Warehouse management is the linchpin of a well-functioning supply chain. A warehouse's organization and operational efficiency significantly impact not only customer satisfaction but also a company’s bottom line. I remember a time when my friend, who runs a mid-sized retail business, shared how crucial their warehouse was in delivering a good customer experience—accurate stock levels and swift order fulfillment meant the difference between positive reviews and lost customers. In today's competitive market, such details matter immensely. At the center of effective warehouse operations is the Warehouse Management System (WMS), sophisticated software designed to optimize every aspect of the warehouse process. A capable WMS ensures precise inventory tracking, streamlines warehouse tasks, and seamlessly integrates with the broader supply chain, making it indispensable for businesses seeking agility and efficiency.

Understanding WMS

Core Components of a WMS

To truly leverage the power of a WMS, it’s essential to understand its core components:

Inventory Tracking: At the heart of any WMS is the ability to keep a real-time account of inventory. This feature helps businesses know the exact location, quantity, and status of each product, reducing the chances of stock-outs or overstock situations. I remember when I worked with a retailer who used a basic inventory system—upgrading to a WMS was like switching from a flip phone to a smartphone. Suddenly, they could see where every item was stored and get automatic notifications when stock was running low.

Warehouse Layout Optimization: A well-designed warehouse layout can mean the difference between fast, efficient picking and a chaotic process where employees waste time searching for items. A robust WMS can help maximize space utilization and optimize the flow of goods, ensuring that frequently picked items are closer to packing stations, while slower-moving items are stored further back.

Picking and Packing Efficiency: Efficient systems simplify the process of picking and packing, which directly impacts order fulfillment speed. Advanced WMSs use features like batch picking, where similar orders are picked together, or wave picking, which prioritizes certain orders based on shipping deadlines.

Shipping and Receiving Management: Managing the complexities of shipping and receiving is crucial for keeping products flowing through the warehouse smoothly. A strong WMS ensures that incoming shipments are processed quickly and matched accurately against purchase orders, reducing delays and potential errors.

Different Types of WMS

When it comes to WMS solutions, companies have several options to choose from, depending on their needs:

Standalone WMS: These systems focus exclusively on warehouse operations, making them ideal for businesses seeking specialized capabilities without the need for full-scale supply chain integration.

Integrated WMS within ERP: Many companies opt for a WMS that is a module of their broader Enterprise Resource Planning (ERP) system. This approach offers a seamless interface between warehouse management and other business functions like financial reporting, resource management, and procurement.

Cloud-Based WMS: Increasingly popular due to their scalability and lower upfront costs, cloud-based WMS solutions offer the ability to access the system from anywhere, making them ideal for businesses with multiple warehouses or remote management needs.

The choice between these systems often hinges on the company’s operational complexity, existing infrastructure, and future growth plans.

Historic Development of WMS

The evolution of WMS is a reflection of how business needs and technology have changed over time. It’s fascinating to think about how warehouses functioned before the advent of digital tools. My father, who worked in logistics in the 80s, often reminisces about the painstaking manual stock checks they had to do—using pen, paper, and a lot of patience. As global trade expanded and e-commerce emerged, the need for more efficient, data-driven systems became apparent.

Initially, WMSs were developed as simple inventory management tools, but as supply chains grew more complex, so did the capabilities of these systems. Today, advanced WMSs can leverage predictive analytics, suggest optimal storage methods, and automate repetitive tasks, making them a key player in the modern logistics ecosystem.

Benefits of Implementing a WMS

1. Increased Efficiency

Deploying a WMS can dramatically enhance warehouse efficiency by automating routine tasks like data entry and inventory tracking. This allows staff to focus on higher-value activities such as quality control and customer service. In one of my previous roles, we transitioned to a new WMS, and the difference was night and day. Before, we would manually enter shipment data—a time-consuming task that often led to errors. After the switch, automated barcode scanning took over, reducing errors and speeding up the entire process. This kind of improvement not only cuts down on labor costs but also accelerates order processing.

