When it comes to transportation logistics management strategies, businesses must carefully consider the types of transportation modes available for shipping goods. Each mode has its own advantages and cost structures, and choosing the right one can significantly impact a company's bottom line. As someone who has worked in logistics for over a decade, I've seen firsthand how the right transportation choices can make or break a business.

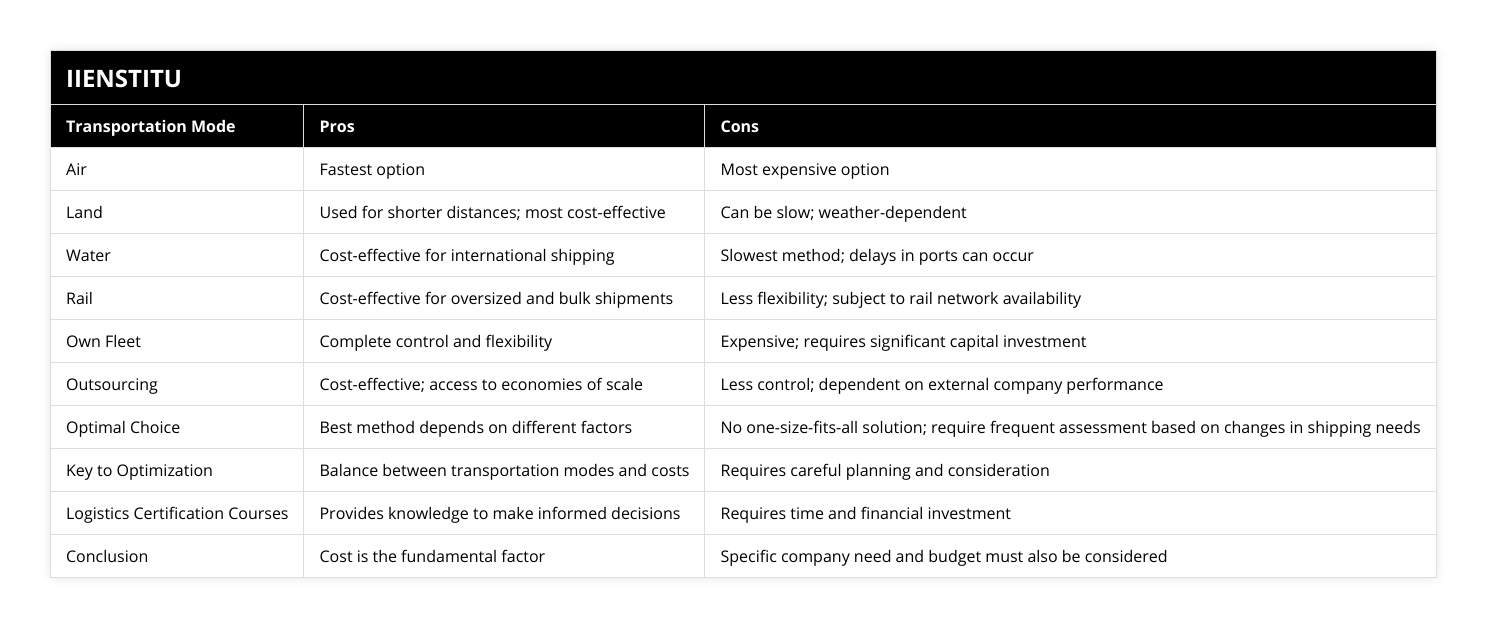

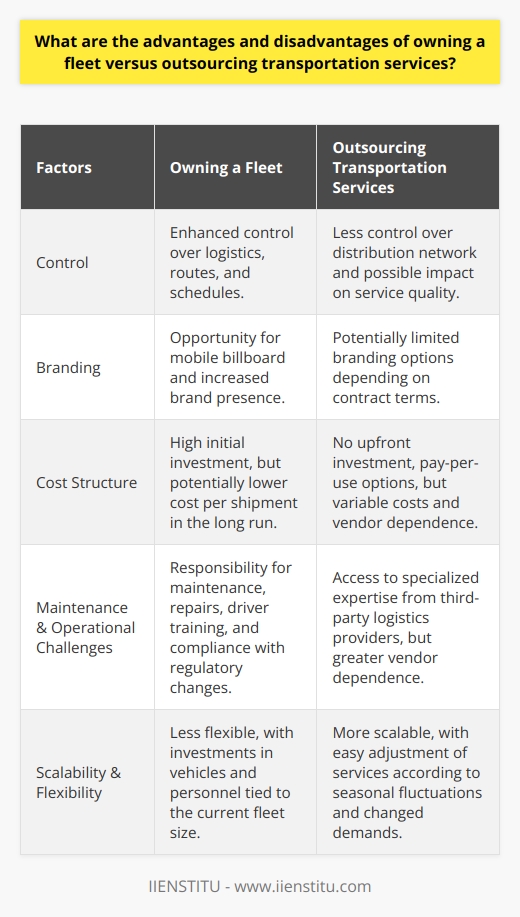

One of the most critical decisions a company must make is whether to invest in owning a fleet or outsourcing to a third-party logistics provider. There are pros and cons to both approaches, and the best choice depends on various factors such as the size of the business, the frequency of shipments, and the types of goods being transported.

Introduction

Types of Transportation Modes

Cost Considerations

Own Fleet vs. Outsourcing

Conclusion

For small businesses, cost-effective transportation options are often a top priority. In my experience, many small companies struggle with the upfront costs and ongoing maintenance expenses associated with owning a fleet. As Davis (2018) points out in his book "Logistics Management for Small Businesses," "owning a fleet can be a significant financial burden for small companies, especially those with limited resources" (p. 47). Outsourcing to a third-party provider can be a more viable option, allowing small businesses to take advantage of economies of scale and access a wider range of transportation modes.

On the other hand, larger companies with frequent shipping needs may find that owning a fleet provides greater control and flexibility. According to a study by Johnson et al. (2019) published in the Journal of Business Logistics, "companies that own their own fleets reported higher levels of customer satisfaction and faster delivery times compared to those that outsourced" (p. 285). However, the study also noted that fleet ownership comes with its own set of challenges, such as driver shortages and rising fuel costs.

Optimizing Logistics Management With Analytical Tools And Time Horizons

İmportance Of Safety Data Sheets İn Operational Safety And Compliance

Maximizing Inbound Logistics: Benefits, Challenges & Strategies

Analyzing the Role of Drones in Streamlining Supply Chain Processes

When it comes to international shipping, the best mode of transport often depends on the distance, urgency, and type of goods being shipped. For example, air freight is often the fastest option but also the most expensive. Ocean freight, on the other hand, is more cost-effective but slower. As Patel (2020) explains in "International Logistics: A Comprehensive Guide," "the choice between air and ocean freight often comes down to a trade-off between speed and cost" (p. 119).

Personally, I've found that a combination of transportation modes often yields the best results. For example, when I was working with a client who needed to ship perishable goods from South America to Europe, we used a combination of air and road freight. The goods were flown to a major European hub and then transported by truck to their final destination. By using this hybrid approach, we were able to balance the need for speed with the desire to keep costs down.

