Logistics planning and operations are the backbone of any successful business. Without efficient and effective logistics, a company can quickly find itself struggling to keep up with demand, losing customers, and ultimately facing financial ruin. In today's fast-paced, globalized world, the importance of logistics cannot be overstated. It is a complex and multifaceted field that requires a deep understanding of supply chain management, transportation networks, inventory control, and more.

As someone who has worked in the logistics industry for over a decade, I have seen firsthand the impact that well-executed logistics can have on a company's bottom line. When I first started out as a logistics coordinator at a small manufacturing firm, I was tasked with streamlining our shipping processes to reduce costs and improve delivery times. It was a daunting challenge, but one that I embraced with enthusiasm.

Introduction

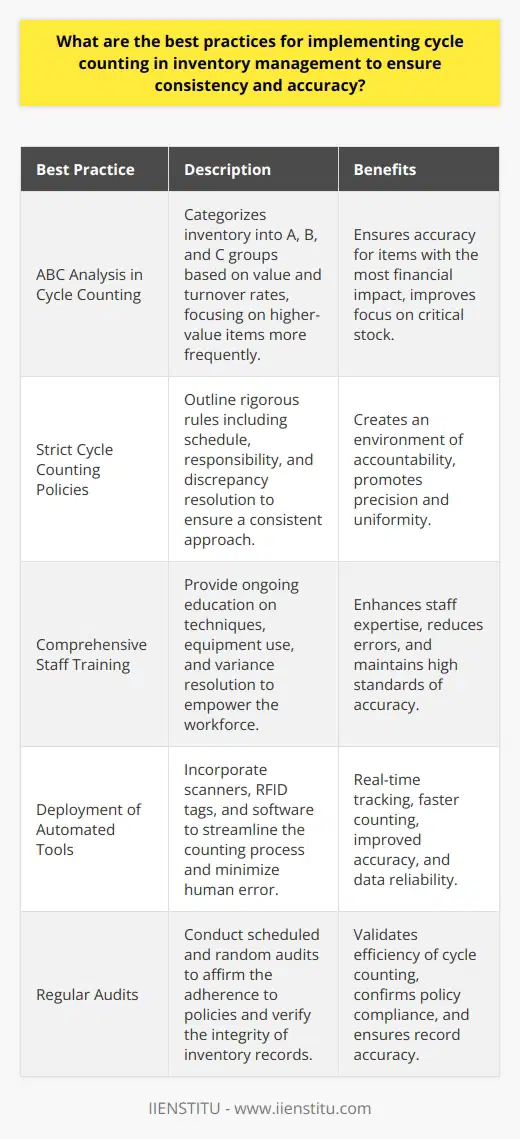

Optimization Models

Simulation Models

Forecast Models

Conclusion

Through careful analysis of our existing systems and a willingness to think outside the box, I was able to implement a series of changes that transformed our logistics operations. By optimizing our routes, consolidating shipments, and negotiating better rates with carriers, we were able to reduce our transportation costs by nearly 20% within the first year. This not only saved the company money but also allowed us to pass those savings on to our customers in the form of lower prices and faster delivery times.

But logistics is not just about cutting costs. It is also about ensuring that products arrive at their destination on time, in good condition, and in the right quantities. This requires a high level of coordination and communication between all parties involved in the supply chain, from manufacturers and suppliers to warehouses and retailers.

One of the most effective tools for achieving this level of coordination is the use of optimization models. These mathematical models allow logistics professionals to determine the most efficient and cost-effective way to move goods from point A to point B, taking into account a wide range of variables such as distance, time, cost, and capacity.

For example, imagine a company that needs to ship products from its manufacturing facility in China to its distribution center in the United States. There are countless possible routes and modes of transportation that could be used, each with its own advantages and disadvantages. An optimization model would take all of these factors into account and calculate the optimal route based on the company's specific needs and constraints.

Timely analysis of Logistics Management leads to optimized results over the long term.

But optimization models are just one piece of the puzzle. Another key tool in the logistics toolbox is simulation modeling. Unlike optimization models, which are based on static data and assumptions, simulation models allow logistics professionals to test different scenarios and see how they would play out in the real world.

For instance, a company might use a simulation model to evaluate the impact of adding a new distribution center or changing its inventory levels. By running multiple simulations with different variables, the company can identify potential bottlenecks or inefficiencies in its supply chain and make adjustments accordingly.

In fact, research has shown that companies that use simulation modeling in their logistics planning can see significant improvements in key metrics such as on-time delivery rates, inventory turns, and transportation costs. A study by the Massachusetts Institute of Technology found that companies that used simulation modeling in their supply chain operations had an average of 5% higher on-time delivery rates and 10% lower inventory levels compared to those that did not (Lee & Billington, 1992).

But perhaps the most important tool in the logistics arsenal is forecasting. After all, it is impossible to plan for the future if you don't know what that future holds. By using historical data and sophisticated statistical models, logistics professionals can predict future demand for products with a high degree of accuracy.

This is particularly important in industries with seasonal or cyclical demand patterns, such as retail or agriculture. By accurately forecasting demand, companies can ensure that they have the right amount of inventory on hand to meet customer needs without tying up too much capital in excess stock.

According to a study by the University of Tennessee, companies that use advanced forecasting techniques can reduce their inventory levels by up to 20% while still maintaining high levels of customer service (Mentzer & Moon, 2005). This not only frees up cash flow but also reduces the risk of obsolescence and spoilage.

But forecasting is not just about predicting demand. It is also about identifying potential risks and opportunities in the market. By monitoring key economic indicators, geopolitical events, and other external factors, logistics professionals can stay ahead of the curve and adapt their strategies accordingly.

For example, when the COVID-19 pandemic hit in 2020, many companies found themselves scrambling to adjust their supply chains to cope with sudden changes in consumer behavior and government regulations. Those that had robust forecasting and risk management systems in place were better able to weather the storm and even capitalize on new opportunities that arose.

Of course, implementing these kinds of advanced analytics tools requires a significant investment in both technology and talent. Many companies, particularly small and medium-sized enterprises, may feel that they lack the resources or expertise to take advantage of these techniques.

But the good news is that there are many third-party logistics providers (3PLs) that specialize in providing these services to businesses of all sizes. By outsourcing their logistics operations to a 3PL, companies can tap into a wealth of expertise and technology without having to build everything from scratch.

In fact, a study by the Aberdeen Group found that companies that used 3PLs for their logistics operations had an average of 9% lower transportation costs and 5% higher on-time delivery rates compared to those that managed everything in-house (Gonzalez, 2014). This is because 3PLs have the scale and specialization to optimize routes, negotiate better rates, and deploy cutting-edge technologies across multiple clients.

But even with the help of a 3PL, effective logistics management still requires a deep understanding of the underlying principles and best practices. This is where education and training come in. Many universities and professional organizations offer courses and certifications in logistics and supply chain management, covering topics such as transportation planning, inventory optimization, and risk management.

One such program is the Master of Science in Logistics and Supply Chain Management offered by the Massachusetts Institute of Technology. This rigorous program covers a wide range of topics, from network design and optimization to data analytics and machine learning. Graduates of the program have gone on to leadership roles at top companies such as Amazon, UPS, and Nike.

But you don't necessarily need a master's degree to succeed in logistics. Many successful professionals have built their careers through a combination of on-the-job experience, professional development courses, and certifications such as the Certified Supply Chain Professional (CSCP) offered by the Association for Supply Chain Management.