2. Reduced Errors and Predictive Capabilities

Human error is a major cause of discrepancies in inventory management. WMS solutions reduce these mistakes by providing real-time updates and ensuring that data is entered accurately. But that’s not all—advanced WMSs can predict potential issues before they become critical. For example, if a particular product is trending down in sales, a predictive WMS might suggest adjusting stock levels before the excess becomes a burden. This type of foresight can save businesses thousands of dollars in lost sales or wasted stock.

3. Improved Customer Service

Customer satisfaction is closely tied to how well a company manages its warehouse operations. A well-implemented WMS ensures orders are picked, packed, and shipped accurately and on time, which directly affects how customers perceive a brand. A great example is that of Company XYZ, which integrated a new WMS and saw their order fulfillment time drop by 20%, while inventory accuracy improved to 99.9%. Their customers noticed the difference—suddenly, orders arrived faster, and the dreaded "out of stock" messages became rare.

The Role of WMS in Supply Chain Management

Integration Within the Supply Chain

A WMS does not operate in isolation—it’s a critical component of a larger supply chain strategy. Integration with procurement, transportation management, and other systems allows for smooth coordination across all facets of the product journey, from the supplier’s warehouse to the customer’s doorstep. When I think back to my experience in managing warehouse operations, it was always the seamless flow of information between systems that made everything run smoothly. The WMS would communicate with our transportation management software to schedule pickups automatically when certain stock levels were reached. This eliminated the need for manual coordination, freeing up time for more strategic tasks.

Importance in Order Fulfillment

Order fulfillment is where the rubber meets the road in warehouse management. The WMS serves as the engine driving the entire fulfillment process, from the moment an order is received until it’s shipped. The efficiency of picking and packing directly affects delivery speed, and by extension, customer satisfaction. In many cases, the WMS can prioritize orders based on urgency, ensuring that critical shipments are dispatched first.

The Role in Logistics Management

WMS also plays a crucial role in broader logistics management. It works hand-in-hand with transport management systems to ensure smooth transfers between warehouses, distribution centers, and transportation modes. For companies operating on a global scale, this functionality is essential. For instance, managing international shipments often involves compliance with various customs regulations. An effective WMS can automate documentation processes, ensuring that shipments comply with international standards and avoid costly delays.

Factors to Consider When Choosing a WMS

1. Size of the Business

When selecting a WMS, it’s vital to align the solution with the scale of operations. Small businesses might opt for simpler systems that focus on the basics, while larger corporations with complex logistics needs will benefit from feature-rich systems capable of managing high inventory turnover and complex order processing. It’s like buying a car: a small, efficient sedan works great for city driving, but if you’re hauling heavy loads across the country, you’ll need a robust truck.

2. Complexity of Operations

Businesses with intricate logistics, such as those dealing in perishable goods, hazardous materials, or diverse product lines, need a WMS that can handle their specific challenges. Features like batch picking, cross-docking, and real-time stock updates are crucial for managing such operations effectively.

3. Cost and Budget Considerations

Implementing a WMS is a significant investment, so understanding the balance between cost and functionality is crucial. Companies should consider both the initial setup cost and the potential return on investment through improved efficiency and reduced errors. A friend of mine who runs a warehouse for an electronics distributor once told me that the ROI from his new WMS was evident within a year, thanks to faster order processing and reduced shrinkage.

4. Compatibility with Existing Systems

The new WMS must integrate smoothly with your existing systems, whether it's an ERP, CRM, or other supply chain management tools. This prevents the need for double data entry and minimizes the risk of inconsistencies. It's like putting together a puzzle—if the pieces don’t fit, you’ll spend more time forcing things to work rather than seeing the big picture come together.

WMS Trends and Future Considerations

Increasing AI and Automation in WMS

AI and automation are rapidly becoming standard features in modern WMSs. Technologies like predictive analytics help businesses anticipate demand surges, while automated storage and retrieval systems (AS/RS) and autonomous mobile robots (AMR) increase warehouse efficiency. I once visited a state-of-the-art warehouse that used AI-driven robots to pick items from shelves. It was like watching a sci-fi movie, but the benefits were real—faster picking times, reduced labor costs, and almost zero picking errors.

