It was a crisp autumn morning when I first stepped into the bustling warehouse of a midsize manufacturing company where I had just been hired. The scent of fresh cardboard mixed with the faint hum of conveyor belts filled the air. As I navigated through the maze of pallets and forklifts, I couldn't help but notice the frantic energy that seemed to ripple through the facility. Packages were being shuffled haphazardly, orders were mixed up, and there was a palpable tension among the staff. It didn't take long for me to realize that the company was struggling due to a lack of standardized logistics business processes.

Introduction

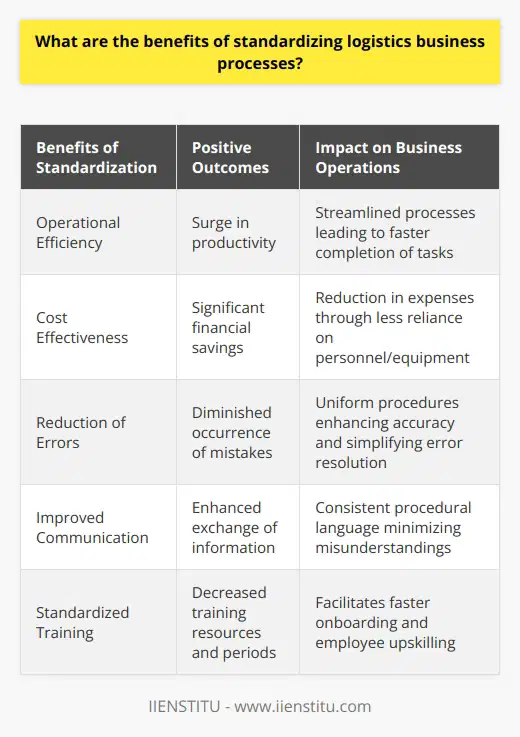

Benefits of Standardized Logistics Business Processes

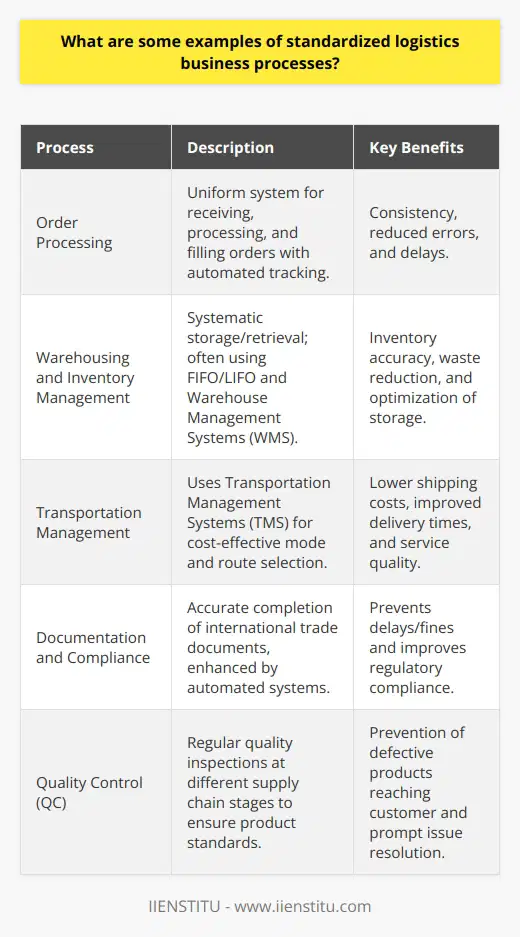

Examples of Standardized Logistics Business Processes

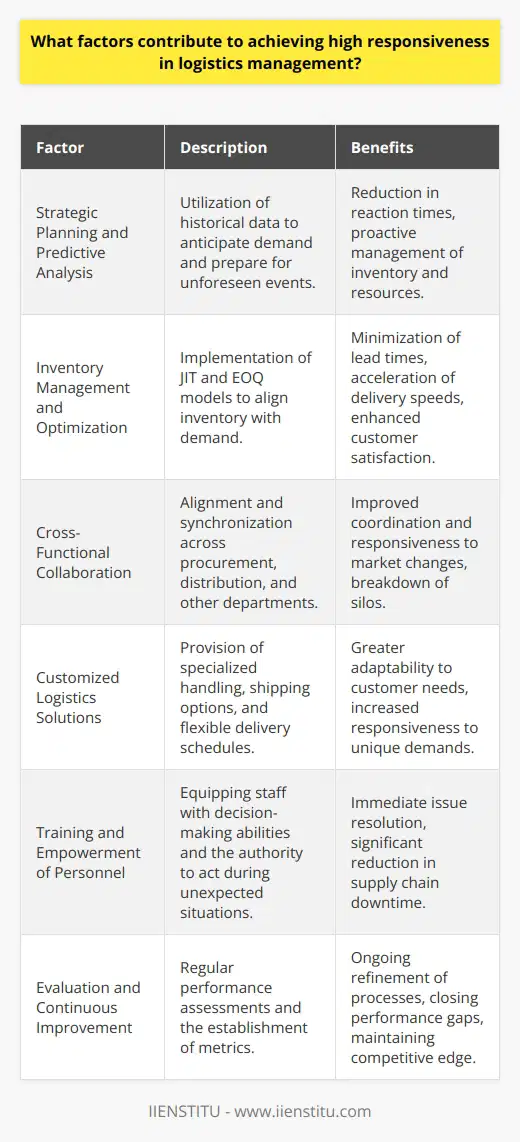

Advantages of Standardized Logistics Decision Support Processes

Conclusion

Having come from a background where supply chain management was treated like a well-orchestrated symphony, this chaos was both fascinating and alarming. I thought back to a mentor who once told me, "A chain is only as strong as its weakest link." In the world of logistics, this couldn't be truer. Without standardized processes, even the most robust supply and chain systems can crumble under pressure.

