In the quest for safety and reliability, Fault Tree Analysis (FTA) has cemented its place as an indispensable tool. At its core, FTA is a deductive reasoning process that systematically explores the ways in which complex systems can fail. By mapping out potential causes of failure in a graphical representation known as a fault tree, engineers and safety professionals are equipped to predict and mitigate catastrophic failures. Fault Tree Analysis has become a cornerstone in critical fields such as aerospace, nuclear power, and chemical processing, where comprehensive risk assessment and system reliability are of paramount importance.

The effectiveness of FTA lies in its ability to not just unearth single points of failure, but to also uncover intricate interdependencies that could lead to a system breakdown. This methodical approach to understanding failure dynamics makes Fault Tree Analysis an exemplar of problem-solving skills training, breaking down seemingly intractable problems into manageable components. The prescient powers of FTA render it more than a mere tool; it is a philosophy of preemptive problem-solving that empowers industries to operate at the pinnacles of safety and reliability.

Historical Background of Fault Tree Analysis

Origins and Evolution of Fault Tree Analysis

Fault Tree Analysis has a storied history, originating in the early 1960s under the auspices of the U.S. Air Force and the Bell Telephone Laboratories. Crafted to secure the intricacies of missile systems, FTA was a pioneering method developed to synthesize both hardware and software reliability concerns. Its utility was quickly recognized by other high-stakes industries, and its adoption spread as a rigorous assessment tool.

As the discourse around system safety evolved, FTA underwent sophisticated refinement, with academic institutions and safety professionals collaborating to enhance its applicability. It rode the wave of the burgeoning safety culture, contributing to the development of standards and regulations designed to safeguard against systemic failures. The DNA of FTA – rigorous, comprehensive, and systematic – remained intact as it adapted to the constantly shifting technological landscape.

Notable Uses and Advancements in the Application of Fault Tree Analysis

Over the years, FTA has been pivotal in analyzing some of the most complex systems engineered by humankind. Notably, NASA integrated Fault Tree Analysis into the safety protocols of its Space Shuttle program, dissecting possible failure scenarios that could endanger missions and crew. The nuclear industry, too, has seen widespread application of FTA, with the approach informing safety designs and accident prevention strategies post-events like the Three Mile Island incident.

The toolkit for conducting FTA has also expanded, with modern software aiding in the creation and analysis of ever more complex fault trees. Additionally, the integration of FTA into online certificate courses has democratized access to this expertise, enabling a wider audience to acquire the knowledge necessary to implement it across various sectors. Fault Tree Analysis continues its evolution, growing in sophistication and accessibility alike.

Understanding the Components of a Fault Tree

Explanation of All the Different Components Used in a Fault Tree: At its core, a fault tree is a graphical representation of the logical connections between failures, malfunctions, and external events. It begins with a "top event," typically a catastrophic failure, and works retroactively through layers of lower-level events and contributing causes. Basic components such as "gates" and "events" constitute the building blocks of the fault tree. These gates represent logical operators like AND and OR, indicating how the combinations of different lower-level events can lead to the top event.

Illustration With Examples of Each Component: To unpack the abstract concepts, let's consider the Fault Tree Analysis for a power plant's emergency shutdown system. The top event would be 'Emergency Shutdown System Failure.' For illustration, an OR gate beneath this top event might connect to two contributing events: 'Sensor Malfunction' and 'Circuit Failure.' If either event occurs, the top event is triggered. Delving further, these might be broken down through AND gates representing events that must happen concurrently to cause the sensor or circuit failure.

Steps Involved in Conducting a Fault Tree Analysis

Identify the Undesirable Event: The process of FTA starts by pinpointing the top event that the analysis seeks to prevent. This event is typically a system collapse or significant failure and sets the stage for the entire fault tree's structure. It is fundamental to have a clear, well-defined top event to ensure the analysis's precision and effectiveness.

Identifying Initiating Events: Once the top event is defined, the analysis moves on to distinguish the initiating events or basic failures that could lead to the top event. These initiating events are often component failures or human errors that, independently or in combination, can precipitate a chain reaction culminating in the top undesirable outcome.

Develop the Fault Tree: The crafting of the fault tree starts with the top event and works downwards, branching out into intermediate events through various logical gates. These gates reflect the conditional relationships between the contributing events and must be mapped with precision for the analysis to hold merit.

