In an increasingly interconnected global economy, the ability to adeptly manage and predict consumer demand is becoming critical for businesses across a myriad of industries. Demand variability stands as a significant factor that can profoundly affect multiple facets of supply chain operations. Understanding its causes, impacts, and management strategies is pivotal to maintaining competitive advantages and achieving operational efficiency.

Demand variability pertains to the fluctuation and uncertainty in customer demand for products or services. Its recognition as a fundamental concept is crucial for companies seeking to optimize their supply chains and ensure a smooth flow of goods to the market. The complex dynamics of modern-day commercial exchanges make mastering the subtleties of demand variability a requisite skill for supply chain professionals, thus highlighting the importance of logistics certification courses and online courses as valuable educational tools.

In the ensuing text, we delve into the nuances of demand variability. We explore its causes, the impact it has on supply chain management, and the strategies and real-world case studies that elucidate how businesses can adapt and thrive amidst such unpredictability.

The Causes of Demand Variability

Unpredictable Consumer Behavior

Consumer patterns can be akin to shifting sands, influenced by a mélange of factors that render them volatile and sometimes inscrutable. The sway of trends and fads, frequently driven by social media and celebrity endorsements, has the power to drastically alter consumer behavior overnight. The lifecycle of these trends is becoming shorter, posing significant challenges to forecast accurately. An understanding of these societal currents is paramount for companies to navigate the waters of consumer demand.

Moreover, economic conditions act as a barometer for consumer spending. In times of financial prosperity, discretionary spending swells, and with it, the demand for certain categories of goods rises. Conversely, economic downturns can lead to a retraction in consumer spending, resulting in diminished demand. This oscillation requires fine-tuned strategies to anticipate and respond to economic shifts, thereby maintaining supply chain resilience.

Seasonal Demand Changes

The cadence of the seasons often dictates the rhythm of consumer demand. For many industries, such as fashion retail or agriculture, demand peaks in accordance with seasonal cycles, necessitating careful planning and inventory control. Supply chains must be attuned to these natural fluctuations and manage resources to align production and distribution schedules with anticipated spikes or drops in demand.

Logistics Mgmt: Optimizing Customer Service During Order Postponement

Optimizing Logistics Mgmt: Production & Distribution Decisions

Optimizing Inventory Control: An Examination of Safety Stock

Product Lifecycle Stages

Every product progresses through a lifecycle — introduction, growth, maturity, and decline — each with its own distinctive demand pattern. Newly launched products might experience a steep uptake as consumer curiosity and marketing efforts combine. As the product matures, demand plateaus before dwindling in the decline phase. This lifecycle necessitates constant vigilance and adaptation from supply chain managers to align operations with each stage's particular demand curve.

Marketing and Promotional Activities

Finally, the influence of marketing efforts and promotional activities on demand cannot be understated. Sales events, advertising campaigns, and product launches serve as catalysts for short-term demand spikes. The timing and intensity of such initiatives must be harmonized with supply chain capabilities to avoid mismatches between demand and inventory levels.

Impact of Demand Variability on Supply Chain Management

The Bullwhip Effect

A concept widely studied and oft-cited in supply chain discourse is the Bullwhip Effect. This phenomenon describes how slight fluctuations in consumer demand can become magnified along the supply chain, leading to substantial variations in orders placed with suppliers. This distortion can wreak havoc on supply chain efficiency, causing overproduction, stockouts, and an increase in holding and shortage costs.

The consequences of the Bullwhip Effect extend beyond mere inventory disarray; it also affects partnerships, production schedules, and overall operational stability. While the genesis of this effect may be the oscillation of end-consumer demand, its amplification is frequently due to a lack of communication and coordination among supply chain stakeholders.

Inventory Management Challenges

Demand variability directly impinges upon inventory management, precipitating scenarios of overstock when demand is overestimated, or understock when it is underestimated. Both situations are undesirable; surplus inventory inflates storage costs and risks obsolescence, whereas insufficient stock can lead to missed sales and customer dissatisfaction.

