Fault Tree Analysis (FTA) is a powerful analytical tool used to identify and evaluate potential failures in complex systems. It provides a systematic approach to understanding the relationships between various components and how their individual faults can contribute to overall system failure. In this comprehensive guide, we will delve into the intricacies of FTA, exploring its components, steps, benefits, and real-world applications across different industries.

As someone who has worked extensively with FTA in various projects, I can attest to its effectiveness in identifying potential points of failure and guiding preventive measures. Throughout this guide, I will share personal experiences and examples to illustrate the practical aspects of conducting an FTA.

The Importance of Fault Tree Analysis

In today's world, where systems are becoming increasingly complex and interconnected, the need for robust failure analysis techniques is more critical than ever. FTA serves as a proactive approach to identifying and mitigating potential failures before they occur, thereby enhancing system reliability, safety, and performance.

By employing FTA, organizations can:

Identify potential failure modes and their root causes

Assess the likelihood and impact of different failure scenarios

Prioritize maintenance and improvement efforts based on risk levels

Comply with industry regulations and safety standards

Improve overall system reliability and customer satisfaction

A Brief History of Fault Tree Analysis

FTA was first developed in the early 1960s by Bell Laboratories for the U.S. Air Force to evaluate the reliability of intercontinental ballistic missile (ICBM) systems. Since then, it has been widely adopted across various industries, including aerospace, nuclear power, automotive, and telecommunications.

Over the years, FTA has evolved to incorporate more advanced techniques and tools, such as computer-aided software and Monte Carlo simulations, to handle the increasing complexity of modern systems.

Understanding the Components of FTA

To effectively conduct an FTA, it is essential to understand its key components and their roles in the analysis process.

Events in Fault Tree Analysis

Basic Events: These are the initiating faults or failures that do not require further development in the fault tree. They represent the lowest level of the tree and are typically independent of each other.

Intermediate Events: These events occur due to the combination of one or more basic events or other intermediate events. They are represented by rectangles in the fault tree diagram and are placed between the basic events and the top event.

Top Event: This is the undesired state or failure that the fault tree is analyzing. It is placed at the top of the tree and is the starting point for the analysis.

Logic Gates in Fault Tree Analysis

Logic gates are used to represent the relationships between events in the fault tree. The two primary types of logic gates are:

AND Gate: This gate indicates that the output event occurs only if all the input events occur simultaneously. It is represented by a flat bottom and a curved top.

OR Gate: This gate indicates that the output event occurs if at least one of the input events occurs. It is represented by a curved bottom and a flat top.

Transfer Symbols in Fault Tree Analysis

Transfer symbols are used to connect different parts of the fault tree or to link to other fault trees. They are represented by triangles and are used to simplify the fault tree diagram and avoid repetition.

Steps in Conducting a Fault Tree Analysis

Conducting an FTA involves several key steps, each of which requires careful consideration and attention to detail.

Step 1: Define the System and Its Boundaries

The first step in conducting an FTA is to clearly define the system under analysis and its boundaries. This involves identifying the system's components, interfaces, and functions, as well as any external factors that may influence its operation.

In one of my previous projects, we were tasked with analyzing the reliability of a complex manufacturing process. We began by defining the system boundaries, which included the equipment, operators, raw materials, and environmental conditions. This helped us focus our analysis on the most critical aspects of the process.

Step 2: Identify the Top Event

The next step is to identify the top event, which represents the undesired state or failure that the fault tree is analyzing. This could be a system failure, a safety hazard, or any other negative outcome that needs to be prevented.

In the manufacturing process example, we identified the top event as a production stoppage due to equipment failure. This helped us orient our analysis towards identifying the potential causes of equipment failure and their impact onthe overall production process.

Step 3: Construct the Fault Tree

Once the top event has been identified, the next step is to construct the fault tree by breaking down the top event into its contributing factors. This is done by asking "how" and "why" questions to identify the immediate, necessary, and sufficient causes of the top event.

The fault tree is constructed using a combination of events and logic gates, as described earlier. It is important to be as detailed and comprehensive as possible when constructing the fault tree to ensure that all potential failure modes are captured.

In the manufacturing process example, we constructed a detailed fault tree that included basic events such as component failures, operator errors, and environmental factors, as well as intermediate events that combined these basic events through various logic gates.

Step 4: Analyze the Fault Tree

Once the fault tree has been constructed, it is analyzed to determine the probability of the top event occurring and to identify the most critical failure paths. This can be done using various techniques, such as:

Qualitative Analysis: This involves identifying the minimal cut sets, which are the smallest combinations of basic events that can cause the top event to occur.

