Have you ever ordered something online and felt that little flutter of excitement when the package arrives at your doorstep sooner than expected? I sure have! Just last month, I ordered a handcrafted mug from a small pottery studio across the country. To my surprise, it arrived within two days, carefully packaged and exactly as described. That experience left me not only thrilled with my new mug but also impressed with the company's efficiency. This got me thinking about the crucial role of order processing in today's businesses.

Reasons why Order Processing is a Crucial Task

Tips for Improving Order Processing

The Heartbeat of Successful Businesses

Order processing isn't just a mundane task that happens behind the scenes; it's the heartbeat that keeps a business alive and thriving. In our rapidly evolving global economy, where customers expect lightning-fast deliveries and impeccable service, the way a company handles its orders can make or break its reputation.

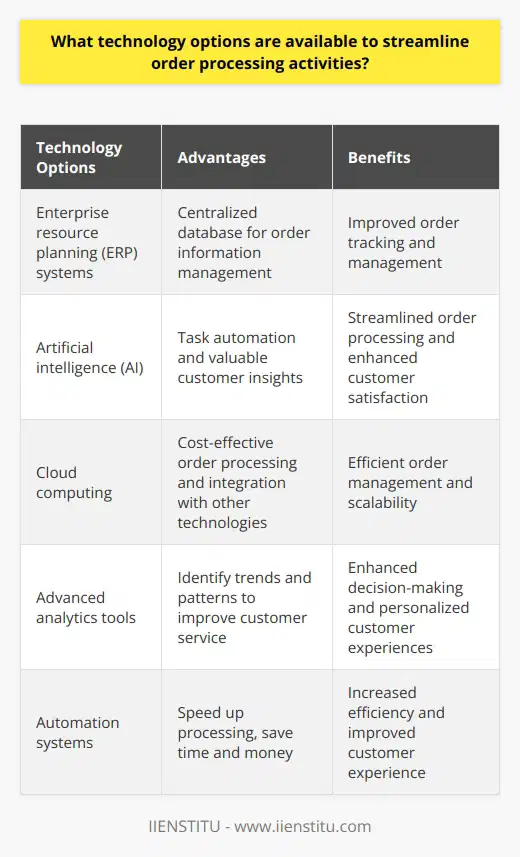

Why Is Order Processing So Important?

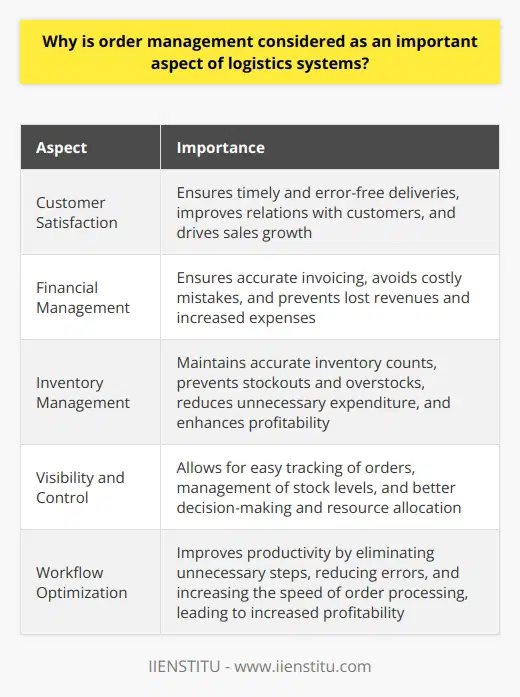

Let's dive a bit deeper into the reasons why order processing is a crucial task:

1- Enhances Customer Satisfaction: When orders are processed promptly and accurately, customers are happier. Think about that mug I received—its timely arrival made me more likely to purchase from that studio again.

Long Tail Keyword: İmpact Of Logistics On Business Performance

Supply Chain Visibility Solutions For İmproved Business Efficiency

Increased Satisfaction of Customers: Delivering orders to customers promptly and accurately leads to improved customer relations. Suppose a customer is satisfied with the order placement and delivery process. In that case, the likelihood of repeat business increases, meaning greater profitability. Furthermore, customers who provide positive feedback and advocate for a business’s products and services create an invaluable form of marketing called “word of mouth” or “social media marketing.”

Shorter Delivery Times: The time taken to complete an order is essential for customer satisfaction. Quick processing time enables customers to receive their purchases quickly, resulting in greater customer satisfaction and loyalty. Furthermore, short delivery times indicate the reliability and efficiency of the logistics operations.

Boosts Profitability: Good order processing performance is critical to increasing profitability. It helps to minimize delivery delays and improve customer experience. Order management services can also help to decrease the costs related to order processing, such as the need for paper invoicing and other documentation related to the process. By preventing order errors and minimizing paperwork, you can save money on rework and mistakes that can eat away at a company’s profits.

2- Reduces Delivery Times: Efficient order processing means products reach customers faster. In an age where two-day shipping is becoming the norm, shorter delivery times can set a business apart from its competitors.

Automated Solutions: Automation is an effective way to streamline order processing operations. Automated processes help reduce manual workloads and the cost and time to fill orders. Automated solutions can also enable companies to monitor and measure order processes more accurately. It is, therefore, essential to monitor customer orders to identify potential areas that require automation to help streamline the process.

Multi-Channel Integration: Multi-channel integration facilitates efficiency in order processing. Multi-channel approaches empower businesses to offer a seamless experience to customers. At the same time, they place orders, receive invoices and receive their products. This approach helps reduce manual processes and offers customers more flexibility in placing orders.

Data Analysis & Reporting: Companies should use data analysis to gain insights into their order processing operations. Collecting data and conducting research will help a company determine how its order fulfillment operations are performing. Such studies can reveal existing efficiency problems and areas for improvement. Companies can ensure their operations run smoothly and efficiently by implementing solutions based on such data-driven insights.

3- Boosts Profitability: By streamlining order processing, companies can save on costs associated with errors, returns, and customer service inquiries. This directly impacts the bottom line in a positive way.

4- Strengthens Brand Loyalty: Satisfied customers are more likely to become repeat buyers and recommend the business to others. This word-of-mouth marketing is invaluable and often stems from positive ordering experiences.

A well-run logistics operation depends on efficient order processing and impeccable accomplishment against the clock.

5- Minimizes Errors: An optimized process reduces the chances of mistakes like wrong shipments or billing errors, which can be costly and damage customer trust.

My Friend's Tale of Two Deliveries

A close friend of mine recently shared her contrasting experiences with two different online retailers. With the first, she ordered a dress for a special occasion. Despite ordering well in advance, the dress arrived a week late, causing her much stress and forcing her to buy a last-minute alternative. The second retailer, however, delivered her order of kitchen gadgets within 24 hours, complete with personalized thank-you notes. Guess which company she's raving about to everyone?

Tips to Optimize Order Processing

Recognizing the importance is one thing, but how can businesses improve their order processing? Here are some practical tips:

1. Embrace Automation

Automation can be a game-changer. By implementing automated systems:

Reduce Manual Errors: Automation minimizes the risk of human error in data entry or processing.

Save Time: Automated systems can process orders faster than manual methods.

Integrate Systems: Automation allows for seamless integration between inventory management, shipping, and customer service platforms.

According to Smith's "Efficiency in Modern Business" (2018), companies that adopted automation in their order processing saw a 30% increase in overall efficiency.

2. Implement Multi-Channel Integration

In today's market, customers might place orders through various channels—websites, mobile apps, social media, or even phone calls. Integrating these channels ensures that:

Consistent Customer Experience: No matter how a customer orders, their experience remains the same.

Streamlined Operations: All orders funnel into one system, simplifying processing.

Better Inventory Management: Real-time updates prevent overselling or stockouts.

3. Utilize Data Analysis & Reporting

Data is king! By analyzing order processing data:

Identify Bottlenecks: Spot where delays or errors commonly occur.

Improve Forecasting: Predict busy periods and adjust staffing or inventory accordingly.

Enhance Decision Making: Make informed choices about process improvements.

As highlighted in Johnson's "Data-Driven Strategies" (2020), businesses leveraging data analytics in their operations often see a 20% improvement in customer satisfaction scores.

Real-World Applications

Adopting an Optimized Supply Chain

Companies looking to optimize supply chain management process tips should consider:

1- Vendor Collaboration: Working closely with suppliers can streamline order fulfillment.

2- Inventory Management Systems: Implementing robust systems to keep track of stock levels.

3- Continuous Improvement: Regularly reviewing processes to find areas for enhancement.

Overcoming Challenges

Implementing these strategies isn't without challenges:

Initial Costs: Investing in new technology or systems can be expensive upfront.

Employee Training: Staff may need training to adapt to new processes.

Resistance to Change: It's natural for teams to be hesitant about overhauling familiar systems.

However, the long-term benefits often outweigh these initial hurdles. As the ancient Chinese philosopher Lao Tzu said, "The journey of a thousand miles begins with a single step."

Personal Reflection

I recall when I worked part-time at a local bookstore during college. We prided ourselves on knowing our regulars and providing personalized recommendations. However, our order processing was outdated. We'd manually check stock, write down orders, and sometimes orders got misplaced. Eventually, the store invested in an automated system. At first, we were skeptical—would this impersonal system change our quaint shop's vibe? But instead, it enhanced our ability to serve customers, reduced errors, and gave us more time to interact with shoppers. It was a win-win!

Conclusion

In essence, order processing is more than just moving products from point A to point B. It's about building trust, ensuring satisfaction, and creating a seamless experience that keeps customers coming back. By embracing automation, integrating multiple channels, and utilizing data analytics, businesses can significantly enhance their operations.

For any company aiming to thrive in today's competitive market, focusing on optimizing their supply chain management processes is not just advisable—it's essential. After all, in the words of renowned business strategist Peter Drucker, "Efficiency is doing things right; effectiveness is doing the right things." Combining both in order processing can propel a business to new heights.

References

Smith, J. (2018). Efficiency in Modern Business. New York, NY: Business Publishing.

Johnson, L. (2020). Data-Driven Strategies. Boston, MA: Analytics Press.

Drucker, P. (1993). Management: Tasks, Responsibilities, Practices. New York, NY: HarperBusiness.