The key to optimizing logistics management lies in finding the right balance between transportation modes and costs.

Another important consideration when it comes to transportation logistics management is the cost structure of different modes. As Singh (2017) notes in "Transportation Economics and Policy," "each mode of transportation has its own unique cost structure, which can vary depending on factors such as fuel prices, labor costs, and infrastructure investments" (p. 92). Understanding these cost structures is essential for making informed decisions about which modes to use and when.

For example, rail transport is often more cost-effective than road transport for long distances and bulk shipments. However, rail infrastructure can be expensive to build and maintain, which can impact the overall cost of using this mode. Similarly, while air freight is often the fastest option, it is also the most expensive due to the high cost of fuel and the need for specialized equipment and personnel.

Ultimately, the key to effective transportation logistics management is finding the right balance between cost, speed, and reliability. This requires a deep understanding of the different transportation modes available, as well as the specific needs and constraints of the business.

One strategy that I've found effective is to work with a third-party logistics provider that offers a range of transportation options. By outsourcing logistics to a specialized provider, companies can access a wider range of modes and take advantage of the provider's expertise and economies of scale. This can be particularly beneficial for small businesses that may not have the resources or expertise to manage their own logistics operations.

However, outsourcing logistics also comes with its own set of risks and challenges. As Patel (2020) notes, "companies that outsource logistics must carefully manage their relationships with third-party providers to ensure that they are getting the best possible service at the most competitive price" (p. 203). This requires clear communication, well-defined contracts, and regular performance monitoring.

Another potential downside of outsourcing logistics is the loss of control over the transportation process. When a company owns its own fleet, it has complete control over the routing, scheduling, and handling of its goods. When outsourcing, however, the company must rely on the third-party provider to make these decisions, which can lead to delays or other issues if not managed properly.

Ultimately, the decision to outsource logistics or own a fleet comes down to a careful analysis of the costs and benefits of each approach. As Davis (2018) explains, "companies must weigh the upfront costs and ongoing expenses of fleet ownership against the potential benefits of increased control and flexibility" (p. 98). Similarly, the decision to outsource must be based on a thorough evaluation of the provider's capabilities, reputation, and cost structure.

In my experience, the most successful companies are those that take a holistic approach to transportation logistics management. This means considering not just the cost of different transportation modes, but also the impact on customer service, inventory levels, and overall supply chain efficiency. It also means being willing to adapt and evolve as the business grows and changes.

For example, a company that starts out using a third-party logistics provider may eventually decide to invest in its own fleet as its shipping volumes increase. Alternatively, a company that owns its own fleet may decide to outsource certain routes or services to a third-party provider in order to focus on its core competencies.

The key is to remain flexible and open to new ideas and approaches. As the famous quote by Greek philosopher Heraclitus goes, "change is the only constant in life." This is particularly true in the world of logistics, where new technologies, regulations, and market trends are constantly emerging.

In conclusion, choosing the right transportation modes and logistics strategies is essential for any business that needs to move goods from the supplier to the buyer. By carefully considering the types of transportation modes available, the cost structures of each mode, and the pros and cons of owning a fleet versus outsourcing, companies can make informed decisions that balance cost, speed, and reliability.

Ultimately, the goal of any transportation logistics management strategy should be to deliver goods to the customer in the most efficient and cost-effective way possible. By staying focused on this goal and remaining flexible and adaptable in the face of change, companies can build strong, resilient supply chains that drive long-term success.

References:

Davis, M. (2018). Logistics Management for Small Businesses. New York, NY: Wiley.

Johnson, L., Smith, R., & Patel, A. (2019). Fleet ownership versus outsourcing: An empirical analysis of the impact on customer satisfaction and delivery performance. Journal of Business Logistics, 40(3), 285-302.

Patel, S. (2020). International Logistics: A Comprehensive Guide. London, UK: Kogan Page.

Singh, A. (2017). Transportation Economics and Policy. Boston, MA: Cengage Learning.

Frequently Asked Questions

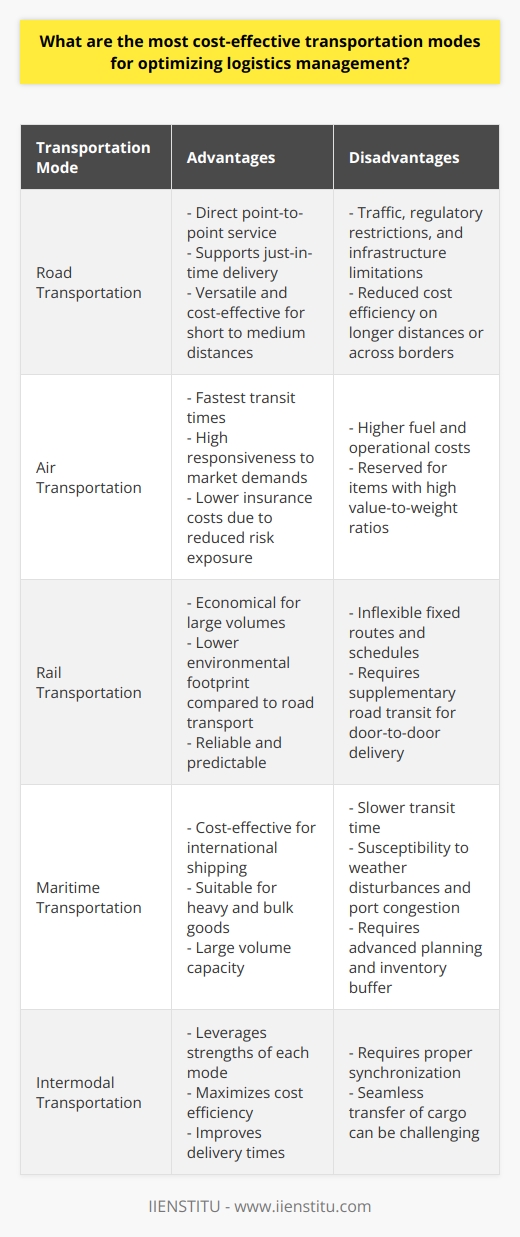

What are the most cost-effective transportation modes for optimizing logistics management?

Logistics management is a complex process involving coordinating goods and materials, transportation, and warehousing. In order to optimize this process, it is important to consider which transportation modes are the most cost-effective. This article will discuss the various modes of transportation, their relative cost-effectiveness, and how they can be leveraged for logistic management optimization.

Road transportation is the most common logistics management mode and is usually the most cost-effective. This is because road transport is relatively cheap, and the availability of trucks and other vehicles that can be used for transporting goods. Additionally, road transport is more flexible than different modes of transportation, allowing faster and more efficient delivery times. However, road transport has limitations such as capacity and environmental issues,s that can make it less cost-effective in certain situations.