Quantitative Evaluation of Top Undesired Event: With the tree structurally complete, each pathway within the tree is assessed to determine the probability of the top event occurring. This quantitative process demands meticulous calculation, often supported by reliability data, to appraise the likelihood of individual components failing within each pathway.

Analyzing the Results: The final stage is the interpretation of these probabilities to gauge the sufficiency of the current safety measures and to identify the areas most in need of reinforcement. This comprehensive analysis enables designers and engineers to prioritize risk management activities effectively.

Illustrated With a Step-By-Step Practical Example: An exemplary FTA might analyze the failure of an aircraft's electrical system. The top event 'Complete Electrical Failure' is broken down into a series of component failures, such as 'Generator Failure' and 'Battery System Failure,' which are further decomposed until basic initiating events like 'Short Circuit' and 'Overheating' are identified. Each path is analyzed for probability, leading to a systemic understanding of the electrical system's vulnerabilities.

Understanding the Advantages and Limitations of Fault Tree Analysis

Presenting the Practical Benefits of Using Fault Tree Analysis: The advantages of employing Fault Tree Analysis are myriad. It offers a visual and systematic approach to understanding complex system failures that might be overlooked by less structured methods. The quantitative aspect of FTA allows for nuanced risk management, making it possible to prioritize safety measures based on statistical evidence. Additionally, FTA not only identifies singular failure points but also exposes potential failure interactions within the system, facilitating a more holistic approach to safety.

Discussing the Possible Limitations or Criticisms: However, FTA is not without its limitations. Its effectiveness is contingent upon the accuracy and completeness of the data used. In cases where statistical data is scarce or unreliable, the results of an FTA could be misleading. Additionally, the method can become unwieldy for extremely complex systems, encountering practical limits in terms of time and comprehensibility. It demands a high level of expertise and meticulous attention to detail, which can be resource-intensive.

Applications of Fault Tree Analysis in Various Industries

Demonstrating the Use of Fault Tree Analysis in the Health Sector: In healthcare, FTA serves as a powerful tool for predicting and preventing medical errors. It has been utilized to study system failures that could result in patient harm, contributing to improvements in patient safety protocols. For example, fault trees have been employed to better understand the causative chains leading to medication errors, thus aiding in the design of safer pharmaceutical delivery systems.

Exploring the Application in Safety and Risk Management: FTA is extensively used in the field of safety and risk management to forestall accidents and ensure the operational stability of workplaces, particularly those prone to high risks, such as chemical plants. The method's structured analysis provides invaluable insights into the interactions between various operational elements and their individual contributions to overall risk.

Case Study of Fault Tree Analysis in the Aviation Industry: The aviation sector provides an instructive case study on the efficacy of FTA. Following accidents or near misses, aviation authorities employ Fault Tree Analysis to dissect event sequences and systems to identify and mitigate potential failure points. These analyses contribute to the continuous enhancement of aircraft design and aviation protocols, maintaining an industry-wide commitment to safety improvements.

Comparison of Fault Tree Analysis with Other Risk Assessment Tools

Comparing With Event Tree Analysis: Fault Tree Analysis is often compared to Event Tree Analysis (ETA), another risk assessment technique. Whereas FTA focuses on tracing back from the top event to identify possible causes, ETA starts with an initiating event and examines possible outcomes. Each approach has distinct benefits and together they can provide a more encompassing risk assessment.

Comparing With Failure Modes and Effects Analysis (FMEA): Another tool commonly weighed against FTA is the Failure Modes and Effects Analysis (FMEA). FMEA is an inductive method for evaluating possible failures within a system to assess their impact on overall operation. While FMEA excels at exhaustively cataloging potential failure modes, FTA offers a more interactive exploration of the logical links between failures.

Conclusion

Recapitulation of the Key Points in the Blog

Fault Tree Analysis stands out as a rigorous, structured method to predict and prevent system failures, crucial for risk assessment and system reliability. The technique has a rich history, rooted in aerospace and defense, but its application has extended across diverse industries, demonstrating its broad utility and adaptability. Despite its complexities and the high-quality data it requires, the advantages of FTA—especially its systematic and probabilistic approach to understanding failure mechanisms—are indisputable.

A Brief Outlook on the Future of Fault Tree Analysis

The future of Fault Tree Analysis looks to be one of continued evolution, as it adapts to advancements in technology and increasing system complexity. Its integration into digital platforms and online certificate courses suggests a widening of its accessibility and application. As industries continue to prioritize risk management and safety, the relevance and application of Fault Tree Analysis will undoubtedly expand, reinforcing its status as an essential component of modern engineering and safety science.