Frequently Asked Questions

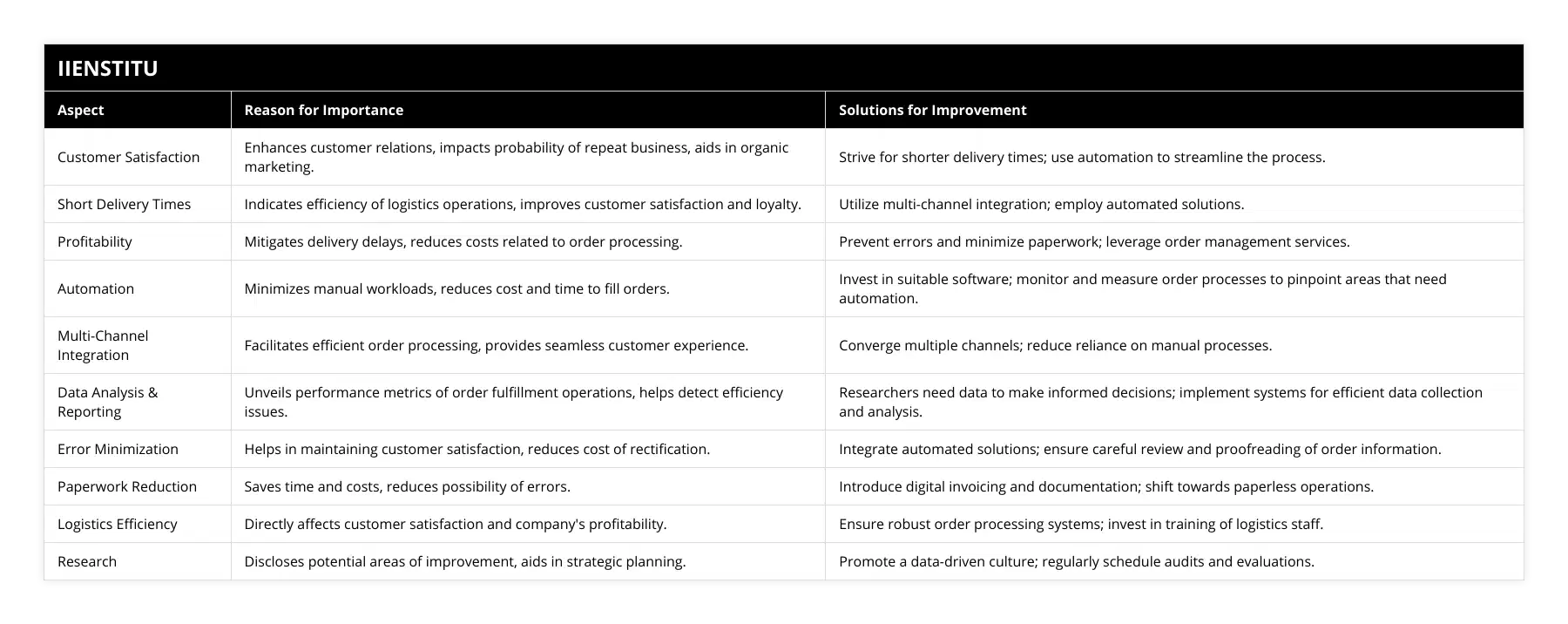

How can order processing be standardized within a logistics operation?

Standardizing the order processing within a logistics operation is an essential element of a successful supply chain; to improve the performance, efficiency, and accuracy of the order and delivery process. However, order standardization can become a complex process and requires an effective system to be implemented. Therefore, this article will discuss the different approaches to order processing standardization and how they can be used to ensure a successful logistics operation.

The system of order processing standardization involves establishing set processes and procedures to organize and track the order-taking, shipping, receiving, and delivery operations. This makes logistics operations more efficient and accurate while providing customers with the best possible experience.

The first approach to standardization of order processing involves centralized systems and databases. This ensures that the order information, including item numbers, descriptions, quantities, and applicable taxes and fees, is accurate, consistently updated, and easily accessible. This data is then linked to the appropriate customer orders, allowing for greater control and accuracy of the order and delivery process. Centralized systems, such as automated inventory tracking and accounting systems, can also automate certain functions to improve efficiency and increase accuracy.

In addition to centralized systems, other approaches for order processing standardization include barcode technology. Barcode scanners can track orders in real-time, allowing for quicker and more accurate order processing. This helps to reduce errors and delays within the order process. Furthermore, barcodes can provide visibility into the order process so that the order can be tracked to ensure the correct items and quantities are shipped to the right location.

Finally, a logistics operation can seek to develop customer-oriented processes to ensure a more efficient and accurate order process. This enhances customer service by further streamlining order tracking, communication, and customer service processes. This allows the customer to be kept informed of their order status, as well as informing them of any potential delays. It also provides customer feedback to be easily integrated into the understanding process so that the order requirements can be more accurately met.

To summarize, the approach to order processing standardization can significantly impact the overall performance of a logistics operation. Significant improvements can be made in the order and delivery process through centralized data systems, barcode technology, and customer-oriented processes. With suitable systems, a logistics operation can provide customers with a smoother and more accurate delivery experience.

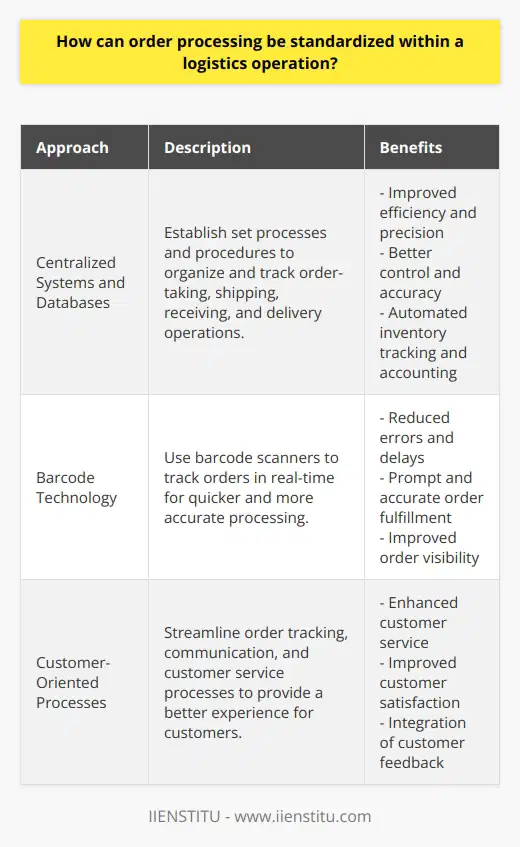

What technology options are available to streamline order processing activities?

.The world of e-commerce has brought a revolutionary change to how businesses operate in the 21st century. It has enabled companies to cut costs, save time, and increase productivity by utilizing technology for order processing activities. This article discusses the various technology options available to streamline order processing activities.

One of the most popular technologies used in order processing is enterprise resource planning (ERP) systems. These systems provide a central database from which order information such as product availability, pricing, customer identification, and order status can be managed and tracked. Additionally, ERP systems offer inventory management and logistics control, making order processing much more efficient.

Artificial intelligence (AI) can also help streamline order processing activities. For example, AI can help identify purchase patterns among customers, predict demand and inventory levels, automate order processing tasks, and accurately recommend relevant products and services to customers. By leveraging AI, businesses can gain insights into customer behaviors and preferences, improving customer experience and increasing sales.

Cloud computing is another technology option available to streamline order processing activities. Cloud computing enables companies to process large volumes of orders cost-effectively. Additionally, cloud systems can be connected to other methods, such as ERP and AI, for greater efficiency and improved customer experiences. Cloud solutions can also reduce order processing time and cost by automatically capturing data and routing orders to the appropriate staff.

Advanced analytics tools are another technology option available to help streamline order processing activities. These tools can identify order trends and patterns and predict customer preferences and future demand. Advanced analytics can also be used to develop customized solutions to order processing issues and improve customer service.

Finally, automated systems often handle order processing tasks such as order entry, processing, delivery, and returns. As a result, automation allows businesses to rapidly and accurately process orders, save time and money, and improve customer experiences.

Technology options like ERP systems, AI, cloud computing, and advanced analytics tools allow businesses to streamline order processing activities and improve efficiency and productivity. By leveraging such technologies, companies can reduce order processing times and costs, minimize manual processing errors, and improve customer experiences.

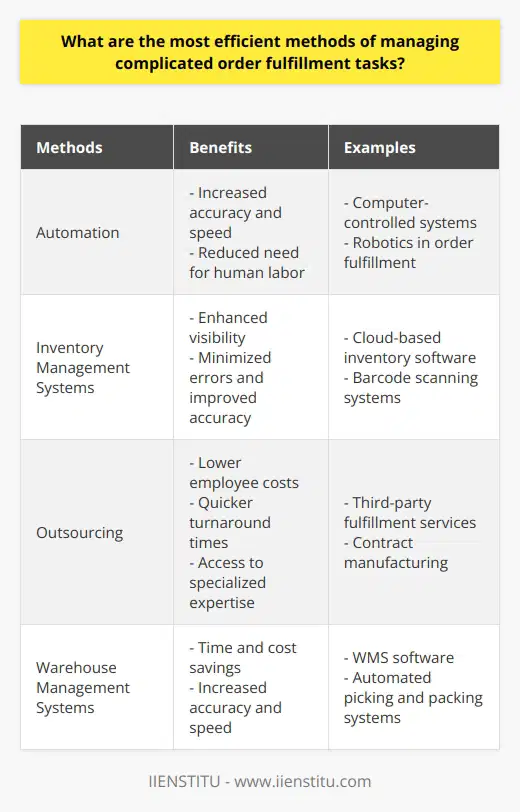

What are the most efficient methods of managing complicated order fulfillment tasks?

Ensuring that the most efficient methods are used to maximize productivity is essential when managing complex tasks. This article explores the various approaches that can be used when managing complicated order fulfillment tasks.

One efficient method of managing complicated order fulfillment tasks is to employ automation. Automation refers to the use of computer-controlled systems to carry out time-consuming tasks. Automation enables complex tasks to be executed with much greater accuracy and speed than that which would have been possible without the use of technology. Furthermore, it can reduce the amount of human labor required and, therefore, diminish employee costs while increasing the accuracy and speed of the order fulfillment process.

Another efficient method of managing complicated order fulfillment tasks is to use inventory management systems. Such systems allow the information within the order fulfillment process to be easily organized, tracked, and managed. As a result, inventory management systems make the order fulfillment process more efficient. In addition, they can reduce the risk of errors by providing enhanced visibility into the ordering and fulfillment process.

A third approach that can be used when managing complicated order fulfillment tasks is to outsource the job to a third party. Outsourcing is the practice of transferring the responsibility of a study to an external provider. By outsourcing, companies can benefit from lower employee costs and quicker turnaround times. Furthermore, by outsourcing, companies can access the resources and expertise of experienced third-party providers, allowing them to ensure that the task is completed efficiently and on time.

Finally, companies may consider utilizing warehouse management systems when managing complicated order fulfillment tasks. These systems provide the information and automation needed to address the storage, receipt, and dispatch of goods more efficiently. By automating tasks such as inventory tracking, receiving, stocking, and fulfillment, warehouse management systems can drastically reduce time and money spent on satisfaction while increasing accuracy and speed.