Ultimately, the key to success in logistics is a combination of technical expertise, strategic thinking, and a willingness to adapt to change. As the famous management consultant Peter Drucker once said, "The greatest danger in times of turbulence is not the turbulence itself, but to act with yesterday's logic" (Drucker, 1980).

In other words, logistics professionals must be willing to embrace new technologies, new ways of thinking, and new approaches to problem-solving if they want to stay ahead of the curve. This requires a certain level of courage and a willingness to take risks, but the rewards can be significant.

By optimizing their logistics operations, companies can not only reduce costs and improve efficiency but also gain a competitive advantage in the marketplace. They can deliver products faster, more reliably, and at a lower cost than their competitors, which can translate into higher customer satisfaction and loyalty.

So if you're a business leader looking to take your company to the next level, don't overlook the importance of logistics. By investing in the right tools, talent, and strategies, you can transform your supply chain into a powerful engine for growth and success.

References:

Lee, H. L., & Billington, C. (1992). Managing Supply Chain Inventory: Pitfalls and Opportunities. Sloan Management Review, 33(3), 65-73.

Mentzer, J. T., & Moon, M. A. (2005). Sales Forecasting Management: A Demand Management Approach. Sage Publications.

Gonzalez, A. (2014). The Value of Third-Party Logistics. Aberdeen Group.

Drucker, P. F. (1980). Managing in Turbulent Times. Harper & Row.

Keywords:

how to use optimization models in logistics planning

benefits of simulation models for supply chain management

forecast models for future demand in logistics

best practices for efficient logistics planning and operations

importance of analytical techniques in logistics management

improving logistics performance through optimization

best ways to reduce transportation costs using simulation

successful forecast model strategies in supply chain

how to identify risks in logistics operations

key analytical tools for logistics and inventory management

Frequently Asked Questions

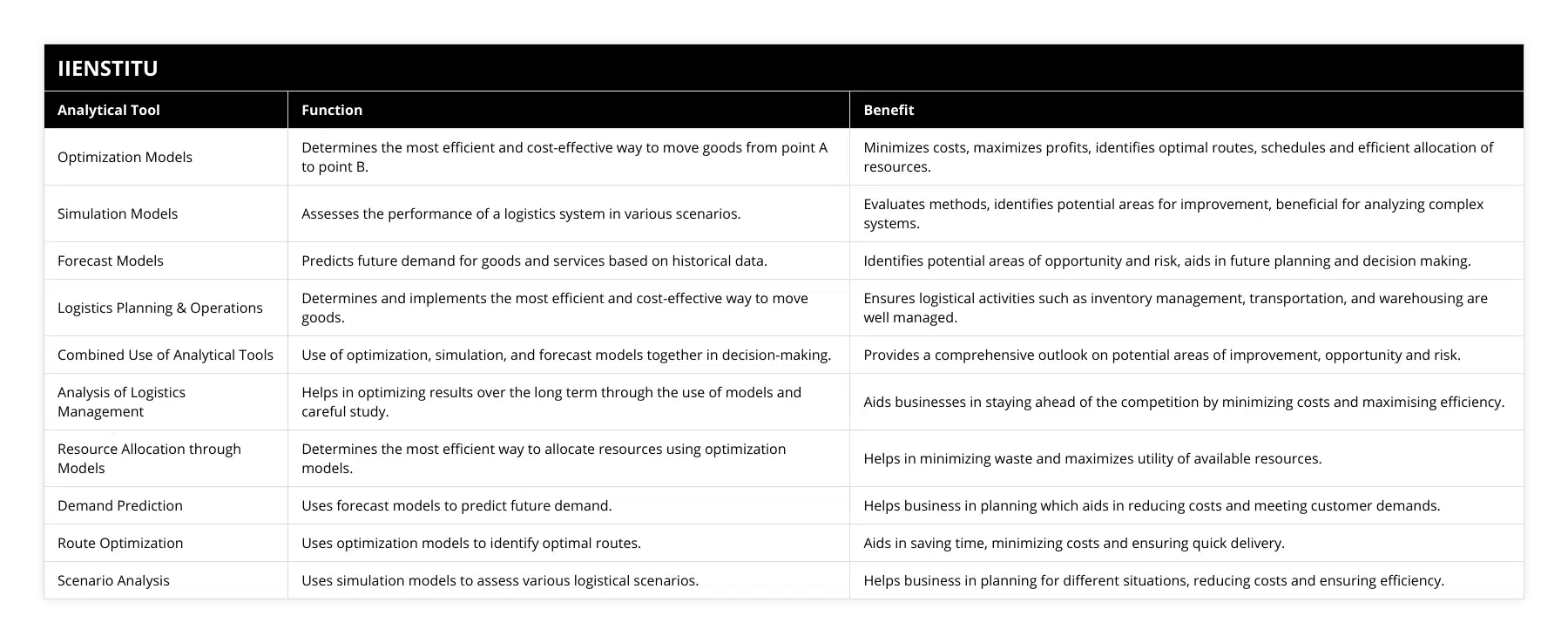

What analytical tools are available to optimize logistics management?

Logistics management is an integral part of any business, as it ensures the efficient, cost-effective, and timely delivery of goods and services. As such, companies must optimize their logistics operations to provide the best possible results and maximum efficiency. Several analytical tools are available to help businesses optimize their logistics management, including computer simulation, optimization models, and mathematical programming.

Computer simulation is a powerful tool for logistics optimization, allowing businesses to model and analyze their operations in a virtual environment. This will enable companies to test different scenarios and observe their outcomes to determine the most efficient and cost-effective solutions. The simulation also provides the ability to “what-if” analyze various methods, such as changes in demand or transportation costs, or to model the impact of new technology or process improvements.

Optimization models allow businesses to identify the most practical combination of resources to maximize a desired outcome, such as cost savings or increased efficiency. These models can be used to solve complex problems, such as route scheduling and inventory management, and can be tailored to the individual needs of a business. Optimization models can also help companies identify cost reduction and process improvement opportunities.

Finally, mathematical programming is a powerful tool for logistics optimization, allowing businesses to develop optimal solutions to complex problems. This technique enables firms to formulate their problems as mathematical models, which can then be solved using advanced algorithms. For example, mathematical programming can solve problems such as route optimization and resource allocation, allowing businesses to identify the most effective solutions to their logistical challenges.

In conclusion, several analytical tools are available to help businesses optimize their logistics management. Computer simulation, optimization models, and mathematical programming are all powerful tools that can help companies to identify the most effective and cost-efficient solutions to their logistical challenges. As such, these analytical tools can be invaluable for companies looking to optimize their logistics operations.