Frequently Asked Questions

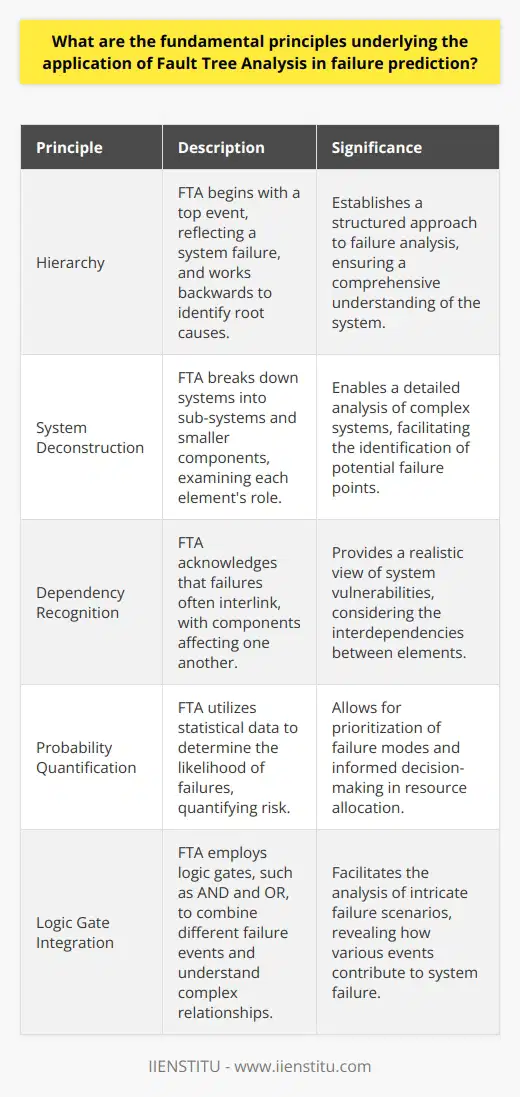

What are the fundamental principles underlying the application of Fault Tree Analysis in failure prediction?

Understanding Fault Tree Analysis

Fault tree analysis (FTA) is crucial in risk management. It focuses on identifying potential faults in a system. It combines logic and mathematics to predict failure.

Principles of FTA

Hierarchy is key. FTA starts with a top event. This event reflects a system failure. We work backwards from here.

Systems consist of sub-systems. FTA deconstructs these into smaller components. Understanding each element's role is essential.

Dependencies matter. We recognize that failures often interlink. Components can affect one another.

Probabilities quantify risk. FTA employs statistical data. This data informs the likelihood of failures.

Logic gates direct the analysis. These gates, like AND and OR, combine different failure events. They help us understand complex relationships.

Predictive Powers of FTA

FTA excels in forecasting unforeseen failures. It systematically explores each possible path to failure.

- Identifying each failure cements understanding

- Quantification allows for prioritization

- Prioritization aids in resource allocation

FTA transcends simple error-checking. It allows for a proactive approach to risk management. Through it, we foresee and mitigate potential system failures.

Consistency across industries is another strength. Whether aerospace or healthcare, FTA applies universally. It sees through the complexity inherent in different systems.

In conclusion, FTA operates on principles that corner systematic and probabilistic analysis. Its focus remains always on pinpointing where and how a system can fail. From these insights, we pave the way for more resilient designs and safer operations. It continues to be a robust tool in the arsenal of engineers and risk managers alike.

