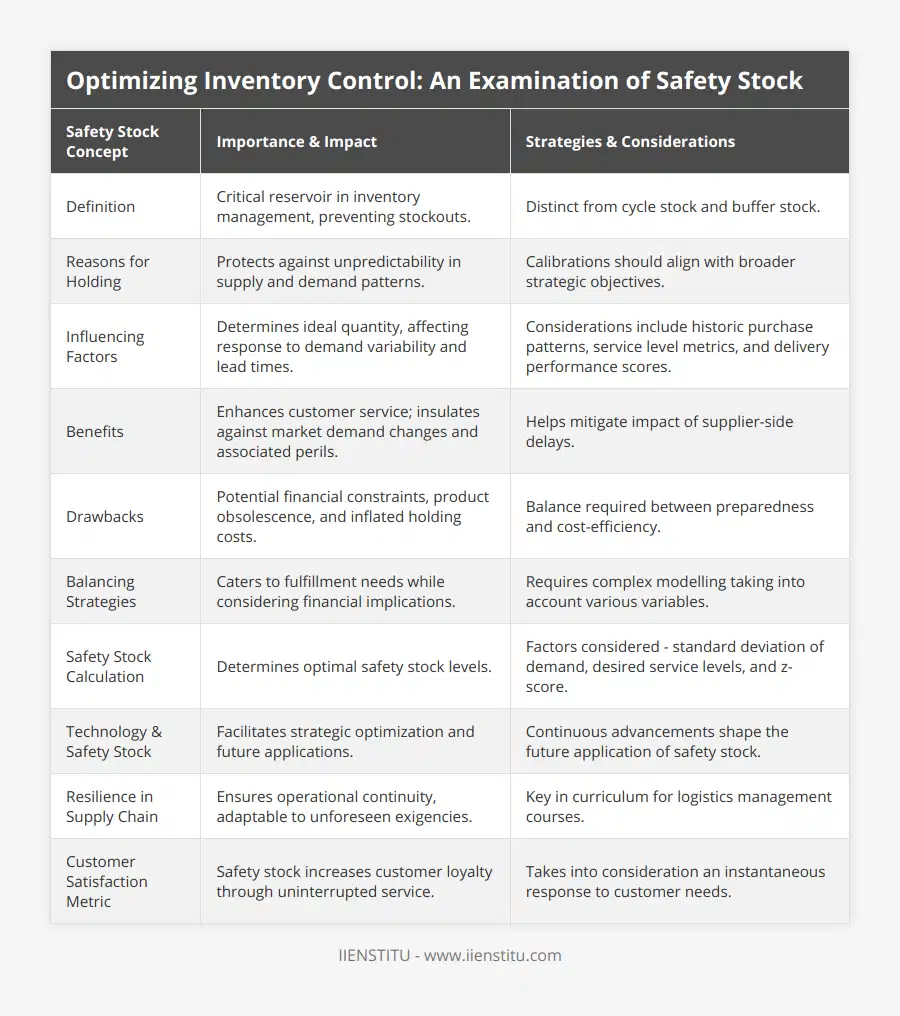

In an intricate tapestry of supply chain management, safety stock holds a pivotal position in the architecture of inventory control. As businesses strive to meet the demands of a dynamic marketplace, the calibration of safety stock levels becomes a cornerstone of operational efficiency. The essentiality of safety stock in inventory management sistemas as a buffer against the unpredictability of supply and demand.

This academic exploration will delve into the multifaceted aspects of safety stock, elucidating its definition, mechanics, and strategic optimization, with an emphasis on benefits, challenges, and technological advancements shaping its future application.

Understanding Safety Stock

Definition of safety stock

Safety stock serves as a critical reservoir in the inventory management equation, positioned to avert the ramifications of stockouts. This safeguard is a quantifiable allotment that insulates an enterprise's operations from the vicissitudes of supply chain disruptions.

While intertwined with overarching inventory management strategies, safety stock is distinctly differentiated from cycle stock, which caters to normal demand patterns, and buffer stock, which specifically addresses short-term variances. The alignment of safety stock with the strategic objectives of logistics management courses often becomes a focal point of curriculum, equipping scholars with the tools to navigate the intricacies of inventory control.

Reasons for holding safety stock

Entities procure safety stock primarily as a fortification against the twin uncertainties of demand and supply. The fluctuations in customer procurement patterns, matched with potential unpredictability among suppliers, mandate a ready reserve.

This reserve acts as a fortification, ensuring continuity of service and fostering resilience in the face of unforeseen exigencies. The acuity of supply chain managers, often honed by certificate courses online, is pivotal in discerning the appropriate magnitude of safety stock warranted for any given operation.