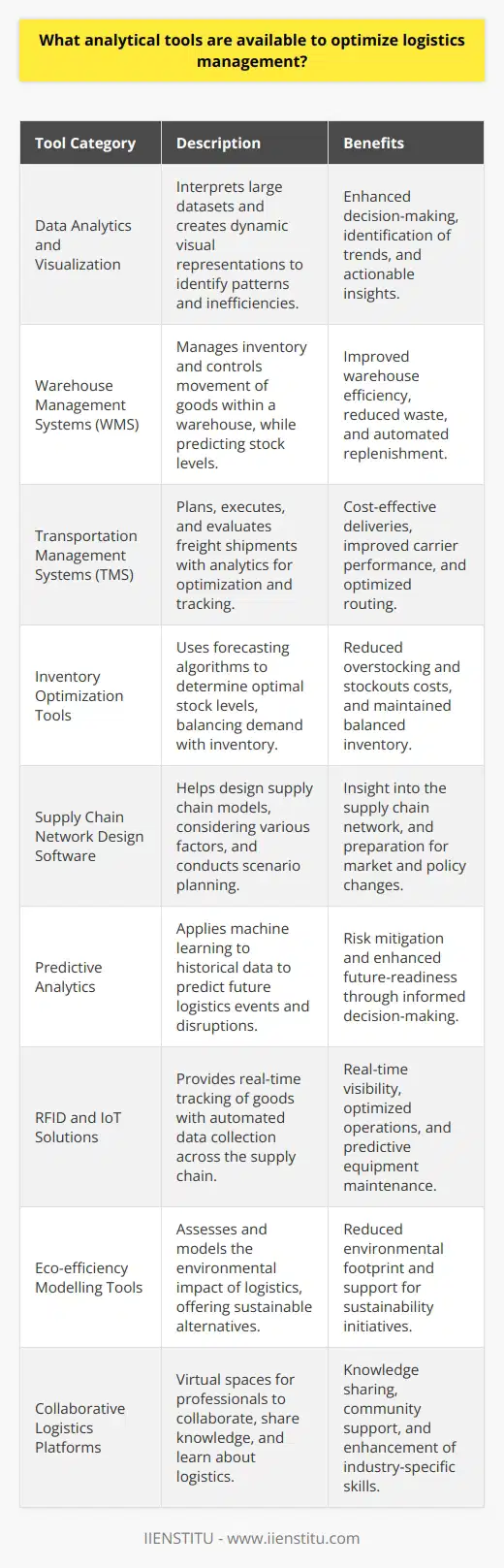

How can time horizons be used to improve logistics planning?

Logistics planning is the process of determining how best to move products from one place to another in an efficient and cost-effective manner. Properly managed logistics can improve customer service and reduce inventory costs. In addition, time horizons can improve logistics planning by providing a framework for decision-making.

Time horizons refer to the time frames in which decisions must be made to achieve desired outcomes. In logistics planning, time horizons evaluate the time needed to complete the various tasks associated with a particular project. For example, a short-term time horizon may be used to plan for the immediate needs of a project, while a longer-term time horizon may be used to prepare for the project's long-term objectives.

Time horizons can also be used to identify potential problems that may arise during a project. They allow planners to identify areas of potential risk or cost overruns and to plan accordingly. This can help ensure the project is completed on time and within budget.

Time horizons are also helpful in assessing the impact of environmental changes on a project's timeline. By identifying potential disruptions or delays, planners can adjust their plans accordingly. This can help ensure that the project is completed successfully and on time.

Time horizons can also be used to identify opportunities for cost savings. By understanding the timeline of a project, planners can identify areas where resources can be used more efficiently. This can help to reduce overall costs and improve the efficiency of the project.

Using time horizons to improve logistics planning can help ensure that projects are completed on time and within budget. It can also help to reduce the risk of cost overruns or delays. In addition, by understanding the timeline of a project and assessing the impact of changes in the environment, planners can adjust their plans accordingly, resulting in improved customer service and reduced costs.

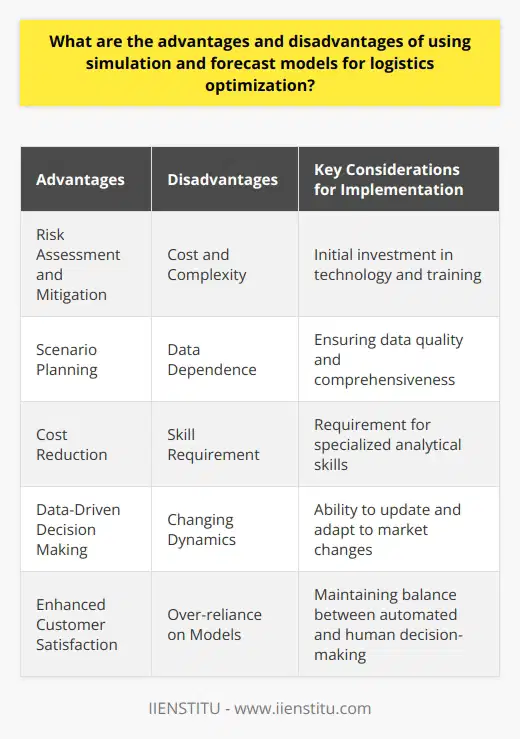

What are the advantages and disadvantages of using simulation and forecast models for logistics optimization?

Simulation and forecast models have become increasingly crucial in logistics optimization, as they are used to analyze different scenarios and predict future trends and events. However, while these models offer numerous benefits, some drawbacks are associated with their use.

One of the main advantages of simulation and forecast models for logistics optimization is that they provide a more systematic approach to problem-solving. The models can identify the most cost-effective and efficient options for meeting the customer's needs by simulating different scenarios. The models also allow for a more proactive approach to problem-solving, as they can be used to anticipate future trends and events and to plan accordingly. For example, a company can use a simulation model to identify potential supply chain disruptions and develop strategies to minimize the impact of such disorders.

Another advantage of simulation and forecast models for logistics optimization is that they allow for greater flexibility and customization. This is because the models can be tailored to the organization's specific needs. For example, a company can use the models to develop customized supply chain strategies or to analyze customer demand patterns. This allows the organization to better align its supply chain with customer needs, resulting in higher customer satisfaction and improved operational efficiency.

On the other hand, some disadvantages are associated with using simulation and forecast models for logistics optimization. The most significant drawback is that the models can be expensive to implement and maintain. Additionally, the complexity of the models can make them difficult to use and interpret, leading to incorrect results. Finally, the models require a certain level of expertise to operate, and they are not always easy to understand or interpret.

In conclusion, simulation and forecast models offer numerous advantages for logistics optimization, including a more systematic approach to problem-solving, greater flexibility, and customization. However, the models can also be expensive to implement and maintain, requiring a certain level of expertise. Therefore, it is essential for organizations to carefully consider the pros and cons of using simulation and forecast models for logistics optimization before making a decision.

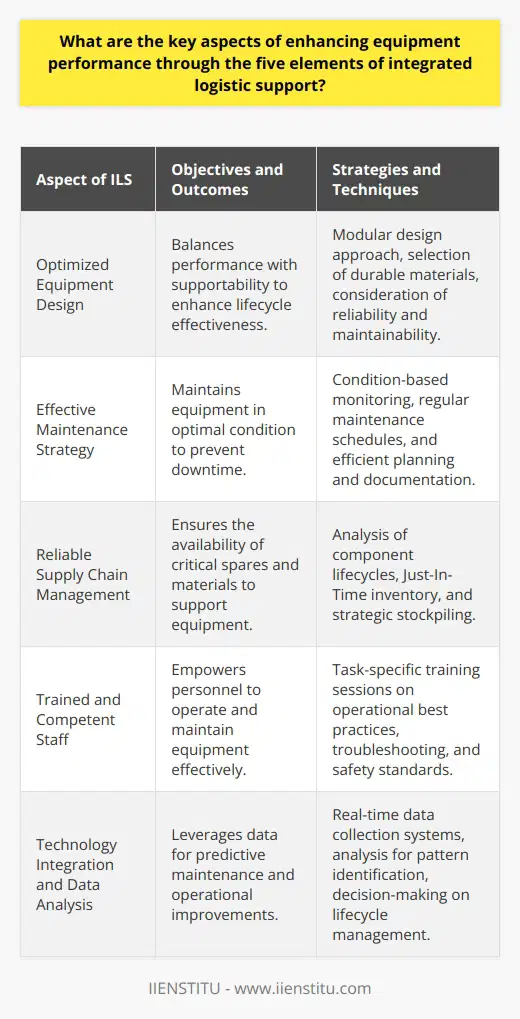

What are the key aspects of enhancing equipment performance through the five elements of integrated logistic support?