The Rise of Cloud-Based WMS

Cloud-based WMS solutions are becoming the go-to for businesses looking for scalability and flexibility. These systems eliminate the need for expensive on-site servers and enable access from anywhere, which is especially useful for businesses with multiple locations. The pay-as-you-go model also allows companies to scale the system up or down as their needs change, offering significant savings compared to traditional setups.

WMS for E-Commerce

With the explosive growth of e-commerce, WMSs have evolved to meet the demands of online retail. E-commerce warehouses must handle a high volume of small orders, offer quick returns processing, and maintain real-time inventory visibility. A robust WMS is essential in ensuring these operations run smoothly and that customers can see what’s in stock as they shop.

Adjusting to Global Distribution Challenges

As companies expand into new international markets, their WMS must adapt to complex global distribution networks. Features that support various customs regulations, currency handling, and multi-language capabilities are becoming essential. These tools help businesses navigate the challenges of global trade and keep their supply chains moving, even across borders.

Conclusion

Recap of WMS Importance, Benefits, and Future Trends

In sum, a robust WMS is foundational to the success of modern warehouse operations and, by extension, the entire supply chain. The advantages, from increased efficiency and reduced errors to improved customer service, underscore why investing in a capable WMS is a wise decision. As AI, automation, and cloud-based systems reshape the logistics landscape, companies that stay ahead of these trends will be well-positioned for future success.

Final Thoughts on the Future of Warehouse Management Systems

As businesses navigate an increasingly dynamic market landscape, the reliance on advanced WMSs will only grow. Investing in scalable, forward-looking solutions will enable companies to handle the challenges of tomorrow’s logistics and supply chain environment. For those eager to dive deeper into this field, exploring online certification courses in WMS or logistics management can provide the expertise needed to harness the full potential of these systems. The future of WMS is bright, promising more efficiency, precision, and innovation in the lifeblood of commerce—inventory management.

References

"Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse" by Gwynne Richards – This book provides an in-depth look at the evolution of warehouse management practices, including the role of WMS in modern supply chains. It is an excellent resource for understanding both basic principles and advanced strategies in warehouse management.

"Supply Chain Management: Strategy, Planning, and Operation" by Sunil Chopra – This widely respected textbook covers the broader supply chain context in which WMS operates. It explains how WMS integrates with other supply chain systems, providing insights into its strategic importance in logistics.

Gartner Research Reports – Gartner frequently publishes reports on trends in warehouse management systems, including evaluations of leading WMS providers, the rise of AI and cloud-based solutions, and how WMSs adapt to changing business needs. These reports can offer a data-driven perspective on the current state of the industry.

"Digital Warehouse of the Future: How AI, IoT, and Automation are Changing Warehouse Management" - Deloitte Insights – Deloitte’s industry analysis offers a forward-looking view on how AI and automation are reshaping WMS. It provides examples of how these technologies are being applied in real-world settings, making it a valuable resource for understanding future trends.

"The Impact of Cloud Computing on Logistics" - Journal of Business Logistics – This academic article explores the rise of cloud-based WMS solutions and their impact on logistics and warehouse management. It examines the benefits of flexibility, scalability, and cost-efficiency offered by cloud technologies in the logistics space.

"The Future of Warehouse Management: Robotics and Automation" - McKinsey & Company – This report dives into the potential of robotics and automated systems in warehouse management, focusing on how advanced WMS systems can optimize operations. It’s a great resource for those interested in the intersection of technology and warehouse operations.

"E-commerce and Its Impact on Warehouse Management" - Harvard Business Review – This article discusses how the growth of e-commerce has led to the evolution of WMS to meet the needs of online retail. It explores the challenges e-commerce presents for warehouses and how WMS solutions have adapted to address them.

"Cloud-Based Warehouse Management Systems (WMS): A New Era in Logistics" - Logistics Management Magazine – This publication often features industry experts discussing the latest trends in WMS technology, including the transition to cloud-based systems and the benefits for small and medium-sized businesses.

