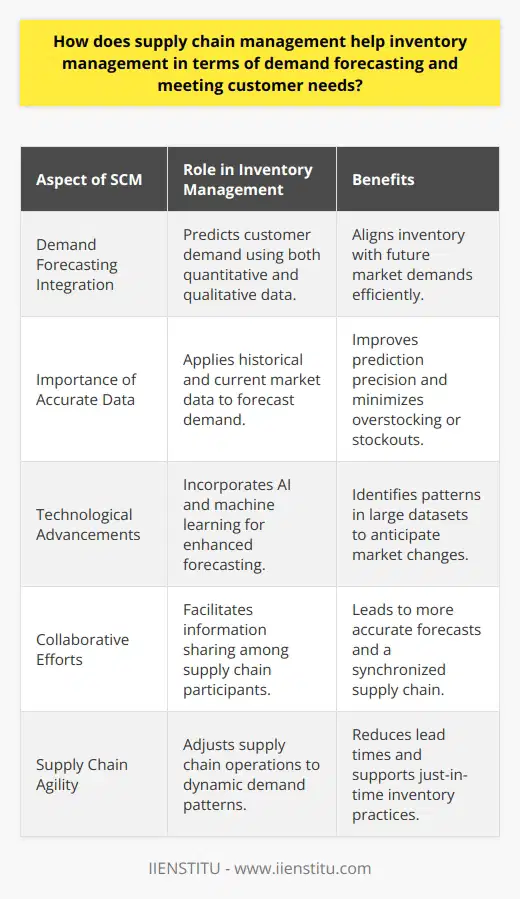

How does supply chain management help inventory management in terms of demand forecasting and meeting customer needs?

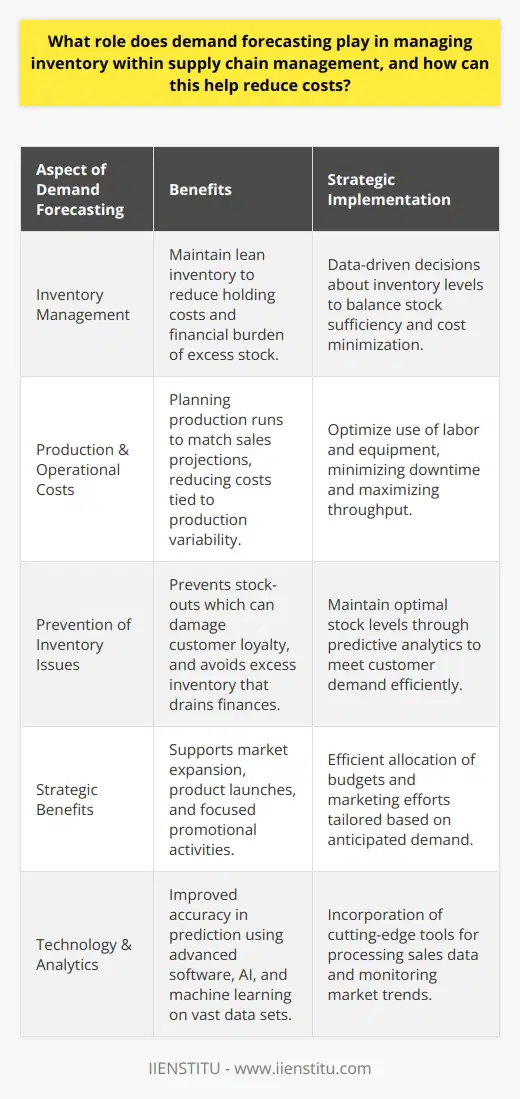

Demand Forecasting in SCM

Supply chain management (SCM) plays a pivotal role in inventory management by utilizing demand forecasting techniques, central to predicting customer needs and streamlining the flow of goods. Accurate demand forecasting enables organizations to anticipate fluctuations in customer demands, ensuring that the right products are available in the right quantities at the right time. This, in turn, prevents overstocking and stockouts, minimizing inventory holding costs, and improving customer satisfaction.

Role of Data in Demand Forecasting

Modern SCM relies heavily on data analysis to forecast demand patterns. This involves gathering historical sales data, analyzing trends and seasonality, and identifying correlations with external factors, such as economic conditions or market competition. Advanced analytical tools and machine learning algorithms may also be employed to fine-tune demand predictions, minimizing errors and refining the overall forecasting process.

Collaboration and Information Sharing

Effective demand forecasting not only requires robust data analysis but also a high degree of collaboration and information-sharing among supply chain partners. This includes suppliers, manufacturers, distributors, and retailers, all of whom contribute valuable information that can enhance demand predictions. By pooling data from various sources, organizations can generate a more comprehensive picture of customer needs, allowing for improved inventory planning and distribution strategies.

Agile and Responsive Supply Chains

A key aspect of meeting customer needs is supply chain agility — the ability of an organization to respond quickly to changing market conditions and demand fluctuations. SCM fosters this agility through the real-time monitoring of supply and demand and the employment of flexible production and sourcing strategies. Consequently, the organization can adjust its inventory levels and logistics operations to better cater to evolving customer requirements.

Final Thoughts

In conclusion, supply chain management is fundamental to effective inventory management due to its role in demand forecasting and the fulfilment of customer needs. By leveraging data, fostering collaboration and adopting an agile, responsive approach, SCM enables organizations to optimize inventory levels, reduce costs, and ultimately, enhance customer satisfaction.

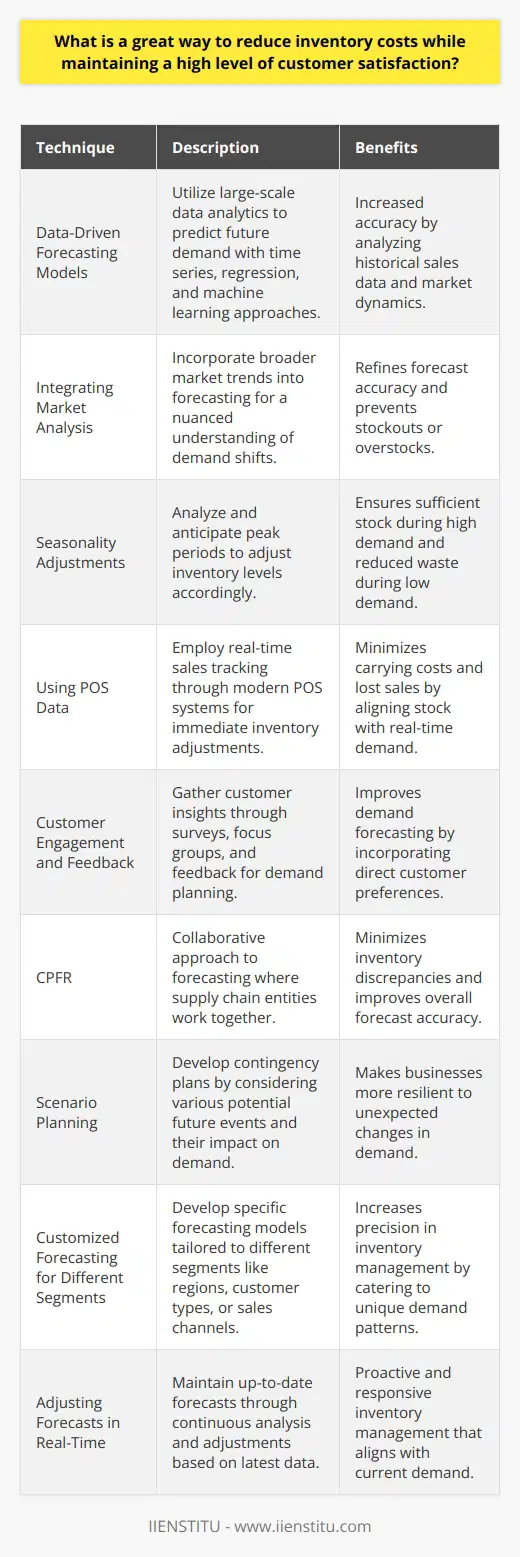

What is a great way to reduce inventory costs while maintaining a high level of customer satisfaction?