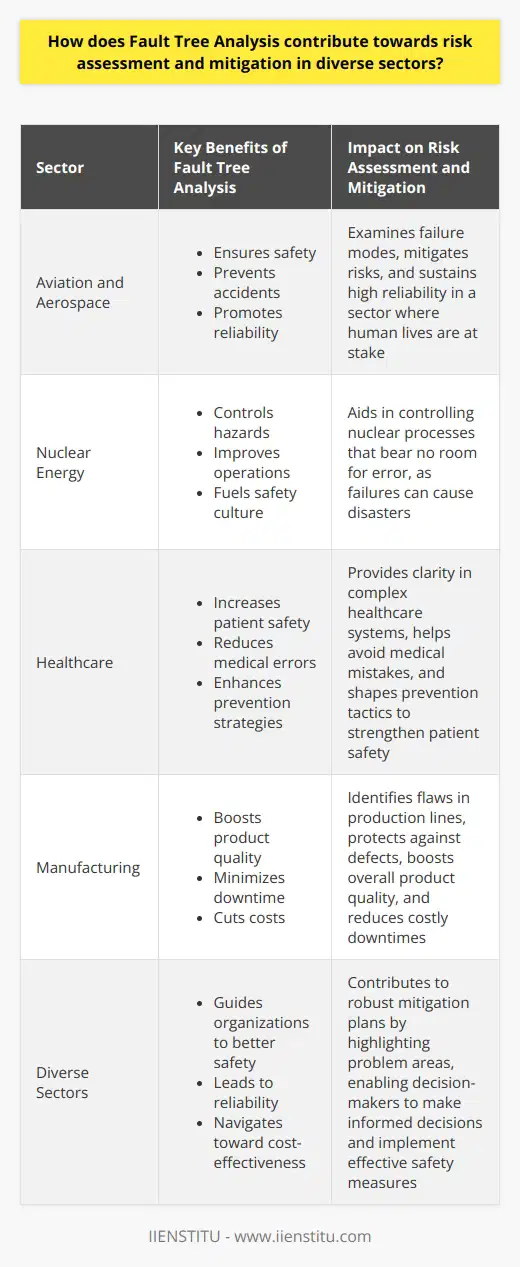

How does Fault Tree Analysis contribute towards risk assessment and mitigation in diverse sectors?

Understanding Fault Tree Analysis

Fault Tree Analysis (FTA) serves as a cornerstone. It shapes risk assessment in multiple sectors. Experts rely on it vastly. They see it as an essential tool. FTA breaks down complex processes. It does this into simpler, understandable parts. It identifies critical failures. These can lead to undesirable events.

FTA's Role in Risk Assessment

FTA aids in visualizing risk. It uses logic diagrams. These illustrate paths to failure. Analysts identify potential faults. They evaluate their impacts. FTA involves systematic thinking. It encourages problem-solving.

It starts with a top event. This event is often catastrophic. Analysts work backwards from there. They use "AND" and "OR" gates. These model relationships between faults. They guide the identification of root causes. Analysts use these insights. They pinpoint vulnerabilities within systems.

Benefits in Different Sectors

Aviation and Aerospace

- Ensures safety.

- Prevents accidents.

- Promotes reliability.

In aviation, FTA examines failure modes. This assessment impacts safety. FTA mitigates risks. It helps sustain high reliability. The sector demands this. Human lives often hang in the balance.

Nuclear Energy

- Controls hazards.

- Improves operations.

- Fuels safety culture.

Nuclear sectors thrive on it. They need stringent risk management. FTA aids in controlling nuclear processes. These processes bear no room for error. A failure can cause disasters.

Healthcare

- Increases patient safety.

- Reduces medical errors.

- Enhances prevention strategies.

Healthcare systems stay complex. FTA provides clarity. It helps avoid medical mistakes. This becomes crucial in saving lives. It shapes prevention tactics. These strengthen patient safety.

Manufacturing

- Boosts product quality.

- Minimizes downtime.

- Cuts costs.

Manufacturing industries gain from FTA. It identifies flaws in production lines. This identification protects against defects. It boosts overall product quality. It also reduces costly downtimes.

Enhancing Mitigation Strategies

FTA contributes to robust mitigation plans. It does so by highlighting problem areas. Decision-makers gain reliable information. They then make informed decisions. These include the implementation of safety measures. This may involve redundant systems. Or it could require additional checks.

Conclusion

Fault Tree Analysis transcends sectors. It plays a crucial role in risk management. It guides organizations to better safety. It leads them to reliability. It navigates them toward cost-effectiveness. FTA remains an invaluable method. Its structured approach simplifies complexity. It turns uncertainty into actionable insights. These insights then foster enhanced system integrity. Across diverse sectors, FTA stands firm. It stands as a bastion for risk assessment and mitigation.