In conclusion, there are a variety of methods that can be used to manage complicated order fulfillment tasks. For example, automation, inventory management systems, outsourcing, and warehouse management systems can help ensure that the order fulfillment process is completed efficiently, cost-effectively, and timely. Therefore, companies should consider these methods when managing complex order fulfillment tasks.

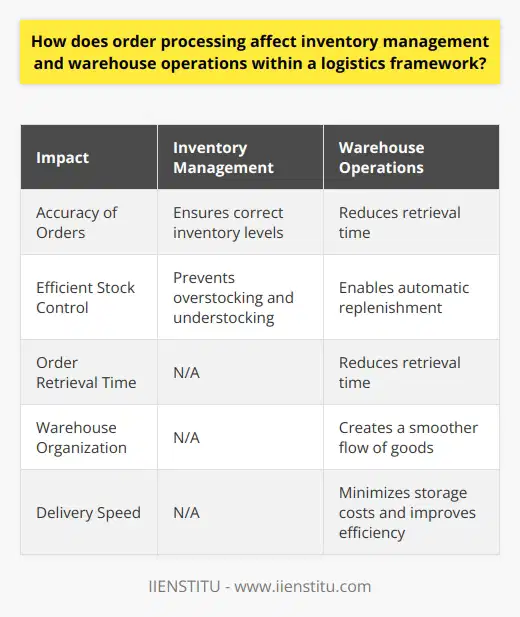

What is the role of order processing in logistics?

Role of Order Processing in Logistics

Significance of Order Processing

Order processing plays a crucial role in logistics as it serves as the backbone that supports the efficient flow of goods from suppliers to customers. This function is responsible for managing customer orders and ensuring that all required documentation is accurately completed to facilitate a smooth flow of products and services throughout the supply chain.

Emphasis on Customer Satisfaction

In logistics, customer satisfaction is essential, and one of the primary areas where this satisfaction can be achieved is through effective order processing. Efficiently managing customer orders helps achieve quick and accurate deliveries resulting in satisfied customers. Furthermore, prompt order processing reduces lead times and enhances the overall customer experience, leading to increased customer retention and brand loyalty.

Integration with Inventory Management

Order processing is closely connected with inventory management, as processing customer orders has a direct impact on stock levels. An effective order processing system helps maintain optimal inventory levels by making sure that the stock is replenished on time and in the appropriate quantities. Proper inventory management leads to the prevention of stockouts or overstocking, avoiding potential disruptions in the supply chain and meeting customer demands timely.

Automation and Technology

Automation and technology advancements have revolutionized order processing in logistics, streamlining operations, and reducing manual errors. The implementation of technologies such as Electronic Data Interchange (EDI) and Enterprise Resource Planning (ERP) systems facilitates seamless communication between different logistic entities. This synchronizes processes like order management, shipping, and invoicing – overall improving efficiency, cutting down costs, and strengthening relationships with suppliers and customers alike.

Impact on Profitability

Efficient order processing enables logistics companies to optimize operational efficiency and minimize costs. Faster order processing reduces order cycle times and improves cash flow, while minimizing instances of returns or rejections due to errors in documentation or shipment execution. These enhancements in the order processing system positively influence the organization's profitability and competitiveness in the market.

In conclusion, order processing significantly impacts logistics operations by ensuring customer satisfaction, maintaining inventory accuracy, and improving profitability. Leveraging technology and integrating order management systems can further enhance its effectiveness and enable a seamless supply chain operation, critical for surviving and thriving in the competitive logistics industry.

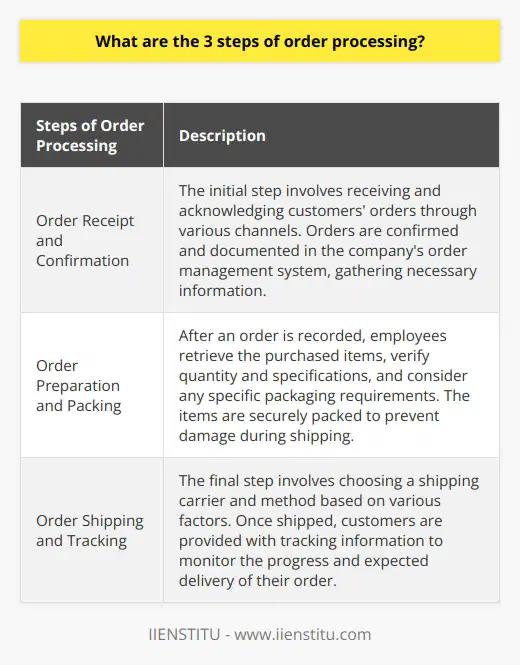

What are the 3 steps of order processing?

Introduction of Order Processing

Order processing is a crucial aspect of any business, as it facilitates the efficient handling and fulfillment of customer orders. The process consists of three main steps: (1) order receipt and confirmation, (2) order preparation and packing, and (3) order shipping and tracking.

Order Receipt and Confirmation

The first step in order processing involves receiving and acknowledging customers' orders. This can happen through various channels, such as phone calls, emails, or online forms. When an order is received, it must be swiftly confirmed and recorded in the company's order management system. It is essential to ensure that all necessary information is collected, such as customer contact details, shipping address, and product specifications—this enables businesses to accurately execute subsequent steps.

Order Preparation and Packing

Once an order is recorded in the system, it moves to the preparation stage. Employees collect the purchased items from inventory or warehouse shelves and ensure the correct quantity and specifications. Any specific packaging requirements, such as gift wrapping or special handling instructions, must be taken into account during this step. Finally, the items are packed securely, with appropriate materials to protect from damage during shipping. Proper packing is essential to maintain product quality and customer satisfaction.

Order Shipping and Tracking

The final step of the order processing involves shipping the prepared packages to customers. The choice of shipping carrier and method depends on factors such as delivery location, speed requirements, and shipping costs. Once the order is shipped, businesses typically provide customers with tracking information, allowing them to monitor their order's progress and expected delivery date. Continuous communication ensures the customers are well-informed and helps build trust and confidence in the company's services.

Conclusion

In sum, the three fundamental steps of order processing are receiving and confirming the order, preparing and packing the ordered items, and shipping the package with tracking information. Following these steps diligently ensures timely delivery, product quality, and customer satisfaction. Companies must continuously optimize and streamline their order processing system to strengthen their competitiveness and maintain strong customer relationships.

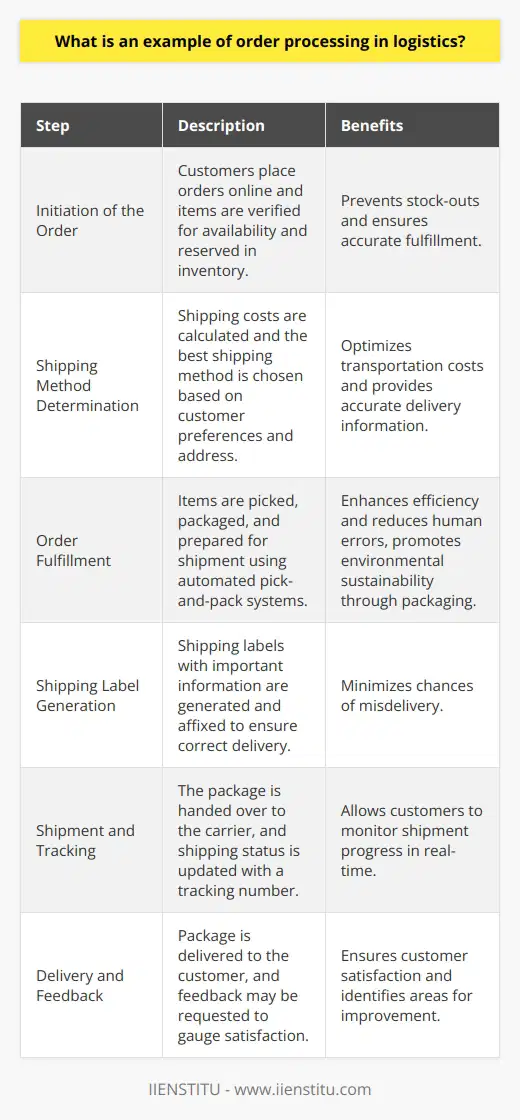

What is an example of order processing in logistics?

Order Processing in E-commerce

An example of order processing in logistics can be observed in the e-commerce sector, specifically through the operations of online retail platforms such as Amazon. Order processing in e-commerce involves a series of interconnected steps that ensure customers' orders are efficiently and accurately fulfilled.

Initiating Order Processing

First, the customer places an order online for one or more items. Once the order is submitted, the e-commerce platform verifies the availability of the purchased items and reserves them from the inventory. In doing so, it helps prevent stock-outs and customer dissatisfaction.

Determining Shipping Methods

Next, the order processing system calculates the shipping costs and determines the best shipping method based on the customers' preferences and delivery address. This step optimizes transportation costs and estimates delivery times, providing accurate information to the shopper.

Order Fulfillment and Packaging

Subsequently, the order items are picked from the inventory and packaged for shipment. Often automated pick-and-pack systems are employed to reduce human errors and enhance efficiency in large warehouses. The packaging materials used are designed to protect the goods during transit and promote environmental sustainability.

Generating Shipping Labels

Shipping labels containing information such as the consignee's address, package content, and shipping instructions are generated and affixed to the package. This step ensures that the shipment reaches the correct recipient through an error-free labeling system.

Shipping and Tracking

The packaged order is then handed over to the selected carrier, who transports the package to the customer's designated address. Meanwhile, the order processing system updates the shipping status and provides a tracking number, allowing the customer to monitor their shipment in real-time.

Final Delivery and Feedback

Finally, the order arrives at the customer's doorstep, ready for unboxing and use. Post-delivery, the e-commerce platform may request customers to provide feedback or rate their shopping experience. This helps gauge customer satisfaction and identify areas for improvement in the entire order processing cycle.

In conclusion, order processing in logistics is an integral aspect of e-commerce operations, ensuring customer satisfaction and maintaining a seamless supply chain. By implementing efficient order processing systems, online retail platforms like Amazon can deliver products in a timely and accurate manner, contributing to their success and reputation in the market.

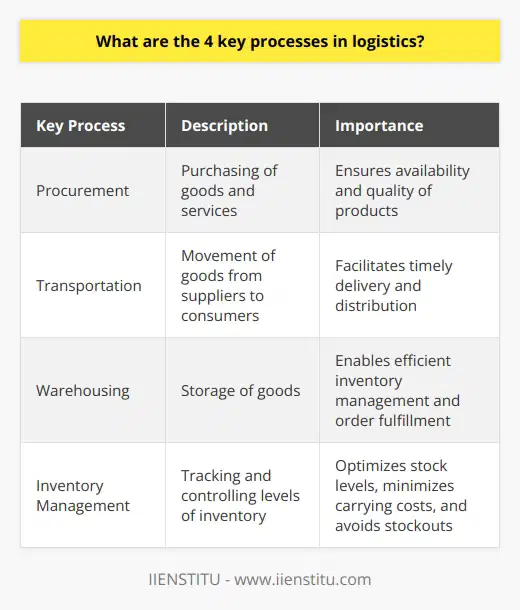

What are the 4 key processes in logistics?