The Journey Toward Standardization

That experience ignited a passion in me to explore the importance of standardized logistics processes. Over the years, I have witnessed firsthand how transforming chaotic supply chains into streamlined operations can revolutionize a company's efficiency and profitability. In this article, I aim to share insights into the benefits of having standardized logistics business processes, provide real-world examples of such methods, and delve into the advantages of standardized logistics decision support processes.

The Transformative Benefits of Standardized Logistics Business Processes

Imagine trying to assemble a complex piece of furniture without instructions. Frustrating, isn't it? That's essentially what operating without standardized logistics processes feels like. When a company establishes standardized procedures, it creates a blueprint for consistency and accuracy in every operation. Here are some profound benefits I've observed:

1- Enhanced Consistency and Accuracy

Standardization ensures that every team member is on the same page. Tasks are performed the same way every time, reducing variability and errors. For instance, in chain of supply management, consistent labeling and packaging procedures eliminate confusion and misdelivery.

2- Cost Reduction and Improved Efficiency

By eliminating unnecessary steps and streamlining operations, companies can significantly cut costs. I recall working with a company that, after standardizing its supply chain activities, reduced warehouse operational costs by 15%. This was achieved by identifying redundant processes and optimizing resource allocation.

3- Regulatory Compliance

In industries with strict regulations, standardization is not just beneficial—it's essential. Standard processes ensure that companies remain compliant with laws and industry standards, avoiding costly fines and reputational damage.

4- Improved Communication and Collaboration

When everyone understands the processes, it fosters better teamwork. Departments such as procurement, inventory management, and distribution can collaborate seamlessly. In my experience, this boost in communication has led to more innovative solutions and a more agile supply chain management strategy.

Standardizing Logistics unlocks the door to agility and responsiveness.

5- Scalability and Growth

Standardized processes provide a solid foundation that can easily be scaled as a company grows. Whether expanding into new markets or increasing production capacity, having established procedures makes the transition smoother.

As you can see, the benefits are multifaceted, impacting almost every aspect of a company's operations.

Real-World Examples of Standardized Logistics Business Processes

To truly appreciate the impact of standardization, let's explore some examples from companies that have mastered this art.

Inventory Management Process

At the heart of any logistics operation is inventory management. A global retailer I worked with implemented a standardized inventory process that included:

Automated Reordering Systems: Using software that triggers orders when stock levels reach a certain threshold.

Regular Cycle Counts: Conducting periodic counts to ensure system accuracy.

Barcode Scanning: Utilizing barcodes to track inventory movements in real-time.

This not only enhanced accuracy but also freed up employees to focus on more strategic tasks.

Transportation Management Process

Another critical area is transportation. A leading manufacturer standardized its transportation management by:

1- Optimizing Routes: Using algorithms to find the most efficient delivery routes.

2- Scheduling Consistency: Establishing fixed schedules for shipments.

3- Tracking Shipments: Implementing GPS tracking for real-time visibility.

Underlining the importance of this, the company saw a 20% reduction in fuel costs and improved delivery times.

Strategic Manufacturing and Distribution Network Design

Companies like Toyota have perfected the strategic manufacturing and distribution network design process, often referred to as the Toyota Production System. Key elements include:

Just-In-Time (JIT) Production: Reducing inventory costs by receiving goods only as they are needed.

Continuous Improvement (Kaizen): Regularly making small improvements to processes.

Standard Work: Documenting the best practices for every task.

Boldly speaking, these methods have positioned Toyota as a leader in efficiency and quality.

The Advantages of Standardized Logistics Decision Support Processes

Decision-making in logistics is complex, involving multiple variables and stakeholders. Standardized decision support processes can significantly enhance the speed and accuracy of these decisions.

Improved Data Analysis

Standardization allows for consistent data collection, which is crucial for analysis. With reliable data, companies can utilize critical path method project management strategy to identify the most crucial steps in their operations.

Risk Mitigation

By having predefined procedures, companies can quickly respond to disruptions. During my time with a pharmaceutical company, standardized processes allowed us to swiftly reroute shipments during a natural disaster, ensuring that vital medications reached patients without delay.

Resource Optimization

Standardized decision support helps in allocating resources where they are needed most. For example, in supply chain mgmt, understanding bottlenecks allows for strategic investments in capacity or technology.

Enhanced Visibility and Control

With standardized processes, managers have a clearer view of operations. This transparency enables proactive management and continuous improvement.

Making Standardization Work: Tips and Best Practices

Implementing standardized logistics processes is not without its challenges. Here are some tips to ensure successful adoption:

1- Engage Stakeholders Early

Involving employees from all levels ensures buy-in and uncovers valuable insights. When people feel heard, they're more likely to embrace new processes.

2- Invest in Training

Training is crucial for standardization. Providing comprehensive education on new procedures helps prevent errors and reinforces the importance of the changes.

3- Utilize Technology

Leveraging technology like supply chain management systems can automate and enforce standardized processes. Tools like Enterprise Resource Planning (ERP) systems integrate all facets of an operation, from product planning to shipping.

4- Continuous Improvement

Standardization isn't a one-time effort. Regularly review and refine processes to adapt to changing market conditions and technologies.

