The methodological framework known as Design of Experiments (DOE) is transformative in various disciplines, allowing researchers and practitioners the ability to plan, conduct, analyze, and interpret controlled tests to evaluate the factors that may influence a particular outcome. Historically grounded in agricultural and scientific research, DOE has burgeoned into an indispensable tool across a myriad of industries, including manufacturing, healthcare, and marketing. This article aims to elucidate the concepts and applications of Design of Experiments, providing a panoramic as well as an in-depth view of its various principles, types, statistical underpinnings, and practical applications.

Introduction to Design of Experiments (DOE)

Definition and basics of Design of Experiments

Design of Experiments, at its core, is a structured methodological approach used to determine the relationship between factors affecting a process and the output of that process. It encompasses a vast array of strategies for testing hypotheses concerning the factors that could influence a particular variable of interest. The primary aim is not only to affirm the effect of these factors but also to quantify the extent to which they influence results, thus providing a scientific basis for decision-making.

Importance and relevance of DOE

In the contemporary landscape of problem-solving, the significance of DOE is multifaceted. It facilitates a systematic approach to experimentation that is both efficient and economical, reducing the number of trials needed to gather meaningful data. For instance, industries seeking to enhance their product quality can rely on DOE to guide them in identifying significant variables and their optimal settings. Moreover, DOE is an integral component of an effective problem solving techniques course or online certificate courses, as it equips students and professionals with the analytical skills necessary to tackle complex challenges.

Brief history and development of DOE

The foundations of Design of Experiments can be traced back to the early 20th century with the pioneering work of Ronald A. Fisher in the realm of agricultural research. His seminal contributions laid the groundwork for modern DOE, particularly in the context of controlling variation and maximizing information gain. As statistical methods have evolved, DOE has continued to grow in sophistication, integrating advances in computation and information technology to broaden its applicability across various fields.

Key Principles of Design of Experiments (DOE)

Randomization

What is randomization in DOE

Randomization is the backbone of a rigorous experimental design as it mitigates the effects of uncontrolled variables, or confounding factors, ensuring that the treatment groups are comparable. By assigning experimental units to treatment conditions randomly, researchers can confidently attribute differences in outcomes to the factors under study rather than to extraneous variables.

Benefits and significance of randomization

The paramount importance of randomization lies in its capacity to elevate the internal validity of an experiment. It reduces bias and ensures an unbiased estimate of the treatment effect, thus bolstering the credibility of the experimental results. This key principle is an assurance that the experiment's findings can be generalized beyond the study parameters.

Examples illustrating randomization

Consider a clinical trial for a new pharmaceutical product. If participants are randomized into the control and treatment groups, any difference observed in outcomes can be attributed to the drug's effectiveness rather than patient characteristics. This methodological rigor is what makes randomization indispensable in DOE.

Replication

Understanding replication in the context of DOE

Replication is the repeated application of certain conditions within an experiment to ensure that results are not anomalies. It adds precision to the experiment by allowing variance estimation, which is crucial for assessing the reliability of the findings.

Its role and importance in DOE

The role of replication in DOE cannot be overstressed. It affords the experimenter the ability to discern true effects from random errors, thus confirming the consistency of experimental results. When used judiciously, replication improves the power of the experiment, enabling more definitive conclusions.

Applicable examples of replication

For instance, verifying the strength of a newly engineered material could involve subjecting multiple samples to stress tests under identical conditions. The consistency in the failure threshold across these samples would indicate the reliability of the material's design as determined through replication.

Blocking

Concept of blocking in DOE

Blocking is a technique used to account for variability among experimental units that cannot be eliminated. By grouping similar experimental units together and carrying out the same experimental conditions within these blocks, one can control the variables leading to variability within each group, thus reducing overall experimental error.

Advantages of using blocking in DOE

Employing blocking in an experiment minimizes the confounding effects of variables that are known but not directly of interest to the study. This approach increases the precision of the estimates of main effects and interactions by isolating the block-to-block variability from the treatment effects. It is particularly useful when one wants to account for heterogeneity among subjects or any other nuisance variable.