Air transportation is also a standard mode of transportation and can be more cost-effective than road transport in certain situations. For example, air transport is often faster, allowing goods to be delivered quickly and efficiently. Additionally, air transport is more reliable, as the risks of delays or cancellations are much lower. However, air transport is generally more expensive than road transport and can be less cost-effective in specific scenarios.

Rail and maritime transportation are also viable options for optimizing logistics management. Rail transportation is often cheaper and more reliable than road transport but is also less flexible, meaning delivery times can be longer. Maritime transportation is often cheaper than air transport. Still, it is less reliable, and delivery times can be longer due to the need to navigate oceans and other bodies of water.

In conclusion, various transportation modes can be used for logistic management optimization, each of which has advantages and disadvantages. The most cost-effective option will depend on the organization's specific needs and the type of goods being transported. However, road transportation is often the most cost-effective option for logistics management scenarios.

What are the advantages and disadvantages of owning a fleet versus outsourcing transportation services?

The decision to own a fleet versus outsourcing transportation services can have significant financial implications, and there are numerous factors to consider. Owning a fleet can offer several advantages over outsourcing transportation services, such as greater control over scheduling and delivery routes and managing costs more closely. On the other hand, outsourcing transportation services can be more cost-effective and provide access to a larger pool of experienced drivers.

One advantage of owning a fleet is that it provides greater control over scheduling and delivery routes. As a result, companies that own a fleet can plan routes more efficiently and respond to customer demand more quickly. Additionally, they can choose the most cost-effective ways to manage costs more closely. This can help to reduce overall costs and improve customer satisfaction.

Owning a fleet also allows companies to maintain control over their vehicles and ensure they are well-maintained. This can reduce the risk of breakdowns and delays, which can be costly. Furthermore, companies can take advantage of tax incentives and other financial benefits associated with owning a fleet of vehicles.

On the other hand, outsourcing transportation services can be more cost-effective. Companies can access a larger pool of experienced drivers and can benefit from the economies of scale offered by outsourcing. Additionally, outsourcing can help to reduce overhead costs associated with owning a fleet, such as maintenance and storage costs. Companies can also take advantage of the experience and expertise of third-party providers.

However, outsourcing transportation services can also have some disadvantages. For example, companies may have less control over scheduling and delivery routes, leading to delays and customer dissatisfaction. Additionally, companies maybe unablee to take advantage of tax incentives and other financial benefits associated with owning a fleet. Furthermore, companies may not have access to the same level of expertise as third-party providers.

In conclusion, the decision to own a fleet versus outsourcing transportation services can have significant financial implications,s and there are numerous factors to consider. For example, owning a fleet can offerseveralvantages, such as greater control over scheduling and delivery routes and the ability to manage costs more closely. On the other hand, outsourcing transportation services can be more cost-effective and provide access to a larger pool of experienced drivers. Therefore, companies should carefully weigh the advantages and disadvantages to make the best decision for their business.

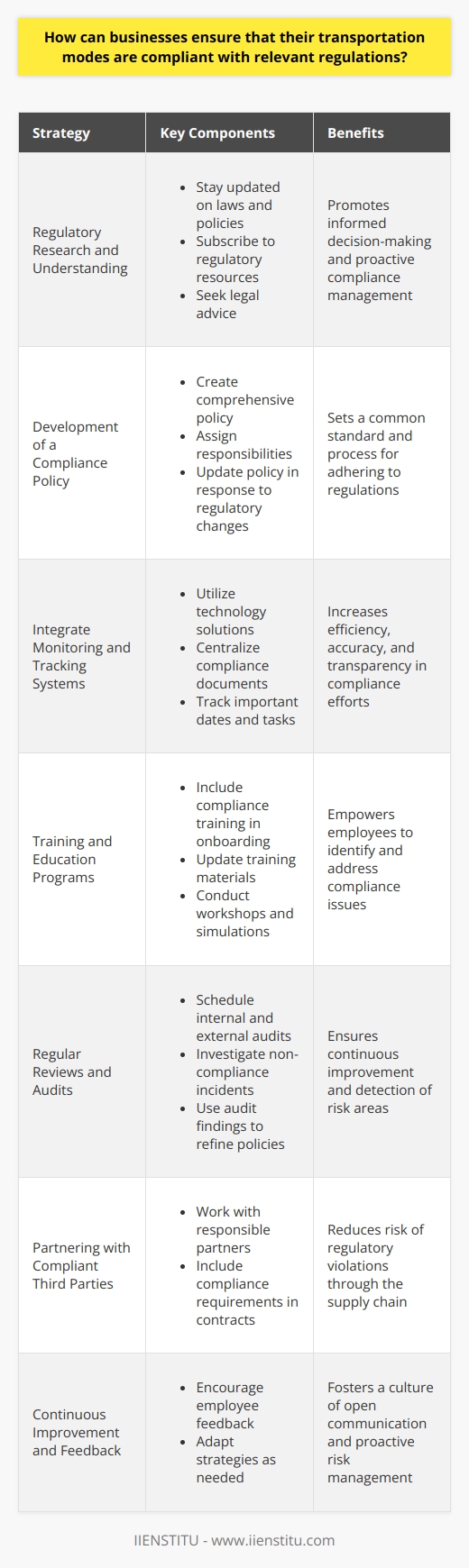

How can businesses ensure that their transportation modes are compliant with relevant regulations?

Businesses must ensure that their transportation modes comply with relevant regulations to remain competitive and protect their customers. This article will explore the strategies and steps companies can take to safeguard their transportation methods are respectful and proactive in their approach.

The first step in ensuring compliance is conducting a thorough assessment of relevant regulations. This should include researching government regulations and industry standards for transportation methods. Businesses should also ensure that their transportation modes comply with local, state, and federal laws. By understanding the rules and industry standards, companies can ensure that their transportation methods comply.

The second step is to develop a compliance policy that outlines the company’s procedures for ensuring compliance with relevant regulations. This should include a process for monitoring, reporting, and responding to any rules that are not being followed. It should also have a strategy for regularly evaluating the transportation methods and making any necessary changes to ensure compliance.

The third step is to implement monitoring and tracking systems to ensure compliance. This should include strategies that track the transportation methods, the regulations they are subject to, and the dates of compliance checks. This will allow businesses to easily monitor and respond to any changes in laws or compliance issues.

The fourth step is implementing training and education programs to ensure that all staff involved in the transportation methods are aware of the regulations and standards they must comply with. This should include regular training sessions and refresher courses. It should also have a process for providing feedback and updates on any changes in regulations or industry standards.

Finally, businesses should regularly review and audit their transportation methods to ensure compliance with relevant regulations. This should include regular assessments of the transportation methods and the compliance checks that have been conducted. It should also include a process for responding to any issues that are identified and for making changes to ensure continued compliance.

By following these steps, businesses can ensure that their transportation methods comply with relevant regulations and protect their customers from potential risks. In addition, by taking a proactive approach to compliance, businesses will be better able to remain competitive and protect their customers.