Key Aspects of Equipment Performance Enhancement

Optimal Equipment Design

One crucial aspect of improving equipment performance is ensuring optimal design before implementation. This entails carefully considering factors such as functionality, maintainability, and integration with existing systems to create an efficient and reliable solution.

Effective Maintenance Strategy

A proactive and comprehensive maintenance plan is integral to enhancing equipment performance. By establishing detailed procedures for routine and corrective maintenance, equipment downtime can be minimized, while ensuring maximum operational efficiency and asset longevity.

Reliable Supply Chain Management

The availability of spare parts and consumables directly impacts equipment performance. Therefore, building an effective supply chain management system, which combines accurate forecasting with timely procurement and delivery, is key to sustaining seamless operations and reducing downtime.

Trained and Competent Staff

Investing in the continuous training and development of personnel responsible for operating and maintaining equipment is essential for optimal performance. Proficient staff not only ensures a smooth functioning of equipment but also identifies potential issues before they escalate, maintaining maximum uptime.

Technology Integration and Data Analysis

Lastly, leveraging technology to monitor equipment in real-time, and analyzing available data for trends and patterns, can provide valuable insights for informed decision-making. The proper use of data-driven technology helps in predicting equipment failures, optimizing asset utilization, and enabling strategic planning for continuous improvement.

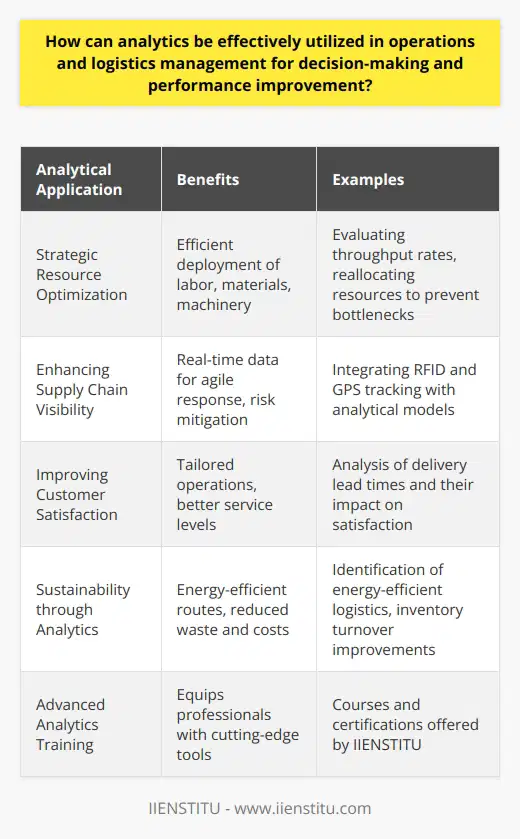

How can analytics be effectively utilized in operations and logistics management for decision-making and performance improvement?

Importance of Analytics in Operations and Logistics Management

Analytics plays a crucial role in operations and logistics management by providing valuable insights into the efficiency and effectiveness of organizational processes. It offers various tools and techniques that enable decision-makers to identify areas of improvement, optimize resource allocation, and enhance overall performance.

Data-driven Decision-making

One of the key benefits of utilizing analytics in operations and logistics management is the ability to make informed, data-driven decisions. By analyzing performance metrics, managers can pinpoint key performance indicators (KPIs) and create evidence-based strategies to improve operations. This allows organizations to maximize efficiency, reduce costs, and streamline workflows.

Predictive Analytics for Proactive Management

Predictive analytics, a subset of analytics, enables managers to forecast trends and potential issues related to operations and logistics management. By utilizing historical data, predictive models can anticipate future challenges and opportunities, such as demand fluctuations, supply chain disruptions, and resource bottlenecks. This proactive approach to management allows for better planning and risk mitigation, ultimately improving performance.

Process Optimization through Continuous Improvement

The data generated by analytics tools can be used to implement continuous improvement initiatives within operations and logistics management. By identifying inefficiencies, underperforming areas, and waste, managers can iteratively refine processes to drive constant enhancement. This leads to the development of leaner, more effective operations that directly contribute to improved performance.

In conclusion, the effective use of analytics in operations and logistics management has the potential to significantly enhance decision-making processes and improve overall performance. By leveraging data-driven insights, managers can optimize resource allocation, predict future trends, and facilitate continuous improvement within their organizations. This ultimately leads to streamlined operations and a more competitive business environment.

In what ways can the 7 R's be implemented to ensure better logistics management and streamlined processes?

Effective Implementation of the 7 R's

To achieve better logistics management and streamlined processes, the implementation of the 7 R's - Right Product, Right Quantity, Right Quality, Right Time, Right Place, Right Customer, and Right Price - is crucial.

Right Product

The first step involves ensuring the selection of appropriate products, fully aligned with customer demand and market expectations. Leveraging market research and advanced analytics tools can significantly improve this aspect by providing insights into consumers' preferences.

Right Quantity

Optimal inventory levels are essential for avoiding stockouts or overstocks. Companies should adopt demand forecasting techniques and inventory management systems to maintain the right amount of goods while minimizing costs.

Right Quality

Adhering to product quality standards is paramount for achieving customer satisfaction and maintaining brand reputation. Rigorous quality control processes and certification procedures help ensure that goods meet technical specifications and desired performance levels.

Right Time

Timely delivery of products is critical for meeting customers' expectations and ensuring order fulfillment. To achieve this, businesses should optimize their transportation routes, adopt JIT (Just-in-Time) strategies, and invest in advanced tracking systems to monitor shipments throughout the supply chain.

Right Place

Proper location and layout of distribution facilities (warehouses, distribution centers, retail outlets) ensure efficient storage and transport of goods. Companies should consider factors such as proximity to customers, transportation infrastructure, and local regulations when selecting these locations.

Right Customer

Accurate identification of target customers enhances market penetration and prevents incorrect product allocation. Through customer segmentation and data analysis, businesses can develop targeted marketing and sales strategies that cater to the needs of their intended audience.

Right Price

Lastly, developing competitive pricing models is crucial for ensuring profitability and retaining customers. By analyzing market trends and competitors' strategies, companies can establish an appropriate balance between production costs, profit margins, and consumer demand.

Through the effective implementation of the 7 R's, businesses can greatly improve their logistics management and streamline processes, thus enhancing customer satisfaction and achieving overall operational efficiency.

What are the key components and benefits of the 7 R's in achieving more efficient logistics management?

Key Components of the 7 R's

The 7 R's of logistics management are essential principles for achieving efficiency and effectiveness in coordinating the movement, storage, and flow of goods and services. These key components comprise the right product, right quantity, right condition, right place, right time, right customer, and right cost.

Right Product and Quantity

The initial R's, right product, and right quantity, ensure that the appropriate items are delivered according to customer demand. Identifying and understanding customer preferences enhances the supply chain's responsiveness and minimizes the risk of stockouts or overstock situations.

Right Condition and Place

Maintaining the right condition of goods during transportation and storage is crucial in ensuring product quality and reducing waste. The right place component ensures that products reach their intended destination efficiently, which may result in lower distribution costs and increased customer satisfaction levels.