Real-world blocking examples

In an agricultural study, fields could be blocked by soil type before the application of different fertilization regimes. This ensures that variation due to soil composition does not skew the results, thus giving a clearer understanding of the fertilizers' effectiveness.

Categories of Design of Experiments (DOE)

Full-factorial Design

Overview and basic understanding

Full-factorial design involves the investigation of every possible combination of factors and their levels. Each treatment combination is applied to separate units in an experiment, making it a comprehensive approach that allows for the assessment of both main effects and interactions between factors.

Strengths and limitations

While the full-factorial design provides a wealth of information about the factors in question, it can be resource-intensive and impractical when dealing with a large number of factors. However, if resources allow, this type of design delivers the most exhaustive data on the effects and possible interactions.

Use case example of full-factorial design

A manufacturer could use a full-factorial design to understand the impact of temperature and pressure on the strength of a welded joint. By varying these factors systematically across all levels, the manufacturer could determine the optimal conditions for the welding process that ensure joint strength.

Fractional-factorial Design

Definition and understanding of the concept

Fractional-factorial design is an efficient variation of the full-factorial design that investigates only a subset of the possible combinations of factor levels. By strategically selecting a fraction of the full design, researchers can still gather information on the most crucial factors influencing an outcome while significantly reducing the number of experiments.

Advantages and drawbacks

This design's main advantage is its economy in terms of time and resources. Nonetheless, this comes with the potential drawback of confounding, which is when two or more factor effects cannot be separated due to the design's reduced size. Researchers must balance the need for information with the constraints of their experimental budget.

Case study demonstrating the use of fractional-factorial design

A tech company wanting to assess the design features impacting user engagement might employ a fractional-factorial design to investigate a manageable subset of combinations rather than exhaust every potential variation, thereby identifying critical design elements efficiently.

Response Surface Design

Explaining Response Surface Design

Response Surface Design (RSD) is focused on modeling the relationship between a response and a set of quantitative variables. It is particularly useful when the goal is optimization, as RSD can identify the levels of factors that lead to the best possible outcome.

Pros and cons of using Response Surface Design

RSD exhibits potency in exploring complex, nonlinear relationships and can be pivotal in honing in on optimal conditions. However, constructing a suitable response surface model often requires a more significant number of experimental runs compared to simpler designs, and interpreting the resulting model may necessitate a substantial level of statistical expertise.

Applicable example of response surface design

An example might involve a food scientist employing RSD to optimize a recipe for flavor and texture by manipulating ingredient ratios and cooking times. By analyzing the response surface, the scientist can pinpoint the exact conditions that yield the best culinary result.

Statistical Analysis in Design of Experiments (DOE)

Role of statistical analysis in DOE

Statistical analysis is fundamental in DOE, as it transforms experimental data into meaningful insights. Here, analytic techniques are employed to discern patterns, test hypotheses, and derive conclusions that can withstand scrutiny within the scientific community.

Various statistical techniques applied in DOE

The array of statistical methods applied within DOE is expansive, encompassing t-tests, ANOVA, regression analysis, and multivariate techniques, among others. Selecting the appropriate method hinges on the complexity of the data structure and the goals of the research.

Examples demonstrating the importance of statistical analysis in DOE

For instance, a multinational corporation might conduct a series of experiments to improve a product feature. Utilizing ANOVA, researchers can determine whether differences in quality metrics across various production sites are statistically significant, guiding quality improvement efforts.

Practical Applications of Design of Experiments (DOE)

DOE in product and process development

DOE plays a critical role in new product development and process refinement. By assessing the impact of variable changes, designers and engineers can develop superior products and streamline processes for improved performance and cost-efficiency.

The role of DOE in industrial manufacturing

In the context of industrial manufacturing, DOE is an invaluable asset. It assists in identifying key process factors and optimizing manufacturing conditions, resulting in enhanced quality control and reduced production costs—a boon for competitiveness in the market.

