In today's fast-paced business world, companies are constantly seeking ways to optimize their operations, enhance efficiency, and ultimately, drive growth. As someone who has been involved in various process improvement initiatives throughout my career, I can attest to the transformative power of this approach. In this blog post, I will delve into the concept of process improvement, share personal experiences, and provide insights on how businesses can leverage this strategy to achieve their goals.

Understanding Process Improvement

What is Process Improvement?

At its core, process improvement is a systematic approach to identifying, analyzing, and optimizing existing business processes. It involves critically examining each step of a process, eliminating inefficiencies, and implementing changes that lead to better outcomes. Whether it's reducing waste, improving quality, or increasing productivity, the goal of process improvement is to create a more streamlined and effective organization.

Why is Process Improvement Crucial for Businesses?

In my experience, businesses that prioritize continuous improvement are the ones that thrive in the long run. By constantly seeking ways to refine their processes, these organizations can:

Enhance operational efficiency

Reduce costs and minimize waste

Improve product or service quality

Boost customer satisfaction

Gain a competitive edge in the market

I vividly remember a project I worked on a few years ago where we implemented a process improvement initiative in a manufacturing company. By streamlining their production line and optimizing inventory management, we were able to reduce lead times by 30% and increase overall output by 25%. The impact on the company's bottom line was significant, and it showcased the tangible benefits of process improvement.

The Process Improvement Lifecycle

Step 1: Identify Areas for Improvement

The first step in any process improvement initiative is to identify which processes need attention. This requires a thorough understanding of the organization's operations and a keen eye for spotting inefficiencies. In my experience, engaging employees at all levels is crucial at this stage. They are often the ones closest to the processes and can provide valuable insights into pain points and potential solutions.

Step 2: Analyze and Map Out the Process

Once you have identified a process for improvement, the next step is to analyze it in detail. This involves mapping out each step of the process, gathering data, and identifying bottlenecks or areas of waste. I find that visual tools like flowcharts and value stream maps can be incredibly helpful in this phase, as they provide a clear picture of the process flow and highlight areas for improvement.

Step 3: Develop and Implement Solutions

Armed with a deep understanding of the process, the next phase is to develop and implement solutions. This is where creativity and problem-solving skills come into play. I always encourage my teams to think outside the box and challenge the status quo. Sometimes, the most effective solutions are the ones that require a complete reimagining of the process.

One of the most memorable process improvement projects I worked on involved a healthcare organization struggling with long patient wait times. By completely redesigning their appointment scheduling system and implementing a triage protocol, we were able to reduce average wait times by 50% and significantly improve patient satisfaction scores.

Step 4: Monitor and Continuously Improve

Process improvement is not a one-time event but rather an ongoing journey. Once changes have been implemented, it's crucial to monitor their impact and continuously look for ways to further optimize the process. This requires a culture of continuous improvement, where everyone in the organization is encouraged to identify opportunities for growth and share ideas.

Methodologies for Process Improvement

There are several established methodologies that organizations can adopt for their process improvement initiatives. Some of the most popular ones include:

Lean Management

Lean Management is a methodology that focuses on maximizing value for the customer while minimizing waste. It involves streamlining processes, reducing non-value-added activities, and fostering a culture of continuous improvement. I have seen Lean principles applied successfully across various industries, from manufacturing to healthcare to software development.

Six Sigma

Six Sigma is a data-driven approach to process improvement that aims to reduce defects and variability. It follows a structured problem-solving methodology known as DMAIC (Define, Measure, Analyze, Improve, Control) and relies heavily on statistical analysis. I have found Six Sigma to be particularly effective in industries where quality and consistency are paramount, such as aerospace and automotive.

Kaizen

Kaizen is a Japanese philosophy that emphasizes continuous, incremental improvements. It involves engaging all employees in the process improvement effort and encouraging them to identify small changes that can add up to significant results over time. I have seen Kaizen work wonders in creating a culture of ownership and empowerment within organizations.