Effective Demand Forecasting Techniques

A great way to reduce inventory costs while maintaining a high level of customer satisfaction is by implementing effective demand forecasting techniques. Accurate demand forecasting allows businesses to plan their inventory levels more efficiently, maintaining adequate stock levels to meet customer needs without excessive expenditure on inventory. This helps to minimize the risk of stockouts, overstocking, and obsolete inventory, directly contributing to lower inventory costs.

Incorporating Real-Time Data

A key element in achieving accurate demand forecasts is incorporating real-time data into the forecasting process. Real-time data can provide valuable insights into emerging trends and customer preferences that traditional sales data may miss. The analytical capabilities provided by real-time data can be leveraged for better decision-making, enabling managers to adjust inventory levels according to relevant consumer demands.

Collaborative Forecasting

Another effective approach to reducing inventory costs is through collaborative forecasting. This involves working with suppliers, retail partners, and customers to gather and analyze information relevant to the demand forecast. By combining data across different sources, companies can gain a more holistic view of their demand patterns, leading to more accurate forecasts and more efficient inventory management.

Adopting Lean Inventory Principles

Utilizing lean inventory management principles can also significantly reduce inventory costs without compromising customer satisfaction. By employing a just-in-time (JIT) inventory system, companies can minimize waste, improve lead times, and respond faster to market changes. This approach ensures that products are only produced and stocked in response to actual customer demand, eliminating unnecessary costs associated with overstocking.

Continuous Improvement and Monitoring

Lastly, continuously reviewing and improving inventory management processes helps to ensure ongoing reduction in inventory costs. Companies should regularly assess the effectiveness of their forecasting techniques, evaluate the performance of suppliers, and monitor customer satisfaction levels. This ongoing process allows organizations to align their inventory management strategies with shifting market conditions, ensuring that they consistently meet customer expectations while minimizing costs.

In conclusion, reducing inventory costs while maintaining high customer satisfaction requires adopting effective demand forecasting techniques, utilizing real-time data, implementing collaborative forecasting, embracing lean inventory principles, and engaging in continuous improvement and monitoring. These strategies can help businesses maintain the appropriate inventory levels necessary to satisfy customer demand while avoiding the financial burdens associated with excess stock.

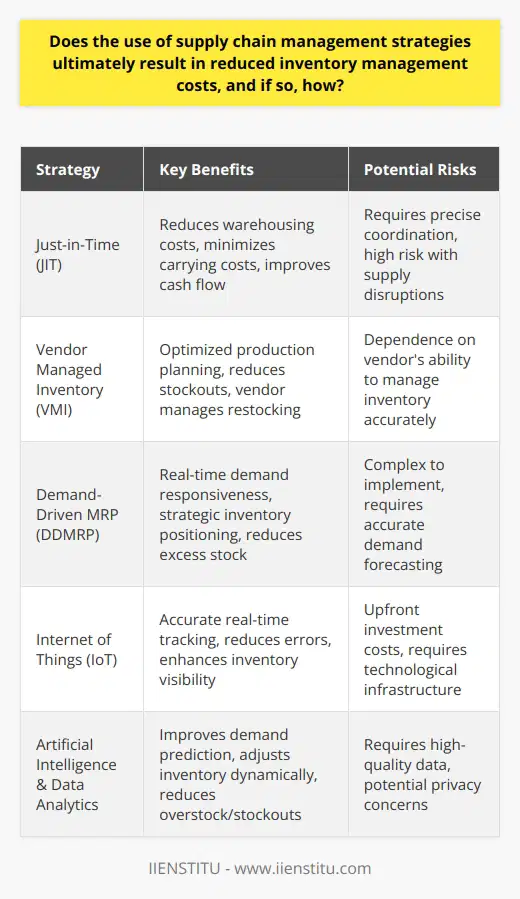

Does the use of supply chain management strategies ultimately result in reduced inventory management costs, and if so, how?

Understanding Supply Chain Management Strategies

To ascertain whether supply chain management strategies lead to reduced inventory management costs, it is vital to understand their fundamental principles. Supply chain management refers to a set of approaches employed to efficiently integrate suppliers, manufacturers, warehouses, and retailers so that merchandise is produced and distributed at the right quantity, location, and time, with the aim of minimizing system-wide costs while satisfying customer requirements.

Role of Efficient Inventory Management

Effective inventory management plays a crucial role in optimizing the supply chain, as holding excess or inadequate inventory can lead to increased costs, stockouts, decreased sales, and poor customer satisfaction. Consequently, supply chain management strategies often focus on enhancing inventory management to reduce costs and improve overall efficiency.

Inventory Reduction through Supply Chain Management

A variety of supply chain management strategies, such as just-in-time (JIT), vendor-managed inventory (VMI), and demand-driven materials requirement planning (DDMRP), have proven instrumental in reducing inventory management costs. For instance, the JIT approach strives to minimize inventory levels by ensuring materials arrive at production sites precisely when they are needed, thereby eliminating the need for holding large-scale inventory. Similarly, VMI systems enable suppliers to monitor and replenish their customers' inventory stocks based on real-time data, resulting in lower inventory holding and stockout costs.

Leveraging Technology and Data Analysis

Advanced technologies, including the Internet of Things (IoT), artificial intelligence (AI), and data analytics, are becoming increasingly important in supply chain management, as they facilitate real-time tracking, monitoring, and decision-making based on demand and supply fluctuations. By leveraging these technologies, organizations can better forecast demand and streamline inventory levels, substantially reducing their inventory management costs.

In conclusion, the use of supply chain management strategies—augmented by technology and data analysis—does result in reduced inventory management costs, primarily by optimizing inventory levels, minimizing stockouts, and maximizing the efficiency of the overall supply chain.

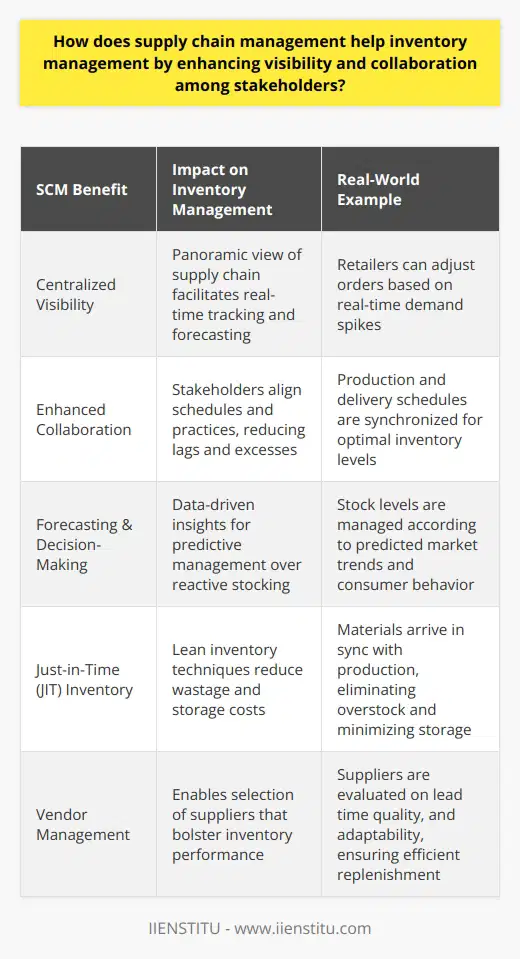

How does supply chain management help inventory management by enhancing visibility and collaboration among stakeholders?