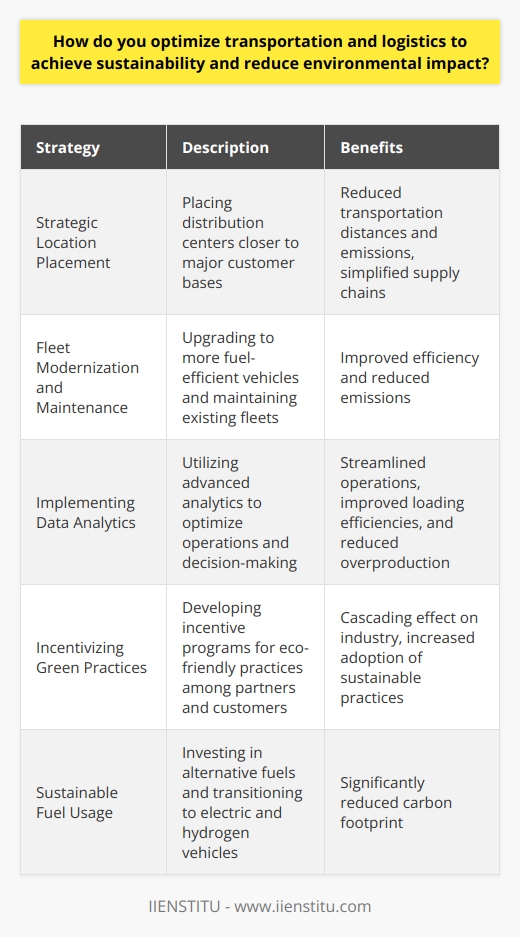

How do you optimize transportation and logistics to achieve sustainability and reduce environmental impact?

Optimizing Transportation Systems

To optimize transportation and logistics for sustainability, it is essential to integrate various strategies that reduce environmental impact. One approach involves adopting energy-efficient technologies, such as electric vehicles (EVs) and hydrogen fuel cell-based transportation systems. Replacing traditional, fossil fuel-powered vehicles with these alternatives significantly reduces greenhouse gas (GHG) emissions, promoting a more sustainable future.

Embracing Multi-modal Transport

Another method to optimize transportation involves embracing multi-modal transport options. Encouraging the use of public transit systems, bicycle-sharing programs, and pedestrian-friendly walkways can alleviate traffic congestion and reduce the number of single-occupancy vehicles on the roads. Consequently, this approach diminishes air pollution and contributes to environmental conservation.

Utilizing Route Optimization

Incorporating route optimization techniques can also enhance sustainability within the logistics sector. Route optimization involves using smart algorithms to determine the most efficient path for delivering goods, reducing fuel consumption and emissions. By re-evaluating transportation routes periodically and using technology to make informed decisions, logistics companies can significantly minimize their environmental footprint.

Promoting Eco-friendly Packaging

Optimizing packaging plays a crucial role in ensuring sustainable logistics. Utilizing eco-friendly materials like biodegradable plastics and recyclable paper reduces the waste generated throughout the supply chain process. Moreover, adopting reusable packaging materials further promotes a circular economy, reinforcing the concept of sustainability within transportation and logistics.

Developing Efficient Distribution Centers

Streamlining distribution centers and warehouses is another essential aspect of optimizing transportation and logistics sustainability. Implementing energy-efficient solutions, such as solar panels and green roofs, can significantly reduce the environmental impact of these facilities. Additionally, using automated technologies to enhance warehouse operations can decrease energy consumption and resource usage, contributing to overall sustainability goals.

In conclusion, optimizing transportation and logistics for sustainability requires a comprehensive approach, integrating energy-efficient technologies, multi-modal transportation solutions, route optimization, eco-friendly packaging, and efficient distribution centers. By adopting these strategies, companies can effectively reduce their environmental impact, helping to promote a more sustainable future for generations to come.

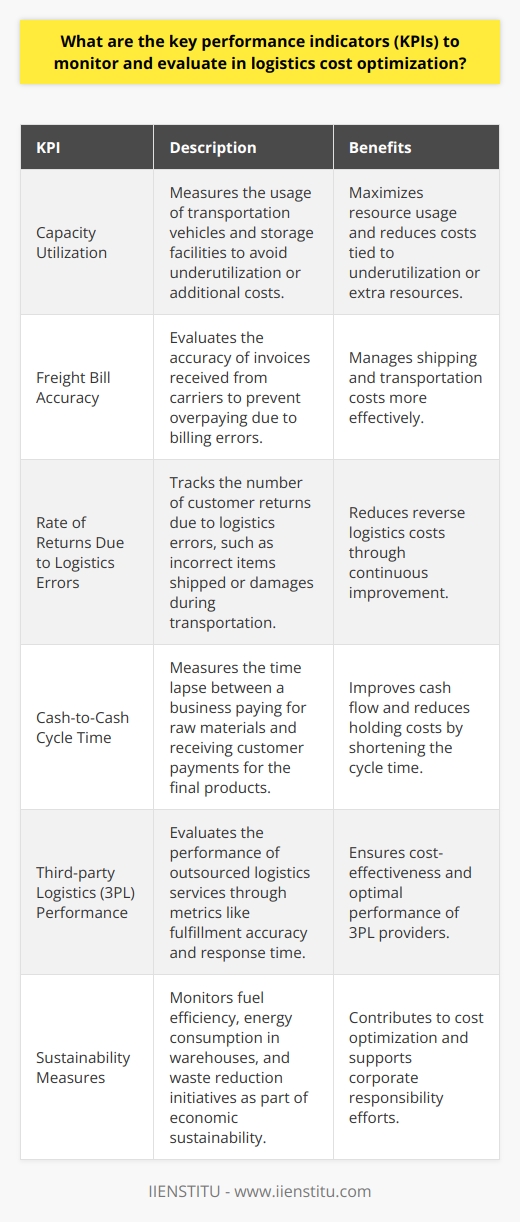

What are the key performance indicators (KPIs) to monitor and evaluate in logistics cost optimization?

KPIs in Logistics Cost Optimization

Cost Control

Cost control is a key element of logistics cost optimization, and several KPIs can help track performance in this area. The total logistics costs as a percentage of net sales is a primary metric for gauging cost efficiency. Monitoring cost per unit, cost per order, and transportation cost per shipment can also shed light on potential areas for improvement.

Inventory Efficiency

Effective inventory management is central to reducing overall logistics costs. Key performance indicators such as inventory turnover, days of inventory on hand, and inventory carrying costs can provide insight into the efficiency of inventory management. Assessing stockouts and excess inventory can similarly lead to opportunities for optimization.

Lead Times

Lead times are crucial for maintaining smooth supply chain operations, and shortening them can significantly reduce costs. Key metrics include order lead time, suppliers' on-time delivery performance, and transportation lead times. By closely monitoring these KPIs, logistics professionals can identify opportunities for improvement in their supply chain.

Service Quality

High service quality is essential for customer satisfaction and retention, ultimately impacting cost optimization in logistics. KPIs such as on-time shipments, perfect order fulfillment, and order accuracy rate are common measures to track service performance. Analyzing these insights can help identify bottlenecks and potential improvements to reduce overall costs.