Frequently Asked Questions

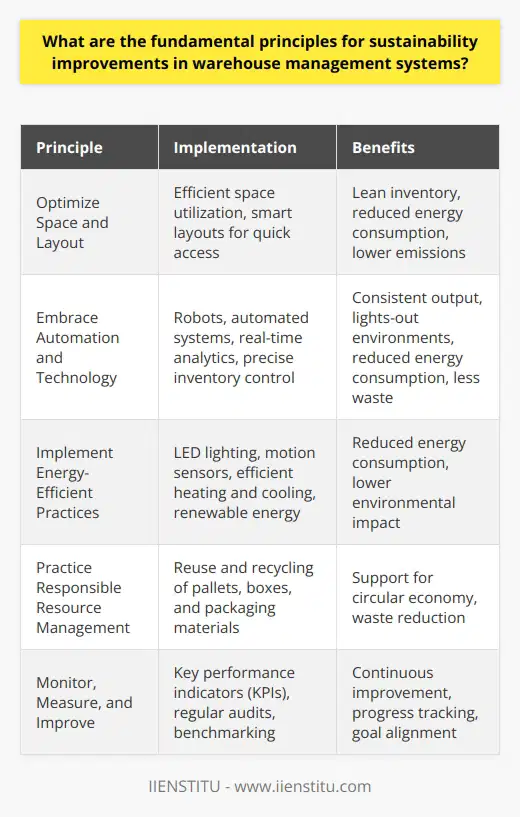

What are the fundamental principles for sustainability improvements in warehouse management systems?

Fundamental Principles for Sustainability in Warehouse Management

Sustainability now drives innovation in warehouse management systems (WMS). Warehouses face increasing demands to reduce ecological footprints. Managers must adapt. They adopt key principles for sustainability. These ensure efficiency. They also promote environmental stewardship.

Optimize Space and Layout

Efficient space use is crucial. It permits lean inventory. It also minimizes energy use. Smart layouts facilitate quick access. This reduces the need for movement. Fewer movements lead to lower emissions.

Embrace Automation and Technology

Automation enhances operational efficiency. Robots and automated systems do not tire. They provide consistent output. They can also function in lights-out environments. This reduces energy consumption.

Technology integration aids in data collection. Real-time analytics predict demand. They enable precise inventory control. Less waste occurs.

Implement Energy-Efficient Practices

Energy conservation matters. Managers invest in LED lighting. They install motion sensors. Efficient heating and cooling systems follow. Renewable energy sources join the mix. These practices cut down on energy use.

Practice Responsible Resource Management

Resource management focuses on reuse and recycling. Pallets, boxes, and packaging materials get a second life. This principle supports a circular economy. It also leads to waste reduction.

Invest in Training and Engagement

Sustainability thrives with informed teams. Training programs enlighten workers. They learn about eco-friendly practices. Employee engagement ensures everyone contributes. Staff can offer innovative ideas. Collective effort pushes sustainability forward.

Monitor, Measure, and Improve

Continuous improvement is a must. Key performance indicators (KPIs) track progress. They measure energy use, waste levels, and efficiency. Regular audits identify areas for improvement. Benchmarks guide toward sustainable goals.

By adopting these principles, warehouses can vastly improve their sustainability efforts. They also set a standard for industries to follow. Sustainable practices combine ecological responsibility with operational excellence. This results in a balanced approach. It benefits both the environment and the bottom line.