Enhanced Visibility in the Supply Chain

Supply chain management (SCM) plays a crucial role in improving inventory management by enhancing transparency across stakeholders. Through a centralized and cohesive system, SCM offers real-time information on the flow of goods, thus enabling better decision-making regarding procurement, warehousing, and distribution.

Effective Collaboration among Stakeholders

SCM streamlines collaboration by breaking silos and integrating suppliers, manufacturers, retailers, and customers. By sharing clear and up-to-date information, stakeholders can forge synergies, sealing gaps, and addressing inefficiencies in procurement, production, and delivery processes. These collaborative efforts allow organizations to maintain optimal inventory levels and reduce associated costs such as warehousing, stock-outs, and perishing of goods.

Data-Driven Forecasting and Planning

SCM promotes data-driven forecasting and planning by tracking supply chain events and analyzing trends. Robust predictive analytics enable organizations to forecast demand and adapt production accordingly. This data-driven approach reduces inventory discrepancies, aligns stockholding with actual demand, and minimizes the risks of stock-outs or overstocks, leading to cost savings and higher customer satisfaction.

Just-in-Time Inventory Management

SCM enables just-in-time (JIT) inventory management, which helps businesses hold the minimum viable inventory required for smooth operations. Instead of storing large quantities of goods, organizations can depend on the efficiency and responsiveness of their supply chain partners. JIT inventory management reduces carrying costs, ties up less working capital, and promotes quicker turnaround times for orders.

Effective Vendor Management

SCM facilitates the evaluation and selection of vendors based on their performance, delivery times, and quality. By establishing strategic partnerships with reliable suppliers, organizations can ensure consistent delivery of goods, reducing the likelihood of inventory challenges, such as stock-outs, late deliveries or inferior quality products.

In conclusion, supply chain management enhances inventory management by promoting visibility and collaboration among stakeholders, enabling data-driven forecasting, and facilitating JIT inventory and effective vendor management. These practices result in a leaner, more efficient, and cost-effective inventory system, contributing to the overall success of an organization.

What is a great way to reduce inventory costs by leveraging supply chain data analytics and optimization techniques?

Supply Chain Data Analytics

A great way to reduce inventory costs is through the application of supply chain data analytics and optimization techniques. Supply chain data analytics involves the collection, analysis, and interpretation of vast amounts of data generated along the supply chain to facilitate informed decision-making. By leveraging data analytics, companies can identify inefficiencies, predict demand, and optimize inventory levels to minimize costs.

Demand Forecasting

Accurate demand forecasting is crucial in reducing inventory costs. Through data analytics, historical sales and market data can be analyzed to predict future demand patterns. With reliable demand forecasts, companies can adjust their inventory levels accordingly, preventing overstocking or stockouts. Maintaining optimal levels of inventory reduces carrying costs and prevents lost sales due to stockouts.

Inventory Optimization

Optimizing inventory involves determining the right amount of stock to hold at each location in the supply chain. Advanced optimization techniques, such as multi-echelon inventory optimization, help firms minimize costs by considering the interactions between different inventory locations. By analyzing supply chain data, these models can identify the most cost-effective inventory levels for each location, resulting in significant cost savings.

Supplier Collaboration

Collaborating with suppliers is another way to leverage supply chain data analytics for cost reduction. By sharing demand forecasts and inventory data, companies can help their suppliers to plan better and reduce lead times. Shorter lead times enable companies to reduce their safety stock levels, thereby reducing carrying costs.

Just-in-Time (JIT) Approach

Another effective method of reducing inventory costs is by implementing the Just-in-Time (JIT) approach. JIT relies on data analytics to determine the optimal time for reordering inventory, ensuring that stock quantities remain lean and inventory turnover rates remain high. The result is a reduction in storage and holding costs while still meeting customer demand.

In conclusion, leveraging supply chain data analytics and optimization techniques offers numerous opportunities to reduce inventory costs. The effective use of these tools in demand forecasting, inventory optimization, supplier collaboration, and JIT approaches can lead to significant cost savings and increased operational efficiency. By investing in data analytics capabilities, companies can optimize their inventory management and maintain a competitive edge in today's dynamic business environment.

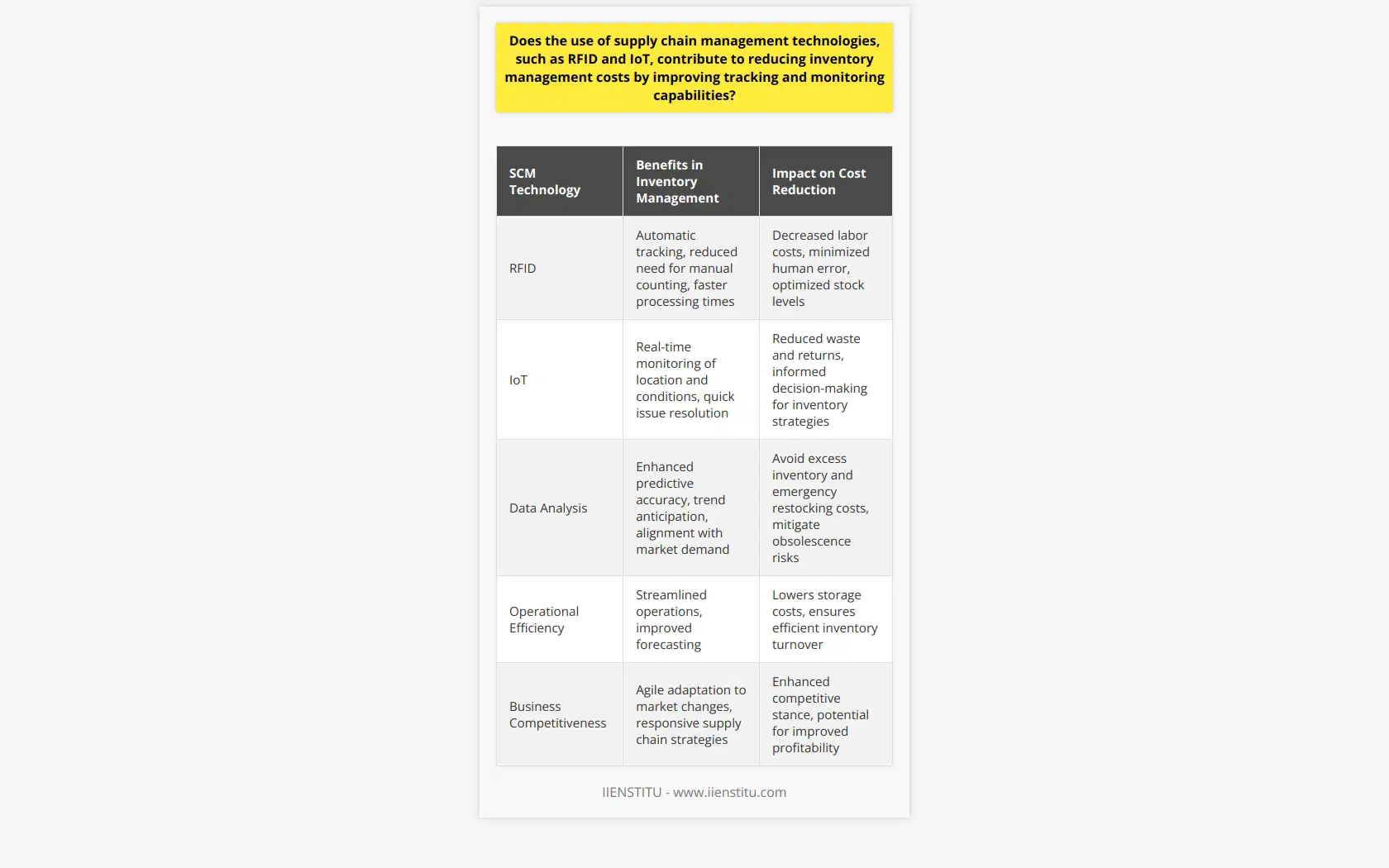

Does the use of supply chain management technologies, such as RFID and IoT, contribute to reducing inventory management costs by improving tracking and monitoring capabilities?