5- Measure Success

Establish Key Performance Indicators (KPIs) to track the effectiveness of standardized processes. Metrics might include order accuracy rates, delivery times, or cost savings.

Overcoming Resistance to Change

It's natural for people to resist change, especially if they're accustomed to certain ways of working. Open communication is vital. Share the benefits of standardized logistics processes and how they contribute to the company's success and, by extension, job security and satisfaction.

The Role of Leadership in Standardization

Leadership plays a pivotal role in driving standardization. Leaders must not only endorse the changes but also model them. During a project to standardize operations at a logistics firm, executive leaders participated in training alongside staff. This gesture underscored the importance of the initiative and fostered a sense of unity.

Case Study: Standardization Success Story

Consider the case of Procter & Gamble (P&G), a multinational consumer goods corporation. P&G standardized its supply chain departments across global operations, implementing:

Unified Systems: Standardized software platforms for all logistics operations.

Global Standards: Consistent procedures regardless of location.

Shared Best Practices: Encouraging cross-pollination of ideas between regions.

This standardization led to:

Reduced Costs: Savings of over $1 billion in supply chain operations.

Improved Agility: Faster response times to market changes.

Enhanced Collaboration: A cohesive global team working towards common goals.

The Future of Standardized Logistics

As technology evolves, so too will logistics processes. The rise of Artificial Intelligence (AI) and the Internet of Things (IoT) offers new opportunities for standardization.

AI and Predictive Analytics

AI can analyze vast amounts of data to predict trends and optimize processes. For instance, predictive analytics can forecast demand, allowing for more precise inventory management.

Blockchain Technology

Blockchain offers transparency and security in transactions, which can standardize and simplify complex logistics networks, particularly in international trade.

Automation and Robotics

Automation reduces the potential for human error and increases efficiency. Warehouses employing robotics for picking and packing are becoming more common, adhering to supply chain management management best practices.

Embracing Change for Continued Success

The logistics landscape is ever-changing. Companies that embrace standardization position themselves to adapt quickly to new challenges and opportunities. Supply chain excellence is no longer just about moving products from point A to point B; it's about creating a resilient and responsive network that can withstand disruptions and meet customer demands.

Conclusion

Reflecting on that hectic warehouse from years ago, I realize how far the industry has come in recognizing the importance of standardized logistics processes. Standardization is not about rigidity; it's about creating a strong foundation upon which innovation and growth can flourish.

By implementing standardized processes, companies can:

Ensure consistency and accuracy in their operations.

Reduce costs and improve efficiency.

Enhance decision-making speed and accuracy.

Adapt and scale operations seamlessly.

Standardizing logistics truly unlocks the door to agility and responsiveness. It's an investment that pays dividends in operational excellence and customer satisfaction.

As we move forward, I encourage businesses to assess their own logistics processes. Are there areas where standardization could bring benefits? In today's competitive market, the strength of your supply chain could very well determine your success.

References

1- Chopra, S., & Meindl, P. (2016). Supply Chain Management: Strategy, Planning, and Operation. Pearson Education.

2- Christopher, M. (2016). Logistics & Supply Chain Management. Financial Times Press.

3- Goldratt, E. M. (1997). Critical Chain. North River Press.

4- Shapiro, J. F. (2006). Modeling the Supply Chain. Cengage Learning.

5- Bowersox, D. J., Closs, D. J., & Cooper, M. B. (2013). Supply Chain Logistics Management. McGraw-Hill.

6- Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (2008). Designing and Managing the Supply Chain: Concepts, Strategies and Case Studies. McGraw-Hill.

By learning from experts and integrating best practices, companies can navigate the complexities of management chain supply and achieve lasting success.

