It was not so long ago when I found myself standing in the bustling warehouse of the company I had just joined. The sheer complexity of the operations nearly overwhelmed me. Pallets of goods moved in and out, forklifts whizzed by, and orders were being processed at a breakneck speed. I remember thinking, "How does everything manage to fall into place?" It was then that I realized the immense power of mapping the supply chain journey.

Creating a Map

Benefits of Mapping

Challenges of Mapping

Understanding the Importance of Mapping

In today's fast-paced world, supply chains have become more intricate than ever before. With globalization, we have multiple suppliers scattered across the globe, various stakeholders with different interests, and countless variables that can affect the smooth delivery of products. Mapping the supply chain isn't just a theoretical exercise—it's essential for anyone serious about improving logistics operations.

My First Encounter with Supply Chain Mapping

I recall the day my mentor handed me a rolled-up blueprint. At first glance, it seemed like a maze. But as he started explaining, the lines and symbols began to make sense. This map wasn't just a diagram; it was a living representation of every step our products took from raw materials to the customer's hands. That hands-on experience was invaluable. It highlighted the benefits of supply chain mapping, and how it could unveil inefficiencies we hadn't even noticed before.

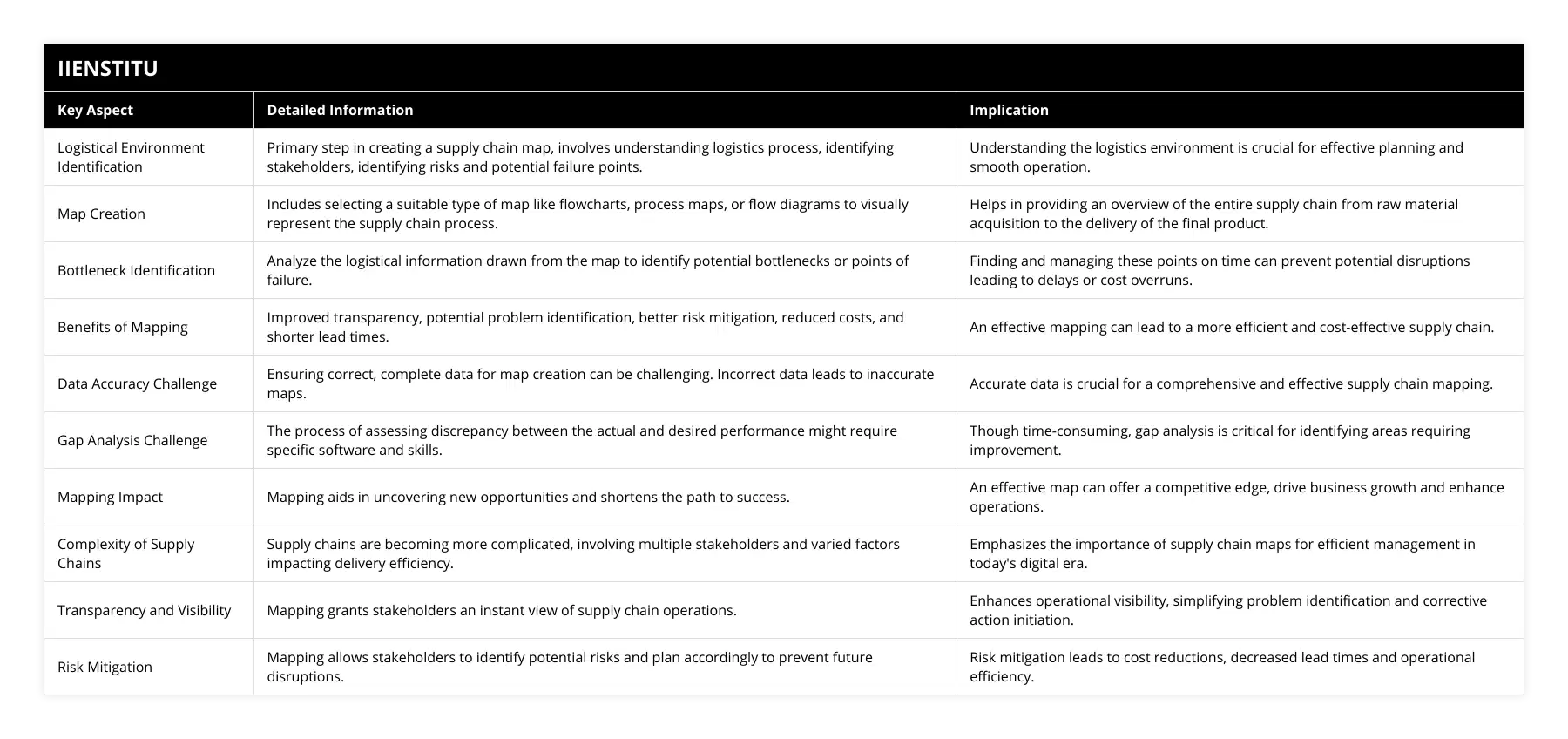

Creating a Map: Step by Step

So, how does one begin to create such a map?

1. Identifying the Logistical Environment

The first step is to understand the logistical environment. This means diving deep into:

The nature of your logistics process

The stakeholders involved (from suppliers to customers)

Potential risks and points of failure

For instance, when we started, we listed out every single entity involved in our supply chain. That included raw material suppliers, manufacturing plants, distribution centers, and even the transportation modes used.

2. Choosing the Right Mapping Tools

There are several types of maps you can use:

1- Flowcharts: These provide a simple visual representation. They are great for high-level overviews.

2- Process Maps: Offer more detailed insights into each step.

3- Flow Diagrams: Useful for complex processes with multiple branches.

We opted for a combination. The flowcharts helped our upper management grasp the big picture, while the process maps were invaluable for the operations team.

3. Analyzing Logistical Information

Once the map is created, the next step is to analyze it to identify potential bottlenecks. This involves:

Tracking the flow of information between stakeholders

Identifying areas where delays occur

Spotting redundancies in the process

During our analysis, we discovered that our lead times were longer than necessary. Further digging revealed that a particular approval process was causing delays. By streamlining this step, we reduced our delivery times by 15%.

The Benefits of Mapping the Supply Chain Journey

The advantages of mapping are manifold.

Improved Transparency and Visibility

Perhaps the most immediate benefit is enhanced transparency. Everyone involved can get an instant view of the operations. This clarity helps in:

Making informed decisions quickly

Enhancing collaboration among stakeholders

Building trust with partners and customers

Identifying Bottlenecks and Inefficiencies

A good map of the supply chain journey can uncover new opportunities and shorten the path to success.

Mapping allows us to spot:

Bottlenecks that slow down operations

Redundant processes that add no value

Areas where resources are over or under-utilized

For example, after mapping, we found out that two departments were performing similar quality checks independently. By integrating these checks, we saved time and resources.

Better Risk Mitigation

Supply chains are fraught with risks. From natural disasters affecting suppliers to sudden demand spikes, anything can happen. By having a mapped-out supply chain, we can:

Anticipate potential disruptions

Develop contingency plans

Reduce operational costs associated with unexpected events

Improved Customer Satisfaction

At the end of the day, our goal is to satisfy the customer. By optimizing our supply chain:

Delivery times are reduced

Product quality improves

Customer complaints decrease

I remember a time when a significant client was on the verge of switching to a competitor due to delayed deliveries. Thanks to our mapped supply chain, we quickly identified the issue and rectified it, retaining the client and even strengthening our relationship.

Challenges in Mapping the Supply Chain

Of course, it's not all smooth sailing.

Data Accuracy Issues

One of the biggest challenges is ensuring the accuracy of data. If the information fed into the map is incorrect, the insights drawn will be misleading. This means:

Regularly updating data

Validating information from multiple sources

Training staff to maintain data integrity

Time and Resource Intensive

The process of mapping itself can be:

Time-consuming

Require specialized software

Need skilled personnel to interpret and analyze the maps

In our case, we had to invest in training sessions for our team. While it was an upfront cost, the long-term benefits far outweighed it.

Resistance to Change

Human nature often resists change. Implementing new processes based on mapping insights can face pushback from:

Employees set in their ways

Departments fearing additional workload

Stakeholders uncomfortable with transparency

Addressing this requires:

Effective communication

Demonstrating the benefits clearly

Involving everyone in the process

Embracing Digital Transformation

In the digital era, supply chain mapping has evolved. Technologies like:

Artificial Intelligence (AI)

Blockchain

Internet of Things (IoT)

have revolutionized how we approach mapping.

Leveraging Technology for Better Mapping

We incorporated an AI-driven platform that:

Monitored real-time data

Predicted potential disruptions

Offered optimization suggestions

This proactive approach made our supply chain more resilient.

The Role of Collaboration Tools

With stakeholders spread globally, tools that facilitate communication are crucial. Platforms that allow:

Real-time updates

Shared access to maps

Collaborative editing

ensure that everyone stays on the same page.

Reassignment Requests and Supply Chain Optimization

Sometimes, mapping the supply chain uncovers the need to reassign resources or personnel. For employees facing such changes, understanding the process is vital. If you ever find yourself needing to navigate this landscape, seeking reassignment request letter tips and information can be incredibly helpful. It ensures that the transition is smooth and aligns with both personal and organizational goals.

Real-World Example: The Automotive Industry

The automotive industry provides a great example of the importance of supply chain mapping.

Supply Chain Complexity

An automobile comprises thousands of parts sourced globally. Mapping helps:

Coordinate multiple suppliers

Manage just-in-time inventory

Ensure quality control across borders

Risk Mitigation

When the 2011 tsunami hit Japan, many car manufacturers faced disruptions. Those with well-mapped supply chains could quickly:

Identify affected suppliers

Shift production elsewhere

Minimize production halts

Reference: Johnson, P. F., & Flynn, A. E. (2015). Purchasing and Supply Management. McGraw-Hill Education.

