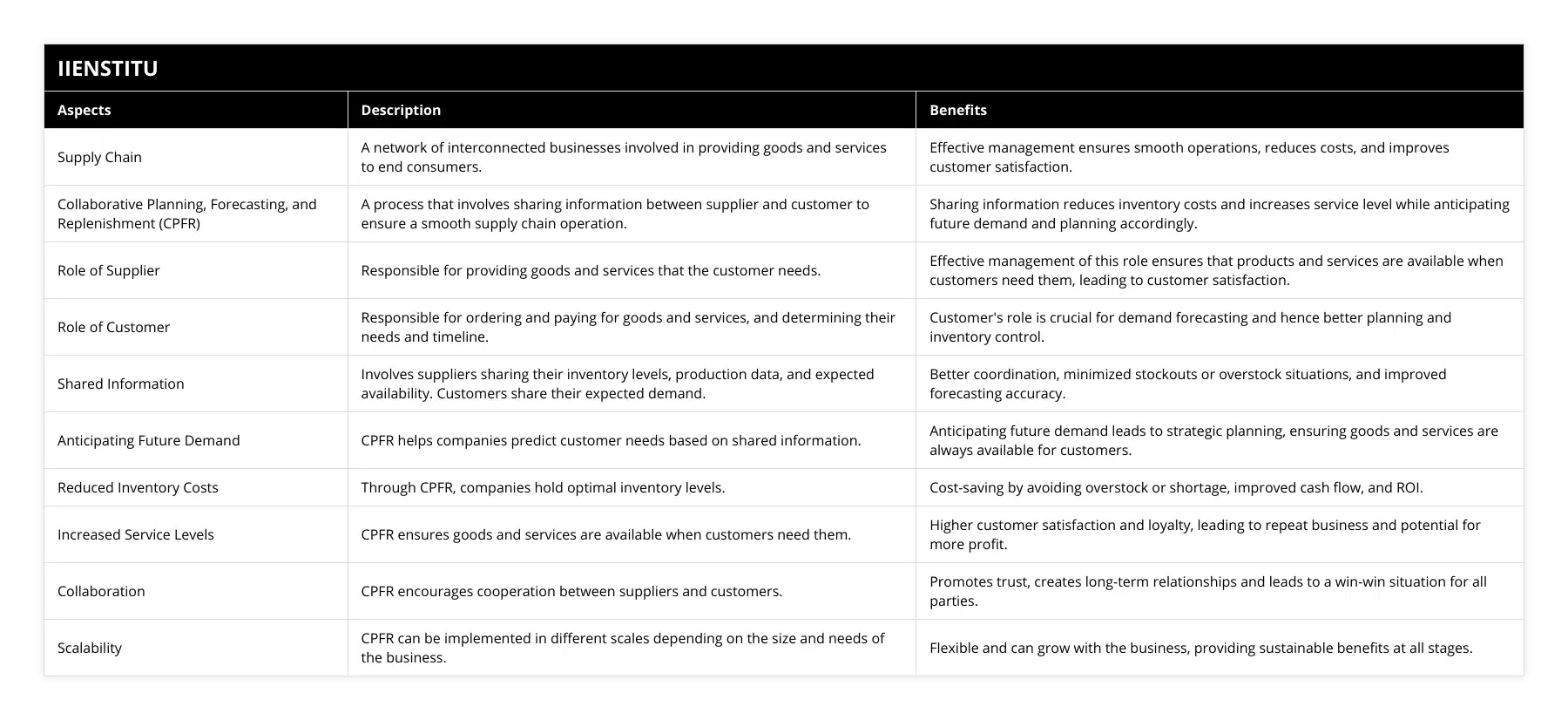

CPFR is a process used by companies in the supply chain to ensure that goods and services are available when customers need them. It involves the sharing of information between the supplier and the customer, such as inventory levels, production, and expected demand. This helps the supplier plan and prepare for the customer’s needs, reducing inventory costs and increasing service levels. CPFR also helps companies anticipate future demand and plan accordingly.

Introduction

Supplier vs. Customer

Benefits of Collaborative Planning

How CPFR Works

Conclusion

Introduction: The supply chain is a complex web of companies that work together to get goods and services to customers. Each company in the supply chain impacts the others, and if one company surprises another with a large order, it can cause problems and cost the supplier money.

Companies use collaborative planning, forecasting, and replenishment (CPFR) to ensure that everyone in the supply chain is working together. CPFR helps companies share information and work together to achieve high service levels with lower inventory quantities.

Supplier versus Customer

In the supply chain, the supplier is responsible for providing the goods and services the customer needs. The customer is responsible for ordering the goods and services and for paying for them. The customer also has the power to determine what type of goods and services they need and when they need them. The supplier, however, is responsible for ensuring that the goods and services are available when the customer needs them. This is where CPFR comes in.

Benefits of Collaborative Planning

CPFR helps companies in the supply chain work together to ensure that the customer gets the goods and services they need when needed. By sharing information and working together, companies can reduce inventory costs and increase service levels. CPFR also helps companies anticipate future demand and plan accordingly. This helps companies reduce their inventory costs and increase their service levels.

How CPFR Works

CPFR is a process that involves sharing information between the supplier and the customer. The supplier shares information about their inventory levels, what they are producing, and when they expect to have the goods and services ready. The customer shares their expected demand, what they need, and when they need it. This information helps the supplier plan and prepare for the customer’s needs.

The supplier and the customer then use this information to create a plan that meets the customer’s needs. They can use this plan to determine how much inventory the supplier needs to produce and when the customer needs the goods and services. This helps the supplier plan their production schedule and the customer plans their orders.

Conclusion

CPFR is a process that helps companies in the supply chain work together to ensure that the customer gets the goods and services they need when they need them. By sharing information and working together, companies can reduce inventory costs and increase service levels. CPFR is an effective tool for helping companies in the supply chain collaborate and achieve success.

Collaborative planning in supply chain management is the key to unlocking greater efficiency and success.

The article elucidates the concept and importance of Collaborative Planning, Forecasting, and Replenishment (CPFR) in supply chain management. It details how CPFR facilitates effective dialogue between suppliers and customers, enabling them to share critical information like inventory levels, production details, and expected demand. This collaborative approach ensures that goods and services are readily available for customers, thereby reducing inventory costs and enhancing service levels. The process of CPFR makes one an efficient master of supply chain management by empowering businesses to predict future demand accurately and plan their operations accordingly.

The text discusses the concept of Collaborative Planning, Forecasting, and Replenishment (CPFR), a strategy used by companies within a supply chain to ensure the availability of goods and services as per customer requirements. It necessitates the sharing of crucial data such as inventory levels, production details, and expected demand between the supplier and the customer to effectively plan for future needs and maintain high service levels. By implementing CPFR, corporations can anticipate future demand, plan more efficiently, and significantly reduce inventory expenses. This information would be beneficial to several professionals, and taking supply chain courses online could provide additional insight and understanding of the intricacies of CPFR and its effective implementation in real-world settings.

Frequently Asked Questions

What are the main benefits of collaborative planning in supply chain management?

Collaborative planning in supply chain management (SCM) is gaining recognition as an important tool for improving performance and efficiency. The use of collaborative planning in SCM enables companies to take advantage of the latest technology and data analytics to improve the flow of products and materials between different nodes in the supply chain. This article will discuss the main benefits of collaborative planning in SCM, including improved supply chain visibility, increased efficiency, and reduced costs.

One of the primary benefits of collaborative planning in SCM is improved supply chain visibility. Collaborative planning tools allow companies to gain visibility into the entire supply chain, including the flow of goods and materials, production processes, and customer demand. By gaining visibility into the entire supply chain, companies can make informed decisions about where to source materials and how to optimize production processes. This improved visibility can help companies respond quickly to changes in customer demand and better manage inventory levels.

Another benefit of collaborative planning in SCM is increased efficiency. By utilizing technology and data analytics, companies can reduce the need for manual intervention in supply chain operations and streamline processes. This leads to faster throughput times and improved customer service. Collaborative planning also enables companies to identify and address bottlenecks in the supply chain, leading to increased efficiency and improved performance.

Finally, collaborative planning in SCM can help reduce costs. By making use of the latest technology and data analytics, companies can reduce the need for manual intervention in supply chain operations, leading to cost savings. Additionally, collaborative planning can help companies identify and address inefficiencies in the supply chain, leading to further cost savings.

In conclusion, collaborative planning in SCM can provide numerous benefits to companies, including improved supply chain visibility, increased efficiency, and reduced costs. By utilizing the latest technology and data analytics, companies can gain a competitive advantage in the marketplace and improve their bottom line.

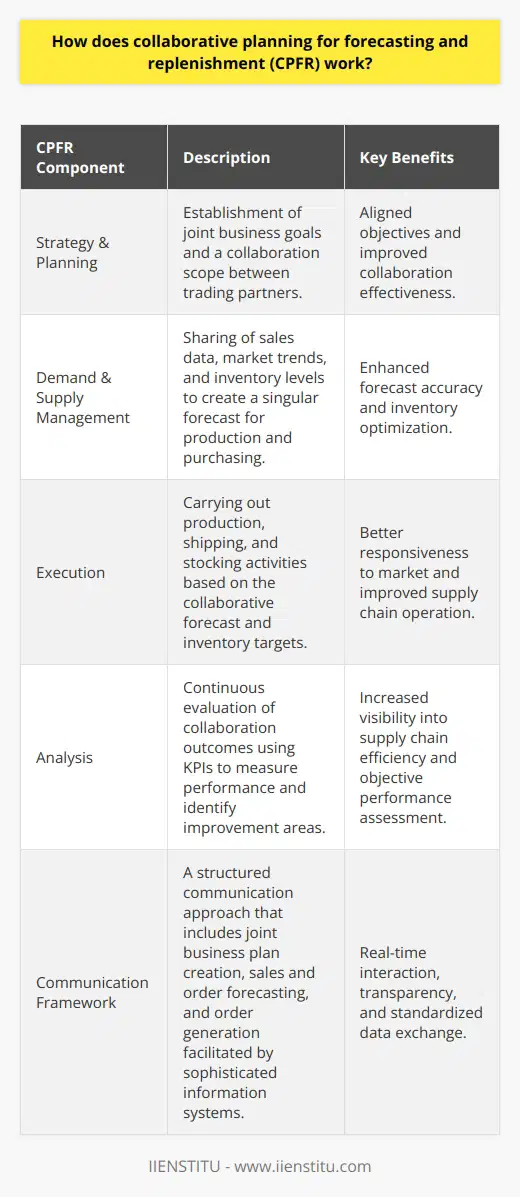

How does collaborative planning for forecasting and replenishment (CPFR) work?