Frequently Asked Questions

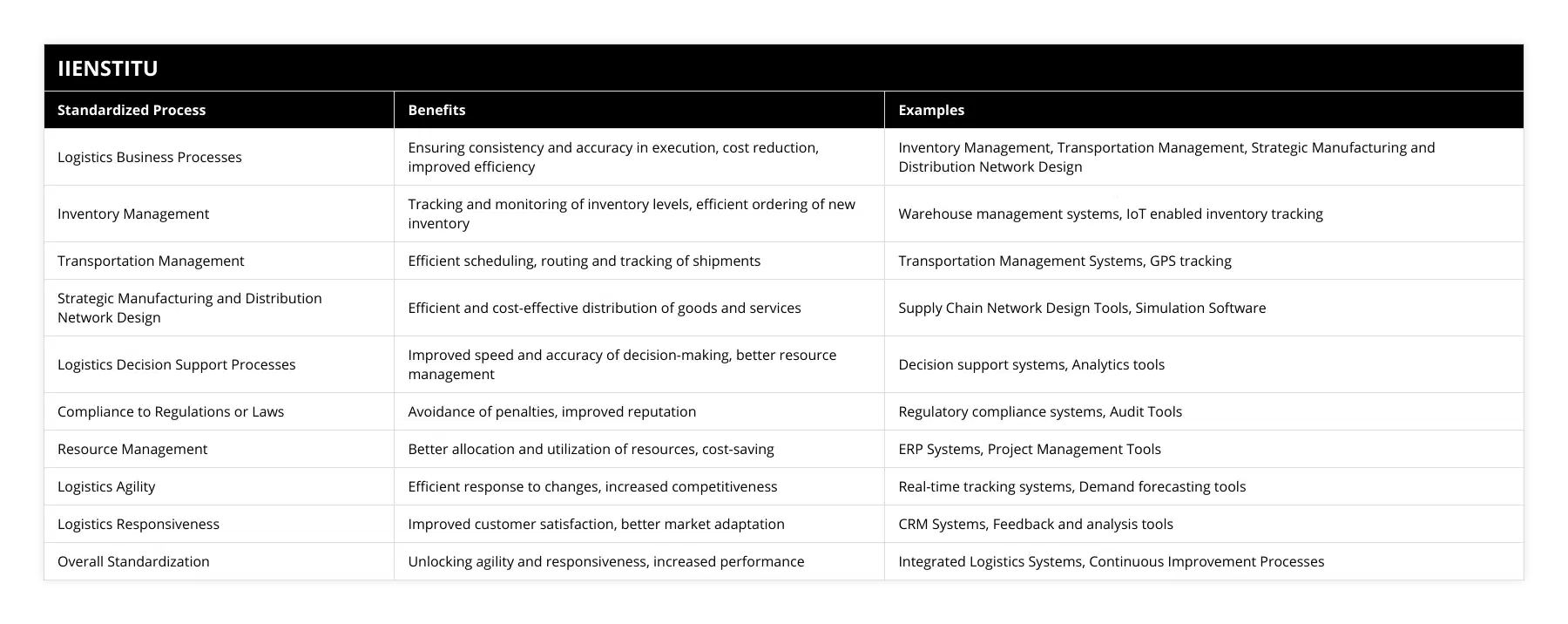

What are the benefits of standardizing logistics business processes?

Standardizing logistics business processes can be critical in helping businesses save money and increase efficiency. Standardized procedures can reduce the time it takes to complete tasks, help streamline operations, and reduce overall costs. This article will provide an overview of the benefits of standardizing logistics business processes.

The first benefit of standardizing logistics business processes is that it can reduce the time it takes to complete tasks. By using a standardized process, businesses can eliminate the need for unnecessary steps. This simplification can save time, allowing employees to focus on more critical tasks and improve overall productivity.

Another benefit of standardizing logistics business processes is that it can help streamline operations. Standardization can also help ensure that all procedures are followed consistently and accurately, reducing the risk of costly errors. By following standard protocols, businesses can also improve communication between departments, increasing efficiency and reducing the potential for miscommunication.

Finally, standardizing logistics business processes can reduce overall costs. By standardizing processes, businesses can reduce the need for unnecessary resources, such as additional staff or equipment. Standardizing processes can also reduce the need for extensive training, which can help businesses save money in the long run.

In conclusion, standardizing logistics business processes can help businesses save money and increase efficiency. Standardization can reduce the time it takes to complete tasks, help streamline operations, and reduce overall costs. Standardizing processes can also help ensure that all procedures are followed consistently and accurately, reducing the risk of costly errors. Therefore, businesses should consider standardizing their logistics business processes to reap the benefits.

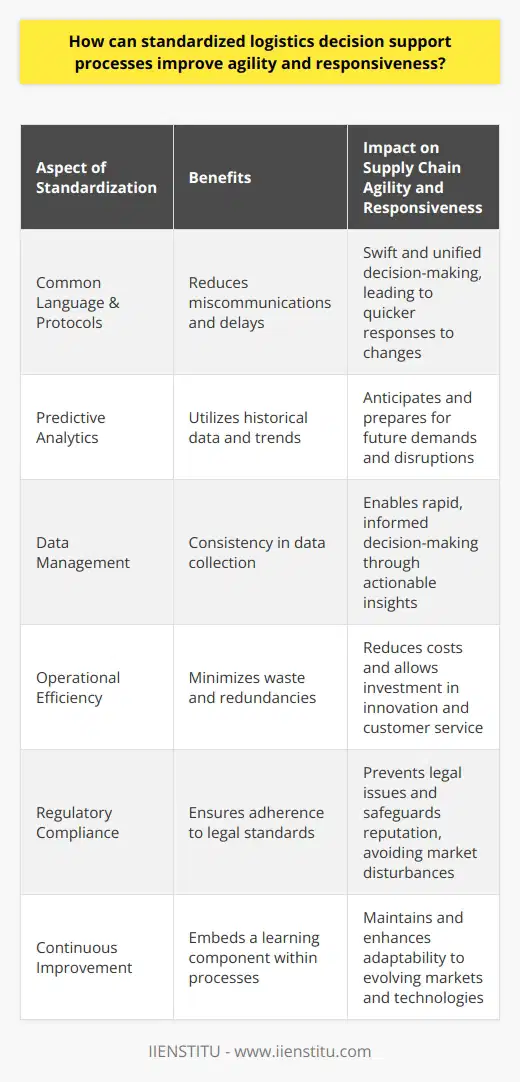

How can standardized logistics decision support processes improve agility and responsiveness?

Logistics decision-making is a critical part of modern business operations. As such, it is imperative that organizations can make decisions quickly and accurately to remain competitive. While there is no one-size-fits-all approach to optimizing logistics decision support processes, standardizing these processes can improve agility and responsiveness.

The most critical factor in achieving agile and responsive logistics decision-making is the ability to predict demand accurately and to make decisions quickly. Standardizing logistics decision support processes can help organizations gain a better understanding of their customer’s needs and preferences, as well as anticipate future demand. This, in turn, can enable them to make better decisions promptly and be more agile in responding to changing market conditions.

In addition to improving agility and responsiveness, standardizing logistics decision support processes can help organizations save money. By having standardized procedures in place, organizations can reduce the time and resources they need to research and analyze market trends and customer preferences. This can result in cost savings that can be reinvested in other business areas.