Uncovering Strength in Decision Making Using Sensitivity Analysis

Analyzing the Critical Role of Cold Chain Logistics in the Industry

Factors influencing safety stock levels

Deciphering the appropriate quantity of safety stock involves a multitude of considerations. Lead Time—the elapsed interval between order placement and receipt—bears significant weight in this equation. Moreover, the capricious nature of demand variability introduces another layer of complexity, compelling a careful analysis of historic purchase patterns. Service Level metrics and Delivery Performance scores also inform this calibration, prescribing the degree of buffer necessary to achieve desired customer satisfaction standards.

An anecdotal illustration of safety stock might involve a retailer who, having analyzed sales during holiday peaks and supplier delays, maintains a calculated reserve of a popular toy to ensure fulfillment of any unanticipated demand surges.

Benefits and Drawbacks of Safety Stock

Benefits of safety stock

The institution of safety stock harbors substantial advantages. It empowers enterprises to contend with unexpected market demand and to prevent the perils associated with stockouts and consequent backorders.

Customer service sees tangible improvements when companies leverage safety stock to address instantaneous needs without delay, enabling the constructor of customer loyalty. Furthermore, the incorporation of safety stock buffers the impact of lead time variations, precluding the potential operational disruptions attributable to supplier-side delays.

Drawbacks of safety stock

Notwithstanding the merits, safety stock sustains intrinsic limitations. Capital tied up in unnecessary excess can inflate holding costs, with resources languishing dormant in warehouses. This capital, otherwise employed in revenue-generating activities, can impinge on financial liquidity.

In parallel, overstocking carries the peril of product obsolescence—items may depreciate or become outdated, leading to unsellable inventory. Therefore, identifying the equilibrium point in safety stock levels where benefits overshadow drawbacks is a managerial tightrope walk of strategic importance.

Balancing safety stock levels for optimal benefits

The quest for balance in safety stock levels is a relentless pursuit—a dynamic interplay between cost-efficiency and preparedness. Systematic approaches for equilibrium-seeking involve complex modeling that takes into account the aforementioned variables. Striking this balance channels into ensuring material readiness for fulfillment needs while also considering the financial constraints that excess stocking imposes.

Calculating Safety Stock

Formulae for safety stock

Safety stock calculation manifests through various formulae, each dissecting different aspects of inventory dynamics. At the core of these formulae lie elements such as standard deviation of lead time and demand, desired service levels, and the z-score or the statistical measure of service level confidence. Each factor's quantification amalgamates into a holistic portrayal of the requisite safety stock—a representation of statistics harnessed for operational fortitude.

Factors to consider when calculating safety stock

When embarking upon the safety stock calculation, meticulous consideration is paramount. Factors including the standard deviation of historical demand data, lead time variability, and the company's risk tolerance levels in terms of service level objectives come into play. Each of these factors feeds into the computational matrix, dictating the final safety stock figure.

Example calculation of safety stock

Envision a scenario in which a company desires a service level of 95%, with a lead time standard deviation of one day and daily demand standard deviation of 10 units. By applying a suitable formula, the safety stock can be calculated to meet these specified parameters, thereby rendering a numerical representation of the inventory buffer required to maintain the 95% service level.

Strategies for Optimizing Safety Stock

Just in Time (JIT) strategy

The Just in Time inventory approach epitomizes the lean philosophy, necessitating precise coordination and finely-tuned processes to minimize safety stock. JIT's core tenet lies in the synchronization of supply with demand, thus negating the need for large safety stock holdings. However, its successful implementation pivots on the near-perfect predictability of supply and demand—an ideal that is often elusive in the tumultuous terrain of global trade.

Vendor Managed Inventory (VMI)

Under VMI paradigms, suppliers assume stewardship of inventory levels, optimizing safety stock according to a mutually agreed framework. This collaboration yields a streamlined supply chain ecosystem, with vendors leveraging their insights and operational competencies to safeguard their clients' inventory health.

Use of technology and inventory management systems

Advances in technology, particularly inventory management systems, have revolutionized the science of safety stock optimization. These platforms harness real-time data, affording unprecedented visibility and agility in inventory dynamics. Drawing on perpetual analytics, these systems facilitate a proactive rather than reactive approach to safety stock maintenance, enabling continuous alignment with evolving market forces.