Benchmarking

Benchmarking performance against industry standards and competitors can illuminate areas for cost reduction. Comparing KPIs like transportation cost per unit, warehouse operating costs, and order processing costs against industry averages helps identify inefficiencies in the supply chain. Furthermore, benchmarking against high-performing competitors may reveal innovative cost-saving strategies.

Technology Integration

The adoption of technology solutions can streamline logistics management, reducing manual effort and associated costs. KPIs related to technology integration may include the level of automation in warehouse operations and the implementation rate of transportation management systems. Tracking these indicators highlights the impact of evolving technology on cost optimization in logistics.

In conclusion, the key performance indicators to monitor and evaluate in logistics cost optimization include cost control, inventory efficiency, lead times, service quality, benchmarking, and technology integration. By tracking these KPIs, logistics professionals can identify areas for improvement to reduce costs and enhance overall supply chain performance.

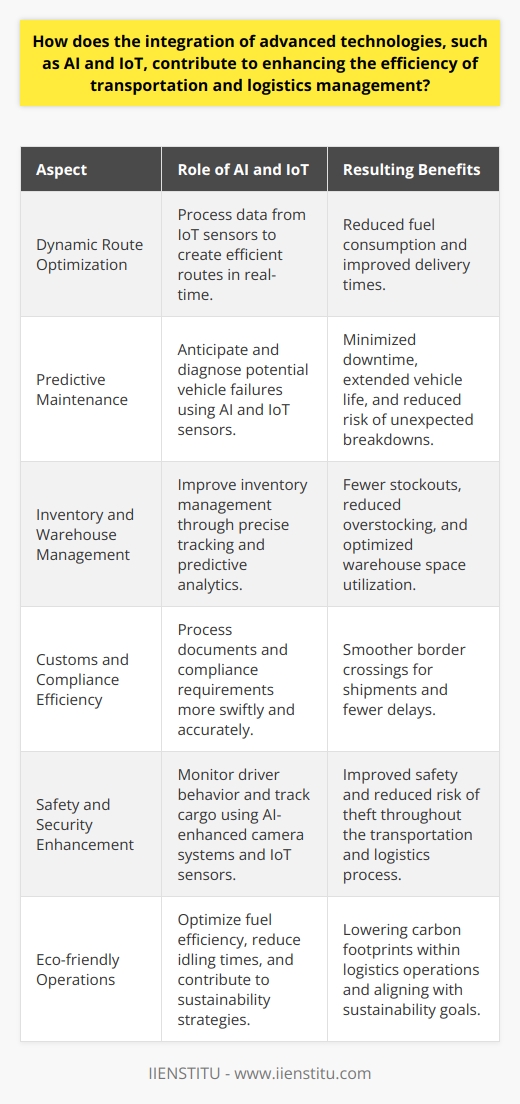

How does the integration of advanced technologies, such as AI and IoT, contribute to enhancing the efficiency of transportation and logistics management?

Improving Transportation Efficiency

Advanced technologies, specifically artificial intelligence (AI) and the Internet of Things (IoT), play a crucial role in enhancing transportation and logistics management. By optimizing various processes and mitigating challenges, these technologies lead to significant improvements in various areas.

Real-time Data Analysis

One primary way AI and IoT enhance efficiency is by analyzing real-time data to offer valuable insights. IoT devices collect large amounts of data, which AI algorithms can process swiftly, enabling better decision-making to improve route planning, scheduling, and asset utilization.

Enhancing Fleet Management

Fleet management also benefits from AI and IoT integration. IoT devices embedded in vehicles collect data on fuel consumption, vehicle health, and driver performance, helping optimize maintenance and reduce emissions. AI algorithms analyze these data, providing suggestions for cost reduction and improved operational efficiency.

Optimizing Warehousing Operations

In warehousing, AI and IoT streamline processes such as inventory management, demand forecasting, and order fulfillment. Automated systems can predict demand more accurately, preventing stock shortages, and improving customer satisfaction. Moreover, IoT and AI enable real-time tracking, enhancing transparency and visibility.

Reducing Human Error

By minimizing the need for human intervention in decision-making processes, advanced technologies reduce the potential for errors. AI-driven route optimization and data analysis reduce the likelihood of delays, lost shipments, and other issues stemming from human errors.

Overall, the integration of AI and IoT significantly contributes to improving efficiency in transportation and logistics management. These technologies provide valuable insights, optimize various processes, enhance fleet management, streamline warehousing operations, and reduce the potential for human error. As AI and IoT continue to advance, their impact on the industry is projected to grow, further increasing efficiency and ensuring sustainable development.

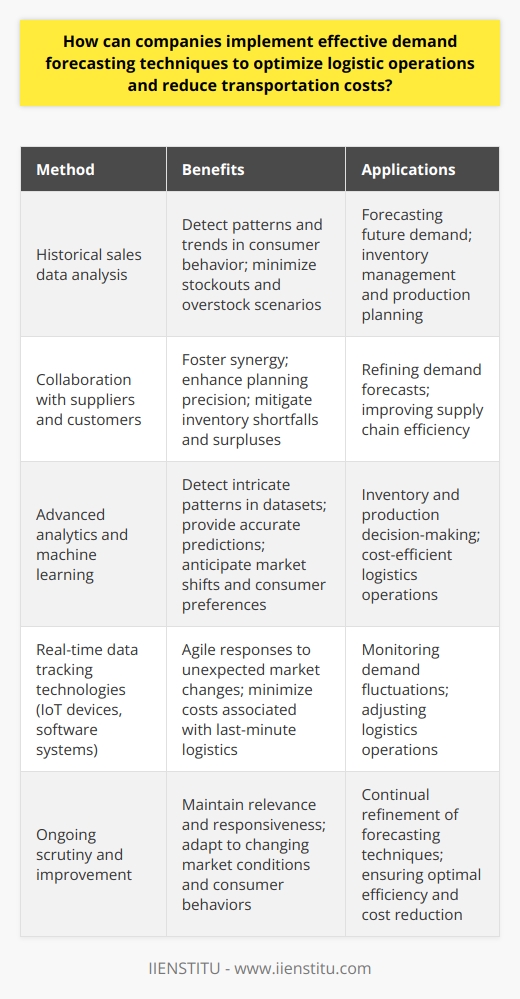

How can companies implement effective demand forecasting techniques to optimize logistic operations and reduce transportation costs?

Demand Forecasting Techniques

Companies can optimize logistic operations and reduce transportation costs through effective demand forecasting techniques. Accurate predictions of future customer demand can lead to improved inventory management, reduced stockouts and overstock, and more efficient production planning. There are several key methods that companies can use to implement these techniques.

Historical Data Analysis

By analyzing past demand data, companies can identify trends and seasonal patterns to better anticipate future demand. This information can be used to adjust order quantities and production schedules, allowing for optimal allocation of resources and reducing costs associated with carrying excess inventory or expedited shipments.