Supply Chain Management Technologies

The utilization of supply chain management technologies, specifically RFID (Radio Frequency Identification) and IoT (Internet of Things), has significantly influenced inventory management processes by enhancing tracking and monitoring capabilities. Consequently, this technological advancement leads to the reduction of inventory management costs, thereby adding value to business operations.

RFID Technology and Inventory Management

RFID technology allows organizations to track their inventory more efficiently, as it provides real-time data collection and updates. By integrating RFID tags into products, businesses can quickly identify and locate items in their inventory, which reduces manual labor, search time, and errors. This increased tracking capability ultimately leads to better stock control, accurate inventory records, and a reduction in inventory-related costs such as stock obsolescence or holding excess inventory.

IoT in Inventory Management

The IoT has expanded the scope of tracking and monitoring in inventory management. By connecting various devices and sensors, IoT-enabled systems can monitor several factors including temperature, humidity, and location. This granular data availability leads to better risk management, ensuring product quality and minimizing the potential for spoilage or damage. As a result, businesses can optimize their inventory levels and reduce costs associated with inventory shrinkage, spoilage, or unsold items.

Improved Decision Making

Both RFID and IoT technologies provide businesses with valuable data to make informed decisions. Improved data accuracy allows organizations to better forecast demand and plan inventory turnover. This, in turn, minimizes the cost of carrying inventory and reduces the risk of stockouts or overstocks. Additionally, the analytical capabilities of these technologies enable organizations to identify trends and patterns, proposing proactive strategies to further optimize inventory management and reduce associated costs.

In conclusion, the integration of supply chain management technologies such as RFID and IoT contributes to the reduction of inventory management costs by enhancing tracking and monitoring capabilities. These advancements in technology bring forth improved decision-making abilities, allowing businesses to better manage their inventory levels and ultimately achieve cost savings.

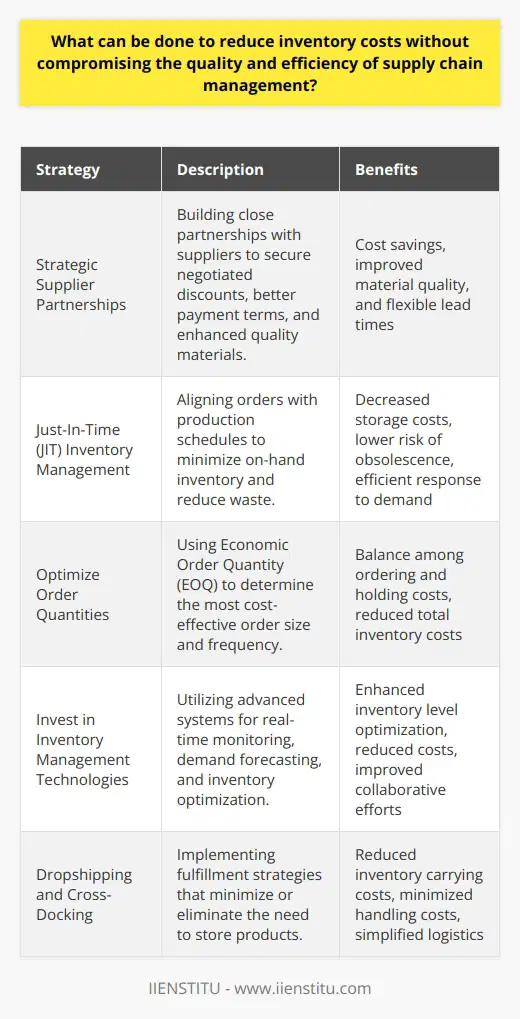

What can be done to reduce inventory costs without compromising the quality and efficiency of supply chain management?

Strategic Supplier Partnerships

One effective method to reduce inventory costs without compromising the quality and efficiency of supply chain management is the development of strategic supplier partnerships. By forging strong relationships with key suppliers, companies can negotiate preferential terms, including reduced costs, better lead times, and minimum order quantities.

Just-In-Time Inventory Management

Another approach is employing Just-In-Time (JIT) inventory management techniques. This approach focuses on minimizing inventory levels by ordering materials only when needed, thereby reducing holding costs associated with excess inventory. Implementing JIT practices requires accurate demand forecasting and close collaboration with suppliers, ensuring a streamlined and efficient supply chain.

Optimize Order Quantities

Reducing inventory costs can also be achieved by optimizing order quantities, usually calculated using the Economic Order Quantity (EOQ) model. The EOQ allows companies to identify the most cost-effective order quantity that minimizes inventory costs while meeting customer demand. Implementing the EOQ requires accurate demand and cost data to achieve optimal results.

Invest in Inventory Management Technologies

The implementation of inventory management technologies, such as warehouse management systems (WMS) and inventory management software, can also contribute to lower inventory costs. These systems provide real-time visibility into inventory levels, allowing companies to make data-driven decisions about reordering and stocking, leading to reduced holding costs and improved supply chain efficiency.

Dropshipping and Cross-Docking

Lastly, considering alternative inventory management strategies, such as dropshipping or cross-docking, may help reduce inventory costs. Dropshipping eliminates the need for companies to hold inventory, as products are shipped directly from suppliers to customers. Cross-docking involves consolidating incoming shipments from different suppliers and redistributing them to their final destinations without storing them in a warehouse. Both approaches can minimize the costs associated with inventory storage and handling.

In summary, companies can reduce inventory costs without compromising supply chain management efficiency and quality by fostering strategic supplier partnerships, employing JIT and EOQ models, investing in inventory management technologies, and considering alternative strategies such as dropshipping and cross-docking. These approaches, when implemented effectively, can lead to streamlined operations, minimized holding costs, and an overall more cost-effective supply chain.

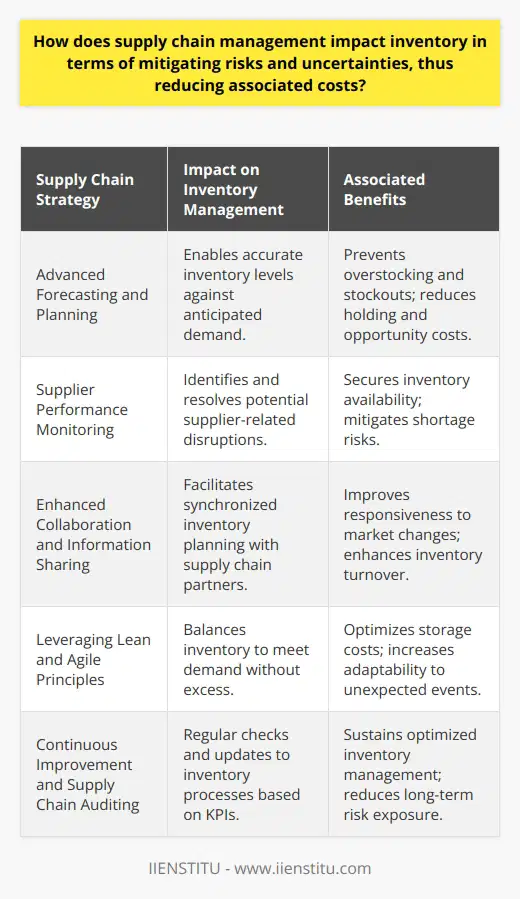

How does supply chain management impact inventory in terms of mitigating risks and uncertainties, thus reducing associated costs?