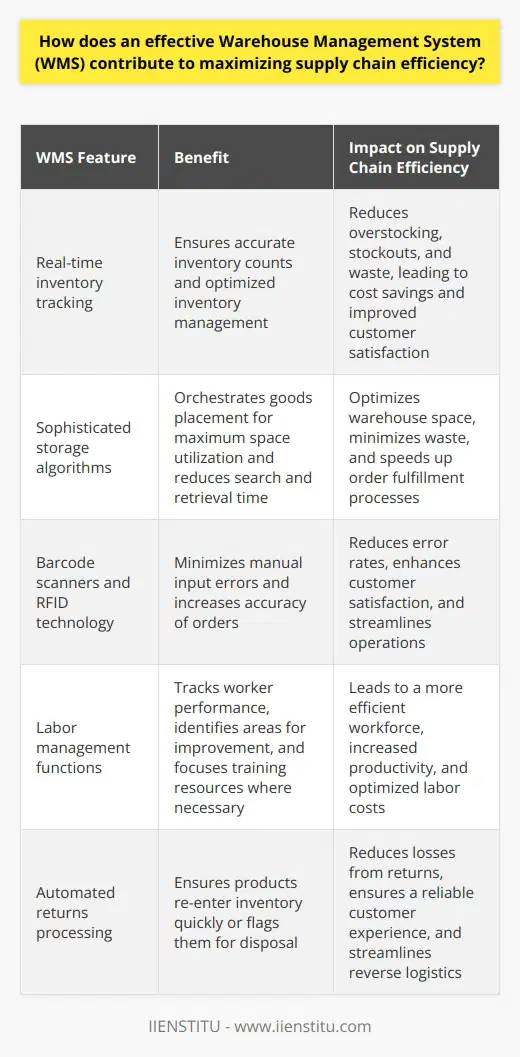

How does an effective Warehouse Management System (WMS) contribute to maximizing supply chain efficiency?

Warehouse Management and Supply Chain Efficiency

Understanding Warehouse Management Systems

A Warehouse Management System (WMS) is pivotal in supply chain operations. It automates various warehouse tasks. This system largely boosts efficiency and productivity.

Efficiency in Inventory Control

Real-time inventory tracking forms WMS's core. It ensures accurate inventory counts. Warehouse teams avoid overstocking and stockouts. Data drives decision-making here. This data leads to optimized inventory management.

Optimization of Warehouse Space

A WMS streamlines storage using sophisticated algorithms. It can orchestrate goods' placement for maximum space utilization. The system often reduces waste. It also reduces search and retrieval time.

Enhancing Picking and Packing Processes

Picking and packing become more precise with a WMS. The system routes workers effectively. It minimizes travel time within the warehouse. Consequently, order fulfillment speeds up.

Reducing Error Rates

WMS technology minimizes manual input errors. It does so by implementing barcode scanners and RFID technology. This increases the accuracy of orders. Errors become less frequent. This, in turn, bolsters customer satisfaction.

Labor Management Optimization

A good WMS includes labor management functions. It tracks worker performance. It also identifies areas for improvement. This leads to a more efficient workforce. Training resources focus where necessary. Productivity increases.

Improved Supplier and Customer Relations

Vendors and customers benefit from WMS insights. Real-time data fosters better communication. It allows for more transparent operations. This transparency builds trust. Predictability and reliability are the results.

Streamlined Shipping and Receiving Operations

When receiving goods, a WMS schedules and records deliveries. It ensures swift unloading and accurate check-ins. The shipping processes, similarly, become more efficient. A WMS selects optimal carriers and shipping methods. Costs reduce. Shipments leave warehouses faster.

Effective Returns Management

Return processes can be complex. A WMS simplifies this by automating returns. It ensures products re-enter inventory quickly. Or it flags them for disposal. This reduces losses from returns. It also ensures a reliable customer experience.

Conclusion

An effective Warehouse Management System (WMS) touches every aspect of warehousing. It secures efficiency, accuracy, and speed in operations. This optimizes the entire supply chain. A WMS turns potential chaos into order. It provides streamlined, comprehensible processes. Organizing warehouses becomes easier. Customer satisfaction increases. Costs reduce. In essence, a WMS is indispensable for a thriving, competitive supply chain.