The Future of Safety Stock

The role of technology in predicting safety stock

The advent of AI and machine learning heralds a paradigm shift in predicting and managing safety stock. By harvesting the power of big data, predictive analytics extends the horizons of accuracy in anticipating demand cycles, thus optimizing inventory efficiency. Driven by algorithms that learn and adapt, the future of safety stock is one characterized by precision and responsiveness, underpinned by intelligent technology.

Safety stock in the era of e-commerce and omnichannel retail

E-commerce and omnichannel retailing intensify the complexities of inventory management—challenging traditional safety stock doctrines with instantaneous, multipoint demands. In response, the calibration of safety stock must incorporate an intricate web of distribution channels, embodying flexibility to cater to diverse consumer touchpoints and fulfillment options.

Case studies highlighting successful safety stock management

Excavating the annals of supply chain success stories yields a treasure trove of insights into prudently managed safety stock. Case studies from leading industry players, whose capacity to deftly navigate the balance of stock availability against financial prudence, serve as educational exemplars. These chronicles embody the principles imparted through rigorous logistics management courses, demonstrating the tangible benefits of adept safety stock management.

The reinforcement of safety stock as an integral element of inventory management is incontrovertible—serving not merely as an operational tool but as a competitive differentiator. In closing, it is incumbent upon businesses to champion the effective management of their safety stock levels—an endeavor that assures not only enhanced productivity but palpable profitability. Embracing this imperative, coupled with the judicious application of technology and continuous recalibration, positions enterprises to thrive amidst the fluidity of global commerce.

Frequently Asked Questions

What parameters should be considered for optimal safety stock determination in inventory control?

Understanding Safety Stock

Safety stock acts as a buffer. It guards against stockouts. Stockouts can disrupt business. They affect customer satisfaction. Safety stock is crucial for inventory control.

Key Parameters for Safety Stock Determination

Demand Variability

Demand is not constant. It fluctuates. Understanding demand patterns is essential. Higher variability increases safety stock needs. Forecasts guide demand estimation. Use past data carefully. Consider seasonal variations too.

Lead Time Variability

Suppliers are not always reliable. Lead time can change. This variability impacts safety stock levels. Longer lead times usually mean more safety stock. Accurate lead time predictions are vital. Work closely with suppliers.

Service Level Goals

Service level reflects customer satisfaction. It represents a performance target. High service levels require more safety stock. Understand customer expectations. Balance service levels with inventory costs. Choose a realistic service level target.

Reorder Point

Reorder point triggers new orders. It affects safety stock calculations. Stock should meet demand during lead times. Reorder points must account for safety stock. Calculate reorder points precisely. Misjudgment increases risk of stockouts or excess inventory.

Supply Chain Efficiency

A robust supply chain helps. It reduces the need for safety stock. Invest in supply chain improvements. Collaboration with suppliers pays off. Enhanced efficiency means lower safety stock levels. Continuous improvement is key.

Best Practices for Safety Stock Determination

- Use accurate data: Historical data must be reliable.

- Analyze trends and patterns: Seasonality and demand trends affect stock needs.

- Regularly review safety stock levels: Markets evolve. Review levels frequently.

- Apply inventory management tools: Software can aid in complex calculations.

- Collaborate with stakeholders: Communication with suppliers and customers is crucial.

- Balance cost and service level: Find a cost-effective safety stock level.

By considering these parameters, businesses can optimize their safety stock. Optimal levels prevent stockouts. They also minimize carrying costs. Ensure parameters reflect the current market dynamics. Use data and tools effectively. Regular assessment and adjustment are necessary. Collaboration enhances accuracy in safety stock calculations. A balanced approach ensures inventory control success.