Managing inventory in the wake of unpredictable demand necessitates sophisticated strategies and tools that can provide accurate demand forecasts and enable responsive replenishment. The quest for the optimal balance between inventory costs and service levels is intense and relentless.

Supplier Relationship Challenges

The ripples of demand variability also extend to supplier relationships. Suppliers striving for stable production schedules may find the erratic order patterns that result from demand fluctuations to be problematic. Collaborative relationships and transparent communication channels can help alleviate the tension by ensuring suppliers are in sync with the demand-related challenges their partners are facing.

Customer Service Concerns

Ultimately, the endgame of adept supply chain management is satisfying customer demand. Variability in demand complicates this objective, risking either a shortfall in product availability or a dilapidated customer experience due to excessive wait times or outdated inventory. The calibration of an agile, customer-centric supply chain is imperative to counteract the potential downsides of demand variability.

Strategies to Manage Demand Variability

Demand Forecasting Techniques

As supply chains grapple with the volatility of demand, forecasting stands as an essential tool. Companies have long relied on time-series analysis, which extrapolates future demand based on historical data patterns. Causal models advance the forecasting process by incorporating exogenous variables such as economic indicators or marketing spend. More recently, machine learning models are being increasingly employed, leveraging vast datasets and computational power to predict demand with unprecedented precision.

Inventory Optimization Tools

To obviate overstocks and stockouts, companies are turning to sophisticated inventory optimization tools. These systems apply algorithms that balance carrying costs against stockout costs, recommend safety stock levels, and determine optimal reorder points. By deploying such tools, businesses can more accurately align their inventories with the irregular cadence of consumer demand.

Flexible Supply Chain Design

A static supply chain is vulnerable to the whims of demand variability. Instead, a flexible design allows for rapid adjustment to changes in demand, be it scaling up production in times of high demand or pivoting to alternative products when demand wanes. This agility can be built through strategies such as multi-sourcing, modularity in manufacturing, and adopting variable cost structures.

Collaborative Planning, Forecasting, and Replenishment (CPFR)

CPFR is a business practice that aligns stakeholders across the supply chain in a collaborative effort to predict demand. By sharing information and jointly developing forecasts and replenishment plans, the entire supply chain can better respond to consumer needs. This cooperation serves to mitigate the detrimental impact of demand variability.

Case Studies of Effective Demand Variability Management

Case Study 1: ZARA – Fast Fashion Retail

A compelling showcase of adept demand variability management is found in ZARA, the Spanish fashion giant. With its rapid supply chain and data-driven design decisions, ZARA responds swiftly to changing fashion trends, translating real-time demand signals into production and inventory decisions. This nimbleness allows the retailer to refresh its product offerings frequently, keeping pace with the fickle inclinations of the fashion-conscious consumer.

Case Study 2: Toyota – Automobile Manufacturing

Another exemplar is Toyota, whose renowned Toyota Production System (TPS) incorporates Just-in-Time (JIT) manufacturing principles. This paradigm hinges on producing only what is needed, when it is needed, and in the amount needed. Toyota's approach minimizes waste, reduces inventory costs, and enables a high degree of responsiveness to fluctuations in demand.

Learnings from the Case Studies

These case studies illustrate that successful demand variability management is not serendipitous but the result of deliberate strategic planning and the implementation of robust processes. The principles gleaned from ZARA and Toyota offer valuable insights that can be extrapolated to other businesses grappling with demand variability.

The canvas of demand variability is vast and complex, embroidered with a multiplicity of causes and repercussions. Its thorough comprehension and adept management are integral to forging a supply chain that is responsive, efficient, and resilient. As we recap the essence of this discourse, it is the interplay of forecasting, collaboration, flexibility, and innovation that emerges as cardinal in managing the undulating patterns of consumer demand.