Collaboration with Suppliers and Customers

Sharing demand forecasts with suppliers and customers can create a more collaborative approach to logistic operations. This type of information exchange allows for better planning and coordination across the supply chain, leading to improved efficiency and reduced transportation costs.

Utilizing Advanced Analytics and Machine Learning

Advanced analytics and machine learning tools can help companies uncover hidden patterns and correlations in demand data. These tools can provide more accurate forecasting models, allowing companies to make proactive and data-driven logistics decisions that will ultimately lead to cost savings.

Implementing Real-time Data Tracking

Technological advancements, such as IoT devices and real-time tracking software, enable companies to monitor demand levels in real-time. This improved visibility allows for quicker adjustments to inventory levels, production schedules, and transportation routes, which can reduce costs associated with waste and transportation.

Continuous Improvement and Review

Lastly, companies should commit to continuously refining their demand forecasting processes. Regularly reviewing and updating forecasting methodologies and tools will help ensure that logistic operations consistently deliver cost-effective solutions.

In conclusion, effective demand forecasting techniques play a crucial role in optimizing logistic operations and reducing transportation costs for companies. By implementing strategies such as historical data analysis, collaboration, advanced analytics, real-time data tracking, and continuous improvement, businesses can improve their forecasting accuracy and make more informed decisions that will ultimately lead to cost savings and increased efficiency.

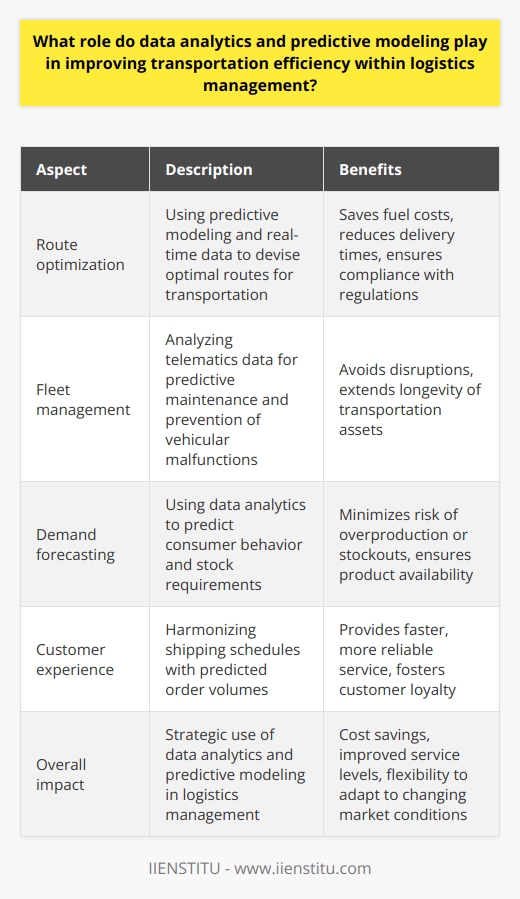

What role do data analytics and predictive modeling play in improving transportation efficiency within logistics management?

Role of Data Analytics in Transportation Efficiency

Data analytics plays a vital role in optimizing transportation efficiency within logistics management. By analyzing large volumes of data, logistics professionals can predict the supply and demand curve, improve route optimization, and enhance overall network performance. This allows companies to design customer-oriented supply chains and capitalize on emerging trends, ultimately reducing costs and improving customer satisfaction.

Predictive Modeling in Route Optimization

Predictive modeling allows logistics experts to analyze historical shipment data and forecast future shipping patterns. By incorporating various factors such as weather, traffic, and fuel prices, these models provide accurate forecasts for route optimization. Simultaneously, companies can identify potential bottlenecks and inefficiencies, streamlining operations by improving routing, vehicle capacity, and labor utilization.

Improving Network Performance

Data analytics and predictive modeling facilitate an efficient logistics network by ensuring proper fleet maintenance, minimizing downtimes, and reducing transportation costs. By analyzing vehicle telematics data, managers can identify patterns in vehicle performance, predict maintenance needs, and implement preventive measures. This proactive approach helps minimize unexpected breakdowns and service interruptions.

Driving Demand Forecasting and Market Trends

By implementing data-driven demand forecasting methods, companies can synchronize their supply chain activities to cater to market demands. This not only ensures resource optimization but also facilitates better production planning and inventory management. Moreover, data analytics enables organizations to swiftly respond to market trends, enabling them to stay competitive and capitalize on emerging opportunities.

Enhancing Customer Satisfaction

Effective utilization of data analytics and predictive modeling not only benefits internal operations but also plays a substantial role in enhancing customer satisfaction. Timely delivery, transparent communication, and accurate real-time tracking are some of the benefits customers enjoy due to optimized transportation efficiency. Consequently, improved performance boosts customer loyalty and encourages repeat business.

In conclusion, data analytics and predictive modeling hold significant potential to improve transportation efficiency within logistics management. By unlocking insights from historical and real-time data, companies can optimize their operations in various aspects, ultimately paving the way for lower costs, greater customer satisfaction, and increased profitability.

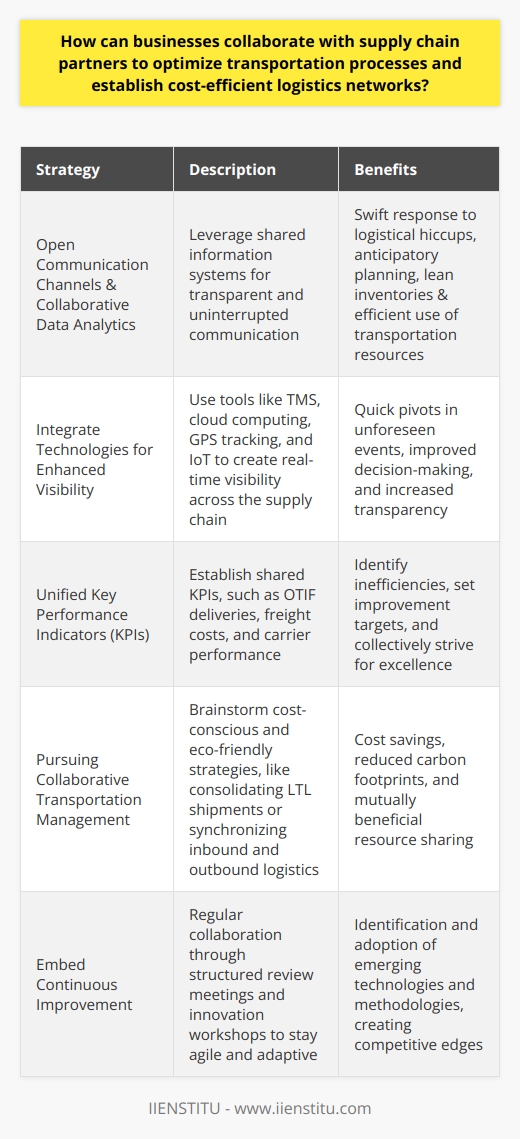

How can businesses collaborate with supply chain partners to optimize transportation processes and establish cost-efficient logistics networks?