Key Process 1: Procurement

The first key process in logistics is procurement, which involves the purchasing of goods and services to meet the demands of businesses and consumers. In this process, companies identify, source, and procure high-quality materials and services necessary for their operations. Procurement activities involve activities such as supplier selection, negotiations, order placement, and monitoring of delivery schedules.

Key Process 2: Transportation

Transportation is a critical process in logistics, ensuring the movement of goods from suppliers to manufacturers, distributors, retailers, and ultimately, to consumers. This process includes the planning and execution of various modes of transport, such as trucking, rail, air, and shipping to efficiently move goods from point A to point B. Efficient transportation management involves optimizing routes, carriers, and transport modes to minimize costs and ensure timely delivery of goods.

Key Process 3: Warehousing

Another crucial process in logistics is warehousing, which refers to the storage of goods between production and distribution stages. Warehousing activities help businesses maintain a continuous supply of products, manage fluctuations in demand, and support order fulfillment operations. Effective warehousing management includes proper storage methods, inventories, order-assembly systems, and warehouse location to optimize accessibility to goods, reduce costs, and improve customer satisfaction.

Key Process 4: Inventory Management

Lastly, effective logistics includes the process of inventory management, which involves tracking and controlling the levels of raw materials, work-in-process items, and finished goods throughout the supply chain. Inventory management aims to maintain a balance between overstocking (which can increase carrying costs and the risk of product obsolescence) and stockouts (which may lead to lost sales and customer dissatisfaction). This process involves elements such as demand forecasting, safety stock calculations, reorder points, and just-in-time inventory systems.

In conclusion, the four key processes in logistics – procurement, transportation, warehousing, and inventory management – are critical for businesses to maintain a smooth and efficient supply chain. When these processes are effectively managed and coordinated, companies can reduce costs, increase customer satisfaction, and adapt to market fluctuations.

How do order processing systems improve customer satisfaction in logistics management?

Order Processing System Efficiency

Order processing systems play a crucial role in logistics management by enhancing efficiency, speed, and accuracy. These systems automate and streamline the process of receiving, fulfilling, and tracking customer orders. As a result, businesses can reduce errors, save time, and optimize resources, ultimately leading to improved customer satisfaction.

Reduced Order Errors

Effective order processing systems minimize human error by automating routine tasks. Consequently, the risk of errors, such as duplicate orders, incorrect product selection, or inaccurate customer information, decreases considerably. As customers receive the correct products delivered to the right address, their satisfaction levels rise.

Shorter Order Fulfillment Time

One of the primary concerns for customers during online transactions is the speed of order fulfillment. A well-designed order processing system reduces processing time by automating various stages in the fulfillment process, from order placement to shipment. This accelerated process enables customers to receive their products sooner, enhancing their overall shopping experience.

Real-Time Order Tracking

Order processing systems often provide real-time tracking capabilities, increasing transparency in the delivery process. Customers can monitor the progress of their orders, fostering confidence in the efficiency of logistics management. Furthermore, real-time tracking allows businesses to address potential issues proactively, avoiding negative customer experiences.

Personalized Customer Experiences

Modern order processing systems can integrate customer data with order information, creating personalized customer experiences. This data-driven approach enables businesses to tailor their services to individual customer preferences, such as customizing shipping options or offering targeted promotional discounts. Personalized customer experiences further elevate satisfaction levels and build brand loyalty.

Easier Returns and Refunds

An efficient order processing system also streamlines the return and refund processes by automating documentation and communication procedures. By making the returns process more accessible, customers can easily submit requests and receive prompt resolution, resulting in higher satisfaction levels.

In conclusion, order processing systems contribute significantly to customer satisfaction in logistics management by optimizing efficiency, reducing errors, and enhancing personalized experiences. These factors combine to create a seamless, enjoyable purchasing process for customers, fostering trust and loyalty in businesses that invest in effective logistics management practices.

Can you provide an overview of the various components involved in order processing within a logistics network?

Order Processing Components

To understand order processing within a logistics network, it is crucial to examine the various components involved. These components are interconnected, working together to ensure the effective flow of products from the point of order placement to the final delivery destination.

Customer Management

The first component involves managing customer relationships and requirements. This includes efficiently handling customer orders, ensuring prompt response times, and providing clear communication channels to address customer queries and concerns.

Inventory Management

A critical aspect of order processing is managing inventory to guarantee product availability. This encompasses demand forecasting, effective stock replenishment, and maintaining adequate safety stock levels. Regular inventory audits and the use of inventory management software can aid in preventing stockouts and overstocks.

Order Entry and Verification

Once a customer places an order, entry into the system and verification are essential to confirm product availability and customer details. This step may involve manual data input or automation through an integrated order management system.

Order Fulfillment

Fulfilling customer orders involves picking the products from the warehouse, packaging them securely, and preparing them for shipment. Efficiently organizing warehouse layout and implementing technologies, such as barcode scanning and warehouse management systems, can enhance the accuracy and speed of this process.

Shipping and Transportation

Selecting an appropriate shipping and transportation option is crucial to delivering orders to customers on time. This involves coordinating with various carriers, negotiating the best shipping rates, and selecting the optimal delivery routes.

Order Tracking and Delivery

Customers expect timely and accurate order tracking information, making this a vital component of the order processing system. Fulfilling this expectation requires effective communication between various parts of the logistics network and providing customers with real-time status updates on their orders.

Returns Management

Finally, an effective return management process must be in place to handle any returned items. This includes efficiently processing returns, refunding customers when necessary, addressing issues causing returns, and restocking returned inventory.

In summary, these components collectively work towards a streamlined and efficient order processing system within a logistics network. Emphasis on customer management, inventory control, and effective communication across various stages helps ensure customer satisfaction and optimize resources within the logistics ecosystem.

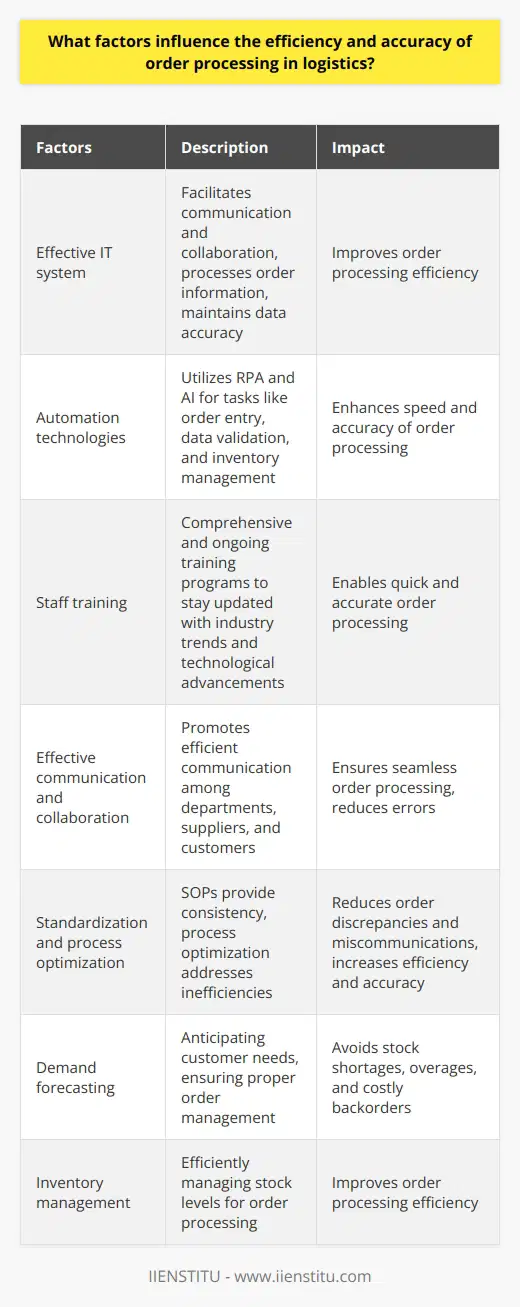

What factors influence the efficiency and accuracy of order processing in logistics?

Factors Influencing Order Processing Efficiency

Several factors contribute to the efficiency and accuracy of order processing in logistics. Firstly, an effective information technology (IT) system is crucial in streamlining communication and collaboration between all parties involved. The IT system should efficiently process order information and maintain data accuracy, thereby reducing manual errors and duplications.

Role of Automation

The adoption of automation technologies such as robotic process automation (RPA) and artificial intelligence (AI) can significantly enhance the speed and accuracy of order processing. Automation tools can assist in tasks like order entry, data validation, and inventory management, leading to reduced human intervention and improved productivity.

Quality of Staff Training

Properly trained staff members can ensure operational efficiency and order accuracy. Comprehensive and ongoing training programs help employees stay abreast of industry trends, technological advancements, and relevant skills. Adequate staff training enables quick and accurate order processing due to the acquisition of competent knowledge and expertise.

Effective Communication and Collaboration

Communication and collaboration between departments, suppliers, and customers are vital in order processing accuracy. Cross-functional collaboration eliminates information siloes, fosters teamwork, and reduces the likelihood of errors. Efficient communication channels like enterprise resource planning (ERP) systems can effectively track and manage orders and inventory levels.

Standardization and Process Optimization

The standardization and optimization of processes and procedures within the supply chain are essential in improving order processing efficiency. Standard operating procedures (SOPs) provide a consistent framework for staff to follow, reducing order discrepancies and miscommunications. Process optimization, on the other hand, involves continuous analysis and improvement of current workflows, leading to increased efficiency and accuracy.

Demand Forecasting and Inventory Management

Accurate demand forecasting and proper inventory management directly influence the effectiveness and efficiency of order processing. Demand forecasting helps organizations anticipate customer needs, enabling better preparation for order management. Effective inventory management ensures the balance of stock levels, reducing stock shortages, overages, and costly backorders.

While several factors impact the efficiency and accuracy of order processing, embracing advancements in IT and automation, providing quality staff training, and maintaining effective communication are vital. Additionally, standardization, process optimization, demand forecasting, and inventory management play essential roles in enhancing order processing in logistics.