Case studies showing the impact of DOE in various fields

Case studies from the pharmaceutical industry to aerospace engineering demonstrate DOE's vital contributions. Whether optimizing drug formulations or adjusting flight parameters, DOE's applications are incredibly diverse and contribute significantly to scientific and technological advancements.

Conclusion: Future Trends and Developments in Design of Experiments (DOE)

Current trends in DOE

The recent trends in DOE point towards the integration of more advanced computational techniques, like machine learning algorithms, to handle complex, high-dimensional data sets and to refine predictive models for experimental outcomes.

Future outlook and potential advancements in DOE

Looking ahead, we may witness the further development of real-time analytics in DOE, enabling even more dynamic exploration of experiment spaces, perhaps leading to adaptive experimentation that could revolutionize fields as disparate as genomics and supply chain management.

Final thoughts and recommendations for further studies in DOE

As the landscape of DOE progresses, so does the need for educational pursuits such as online certificate courses in this area, fostering a new generation of adept experimenters equipped with equipped with the latest tools and techniques. Investigators are encouraged to undertake further studies in DOE to harness its full potential—a testament to the enduring relevance and flexibility of this methodological powerhouse.

Frequently Asked Questions

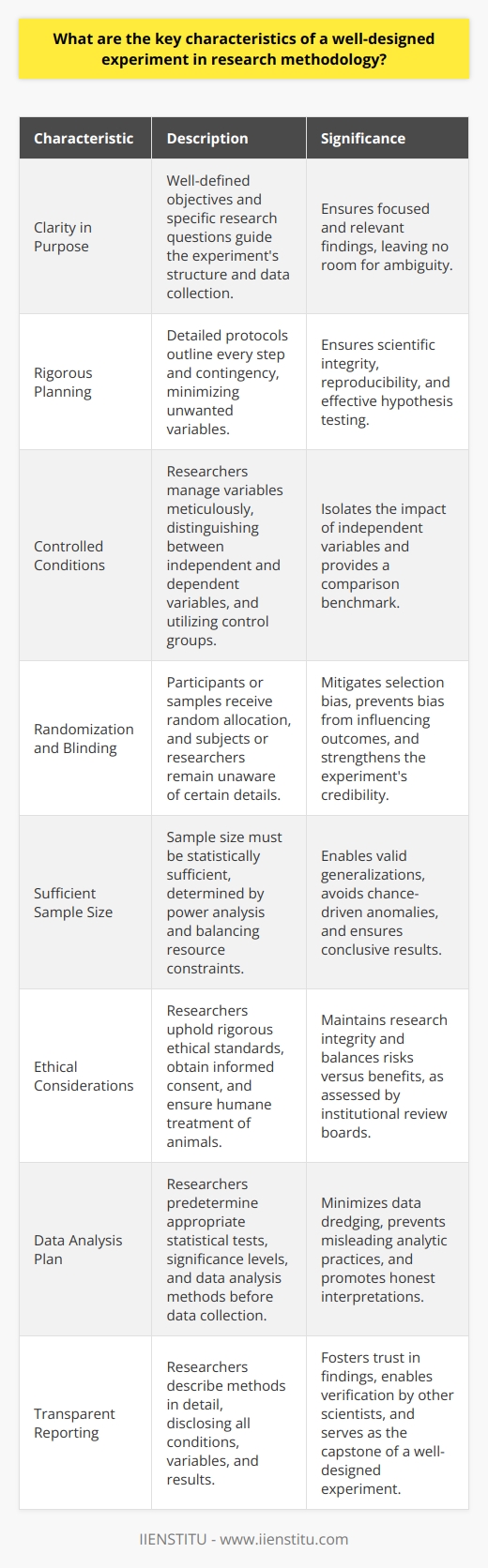

What are the key characteristics of a well-designed experiment in research methodology?