Businesses are encouraged to continuously refine their approaches to demand management, considering the pivotal role of evolving consumer dynamics and economic scenarios. The journey to excellence in supply chain management is perpetual, and through the lens of case studies and strategic frameworks, companies can glean insights and strategies to proactively tackle demand variability, ensuring they remain agile and customer-centric in the face of constant change.

Frequently Asked Questions

What are the key factors contributing to demand variability and how do they impact different stages of the supply chain?

Understanding Demand Variability in the Supply Chain

Demand variability remains a critical challenge. It affects multiple supply chain stages. Various key factors contribute to this variability. They shape the supply chain's resilience and efficiency. Recognizing these factors aids companies in strategizing better.

Economic Fluctuations

Economies often experience ups and downs. These fluctuations impact consumer buying power. Consequently, demand patterns shift. Manufacturers and retailers must then adapt, often rapidly. Sudden economic downturns can cause sharp demand declines. In contrast, upswings can lead to surges.

Market Trends

Consumer preferences evolve. New trends thus influence demand. Businesses must forecast these changes accurately. They rely on market analysis. This helps them align products with consumer desires. Failing to do so can lead to stockouts or excess inventory.

Technological Advancements

Technology changes product lifecycles. It creates new opportunities. Yet, it can also render products obsolete quickly. Supply chains must be responsive. They need innovative approaches to match these technological shifts. Adaptation affects product development to distribution.

Regulatory Changes

Regulations impact product demand. Supply chains must comply with new laws. They may face changes in operating procedures. This impacts costs and, subsequently, demand. Supply chains should maintain flexibility. It allows them to adjust to regulatory environments.

Seasonality Factors

Demand often follows seasonal patterns. Industries like fashion and agriculture experience this keenly. Supply chains must plan for peak seasons. They have to ensure sufficient inventory levels. Equally, they must manage off-peak lulls to avoid overstock.

Competition

Competitors introduce variability. They present alternative products. They also engage in price wars. Firms must monitor competitors closely. They need strategies for competitive positioning. Failure to do so can lead to lost market share.

Supplier Reliability

Suppliers play a critical role. Their ability to meet deadlines affects inventory. Any disruption can create bottlenecks. Strong supplier relationships are vital. They ensure smooth upstream activities. This impacts the entire supply chain.

Global Events

Global incidents, like pandemics or natural disasters, cause massive disruptions. They affect supply chains at all stages. Contingency planning is crucial. Diverse sourcing and distribution methods can mitigate impact.

Impact on Supply Chain Stages

Variability influences supply chain stages differently. It necessitates robust management practices.

Procurement

Variability demands adaptable procurement processes. Sourcing strategies must anticipate changes. They must find reliable suppliers. They have to minimize risk.

Production

Production schedules require careful planning. They must respond to demand shifts. This necessitates a flexible production capacity.

Inventory Management

Demand variability complicates inventory management. Firms need real-time data. They need clear visibility. This helps them manage stock levels effectively.

Distribution

A varied demand impacts logistics. Distribution networks have to be responsive. They must adjust to changing demand patterns.

Customer Service

Finally, variability influences customer expectations. Firms need proactive communication. They must align service levels with demand.

Demand variability shapes supply chain dynamics. Firms need agility. They need to incorporate advanced analytics. This enables better decision-making. A firm grasp of contributing factors allows for strategic adaptation. It fosters resilience across the supply chain.