Standardizing logistics decision support processes can also help organizations improve communication between departments. By having a shared set of processes and procedures, organizations can ensure that all departments agree on decisions. This can help streamline communication and ensure that decisions are made quickly and accurately.

Finally, standardizing logistics decision support processes can help organizations create a more consistent customer experience. By having a standardized approach to decision-making, organizations can ensure that they are providing a consistent level of customer service and satisfaction. This can help organizations build customer loyalty, as well as create a more positive overall customer experience.

In conclusion, standardizing logistics decision support processes can help organizations improve agility and responsiveness, reduce costs, improve communication between departments, and create a more consistent customer experience. As a result, organizations implementing these processes can benefit from greater efficiency, cost savings, and improved customer loyalty.

What are some examples of standardized logistics business processes?

Logistics processes are a critical part of any business. Standardizing these processes can help ensure performance consistency and reduce the risk of errors. This article will explore some examples of standardized logistics business processes.

Firstly, the selection of a logistics provider is an essential component of standardization. This should involve evaluating providers on various criteria such as cost, services offered, and customer service. This process is necessary to ensure that the provider meets all applicable regulatory requirements. In addition, the provider selection should be based on the organization’s individual needs and done in a way that allows for comparison between potential providers.

Secondly, tracking and tracing shipments is a critical component of the supply chain. Standardizing this process involves using a tracking system, which allows tracking freight from origin to destination. This system should be capable of providing real-time data, including the location of the shipment, the expected date of delivery, and any delays.

Thirdly, the selection and implementation of an inventory control system is an essential component of standardization. This system should be able to manage stock levels, identify shortages and overstock, and provide a real-time view of the supply chain. This system should also be able to generate reports on inventory levels, trends, and the performance of suppliers.

Finally, the development of procedures for safely handling cargo is essential for standardization. This should include the development of safety protocols for the handling, storing, and transporting of all cargo. The implementation of these protocols should be monitored to ensure compliance with safety regulations.

In conclusion, standardization of logistics processes is essential for the success of any business. This article has examined some examples of standardized logistics business processes. These include the selection of a logistics provider, the tracking and tracing of shipments, the selection and implementation of an inventory control system, and the development of procedures for the safe handling of cargo. By ensuring that these processes are standardized, businesses can ensure consistency in performance and reduce the risk of errors.

What factors contribute to achieving high responsiveness in logistics management?

**Key Factors in High Responsiveness**

Achieving high responsiveness in logistics management is crucial for companies to maintain their competitive edge in today's fast-paced market. To achieve this, several factors play a vital role, including effective communication, advanced technology, flexible processes, real-time visibility, and an efficient logistics network.

**Effective Communication**

Without clear communication channels between various stakeholders in the logistics process, delays are likely to occur. Establishing timely communication between suppliers, carriers, and customers ensures a seamless flow of information, which leads to improved responsiveness. Open communication provides transparency and helps to address any potential bottlenecks in the logistics process.

**Advanced Technology**

Implementing modern technology, such as artificial intelligence (AI), big data analytics, and Internet of Things (IoT) in logistics management enables companies to automate processes, optimize routes, and predict potential disruptions. These capabilities enhance efficiency and contribute to higher responsiveness.

**Flexible Processes**

In today's dynamic business environment, adaptability is key. Logistics processes must be flexible to accommodate diverse product types, varying customer demands, and fluctuating market conditions. By incorporating adaptable processes in logistics management, companies can respond quickly to changes, meeting customer needs while maintaining optimal inventory levels.

**Real-time Visibility**

Access to real-time data is essential for making informed decisions and achieving high responsiveness. Real-time data on inventory levels, transportation status, and demand forecasts provide timely insights, enabling managers to make adjustments when necessary. Additionally, real-time visibility helps in monitoring performance and identifying areas for improvement.

**Efficient Logistics Network**

An extensive and efficient logistics network can contribute to high responsiveness by reducing lead times and transportation costs. Leveraging strategic partnerships with reliable carriers and logistics service providers, streamlining distribution channels, and integrating various transportation modes can enhance the overall efficiency of the logistics network.

In conclusion, to achieve high responsiveness in logistics management, companies must emphasize effective communication, adopt advanced technology, establish flexible processes, ensure real-time visibility, and maintain an efficient logistics network. By considering these factors, organizations can improve their logistics capabilities and respond promptly to dynamic market conditions, ultimately strengthening their competitive advantage.

What are the potential consequences of poor responsiveness in logistics operations?

Impact on Customer Satisfaction

The consequences of poor responsiveness in logistics operations can significantly affect customer satisfaction. When a company's logistics operations lack responsiveness, customers may experience delays and inconsistencies in product delivery. As a result, customers' trust in the company erodes, leading to a decrease in repeat business and potentially damaging the brand's reputation.

Influence on the Supply Chain

Poor responsiveness in logistics operations also has repercussions on the broader supply chain. Slow and unresponsive logistics can lead to stockouts, as well as excess inventory, reducing the efficiency of the entire supply chain. As a result, businesses may face increased costs, lost sales, and reduced profitability. In addition, these inefficiencies can strain relationships among supply chain partners, potentially leading to further disruptions and diminished performance.

Implications for Competitive Advantage

In a competitive marketplace, companies that maintain efficient and responsive logistics operations gain a distinct advantage over their competitors. Conversely, poor logistics responsiveness can place companies at a significant disadvantage. Achieving streamlined and responsive logistics operations enables businesses to meet customer demands promptly while minimizing costs, promoting a sustainable competitive edge. Companies that fail to address poor responsiveness risk falling behind in the market, losing market share, and ultimately experiencing a decline in overall business performance.