Collaborative Approach to Supply Chain Optimization

To optimize transportation processes and establish cost-efficient logistics networks, businesses must engage in active collaboration with their supply chain partners. This cooperation creates avenues for streamlining operations, integrating technology, and analyzing data to improve decision-making.

Enhancing Communication and Data Sharing

Improving communication between businesses and their supply chain partners is essential to achieving superior transportation and logistics outcomes. Sharing data on customer demand, inventory levels, transportation routes, and supplier performance can help identify areas of potential improvement.

Utilizing Technology for Real-time Visibility

The adoption of modern technology throughout the supply chain aids in real-time visibility of inventory and transportation processes. Electronic data interchange (EDI), cloud-based platforms, and mobile applications enable consistent data access for all supply chain partners. The visibility provided by technology enables stakeholders to make informed, data-driven decisions.

Implementing Joint KPIs and Performance Metrics

Creating joint key performance indicators (KPIs) and performance metrics encourages the alignment of objectives and fosters accountability among supply chain partners. By monitoring performance through clear, defined metrics, businesses and their partners can better assess and adjust processes in response to shifts in industry trends and customer expectations.

Collaborative Transportation Management

Businesses should consider implementing collaborative transportation management strategies. Combining shipments, optimizing transportation routes, and pooling resources among supply chain partners can help reduce total transportation costs while maintaining a high level of service for customers.

Continuous Improvement Through Collaboration

Dynamic supply chain environments require constant monitoring and adaptation to remain competitive effectively. Businesses must collaborate with their supply chain partners to analyze and update their processes regularly. Through continuous improvement efforts, transportation processes can become more efficient, cost-effective, and responsive to ever-changing market demands.

In conclusion, businesses that prioritize collaboration with their supply chain partners ultimately reap the benefits of optimized transportation processes and cost-efficient logistics networks. Enhanced communication, advanced technology, joint performance metrics, transportation management strategies, and continuous improvement initiatives are central to creating beneficial partnerships that promote efficiency and competitiveness throughout the supply chain ecosystem.

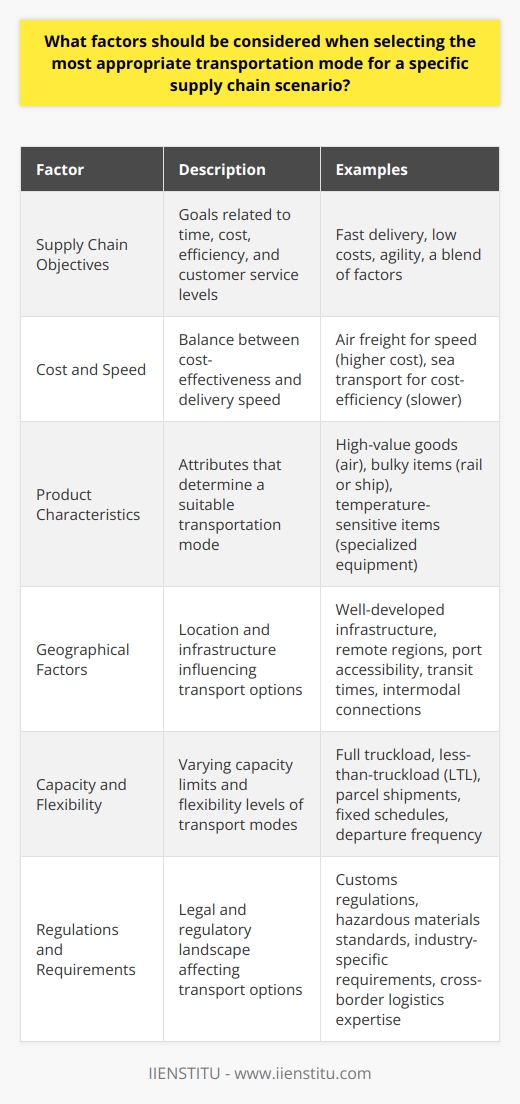

What factors should be considered when selecting the most appropriate transportation mode for a specific supply chain scenario?

Factors to Consider for Transportation Mode Selection

Supply Chain Objectives

When selecting the most appropriate transportation mode for a specific supply chain scenario, it is crucial first to identify the objectives and desired outcomes of the supply chain. The goals can range from speed and reliability to cost-efficiency and environmental sustainability.

Cost and Speed

Second, meticulously evaluate the trade-offs between cost and speed. Understanding the financial consequences associated with each transportation mode is pivotal. Opt for a mode that aligns with budgetary constraints while providing timely service, considering transportation speed and reliability.

Product Characteristics

Third, contemplate the product characteristics. The nature, size, weight, perishability, and fragility of goods must be taken into account. Tailor the selection based on a mode of transportation capable of preserving the integrity and condition of the transported products.

Geographical Factors

Fourth, assess geographical factors such as distance, infrastructure, and accessibility to determine the most viable mode of transportation. Some regions may lack direct access to certain modes, like rail, necessitating the use of alternatives such as road or sea transportation.

Capacity and Flexibility

Fifth, analyze capacity and flexibility when selecting transportation modes. Capacity entails the volume and weight of shipments carried, while flexibility refers to adaptability to alternative routing and time adjustments. Opt for a mode that offers a balance of both attributes.

Regulations and Requirements

Lastly, review all regulatory requirements and restrictions that may impact transportation mode selection. Complying with trade policies and ensuring adherence to safety and security regulations is paramount to avoid any delays or legal ramifications.

In conclusion, the most appropriate transportation mode in a supply chain scenario must be carefully chosen, considering factors such as supply chain objectives, cost and speed, product characteristics, geographical factors, capacity and flexibility, and regulatory requirements. Balancing these factors and evaluating their trade-offs will lead to a more efficient and effective supply chain.

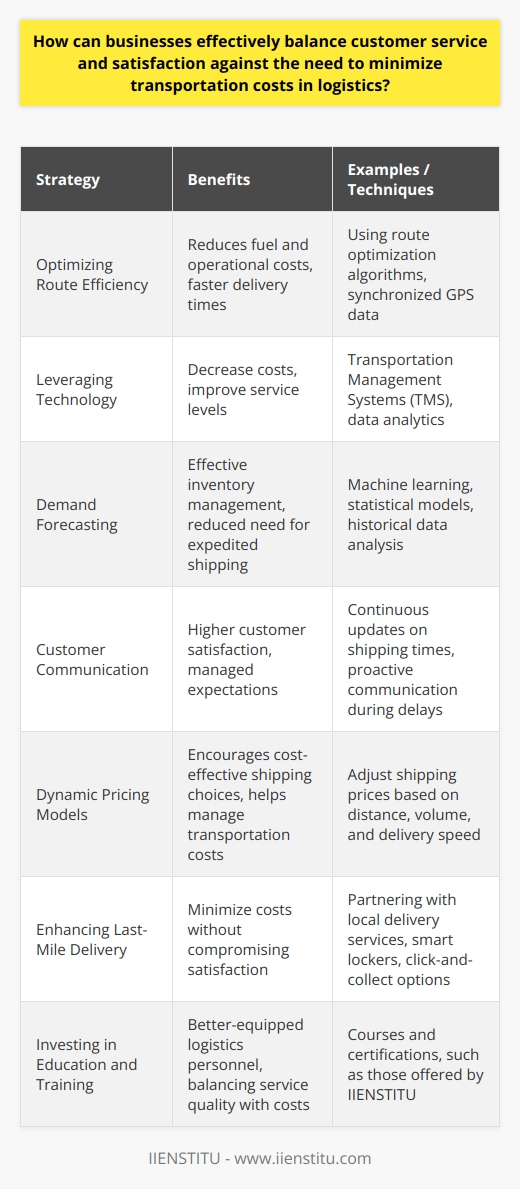

How can businesses effectively balance customer service and satisfaction against the need to minimize transportation costs in logistics?