Well-Designed Experiment Essentials

Clarity in Purpose

A well-crafted experiment begins with a crystal-clear objective. Researchers should articulate their primary questions. These drive the experiment. Specific goals guide the study's structure. Precise objectives leave no room for ambiguity. Clear aims ensure focused data collection. This results in robust and relevant findings. Clarity underscores every experiment layer.

Rigorous Planning

Rigorous planning underpins scientific integrity. Researchers craft detailed protocols. These serve as experiments' blueprints. They outline every step and contingency. Careful design minimizes unwanted variables' intrusion. It ensures the experiment can test hypotheses effectively. Predefined procedures guarantee the study's repeatability. Other scientists can replicate the study with ease.

Controlled Conditions

Experiments thrive under control. Researchers strive for controlled environments. They manage variables meticulously. Control is not absolute but optimized. Key is distinguishing between independent and dependent variables. Independent variables undergo deliberate changes. Researchers measure dependent variables for effect assessments. Control groups provide a comparison benchmark. They remain untouched, isolating the independent variable’s impact.

Randomization and Blinding

Randomization promotes objectivity. It mitigates selection bias. Participants or samples receive random allocation. This ensures equal distribution of confounding variables. Blind or double-blind setups conceal information. Subjects or researchers remain unaware of certain details. This prevents bias from influencing outcomes. Blinding strengthens an experiment's credibility.

Sufficient Sample Size

Sample size holds crucial importance. It must be statistically sufficient. Adequacy enables valid generalizations. Small samples undermine the study's validity. They invite chance-driven anomalies. Optimal size depends on the expected effect size. Power analysis often determines the required sample. Researchers seek a balance. Overly large samples waste resources. Insufficient samples yield inconclusive results.

Ethical Considerations

Ethical concerns stand paramount. Researchers uphold rigorous ethical standards. Participants give informed consent. They understand the experiment's nature. Ethical treatment extends beyond humans. Animal studies require humane conduct. Ethical oversight comes from institutional review boards. They assess risks versus benefits. They ensure research integrity.

Data Analysis Plan

Planning extends to data analysis. Researchers must decide on this before data collection. They determine which statistical tests fit their data. They predefine significance levels. This minimizes data dredging after the fact. A thorough plan prevents misleading analytic practices. It directs researchers to honest interpretations.

Transparent Reporting

Finally, clarity in reporting is essential. Researchers describe their methods in detail. They disclose all conditions, variables, and results. Transparency fosters trust in the findings. It enables other scientists to verify results. Clear reporting is the capstone of a well-designed experiment.

In summary, these characteristics thread through exemplary research. They elevate experiments from mere inquiry to scientific evidence. They bolster confidence in the knowledge we gain. Researchers must adhere to these tenets. Only then can we rely on their discoveries.

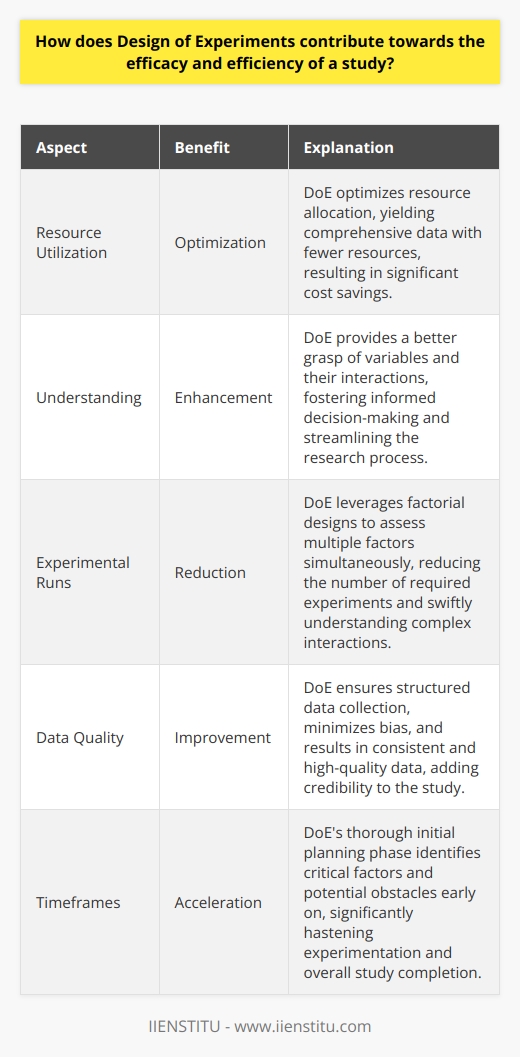

How does Design of Experiments contribute towards the efficacy and efficiency of a study?