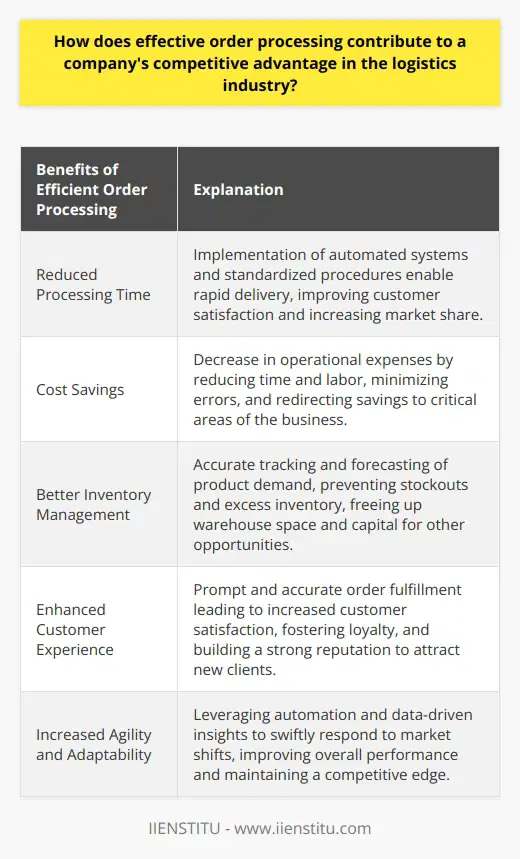

How does effective order processing contribute to a company's competitive advantage in the logistics industry?

**Efficient Order Processing: A Key to Competitive Advantage**

Effective order processing plays a crucial role in ensuring a company's success in the highly competitive logistics industry. By streamlining the flow of products and information between businesses, efficient order handling enables firms to meet customer demands promptly and accurately.

**Reduced Processing Time**

One of the primary benefits of efficient order processing is the reduction in processing time. By implementing automated systems and standardized procedures, companies can significantly expedite the steps involved in receiving, picking, packing, and shipping goods. As a result, they can meet customer expectations of rapid delivery, which translates into improved customer satisfaction and increased market share.

**Cost Savings**

Efficient order processing also contributes to cost savings. By reducing the time and labor involved in handling orders, companies can decrease operational expenses. Moreover, optimized processes help minimize errors and mitigate the need for costly returns or rework. These savings can be directed towards other critical areas of the business, such as innovation or market expansion.

**Inventory Optimization**

An effective order management system contributes to better inventory management. By accurately tracking and forecasting product demand, companies can maintain optimal inventory levels, avoiding both stockouts and excess inventory. Properly managed inventory ensures a continuous flow of goods to customers while freeing up warehouse space and capital for other opportunities.

**Enhanced Customer Experience**

Efficient order processing directly influences the overall customer experience. By promptly and accurately fulfilling orders, companies can boost customer satisfaction and foster long-term loyalty. A positive customer experience also helps to build a strong reputation, which is crucial in attracting new clients and sustaining a competitive edge in the industry.

**Increased Agility and Adaptability**

Finally, efficient order processing enhances a company's adaptability and agility in navigating the dynamic logistics landscape. By leveraging automation and data-driven insights, companies can swiftly respond to market shifts, improve their overall performance, and maintain a competitive edge in the face of ever-changing customer demands and industry pressures.

In conclusion, by adopting efficient order processing practices, logistics companies can achieve significant competitive advantages in terms of reduced processing time, cost savings, inventory optimization, enhanced customer experiences, and increased agility. These factors ultimately contribute to a firm's long-term success and ability to thrive in the fast-paced logistics industry.

In what ways can data analytics be utilized to optimize order processing operations within a logistics framework?

Importance of Data Analytics

Data analytics plays a crucial role in optimizing order processing operations within a logistics framework. By employing data analytics techniques, organizations can gain a better understanding of the various factors that affect their order processing operations, thereby enabling them to optimize these processes for improved efficiency and cost savings.

Improving Forecasting Accuracy

One of the ways data analytics can be utilized in logistics is by improving forecasting accuracy. Accurate forecasting is crucial for companies to manage inventory levels, plan for changing demand patterns, and reduce instances of stockouts or overstocking. With the help of historical data and advanced algorithms, data analytics can help organizations refine their forecasting models, leading to better inventory management and more efficient order processing.

Identifying Bottlenecks and Enhancing Efficiency

Data analytics can also identify bottlenecks and inefficiencies within the order processing operations. By analyzing patterns in large datasets, companies can uncover hidden inefficiencies or areas for improvement related to the movement of goods, warehouse management, or labor allocation. Once these bottlenecks are identified, organizations can implement targeted solutions to minimize these inefficiencies, resulting in a smoother and more efficient order processing system.

Streamlining Transportation and Routing

Another area where data analytics can aid in logistics optimization is transportation and routing. By gathering data on shipment and delivery routes, organizations can analyze this information to identify the most efficient routes, factoring in aspects such as fuel consumption, distance, and traffic patterns. This, in turn, can lead to reduced costs, faster delivery times, and improved customer satisfaction.

Enhancing Collaboration and Decision-Making

Finally, data analytics can facilitate better collaboration and decision-making across the supply chain. By providing a clear and actionable view of the relevant data, organizations can make informed decisions, collaborate more effectively with partners and vendors, and ultimately, operate in a more streamlined and efficient manner.

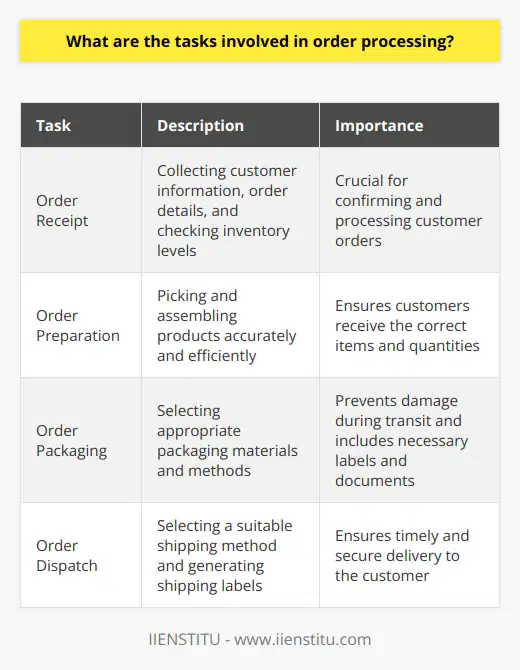

What are the tasks involved in order processing?

Understanding Order Processing Tasks

The process of order fulfillment encompasses several indispensable tasks that ensure efficient delivery of products to customers. These tasks can be broadly categorized into four stages: order receipt, order preparation, order packaging, and order dispatch.

Stage 1: Order Receipt

The first task in order processing is receiving and recording customer orders. This involves collecting essential information such as the customer's name, contact details, delivery address, item specifications, and payment details. Additionally, inventory levels must be checked to ensure product availability before confirming the order.

Stage 2: Order Preparation

Once confirmed, the order moves into the preparation phase, which includes picking and assembling the products. This step may involve identifying the location of items within a warehouse, retrieving them, and preparing them for packaging. This task requires accuracy and efficiency to ensure that customers receive the correct items and quantities.

Stage 3: Order Packaging

Upon completion of order preparation, the items need to be packed securely to prevent damage during transit. This task involves selecting appropriate packaging materials and methods that ensure the safety and integrity of the products. Additionally, packaging labels, such as shipping and handling instructions, must be attached, and an invoice or packing slip must be included.

Stage 4: Order Dispatch

The final task in the order processing workflow is dispatching the packaged orders. This entails selecting a suitable shipping method based on factors such as destination, speed, and cost. Once a carrier is chosen, the shipping labels must be generated and attached to the packages, and the shipment must be handed over to the carrier for delivery to the customer.

In conclusion, order processing tasks are crucial for ensuring smooth and efficient fulfillment of customer orders. By completing each of these tasks accurately and efficiently, businesses can optimize their supply chain operations, ensure customer satisfaction, and ultimately improve their overall competitiveness in the market.

Which are the crucial activities involved in logistics?

Crucial Activities in Logistics

Supply Chain Network Design

A crucial activity in logistics involves the development of an optimized and efficient supply chain network. This entails determining the ideal location of facilities, transportation routes, and inventory storage points, ensuring the smooth flow of goods and reducing overall costs.

Inventory Management

Properly managing inventory is essential in minimizing stockouts and reducing unnecessary expenses. This involves monitoring stock levels, implementing demand forecasting techniques, and maintaining appropriate margin of safety stocks to ensure timely fulfillment of customer orders.

Transportation Management

An effective transportation management strategy helps in optimizing freight movement by selecting the most cost-effective mode of transportation, consolidating shipments, and negotiating contracts with carriers. It also involves implementing real-time tracking systems to enhance visibility and improve overall supply chain performance.

Warehousing and Storage

Efficient warehousing and storage solutions contribute significantly to logistics success. These activities include designing warehouse layouts, implementing warehouse management systems, and employing best practices for inventory control, such as the First-In, First-Out (FIFO) method, which minimizes product obsolescence and spoilage.

Order Fulfillment and Customer Service

Timely order fulfillment and excellent customer service are vital in achieving customer satisfaction and loyalty. Logistics professionals must develop strategies for effective order processing, accurate picking and packing, and prompt delivery of goods. In addition, they need to address customer queries and resolve issues promptly to enhance customer relationships.

Information Technology Integration

Integrating information technology (IT) solutions in logistics management, such as using Enterprise Resource Planning (ERP) systems or Transportation Management Systems (TMS), significantly improves operational efficiency. Harnessing IT solutions enables logistics providers to automate processes, enhance visibility and communication, and facilitate real-time decision-making through data analytics.

Risk Management and Contingency Planning

Identifying and mitigating potential risks in the supply chain is a critical aspect of logistics management. This involves assessing vulnerabilities, conducting scenario analyses, and developing contingency plans for potential disruptions, such as natural disasters, geopolitical events, or supplier failures.

In conclusion, logistics professionals must address several crucial activities to ensure a smooth, efficient, and cost-effective supply chain. These activities include network design, inventory management, transportation management, warehousing and storage, order fulfillment and customer service, information technology integration, and risk management and contingency planning. When executed effectively, these activities contribute to a streamlined and successful logistics process.

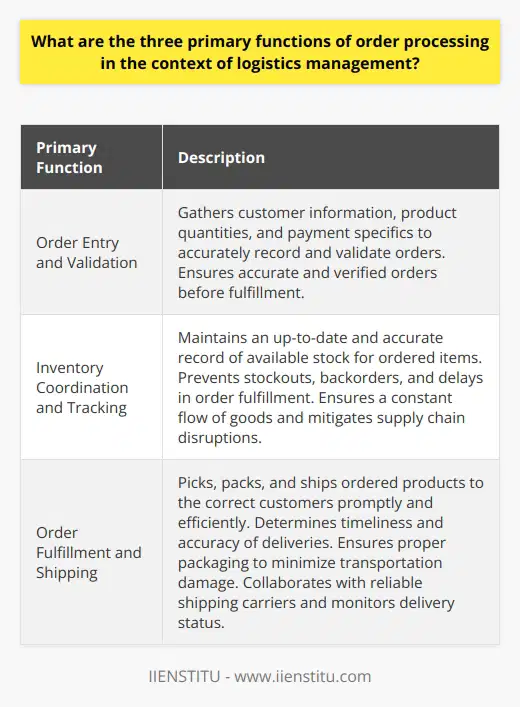

What are the three primary functions of order processing in the context of logistics management?