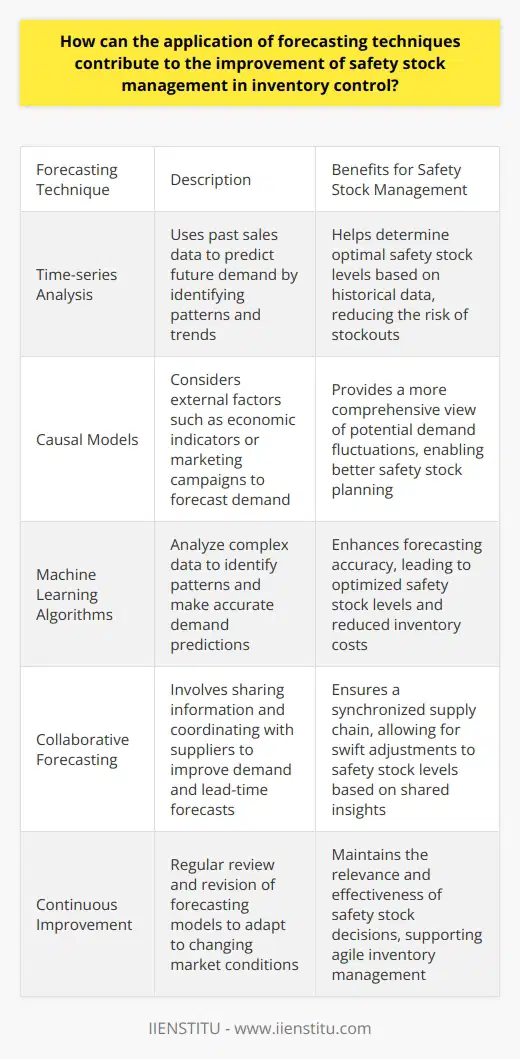

How can the application of forecasting techniques contribute to the improvement of safety stock management in inventory control?

Safety Stock Management in Inventory Control

Forecasting is central to inventory control. It determines how much stock a business should maintain. Safety stock acts as a buffer. It mitigates the risk of stockouts. This stock absorbs demand and lead-time variability.

ItalicSafety stock protects against uncertainties. These may include sudden demand spikes or supplier delays. Proper forecasting techniques harness historical data. They also analyze market trends. This helps determine the optimal safety stock level.

Forecasting Techniques Enhance Safety Stock Decisions

Forecasting involves complex statistical models. Time-series analysis is one example. It uses past sales data to predict future demand. Causal models consider external factors. These might be economic indicators or marketing campaigns.

BoldBetter demand forecasts reduce safety stock needs. This results in lower holding costs. Companies benefit from improved capital efficiency. They do not overinvest in inventory. Nor do they under-prepare for demand.

Quantitative and Qualitative Forecasting

Forecasting combines quantitative and qualitative methods. Quantitative forecasting uses numerical data. It applies mathematical models. This approach is objective. Yet, it often requires plentiful and high-quality data. Qualitative forecasting involves expert judgment. It accounts for factors beyond historical data. Combining both leads to more robust safety stock levels.

Forecasting accuracy directly affects inventory performance. Improved forecasts lead to optimized safety stock. This minimizes the cost of overstocking. At the same time, it prevents stockouts.

BoldCompanies that forecast effectively hold a competitive edge. They respond better to market fluctuations. They maintain customer satisfaction by having products available.

Impact on Operational Efficiency and Customer Service

Balanced safety stock levels are crucial for operational efficiency. With accurate forecasting, businesses adjust inventory levels swiftly. They align with current market conditions. Increased accuracy in forecasts reduces excess stock. It frees cash flow for other strategic investments.

ItalicOn-time delivery improves with managed safety stock. This forecasting directly ties to customer service quality. A product's availability hinges on these stock levels. If forecasts are off, customer service falters.

Collaboration with Suppliers for Improved Forecasts

Collaboration with suppliers can enhance forecasting. Sharing information leads to better inventory decisions. It ensures a synchronized supply chain. Both parties can plan for changes in demand. They can adjust their production and distribution accordingly.

- Improved lead-time forecasts result from collaboration.

- Shared data can highlight potential supply chain disruptions.

- Partnerships allow for coordinated responses.

BoldLean inventory techniques benefit from accurate forecasts. These techniques strive for minimal stock levels. Efficient forecasting ensures these levels still prevent stockouts.

Technological Advancements in Forecasting Techniques

Technological advancements are refining forecasting methods. They increase their accuracy. Machine learning algorithms analyze complex data. They identify patterns that human analysts might miss.

ItalicOrganizations invest in such technologies. They aspire to achieve near-perfect forecasting accuracy. This investment contributes to optimal inventory management. Up-to-date forecasting systems provide a strategic advantage.

The Role of Continuous Improvement

Forecasting processes require continuous improvement. This ensures forecasts and safety stock levels stay relevant. Adapting to changing market conditions is a must. Firms must review and revise their forecasting models regularly.

- Regular analysis identifies forecasting errors.

- Continuous training enhances team expertise.

- Ongoing system upgrades integrate the latest technologies.

BoldEffective inventory management demands resilient forecasting processes. They must remain agile and responsive to change. Firms must commit to these processes. They need to support them with resources and attention.

In Conclusion

Applying robust forecasting techniques is key. It leads to improved safety stock management. Firms reduce financial risks and optimize inventory levels. They also improve service levels and operational efficiency. In a rapidly changing market, precise forecasting is indispensable. It supports resilient and responsive inventory control. Firms that master this discipline gain a strategic edge. They thrive despite the uncertainties of supply and demand.