Collaborative Planning for Forecasting and Replenishment (CPFR) is a supply chain management system that combines the use of technology and collaborative planning between trading partners to improve forecasting and replenishment processes. It is a proactive approach to inventory management that facilitates quicker response times and better customer service.

CPFR works by leveraging a combination of technology, collaboration, and process integration to create an information-sharing environment between trading partners. This allows them to gain real-time visibility into the entire supply chain, providing better insight into current and future customer demand. This enables accurate forecasting and replenishment of products, ensuring that customers receive the right product at the right time.

The CPFR process includes several steps. First, both trading partners must agree to collaborate and share information. Then, each partner must define the demand plans for their products and the forecasting criteria. Once the demand plans are established, the partners must agree on the replenishment criteria, such as the lead times and minimum order quantities.

Next, the partners must agree on the data format to be used for sharing information. This data format is usually an electronic data interchange (EDI) format or a web-based system. The data format must be agreed upon by both partners in order to facilitate the sharing of data.

Once the data format is established, the partners must agree on the data exchange frequency and the content of the exchange. This includes the data fields that will be included in the exchange, such as product codes, inventory levels, and customer orders. This will allow the partners to access the same set of data in order to accurately forecast customer demand and replenish inventory accordingly.

Finally, the partners must agree on the process for resolving any discrepancies in the data. This includes a process for resolving any discrepancies in the data that is shared between the trading partners. This process must be agreed upon by both partners in order to ensure that the data is accurate and up-to-date.

Collaborative Planning for Forecasting and Replenishment (CPFR) is a powerful supply chain management system that enables trading partners to gain real-time visibility into their supply chain. By leveraging technology and collaboration between partners, CPFR allows for more accurate forecasting and replenishment of products, which leads to improved customer service. The CPFR process includes several steps which must be agreed upon by both trading partners in order to facilitate the sharing of data and ensure accuracy.

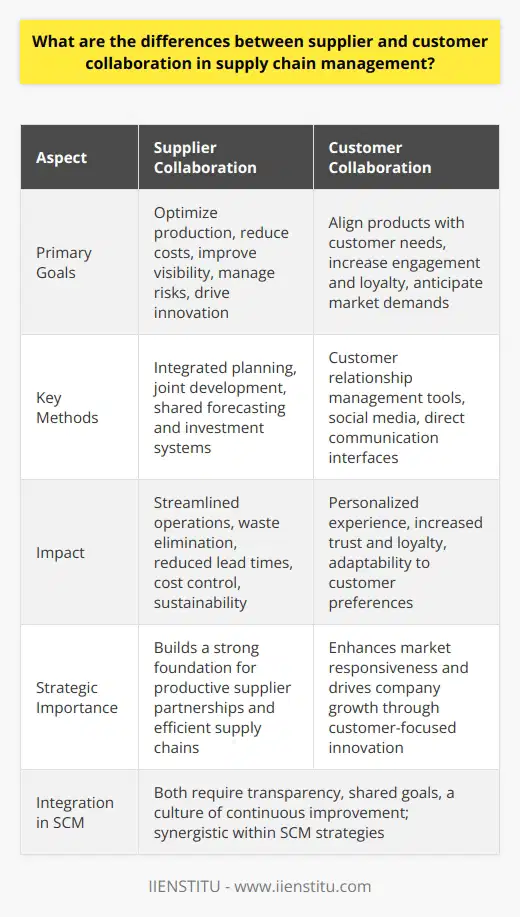

What are the differences between supplier and customer collaboration in supply chain management?

Supply chain management (SCM) is an important part of any successful business. It involves the coordination of resources across multiple parties, including suppliers, customers, and logistics providers. As such, supplier and customer collaboration plays a critical role in the successful management of supply chains. However, there are several key differences between supplier and customer collaboration that must be understood in order to effectively manage a supply chain.

Firstly, the goals of supplier and customer collaboration are distinct. Supplier collaboration typically focuses on developing long-term relationships between suppliers and customers. These relationships are designed to foster trust, communication, and mutual understanding, which can lead to improved quality and cost savings. On the other hand, customer collaboration is typically focused on meeting customers' specific needs. This can involve the customization of products and services, as well as the development of new products and services.

Secondly, the methods used to facilitate supplier and customer collaboration differ. Supplier collaboration usually involves the development of formal agreements and contracts between suppliers and customers. These documents outline the terms and conditions of the relationship and are typically reviewed and updated on a regular basis. On the other hand, customer collaboration often involves using online tools and platforms.

Through these tools, customers can provide feedback and request changes to products and services, which suppliers can then implement.

Thirdly, the impact of supplier and customer collaboration is distinct. Supplier collaboration can lead to improved quality, cost savings, and a stronger relationship between suppliers and customers. On the other hand, customer collaboration can help to ensure that products and services meet customer needs and expectations. This can lead to increased customer satisfaction and loyalty, as well as improved sales and profits.

In conclusion, supplier and customer collaboration are both important components of managing a successful supply chain. However, there are numerous differences between the two that must be taken into account. These include the goals of the collaboration, the methods used to facilitate it, and the potential impacts it can have. Understanding these differences is essential for the effective supply chain management.

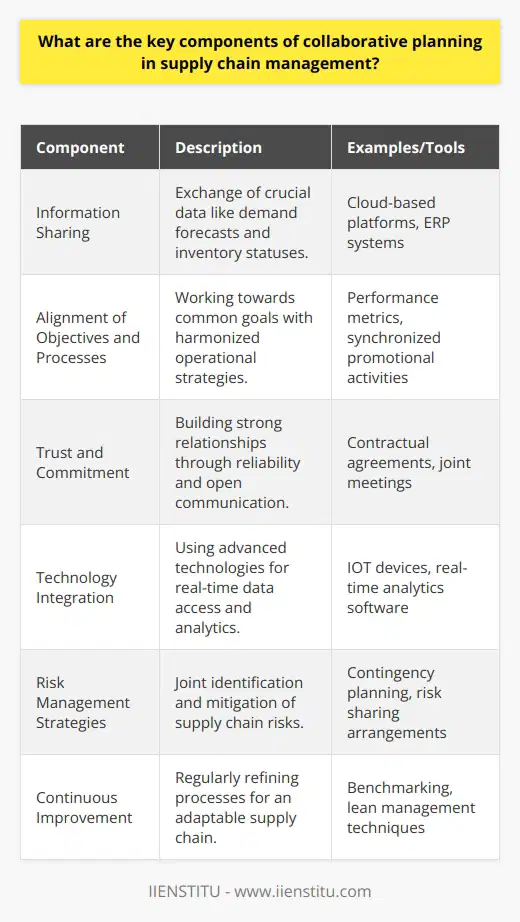

What are the key components of collaborative planning in supply chain management?

Collaborative Planning Components

One critical component of collaborative planning in supply chain management is information sharing. Companies should willingly exchange vital data such as sales forecasts, production schedules, and inventory levels with their supply chain partners. Transparent communication enables organizations to effectively plan, respond to changes, and mitigate risks that could disrupt the supply chain.

Another essential element is aligned processes and goals. Supply chain partners must develop mutually agreed-upon processes, objectives, and performance metrics to ensure smooth collaboration. This alignment enables the optimization of the entire supply chain and avoids conflicts or redundancies.

Trust and Commitment

Establishing trust and commitment between all supply chain participants forms a solid foundation for collaboration. Trust must be earned through consistent reliability, transparency, and mutual understanding. Commitment is demonstrated by investing in long-term relationships, sharing resources, and developing joint projects. These qualities create a trusting environment where partners work together towards collective success.

Technology Integration

Integrating advanced technology into collaborative planning is crucial for efficient data sharing and process automation. Implementing tools like enterprise resource planning (ERP) systems, transportation management systems (TMS), and cloud-based platforms facilitate information exchange and streamline decision-making. Advanced analytics can identify trends or potential issues, while the Internet of Things (IoT) devices enable real-time tracking, monitoring, and control of assets.

Risk Management Strategies

Collaborative risk management strategies are imperative to ensure supply chain resilience. Partners must identify and assess potential risks, including economic volatility, supply disruptions, and regulatory changes. Implementing proactive measures, such as contingency plans and backup suppliers, or using risk-sharing arrangements, can minimize the impact of unforeseen events on the supply chain.

Continuous Improvement

Lastly, continuous improvement should be an integral part of collaborative planning in supply chain management. By regularly assessing and refining processes, strategies, and technologies, supply chain partners can adapt to evolving market demands and stay ahead of the competition. Feedback loops, benchmarking, and collaborative problem-solving initiatives drive these improvements by identifying areas for enhancement and fostering innovation.

In conclusion, collaborative planning in supply chain management encompasses information sharing, aligned processes and goals, trust and commitment, technology integration, risk management, and continuous improvement. By adopting these key components, companies can maximize the efficiency and resilience of their supply chains, ultimately driving greater profitability and customer satisfaction.