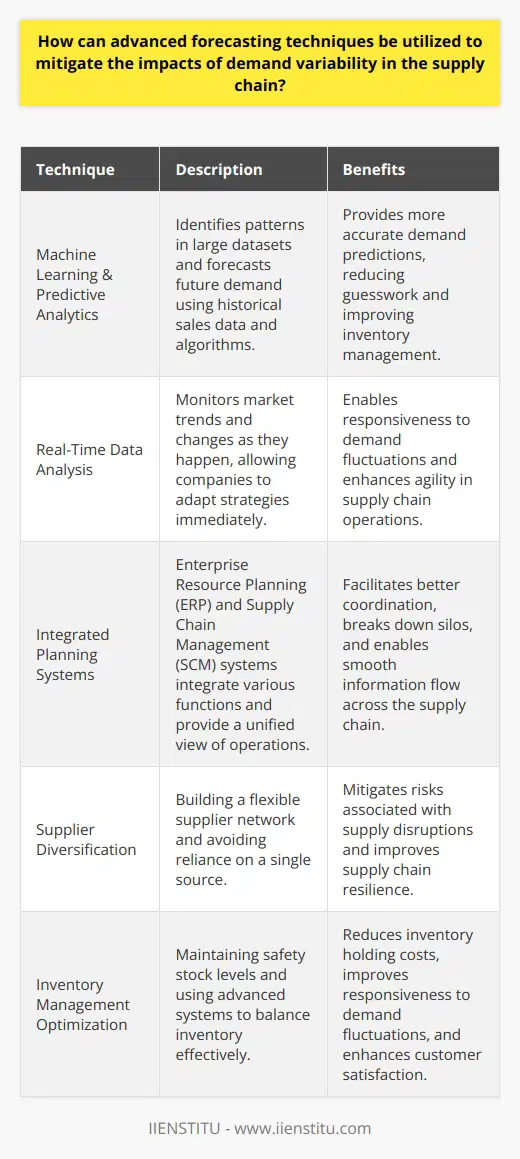

How can advanced forecasting techniques be utilized to mitigate the impacts of demand variability in the supply chain?

Understanding Demand Variability

Demand variability poses a significant challenge. Companies must adapt constantly. Supply chains suffer without the right tools.

The Role of Advanced Forecasting

Advanced forecasting stands as the antidote. It turns unpredictability into manageable data. Companies gain valuable insights. These insights guide inventory management. They inform production schedules. They help adjust procurement activities.

Machine Learning & Predictive Analytics

Machine learning changes the forecasting game. It identifies patterns in large datasets. Predictive analytics forecast future demand. Historical sales data becomes a treasure trove. Algorithms can predict demand more accurately. Businesses reduce the guesswork.

Real-Time Data Analysis

Supply chains are dynamic. Real-time data analysis is critical. It allows responsiveness to market changes. Companies monitor trends as they happen. They can adapt their strategies immediately.

Integrated Planning Systems

ERP and SCM systems are vital. They integrate various functions. They offer a unified view of operations. This leads to better coordination. Silos break down. Information flows smoothly.

Mitigating The Impacts

To mitigate impacts:

- Diversify Suppliers

- Do not rely on a single source.

- Build a flexible supplier network.

- Improve Inventory Management

- Keep safety stock.

- Use advanced systems. They help balance inventory.

- Enhance Demand Planning

- Collaborate with stakeholders.

- Share forecasts with suppliers and customers.

- Implement Lean Principles

- Reduce waste.

- Focus on value-adding activities.

Adopting these techniques brings resilience. Supply chains can withstand fluctuations. This reduces lost sales. It minimizes inventory holding costs. Customer satisfaction improves.

Advanced forecasting is not optional. It's a necessity for modern supply chains. It enables companies to navigate demand variability. Businesses must invest in this area. The rewards far outweigh the costs.