Risk Mitigation in Inventory Management

Effective supply chain management plays a crucial role in mitigating risks and uncertainties in inventory, leading to reduced costs. Integrating sophisticated planning and forecasting tools to anticipate demand fluctuations and avoid potential stockouts or overstocks is essential in maintaining a well-balanced inventory. By closely monitoring supplier performance, businesses can prevent disruptions in supply and thus ensure the timely availability of products for customers.

Enhanced Collaboration for Business Resilience

Establishing close relationships with suppliers and partners contributes significantly to risk reduction in inventory management. Through collaboration and data sharing, businesses can improve visibility across the entire supply chain, allowing them to react promptly to unforeseen events or production hiccups. Aligning inventory policies with suppliers can also minimize the bullwhip effect, thereby reducing safety stock levels and associated holding costs.

Lean and Agile Combines

Adopting lean and agile strategies in inventory management can also contribute to risk mitigation. Lean practices, such as just-in-time (JIT) manufacturing, focus on reducing waste by emphasizing the consistently streamlined flow of inventory. Meanwhile, an agile inventory strategy prioritizes responsiveness and adaptability, enabling businesses to swiftly reallocate resources in case of demand changes or supply disruptions. By combining these approaches, companies can optimize inventory levels, ensuring both cost-efficiency and flexibility in the face of uncertainties.

Continuous Improvement and Monitoring

To maintain reduced risks and costs in inventory, businesses must continually assess and monitor their supply chain performance. Implementing key performance indicators (KPIs) and advanced analytics can provide valuable insights on potential areas for improvement. Moreover, regular audits of the supply chain can help identify vulnerabilities and mitigate the risk of theft, fraud, and other threats to inventory.

In conclusion, effective supply chain management mitigates risks and uncertainties in inventory by optimizing inventory levels, enhancing collaboration and visibility, and enabling adaptability through lean and agile strategies. Regular monitoring and assessment of supply chain performance further contribute to maintaining decreased risks and costs.

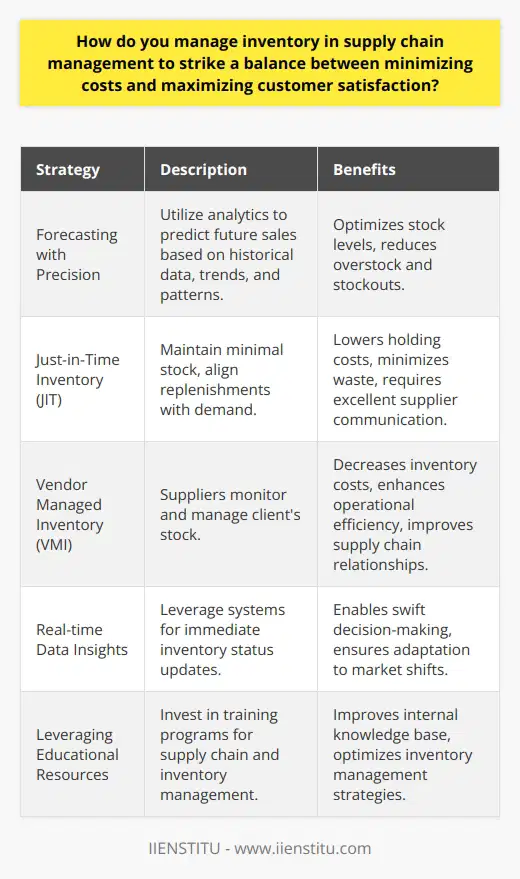

How do you manage inventory in supply chain management to strike a balance between minimizing costs and maximizing customer satisfaction?

Effective Inventory Management Strategies

To strike a balance between minimizing costs and maximizing customer satisfaction in supply chain management, effective inventory management strategies are crucial. These strategies require accurate forecasting, efficient inventory control systems, and continuous coordination with suppliers.

Accurate Forecasting

Accurate forecasting of customer demand is a critical factor in inventory management. By analyzing historical sales data, market trends, and customer preferences, companies can anticipate future product needs. This enables them to procure and store an optimal amount of inventory, preventing stockouts that lead to customer dissatisfaction and excessive inventory that incurs holding costs.

Just-in-Time Approach

One popular inventory control technique is the Just-in-Time (JIT) approach, wherein inventory is kept at a minimal level, and reorders are timed precisely to arrive when needed. This method reduces carrying costs and the risk of product obsolescence. However, implementing JIT requires strong communication and trust with suppliers, as delays in deliveries can result in stockouts and unsatisfied customers.

Vendor Managed Inventory

Another effective inventory management strategy is Vendor Managed Inventory (VMI). In this approach, the responsibility of maintaining the inventory is placed on the supplier, who monitors stock levels and replenishes when necessary. VMI can reduce the risk of stockouts, lower inventory holding costs, and improve the overall supply chain performance by fostering closer collaboration between the buyer and supplier.

Real-time Data Analysis

Leveraging technology to gather and analyze real-time data on inventory levels, sales, and customer preferences can further contribute to effective inventory management. This information can be vital for making informed decisions on inventory replenishment, reordering, and product prioritization. Real-time data analysis also enables businesses to swiftly respond to fluctuations in demand, ensuring that customers receive their desired products at the right time.

In conclusion, managing inventory in supply chain management to achieve the balance between cost reduction and customer satisfaction relies on accurate forecasting, efficient inventory control techniques, and strong supplier coordination. By employing these strategies, companies can effectively minimize costs and optimize their inventory levels, leading to improved business performance and higher customer satisfaction.

How does supply chain management impact inventory in terms of ensuring timely and cost-effective replenishment to maintain optimal stock levels?

Supply Chain and Inventory Effectiveness

An effective supply chain management (SCM) system plays a crucial role in inventory management to maintain optimal stock levels in a timely and cost-effective manner. By encompassing the entire process from procurement to distribution, SCM facilitates the systematic flow of goods and information to enable businesses to synchronize demand and supply.

Optimizing Inventory Replenishment

SCM strategies determine the most efficient methods for replenishing inventory. This involves considering various factors such as order quantities, lead times, and shipping costs. By developing appropriate procurement policies that account for fluctuations in demand and supply, SCM ensures retailers can avoid stockouts and overstocking.

Impact on Cost Reduction

By closely monitoring inventory levels and responding effectively to market dynamics, SCM allows organizations to reduce carrying costs associated with inventory such as warehousing and obsolescence. Efficient SCM practices enable businesses to invest in safety stocks, which act as buffers against sudden changes in demand, thereby minimizing the chances of stockouts and lost sales. This in turn contributes to more cost-efficient inventory management.

Enhancing Stock Visibility

Effective SCM enhances stock visibility via smooth flow of information, enabling businesses to track their inventory levels in real-time. This allows retailers to make informed decisions regarding stocking policies, reducing both lead times and costs of replenishment. Timely updates on stock levels also facilitate better inventory turnover rates, which can lead to increased profitability.

Demand Forecasting and Collaborations

SCM systems incorporate demand forecasting techniques to help businesses anticipate market demands. By analyzing historical data, trends, and patterns, organizations can make proactive replenishment decisions. Furthermore, SCM promotes collaboration between suppliers and retailers, allowing both parties to share information and improve inventory management practices.

Adaptation to Market Fluctuations

Uncertainty in market conditions can lead to disruptions in inventory management. SCM's emphasis on risk mitigation enables businesses to respond to shifts in consumer demand or supply chain disruptions promptly. By continuously monitoring trends and leveraging contingency planning, SCM promotes the maintenance of optimal stock levels to mitigate potential negative impacts.

In conclusion, supply chain management is crucial for effective inventory management, ensuring timely and cost-effective replenishment while maintaining optimal stock levels. Through demand forecasting, collaboration, and proactive replenishment strategies, SCM enables organizations to adapt to market fluctuations and maintain a competitive edge in the market.