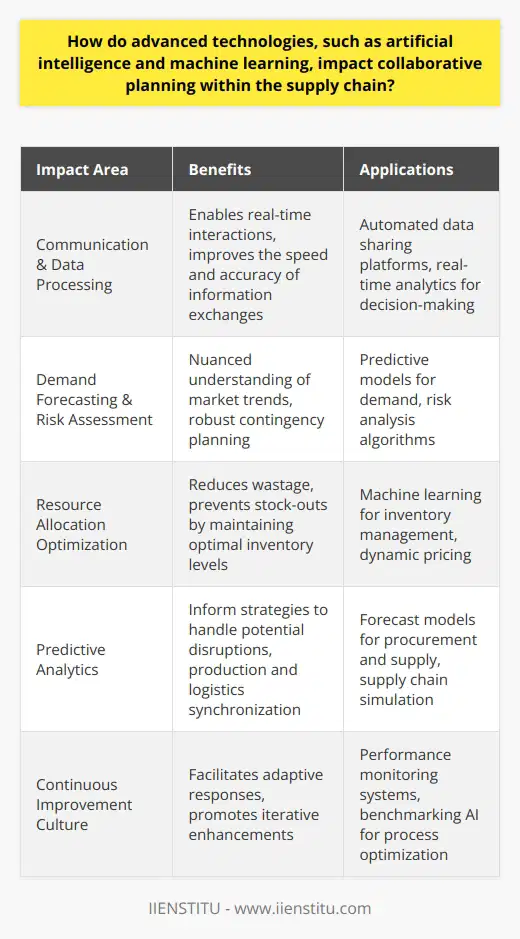

How do advanced technologies, such as artificial intelligence and machine learning, impact collaborative planning within the supply chain?

Significance of Advanced Technologies

Advanced technologies, particularly artificial intelligence (AI) and machine learning (ML), are creating new opportunities for enhancing collaborative planning within the supply chain. These sophisticated tools facilitate seamless information flows, improve decision-making processes, and increase operational efficiency. By incorporating AI and ML, organizations can optimize and transform their traditional supply chain management approaches.

Elevating Communication and Data Management

One key impact of AI and ML is their ability to facilitate better communication and data management within the supply chain. The implementation of these technologies enables real-time information sharing between stakeholders, minimizing errors and discrepancies. Consequently, advanced analytics capabilities allow accurate demand forecasting and proactive risk mitigation. This streamlined system fosters improved collaboration across the entire network, leading to more strategic decision-making.

Optimizing Resource Allocation

Another significant advantage of utilizing AI and ML within supply chain management is the optimization of resources. As companies deal with growing complexities, leveraging intelligent tools can help balance supply and demand efficiently. For instance, AI and ML algorithms can identify patterns and trends in data, predicting future scenarios and optimizing inventory levels. This forward-looking approach can lead to reduced costs, minimized risks, and enhanced system-wide productivity.

Leveraging Predictive Analytics

Predictive analytics is a crucial component of AI and ML applications within the supply chain. By processing vast amounts of data and generating actionable insights, these technologies enable more informed decision-making. For example, predictive models can anticipate demand fluctuations, supplier disruptions, and various external factors that may impact operations. As a result, organizations can collaborate effectively to formulate contingency plans and ensure supply chain resilience.

Emphasizing Continuous Improvement

Lastly, the integration of AI and ML within the supply chain promotes a culture of continuous improvement. These technologies can identify inefficiencies, performance gaps, and opportunities for enhancement. By analyzing historical data and providing real-time feedback, organizations can adjust their strategies and dynamically adapt to the ever-evolving market conditions. With AI and ML, supply chain stakeholders can collaborate to drive innovation, revenue growth, and long-term success.

In conclusion, advanced technologies such as AI and ML not only enable improved collaboration within the supply chain but also foster innovation, efficiency, and resilience. By leveraging these tools, organizations can optimize their planning processes, manage resources effectively, and achieve sustainable growth in an increasingly competitive market landscape.

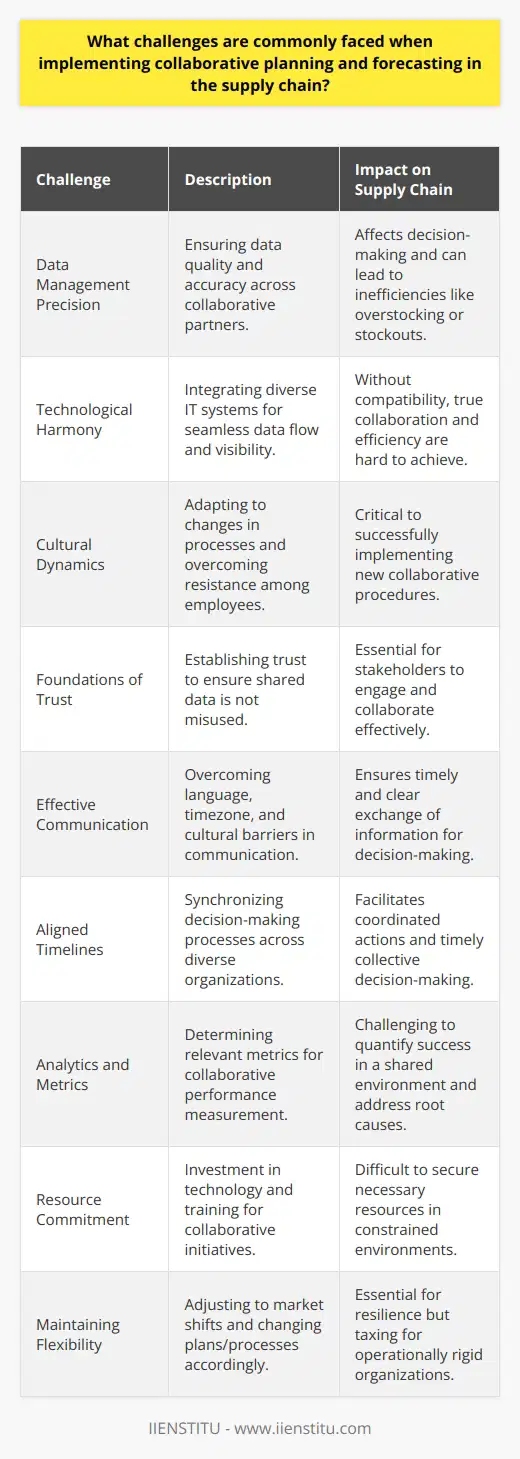

What challenges are commonly faced when implementing collaborative planning and forecasting in the supply chain?

Challenges in Collaborative Planning

Data Quality and Accuracy:

One major challenge in implementing collaborative planning and forecasting is ensuring data quality and accuracy. Inaccurate or outdated information can lead to poor forecasting, resulting in inventory imbalances, missed sales opportunities, and added costs.

Integration of Systems:

Another significant challenge is integrating disparate systems and processes across multiple organizations. Various systems may use different formats, leading to a lack of compatibility and seamless data exchange.

Resistance to Change:

Implementing collaborative planning often requires overcoming resistance to change from employees within the organization. Employees may be hesitant to abandon familiar processes or reluctant to share information, hindering the adoption of new systems and methodologies.

Establishing Trust:

A key ingredient for successful collaboration is trust between different stakeholders within the supply chain. Developing trust can be difficult, as sharing sensitive information carries a risk of competitors exploiting it for their advantage.

Communication Barriers:

Effective communication is crucial for collaborative planning and forecasting. However, language barriers, time zone differences, and cultural differences can hamper communication and impede the implementation process.

Synchronization of Timelines:

Synchronizing timelines for decision-making and implementation across different organizations is another challenge in collaborative planning. Aligning stakeholders' priorities, goals, and schedules must occur for successful collaboration.

Performance Measurement and Analytics:

Identifying and measuring relevant performance indicators for collaborative planning can be difficult, as they may differ from traditional supply chain metrics. Additionally, determining which adjustments resulted in improvements may require further analysis.

Resource Allocation:

Allocating the necessary resources for implementing collaborative planning and forecasting can be difficult due to competing priorities and budget constraints. The skills required for successful implementation may be scarce, and the investment required may be significant.

Agility and Adaptability:

While collaboration can lead to improved performance and reduced risks, it also requires organizations to adapt to change rapidly. Constantly reassessing and adapting to new information and changing circumstances is essential, but can be challenging to execute effectively.

In conclusion, implementing collaborative planning and forecasting within the supply chain is a complex process fraught with challenges. Overcoming these obstacles is critical to achieving the full potential of collaborative efforts in improving supply chain performance, reducing costs, and increasing competitiveness.

What are the critical factors for successful implementation of collaborative planning and forecasting in supply chain management?

Critical Factors in Collaborative Planning and Forecasting

Effective Communication

One critical factor for successful implementation of collaborative planning and forecasting in supply chain management is effective communication. Achieving a consistent flow of accurate and relevant information between all participants enables better decision-making and enhances overall coordination.

Alignment of Objectives

The alignment of objectives among various supply chain partners is also essential. Clearly defined shared goals help synchronize actions, avoid unforeseen conflicts, and promote an environment of mutual trust and understanding that fosters collaboration.

Data Quality and Sharing

The quality of data used in planning and forecasting processes greatly affects the decision-making process. Providing all members of the supply chain with access to reliable and accurate data improves transparency and expedites decision-making.

Advanced Forecasting Techniques

Applying advanced forecasting techniques, such as statistical methods, machine learning, and artificial intelligence (AI) tools, helps achieve more accurate and timely predictions. These advanced techniques reduce uncertainties and enable more efficient resource allocation.

Internal Integration

Collaborative planning and forecasting necessitates robust internal integration within each participating organization. Ensuring that all departments and functional units are aligned and fully informed supports timely execution of plans and reduces disruption in the supply chain.