Overcoming Challenges in Process Improvement

While process improvement can yield significant benefits, it's not without its challenges. Some common obstacles include:

Resistance to Change

One of the biggest hurdles in any process improvement initiative is getting people on board with the changes. Employees may be resistant to new ways of working, especially if they have been doing things a certain way for a long time. I have found that clear communication, involving employees in the process, and celebrating small wins can go a long way in overcoming resistance to change.

Lack of Resources

Process improvement initiatives often require an investment of time, money, and human resources. In resource-constrained environments, it can be challenging to justify these investments. However, I have seen that by starting small, focusing on high-impact areas, and demonstrating quick wins, organizations can build momentum and secure the necessary resources to sustain their process improvement efforts.

Sustaining Improvements

Another challenge is sustaining the improvements made through process improvement initiatives. It's not uncommon for organizations to see initial gains, only to have them erode over time as people revert to old ways of working. To combat this, I recommend establishing clear ownership and accountability for maintaining the new processes, regularly monitoring performance, and celebrating successes along the way.

Conclusion

In conclusion, process improvement is a powerful tool for driving business growth and success. By systematically analyzing and optimizing processes, organizations can enhance efficiency, reduce waste, and ultimately, improve their bottom line. However, process improvement is not a one-time event but rather an ongoing journey that requires commitment, collaboration, and a willingness to embrace change.

As someone who has witnessed the transformative power of process improvement firsthand, I encourage all business leaders to make it a priority within their organizations. By fostering a culture of continuous improvement and empowering employees to identify opportunities for growth, companies can position themselves for long-term success in an ever-evolving business landscape.

I hope this blog post has provided valuable insights and inspiration for your own process improvement journey. I would love to hear your thoughts, experiences, and success stories in the comments below. Together, let's unlock the full potential of process improvement and drive our businesses to new heights!

Frequently Asked Questions

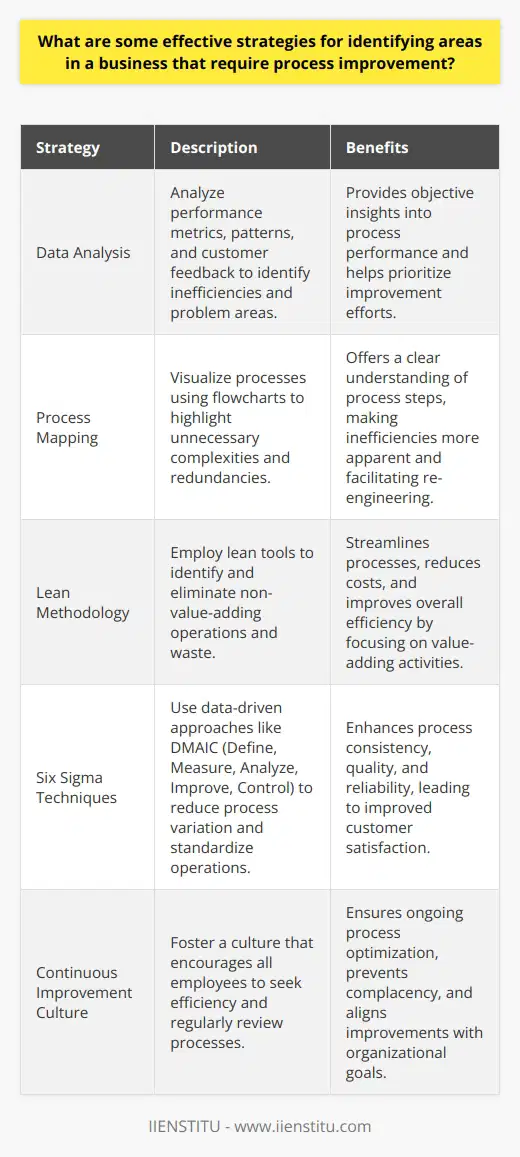

What are some effective strategies for identifying areas in a business that require process improvement?

Identifying Business Process Improvement Areas

Businesses seek constant improvement. They strive to optimize operations, enhance efficiency, and increase profitability. Identifying areas for process improvement presents a significant challenge. It requires a deep understanding of operational workflows and an ability to detect inefficiencies.