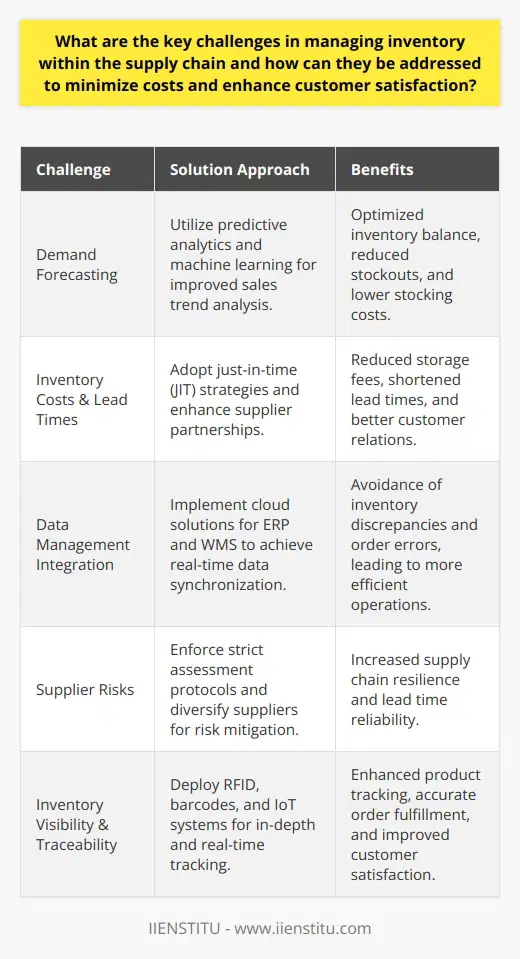

What are the key challenges in managing inventory within the supply chain and how can they be addressed to minimize costs and enhance customer satisfaction?

Challenges in Inventory Management

One of the primary challenges in managing inventory within the supply chain is demand forecasting. Accurate demand forecasts are crucial for maintaining the right inventory level, avoiding stockouts, and reducing holding costs. Companies can improve their forecasting processes by utilizing advanced analytical tools and techniques, such as machine learning algorithms, that analyze historical sales data and adapt to changing market conditions.

Managing Inventory Costs and Lead Time

Another key challenge is reducing inventory carrying costs and lead time. High carrying costs result from excess stock and increased warehousing expenses, while long lead times affect customer satisfaction and can result in lost sales. To address these issues, organizations should optimize their inventory policies, implement just-in-time (JIT) inventory management systems, and establish close relationships with suppliers for better collaboration and to shorten lead times.

Data Management and Integration

Effective inventory management also requires seamless data integration between systems, including enterprise resource planning (ERP) systems and warehouse management systems (WMS). Poor data management can lead to inaccurate inventory levels, stock discrepancies, and order fulfillment errors, which may result in lost sales and customer dissatisfaction. Integrating data from multiple sources and implementing real-time data sharing through cloud-based systems can help organizations improve visibility and control over their inventory processes.

Supplier Issues and Risk Management

Furthermore, companies often face challenges related to supplier performance, such as supply disruptions and quality issues. To mitigate these risks, organizations should develop robust supplier evaluation and selection criteria, focusing on factors such as lead time, consistency in quality, and financial stability. Implementing supplier diversification strategies and monitoring supplier performance can also help to minimize supply chain risks and enhance resilience.

Inventory Visibility and Traceability

Lastly, maintaining inventory visibility and traceability is essential for managing inventory efficiently, ensuring timely and accurate order fulfillment, and maintaining customer satisfaction. To achieve this, organizations should leverage advanced technologies, such as radio frequency identification (RFID) and barcode systems, to track products throughout their supply chain journey. Implementing IoT-based real-time tracking systems can also provide valuable insights to support decision-making and allow for proactive management of potential inventory issues.

In conclusion, by addressing key challenges in inventory management within the supply chain – including demand forecasting, inventory costs and lead time, data management and integration, supplier issues and risk management, and inventory visibility and traceability – organizations can minimize costs, enhance customer satisfaction, and ensure operational efficiency.

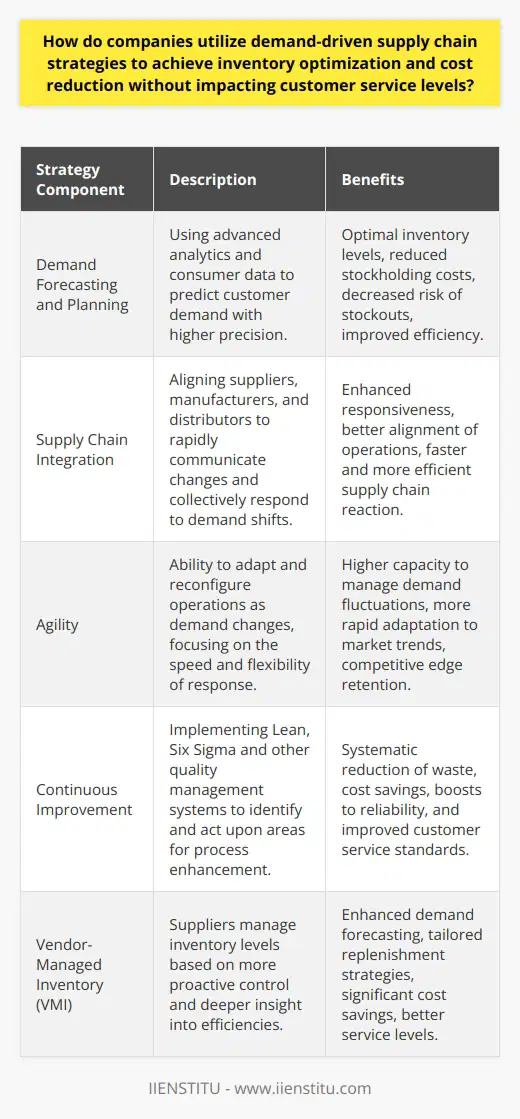

How do companies utilize demand-driven supply chain strategies to achieve inventory optimization and cost reduction without impacting customer service levels?

Demand-Driven Supply Chain Strategies

Companies exploit demand-driven supply chain strategies to attain inventory optimization and cost reduction while maintaining high customer service levels. Implementing these strategies involves forecasting and accurately aligning supply with customer demands.

Demand Forecasting and Planning

By effectively forecasting demand, firms can predict product needs and adjust their inventory accordingly. Accurate demand planning prevents stockouts and excess inventory, reducing carrying and obsolescence costs. Additionally, accurate demand predictions help companies maintain customer satisfaction by ensuring product availability on time.

Integrated and Agile Supply Chains

To achieve inventory optimization, companies must establish an integrated supply chain that links all stakeholders, including suppliers, manufacturers, and distributors. This integration facilitates real-time communication, allowing firms to promptly respond to demand fluctuations and maintain optimal inventory levels. Agility in the supply chain enables rapid response to market changes, preventing stockouts and excess inventory, ultimately reducing overall costs.

Continuous Improvement

Companies commit to continuous improvement through analyzing and assessing their supply chain performance. Lean principles and Six Sigma methodologies are incorporated to identify inefficiencies and waste, and to develop strategies for process improvement. By consistently examining their processes, companies can refine their demand-driven supply chain strategies and achieve cost reduction without impacting customer service levels.

Vendor Managed Inventory

Adopting vendor managed inventory (VMI) allows suppliers to monitor and manage their clients' inventory. This partnership results in better demand forecasting and inventory optimization. In turn, it reduces the risk of stockouts and excess inventory, decreasing costs while preserving customer satisfaction.

In conclusion, companies employ demand-driven supply chain strategies to simultaneously optimize inventory and reduce costs without negatively affecting customer service levels. Techniques such as demand forecasting, supply chain integration, continuous improvement, and vendor managed inventory enable businesses to achieve these goals. Implementing these strategies leads to efficient supply chain management, ensuring product availability while effectively managing costs.