Quantitative Analysis: This involves assigning probabilities to the basic events and using mathematical techniques to calculate the probability of the top event occurring.

In the manufacturing process example, we performed both qualitative and quantitative analyses to identify the most critical failure paths and to calculate the overall probability of a production stoppage.

Step 5: Interpret the Results and Implement Improvements

The final step in conducting an FTA is to interpret the results and use them to implement improvements to the system. This may involve:

Identifying and prioritizing the most critical failure modes

Developing and implementing preventive measures to reduce the likelihood of failure

Establishing monitoring and maintenance procedures to detect and correct potential failures before they occur

Updating the fault tree as the system evolves or new information becomes available

In the manufacturing process example, we used the results of the FTA to develop a comprehensive maintenance and monitoring plan that focused on the most critical equipment components and failure modes. This helped to significantly reduce the frequency and duration of production stoppages.

Benefits and Applications of Fault Tree Analysis

FTA offers numerous benefits to organizations across various industries. Some of the key benefits include:

Improved System Reliability: By identifying and addressing potential failure modes, FTA helps to improve the overall reliability and availability of systems.

Enhanced Safety: FTA is particularly useful in identifying and mitigating safety hazards, thereby reducing the risk of accidents and injuries.

Compliance with Regulations: Many industries have specific regulations and standards that require the use of failure analysis techniques such as FTA.

Cost Savings: By preventing failures and downtime, FTA can help organizations save significant costs associated with repairs, replacements, and lost productivity.

FTA is widely used in various industries, including:

Aerospace: FTA is used to analyze the reliability and safety of aircraft systems, such as engines, avionics, and flight controls.

Nuclear Power: FTA is a critical tool in ensuring the safe operation of nuclear power plants and identifying potential failure modes that could lead to accidents.

Automotive: FTA is used to analyze the reliability and safety of vehicle systems, such as brakes, steering, and powertrain.

Telecommunications: FTA is used to analyze the reliability of communication networks and identify potential points of failure that could disrupt service.

Real-World Examples of Fault Tree Analysis

To illustrate the practical applications of FTA, let's consider a few real-world examples:

Example 1: NASA's Mars Climate Orbiter

In 1999, NASA's Mars Climate Orbiter spacecraft was lost due to a navigation error caused by a mix-up between metric and imperial units. An FTA was conducted to identify the root causes of the failure, which included:

Lack of communication between different teams

Inadequate verification and validation processes

Insufficient documentation and configuration management

The results of the FTA were used to implement improvements to NASA's project management and quality assurance processes, helping to prevent similar failures in future missions.

Example 2: Deepwater Horizon Oil Spill

In 2010, the Deepwater Horizon oil rig exploded and sank, causing the largest marine oil spill in history. An FTA was conducted to identify the root causes of the disaster, which included:

Faulty well design and construction

Inadequate testing and maintenance of safety systems

Lack ofoversight and regulation by government agencies

The results of the FTA led to significant changes in the regulation and oversight of offshore drilling operations, as well as improvements to the design and maintenance of deep-water oil rigs.

Example 3: Toyota's Unintended Acceleration Incidents

In 2009-2010, Toyota faced a series of incidents involving unintended acceleration in its vehicles, leading to recalls of millions of cars worldwide. An FTA was conducted to identify the potential causes of the problem, which included:

Faulty accelerator pedal design

Inadequate fail-safe mechanisms

Insufficient testing and quality control

The results of the FTA were used to implement design changes and improve quality control processes, helping to restore consumer confidence in Toyota's vehicles.

Challenges and Limitations of Fault Tree Analysis

While FTA is a powerful tool for analyzing system failures, it is not without its challenges and limitations. Some of the key challenges include:

Complexity: As systems become more complex, the fault trees can become very large and difficult to construct and analyze.

Data Availability: FTA relies on accurate data about the reliability and failure rates of system components, which may not always be available or up-to-date.

Human Factors: FTA can be challenging to apply to systems that involve significant human interaction, as human behavior is often difficult to predict and quantify.

Cost and Time: Conducting a thorough FTA can be time-consuming and costly, particularly for large and complex systems.

Despite these challenges, FTA remains a valuable tool for organizations seeking to improve the reliability, safety, and performance of their systems.

Conclusion

Fault Tree Analysis is a powerful technique for identifying and evaluating potential failures in complex systems. By breaking down the top event into its contributing factors and analyzing the relationships between them, FTA provides a systematic approach to understanding and mitigating failure risks.