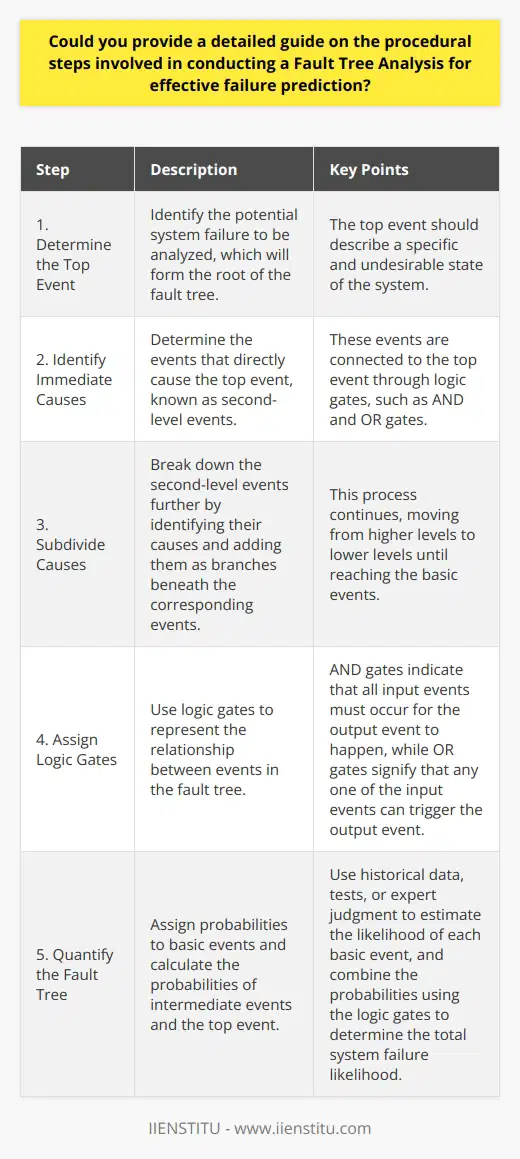

Could you provide a detailed guide on the procedural steps involved in conducting a Fault Tree Analysis for effective failure prediction?

Understanding Fault Tree Analysis

Fault Tree Analysis (FTA) stands as a key method in system reliability, safety, and risk assessment. It allows engineers and analysts to understand complex systems. These professionals use it to predict and mitigate failure modes. The process requires systematic and detailed work. FTA centers around constructing a fault tree. The tree helps visualize pathways to system failure.

Getting Started with FTA

First, define the system under study. Specify the undesired state, often a failure event. This event will form the root of the fault tree. Gather relevant system data and information. Identify components, their interactions, and possible failure modes. Expertise in the system's design and operation is crucial here.

Constructing a Fault Tree: Basic Steps

Step 1: Determine the Top Event

The top event represents the system's potential failure you're analyzing. It sits at the root of the fault tree. The top event should describe a specific and undesirable state.

Step 2: Identify Immediate Causes

Next, identify events that directly cause the top event. These are your second-level events. They connect to the top event through logic gates, typically AND and OR.

Step 3: Subdivide Causes

Break down these second-level events further. Identify their causes in turn. Add these as branches beneath the corresponding second-level events. The process continues, moving from higher levels to lower levels.

Step 4: Assign Logic Gates

Use logic gates to show the relation between events. An AND gate means all input events must occur for the output event to happen. An OR gate means any one of the input events can trigger the output event.

Step 5: Include Basic Events

Once you reach the lowest level, you add basic events. These are the fundamental failures or errors within the system. They need no further development in the tree.

Quantifying the Fault Tree

The fault tree gives a qualitative view of failure. For a quantitative analysis, follow these steps:

Step 6: Assign Probabilities to Basic Events

Research or estimate the likelihood of each basic event. Use historical data, tests, or expert judgment.

Step 7: Calculate Intermediate Event Probabilities

Combine basic event probabilities using the logic gates. Compute the probabilities of intermediate events working up the tree.

Step 8: Determine the Top Event Probability

Finally, calculate the top event probability. This gets you the total system failure likelihood. You can use this to assess the risk and identify critical areas.

Additional Considerations

Perform a Sensitivity Analysis. See how changes in basic event probabilities affect the top event.

Review Common Cause Failures. These occur when a single cause leads to multiple failures. Account for these in your analysis.

Update the Fault Tree Regularly. As systems evolve, so must the fault tree.

Keep It Iterative. The FTA process benefits from repetition. Teams often find areas for improvement.

Concluding Steps

Once complete, use the fault tree to inform decisions. It acts as a guide to improving system reliability and safety. Act on the identified critical areas. Develop risk mitigation strategies and increase system robustness. The fault tree becomes a living document that evolves with the system. Regular updates ensure its relevance and effectiveness in predicting failures.

Fault Tree Analysis serves as a strategic tool. Practitioners employ it to foresee and forestall potential system failures. The process demands meticulousness and expertise but pays off in heightened awareness and proactive management of risks.