Personal Touch: My Journey in Supply Chain Mapping

Over the years, I've come to appreciate the nuances of supply chain mapping. It's not just about lines and charts but about understanding the heartbeat of an organization's operations.

Lessons Learned

Never underestimate the value of accurate data.

Communication is key—keep all stakeholders informed.

Flexibility allows you to adapt to unforeseen challenges.

One of the most rewarding experiences was mentoring a junior colleague who was struggling to grasp the concepts. Sharing my experiences and watching them grow was fulfilling.

The Future of Supply Chain Mapping

Looking ahead, the importance of supply chain mapping will only grow. With increasing complexities and uncertainties, organizations need to be more agile and responsive.

Sustainability and Ethical Considerations

Consumers are becoming more conscious of:

Environmental impacts

Ethical sourcing

Sustainable practices

Mapping the supply chain can help companies ensure they meet these expectations by:

Tracking the source of materials

Monitoring carbon footprints

Ensuring compliance with regulations

Integrating Advanced Analytics

The next frontier in supply chain mapping involves:

Machine learning algorithms

Predictive analytics

Real-time monitoring

These tools can provide deeper insights and allow for dynamic adjustments to the supply chain.

Conclusion: The Road Ahead

Supply chain mapping is more than a tool—it's a strategy for success. In an ever-changing world, staying ahead requires:

1- Proactive planning

2- Embracing new technologies

3- Continuous improvement

4- Effective communication

5- Fostering collaboration among stakeholders

As I wrap up, I'd like to leave you with this thought: a well-mapped supply chain is like a well-planned journey. You know where you're going, how to get there, and you're prepared for any detours along the way. Investing time and resources into mapping can uncover new opportunities and shorten the path to success.

References

1- Johnson, P. F., & Flynn, A. E. (2015). Purchasing and Supply Management. McGraw-Hill Education.

2- Christopher, M. (2016). Logistics & Supply Chain Management. Pearson UK.

3- Chopra, S., & Meindl, P. (2019). Supply Chain Management: Strategy, Planning, and Operation. Pearson.

4- Mentzer, J. T. (2004). Fundamentals of Supply Chain Management. Sage Publications.

5- Handfield, R., & Nichols, E. (2002). Supply Chain Redesign: Transforming Supply Chains into Integrated Value Systems. Financial Times Prentice Hall.

Note: The above references are provided to enrich the content and are based on established publications in the field of supply chain management.

Frequently Asked Questions

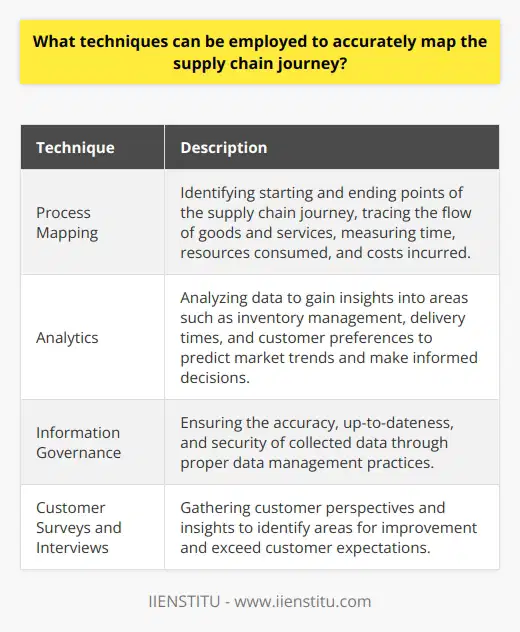

What techniques can be employed to accurately map the supply chain journey?

This blog post explores the importance of accurately mapping a supply chain journey and discusses the techniques employed. It is becoming increasingly important for supply chains to be effectively mapped to secure customer satisfaction, reduce risk and ensure streamlined processes.

Analyzing a supply chain journey is a complex task. However, it is essential to provide insights and manage resources. An accurate mapping process involves obtaining data, outlining objectives, summarizing activities, and monitoring progress to identify potential bottlenecks, improve service quality and increase efficiency. A range of techniques can be employed to effectively and accurately map the supply chain journey.

One approach that is often employed is process mapping. Process mapping identifies the beginning and end points of a supply chain journey. It traces the flow of goods and services from one point to another. This technique can measure the time, resources consumed, and cost incurred to identify improvement areas and create an efficient process.

Analytics is another essential tool for mapping the supply chain journey. Data analysis can gain insights into various areas, such as inventory management, delivery times, and customer preferences. This information is critical in predicting trends in the market and making informed decisions.

Other techniques that can be employed include information governance, which ensures that the data obtained is accurate, up-to-date, and secure. Additionally, customer surveys and interviews can provide invaluable feedback on the effectiveness of your supply chain journey, which can then be used to make necessary changes.

In conclusion, there are a variety of techniques that can be employed to accurately map the supply chain journey. These include process mapping, analytics, information governance, customer surveys, and interviews. By correctly utilizing these tools and tracking customer satisfaction, the supply chain journey can be optimized, and customer expectations can be exceeded.

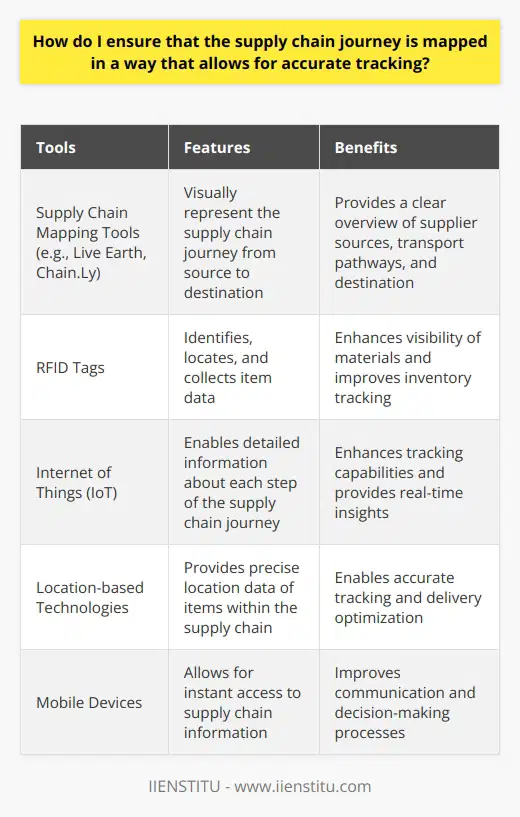

How do I ensure that the supply chain journey is mapped in a way that allows for accurate tracking?

In today's ever-evolving digital environment, it is essential to have a complete understanding of the supply chain journey to ensure accurate and timely tracking of materials. By mapping the entire journey and understanding each component, businesses can gain insight into potential problems and implement measures to mitigate risks and improve service from start to finish.

Firstly, organizations must ascertain the flow of their supply chain journey from the source of materials to their intended destination. This can be achieved through supply chain mapping tools, such as Live Earth and Chain.Ly, which allow businesses to create visual representations of their supply chain journey. Companies can use such mapping tools to see their various supplier sources, transport pathways, and destination.

In addition to mapping the journey, organizations must also consider the process by which the materials are being tracked. For example, an effective tracking system should include RFID tags capable of identifying, locating, and collecting item data. Such tracking capabilities allow for better visibility of materials and improved inventory tracking. In addition, using the Internet of Things (IoT), location-based technologies, and mobile devices can provide even more in-depth elements for hunting throughout each step of the supply chain journey.

Furthermore, collaboration amongst the various actors within the supply chain should be encouraged. By sharing information, businesses within the supply chain journey can more effectively coordinate the entire process, allowing for better tracking capabilities. Such coordination can also help identify potential problems and inefficiencies within the process, thereby allowing for corrective action.

In conclusion, organizations should leverage mapping tools, RFID tags, IoT, and other technologies to ensure the supply chain journey is mapped correctly to allow accurate tracking. Furthermore, collaboration among members within the supply chain should be actively pursued. By doing so, organizations can identify and address problems, leading to a more efficient and streamlined supply chain journey.

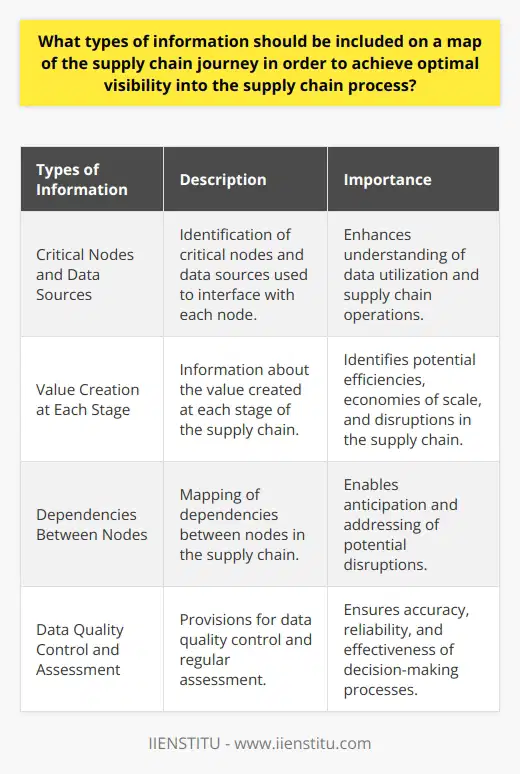

What types of information should be included on a map of the supply chain journey in order to achieve optimal visibility into the supply chain process?