Trust and Commitment

Mutual trust and commitment among supply chain partners pave the way for successful collaboration. Trust accelerates communication, encourages sharing of valuable information, and promotes a cooperative mindset that mitigates the risk of opportunistic behavior from partners.

Performance Measurement and Monitoring

Constant monitoring of existing processes and performance measurement fosters continuous improvement. Establishing key performance indicators (KPIs) that reflect the goals of collaborative planning and forecasting helps track progress and ensure that the supply chain remains adaptable and responsive to changes in the overall environment.

In conclusion, the critical factors for successful implementation of collaborative planning and forecasting in supply chain management include effective communication, alignment of objectives, data quality and sharing, advanced forecasting techniques, internal integration, trust and commitment, and performance measurement and monitoring. By addressing these factors, organizations can promote efficient and effective collaboration that drives value in the supply chain.

How does collaborative planning and coordination enhance the overall performance and efficiency of a supply chain?

Collaboration and Coordination

When organizations within a supply chain commit to collaboration and coordination, they establish a communal environment that benefits all parties involved. Collaboration refers to the sharing of information, resources, and risk between supply chain partners, while coordination involves aligning activities and processes to create a seamless flow of goods and services from suppliers to customers.

Improved Information Sharing

Effective communication is the backbone of any successful supply chain. Collaborative planning allows for better information sharing between partners, facilitating real-time decision-making and decreasing the risk of errors or delays. Transparency among supply chain members enhances the availability of accurate data, enabling organizations to make informed choices regarding inventory levels, order quantities, and delivery schedules.

Resource Optimization

Collaborative planning addresses resource constraints in the supply chain by allocating them efficiently. Supply chain partners can align their production schedules, transportation capacity, and warehousing resources to avoid redundancies and minimize costs. By working together, companies can identify opportunities for sharing resources, such as consolidating transportation or utilizing warehouse space more efficiently. This, in turn, leads to an overall improvement in the utilization of resources, reducing costs, and increasing profitability for all involved partners.

Risk Mitigation

Proactive risk management is essential for maintaining a responsive and resilient supply chain. Through collaborative planning and coordination, partners can identify potential risks and develop contingency plans to address these issues effectively. By jointly assessing the likelihood and impact of disruptions, supply chain partners can prioritize resources, reduce potential damages, and ensure a quicker recovery.

Enhanced Customer Satisfaction

The effectiveness of a supply chain directly impacts the satisfaction of end customers. Collaborative planning and coordination lead to timely deliveries, accurate order fulfillment, and reduced lead times, which are crucial for meeting customers' expectations. By streamlining the flow of goods and services, companies can better respond to variations in demand, ensuring that products are available when and where customers need them.

In conclusion, collaboration and coordination play a vital role in enhancing the performance and efficiency of supply chains. By working together, organizations can share information, optimize resources, mitigate risks, and deliver greater value to their customers. As a result, supply chain partners can achieve increased profitability and a sustainable competitive advantage in the marketplace.

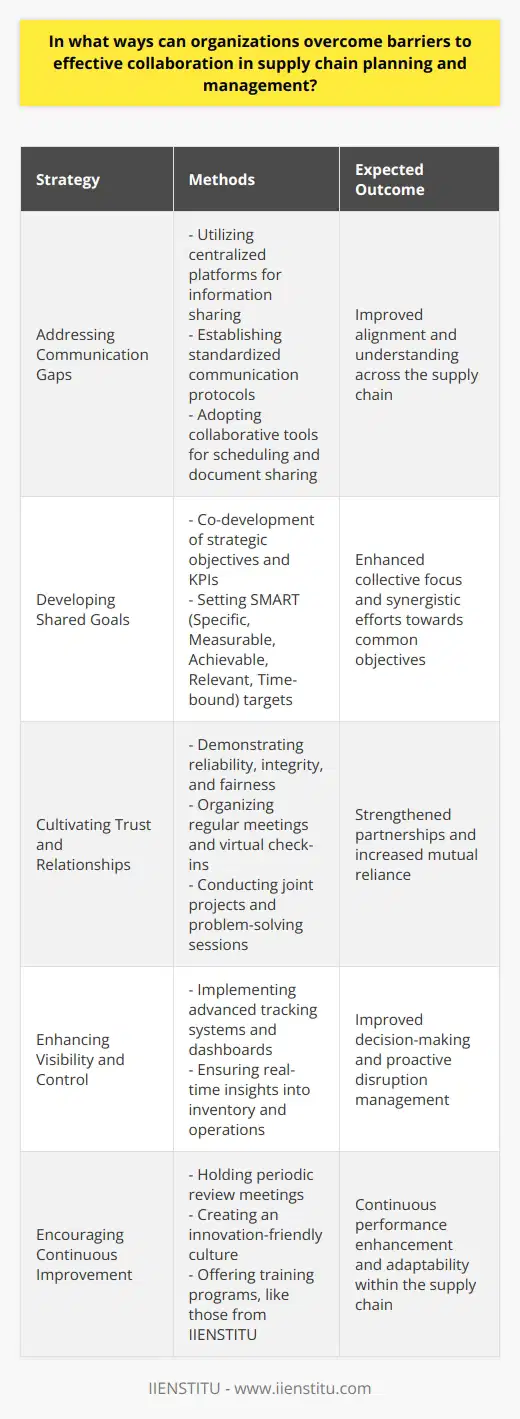

In what ways can organizations overcome barriers to effective collaboration in supply chain planning and management?

Addressing Communication Gaps

Organizations can overcome barriers to effective collaboration in supply chain planning and management by investing in communication tools and strategies that promote transparency and information sharing. Adopting advanced technology platforms, like cloud-based systems or data analytics tools, can enable organizations to track real-time information and streamline the flow of data among partners.

Developing Shared Goals

Another way to overcome collaboration barriers is by establishing shared goals and performance metrics for supply chain partners. By aligning objectives and KPIs, organizations can ensure that everyone is working towards the same targets, fostering a collaborative environment. This alignment also supports effective decision-making and performance management throughout the supply chain.

Cultivating Trust and Relationships

Building trust among supply chain partners is a critical aspect of overcoming collaboration barriers. Companies can advance trust by promoting regular interactions through meetings and workshops, enabling open dialogue, and resolving disputes or conflicts in a timely manner. This commitment to building relationships fosters a sense of reliability and interdependence among collaborators.

Enhancing Visibility and Control

Organizations can improve their collaborative efforts by enhancing visibility and control across the entire supply chain. This can be achieved by implementing technologies and practices, such as real-time monitoring, that offer deeper insights into the supply chain’s dynamics. Increased visibility enables proactive decision-making and reinforces transparency among partners, ultimately fostering more effective collaboration.

Encouraging Continuous Improvement

Finally, organizations can strive for continuous improvement in supply chain planning and management by embracing a culture of learning and innovation. Encourage partners to share their knowledge and best practices, and support professional development opportunities to enhance expertise within the supply chain. As partners develop new skills and knowledge, they can identify innovative solutions to overcome barriers and improve overall collaborative efforts.

In conclusion, addressing communication gaps, developing shared goals, cultivating trust and relationships, enhancing visibility and control, and encouraging continuous improvement are all essential factors for organizations aiming to overcome barriers to effective collaboration in supply chain planning and management. Each of these strategies contributes to creating a more unified and efficient supply chain partnership.

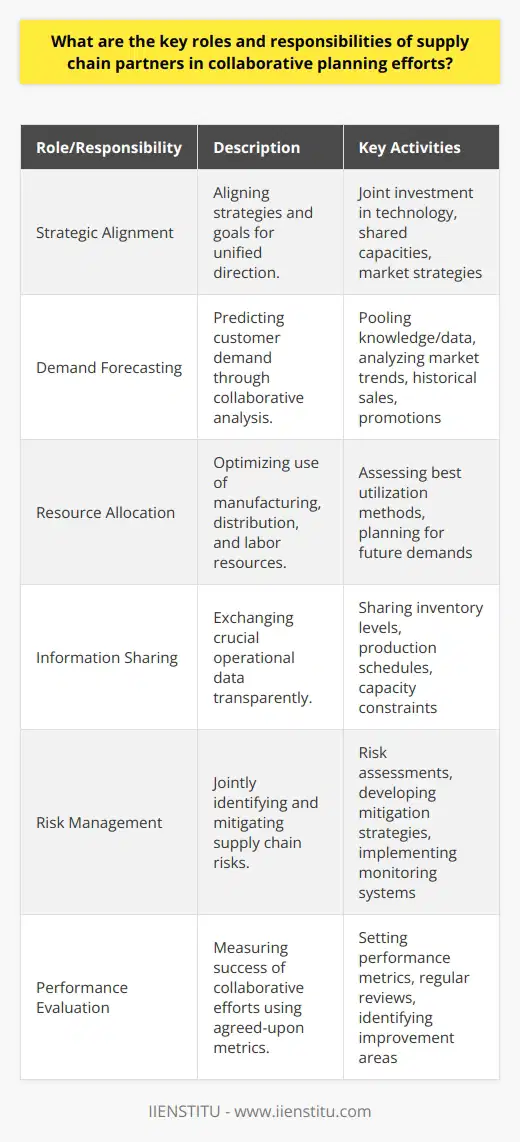

What are the key roles and responsibilities of supply chain partners in collaborative planning efforts?

Key Roles of Supply Chain Partners in Collaborative Planning Efforts

Strategic Alignment

The primary role of supply chain partners in collaborative planning efforts is to align their strategic objectives and priorities. This involves setting common goals, sharing information, and coordinating decision-making processes to improve overall supply chain performance.

Demand Forecasting

Accurate demand forecasting is central to collaborative planning efforts. Supply chain partners work together to forecast consumer demand and plan their production accordingly. This enables partners to minimize stockouts and overstock situations, leading to reduced costs and improved customer satisfaction.