Order Entry and Validation

The first primary function of order processing within logistics management is order entry and validation. This process involves gathering customer information, product quantities, and payment specifics to accurately record and validate orders for fulfillment. Order entry and validation is essential for maintaining customer satisfaction, appropriately allocating resources, and ensuring accurate financial records.

Inventory Coordination and Tracking

The second primary function is inventory coordination and tracking. This involves maintaining an up-to-date and accurate record of the available stock for the ordered items. Accurate inventory tracking prevents stockouts, backorders, and delays in order fulfillment. Additionally, it ensures that there is a constant and reliable flow of goods, meeting customers' demands while mitigating potential supply chain disruptions.

Order Fulfillment and Shipping

Finally, the third primary function is order fulfillment and shipping. This entails picking, packing, and shipping the ordered products to the correct customers promptly and efficiently. Order fulfillment and shipping directly impact customer satisfaction by determining the timeliness and accuracy of deliveries. It includes the proper packaging of items to minimize damage during transport, working with reliable shipping carriers, and monitoring delivery status.

In conclusion, the three primary functions of order processing within logistics management are order entry and validation, inventory coordination and tracking, and order fulfillment and shipping. These functions work together to ensure a seamless and efficient procurement process, minimizing potential disruptions and maintaining high levels of service quality and customer satisfaction.

Why is order processing important in logistics?

Significance of Order Processing in Logistics

Efficiency in Supply Chain Management

Order processing plays a crucial role in logistics with a direct impact on supply chain management efficiency. It involves various activities such as order receipt, items selection, packaging, and shipping. Proper order processing can lead to increased customer satisfaction, timely deliveries, and reduced operational costs.

Customer Satisfaction and Retention

Order processing constitutes an integral aspect of customer service. Efficient and accurate order management ensures that customers receive their products on time and in good condition, leading to high satisfaction levels. Satisfied customers tend to be loyal and more likely to make repeat purchases, contributing to a company's long-term success.

Inventory Management

Order processing closely aligns with inventory management, as timely and precise order fulfillment requires maintaining accurate inventory records. Efficient inventory management minimizes instances of order cancellations and stock-outs, contributing to overall effectiveness in the logistics process.

Cost Reduction and Profitability

Automation and streamlining of order processing can result in significant cost savings. It reduces the possibility of errors in order fulfillment, decreasing the need for returns and refunds. Additionally, faster processing contributes to reduced warehousing costs, as products spend less time in storage.

Competitive Advantage

A company that excels in order processing can achieve a competitive advantage over its rivals. Timely and accurate order fulfillment can lead to positive customer reviews and recommendations, resulting in increased market share and profitability.

In conclusion, order processing is of paramount importance in logistics due to its impact on customer satisfaction, inventory management, cost reduction, and competitive advantage. Therefore, companies should continually invest in improving their order processing systems to ensure efficiency and effectiveness in their logistics operations.

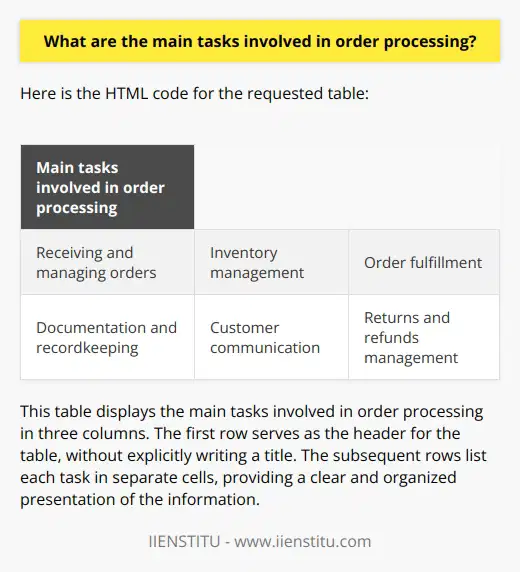

What are the main tasks involved in order processing?

Order Processing Tasks

One of the main tasks in order processing is receiving and managing customer orders. This involves properly recording and organizing incoming orders from various channels, such as sales teams, websites, or phone calls. Clarifying and handling any special requests made by customers are often part of this task, ensuring that orders are correctly customized per the client's requirements.

Inventory Management

Another crucial task in order processing is inventory management, which encompasses tracking the levels of available products or components needed to fulfill orders. This helps businesses ensure that they have a consistent supply of items to meet customer demand, which may require coordinating with suppliers or adjusting production schedules as necessary.

Order Fulfillment

The next step in the process is order fulfillment, which entails preparing, packaging, and shipping the ordered products to customers. This task requires accurate and efficient handling of physical items or digital files, as well as coordination with delivery services to ensure that orders are delivered promptly and in good condition.

Documentation and Recordkeeping

Accurate documentation and recordkeeping are essential components of order processing, as they help businesses track their performance and financial transactions. This typically involves generating invoices, receipts, and shipping manifests, as well as updating order status information in databases or project management systems.

Customer Communication

Throughout the order processing cycle, effective communication with customers is a key task. This could include providing updates on order progress, addressing any concerns or inquiries that customers may have, and resolving any issues that arise during the process, such as delays, damages, or returns.

Returns and Refunds

Lastly, order processing entails managing returns and refunds, when applicable. This can be a crucial aspect in maintaining customer satisfaction, as businesses must have a clear policy and system in place for accepting returns, offering refunds or exchanges, and handling situations wherein customers are dissatisfied with their purchases.

In conclusion, the main tasks involved in order processing include receiving and managing orders, inventory management, order fulfillment, documentation and recordkeeping, customer communication, and returns and refunds management. Effectively executing these tasks is crucial for ensuring smooth business operations, satisfied customers, and overall success in today's competitive marketplace.

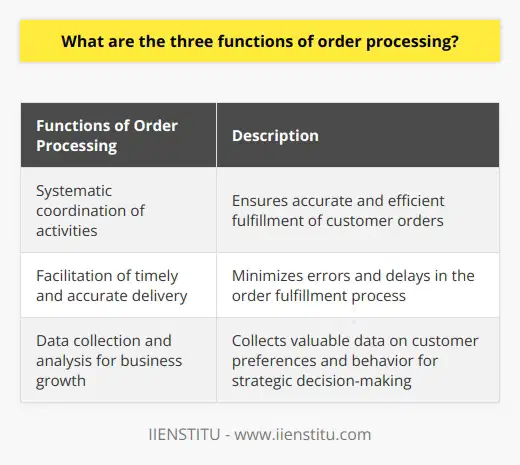

What are the three functions of order processing?

Order Processing Functions

Systematic Coordination of Activities

The primary function of order processing is to systematically coordinate activities involved in fulfilling customer orders. This coordination ensures accurate and efficient processing, from receiving the customer's purchase request to delivering the product or service. Utilizing order management software, businesses can streamline their order processing systems by tracking order progress, managing inventory, and updating customer information in real-time.

Facilitation of Timely and Accurate Delivery

The second function of order processing is to facilitate timely and accurate delivery of products and services to customers. Effective order processing systems minimize the potential for errors or delays throughout the order fulfillment process by overseeing and communicating pertinent details, such as product availability, shipping information, and transaction status. This decreases processing time, increases customer satisfaction, and helps maintain a positive reputation for the business.

Data Collection and Analysis for Business Growth

The third function of order processing is data collection and analysis for business growth. Order processing systems regularly gather valuable data related to customer preferences, purchasing patterns, and product performance. Businesses can leverage this information to make strategic decisions regarding inventory management, marketing efforts, and the development of new products and services. This data-driven approach allows companies to improve their overall operation, adapt to market trends, and better serve their customers.

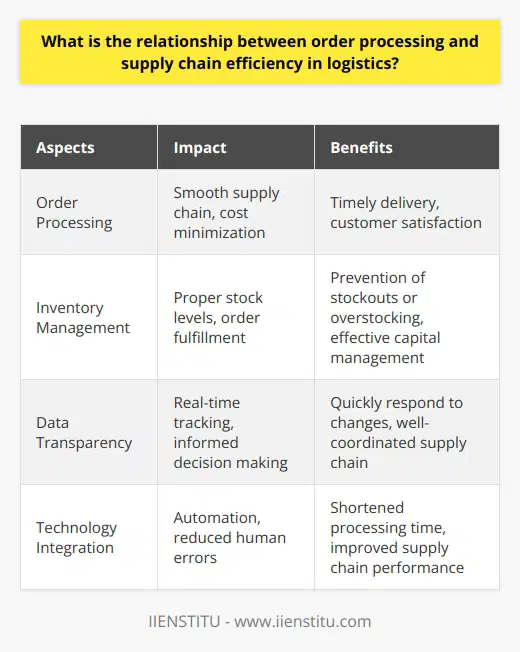

What is the relationship between order processing and supply chain efficiency in logistics?

Relationship Overview

The relationship between order processing and supply chain efficiency in logistics is crucial for enhancing overall productivity and customer satisfaction. Effective order processing ensures that the supply chain runs smoothly, fostering cost minimization and timely delivery of goods to end-users.

Order Processing Impacts

Efficient order processing involves prompt order receipt, accurate data entry, and quick order confirmation. Streamlined order processing minimizes the potential for errors, reduces lead times, and bolsters customer satisfaction. Inefficient order processing, on the other hand, can create bottlenecks within the supply chain and increase operational costs.

Inventory Management Connection

An accurate and prompt order processing system directly influences inventory management. Proper inventory levels facilitate order fulfillment and prevent stockouts or overstocking. As a result, companies can manage their capital effectively and maintain optimal stock levels to meet client demands.

Data Transparency Benefits

An additional aspect of the relationship between order processing and supply chain efficiency is data transparency. Seamless data flow between the order processing system and the supply chain enables real-time tracking of orders, inventory levels, and delivery status. Shared data allows all stakeholders to make well-informed decisions and respond promptly to any changes within the supply chain.

Technology Integration

Integrating advanced technology like artificial intelligence, machine learning, and automation in order processing significantly impacts supply chain efficiency. Automated order processing systems can process large volumes of orders, reduce human errors and expedite order validation. Technology integration reduces manual labor, shortens processing time, and enhances overall supply chain performance.

Conclusion

In summary, the relationship between order processing and supply chain efficiency is undeniable in logistics. Efficient order processing is indispensable for preventing bottlenecks, ensuring optimal inventory management, promoting data transparency, and integrating technology within the supply chain. As a result, companies can deliver products to customers faster and at a lower cost, which ultimately contributes to an improved customer experience.