Unveiling the Power of Design of Experiments

Efficient Resource Utilization

Design of Experiments (DoE) stands pivotal. It optimizes resource allocation. Fewer resources yield comprehensive data. This translates into significant cost savings. Each experiment harnesses maximal information gain.

Enhanced Understanding

DoE allows for a better grasp of variables. It clarifies the interaction between factors. Such insights foster informed decision-making. They also streamline the research process considerably.

Systematic Approach

The approach of DoE is inevitably systematic. It eliminates the hit-and-miss experiments. Every trial becomes a well-thought-out step. Researchers work with clear objectives and methods.

Reduction of Experimental Runs

One key benefit is reduced experimental runs. DoE leverages factorial designs. These designs assess multiple factors simultaneously. They aid in understanding complex interactions swiftly. Thus, they reduce the number of required experiments.

Data Quality Improvement

With DoE, data quality improves. The method ensures a structured data collection. Bias minimization is a direct outcome. Consistent and high-quality data is the result. This robustness adds credibility to the study.

Accelerated Timeframes

DoE can significantly hasten experimentation. A thorough initial planning phase foresees potential obstacles. It also identifies the most critical factors early on. Time saved here quickens overall study completion.

Risk Mitigation

Risk reduction is another aspect. DoE helps in anticipating variability. Researchers understand possible outcomes better. Preemptive measures are then easier to implement.

Decision-Making Precision

DoE offers precise guidance for decision-making. It sorts critical from trivial factors. Decisions are therefore more data-driven. Their precision enhances the study's value.

Optimization of Conditions

It aids in the optimization of experimental conditions. Optimal settings are quickly identified. This leads to better product quality or process efficiency.

Conclusion

Design of Experiments revolutionizes research efficacy and efficiency. Researchers see DoE as more than a tool. It's a strategic ally in scientific inquiry. Its methodical, efficient, and data-centric approach is unmatched. The results? Enhanced understanding, quality, and breakthroughs in less time.