Technological advances within the global landscape have fundamentally altered supply chain governance and management. With digital networks and systems providing unprecedented connectivity and visibility between nodes of the supply chain, mapping contemporary supply chains have become an increasingly important component of overall supply chain management. To ensure optimal visibility into the supply chain process, the following information should be included on a map of the supply chain journey:

Firstly, enhanced visibility into the entire supply chain process requires specifying critical nodes and listing the surrounding data-driven sources used to interface with each node. These sources include inventory management platforms, demand forecasting software, and predictive analytics models. By making these sources visible, a greater level of understanding is gained as to how data can be used to facilitate operations more efficiently along the supply chain.

Secondly, a supply chain map needs to include information about the value created at each supply chain node. By explicitly stating the nature of the output from each stage, a comprehensive assessment can be built to identify the economies of scale within the supply chain that can be leveraged to maximize efficiency. Furthermore, these value metrics can serve as the basis for assessing potential disruptions in the supply chain that could be caused by externalities or internal inefficiencies.

Thirdly, data visibility within the supply chain requires mapping out the dependencies between nodes of the supply chain. Dependencies exist throughout the entire supply chain, and highlighting these dependencies can help identify vulnerable points in the supply chain where system disruption could simultaneously impact multiple issues.

Finally, it is essential to include provision for data quality control and assessment on a map of the supply chain journey. The precision and accuracy of the decisions made from the data can be maximized by assessing the data provided at each stage of the supply chain journey. Furthermore, the results of these data quality control initiatives can provide a deeper understanding of the overall performance of the supply chain, enabling further optimization and efficiency gains.

In conclusion, leveraging existing systems and technologies to gain enhanced visibility into the supply chain process requires a granular approach to mapping the internal workings of the supply chain. As such, a map of the supply chain journey should incorporate information about the surrounding data-driven sources, value creation, dependencies between nodes, and the data quality control process to ensure the optimal visibility and performance of the supply chain.

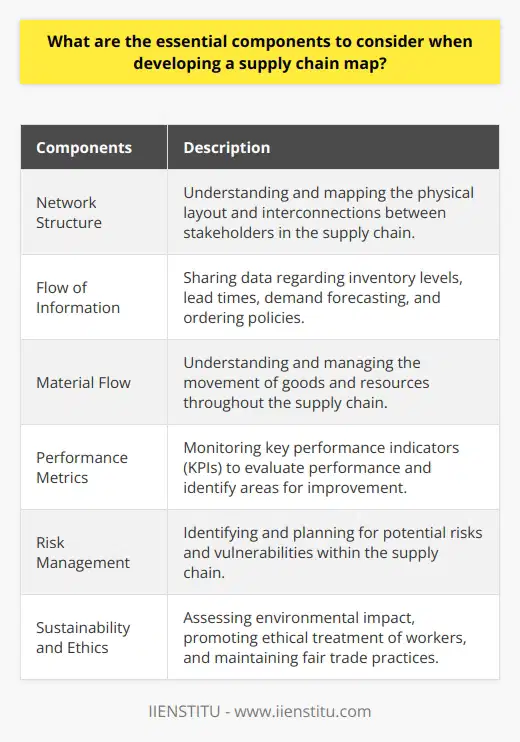

What are the essential components to consider when developing a supply chain map?

Supply Chain Components

Developing a comprehensive supply chain map involves understanding and integrating various essential components. These components are instrumental in ensuring efficiency, transparency, and resilience of the entire supply chain network.

Network Structure

The first component to consider is the network structure, which encompasses the physical layout and interconnections between different stakeholders. This includes suppliers, manufacturers, distribution centers, retail outlets, and end consumers. Identifying and mapping the relationships between these parties is vital to optimize flow, reduce costs, and enable effective decision-making.

Information Flow

Another critical aspect to consider is the flow of information between supply chain participants. This includes sharing data regarding inventory levels, lead times, demand forecasting, and ordering policies. Proper communication and data integration are crucial for coordination, risk management, and mitigating potential disruptions.

Material Flow

Material flow refers to the movement of goods and resources throughout the supply chain. This encompasses procurement, production, warehousing, distribution, and even product returns. Effective supply chain mapping must ensure smooth material flow to reduce lead times, minimize waste, and optimize inventory management.

Performance Metrics

Tracking and evaluating relevant performance metrics contribute to the overall effectiveness and improvements in a supply chain map. These might include key performance indicators (KPI) such as on-time delivery rate, order accuracy, inventory turns, and overall supplier performance. Monitoring these metrics enables organizations to make informed decisions and adjust strategies to enhance performance.

Risk Management

Identifying potential risks and vulnerabilities within the supply chain is yet another vital component. A robust risk management plan must account for risks arising from supplier reliability, transportation disruptions, natural disasters, and geopolitical events. Considering these factors while developing a supply chain map helps in designing contingency plans and maintaining resilience.

Sustainability and Ethics

Lastly, considering sustainability and ethical practices throughout the supply chain is essential. This encompasses assessing the environmental impact, ethical treatment of workers, and maintaining fair trade practices. Ensuring sustainability and ethical practices not only fosters a positive brand image but also contributes to long-term organizational success.

In conclusion, the essential components to consider when developing a supply chain map include the network structure, information flow, material flow, performance metrics, risk management, and sustainability and ethics. Integrating these components effectively can result in a seamless and resilient supply chain that drives organizational growth and profitability.

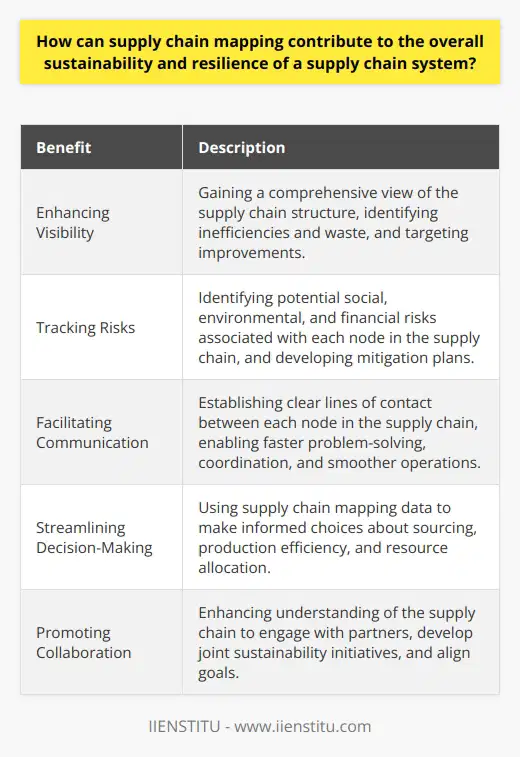

How can supply chain mapping contribute to the overall sustainability and resilience of a supply chain system?

Understanding Supply Chain Mapping

Supply chain mapping contributes to overall sustainability and resilience by enhancing visibility, tracking risks, and facilitating communication. These factors play a crucial role in developing effective, sustainable strategies for a supply chain system.

Enhancing Visibility

Visibility encompasses understanding the various components, suppliers, and sub-suppliers within a supply chain. When businesses map their supply chain, they gain a comprehensive view of its structure. This knowledge enables organizations to identify inefficiencies, reduce waste, and execute targeted improvements. Consequently, supply chain mapping contributes to increased sustainability and performance.

Tracking Risks

Mapping supply chains also allows businesses to track risks effectively. With greater understanding comes the ability to identify potential social, environmental, and financial risks associated with the supply chain. This early identification and assessment of risks enables companies to develop mitigation plans that bolster resilience and further contribute to supply chain sustainability.

Facilitating Communication

Effective communication is essential for maintaining a sustainable and resilient supply chain. Supply chain mapping facilitates communication by establishing clear lines of contact between each node in the system. Improved communication enables faster problem-solving, better coordination, and smoother operations, thereby contributing to the overall resilience of the supply chain system.

Streamlining Decision-Making

A mapped supply chain facilitates streamlining decision-making processes. Businesses can use mapped data to make informed choices about sourcing, production efficiency, and resource allocation. In turn, this leads to better decision-making and increased sustainability throughout the supply chain.

Promoting Collaboration

Supply chain mapping can also foster collaboration between stakeholders throughout the system. By enhancing supply chain understanding, organizations can engage with their partners to develop joint sustainability initiatives or align their goals to achieve a more sustainable supply chain.

In conclusion, supply chain mapping plays a significant role in enabling businesses to optimize their operations for sustainability and resilience. By providing visibility, tracking risks, facilitating communication, streamlining decision-making, and promoting collaboration, supply chain mapping sets the foundation for a sustainable and resilient supply chain system.

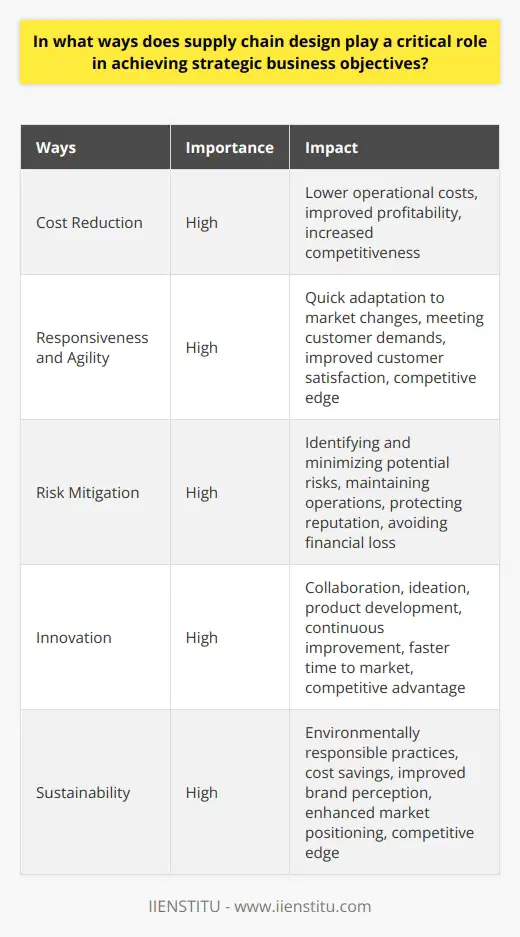

In what ways does supply chain design play a critical role in achieving strategic business objectives?