How can supply chain management contribute to reducing inventory-related costs while still maintaining sufficient stock levels to meet customer demand?

Effective Inventory Management

Effective supply chain management (SCM) can significantly reduce inventory-related costs. SCM strategies ensure the efficient flow of goods from suppliers to customers. This often requires maintaining an optimal level of inventory to achieve a balance between holding costs and stock-outs.

Optimization Techniques

Optimization techniques play a crucial role in controlling inventory costs. For example, the economic order quantity (EOQ) model determines the optimal amount of inventory to order. This minimizes the combined cost of ordering and holding inventory.

Just-In-Time Approach

The Just-In-Time (JIT) approach is another important strategy. It allows firms to reduce safety stock levels and holding costs. Under JIT, firms order inventory only when they need it. This makes their operations leaner and more cost-effective.

Cross-Functional Collaboration

SCM also relies on cross-functional collaboration. Sales, production, and procurement departments must work together to determine accurate demand forecasts. Accurate forecasts can reduce the likelihood of over-stocking or under-stocking, thus avoiding unnecessary costs.

Vendor-Managed Inventory

Vendor-managed inventory (VMI) is a partnership in which suppliers take the responsibility to replenish the inventory of the customers. In VMI, suppliers use sales data to forecast demand and manage stock levels for customers. This reduces the customers' inventory holding and ordering costs.

Notably, SCM should aim for cost reduction without compromising the customers' need for product availability. In this way, companies can reduce inventory-related costs, maintain customer satisfaction, and enhance their competitiveness in the market.

What role does demand forecasting play in managing inventory within supply chain management, and how can this help reduce costs?

Significance of Demand Forecasting in Supply Chain Management

Demand forecasting serves as a crucial aspect in inventory management within supply chain management. Accurate predictions of customer demand enable organizations to produce the correct quantity of goods. This reduces inventory costs, production costs, and minimizes holding costs.

Role in Inventory Management

Specifically, in managing inventory, demand forecasting helps determine how much stock to keep. By accurately predicting customer demand, managers can optimize warehouse space, reducing unnecessary storage costs. Furthermore, it decreases the risk of stock obsolescence, ensuring resources do not go to waste.

Improving Operational Efficiency

Additionally, demand forecasting promotes operational efficiency. The accurate estimation of future demand allows for streamlined production processes. It lowers the chance of overproduction, saving resources, and reducing waste. It also ensures timely delivery, enhancing customer satisfaction and retaining client relationships.

Preventing Stock-Out Situations

Moreover, it prevents stock-out situations. The inability to fulfill customer orders due to inventory shortages can have a catastrophic impact on an organization's reputation. However, with strong demand forecasting, companies can maintain optimal inventory levels and meet customer demands promptly.

In conclusion, demand forecasting forms an integral component of inventory management within supply chain management. It helps in reducing costs, enhancing operational efficiency, and ensuring customer satisfaction. Therefore, organizations should invest in effective demand forecasting techniques for effective inventory management.

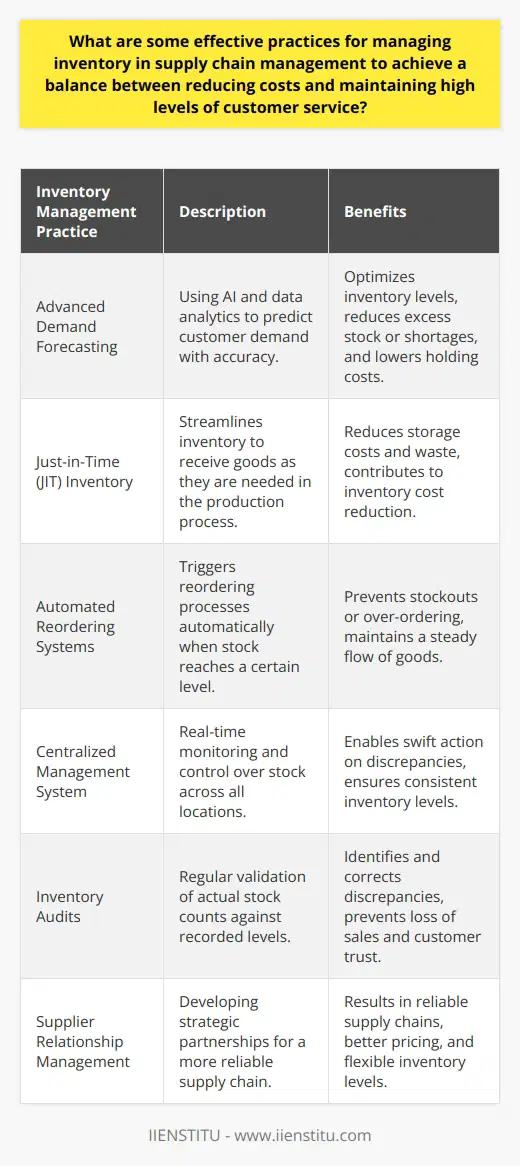

What are some effective practices for managing inventory in supply chain management to achieve a balance between reducing costs and maintaining high levels of customer service?

Efficient Inventory Management

Efficient inventory management in supply chain management embodies certain effective practices and strategies. Its primary goal: achieving an optimal balance between reducing costs and maintaining high customer service levels.

Utilize Demand Forecasting

The practice of demand forecasting stands crucial. By predicting potential customer demand, businesses can avoid overstocking or understocking scenarios, significantly reducing expenses and enhancing customer satisfaction.

Employ Just-in-time (JIT) Strategy

The just-in-time strategy can also be a game-changer. This technique aims at reducing inventory-related costs by only ordering inventory as and when needed. Minimal inventory levels mean lower storage costs and fresher stock for customers.

Implement Automated Reorder Points

Implementing automated reorder points also proves beneficial. This alerts when the inventory hits the minimum acceptable level, ameliorating the risk of sudden stockouts. It ensures a seamless supply chain, mitigating the risk of unfulfilled orders, and thus boosting customer service.

Adopt a Centralized Inventory Management System

Adopting a centralized inventory management system is another key practice. This allows real-time tracking and central control of inventory across different channels and locations. It ensures consistent stock availability and prevents discrepancies that may cause customer dissatisfaction.

Regularly Audit Inventory

Perform regular inventory audits to verify records. This promotes accuracy in stock count, minimizes stock discrepancies and discrepancies, and prevents customer disappointment due to unavailability of items.

Tactical Supplier Relationships

Establish strong relationships with suppliers based on mutually beneficial terms. It aids in securing consistent stock supply, prompt delivery, and possible discounts, maximizing both cost-effectiveness and customer satisfaction.

In conclusion, effective inventory management in supply chain strategies entails a blend of demand forecasting, JIT strategy, automated reorder points, centralized systems, regular audits, and strong supplier relationships. An intelligent approach to these areas paves the way for reduced costs and enhanced customer service quality.