Right Time and Customer

Timeliness is a critical aspect of efficient logistics management, as delivering the right product at the right time can have a significant impact on customer satisfaction. Moreover, delivering goods to the right customer is vital for maintaining customer relationships and ensuring effective market penetration.

Right Cost

The final R, right cost, emphasizes the importance of cost optimization in logistics management. By focusing on cost reduction, organizations can enhance their competitive advantage and allocate saved resources towards other aspects like research and development or marketing strategies.

Benefits of Effective Implementation

Implementing the 7 R's framework in logistics management can lead to numerous benefits such as reduced costs, improved customer satisfaction, greater supply chain efficiency, and enhanced competitiveness. By focusing on these principles, organizations can proactively address potential supply chain issues and meet customer expectations more effectively. Ultimately, adherence to the 7 R's of logistics management is a critical step towards the overall success of an organization in today's fast-paced and competitive market.

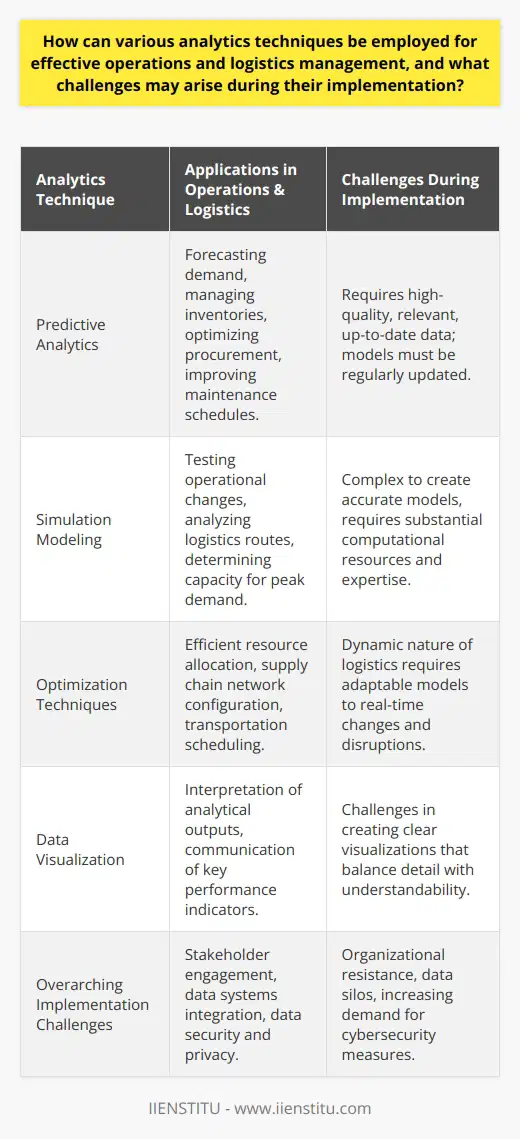

How can various analytics techniques be employed for effective operations and logistics management, and what challenges may arise during their implementation?

Utilizing Analytics Techniques

Effective operations and logistics management can benefit greatly from the application of various analytics techniques. These techniques help businesses improve efficiency, reduce costs, and optimize their operations. The following are some examples of analytics methods employed in operations and logistics management and the potential challenges that may arise during their implementation.

Predictive Analytics

Predictive analytics involves using historical data to forecast future trends, enabling businesses to make data-driven decisions. This technique can help identify potential bottlenecks, schedule maintenance, and optimize inventory levels. However, a challenge in implementing predictive analytics is the accuracy of the predictions, which depends on the quality and completeness of the data collected.

Simulation Modeling

Simulation modeling allows businesses to create digital representations of their systems and processes, facilitating analysis and optimization. This method can be employed to test the impact of different scenarios on the overall system before implementing them in reality. One challenge of simulation modeling is the time and effort required to develop accurate models and validate their results.

Optimization Techniques

These techniques focus on identifying the most efficient solutions to specific problems, such as minimizing transportation costs, maximizing resource utilization, or determining optimal inventory levels. While optimization techniques are valuable, their implementation may be constrained by the complexity of the problem, the availability of accurate data, and the computational power required to solve them.

Data Visualization

Visual representations of data can help decision-makers quickly comprehend complex information and identify trends, patterns, or anomalies. However, creating effective visualizations can be challenging, as it requires selecting the appropriate graphical elements, color schemes, and level of detail to communicate the desired insights.

Challenges in Implementation

Implementing analytics techniques in operations and logistics management is not without challenges. Businesses may encounter resistance from employees who are hesitant to adopt new technologies or practices. Additionally, collecting sufficient and accurate data for analysis can be a daunting task, especially when dealing with legacy systems or incomplete records. Ensuring data privacy and security is also an essential concern for organizations seeking to leverage analytics techniques.

In conclusion, employing analytics techniques can greatly enhance operations and logistics management, leading to cost savings and improved efficiency. However, organizations must navigate various implementation challenges to fully harness the potential benefits of these methods. With careful planning, training, and investment in advanced analytics tools, businesses can overcome these obstacles and drive significant improvements in their operations and logistics systems.

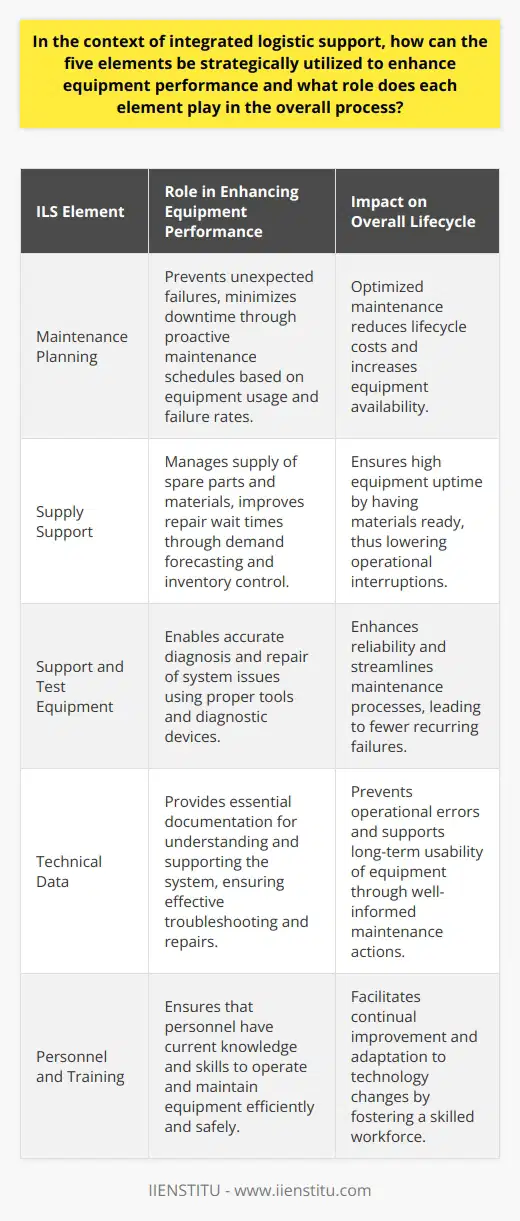

In the context of integrated logistic support, how can the five elements be strategically utilized to enhance equipment performance and what role does each element play in the overall process?

**Utilizing the Five Elements Strategically**

In the context of integrated logistic support (ILS), the strategic utilization of the five elements—maintenance planning, supply support, support and test equipment, technical data, and personnel and training—can significantly enhance equipment performance. Each element plays a crucial role in the optimal functioning of the entire process.