**Importance of Supply Chain Design**

Supply chain design plays a crucial role in achieving strategic business objectives in several ways. First, it impacts cost reduction, a key factor affecting a company's competitiveness. By designing efficient processes and streamlining product flow, the supply chain can lower operational costs, thus enhancing profitability.

**Responsiveness and Agility**

A well-designed supply chain ensures increased responsiveness and agility. The ability to adapt to market changes and customer demands allows businesses to maintain a competitive edge. A flexible and robust supply chain provides quick responses and prevents stockouts or excess inventory, leading to improved customer satisfaction.

**Risk Mitigation**

Effective supply chain design includes risk mitigation, which is vital for business success. By identifying potential risks and addressing them through contingency planning, businesses can withstand disruptions and minimize the impact on operations or customers. This resilience translates to sustained growth, enhanced reputation, and a reduced likelihood of financial loss.

**Innovation Support**

Supply chain design also supports innovation, a key strategic business driver. By fostering close collaboration between suppliers and other stakeholders, businesses can create platforms for ideation, product development, and continuous improvement. This approach yields novel solutions and a faster time-to-market, reinforcing the organization's competitive advantage.

**Sustainability Integration**

An increasingly important aspect of achieving strategic business objectives is incorporating sustainability into supply chain design. A focus on reducing the environmental footprint of products and operations not only promotes responsible practices but also drives cost savings and improves brand perception. As consumer expectations continue to evolve, businesses that embrace sustainable supply chains benefit from enhanced market positioning and competitive differentiation.

In conclusion, supply chain design plays a critical role in achieving strategic business objectives through cost reduction, enhanced responsiveness, risk mitigation, innovation, and sustainability. By incorporating these elements into supply chain design, organizations can realize significant competitive advantages and position themselves for long-term success.

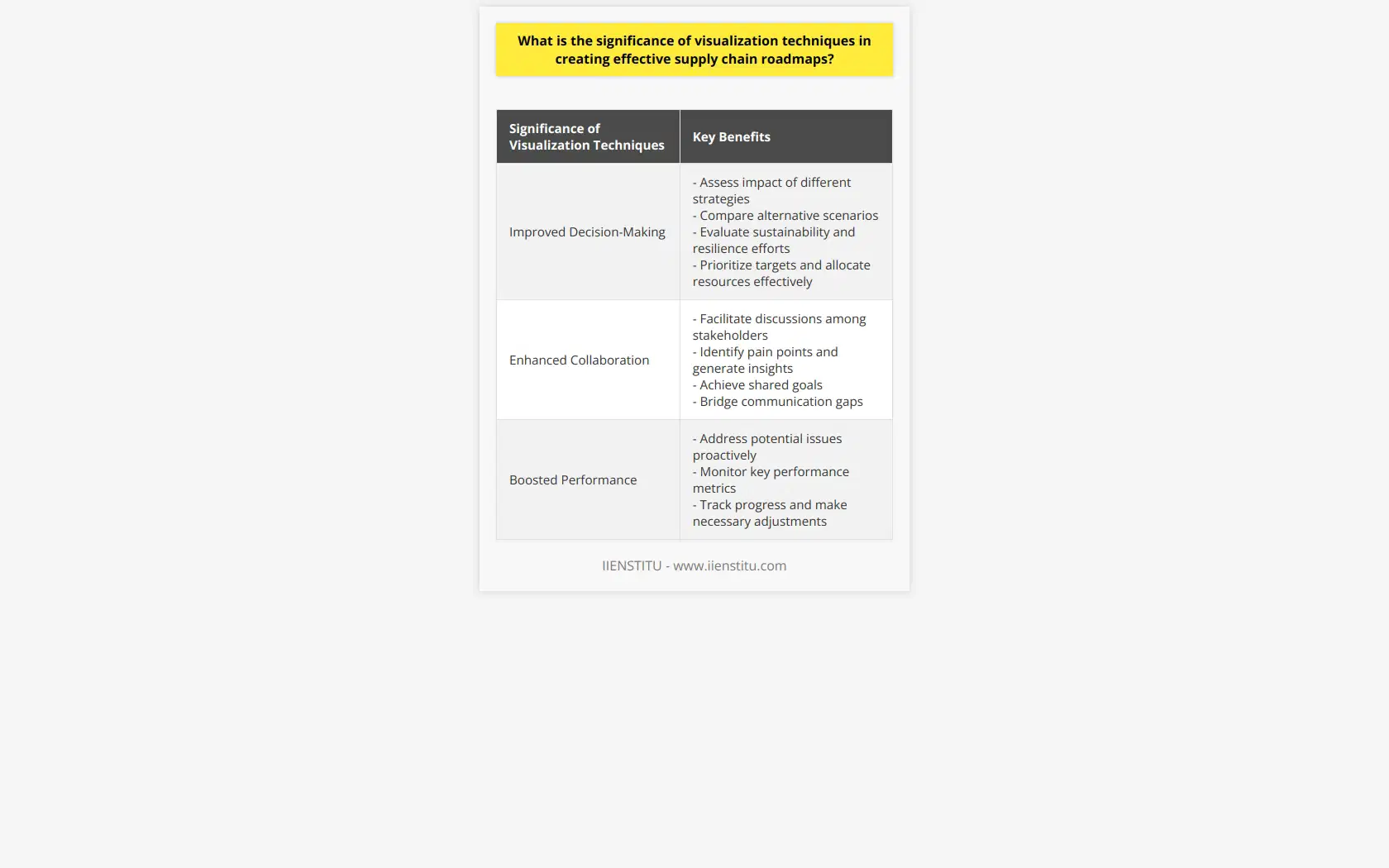

What is the significance of visualization techniques in creating effective supply chain roadmaps?

**Visualization Techniques and Supply Chain Roadmaps**

The significance of visualization techniques in creating effective supply chain roadmaps lies in their ability to facilitate decision-making, foster collaboration, and enhance overall performance. Visualization tools, such as network diagrams, flowcharts, and Gantt charts, translate complex data into an easily digestible format, enabling supply chain leaders to quickly identify potential bottlenecks or risks and implement timely, data-driven decisions to optimize processes.

**Improving Decision-Making**

Clear and concise visual representations of supply chain processes and projected outcomes allow leaders to better understand the current state of their supply chains and make more informed decisions. Through these visualizations, they can assess the impact of different strategies, compare alternative scenarios, and evaluate sustainability and resilience efforts. Furthermore, data-driven visualizations allow organizations to prioritize targets and allocate resources more effectively, thus leading to a more optimized supply chain system.

**Enhancing Collaboration**

Visualization techniques in supply chain roadmaps can significantly improve cross-functional collaboration by offering a common platform for stakeholders to engage in meaningful discussions. These platforms enable various supply chain partners, such as manufacturers, suppliers, and logistics providers, to identify pain points, generate meaningful insights, and achieve shared goals. Moreover, visualization techniques help bridge communication gaps by presenting information in a manner that is easily understood by different stakeholders, regardless of their technical expertise.

**Boosting Performance**

The use of visualization techniques in supply chain roadmaps contributes to improved performance by enabling proactive problem-solving and increased agility. By exposing potential issues, organizations can address them before they escalate, ensuring smooth operations and minimal disruption. Additionally, these techniques can help monitor various performance metrics, such as lead times, inventory levels, and transportation costs, allowing organizations to track progress and adjust strategies as needed.

In conclusion, the use of visualization techniques in creating effective supply chain roadmaps has a significant and positive impact on decision-making, collaboration, and performance. By leveraging these visual tools, organizations can gain a better understanding of their supply chains, establish a more cohesive operational strategy, and ultimately improve overall efficiency and competitiveness in today's global marketplace.

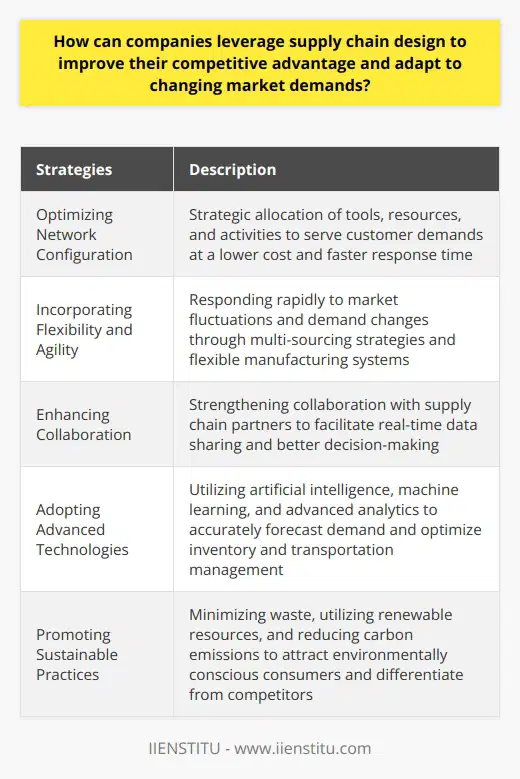

How can companies leverage supply chain design to improve their competitive advantage and adapt to changing market demands?