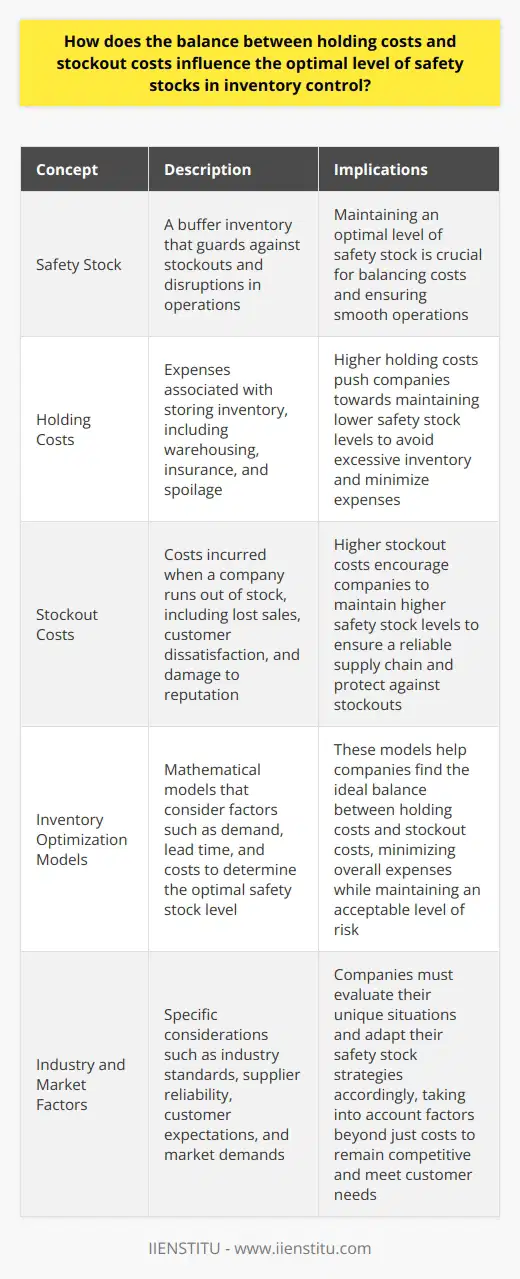

How does the balance between holding costs and stockout costs influence the optimal level of safety stocks in inventory control?

Explaining Safety Stocks

Safety stock acts as a buffer. It guards against stockouts. Stockouts disrupt operations. They also disappoint customers. Inventory control focuses on balancing risks. It seeks an optimal safety stock level. This balance reduces overall costs.

The Costs Involved

Two primary costs matter here. They are holding costs and stockout costs.

Holding Costs

Holding costs cover storage and related expenses. These include warehousing, insurance, and spoilage. High inventory levels lead to high holding costs. Every extra unit carries a cost.

Stockout Costs

Stockout costs come from not having stock. They include lost sales and customer dissatisfaction. They may also hurt reputation. Stockouts can erode customer trust.

The Balancing Act

Inventory control optimizes the stock level. It reduces cumulative costs. Optimization is complex. It requires precise calculations. Companies use inventory models. The models consider various factors. Demand, lead time, and costs are primary factors.

Calculating Safety Stocks

Calculations should minimize risk. They should reduce the likelihood of stockouts. They do not aim for zero risk. That would require excessive inventory. It would inflate holding costs unreasonably.

Formulas take in demand variability. They also account for lead time uncertainty. They give an ideal safety stock level. This level balances costs effectively.

Effects on Optimal Safety Stock Levels

Higher holding costs push towards lower safety stocks. The cost per unit stored is significant. Companies lean towards less inventory. They avoid overstocking.

In contrast, higher stockout costs push the other way. Reliability matters to customers. A reliable supply chain becomes a priority. Companies may hold more safety stock. This protects against stockouts.

Balancing these costs, a middle ground emerges. The optimal safety stock level is not static. It reflects an individual company's costs. It also reflects risk tolerance and market demands.

Practical Considerations

Companies must evaluate their specific situation. They consider industry standards. They assess supplier reliability. They also consider customer expectations. This leads to tailored inventory strategies.

Costs are not the sole factor. Flexibility, responsiveness, and service levels also weigh in. They impact safety stock decisions.

In Conclusion

The balance affects safety stock levels considerably. Companies seek to minimize total costs. They want to serve customers well. Optimal safety stock is a moving target. It shifts with changes in holding costs, stockout costs, and market conditions. Inventory control is an ongoing process. It requires assessment and adaptation.