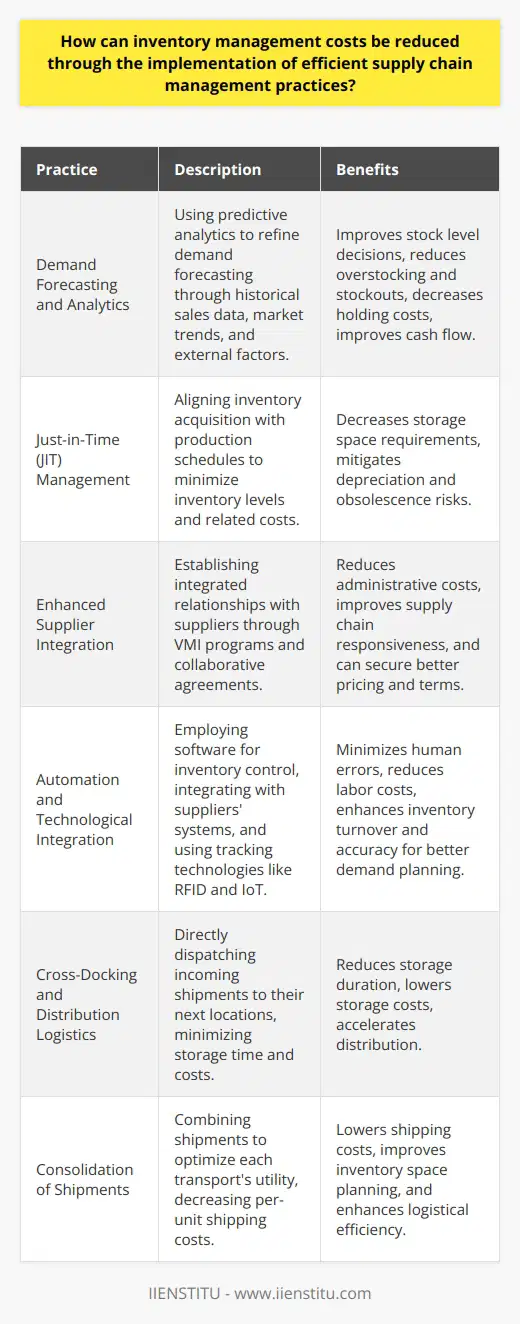

How can inventory management costs be reduced through the implementation of efficient supply chain management practices?

Efficient Supply Chain Practices

Efficient supply chain management practices can greatly reduce inventory management costs. One method is through utilizing demand forecasting. Accurate demand prediction can reduce overstocking or understocking incidents. This helps in optimizing the inventory levels, therefore minimizing holding costs.

Inventory Reduction through Lean Techniques

Implementing lean techniques also minimizes costs. Lean inventory management eliminates waste, reducing unnecessary stock. It increases efficiency by streamlining processes. It also minimizes the risk of obsolete inventory. Reduced inventory leads to lower storage costs, contributing to overall cost reduction.

Role of Supplier Relationships

Fostering good supplier relationships is vital in effective inventory management. Collaborative supplier partnerships ensure a steady supply of necessary materials. Reliable suppliers guarantee timely deliveries, reducing the need for excessive safety stocks. This again leads to inventory cost reduction.

Automation in Inventory Management

Finally, automating inventory control can save costs. Automation minimizes data entry errors and quickens inventory tracking. Automated inventory systems can also provide real-time analytics. This data-driven approach aids in more accurate decision-making. Consequently, businesses can maintain optimal inventory levels. Less human resource engagement leads to additional savings.

In summary, effective supply chain management practices like accurate demand forecasting, lean techniques, favorable supplier relationships, and automation can significantly reduce inventory management costs. They achieve this by reducing wastages, optimizing inventory levels, avoiding overstock and understock situations, fostering timely deliveries, and hastening inventory tracking.

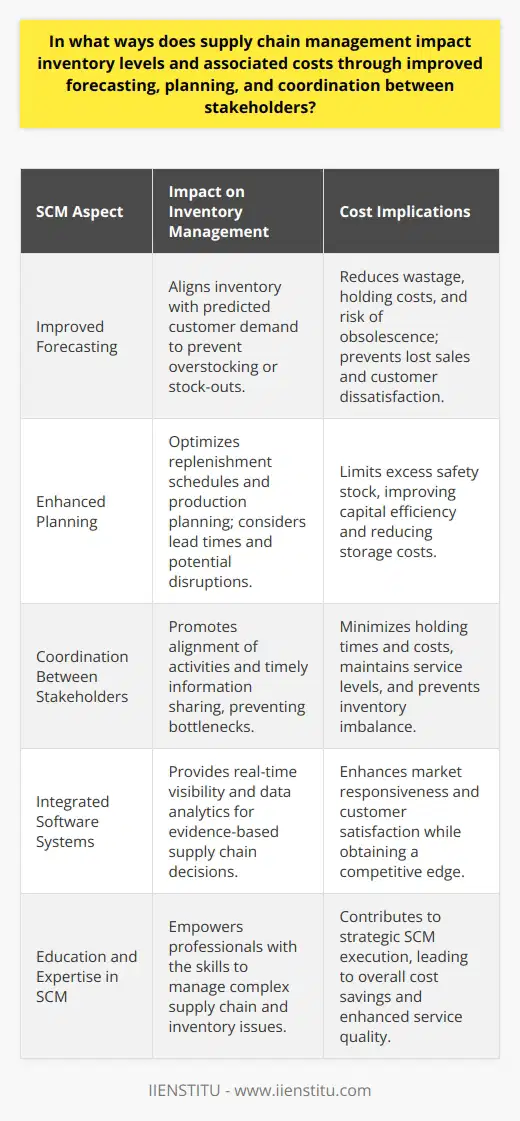

In what ways does supply chain management impact inventory levels and associated costs through improved forecasting, planning, and coordination between stakeholders?

Efficiency in Forecasting

Supply chain management substantially influences inventory levels through enhanced forecasting. Accurate demand forecasts allow companies to make informed procurement decisions, consequently maintaining optimal inventory levels. This significantly negates potential inventory holding costs and the risk of stock-outs.

Improved Planning

Additionally, effective supply chain management contributes to improved planning. That facilitates companies to schedule their inventory replenishment accurately. In this way, supply chain management helps to avoid excessive inventory levels or shortages. Both scenarios can have detrimental financial implications including storage costs, sales losses, and diminished customer satisfaction.

Coordination Between Stakeholders

Supply chain management also promotes effective coordination between stakeholders. Such coordination can result in a smoother flow of materials, reducing lead times and ensuring timely inventory availability. It aids in keeping inventory and associated costs under control, by avoiding unanticipated demand fluctuations or supplier issues.

So, by improving forecasting, planning and coordination among stakeholders, supply chain management can greatly optimize inventory levels and reduce associated costs. This kind of effective supply chain management not only enhances the competitiveness of the company but also leads to greater customer satisfaction and profitability.

What are the main inventory-related costs in supply chain management, and how can these be effectively managed and minimized to improve overall profitability and performance?

Inventory carrying costs:

Inventory-related costs in Supply Chain Management (SCM) mainly include carrying costs, ordering costs and shortage costs. Inventory carrying costs constitute a significant proportion of total inventory-related costs. These involve costs for handling, storing, insuring, depreciating, and obsolescing stock.

Ordering costs and shortage costs:

Other considerable costs involve ordering costs, which pertain to costs of replenishing inventory. Cost of placing orders, transport, and receiving goods include in this category. Shortage costs occur due to inventory depletion, causing potential loss of sale, back-orders, or customer dissatisfaction.

Cost management:

To manage these costs effectively, companies often implement strategies such as Just-in-Time (JIT) inventory management. This strategy minimizes carrying costs by keeping stock levels low and ordering goods only when required.

Technology and Inventory Management:

In addition, modern SCM utilizes technology for inventory management. Inventory management systems provide data on stock levels in real-time. They keep track of inventory in transit, in warehouses or on shelves. The information aids businesses in avoiding shortage costs and minimizing carrying and ordering costs.

Advancements like Artificial Intelligence and Machine Learning can forecast demand. Their proper use keeps supply in line with demand, cutting down the unnecessary inventory holding.

Vendor-managed inventory:

Another strategy involves vendor-managed inventory where suppliers maintain stock levels. This approach manages costs by transferring holding costs to suppliers.

Summary:

To conclude, the main inventory-related costs in SCM are carrying, ordering and shortage costs. Effective management of these costs through strategies like JIT, technology utilisation and vendor-managed inventory can minimize these costs. Consequently, improved profitability and overall performance can be achieved.