Leveraging Supply Chain Design for Competitive Advantages

Optimizing Network Configuration

Companies can improve their competitive advantage and adapt to changing market demands by optimizing their supply chain network configuration. Effective network configuration includes strategic allocation of tools, resources, and activities to serve customer demands at a lower cost and better response time. Adopting this approach enables firms to enhance their efficiency, minimize operational costs, and improve overall profitability.

Incorporating Flexibility and Agility

Incorporating flexibility and agility within supply chain design enables companies to respond to market fluctuations and demand changes rapidly. This can range from leveraging multi-sourcing strategies to utilizing flexible manufacturing systems. Consequently, flexible and agile supply chains provide businesses with the ability to adapt to uncertainties, seize new opportunities, and mitigate potential risks.

Enhancing Collaboration Across the Supply Chain

Strengthening collaboration amongst all supply chain partners, including suppliers, manufacturers, logistics providers, and retailers, improves competitive advantage by ensuring that all parties have access to real-time data and insights. Enhanced collaboration facilitates better decision-making and encourages innovation, leading to a more efficient, adaptable, and resilient supply chain.

Adopting Advanced Technologies and Analytics

Investing in advanced technologies, such as artificial intelligence, machine learning, and advanced analytics, can lead to significant improvements in supply chain design. These technologies enable companies to forecast demand accurately, optimize inventory levels, and improve transportation management. Consequently, firms equipped with cutting-edge technologies can better anticipate market changes and make data-driven decisions on how to adapt their supply chain design.

Promoting Sustainable Practices

Incorporating sustainability into supply chain design not only contributes to environmental conservation but also enhances an organization's competitive advantage. By adopting sustainable practices, such as minimizing waste, using renewable resources, and reducing carbon emissions, companies can attract environmentally conscious consumers, demonstrate regulatory compliance, and differentiate themselves from competitors.

In conclusion, companies can leverage supply chain design to improve their competitive advantage and adapt to changing market demands through various approaches. By optimizing their network configuration, incorporating flexibility and agility, enhancing collaboration, adopting advanced technologies, and promoting sustainable practices, businesses can create resilient, efficient, and adaptable supply chains that ultimately enhance their market competitiveness.

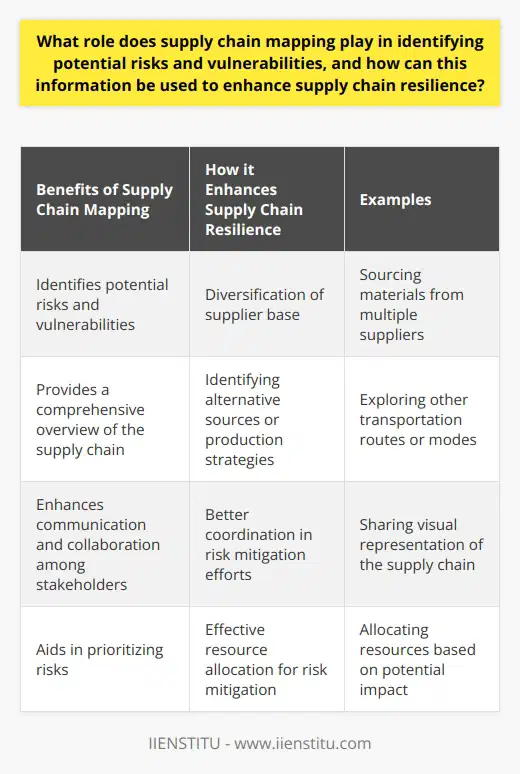

What role does supply chain mapping play in identifying potential risks and vulnerabilities, and how can this information be used to enhance supply chain resilience?

Role of Supply Chain Mapping in Risk Identification

Supply chain mapping refers to the process of creating a visual representation of a company's supply chain. It plays a crucial role in identifying potential risks and vulnerabilities by providing a comprehensive picture of various elements, such as suppliers, production sites, warehouses, and transportation routes. Through this visual aid, organizations can better analyze their existing processes, pinpoint weaknesses, and anticipate disruptions.

Enhancing Supply Chain Resilience with Risk Information

The information derived from supply chain mapping can be used to improve supply chain resilience in multiple ways. First, it enables organizations to diversify their supplier base, reducing the susceptibility to disruptions caused by a single, vulnerable supplier. Diversification involves sourcing materials and components from multiple suppliers or regions to minimize dependency.

Second, supply chain mapping helps in identifying alternative sources or production strategies. It allows companies to uncover potential substitution options, develop backup plans, and maintain business continuity. For example, if a specific transportation route is exposed as a high-risk area, an organization can explore alternative routes or modes of transport to avoid possible disruptions.

Third, the visualization of the supply chain can facilitate better communication and collaboration among stakeholders. By sharing the supply chain map, organizations create a common understanding of potential risks and vulnerabilities, fostering better coordination in risk mitigation efforts. This approach encourages proactive measures and ensures a faster response in case of disruptions.

Lastly, supply chain mapping aids in risk prioritization. The process of visualizing all components enables organizations to evaluate the severity of potential disruptions, allocate resources more effectively, and plan for risk mitigation strategies accordingly. This prioritization reduces the overall risk exposure and strengthens the overall supply chain resilience.

In conclusion, supply chain mapping is a powerful tool for identifying potential risks and vulnerabilities in a supply chain. By harnessing the insights generated through supply chain mapping, organizations can enhance their supply chain resilience through diversifying suppliers, identifying alternative sources, improving communication and collaboration, and prioritizing risk mitigation efforts. This proactive approach to managing risks is crucial in the ever-evolving business landscape, where disruptions can significantly impact organizational success.

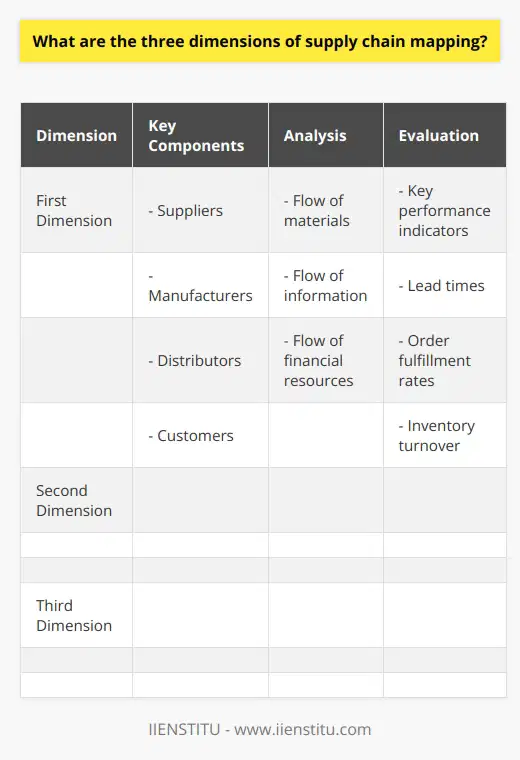

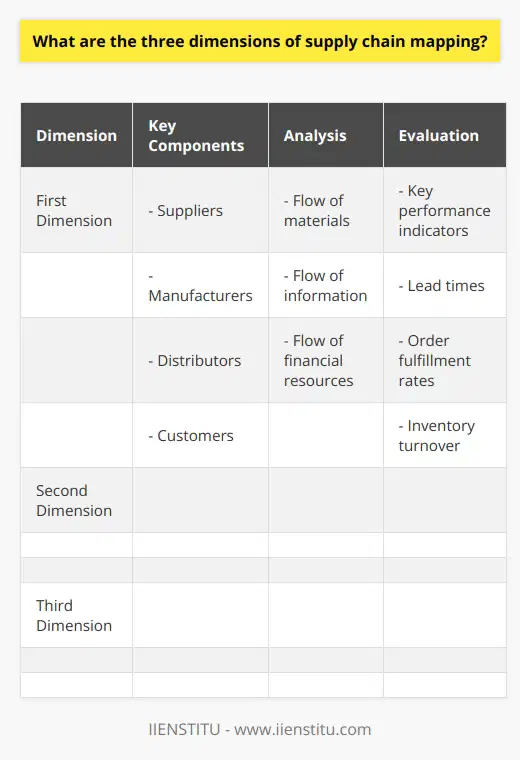

What are the three dimensions of supply chain mapping?

Three Dimensions of Supply Chain Mapping

Identifying Key Components

The first dimension of supply chain mapping involves identifying key components such as suppliers, manufacturers, distributors, and customers. These components form the backbone of a supply chain, allowing for the efficient flow of goods from production to consumption. Proper identification of these components is crucial in understanding how a supply chain functions and pinpointing potential areas of improvement or risk mitigation.

Analyzing Material, Information, and Financial Flows

The second dimension of supply chain mapping entails analyzing the flow of materials, information, and financial resources between the identified components. Examining the physical movement of goods, such as raw materials or finished products, provides insights into bottlenecks and inefficiencies that can hinder overall performance. Meanwhile, understanding the flow of information helps to ensure effective communication between stakeholders and optimize decision-making processes. Lastly, evaluating financial transactions allows organizations to assess cost efficiency and identify potential savings across the supply chain.

Evaluating Performance Metrics

The third dimension of supply chain mapping involves evaluating performance metrics to determine the effectiveness of supply chain operations. Key performance indicators (KPIs) such as lead times, order fulfillment rates, and inventory turnover provide valuable insights into the efficiency of the supply chain, enabling organizations to identify areas that require improvement. Additionally, monitoring KPIs allows for the assessment and continuous improvement of supply chain sustainability and social responsibility, which have become increasingly important in today's business environment.

In conclusion, the three dimensions of supply chain mapping—identifying key components, analyzing material, information, and financial flows, and evaluating performance metrics—are essential in understanding and optimizing a supply chain's operation. By applying a comprehensive approach to supply chain mapping, organizations can enhance their competitiveness, ensure operational efficiency, and ultimately, achieve long-term success.