Throughout this guide, we have explored the key components of FTA, the steps involved in conducting an analysis, and the benefits and applications of FTA across various industries. We have also discussed some of the challenges and limitations of FTA and provided real-world examples to illustrate its practical applications.

As someone who has worked extensively with FTA, I can attest to its value in improving system reliability, safety, and performance. However, it is important to recognize that FTA is not a silver bullet and should be used in conjunction with other tools and techniques as part of a comprehensive failure analysis and risk management strategy.

Looking to the future, I believe that FTA will continue to evolve and adapt to the changing needs of organizations and the increasing complexity of systems. Advances in technology, such as artificial intelligence and machine learning, may help to automate and streamline the FTA process, making it more accessible and efficient.

Ultimately, the success of FTA depends on the skill and expertise of the analysts who conduct it, as well as the commitment of organizations to act on the results and implement improvements. By embracing FTA as a core part of their failure analysis and risk management strategies, organizations can create safer, more reliable, and more resilient systems that deliver value to their stakeholders.

Frequently Asked Questions

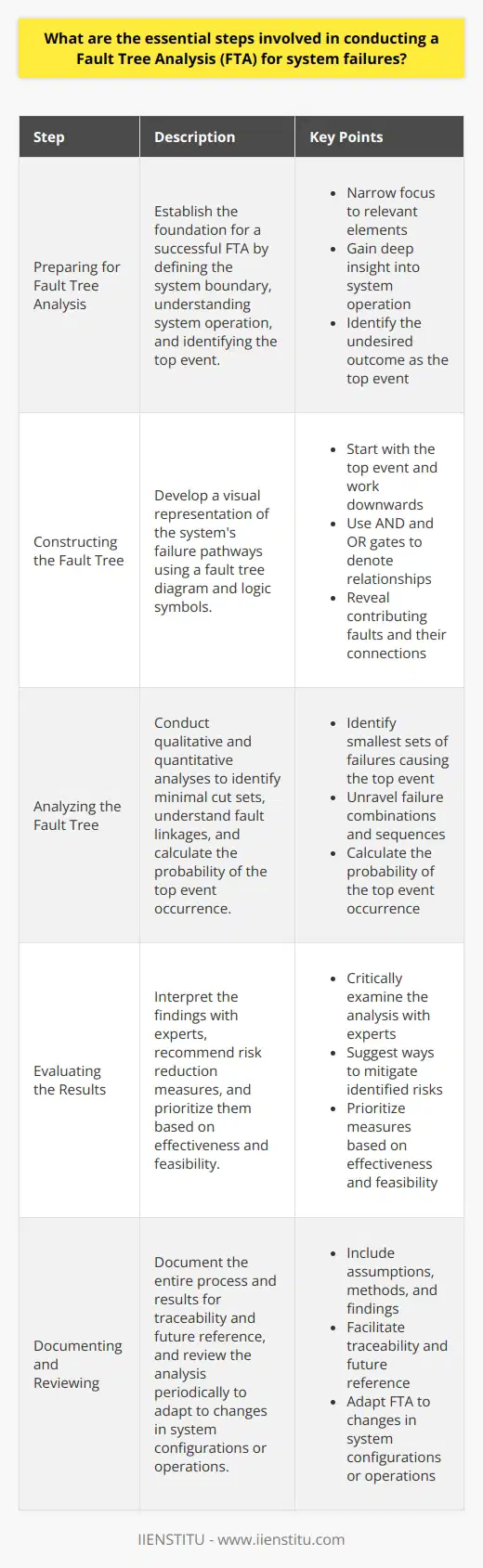

What are the essential steps involved in conducting a Fault Tree Analysis (FTA) for system failures?

Introduction to Fault Tree Analysis

Fault Tree Analysis (FTA) constitutes a methodical and deductive tool. It serves to analyze system reliability and safety. FTA mainly investigates high-level failures. Experts apply it in various fields, from engineering to safety evaluations.

Preparing for Fault Tree Analysis

Define the system boundary. It narrows the focus to relevant elements only. Understand system operation thoroughly. This deepens insight for accurate FTA application. Identify the top event as the starting point of the analysis. This event typically symbolizes a system failure or undesired outcome.

Constructing the Fault Tree

Develop a fault tree diagram. Use it to visualize the system's failure pathways. The diagram starts with a single top event. You then work downwards to reveal contributing faults. Use logic symbols to denote the relationships between events. Common symbols include AND and OR gates.

Analyzing the Fault Tree

Identify minimal cut sets. These are smallest sets of failures that cause the top event. Perform qualitative analysis to understand fault linkages. This step unravels failure combinations and sequences. Conduct quantitative analysis if needed. It calculates the probability of the top event occurrence.