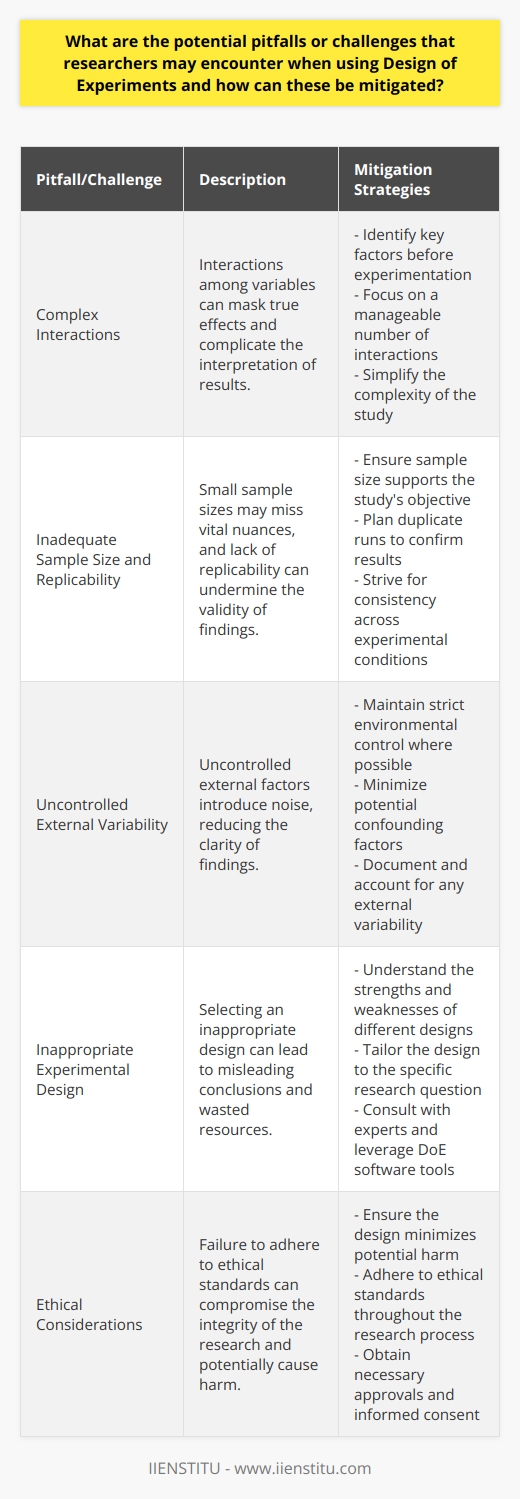

What are the potential pitfalls or challenges that researchers may encounter when using Design of Experiments and how can these be mitigated?

Understanding Design of Experiments

Design of Experiments (DoE) serves as a powerful tool. It enables researchers to systematically explore complexities in various fields. In DoE, potential confounding factors can skew results. Researchers must handle these with care. Proper experimental design is thus pivotal.

Addressing Complex Interactions

Interactions among variables often complicate DoE. These interactions can mask true effects. Identify key factors before experimentation. Focus on a manageable number of interactions. Simplify the complexity of your study.

Adequate Sample Size and Replicability

Sample size directly affects the power of an experiment. Too small a size may miss vital nuances. Ensure the sample size supports your study's objective. Replicability is a cornerstone of scientific research. Repetition validates the initial findings. Plan duplicate runs to confirm results.

Controlling External Variability

Uncontrolled external factors introduce noise. This noise can reduce the clarity of findings. Maintain strict environmental control where possible. Strive for consistency across all experimental conditions.

Choosing the Right Design

Selecting an inappropriate design can lead to misleading conclusions. Understand the strengths and weaknesses of different designs. Tailor the design to your specific research question.

Handling Missing or Outlying Data

Data may go missing or fall outside expected ranges. Develop a plan for dealing with such data. Consider statistical methods like imputation for missing values. Apply outlier tests to determine the fate of anomalies.

Statistical Proficiency

DoE demands statistical knowledge. Interpret results with statistical confidence. Derive meaningful insights without overstepping the data's bounds. Stay educated on statistical methods relevant to DoE.

Ethical Considerations

Ethical concerns must guide any experimental work. Ensure that your design minimizes potential harm. Adhere to ethical standards throughout your research.

Mitigating Challenges in DoE

Researchers can take steps to improve the robustness of their experimental designs.

- Plan Thoroughly: Pre-experimental planning is critical. Anticipate challenges and lay out a clear roadmap.

- Pilot Studies: Conduct preliminary tests. These can highlight unforeseen issues. Address these before proceeding with the full-scale experiment.

- Educate Yourself: Nurture a deep understanding of DoE principles. Attend workshops and seminars. Stay abreast of advancements in experimental design.

- Consult Experts: Do not hesitate to seek advice. Collaborate with statisticians and experts. Their insights can help craft a more sound experiment.

- Software Tools: Leverage software designed for DoE. These can automate complex statistical computations. Ensure accuracy in your design and analysis.

- Documentation: Keep detailed records of every step. Document the rationale behind decisions. This transparency aids in replicating and validating results.

Engagement with these strategies can lead to stronger, more reliable experiments. It enables researchers to maneuver through potential pitfalls confidently. Acknowledge the complexities of DoE. Strive for rigor in design and execution. The reward is valid, reproducible knowledge that advances your field.