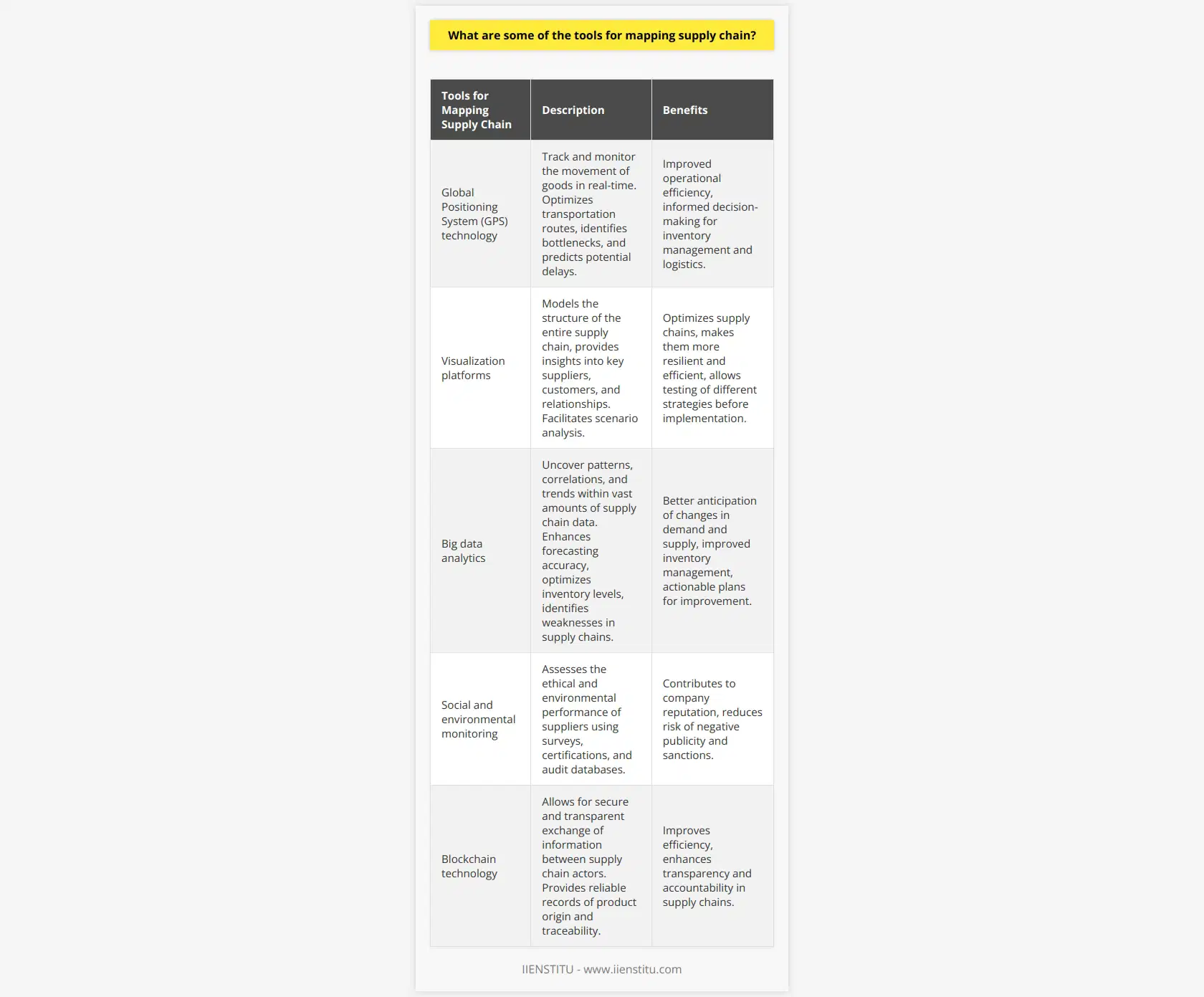

What are some of the tools for mapping supply chain?

Supply Chain Mapping Tools

One crucial tool for mapping supply chain is Global Positioning System (GPS) technology. GPS enables real-time tracking of goods, permitting organizations to optimize transportation routes, pinpoint bottlenecks, and anticipate delays. By leveraging GPS data, companies can make informed decisions about inventory management and logistics, ultimately improving overall operational efficiency.

Visualization Platforms

Another indispensable tool is supply chain visualization platforms. These software solutions can model the structure of a company's entire supply chain, revealing not only key suppliers and customers, but also the relationships between them. Visualization platforms facilitate scenario analysis, enabling decision-makers to test various strategies before implementation. Utilization of such platforms results in more resilient and efficient supply chains.

Big Data Analytics

Big data analytics is a powerful tool to uncover patterns, correlations, and trends within large volumes of supply chain data. By analyzing data from multiple sources, businesses can better anticipate changes in demand and supply, enhance forecasting accuracy, and optimize inventory levels. Advanced analytics also aids companies in recognizing weak points in their supply chains and devising actionable plans for improvement.

Social and Environmental Monitoring

In a world of increasing transparency and scrutiny, it is essential to have insight into social and environmental risks in supply chains. Tools like supplier assessment surveys, environmental certifications, and social audit databases allow companies to assess the ethical and ecological performance of their suppliers. Effective monitoring of these factors contributes to a company's reputation and reduces the risk of negative publicity and sanctions.

Blockchain Technology

Lastly, blockchain technology offers new possibilities for supply chain management. As a decentralized digital ledger, it allows the secure and transparent exchange of information between supply chain actors. Moreover, blockchain can provide reliable records of product origin and traceability, ensuring the quality and authenticity of goods. By adopting this technology, businesses can improve efficiency while enhancing transparency and accountability in their supply chains.

In conclusion, an array of beneficial tools exists for supply chain mapping, including GPS technology, visualization platforms, big data analytics, social and environmental monitoring, and blockchain technology. Harnessing these tools can provide companies with valuable insights, enabling them to design efficient, transparent, and resilient supply chains.

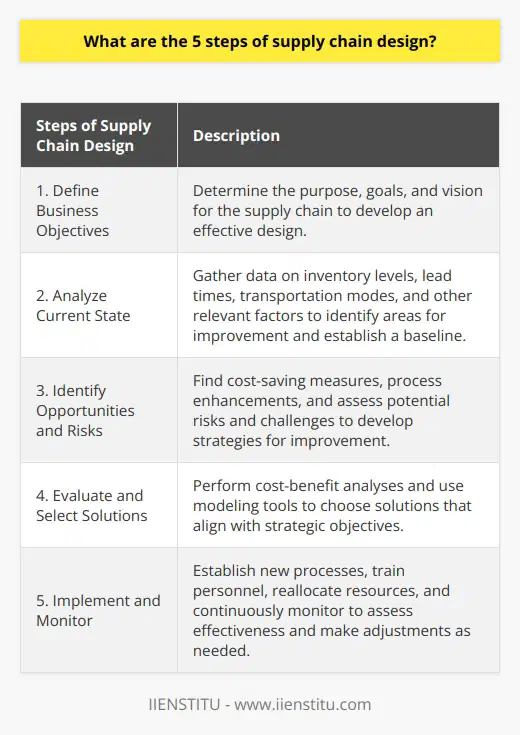

What are the 5 steps of supply chain design?

Understanding the Supply Chain Design Process

The supply chain design process is a crucial aspect of any business's operations, as it optimizes the flow of goods and services within the organization, as well as with external stakeholders, such as suppliers and customers. This academic paragraph will describe the five essential steps of supply chain design.

Step 1: Define Business Objectives

The first step in supply chain design involves defining the specific business objectives that the organization seeks to achieve. This includes determining the overall purpose, goals, and vision for the supply chain, such as maximizing efficiency, reducing operational costs, or ensuring customer satisfaction.

Step 2: Analyze the Current State

Next, organizations must analyze their existing supply chain operations to assess their current state. This involves gathering data about inventory levels, lead times, transportation modes, and other relevant factors. By understanding the current state, decision-makers can identify areas for improvement and establish a baseline for progress.

Step 3: Identify Opportunities and Risks

With a thorough understanding of the current state, companies can identify opportunities for improvement, as well as potential risks and challenges that may be encountered. These opportunities may include cost-saving measures, process improvements, or the adoption of new technologies. Simultaneously, understanding possible risks allows the organization to develop strategies to mitigate or avoid them.

Step 4: Evaluate and Select Solutions

Once opportunities and risks have been identified, decision-makers must evaluate and select the most appropriate solutions for implementation. This may involve performing cost-benefit analyses or using modeling tools to simulate the impact of different options. Ultimately, the goal of this step is to choose the solutions that best align with the organization's strategic objectives.

Step 5: Implement and Monitor

Following the selection of appropriate solutions, organizations must implement the chosen strategies within their supply chain operations. This includes establishing new processes, training personnel, and shifting resources as needed. After implementation, continuous monitoring is required to assess the effectiveness of the new supply chain design, making adjustments as necessary to ensure alignment with business objectives.

In conclusion, the five steps of supply chain design are crucial for organizations to optimize their operations and achieve their desired goals. By defining objectives, analyzing the current state, identifying opportunities and risks, evaluating and selecting solutions, and implementing and monitoring the chosen strategies, businesses can develop an effective and efficient supply chain that delivers optimal results.