**Maintenance Planning**

Effective maintenance planning ensures equipment operability and reduces downtime. By implementing a systematic approach to maintenance tasks, resources can be managed efficiently, downtime can be minimized, and equipment performance can be maximized.

**Supply Support**

A reliable supply chain provides the necessary components and spare parts to maintain equipment functionality. Proper supply support guarantees the availability of resources when equipment maintenance is required, thereby reducing waiting times for parts and enhancing equipment performance.

**Support and Test Equipment**

Utilizing appropriate support and test equipment can drastically improve equipment reliability and availability. By incorporating advanced diagnostic tools and technologies, maintenance personnel can identify issues early in the equipment lifecycle, resulting in reduced repair costs and improved performance.

**Technical Data**

Accurate technical data serves as the foundation for efficient maintenance operations. By providing comprehensive information regarding equipment specifications, troubleshooting procedures, and maintenance guidelines, technical data allows personnel to execute their tasks effectively and maintain optimal equipment performance.

**Personnel and Training**

Lastly, the role of competent personnel and effective training cannot be understated. Ensuring that maintenance staff are skilled and knowledgeable in their respective roles directly impacts the overall performance of equipment. Therefore, investing in proper training programs and retaining experienced personnel is a strategic approach to enhancing equipment performance within integrated logistic support environments.

In conclusion, by strategically utilizing the five elements of integrated logistic support, organizations can significantly enhance equipment performance. This is achieved through a combination of streamlined maintenance planning, efficient supply support, advanced support and test equipment, accurate technical data, and skilled personnel and training programs. Each element plays a critical role in the overall process, ensuring that equipment operates at its maximum potential with minimum downtime.

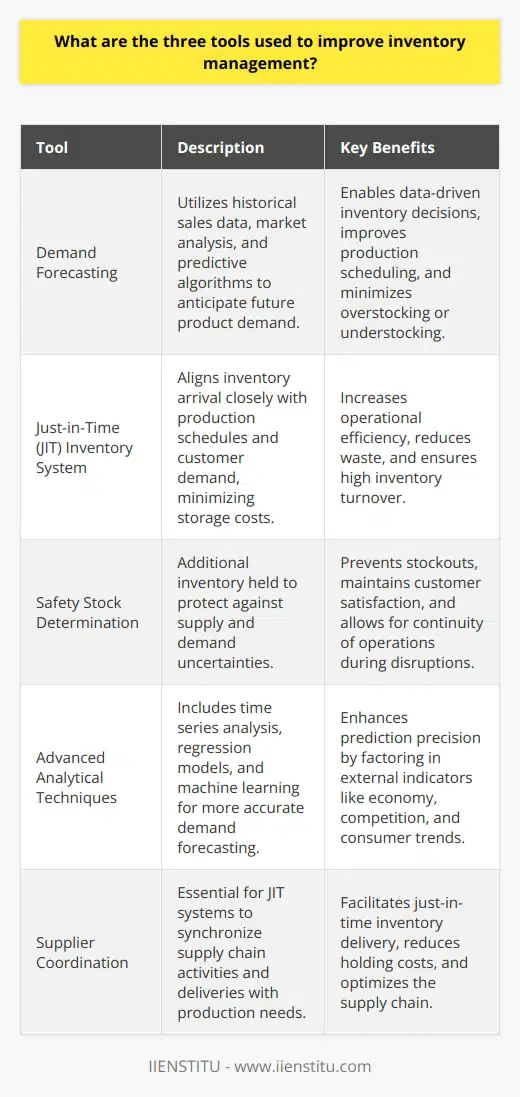

What are the three tools used to improve inventory management?

Effective Inventory Control Techniques

Effective inventory management requires a systematic approach to ensure that stock levels are optimized and stockouts minimized. To achieve this, businesses implement three essential tools in their inventory management strategies: demand forecasting, just-in-time (JIT) inventory management, and safety stock determination.

Demand Forecasting

Effective demand forecasting is crucial for achieving efficient inventory management. It involves analyzing historical sales data, market trends, seasonality, and other factors to predict the future demand for a product accurately. Accurate demand forecasts enable businesses to order the right quantities of inventory, ensuring that there is an optimal stock level and avoiding costly excess stock or stockouts.

Just-in-Time Inventory Management

Another tool used to improve inventory management is the JIT inventory management system. Originating from Japanese manufacturing practices, the JIT approach is focused on reducing the amount of inventory on hand by ordering and producing items as needed. This reduces inventory costs, eliminates waste, and shortens lead times. JIT management relies heavily on accurate demand forecasting and close collaboration with suppliers to ensure timely deliveries.

Safety Stock Determination

To further minimize the risk of stockouts or excessive inventory levels, businesses also need to establish appropriate safety stock levels. Safety stocks act as a buffer for fluctuations in demand or supplier lead times, ensuring that there is enough inventory on hand to meet customer demand even when unforeseen circumstances arise. Determining the appropriate safety stock levels involves assessing factors such as demand volatility, supplier reliability, and inventory management costs.

In summary, demand forecasting, JIT inventory management, and safety stock determination are three vital tools that businesses employ to improve their inventory management processes. Implementing these tools can help achieve more efficient inventory management, ultimately contributing to better customer satisfaction, reduced costs, and increased profitability.

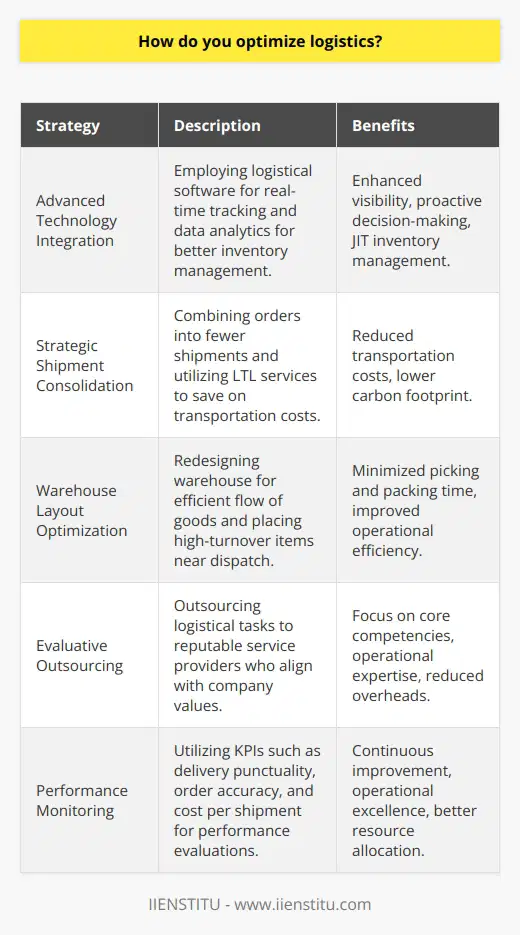

How do you optimize logistics?

Selecting the Ideal Strategies

Optimizing logistics requires the selection of appropriate strategies to achieve cost savings and efficiency. One key element is the careful execution of supply chain orchestration, which relies on collaboration among generated partners, including manufacturers, retailers, and transportation providers, among others.

Utilizing Technological Solutions

Embracing technology is essential to optimizing logistics in today's fast-paced business world. A range of sophisticated software can help businesses track shipments and inventory in real-time, making it easier to detect issues and implement corrective measures. Moreover, using data analytics tools can enable businesses to understand customer preferences and forecast demand to reduce stockouts and overstocking.