Resource Allocation

Effective resource allocation is another vital responsibility of supply chain partners. They must collaborate to allocate their resources optimally, such as labor, production capacities, transportation, and inventory levels, to achieve a more flexible and responsive supply chain.

Information Sharing

Transparent and timely information sharing is crucial in collaborative planning efforts. Supply chain partners are responsible for sharing relevant data, such as demand forecasts, production schedules, inventory levels, and product specifications. This enables partners to make informed decisions and create synergy across the supply chain.

Risk Management

Collaborative planning efforts require supply chain partners to jointly identify and manage risks. This involves assessing potential disruptions, developing contingency plans, and creating a risk management framework that is shared among all partners. Risk management helps to enhance the resilience and agility of the supply chain.

Performance Evaluation

Finally, supply chain partners must establish performance evaluation systems to monitor and measure the effectiveness of their collaborative planning efforts. This involves setting clear performance indicators, collecting data, and assessing the outcomes of collaborative actions. Performance evaluation allows partners to identify areas for improvement and continuously refine their collaborative strategies.

In conclusion, the key roles and responsibilities of supply chain partners in collaborative planning efforts include strategic alignment, demand forecasting, resource allocation, information sharing, risk management, and performance evaluation. By effectively fulfilling these roles, partners can enhance supply chain performance, reduce costs, and improve customer satisfaction.

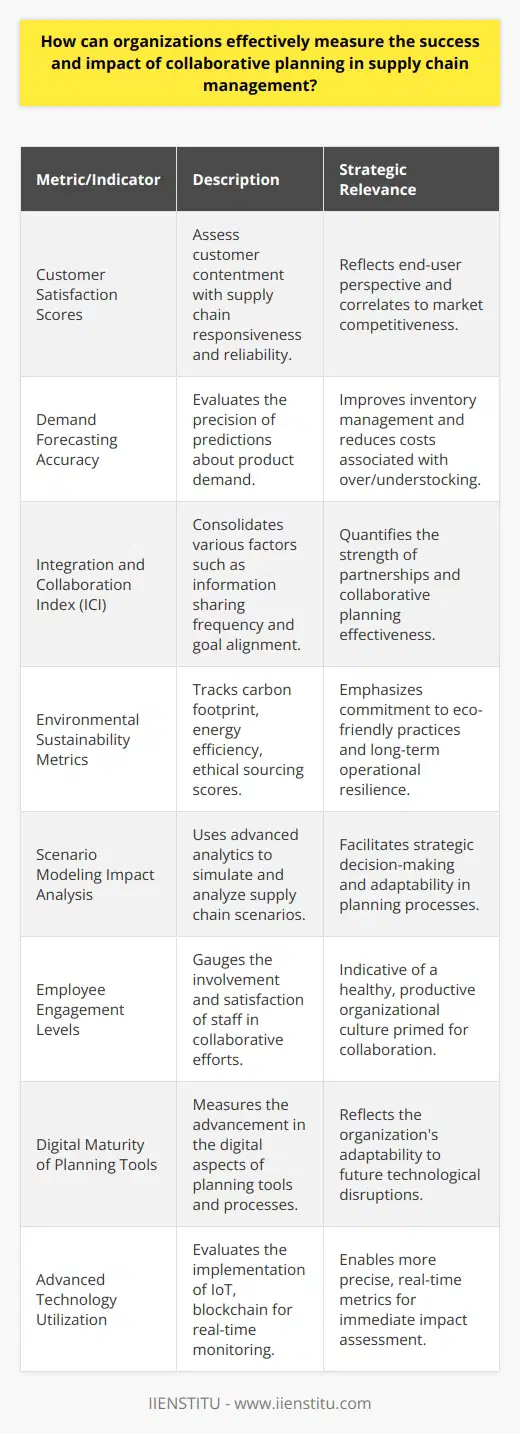

How can organizations effectively measure the success and impact of collaborative planning in supply chain management?

**Defining Success Metrics**

Organizations can effectively measure the success and impact of collaborative planning in supply chain management by defining clear and quantifiable success metrics. These metrics should focus on assessing various aspects of the supply chain, such as efficiency, responsiveness, and cost-effectiveness. By associating meaningful performance indicators with these aspects, organizations can objectively evaluate the outcomes of their collaborative planning efforts.

**Evaluating Efficiency**

Efficiency is a crucial aspect of effective supply chain management. Measuring efficiency involves assessing the utilization of resources, lead times, and throughput rates. Organizations can use metrics such as inventory turnover, order accuracy, and on-time delivery rates to evaluate the effectiveness of their collaborative planning. These metrics can provide valuable insights into how well the organization is managing its resources and if its planning efforts contribute to a more streamlined supply chain.

**Assessing Responsiveness**

Responsiveness in supply chain management is the ability to quickly adapt to changes in market demands and customer preferences. Organizations can effectively measure responsiveness by monitoring order management cycle times, order fulfillment rates, and the agility of the overall supply chain. By tracking these metrics, organizations can determine if their collaborative planning efforts are leading to improved responsiveness and more agile supply chain processes.

**Examining Cost-Effectiveness**

An organization's ability to achieve cost-effective supply chain operations can be determined by examining the overall costs and identifying areas for improvement. Metrics such as total supply chain costs, unit costs, and procurement costs can provide an accurate reflection of an organization's cost-effectiveness. By analyzing these metrics, organizations can assess the impact of their collaborative planning on cost reduction and operational efficiency.

**Benchmarking and Continuous Improvement**

Benchmarking plays a vital role in measuring the success and impact of collaborative planning on supply chain management. Comparing the organization's performance against industry standards and best practices can provide a comprehensive understanding of its relative performance. Additionally, constant monitoring of identified success metrics can equip organizations with the necessary information to refine their collaborative planning efforts continuously.

Overall, organizations can effectively measure the success and impact of collaborative planning in supply chain management by focusing on clearly defined success metrics, evaluating efficiency, assessing responsiveness, examining cost-effectiveness, and embracing benchmarking and continuous improvement. By employing these strategies, organizations can ensure that their collaborative planning efforts lead to tangible benefits in supply chain operations.

In what ways does adopting a collaborative planning approach contribute to risk mitigation and improved resilience within the supply chain?

Collaborative Planning Benefits

Adopting a collaborative planning approach contributes to risk mitigation and improved resilience within the supply chain in several ways. Firstly, it fosters better communication between supply chain partners, enabling them to share valuable information, enhance trust, and streamline decision-making processes. By enhancing these aspects, stakeholders can react more swiftly and appropriately to disruptions that may arise, reducing overall risk.

Alignment of Goals and Expectations

Secondly, collaborative planning allows supply chain partners to align their goals and expectations, promoting a unified vision and approach to risk management. By working together, organizations can identify potential vulnerabilities and develop effective strategies to manage risks. This shared understanding ensures full participation from all parties, mitigating the likelihood of miscommunications, misaligned actions, and the amplification of risks.

Increased Flexibility and Adaptability

Moreover, collaboration contributes to increased flexibility and adaptability within the supply chain. By working closely with other stakeholders, companies can coordinate their actions, adjust their operations, and respond more effectively to changing conditions. This adaptability reduces the potential impact of supply chain disruptions and increases overall resilience.

Resource Optimization and Cost Reduction

Collaborative planning also helps organizations optimize resources and reduce costs, further enhancing supply chain resilience. Sharing information enables companies to effectively monitor the utilization of assets, facilities, and transportation networks, avoiding any unnecessary expenditures. Additionally, cost reductions can be achieved by identifying and exploiting synergies between partners, allowing them to collaboratively improve efficiency and reduce operational vulnerabilities.

Continuous Learning and Improvement

Lastly, a collaborative planning approach promotes accelerated learning and continuous improvement within the supply chain. Cooperation among different entities encourages the sharing of best practices, innovative ideas, and effective risk management strategies. By learning from each other's experiences and leveraging their collective expertise, supply chain partners can develop a comprehensive risk mitigation plan capable of addressing current and future challenges.

In conclusion, adopting a collaborative planning approach within the supply chain can substantially contribute to risk mitigation and improved resilience. The benefits of such an approach include enhanced communication, alignment of goals, increased flexibility, resource optimization, and continuous learning. In today's increasingly interconnected global economy, supply chain collaboration is not only a competitive advantage but also a necessity for companies looking to mitigate risks and ensure long-term success.

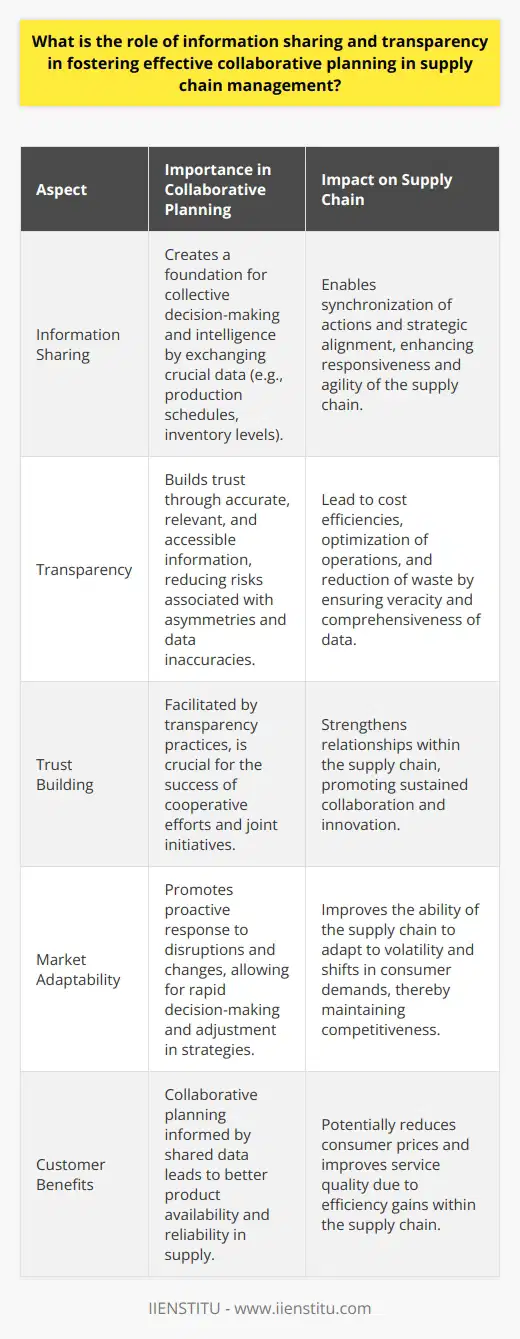

What is the role of information sharing and transparency in fostering effective collaborative planning in supply chain management?