Understand Organizational Goals

Start by understanding the strategic goals. Align improvements with these objectives. Goals guide process assessment. This alignment ensures relevance and direction.

Employ Data Analysis

Data remains critical in identifying improvement areas. Analyze performance metrics. Look for patterns indicating inefficiencies. High error rates or slow task completions point to problems. Use benchmarks for performance comparison. Analyze customer feedback for direct insight into problem areas.

Conduct Employee Interviews

Employees offer valuable perspectives. They provide frontline insights into daily operations. Interview staff members. Ask about pain points and bottlenecks. Listen to their improvement suggestions. Employees often know where improvements can make a significant impact.

Map Processes

Visualize processes with flowcharts. This mapping highlights every step. It reveals unnecessary complexities and redundancies. Process maps make inefficiencies more apparent. They serve as a visual guide for re-engineering.

Apply the Pareto Principle

The Pareto Principle suggests that 80% of problems arise from 20% of causes. Identify the critical 20% within business operations. Focus improvement efforts here for substantial impacts.

Lean on the Lean Methodology

Lean methodology advocates for the elimination of waste. It targets non-value-adding operations. Employ lean tools for waste identification. These include overproduction, waiting times, and excess inventory.

Embrace Six Sigma Techniques

Six Sigma provides a data-driven approach. It focuses on reducing process variation. Use Six Sigma techniques such as DMAIC (Define, Measure, Analyze, Improve, Control). They lead to process standardization and optimization.

Implement Continuous Improvement Culture

Foster a culture of continuous improvement. Encourage all employees to seek efficiency. This culture makes process improvement an ongoing effort, not a one-time project.

Invest in Technology

Adopt technology to automate processes. Automation can significantly improve efficiency. Explore software solutions for repetitive tasks. Invest in tech that offers robust reporting capabilities.

Review Customer Satisfaction

Closely monitor customer satisfaction. Dissatisfaction often signals a flawed process. Use customer complaints as a starting point for investigation. Improved processes should aim to boost customer satisfaction.

Conduct Regular Audits

Schedule process audits regularly. They help maintain a focus on efficiency and effectiveness. Regular reviews prevent complacency. They ensure processes continue to align with organizational goals.

Benchmark Against Competitors

Compare processes with industry leaders. It offers an external perspective on performance standards. Use benchmarking to identify areas for improvement. Strive to match or exceed industry best practices.

Pilot Small Changes

Experiment with small improvements. Test new approaches on a small scale before a full rollout. Evaluate the results. Small-scale testing reduces the risk of costly mistakes.

Seek Feedback at All Levels

Involve stakeholders at all organizational levels. Collect feedback from a diverse range of perspectives. This feedback guides the prioritization of process improvements. It ensures comprehensive solutions.

In conclusion, identifying areas for process improvement requires a multifaceted approach. It involves data analysis, employee engagement, process mapping, and the application of proven methodologies. Regular reviews and stakeholder feedback further aid in pinpointing inefficiencies. By adopting these strategies, businesses can stay on the path of continuous growth and refinement.