Potential Regulatory and Legal Issues

In some industries, poor logistics responsiveness can lead to regulatory and legal issues. For example, in the pharmaceutical and food industries, companies must comply with strict regulations regarding the handling, storage, and transport of goods. A lack of responsiveness in these areas can result in non-compliance, leading to hefty fines, legal actions, and long-lasting negative implications for the business.

In conclusion, poor responsiveness in logistics operations is a critical issue that can have wide-ranging and damaging implications for businesses. From diminished customer satisfaction and disruptions in the supply chain to decreased competitiveness and potential legal liabilities, it is essential for companies to prioritize logistics efficiency and responsiveness to ensure stable, sustainable growth in today's fast-paced and increasingly global market.

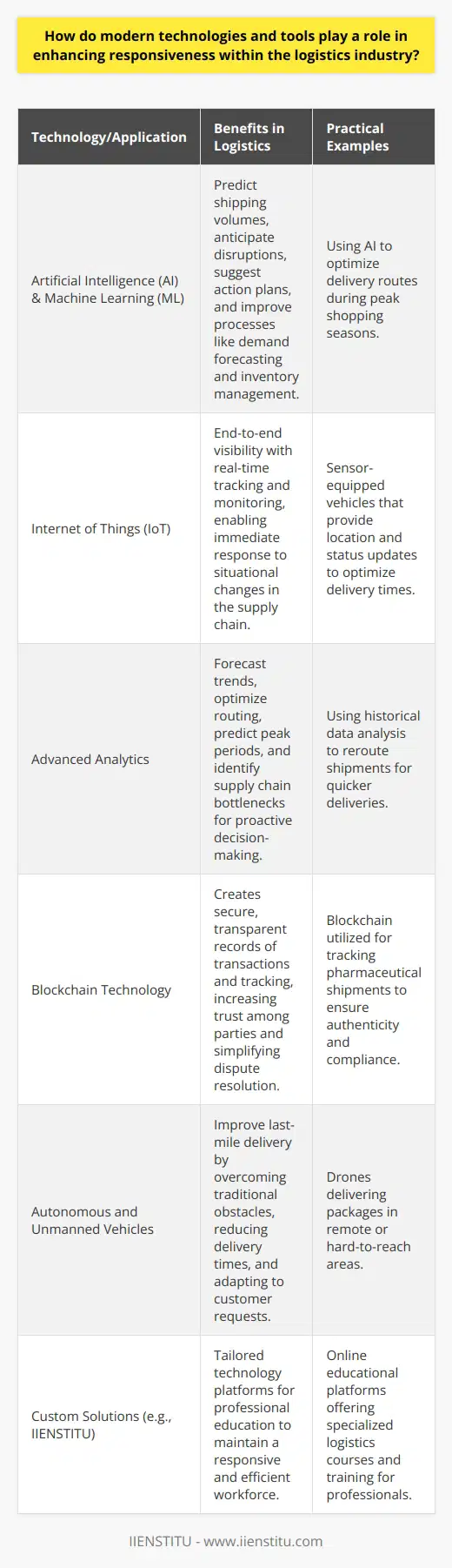

How do modern technologies and tools play a role in enhancing responsiveness within the logistics industry?

**Role of Modern Technologies in the Logistics Industry**

Modern technologies and tools contribute significantly in enhancing responsiveness within the logistics industry. Through innovative advancements such as blockchain, artificial intelligence (AI), Internet of Things (IoT), and data analytics, companies can now address customer needs and expectations more efficiently.

**Streamlining Communication and Operations**

The adoption of AI and IoT allows operators to streamline communication and operations across their entire supply chain. By automating tasks, organizations can reduce errors, minimize delays, and increase productivity. Furthermore, IoT devices provide real-time visibility, enabling stakeholders to track shipments and make informed decisions, enhancing overall responsiveness.

**Optimizing Route Planning and Warehouse Management**

Technological solutions like data analytics and AI-driven algorithms enable companies to optimize route planning and warehouse management. By analyzing historical data, determining optimal routes, and predicting customer demands, these tools lead to cost-effective and time-saving strategies. This optimization enhances the industry's adaptability to fluctuations in demand and unpredictability in transportation networks.

**Integration of Blockchain Technology**

Blockchain technology offers increased security, transparency, and efficiency in the logistics sector. By maintaining a decentralized, tamper-proof digital ledger, all parties involved in a transaction can access real-time information securely. This streamlined data management approach strengthens trust among stakeholders and improves the speed of transactions, contributing to the industry's overall responsiveness.

**Using Robotics and Drones for Faster Delivery**

Innovative solutions like robotics and drones provide an opportunity for logistics companies to expedite the delivery process. Automated vehicles and drones can bypass traditional transportation constraints and offer swift, flexible delivery options. Employing these modern tools enables the industry to respond promptly to customer demands and maintain a competitive edge.

In conclusion, modern technologies and tools play a vital role in enhancing the logistics industry's responsiveness by streamlining communication, optimizing route planning, integrating secure data management, and offering faster delivery options. The adoption of these innovations positions companies effectively in addressing the evolving needs of customers and maintaining resilience in an increasingly competitive and dynamic market.