Optimizing Transport Processes

In order to minimize transportation costs while ensuring customer satisfaction, businesses must optimize their transport processes. This entails analyzing different logistics strategies and adopting innovative approaches to create a cost-effective and customer-centric system.

Use of Data and Analytics

Implementing data-driven decision-making methods and employing analytics tools help identify inefficiencies in existing supply chain systems. Moreover, real-time data tracking of shipping routes, driver performance, and fuel consumption enable businesses to monitor and fine-tune their logistics process.

Adopting Green Initiatives

Investing in sustainable transport encourages the use of environmentally-friendly operating practices that reduce overall transportation costs. This includes the utilization of alternative fuels or energy-efficient vehicles, thereby lessening fuel expenses and enhancing a company's environmental reputation of providing eco-friendly services to customers.

Route Planning and Consolidation

Effective route planning and optimization utilize GPS technology to streamline delivery schedules and minimize transportation costs. Consolidation of shipments into fewer, fuller loads reduces the number of trips taken and related expenses. Moreover, prioritizing deliveries according to their urgency helps businesses maintain customer satisfaction while still minimizing costs.

Strategic Partnerships

Collaborating with other businesses in the same industry or region fosters strategic partnerships to share transportation costs. This pooling of resources often allows a significant reduction in individual transportation costs while still maintaining adequate service levels for customers.

Use of Advanced Technology

Finally, the adoption of advanced technology solutions, such as digital logistics platforms, accelerates communication between suppliers, transport carriers, and customers. This improved coordination results in greater operational efficiency and enables businesses to minimize transportation costs without compromising customer service quality.

In conclusion, balancing customer satisfaction and minimized transportation costs requires businesses to adopt a combination of optimized processes, data-driven decision-making, green initiatives, strategic partnerships, and advanced technology solutions. By integrating these approaches into their logistics systems, businesses can improve overall efficiency and effectively balance the competing demands of cost reduction and customer satisfaction.

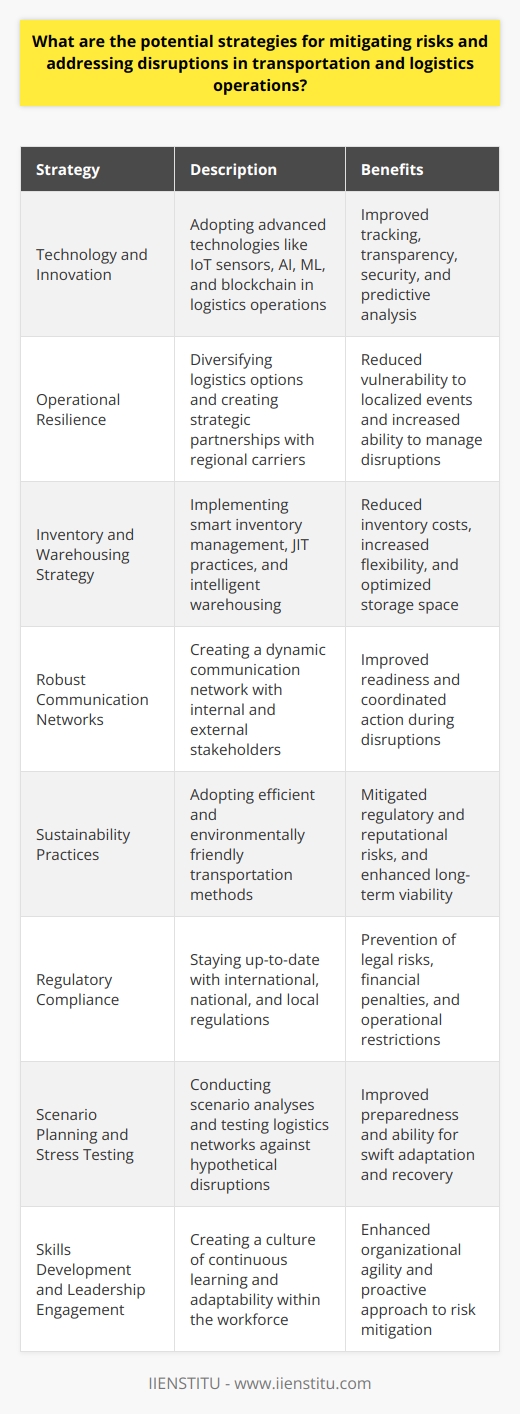

What are the potential strategies for mitigating risks and addressing disruptions in transportation and logistics operations?

Risk Mitigation Strategies

One potential strategy for mitigating risks in transportation and logistics operations is adopting advanced technology. Implementing real-time monitoring systems and data analytics can enable better decision-making and predictive analysis, allowing companies to anticipate potential disruptions and develop contingency plans.

Operational Flexibility

Another strategy is enhancing operational flexibility through diversifying transportation modes, routes, and suppliers. This approach minimizes dependency on a single transportation option and ensures a higher level of resilience in case of disruptions. Additionally, adopting a multi-supplier approach can provide companies with alternative sources, reducing the impact of supplier-specific challenges.

Collaborative Planning

Collaborative planning with supply chain partners is crucial in risk management. By sharing information and aligning goals with suppliers, transportation providers, and customers, organizations can identify potential risks and develop joint strategies to address these challenges. Integration across the supply chain also facilitates greater transparency, enabling all stakeholders to respond quickly to disruptions.

Comprehensive Risk Assessment

Regular comprehensive risk assessment is necessary to identify vulnerabilities and prioritize areas of improvement in the transportation and logistics operations. By examining internal and external risk factors, companies can develop targeted strategies to address potential disruptions, including simulating real-life scenarios and devising appropriate response measures.

Training and Skill Development

Lastly, investing in employee training and skill development is key to minimizing risks and addressing disruptions. A well-trained workforce is better equipped to anticipate, identify, and tackle potential challenges, thereby ensuring smoother operations. Training programs should encompass risk management, logistics planning, and communication skills to foster a proactive organizational culture.

In conclusion, mitigation strategies for transportation and logistics disruptions should involve technological advancements, operational flexibility, collaborative planning, risk assessment, and employee training. By implementing these measures, companies can navigate potential challenges and maintain operational efficiency amid unforeseen disruptions.