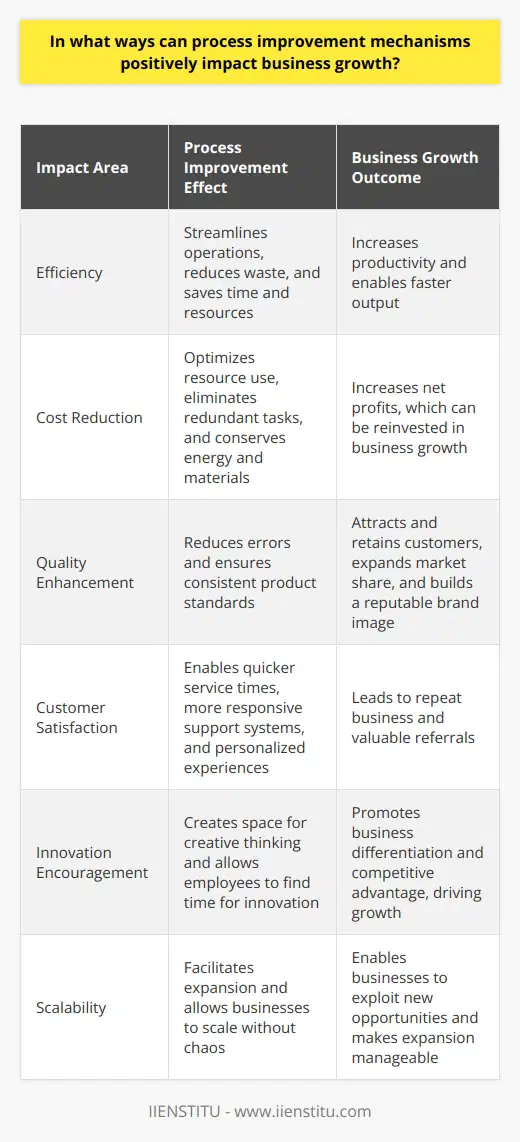

In what ways can process improvement mechanisms positively impact business growth?

Impact on Efficiency

Process improvement mechanisms streamline operations. They make workflows more efficient. This leads to faster output. Waste reduces significantly. Companies save time and resources. Efficiency boosts are crucial. They directly correlate with higher productivity.

Cost Reduction

Improved processes cut costs. They do so by optimizing resource use. Redundant tasks get eliminated. This minimizes resource waste. It also conserves energy and materials. Cost savings increase net profits. These profits can foster business growth.

Quality Enhancement

Quality is paramount. Process enhancements often focus on quality. Better processes reduce errors. They ensure consistent product standards. High-quality offerings attract customers. They also retain them. A reputable brand image forms. This can expand market share.

Customer Satisfaction

Customers demand excellence. Process improvements often target customer satisfaction. Quicker service times become possible. More responsive support systems develop. Personalized experiences increase. Happy customers lead to repeat business. They also provide valuable referrals.

Employee Morale

Employees seek meaningful work. Efficient processes eliminate tedious tasks. This boosts employee morale. Job satisfaction rises. High morale improves productivity. It also decreases turnover. A stable workforce contributes to steady growth.

Innovation Encouragement

Innovation requires a solid foundation. Efficient processes offer this. They create space for creative thinking. Employees find time for innovation. New ideas promote business differentiation. Differentiation can lead to competitive advantage. This advantage drives growth.

Scalability

Growth demands scalability. Improved processes facilitate expansion. They allow businesses to scale without chaos. Systems adapt to increased demand. This ensures smooth transitions. It enables businesses to exploit new opportunities. Expansion becomes manageable.

Regulatory Compliance

Regulations change frequently. Process improvements help maintain compliance. Compliance prevents legal issues. Legal issues can stunt growth. Effective compliance structures ease expansion. They also build trust with stakeholders.

Decision-Making

Better processes deliver better data. Quality data informs decision-making. Leaders make informed strategic choices. Wise decisions promote sustainable growth. Real-time data from efficient processes is invaluable. It enables agile responses to market changes.

Risk Management

Business involves risk. Process improvements manage risk. They identify potential failure points. Mitigation strategies become possible. Predictive approaches to risk management take shape. Anticipating setbacks keeps growth on track.

Conclusion

Process improvements are multifaceted. They influence all business aspects. Efficiency, savings, and quality surge forward. Customers and employees alike feel benefits. Innovation and scalability turn feasible. Compliance and decision-making improve. Risks reduce. Businesses grow. Each improvement step matters. Cumulatively, they ensure long-term success.