Consolidating Shipments

Reducing the number of shipments, either by combining multiple orders into a single shipment or using less-than-truckload (LTL) shipping services, can positively impact transportation costs. Consolidating shipments can save money, reduce emissions, and minimize transportation risks associated with handling separate shipments.

Streamlining Warehouse Layout

Efficient warehouse management is crucial for optimizing logistics. An organized layout can minimize the time spent locating and retrieving items, increase material handling efficiency, and facilitate space utilization by strategically placing frequently picked items close to packing and shipping areas. Furthermore, implementing a coherent inventory management system can prevent issues such as stockouts and inefficiencies.

Evaluating Outsourcing Options

Outsourcing certain logistical functions, such as warehousing or transportation, to a third-party company might be an effective way to save costs and improve efficiency. Choosing an appropriate logistics provider is key to ensuring that the company can maintain control over the end-to-end logistics process and ensure timely deliveries.

Monitoring Performance Metrics

Regularly reviewing logistics performance metrics, such as on-time delivery rates, order accuracy, and transportation expenses, is essential to identify weak areas within the supply chain. By analyzing these performance indicators, businesses can adjust their logistics strategies to optimize performance and better align with organizational goals.

In conclusion, optimizing logistics involves the consideration and implementation of multiple strategies in order to enhance efficiency, reduce costs, and maintain customer satisfaction. By leveraging technological advancements, improving warehouse operations, monitoring key performance metrics, and considering outsourcing options, businesses can build a more robust and effective logistics process.

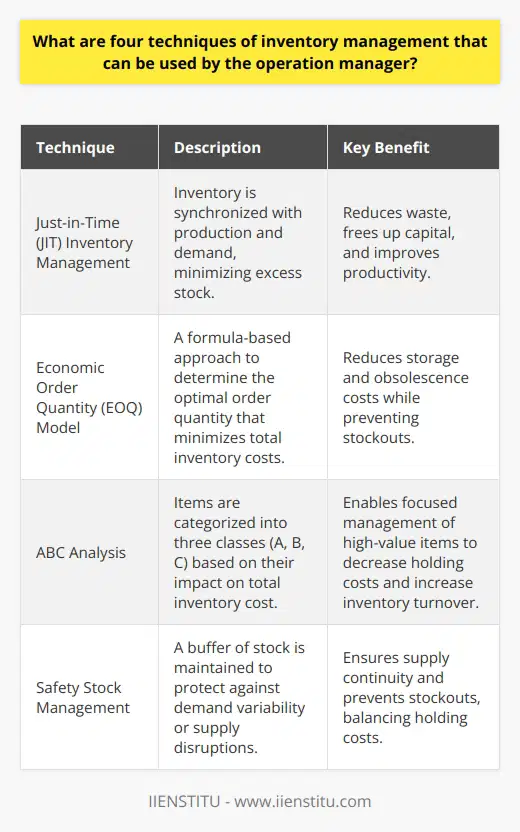

What are four techniques of inventory management that can be used by the operation manager?

Technique 1: Just-in-Time (JIT) Inventory Management

The first technique an operations manager can use is Just-in-Time (JIT) inventory management. This approach minimizes stock holding by only ordering and receiving inventory when it is needed for production or sales, thus reducing storage costs, minimizing capital invested in inventory, and promoting operational efficiency.

Technique 2: Economic Order Quantity (EOQ) Model

The Economic Order Quantity (EOQ) model is a classic technique for inventory optimization. This method calculates the optimal order quantity to minimize costs associated with ordering, holding, and stockouts. By applying the EOQ model, an operations manager can determine the best order size that balances purchase costs, inventory holding costs, and stockout costs.

Technique 3: ABC Analysis

Another valuable technique for inventory management is ABC Analysis, which classifies items based on their importance to the organization. In this method, items are ranked into three categories: 'A' items are high-value items requiring tight control and accurate records, 'B' items hold moderate value and require moderate control, and 'C' items are lower-value items with minimal control. By classifying inventory in this way, operations managers can prioritize management efforts and resources according to the importance of each item in the inventory.

Technique 4: Safety Stock Management

Safety stock management is a crucial technique in inventory management, used to prevent stockouts. It involves keeping a buffer inventory to account for uncertainties in demand and lead times. An operations manager can calculate safety stock based on historical demand data, service levels, and lead times to ensure that a sufficient amount of inventory is maintained to satisfy customer demand without risking lost sales due to stockouts.

In conclusion, effective inventory management is essential for smooth operations. Techniques such as Just-in-Time, Economic Order Quantity, ABC Analysis, and Safety Stock Management can provide operations managers with valuable tools to optimize inventory levels, minimize costs, and ensure customer satisfaction.

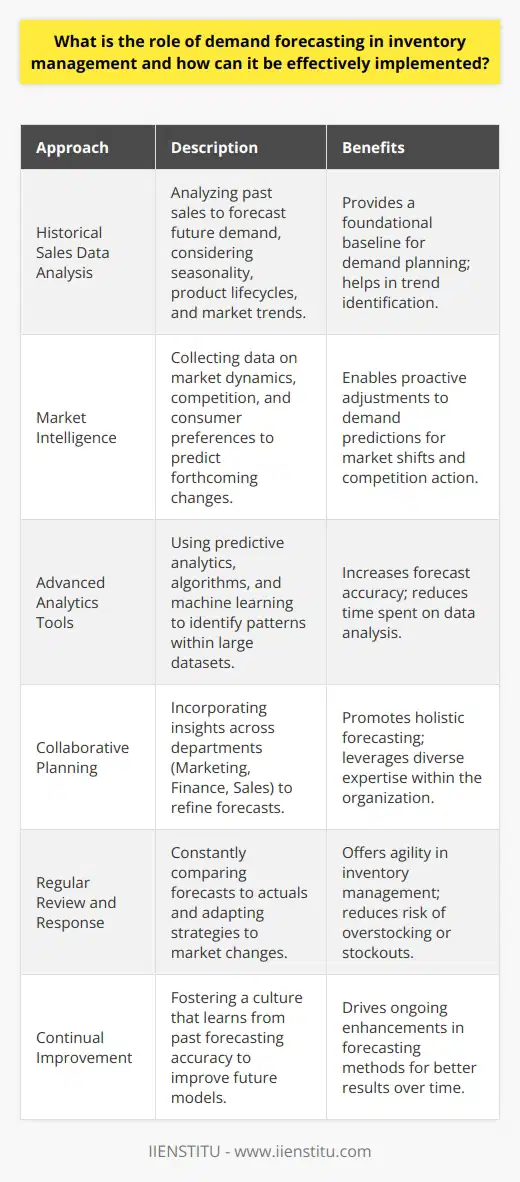

What is the role of demand forecasting in inventory management and how can it be effectively implemented?

Role of Demand Forecasting in Inventory Management

Demand forecasting plays a critical role in inventory management. It provides essential insights into future consumer behavior. By accurately predicting product demands, businesses can manage their inventory effectively. This strategy helps to avoid over-purchasing or under-stocking, ensuring a consistent product supply.

Data Analysis Methodology

Effectively implementing demand forecasting requires a robust data analysis methodology. Understanding past sales patterns gives a baseline for predicting future demands. It involves analyzing historic sales information, market conditions, economic trends, and industry developments.

Use of Predictive Analytics

Moreover, the use of predictive analytics amplifies the efficiency of demand forecasting. Advanced technologies like Machine Learning can process large data sets to produce detailed and accurate predictions. However, this data-driven strategy requires industry expertise to interpret and apply the findings effectively.