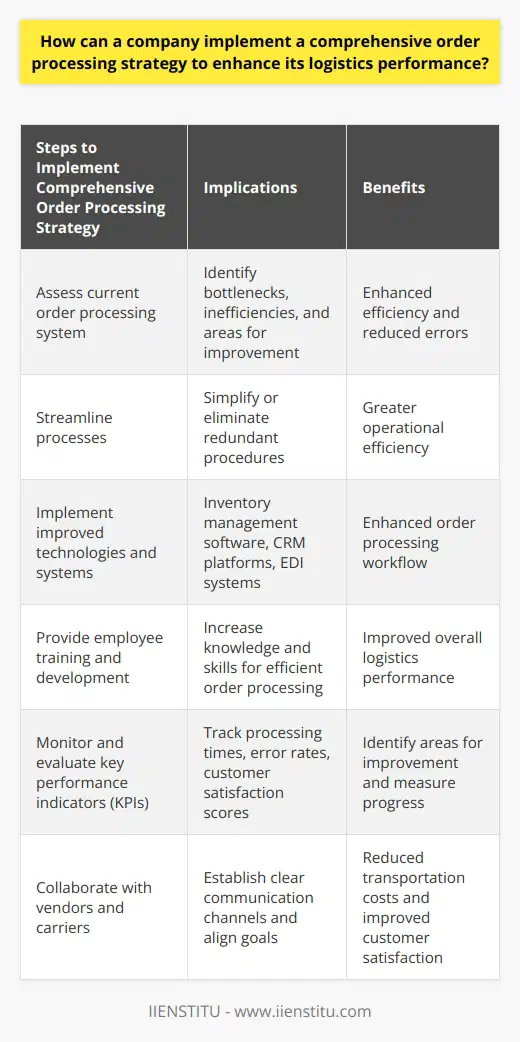

How can a company implement a comprehensive order processing strategy to enhance its logistics performance?

Assessing Current Order Processing

A company can enhance its logistics performance by implementing a comprehensive order processing strategy. First, a thorough evaluation of the existing order processing system should be conducted. This analysis must identify any bottlenecks, inefficiencies, and areas for improvement. This should include factors such as order processing time, error rates, costs, and customer satisfaction levels.

Streamlining Processes

Next, the company should streamline processes to achieve greater efficiency. This may involve the simplification or elimination of redundant procedures, the implementation of standardized practices, and the reduction of manual labor through automation. Improved technologies and systems can also be integrated into the order processing workflow, such as inventory management software, customer relationship management (CRM) platforms, and electronic data interchange (EDI) systems.

Training and Development

Another vital aspect of a comprehensive order processing strategy is the continuous training and development of employees. By providing workers with the necessary knowledge and skills to efficiently process orders and manage customer inquiries, a company can improve its overall logistics performance. Moreover, training programs should be regularly updated to reflect industry best practices and technological advancements.

Monitoring and Evaluation

To ensure the effectiveness of the implemented strategies, the company should routinely monitor and evaluate key performance indicators (KPIs). These KPIs may pertain to processing times, error rates, customer satisfaction scores, and other relevant metrics. Routine assessments can help the company identify areas that require further improvement while simultaneously allowing for the accurate measurement of progress.

Collaboration with Vendors and Carriers

Lastly, fostering strong collaboration with vendors and carriers can significantly enhance the efficiency of a company's order processing strategy. Establishing clear communication channels, aligning goals, and sharing performance data can help create a robust network that works together to optimize logistics performance. This collaboration can result in reduced transportation costs, more accurate inventory management, and improved customer satisfaction.

In conclusion, a comprehensive order processing strategy can significantly improve a company's logistics performance. By assessing current processes, streamlining procedures, providing employee training, monitoring KPIs, and collaborating with external partners, a company can enhance its competitiveness and deliver greater value to its customers.

To what extent does order processing play a part in achieving end-to-end visibility in logistics operations?

The Role of Order Processing

Order processing is a crucial component in achieving end-to-end visibility in logistics operations. This academic paragraph aims to discuss the extent to which order processing contributes to the overall efficiency and effectiveness of logistics and supply chain management.

Importance of Accurate Order Information

Accurate order information plays a significant role in enhancing the visibility of the supply chain. It ensures that accurate product data, quantities, delivery addresses, and other relevant details are recorded and shared among all stakeholders. Accurate information reduces confusion and delays, improving the overall performance of logistics operations.

Integration of Systems and Technologies

The integration of various systems and technologies, such as order management systems, warehouse management systems, and transportation management systems, is vital for achieving end-to-end visibility. Seamless integration enables real-time tracking of orders, shipments, inventory, and customer information. This allows companies to make informed decisions quickly, improving their ability to respond to dynamic market conditions and customer needs.

Collaboration between Stakeholders

Strong collaboration between various stakeholders, including suppliers, manufacturers, transportation providers, and customers, is essential in ensuring end-to-end visibility. Effective coordination and communication among these parties help in the timely exchange of critical operational data related to order processing. This transparency allows for seamless tracking and management of each order, enhancing overall logistics efficiency.

Reducing Lead Times and Enhancing Responsiveness

Efficient order processing directly contributes to reducing lead times and improving an organization's responsiveness in fulfilling customer orders. Streamlined order processing enables companies to reduce order-to-delivery times, increase the speed of product movement, and optimize inventory levels. In turn, this enhances the organization’s capacity to meet customer demands in a timely manner.

In conclusion, order processing plays a significant role in achieving end-to-end visibility in logistics operations. Proper management of order information, integration of systems and technologies, strong collaboration among stakeholders, and the reduction of lead times all contribute to improving visibility across the supply chain. This visibility is essential for logistics companies to serve customers efficiently and effectively, ensuring satisfaction and fostering long-term relationships.

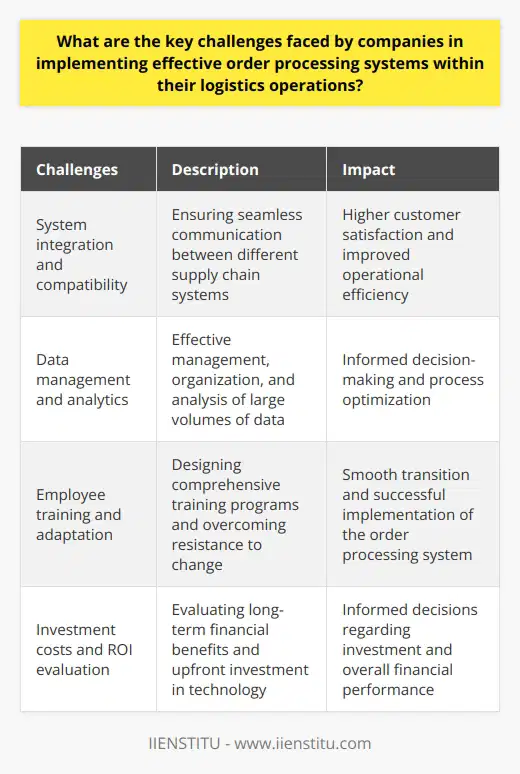

What are the key challenges faced by companies in implementing effective order processing systems within their logistics operations?

Challenges in Implementing Order Processing Systems

System Integration and Compatibility

One of the key challenges faced by companies in implementing effective order processing systems within their logistics operations is ensuring system integration and compatibility. This involves adopting technology solutions that facilitate seamless communication between different elements of the supply chain, such as sales, order management, inventory, and transportation management systems. Integration is essential for achieving real-time visibility and improving order accuracy, which in turn leads to higher customer satisfaction levels and increased operational efficiency.

Data Management and Analytics

Another challenge lies in data management and analytics, as an order processing system generates a significant amount of data. Managing, organizing, and analyzing this data effectively is crucial for informed decision-making and process optimization. Companies need to invest in robust data analytics tools that can handle large volumes of data, identify trends, and generate actionable insights to improve overall logistics efficiency and responsiveness.

Employee Training and Adaptation

Employee training and adaptation pose additional challenges, as the introduction of new systems may require employees to learn new skills and processes. Companies must design comprehensive training programs that familiarize employees with the new technology and empower them to use it efficiently. Facilitating adoption and overcoming resistance to change among employees is essential to ensure a smooth transition and the successful implementation of the order processing system.

Investment Costs and ROI

Lastly, implementing an effective order processing system can require significant upfront investment in technology, making it crucial for companies to evaluate its potential return on investment (ROI). Companies must conduct thorough research and analysis to understand the long-term financial benefits of the system, ensuring they outweigh the costs associated with the initial implementation and ongoing maintenance.

In conclusion, companies face several challenges in implementing effective order processing systems within their logistics operations, including system integration and compatibility, data management and analytics, employee training and adaptation, and investment costs and ROI evaluation. Addressing these challenges through careful planning and investment in appropriate technologies and training programs can significantly enhance logistics efficiency and overall operational performance.

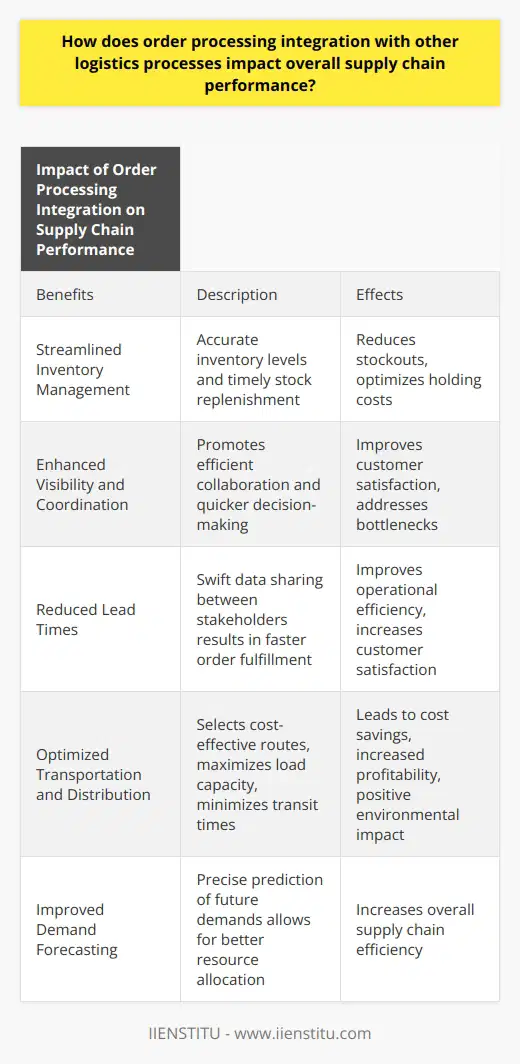

How does order processing integration with other logistics processes impact overall supply chain performance?

Impact on Inventory Management

Order processing integration significantly affects supply chain performance by streamlining inventory management. Through sharing real-time data across the supply chain, accurate inventory levels are maintained, ensuring timely replenishment of stock. This reduces the likelihood of stockouts and optimizes the holding costs associated with excess inventory.