Evaluating the Results

Interpret the findings with experts. This should involve a critical examination of the analysis. Recommend risk reduction measures. It implies suggesting ways to mitigate identified risks. Prioritize these measures based on their effectiveness and feasibility.

Documenting and Reviewing

Document the entire process and results. It facilitates traceability and future reference. Ensure to include assumptions, methods, and findings. Review the analysis periodically. It adapts the FTA to changes in system configurations or operations.

Conclusion

Successful FTA implementation requires precision, attention to detail, and critical thinking. It offers invaluable insight into potential failure modes. FTA paves the way for enhancing system resilience and safety. Regular reviews ensure the FTA remains relevant and effective.

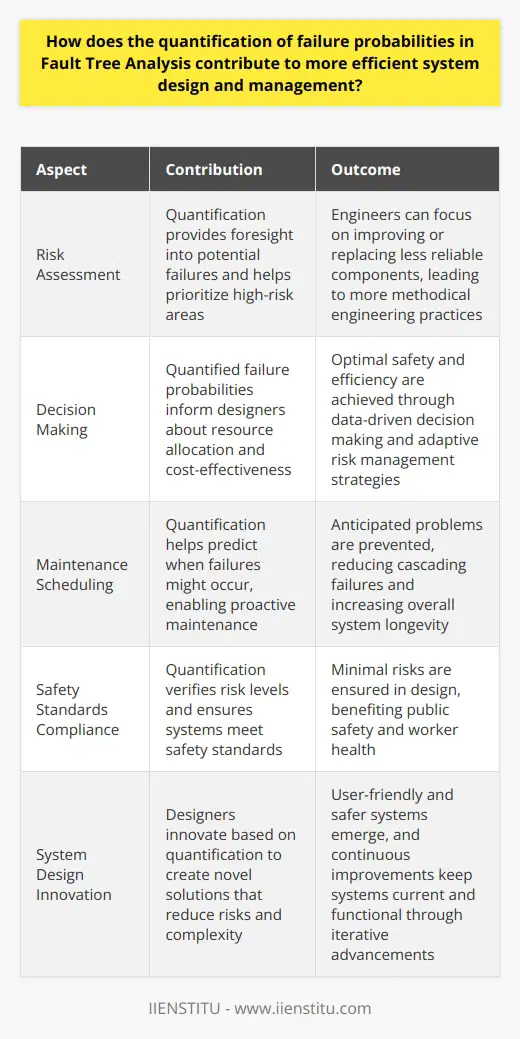

How does the quantification of failure probabilities in Fault Tree Analysis contribute to more efficient system design and management?

Understanding Fault Tree Analysis

Fault Tree Analysis (FTA) exists as a vital method. Experts use it in risk management and system reliability. It helps in identifying potential failures in complex systems. The aim of FTA is to quantify failure probabilities. This quantification allows for better design and management.

Quantification and System Design Optimizations

Insightful Risk Assessment

Engineers gain foresight with quantified failure probabilities. They foresee where failures might occur. Quantification aids in prioritizing. High-risk areas need more attention. Less reliable components can be improved or replaced. This data-driven approach leads to methodical engineering practices.

Informed Decision Making

Decisions become more informed. Designers know where to allocate resources. They strive for optimal safety and efficiency. Cost-effectiveness shapes system design decisions. Risk management strategies adapt accordingly.

Improved Management and Maintenance

Proactive Maintenance Scheduling

Quantification directs maintenance efforts. It helps predict when failures might occur. Maintenance can prevent anticipated problems. This proactive stance prevents cascading failures. Overall system longevity increases.

Resource Allocation Efficiency

Management resources align with real risks. Budgets reflect necessary preventive measures. Focused investments in high-risk areas occur. This strategic approach saves time and money.

Enhancing Safety and Reliability

Safety Standards Compliance

Systems must meet safety standards. Quantification ensures compliance, as it verifies risk levels. It ensures design bears minimal risks. Public safety and worker health benefit.

Building System Resilience

Design changes foster resilience. Systems withstand surrounding hazards. Risk becomes manageable. Continuous operations are more likely. Downtimes reduce with resilient designs.

Advancing Methodological Development

Innovation in System Design

Designers innovate based on quantification. They create novel solutions to reduce risks. Complexity decreases in new designs. User-friendly and safer systems emerge as results.

Continuous Improvement

Systems undergo regular re-evaluation. Designers return to the drawing board. Improvements keep systems current and functional. Iterative advancements become the norm. Every iteration hones system reliability.