Role of Information Sharing

Information sharing plays a crucial role in enhancing collaborative planning in supply chain management (SCM) by enabling organizations to exchange data, insights, and strategies. Through sharing information between partners, SCM can enhance decision making, align objectives, and synchronize processes. A critical element of effective communication, information sharing allows stakeholders to integrate their separate efforts into a cohesive plan for managing the supply chain.

Promoting Transparency

Supply chain transparency is essential to establish trust and foster a collaborative environment between organizations. By sharing necessary information and being open about processes, partners can gain an understanding of each other's objectives, strengths, and weaknesses. Transparency allows stakeholders to identify inefficiencies, monitor progress, and address potential issues proactively. It also encourages accountability, ensuring that all parties are aligned with the overall supply chain strategy.

Effective Collaborative Planning

Collaborative planning enables organizations to jointly develop and execute supply chain processes, improving overall efficiency and effectiveness. Information sharing and transparency support collaborative planning by providing stakeholders with access to relevant data and insights, which can be utilized to optimize processes, manage resources, and minimize risks. A collaborative approach to planning enhances overall supply chain performance by embracing shared objectives, creating economies of scale, and taking advantage of partner expertise.

Impact on Supply Chain Success

Effective information sharing and transparency enable organizations to align their goals and strategies, ensuring that supply chain plans are designed to achieve maximum success. Highly collaborative planning leads to improved resource management, reduced costs, and increased customer satisfaction. In turn, organizations that engage in information sharing and maintain transparency create a more resilient and competitive supply chain. A strong commitment to collaboration enhances overall supply chain efficiency and contributes to long-term success.

Conclusion

In conclusion, information sharing and transparency are crucial in fostering collaborative planning in supply chain management. These elements help to establish trust and accountability, promoting a united effort to optimize processes and drive performance. By encouraging an enhanced understanding of partner objectives and strategies, information sharing and transparency support the alignment of goals, coordination of efforts, and effective decision-making. Ultimately, these practices contribute to building a resilient and competitive supply chain, which significantly impacts an organization's success.

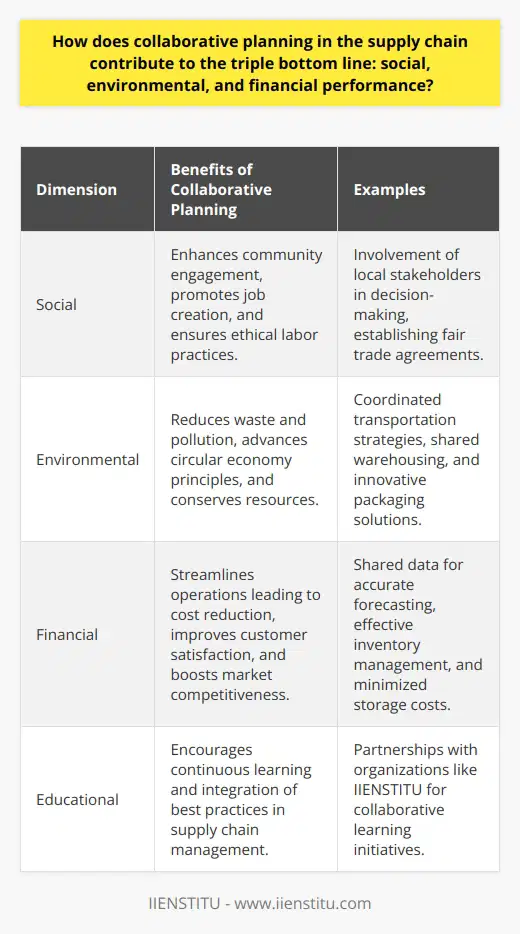

How does collaborative planning in the supply chain contribute to the triple bottom line: social, environmental, and financial performance?

Collaborative Planning: A Path to Triple Bottom Line Performance

Social Benefits

Collaborative planning in the supply chain fosters strong relationships among various stakeholders, generating social capital and promoting cross-functional transparency. By involving all parties in decision-making processes, it ensures equitable distribution of resources and fair treatment, ultimately enhancing trust and social harmony.

Environmental Performance

From a green perspective, collaborative planning aids in minimizing waste and optimizing resource utilization within the supply chain. Companies can collectively develop innovative strategies to optimize logistics, reduce emissions, and promote the use of environmentally friendly materials. This joint commitment to sustainability helps combat pressing global issues, such as climate change and resource scarcity.

Financial Outcomes

Lastly, collaborative planning offers significant financial benefits to supply chain partners. Information sharing and synchronized decision-making enable businesses to identify cost-saving opportunities, streamline processes, and exploit synergies. By effectively managing inventory levels and reducing lead times, organizations can meet customer demands more efficiently, thus bolstering the overall profitability and competitiveness of the supply chain.

In conclusion, the implementation of collaborative planning in the supply chain ensures a positive impact on the triple bottom line. The integration of social, environmental, and financial objectives fosters a culture of shared responsibility, ultimately leading to mutual success and sustainable growth for organizations involved.

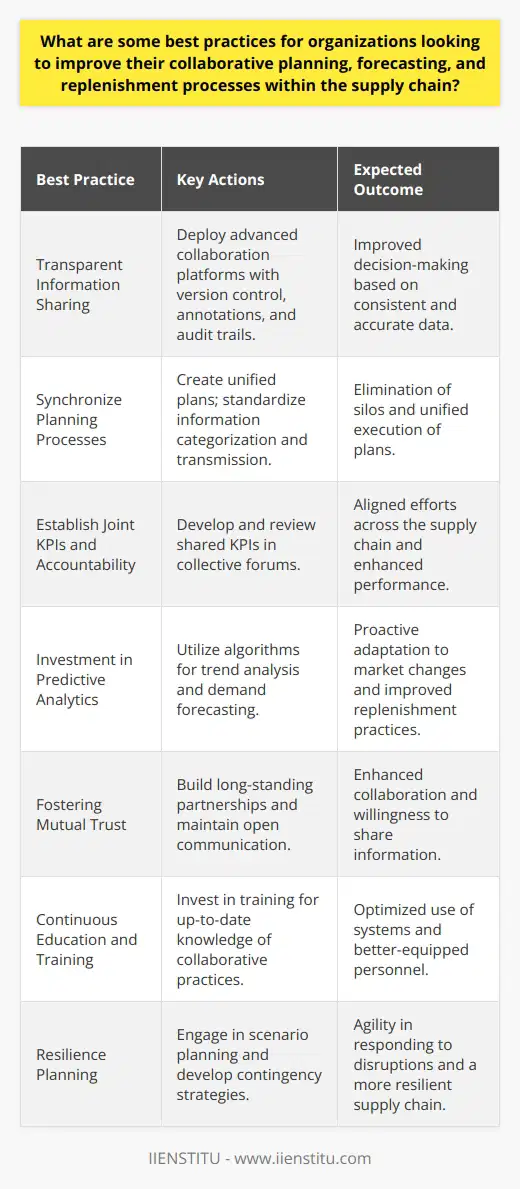

What are some best practices for organizations looking to improve their collaborative planning, forecasting, and replenishment processes within the supply chain?

Supply Chain Collaboration Practices

Organizations seeking to enhance their collaborative planning, forecasting, and replenishment (CPFR) processes within the supply chain should adopt several key best practices. These practices, including information sharing, process alignment, and accountability measures, contribute to more efficient and effective supply chain management.

Effective Information Sharing

One foundational practice for improving CPFR processes is establishing a system for effective information sharing among partners. This system ensures that all participants have access to accurate and timely data, which in turn supports better decision making. Organizations should consider adopting digital tools and platforms, such as cloud-based software and Electronic Data Interchange (EDI) systems, to facilitate seamless data exchanges and increase overall visibility throughout the supply chain.

Alignment of Processes and Objectives

To streamline collaboration efforts, organizations must align their processes and objectives in a transparent manner. This can be achieved through clearly defined goals, KPIs, and performance metrics that are mutually agreed upon by all participating entities. In addition, organizations should ensure regular communication and coordination, enabling them to respond to changes and disruptions more effectively.

Accountability and Performance Monitoring

Ensuring accountability and performance monitoring is crucial in fostering effective collaboration within the supply chain. To achieve this, organizations should implement joint scorecards and benchmarking metrics that evaluate the performance of each partner. These shared metrics will help identify areas of improvement while promoting a culture of continuous learning and improvement among all parties involved.

Investing in Technology and Analytics

Leveraging advanced technology and analytics tools is essential for optimizing CPFR processes. By investing in data-driven solutions that incorporate machine learning, artificial intelligence, and predictive analytics, organizations can gain valuable insights and better anticipate future demand patterns. Furthermore, utilizing these tools can facilitate early detection of potential bottlenecks and enable more agile, data-informed decision-making.