Enhanced Visibility and Coordination

Integrating order processing with other logistics processes facilitates better visibility and coordination among various stakeholders. This promotes efficient collaboration, resulting in quicker decision-making and faster order fulfillment. Consequently, customer satisfaction is improved, and organizations can anticipate and address potential bottlenecks before they escalate into larger issues within the supply chain.

Reduction in Lead Time

By incorporating order processing integration into the supply chain, lead times are significantly reduced. This is achieved as data flows seamlessly between suppliers, manufacturers, and retailers, enabling them to swiftly fulfill orders and shorten the time needed for order processing. In turn, these reduced lead times contribute to higher operational efficiency and customer satisfaction.

Optimization of Transportation and Distribution

Effective order processing integration is crucial for optimizing transportation and distribution processes within the supply chain. It assists in selecting the most cost-effective and efficient transportation routes, while maximizing load capacity and minimizing transit times. This leads to cost savings and increased profitability for organizations, as well as reduced environmental impact.

Improved Demand Forecasting

Lastly, order processing integration supports the improvement of demand forecasting accuracy. By collecting and analyzing historical sales data, organizations can predict with precision future demands, allowing them to adjust production schedules and inventory levels accordingly. Accurate demand forecasting ultimately leads to better resource allocation and overall supply chain efficiency.

In conclusion, the integration of order processing with other logistics processes greatly impacts overall supply chain performance by streamlining inventory management, enhancing visibility and coordination, reducing lead times, optimizing transportation and distribution, and improving demand forecasting. These benefits contribute significantly to overall supply chain efficiency and customer satisfaction.

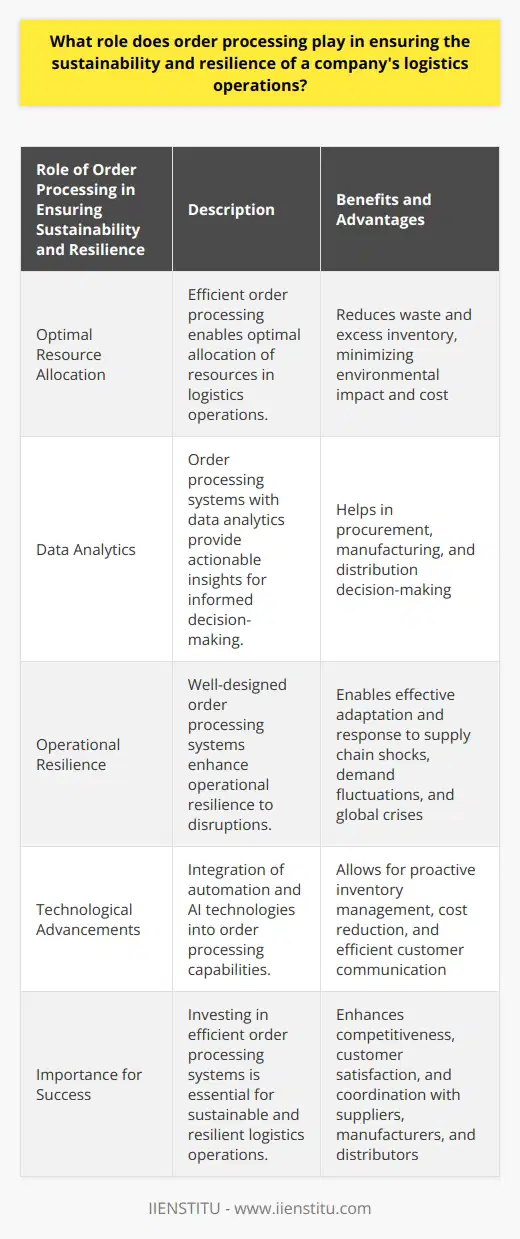

What role does order processing play in ensuring the sustainability and resilience of a company's logistics operations?

The Critical Role of Order Processing

Order processing serves as a cornerstone in building sustainable and resilient logistics operations for any company. It encompasses the entire activity of receiving, processing, and dispatching customer orders. Efficient order processing directly contributes to the company's bottom line and plays a crucial role in driving customer satisfaction.

Influence on Sustainability

Enabling sustainable logistics operations requires effective order processing systems. These systems facilitate optimal resource allocation, reduce waste, and minimize the environmental impact. By ensuring accurate and timely order fulfillment, companies avoid excess inventory and the associated costs. Moreover, order processing systems incorporating data analytics can generate actionable insights, helping businesses make informed decisions about product procurement, manufacturing, and distribution.

Role in Operational Resilience

Inadequate or inefficient order processing can significantly undermine the resilience of a company's logistics operations. The ability to adapt and respond to disruptions, such as supply chain shocks, demand fluctuations, and global crises, hinges on a well-designed order processing system. Rapid and accurate order processing enables companies to meet customer expectations consistently, even during challenging times. It also provides a strong foundation for coordinating with suppliers, manufacturers, and distributors, further strengthening a company's resilience in the face of disruptions.

Technological Advancements

Advancements in technology, such as automation and artificial intelligence (AI), present opportunities to enhance order processing capabilities. For example, machine learning algorithms can help predict customer demand patterns, allowing companies to proactively manage their inventory levels and reduce costs. Similarly, the integration of AI-driven chatbots can streamline customer communication, resulting in faster resolution of inquiries and issues. By leveraging these technologies, companies can further bolster the sustainability and resilience of their logistics operations.

Conclusion

In summary, order processing plays a decisive role in ensuring the sustainability and resilience of a company's logistics operations. Investing in efficient order processing systems and harnessing innovative technologies can significantly contribute to a company's success, enhancing its overall competitiveness in the marketplace.

What are four major activities involved in order processing?

Order processing activities can be grouped into four major stages: receiving the order, executing the order, delivery, and service support.

Receiving the Order:

Order processing commences with the receipt of an order from a customer. This may occur through various channels such as an online system, a telephone call, or a sales representative visit. Companies must have an efficient system for capturing and properly recording all necessary data at this stage to prevent inaccuracies that can lead to delays or errors in subsequent steps.

Executing the Order:

The next activity entails processing the captured order, which involves allocating product inventory, preparing the order documentation, and handling necessary paperwork required for shipping and customs clearances. In some instances, order processing may involve manufacturing the requested items, procuring the required raw materials, and coordinating with partner organizations for production. Streamlining this step is crucial to ensure prompt and accurate order fulfillment.

Delivery:

Once an order is prepared, it proceeds to the delivery stage, which involves selecting the transportation mode, identifying the appropriate carrier, and determining the optimal route to the customer's location. Efficient routing, choosing specific logistics providers, and effective use of shipping resources have a significant impact on the customer's satisfaction level and the overall success of the order processing system.

Service Support:

The final activity in order processing involves post-delivery support. This includes monitoring delivery status, addressing any customer queries or concerns, and providing accurate tracking information for real-time updates. Additionally, managing returns, handling warranty claims, or addressing other issues are vital components to a successful order processing system. At this stage, providing effective customer support can significantly influence the overall customer experience and foster long-term relationships.

In conclusion, the four major activities involved in order processing encompass receiving, executing, and delivering the order, and providing service support. All these activities must be performed harmoniously to ascertain customer satisfaction and maximize the effectiveness of the operation.

What are the three functions of order processing?

**Order Processing: Key Functions**

Order processing plays a crucial role in the effective management of any business. Three primary functions of order processing include order entry, order fulfillment, and post-sale support.

**Order Entry**

Firstly, the order entry function involves the efficient management of incoming orders. This phase entails registering customer orders, validating required information, and promptly initiating the required fulfillment processes. Effective order entry ultimately promotes customer satisfaction and serves as the starting point for all subsequent steps in order processing.

**Order Fulfillment**

Secondly, the order fulfillment function ensures prompt and accurate delivery of the ordered products or services. This function includes efficient inventory management, warehousing, picking, and packaging. Additionally, it involves coordinating with shipping partners and providing customers with accurate shipment tracking information. Efficient fulfillment processes can significantly improve customer satisfaction and promote repeat business.

**Post-Sale Support**

Finally, post-sale support is the third essential function of order processing. This function deals with addressing customer inquiries, resolving any order discrepancies, managing returns or exchanges, and providing efficient after-sales service. Effective post-sale support helps build long-term relationships with customers, fosters trust, and ensures that customers have a positive experience with the business.

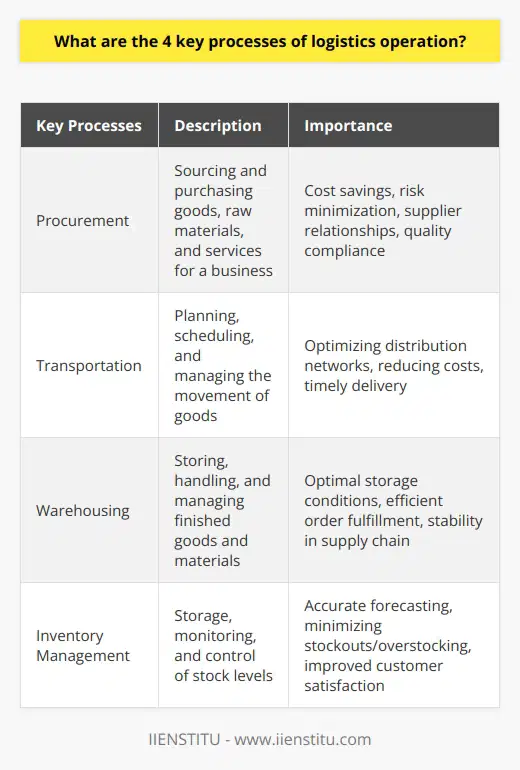

What are the 4 key processes of logistics operation?

**Logistics Operations Overview**

Logistics operations refer to the management of the flow of goods and resources from their origin to their intended destination. These processes play a critical role in ensuring that supply chains operate smoothly and efficiently, ultimately meeting the needs of end-users. There are four key processes involved in logistics operations: procurement, transportation, warehousing, and inventory management.

**Procurement Process**

Procurement is the first key process in logistics operations, involving the sourcing and purchasing of goods, raw materials, and services necessary for a business to function optimally. Through effective procurement strategies, businesses can achieve cost savings, minimize operational risks and disruptions, and enhance supplier relationships. Effective procurement also ensures that goods and services meet quality and compliance requirements, safeguarding customer satisfaction and brand reputation.

**Transportation Process**

The second key process, transportation, encompasses the planning, scheduling, and management of all activities related to the movement of goods. This can involve multiple modes of transportation, such as air, sea, and land freight. Transportation plays a significant role in logistics operations, as it seeks to optimize distribution networks to maximize efficiency, reduce overall costs, and ensure on-time delivery. Factors like fuel costs, environmental impact, and service performance are all vital considerations within this process.

**Warehousing Process**