Conclusion

FTA transforms system design and management. This is clear from improved risk assessment to enhanced safety. Efficient resource allocation to innovative design benefits. Systems achieve better performance, safety, and reliability. Quantification is key in navigating complex system challenges. It fuels the drive for excellence in various industries.

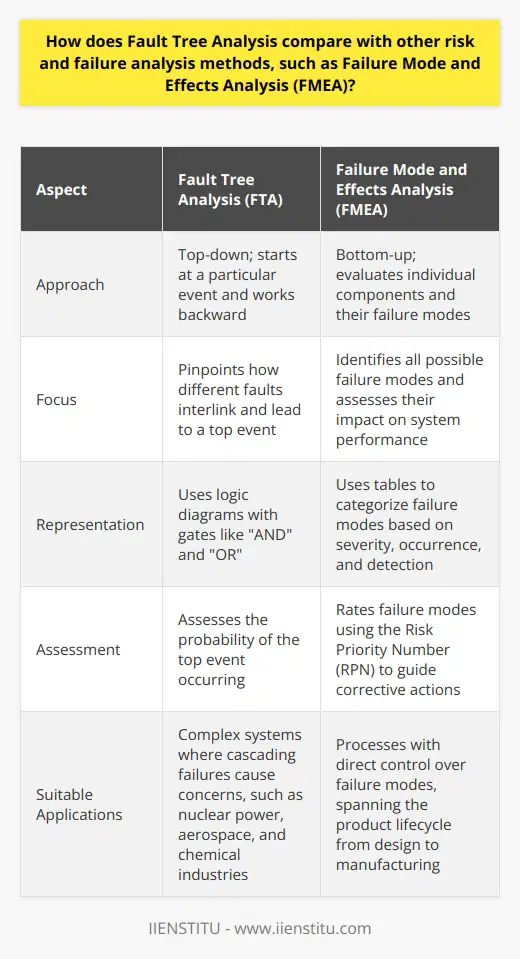

How does Fault Tree Analysis compare with other risk and failure analysis methods, such as Failure Mode and Effects Analysis (FMEA)?

Fault Tree Analysis versus Other Methods

When evaluating risks and failures, multiple methods arise. Each offers unique insights into system reliability and potential weaknesses. Fault Tree Analysis (FTA) and Failure Mode and Effects Analysis (FMEA) stand out as prevalent techniques.

Understanding FTA

Fault Tree Analysis (FTA) identifies faults in complex systems. It starts at a particular event and works backward. Analysts map out possible causes using logic gates like "AND" and "OR". It's a top-down approach.

FTA excels in pinpointing how different faults interlink. It allows for clear visual representation of failure paths. This analysis helps assess the probability of the top event occurring. It serves sectors where failure demands immediate attention. These include nuclear power, aerospace, and chemical industries.

Defining FMEA

In contrast, Failure Mode and Effects Analysis (FMEA) evaluates components. It categorizes failure modes based on their severity, occurrence, and detection. From this, we obtain the Risk Priority Number (RPN). It guides corrective actions.

FMEA offers a systematic, in-depth approach. It focuses on identifying all possible failure modes. It then assesses how each failure impacts system performance. FMEA can span the product lifecycle, covering design and manufacturing processes.

Key Differences

How do FTA and FMEA differ then?

- FTA is top-down; FMEA is bottom-up.

- FTA focuses on one failure at a time. FMEA examines all potential failures.

- FTA uses logic diagrams; FMEA uses tables.

- FTA assesses failure probabilities. FMEA rates failure modes via RPN.

FTA suits complex systems where cascading failures cause concerns. It answers the question: "What if this top event happens?". In contrast, FMEA fits processes with direct control over failure modes. It answers, "What failures could happen?".

Complementary Strengths

Yet, these methods are not at odds. In fact, they complement each other. FTA helps understand system-wide effects. It places a spotlight on big-picture risks. Meanwhile, FMEA drills down. It prioritizes specific components and their failure modes.

For a comprehensive risk assessment, using both proves wise. Analysts gain a broad and detailed perspective.

Practical Applications

Industries employ these analyses per their needs. In aviation, FTA might assess crash potentials. FMEA could focus on engine failure modes. In automotive, FTA might evaluate brake system failures. FMEA could study battery defects.

Both methods require skilled teams. Their insights become invaluable in preventive measures. They guide engineers in designing safer, more reliable systems.

Conclusion

In summary, both FTA and FMEA offer distinct benefits. FTA reveals how different failures connect and compound. FMEA catalogues every possible component failure. Together, they provide a robust framework for anticipating and mitigating risks. Each enhances the other, crafting a fortress against system failures.