Developing Trust and Partnership

Finally, building trust and a sense of partnership among all supply chain participants is vital in ensuring fruitful collaboration. Organizations should prioritize long-term relationships and foster a culture of open communication, reciprocity, and mutual learning. This will result in a positive atmosphere in which all parties work together towards achieving shared objectives and improving supply chain performance.

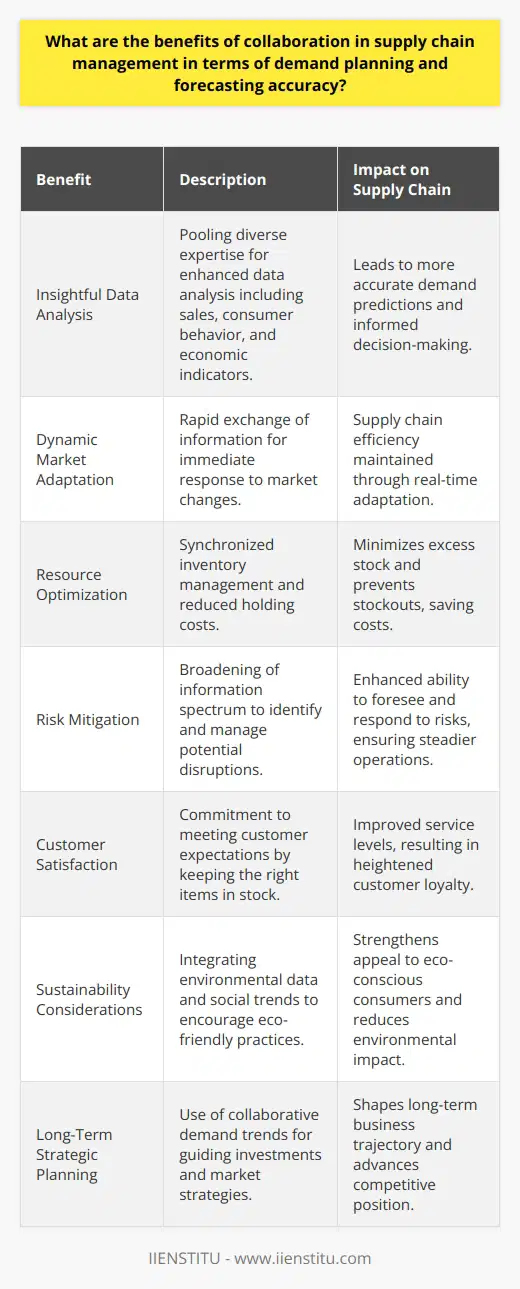

What are the benefits of collaboration in supply chain management in terms of demand planning and forecasting accuracy?

Benefits of Collaboration in Demand Planning

One significant benefit of collaboration in supply chain management is the enhanced accuracy in demand planning and forecasting. By fostering effective communication and information sharing among various entities involved in the supply chain, businesses can better anticipate customer demand and make more informed decisions.

Increased Information Sharing

Sharing detailed information about sales, customer preferences, and market trends across the supply chain allows companies to stay ahead of the competition. Accurate and timely information enables organizations to adjust their inventory and production levels in response to fluctuations in demand.

Better Decision Making

Collaboration in supply chain management enables businesses to integrate a variety of data sources from different partners, leading to more accurate and actionable demand forecasts. This results in smarter business decisions that optimize inventory levels, align production with demand, and minimize lead times.

Reduced Lead Times

Sharing data on demand enables companies to coordinate production schedules more effectively, reducing lead times for key products. Shorter lead times mean that businesses can respond more quickly to market changes, ensuring that they can fulfill customer needs in a timely manner.

Improved Forecast Accuracy

Working together in the supply chain allows for improved communication and collaboration. This leads to better visibility into future demand, which in turn helps to identify patterns, anticipate changes, and develop more accurate forecasts. As a result, businesses can optimize resource allocation and avoid costly over- or under-stocking.

Enhanced Responsiveness

The ability to rapidly respond to changes in demand is a key differentiator in today's competitive landscape. With increased collaboration, organizations can rapidly align their supply chain operations with shifts in demand, making it easier to meet customer expectations.

In conclusion, collaboration in supply chain management is crucial for achieving superior demand planning and forecasting accuracy. By working together and sharing information, businesses can make more informed decisions, optimize resource allocation, and improve their responsiveness to market changes. This not only enhances overall business performance, but also confers an essential competitive advantage.

How can collaborative planning, forecasting, and replenishment (CPFR) help in reducing inventory levels and costs in supply chain operations?

Benefits of CPFR in Supply Chain Operations

Collaborative planning, forecasting, and replenishment (CPFR) is an effective method to enhance supply chain operations. Implementing CPFR aids in reducing inventory levels and costs by fostering communication among all stakeholders.

Improved Forecast Accuracy

CPFR implementation enhances the accuracy of demand forecasting. By sharing information among partners, companies can create more accurate demand forecasts. This approach not only eliminates guesswork but also reduces the risk of stockouts or excess stock.

Reduced Lead Times

Adopting CPFR reduces lead times by coordinating production, distribution, and demand planning. Faster response to demand fluctuations ensures a steady flow of products, reducing the need for high inventory levels.

Better Resource Utilization

Supply chain partners can optimize resource utilization by sharing production schedules and manufacturing capacities. Optimized production processes minimize wasted resources and increase cost savings.

Smarter Inventory Decisions

Collaboration enables supply chain partners to make informed inventory decisions. Knowledge of production timelines, demand forecasts, and shipping schedules leads to smarter stockpiling strategies. Consequently, businesses can cut costs and minimize stock obsolescence.

Enhanced Visibility

CPFR provides clear visibility of the entire supply chain. Real-time information sharing boosts transparency, allowing partners to address issues quickly. Fast issue resolution lowers the likelihood of inventory buildup and reduced costs.

In conclusion, the adoption of CPFR in supply chain operations significantly contributes to the reduction of inventory levels and costs. By increasing visibility, promoting better forecasting accuracy, reducing lead times, optimizing resource utilization, and encouraging smarter inventory decisions, CPFR helps businesses maintain a lean and cost-effective supply chain.

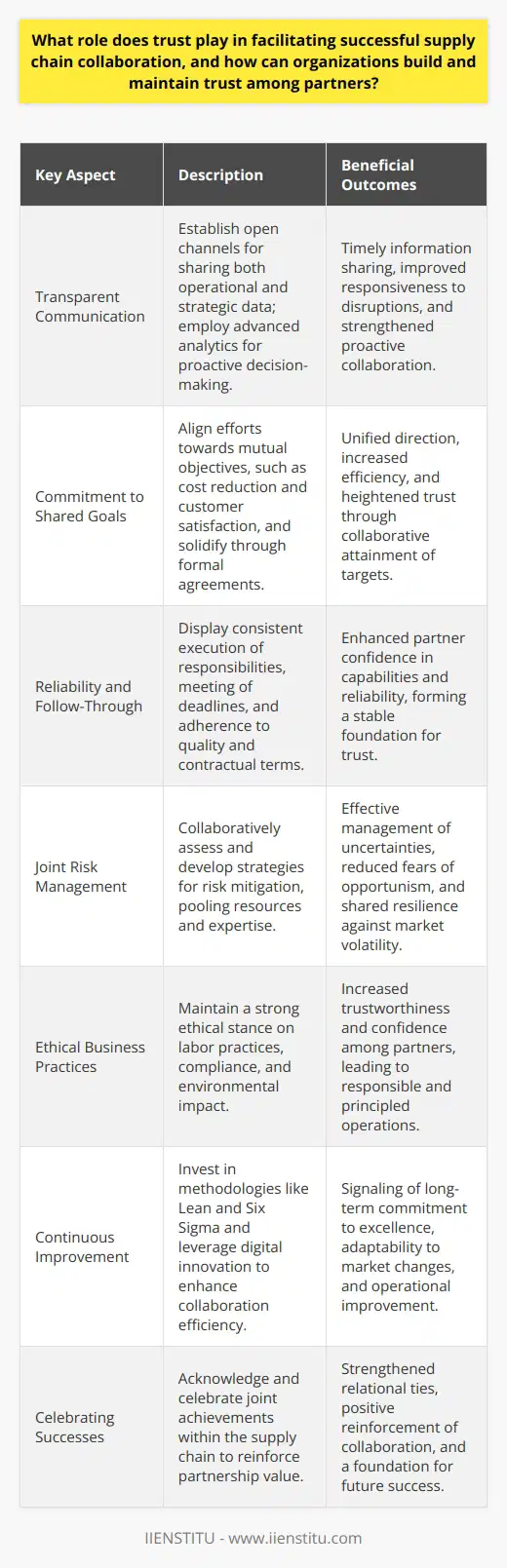

What role does trust play in facilitating successful supply chain collaboration, and how can organizations build and maintain trust among partners?

The Significance of Trust in Supply Chain Collaboration

Trust plays an integral role in facilitating successful supply chain collaboration, enabling partners to share critical information, align goals, and address potential challenges. By fostering a sense of security and shared responsibility among stakeholders, trust enhances the efficiency and effectiveness of supply chain processes. For organizations to build and maintain trust, there are certain strategies they can employ.

Establishing Transparent Communication

Transparent communication serves as the foundation for trust in supply chain collaboration. Organizations must encourage open dialogues and readily share relevant information with their partners. This includes providing updates on inventory, production, lead times, and market trends. By openly exchanging information, partners can develop coordinated strategies for addressing shifts in demand, managing costs, and optimizing resources.

Cultivating Strong Relationships

Building strong relationships with supply chain partners requires a mutual understanding of each party's objectives, coupled with a genuine commitment to collaborative success. Organizations should invest time in cultivating interpersonal relationships through regular meetings, events, and team-building exercises. Encouraging personal connections among supply chain partners fosters a sense of shared purpose and accountability.