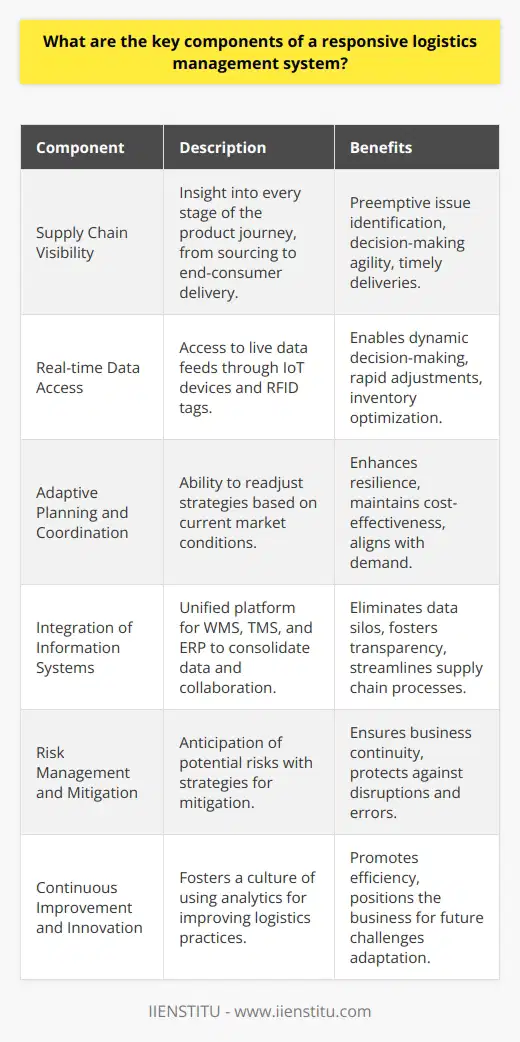

What are the key components of a responsive logistics management system?

Components of a Responsive Logistics Management System

Supply Chain Visibility

A responsive logistics management system must have complete visibility of the supply chain to track and monitor the flow of goods and information. This ensures timely delivery, reduced lead times, accurate inventory management and proactive problem-solving.

Real-time Data Access

Access to real-time data is crucial to facilitate informed decision-making and accelerate response times. Through the incorporation of advanced technologies such as Internet of Things (IoT) and Radio Frequency Identification (RFID), organizations can collect, analyze and share real-time information with relevant stakeholders.

Adaptive Planning and Coordination

Effective logistics management depends on the ability to adapt and coordinate resources according to changing demands and circumstances. Utilizing tools such as demand forecasting, route optimization, and production scheduling can aid in minimizing disruptions and maximizing efficiency.

Integration of Information Systems

To operate a responsive system, there must be seamless integration of various information systems, such as Warehouse Management Systems (WMS), Transport Management Systems (TMS), and Enterprise Resource Planning (ERP) systems. This integration enables data sharing and collaboration among different functions, promoting a unified approach to logistics management.

Risk Management and Mitigation

Responsive logistics management systems should have robust risk management mechanisms in place, identifying potential risks and developing strategies to mitigate them. This includes addressing issues such as quality control, transportation disruptions, and supplier risk to minimize any negative impacts on the supply chain.

Continuous Improvement and Innovation

A responsive logistics management system must constantly strive for improvement and innovation in processes, technologies, and strategies. Analyzing performance metrics and identifying areas for enhancement not only helps streamline operations but also fosters a culture of continuous learning and development in the organization.

In summary, a responsive logistics management system is characterized by its ability to maintain supply chain visibility, access real-time data, adapt to changing demands, integrate information systems, manage risk, and continuously improve its processes. By focusing on these key components, organizations can achieve operational excellence, enhance customer satisfaction, and remain competitive in today's dynamic business landscape.

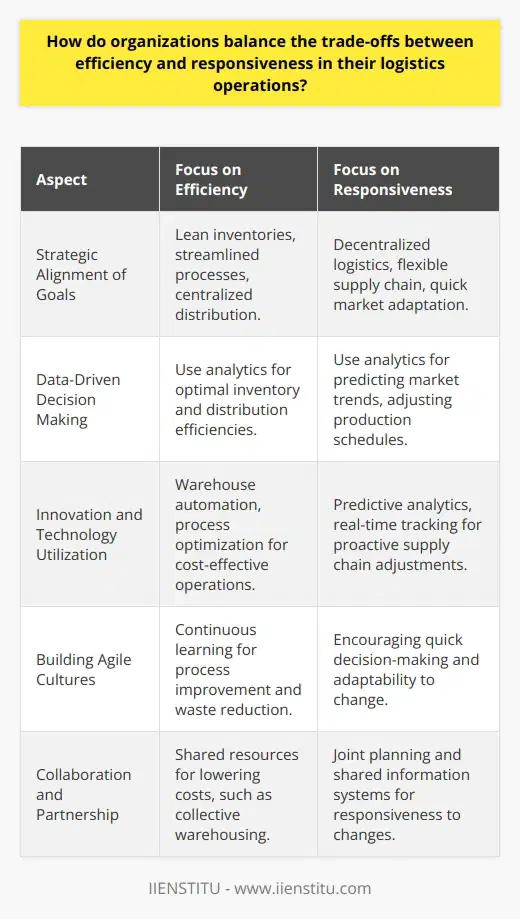

How do organizations balance the trade-offs between efficiency and responsiveness in their logistics operations?

Balancing Efficiency and Responsiveness

Organizations face a crucial challenge in managing their logistics operations: finding the optimal balance between efficiency and responsiveness. On the one hand, they must minimize costs and maximize resource utilization, but on the other hand, they need to be agile and flexible enough to respond quickly to market demands or unexpected disruptions in their supply chains.