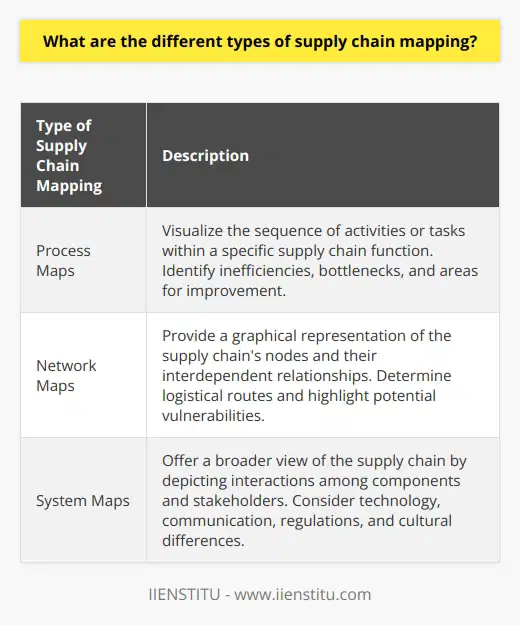

What are the different types of supply chain mapping?

Types of Supply Chain Maps

Supply chain mapping is a crucial component in understanding the flow of goods, services, and information across organizations within the supply chain. It plays a vital role in enhancing transparency, identifying risks, and uncovering optimization opportunities. Three main types of supply chain maps exist: process maps, network maps, and system maps.

Process Maps

Process maps are used to visualize the sequence of activities or tasks within a specific supply chain function. These maps aim to identify inefficiencies in processes, discover bottlenecks, and streamline operations to improve overall performance. Organizations use process mapping as a tool to analyze the current state of their supply chain processes and design future improvements.

Network Maps

Network maps provide a graphical representation of the supply chain's nodes and their interdependent relationships. They present the physical locations of suppliers, manufacturers, distribution centers, and retail outlets. Network maps are essential for determining logistical routes and highlighting potential supply chain vulnerabilities, such as dependency on a single supplier. Organizations can utilize network maps to strategize supply chain redesigns for increased resilience and efficiency.

System Maps

System maps offer a holistic view of the supply chain by depicting the intricate interactions among its various components and stakeholders. These maps consider a broader range of factors, including technology, communication, and external influences such as regulations and cultural differences. System maps allow organizations to better predict the supply chain's overall stability, responsiveness, and flexibility. By understanding the complexities of the interconnected system, supply chain leaders can make informed decisions for long-term strategic planning.

In conclusion, process maps, network maps, and system maps are the three primary types of supply chain mapping, each with specific purposes and benefits. Effectively utilizing these tools enables organizations to identify and address supply chain inefficiencies, mitigate risks, and strive towards continuous improvement.

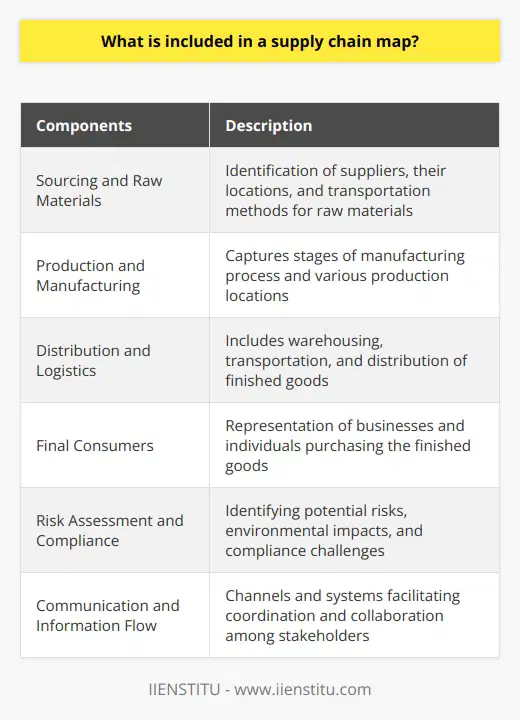

What is included in a supply chain map?

Components of a Supply Chain Map

A supply chain map is a visual representation of the entire process that a product or service undergoes from its conception to its final destination. This entails several key components that are quintessential in understanding and analyzing the functioning of the supply chain.

Sourcing and Raw Materials

The foundation of the supply chain map is the sourcing and procurement of raw materials essential for product creation. The map illustrates the suppliers of these materials, their locations, and the transportation methods required to deliver the materials from their source to the manufacturing facilities.

Production and Manufacturing

While identifying the production and manufacturing sites, the supply chain map captures the path taken by the materials as they transform into finished goods. This consists of different stages of the manufacturing process, various locations in which the goods are produced, and the relationships among these facilities.

Distribution and Logistics

In this stage, the supply chain map encompasses the warehousing, transportation, and distribution of finished goods from the manufacturing facilities to the end consumers. Information about the storage facilities, transportation modes, and intermediary distribution partners such as wholesalers, retailers, and online marketplaces is incorporated.

Final Consumers

The map's endpoint represents the final consumers, both businesses and individuals purchasing the finished goods. It shows the different customer segments, their geographical locations, and the channels through which they access the products or services.

Risk Assessment and Compliance

Apart from displaying the physical flow of goods, the supply chain map helps in identifying potential risks along the supply chain. Examining these aspects can aid in the evaluation of possible disruptions, environmental impacts, and regulatory compliance challenges. The map allows companies to evaluate contingency plans and emphasize sustainability.

Communication and Information Flow

Lastly, an essential component of a supply chain map is the communication and information flow between different entities involved in the supply chain. This incorporates tracking data, communication channels, and information systems that facilitate smooth functioning and adequate coordination among all stakeholders.

In conclusion, a supply chain map grants companies a comprehensive understanding of their operations, helps them identify areas of improvement, reduce costs, and enhance customer satisfaction. By examining the arrangement of these key components, the supply chain map proves to be a valuable tool in effective supply chain management.

What are the three dimensions of supply chain mapping?

Identifying the Three Dimensions of Supply Chain Mapping

Visual Representation

Supply chain mapping entails a comprehensive visual representation of the entire network of organizations, such as suppliers, manufacturers, and distributors, involved in the process of producing and delivering products or services to consumers. This graphical illustration allows businesses to gain better visibility and understanding of their operations, relationships, and dependencies, thereby contributing to the optimization of supply chains and the enhancement of overall efficiency.

Geographical Perspective

A critical dimension of supply chain mapping involves considering the geographical locations and spatial relationships of various stakeholders. This insight enables companies to analyze the transportation and logistics aspects of their supply chain, such as transit times, shipping routes, and the proximity to end-users. By identifying potential risks, bottlenecks, and inefficiencies, organizations can develop appropriate strategies to reduce costs, enhance responsiveness, and mitigate potential disturbances, such as natural disasters or geopolitical events.

Information Flow

The third crucial dimension in supply chain mapping is the flow of information among the different stakeholders comprising the network. The ability to track and trace the status and progress of products and services, both upstream and downstream the supply chain, is essential for maintaining accurate and timely communication, collaboration, and decision-making. The exchange of data regarding inventory levels, production schedules, demand forecasts, and other critical aspects allows organizations to enhance coordination, responsiveness, and reliability, ultimately leading to improved customer satisfaction, reduced lead times, and increased profitability.

In conclusion, the three dimensions of supply chain mapping, which include a visual representation, geographical perspective, and information flow, are critical factors in helping companies understand and optimize their intricate network of relationships and operations. By analyzing these dimensions, organizations can uncover inefficiencies, identify potential risks, and enhance their responsiveness to meet evolving customer needs, leading to improved overall performance and competitiveness in the global business landscape.