Cross-Functional Collaboration

A cross-functional collaborative approach also nurtures effective demand forecasting. Aligning marketing, finance, and sales perspectives supports informed inventory decisions. This team effort ensures an inclusive view of consumer demand, yielding accurate predictions.

Continuous Monitoring and Adjustment

Demand forecasting is not a one-time activity but requires continuous monitoring and adjustment. Changing market dynamics, trends, and customer preferences necessitate timely revisions. Regularly updating forecasts allows the business to adapt to real-time conditions, ensuring optimal inventory management.

So, demand forecasting is crucial in inventory management. It allows companies to balance the delicate trade-off between under and over-stocking. This strategy underpins efficient use of resources, increased customer satisfaction, and ultimately, improved business profitability. It requires a rigorous data analysis, predictive analytics, a collaborative approach, and continuous adjustment to be effectively implemented.

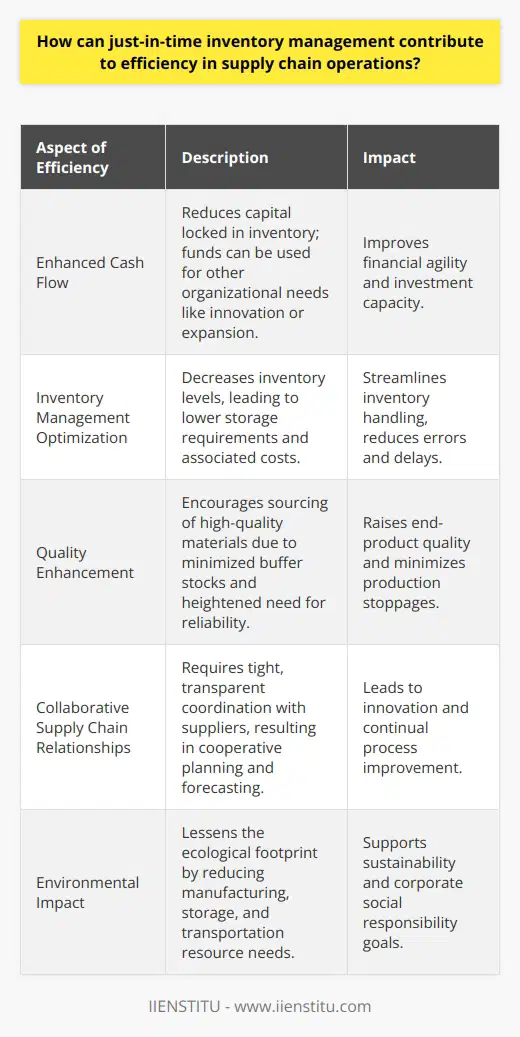

How can just-in-time inventory management contribute to efficiency in supply chain operations?

Just-in-time Inventory Management: A Boost for Efficiency

Just-in-time (JIT) inventory management plays a pivotal role in enhancing supply chain operations' efficiency. JIT is a mechanism that aligns raw material orders from suppliers directly with production schedules. Its key strength is reducing inventory-related costs, by buying and producing only when needed.

Decreased Inventory Costs

JIT inventory management dramatically reduces the costs related to the storage of excess inventory. Avoiding the unnecessary tie-up of capital in excessive stock frees up resources. These resources fuel crucial business operations, thereby tremendously boosting efficiency.

Reduced Wastage

This system also curtails waste significantly. Businesses no longer have to deal with obsolete inventory. Such optimization helps refine the supply chain process, thereby contributing to increased efficiency.

Prompt Responsiveness

JIT's unique 'pull' approach to inventory management makes it highly responsive. This approach enables businesses to meet customer demand more accurately and swiftly. The rapid response to market demand is vital for operational efficiency.

Improved Supplier Relationships

Finally, JIT inventory management aids in strengthening supplier relationships. This is because the focus shifts from the quantity to the quality of goods. Improved relationships lead to better communication and more efficient and reliable deliveries, enhancing overall supply chain efficiency.

In conclusion, JIT inventory management is an effective strategy for improving supply chain efficiency. By optimizing costs, reducing waste, being responsive to market demand, and fostering strong supplier relationships, businesses can enjoy a streamlined and efficient supply chain.

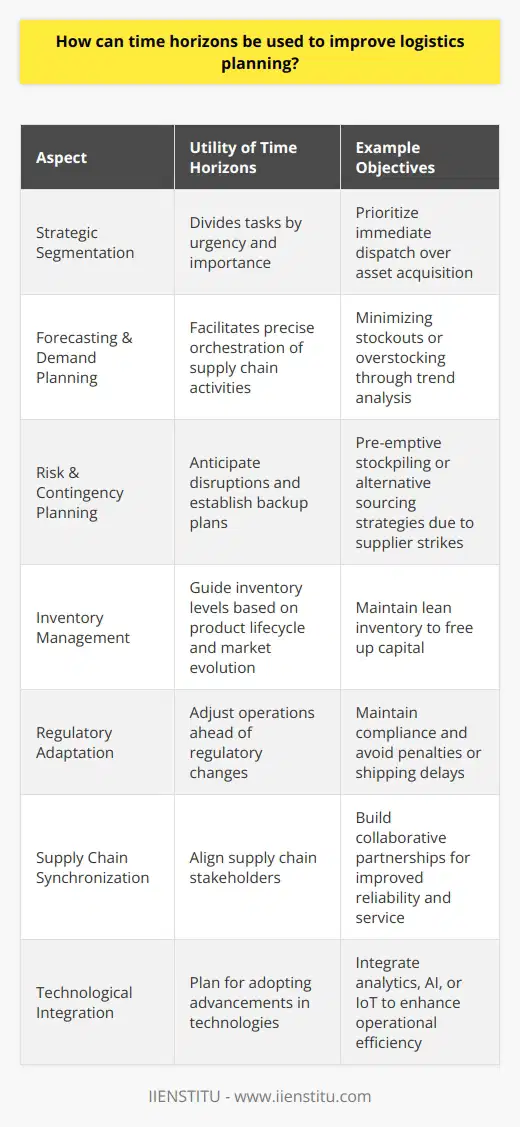

What are the best practices for implementing cycle counting in inventory management to ensure consistency and accuracy?

Effective Cycle Counting Techniques

Learning best practices for cycle counting is crucial for efficient inventory management. Counting inventory involves various steps that businesses need to implement consistently and accurately.

Choosing the Right Cycle Counting Method

Firstly, consider the appropriate cycle counting method for your business. Select a counting method that suits your operations, such as the ABC method or the control group method, to ensure accuracy.

Enforcing Strict Cycle Counting Policies

Secondly, establish strict cycle counting policies. Everyone involved must understand the procedure, which will lead to consistency and eliminate inaccuracies. Mandatory cycle count documentation can reinforce accuracy.

Training Staff Appropriately

Thirdly, proper training of staff is essential. Employees need detailed training on cycle counting procedures to maintain the accuracy of inventory levels and ensure consistency in counting methods.

Using Automated Tools

The use of automated tools, fourthly, can significantly improve accuracy and speed up the process. These tools can eliminate human error and allow real-time data tracking, enhancing the reliability of cycle counts.

Integrating Regular Audits

Lastly, incorporate regular audits into your cycle counting procedures. Alongside maintaining a regular cycle count schedule, periodic audits can verify the accuracy and consistency of inventory records.

Overall, consistent and accurate inventory management relies on selecting the right cycle counting method, establishing strict counting procedures, training staff appropriately, using automated tools, and incorporating regular audits. These practices should aid businesses in implementing a successful cycle counting strategy in their inventory management.