Strategic Alignment of Goals

To address this trade-off effectively, organizations must align their logistics strategies with their overarching business goals. For instance, if a company prioritizes cost reductions, it will emphasize efficiency in its logistics operations, whereas if responsiveness to customer needs is the primary objective, supply chain flexibility becomes the focal point. By clearly identifying and prioritizing their business objectives, companies can strike the right balance between efficiency and responsiveness in their logistics operations.

Process Optimization and Synchronization

Successful balancing of trade-offs also requires process optimization and synchronization throughout the supply chain. By implementing Lean and Six Sigma methodologies and other continuous improvement tools, companies can streamline their processes, reduce waste and improve overall efficiency. Additionally, better coordination and integration of activities between suppliers, manufacturers, and customers can enhance supply chain responsiveness.

Investment in Technology

Investing in advanced technology is another key element for balancing efficiency and responsiveness in logistics operations. The use of inventory management systems, warehouse automation, and real-time data analytics can significantly enhance operational efficiency by reducing manual intervention and decision-making based on outdated information. Similarly, adopting technologies such as IoT, artificial intelligence, and machine learning can help companies monitor and predict market changes, identify potential disruptions, and promptly adapt their strategies to maintain a high level of responsiveness.

Human Capital and Expertise

Organizations must also prioritize developing human capital to effectively manage logistics operations. By providing regular training and development opportunities, companies ensure that their teams have the necessary skills and knowledge to continuously improve processes and adapt to changing market conditions. By fostering a culture of innovation, collaboration, and continuous learning, organizations can effectively juggle the conflicting objectives of efficiency and responsiveness.

In conclusion, organizations can balance the trade-offs between efficiency and responsiveness in their logistics operations by aligning their strategies with business goals, optimizing processes, investing in technology, and nurturing human capital. By skillfully managing these factors, companies can create an agile, flexible, and efficient supply chain that supports their long-term success while meeting the diverse needs of their customers.

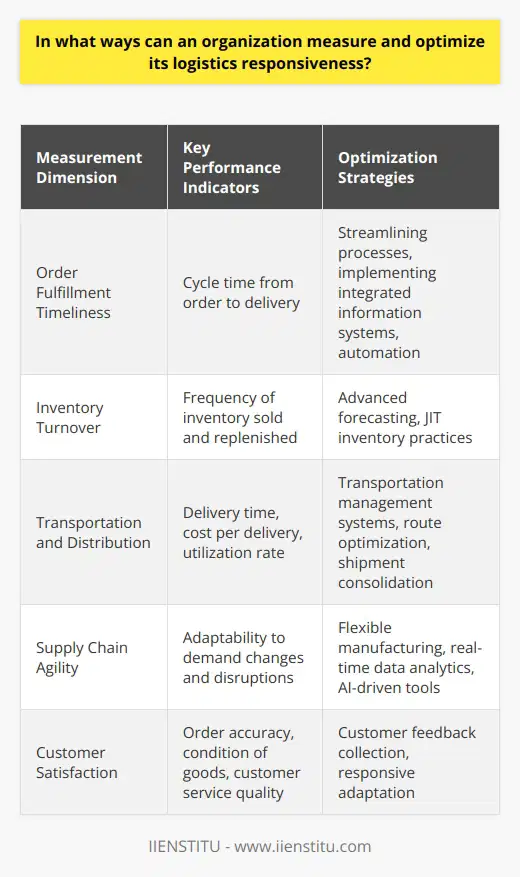

In what ways can an organization measure and optimize its logistics responsiveness?

Assessing Logistics Performance Indicators

An organization can measure its logistics responsiveness by focusing on key performance indicators (KPIs). Some essential KPIs involve analyzing order fulfillment cycles, inventory management, and transportation efficiency. By monitoring these aspects, organizations can identify areas for improvement and optimize their logistics responsiveness.

Evaluating Order Fulfillment Cycle Times

One way to measure logistics responsiveness is by evaluating order fulfillment cycle times. This refers to the time taken from receiving an order to its delivery to the end customer. Shorter cycle times indicate better responsiveness, while longer times suggest potential inefficiencies. Organizations can enhance their performance by analyzing each stage of the order fulfillment process and identifying bottlenecks to address.

Examining Inventory Management Processes

Effective inventory management is crucial for logistics responsiveness. Organizations can assess their inventory turnover ratios, which reflect the number of times inventory is sold and replaced within a given period. A higher ratio implies that the organization efficiently manages its stock and quickly responds to changes in demand. To optimize inventory management, organizations can implement demand forecasting techniques and adopt inventory control systems.

Analyzing Transportation Efficiency

Analyzing transportation efficiency helps organizations gauge their logistics responsiveness. Key indicators include transportation cost per unit, on-time delivery rates, and vehicle utilization rates. Lower costs, higher on-time rates, and better vehicle utilization show efficient transportation management. To optimize transportation efficiency, organizations can evaluate carrier performance, optimize delivery routes, and implement real-time tracking technology.

Tracking Customer Satisfaction Levels

Customer satisfaction is another aspect to consider when measuring logistics responsiveness. By analyzing metrics such as average wait time, order accuracy, and customer feedback, organizations can identify areas that impact customer satisfaction. Improving these factors can lead to enhanced logistics responsiveness, contributing to overall organizational success.

In conclusion, measuring and optimizing logistics responsiveness involves focusing on various KPIs, such as order fulfillment cycle times, inventory management, and transportation efficiency. Additionally, assessing customer satisfaction levels can provide valuable insights for continuous improvement. By addressing these aspects, organizations can enhance their logistics performance, resulting in increased efficiency and competitiveness.