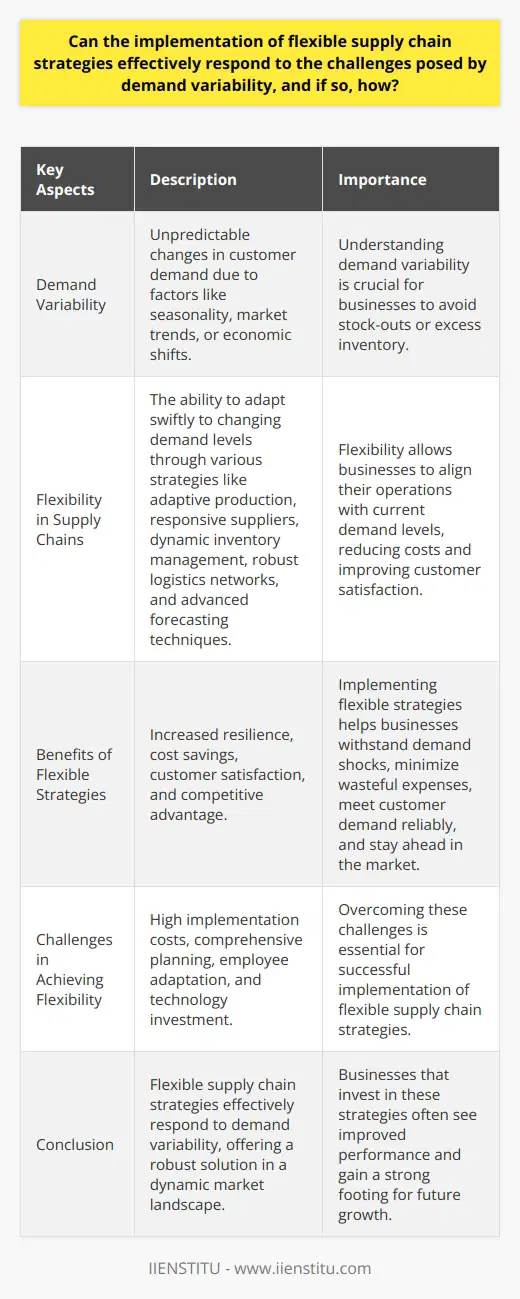

Can the implementation of flexible supply chain strategies effectively respond to the challenges posed by demand variability, and if so, how?

Flexibility in Supply Chains

Variability in demand presents a significant challenge. Companies often struggle to match supply with the ever-changing demand patterns. Flexible supply chain strategies have emerged as a key response. These strategies enable companies to adapt to demand fluctuations quickly and efficiently.

Understanding Demand Variability

Demand variability refers to changes in customer demand. These changes can be unpredictable. They can stem from various factors like seasonality, market trends, or economic shifts. Businesses face challenges in predicting such changes. They must adapt to avoid stock-outs or excess inventory.

Role of Flexibility in Supply Chains

Flexibility within the supply chain is vital. It allows for swift adjustments in operations. This agility ensures better alignment with current demand levels. A flexible supply chain can reduce costs and improve customer satisfaction.

How Flexibility Addresses Demand Variability

Flexibility manifests in several ways within the supply chain:

- Adaptive Production: Manufacturing processes can scale up or down. This ability is crucial for adapting to demand shifts.

- Responsive Suppliers: Partners must share this commitment to flexibility. They must adapt their production in line with demand signals.

- Dynamic Inventory Management: This system responds to real-time demand data. It reduces inventory holding costs.

- Robust Logistics Networks: These networks can reroute and prioritize shipments. They react to urgent demand needs.

- Advanced Forecasting Techniques: Data-driven approaches can predict changes. They can trigger adjustments early in the supply chain.

Benefits of Implementing Flexible Strategies

Flexible strategies bring notable benefits:

- Increased resilience: Businesses can withstand demand shocks better.

- Cost savings: They minimize wasteful expenses due to over- or under-stocking.

- Customer satisfaction: Meeting demand reliably ensures customer loyalty.

- Competitive advantage: Quick responses to market changes keep businesses ahead.

Challenges in Achieving Flexibility

Achieving flexibility is not without its challenges:

- High implementation costs can deter businesses.

- Changes require comprehensive planning.

- Employees must embrace new approaches.

- Technology investment is often necessary.

Conclusion

In sum, flexible supply chain strategies effectively respond to demand variability. They offer a robust solution in a dynamic market landscape. Businesses that invest in these strategies often see improved performance. They also gain a strong footing for future growth.