Implementing Robust Monitoring Mechanisms

To instill trust in the collaborative process, organizations must implement robust monitoring mechanisms for tracking performance indicators and identifying potential bottlenecks. Through proactive analysis and timely interventions, companies can maintain consistent quality, delivery, and compliance within their supply chain. By fostering a culture of continuous improvement, partners will feel confident in the sustainability and effectiveness of their collaboration.

Addressing Conflicts Constructively

Conflicts can arise in any complex collaboration, making it imperative for organizations to devise strategies for navigating and resolving disputes. Supply chain partners can establish formal conflict resolution processes to ensure fair, unbiased, and constructive outcomes. When conflicts are addressed proactively and transparently, it strengthens trust among partners and bolsters the long-term success of the collaboration.

In conclusion, trust is essential in forging successful supply chain collaboration, mitigating risks, and optimizing performance. Organizations should prioritize building and maintaining trust by establishing transparent communication, cultivating strong relationships, implementing robust monitoring mechanisms, and addressing conflicts constructively. By embracing these strategies, companies can achieve sustainable supply chain partnerships with enhanced efficiency, resilience, and competitiveness.

What are the key success factors in establishing effective collaborative planning, forecasting, and replenishment (CPFR) initiatives in supply chain management?

Clear Communication

The success of collaborative planning, forecasting, and replenishment (CPFR) initiatives in supply chain management largely hinges on clear communication. Accurate information sharing among all parties contributes to seamless operations.

Technological Infrastructure

Robust technological infrastructure is another key factor. In this digital age, leveraging technology to streamline operations, simplify data analysis, and enhance information sharing is vital. Advanced software solutions can automate processes and save time.

Trust and Collaboration

Trust and collaboration form the core of successful CPFR initiatives. The businesses involved must work together towards a common goal, sharing vital information openly. The parties should focus on achieving mutual benefits to create harmonious work relationships.

Strategy and Planning

Developing an efficient strategy and diligent planning also play a pivotal role. Organizations should devise a strategic approach that encompasses fact-based forecasting and demand planning. Regular monitoring and adjustments help in achieving the desired output.

Resource allocation

Proper resource allocation is also critical. Organizations must ensure they have adequate finances, manpower, and time to execute their CPFR initiatives successfully. An imbalance in resource distribution can hinder the progress.

Continuous Learning

Lastly, the ability to learn from past mistakes and improve processes continuously is a crucial success factor. The most successful organizations are those that assess their CPFR initiatives constantly, proactively addressing any shortfalls.

In conclusion, clear communication, robust technological infrastructure, trust and collaboration, efficient strategy and planning, proper resource allocation, and continuous learning are key to the success of CPFR initiatives in supply chain management.

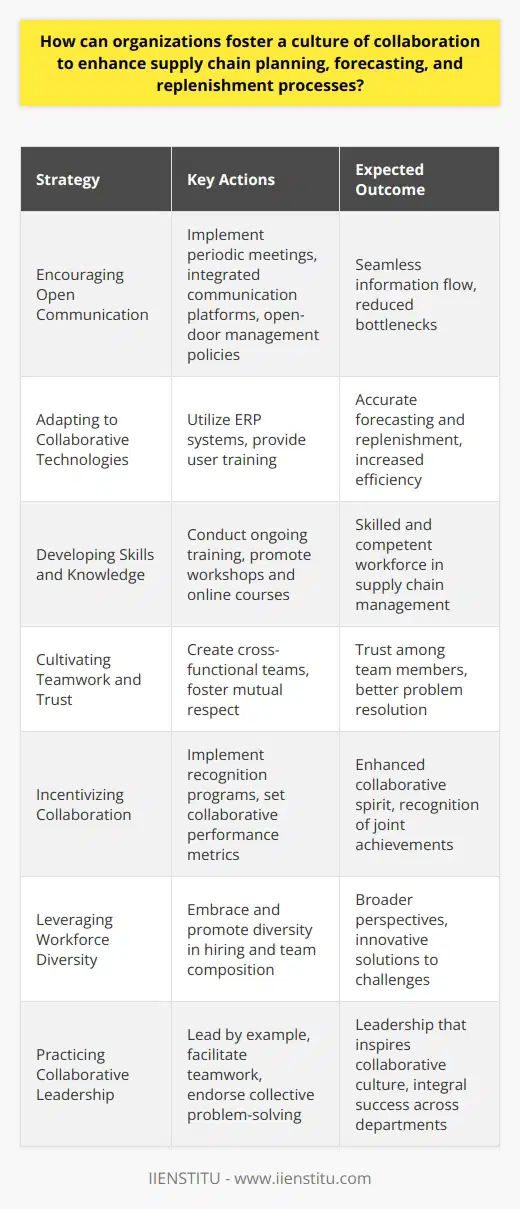

How can organizations foster a culture of collaboration to enhance supply chain planning, forecasting, and replenishment processes?

Creating a Collaborative Culture

Organizations can foster a culture of collaboration in several ways. Encouraging communication across teams is crucial. Cross-functional communication reduces misunderstandings and increases efficiencies, enhancing supply chain planning, forecasting, and replenishment processes.

Implementing Collaborative Technologies

The use of collaborative technologies like Enterprise Resource Planning (ERP) systems and cloud platforms can facilitate real-time sharing of information and resources. These technologies unify different business processes, making planning and forecasting more streamlined and accurate.

Training and Skill Development

Investing in employee training is another important step. Providing staff with adequate skills and knowledge fosters cooperation and openness, which leads to more effective cross-departmental collaboration.

Promoting Teamwork

Promoting teamwork through team-building activities and collaborative projects creates an atmosphere of trust, openness, and mutual respect. These factors enhance cooperation among employees, leading to better decision-making in supply chain processes.

Rewarding Collaborative Efforts

Moreover, offering rewards for collaborative efforts can motivate employees to work more collaboratively. Recognition of well-performing teams can inspire others to align their efforts with the organization's objectives.

Workforce Diversity

A diverse workforce may also foster a culture of collaboration. Different perspectives lead to innovative solutions, improving supply chain planning, forecasting, and replenishment processes.

Employing Collaborative Leadership

Lastly, collaborative leadership plays an essential role. Leaders must promote and model collaborative behavior themselves. By demonstrating the value collaboration brings, leaders can significantly influence their employees' attitudes and actions, cultivating a collaborative organizational culture.

In conclusion, fostering a culture of collaboration can significantly enhance supply chain planning, forecasting, and replenishment processes. This can be achieved through promoting communication, employing collaborative technologies and leadership, investing in training and skills development, rewarding collaborative efforts and workforce diversity.

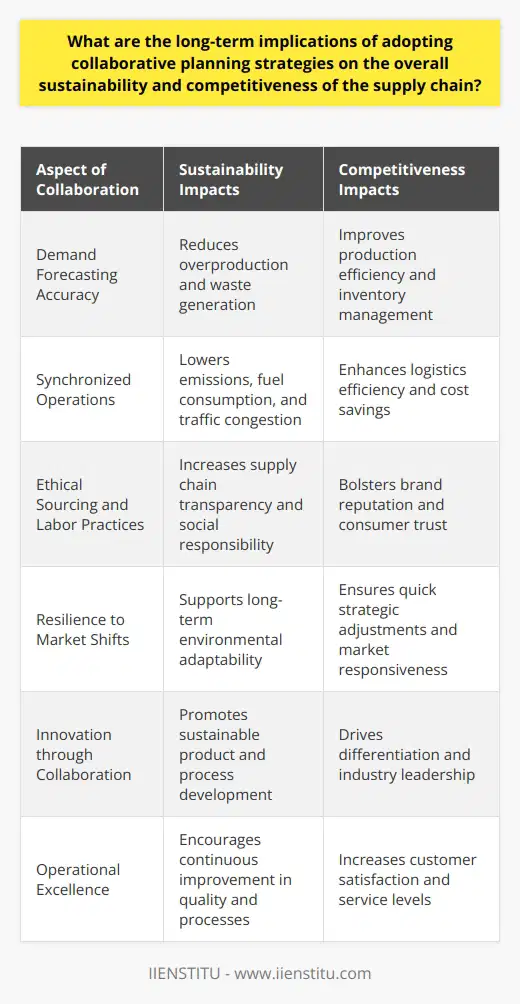

What are the long-term implications of adopting collaborative planning strategies on the overall sustainability and competitiveness of the supply chain?

Enhanced Supply Chain Sustainability

Adopting collaborative planning strategies has profound long-term implications on the sustainability of a supply chain. Collaborative planning calls for sharing and synchronizing information between suppliers, manufacturers, and customers. This strategy significantly reduces the uncertainties in demand forecasting, leading to improved resource efficiency.

Reduction in Waste and Costs

Collaborative planning strategies also result in reduced overproduction, a dominant source of waste in the supply chain, thereby supporting environmental sustainability. Additionally, it minimizes storage, handling and transportation costs due to better demand-supply coordination. This not only saves resources but also optimizes inventory cost, improving the economic aspect of sustainability.

Increased Supply Chain Competitiveness

On the competitiveness front, collaborative planning strategies can enhance the agility, adaptability, and alignment among the supply chain entities. These three ‘A’s are considered strategic for any competitive supply chain. An agile supply chain can respond swiftly to sudden demands, an adaptable one can adjust with changing scenarios, and an aligned supply chain ensures coherence in goals at all levels.

Building Strong Relationships

Moreover, this collaboration fosters stronger relationships, leading to improved reliability and robustness of the supply chain. Supply chains that can offer reliability and robustness are more likely to thrive in competitive markets. Furthermore, the transparency that comes with collaborative planning can boost trust among stakeholders and improve the brand image of the firms involved.

In summary, adopting collaborative planning strategies promises significant gains in the long-term. It not only enhances the overall sustainability of the supply chain by reducing waste and optimizing resource utilization, but it also elevates its competitiveness through improved agility, adaptability, alignment and reliability.