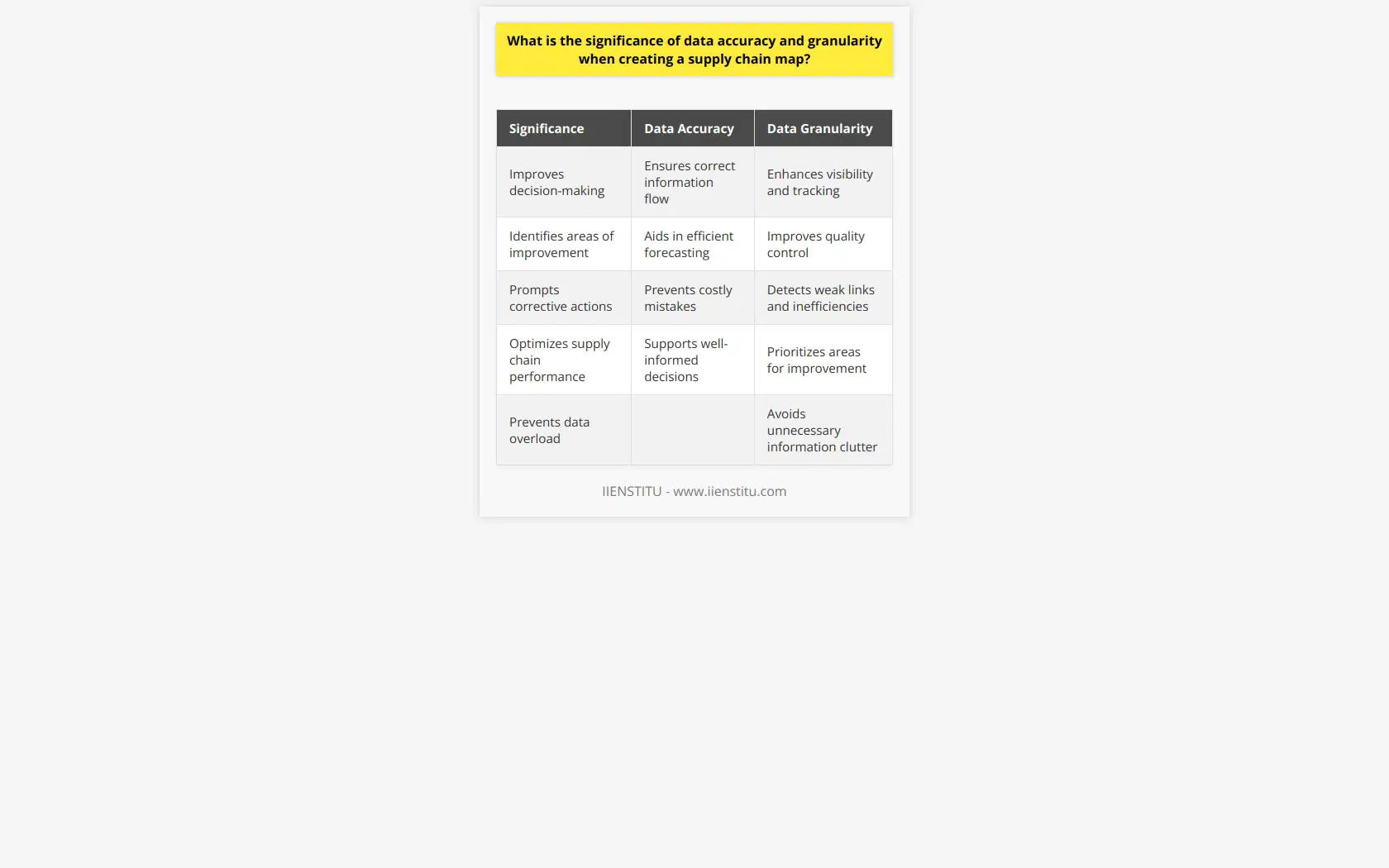

What is the significance of data accuracy and granularity when creating a supply chain map?

Data Accuracy: A Crucial Determinant of Supply Chain Adequacy

Data accuracy significantly influences supply chain mapping. It ensures the right information is passed along the supply chain. Accurate data about suppliers, goods and their locations supports informed decision-making for businesses. It helps identify areas of inefficiency or bottlenecks, and enables prompt corrective actions. Moreover, accurate data prevents inaccurate forecasting or business intelligence.

Granularity and its Implication on Supply Chain Details

A more granular supply chain map provides detailed insights into the supply chain. High granularity means each end-to-end process is broken down into smaller parts. This improves visibility into each process and tracking becomes easier. It enhances quality control and accountability as weak links become easily detectable.

Granularity also aids companies in identifying the value generated at each step. It enables them to determine their impact on costs and benefits within different levels of the supply chain. By understanding this, companies can prioritize areas that require improvement.

Balancing Accuracy and Granularity for an Efficient Supply Chain Map

Accuracy and granularity should go hand in hand for effective supply chain management. The two compounding each other optimizes supply chain performance. Proper balance between these elements ensures all information is both precise and detailed enough for decision-making.

However, businesses need to be conscious of data overload. Too much granularity can clutter the supply chain map, making it difficult to direct attention to critical areas. Finding a balance enables sufficient visibility without overwhelming users with unnecessary information.

In conclusion, the significance of data accuracy and granularity in a supply chain map cannot be overstated. They lay the foundation for an efficient and transparent supply chain, aiding companies in seizing valuable opportunities and improving their performance.

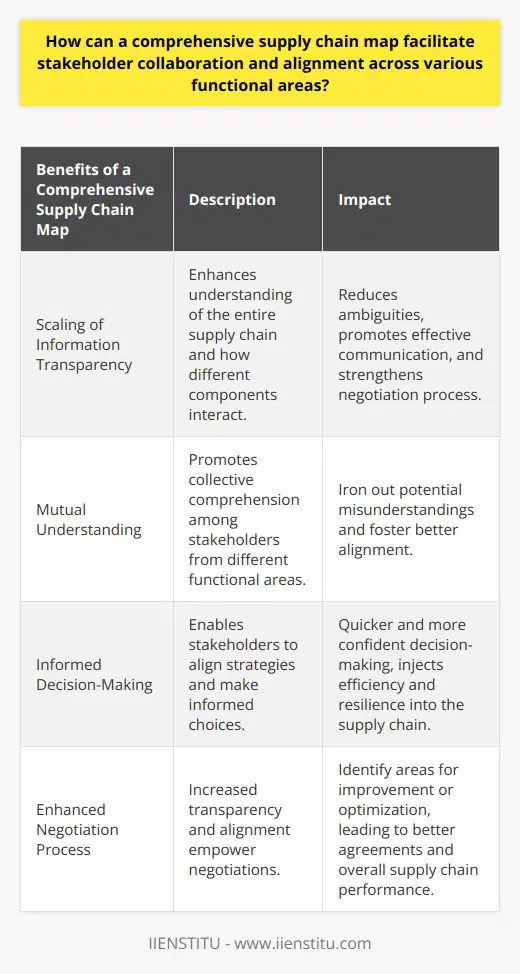

How can a comprehensive supply chain map facilitate stakeholder collaboration and alignment across various functional areas?

Enhancement of Stakeholder Collaboration

A well-drawn supply chain map can magnify stakeholder collaboration. The map provides a common platform for stakeholders from various functional areas to converse. The shared information improves transparency, promotes mutual understanding, and facilitates cohesion in decision-making.

Scaling Information Transparency

Supply chain mapping elevates the level of information transparency. It allows stakeholders to visualize the flow of materials, information, and finances across the supply chain. This thorough understanding can deflate ambiguities, enhancing effective communication, aligning cross-functional departments, and strengthening the negotiation process.

Mutual Understanding Promotion

The provision of a common visual tool promotes mutual understanding among different stakeholders. It ensures that everyone grasps the operational standpoint of the supply chain, regardless of their functional area. This collective comprehension can iron out possible misunderstandings, fostering better alignment.

Consensus in Decision Making

Supply chain mapping aids stakeholders in aligning their strategies. They can identify the nodes and links within the supply chain where intervention can create value or reduce risk. A common visual representation helps stakeholders agree on key decisions more rapidly and confidently.

Leveraging Negotiations

Increased transparency and alignment can significantly power the negotiation process. As stakeholders understand each other's perspectives and align their objectives, they can negotiate better agreements. Such alignments, fueled by a comprehensive supply chain map, can inject more efficiency and resilience into the supply chain.

In a nutshell, a comprehensive supply chain map acts as a catalyst, bolstering collaboration and aligning interests among stakeholders from diverse functional areas. It unlocks a holistic understanding of the supply chain, paves the way for strategic alignment, and uplifts the negotiation process. These factors, combined, optimize overall supply chain performance.

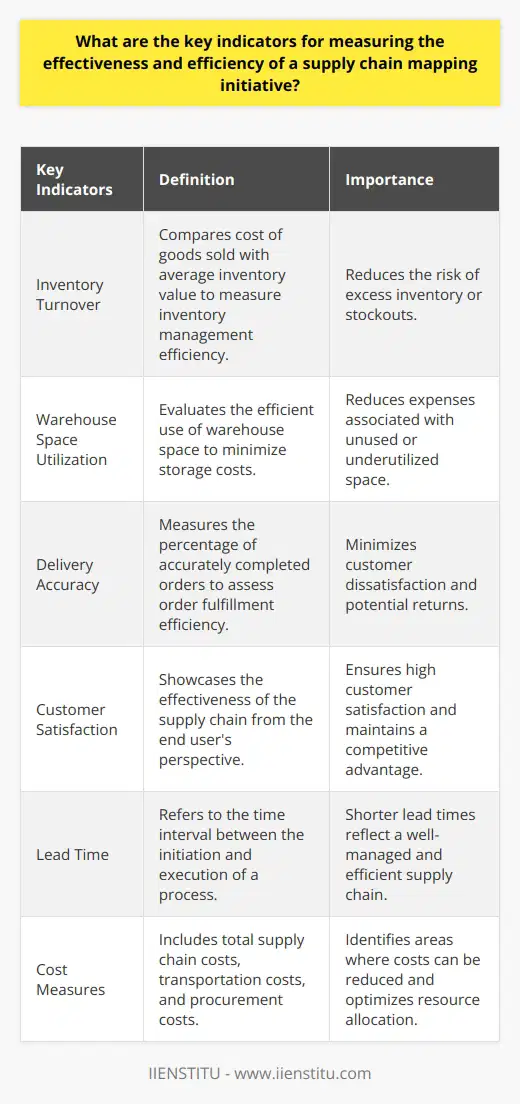

What are the key indicators for measuring the effectiveness and efficiency of a supply chain mapping initiative?

Supply Chain Performance Indicators

Several key indicators can measure the effectiveness and efficiency of a supply chain mapping initiative. Inventory turnover, often assessed by comparing the cost of goods sold with the average inventory value, is one such indicator. This measure helps determine whether a business is effectively managing its stock.

Warehouse Space Utilization

Another critical gauge is warehouse space utilization, evaluating whether a business makes the best use of its storage facilities. Higher metrics indicate more efficient use of available space, which in turn reduces storage costs.

Delivery Accuracy

Looking at delivery accuracy offers insight into order fulfillment. A high percentage of accurately completed orders implies that the supply chain mapping process is functioning efficiently.

Customer Satisfaction

Customer satisfaction in supply chain management mirrors the end user's perspective. This measure is also important because supply chain efficiency often translates into overall customer satisfaction.

Lead Time

Furthermore, lead time, or the period between the initiation and execution of a process, can underline supply chain competence. Shorter lead times can indicate a well-managed and efficient supply chain.

Cost Measures

Lastly, cost measures such as total supply chain costs, transportation costs, and procurement costs can provide a comprehensive understanding of supply chain efficiency. Reduced costs typically signify increased operational efficiency.

Cumulatively, these indicators can paint a clear picture of how efficiently and effectively a supply chain operates. Continuous monitoring of these indicators helps enhance supply chain mapping initiatives and add value to business operations.