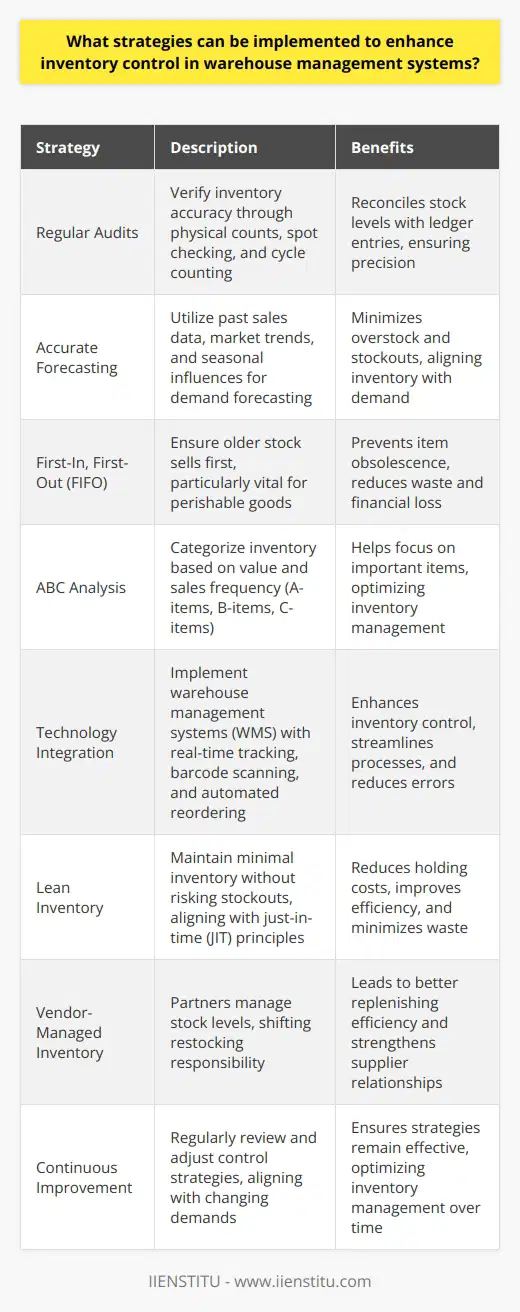

What strategies can be implemented to enhance inventory control in warehouse management systems?

Effective Inventory Control Strategies

Understanding Inventory Control

Inventory control forms the backbone of successful warehouse management. It determines a company's capacity to meet demand without overstocking. Strategy implementation must be thorough. It must focus on having the right products, in the right quantity, at the right time.

Essential Strategies for Improvement

Regular Audits

Regular audits verify inventory accuracy. They reconcile stock levels with ledger entries. These audits can take several forms:

- Physical counts

- Spot checking

- Cycle counting

Accurate Forecasting

Demand forecasting informs inventory control. Past sales data, market trends, and seasonal influences are critical inputs. Forecasts should be as precise as possible. This precision minimizes overstock and stockouts.

First-In, First-Out (FIFO)

A FIFO approach ensures older stock sells first. It prevents item obsolescence. It is particularly vital for perishable goods. This approach reduces waste and financial loss.

Prioritize with ABC Analysis

An ABC analysis categorizes inventory:

- A-items: High value with a low frequency of sales.

- B-items: Moderate value and sales frequency.

- C-items: Low value with high sales frequency.

This categorization helps focus on important items.

Use of Technology

Modern warehouse management systems (WMS) enhance control.

- Real-time tracking

- Barcode scanning

- Automated reordering

Lean Inventory

Maintain minimal inventory without risking stockouts. Lean inventory reduces holding costs. It aligns with just-in-time (JIT) principles.

Vendor-Managed Inventory

Partners manage stock levels. This approach shifts the restocking responsibility. It can lead to better replenishing efficiency.

Continuous Improvement

A commitment to Kaizen or continuous improvement is fundamental. It requires regular reviews of control strategies. Adjustments should align with changing demands.

Integrating Technology with Strategy

Automate Data Collection

Automated data collection reduces errors. It streamlines processes. Use RFID tags and handheld scanners.

Implement an ERP System

An Enterprise Resource Planning (ERP) system provides:

- Centralized data management

- Real-time inventory levels

- Integration with other business functions

Continuous Process Improvement

Regular Training

Staff require regular training. They must understand system updates. They must adopt best practices.

Measure Performance

Key performance indicators (KPIs) gauge success. Common KPIs include:

- Inventory accuracy rate

- Order lead times

- Stock turnover rate

Regular reviews ensure strategies remain effective. Updates to inventory control should happen as necessary.

Partner Collaboration

Engage with Suppliers

Strong supplier relationships support inventory control. Discuss lead times and reorder points. Opt for suppliers who provide quality products consistently.

Collaborate Across Departments

Collaboration between purchasing, sales, and warehouse teams is essential. Each department influences inventory levels. Open communication aligns operational goals.

Conclusion

Enhanced warehouse management requires regarded strategy implementation. Inventory control is complex. Yet, the right combination of these strategies can lead to optimized operations. It enables businesses to reduce costs, increase efficiency, and satisfy customer demands. Regular assessment and adaptation are the keys to maintaining effective inventory control.