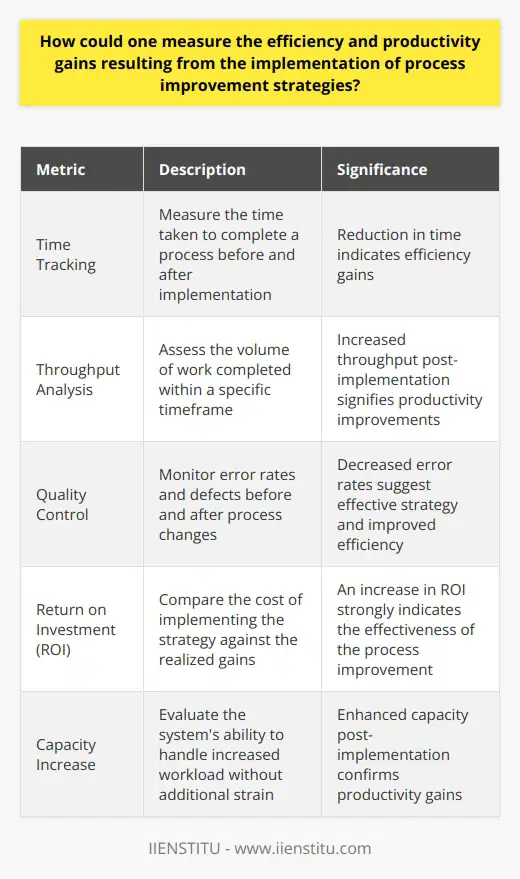

How could one measure the efficiency and productivity gains resulting from the implementation of process improvement strategies?

Measuring Efficiency and Productivity Gains

Understanding the Metrics

Productivity and efficiency represent critical aspects of performance. They reflect the effectiveness of process improvement strategies. Organizations commonly strive to enhance these metrics. They aim for better returns on time and resource investments. Thus, measuring improvements becomes essential.

Baseline Establishment

Before introducing any changes, establish a baseline. This implies documenting current performance levels. It includes capturing the throughput, the rate of output, and any prevailing inefficiencies. It sets the stage for any forthcoming comparative analysis.

Time Tracking

Time remains a universal measure of efficiency. How quickly does a process complete post-implementation? Compare this to the baseline. Any reduction in time points to efficiency gains. This approach proves simple yet effective.

Throughput Analysis

Consider the volume of work completed within a timeframe. Has this increased after the implementation? If yes, this signals productivity gains. Throughput analysis offers concrete data for comparison.

Quality Control

Do not overlook the quality aspect. Efficiency means little if quality diminishes. Thus, measure error rates before and after changes. An improvement signifies an effective strategy.

Employee Feedback

Gather insights from those involved in the processes. Do they report less strain and increased output? Their feedback can provide invaluable qualitative data. It often complements the hard metrics.

Financial Metrics

Examine the impact on the bottom line. This involves cost savings and revenue impacts. Reductions in operational costs or increases in revenue indicate success. Always correlate financial metrics to specific process changes.

Return on Investment (ROI)

Calculate the ROI from the process improvement. This compares the cost of implementing the strategy against gains. An ROI increase stands as a strong indicator of effectiveness.

Utilization Rates

Monitor the usage of resources before and after. An increase implies better productivity. It often shows more effective resource allocation.

Efficiency Ratios

Various industry-specific efficiency ratios exist. They relate inputs directly to outputs. Find the ones applicable to your domain and deploy them.

Cycle Time Reduction

Has the cycle time for processes reduced? If yes, efficiency has likely increased. This metric can prove straightforward to track and understand.

Error Reduction

Counts of mistakes or defects shed light on quality improvements. Fewer errors mean higher efficiency. It also speaks volumes about the maturation of processes.

Learning Curve Assessments

Assess how quickly teams adapt to new processes. Faster learning curves can indicate intuitive improvements. They also suggest productivity gains from reduced training times.

Capacity Increase

Can the system handle more work without additional strain? If so, the strategy likely boosted productivity. Measure increases in capacity to confirm this.

When measuring efficiency and productivity gains, utilize a combination of these metrics. They offer a comprehensive view of performance. Always remember—all measurements are comparative. They get their significance against a known standard or baseline. Hence, the rigor in establishing and maintaining baselines cannot be overstated.

In conclusion, the implementation of process improvement strategies requires careful measurement. By tracking relevant metrics, organizations can not only measure but also validate the effectiveness of their efforts. This evidence-based approach ensures continuous and strategic improvement, iron-clad with verifiable data.